Spinodal Decomposition in (Ti, Zr)(C, N) Ceramics: Data-Driven Efficient Design and Hardness-Toughness Synergy

-

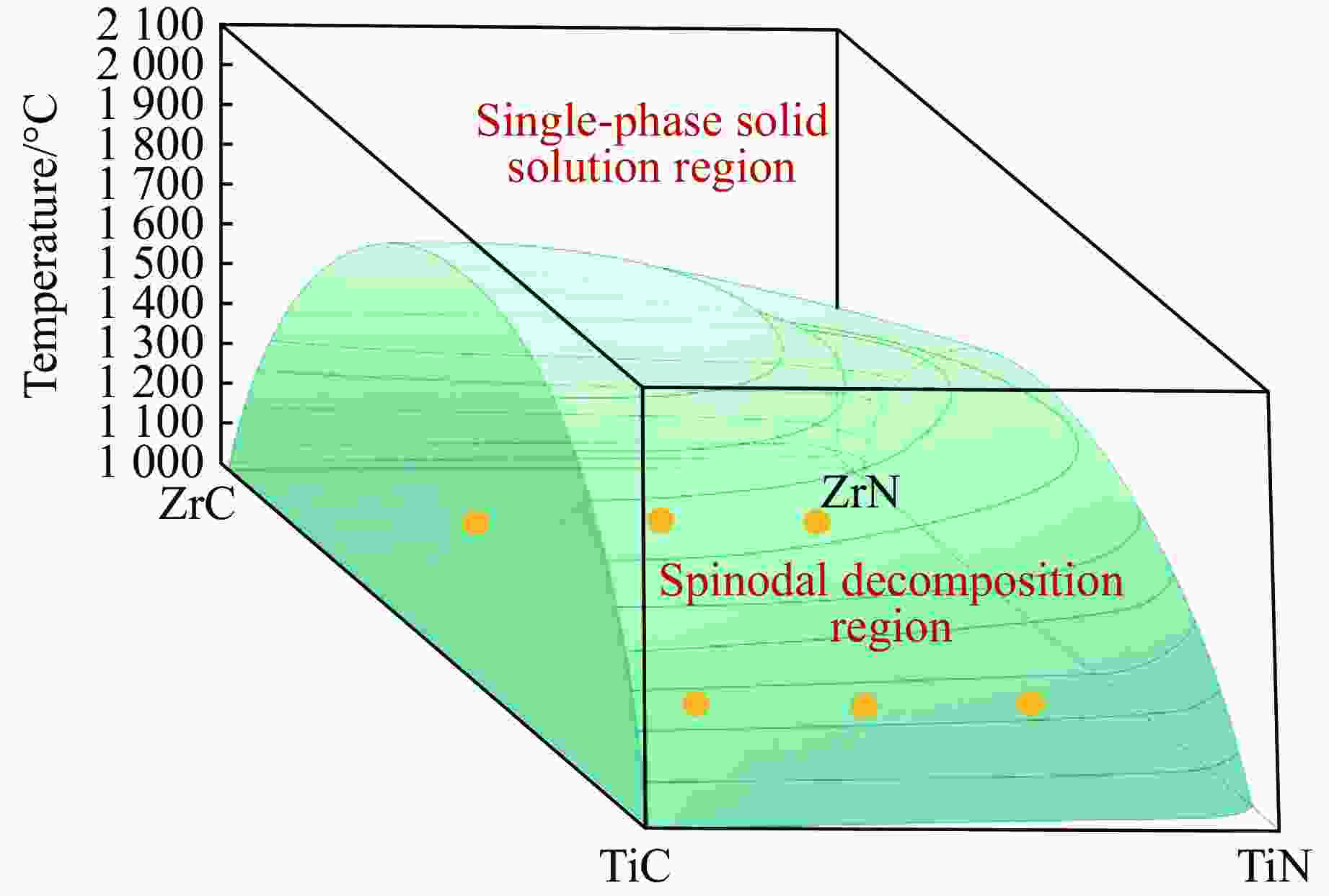

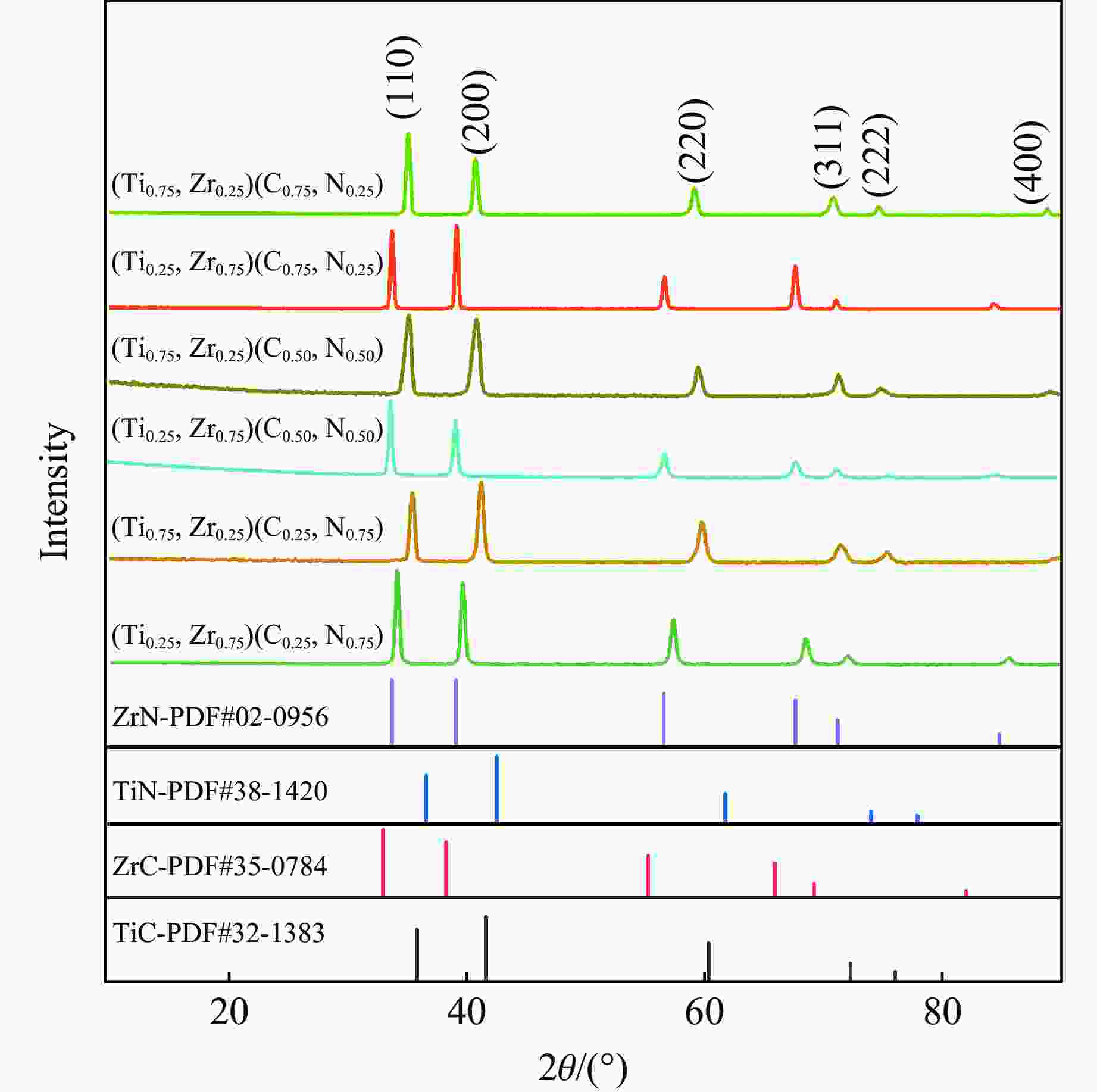

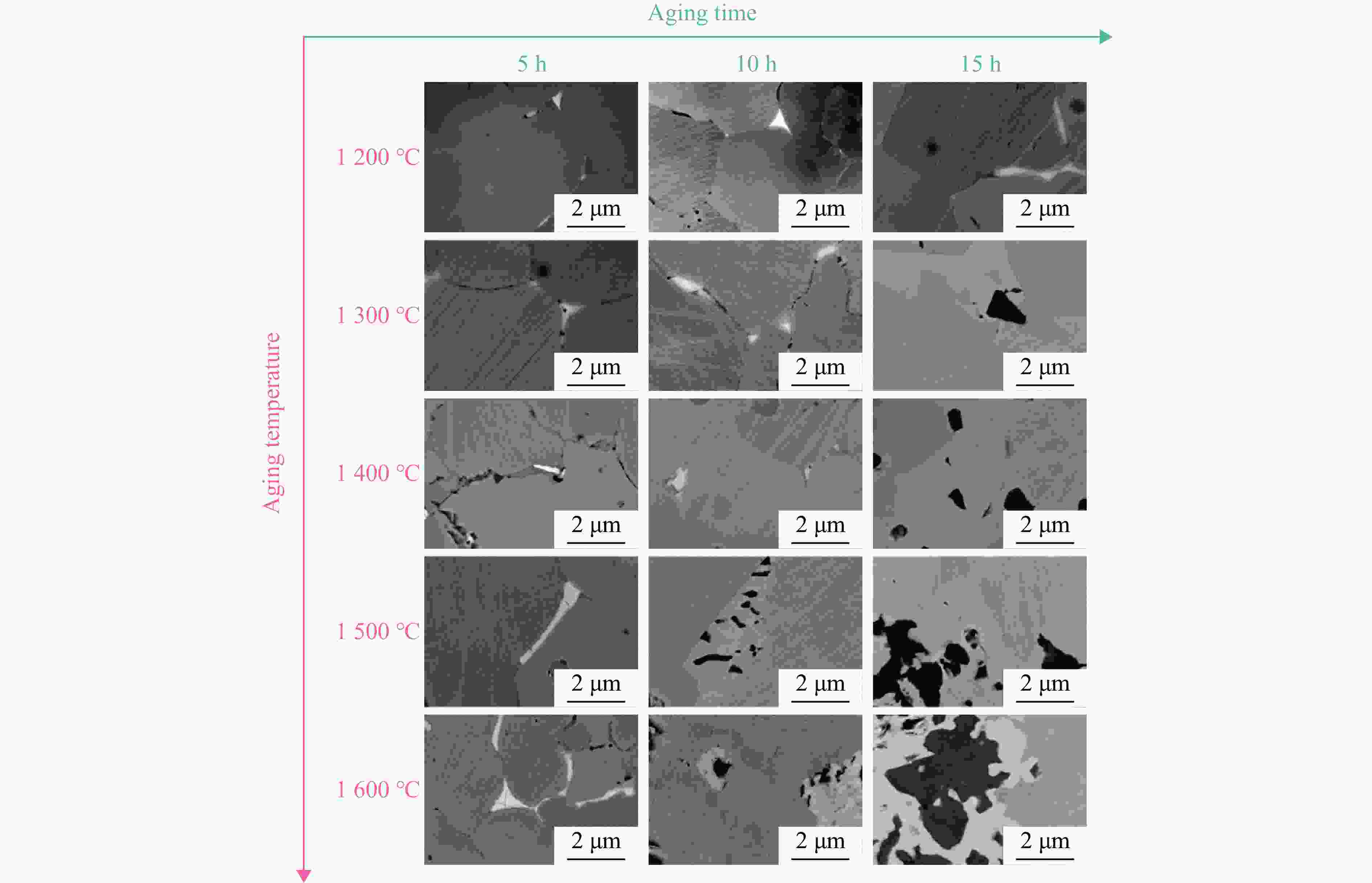

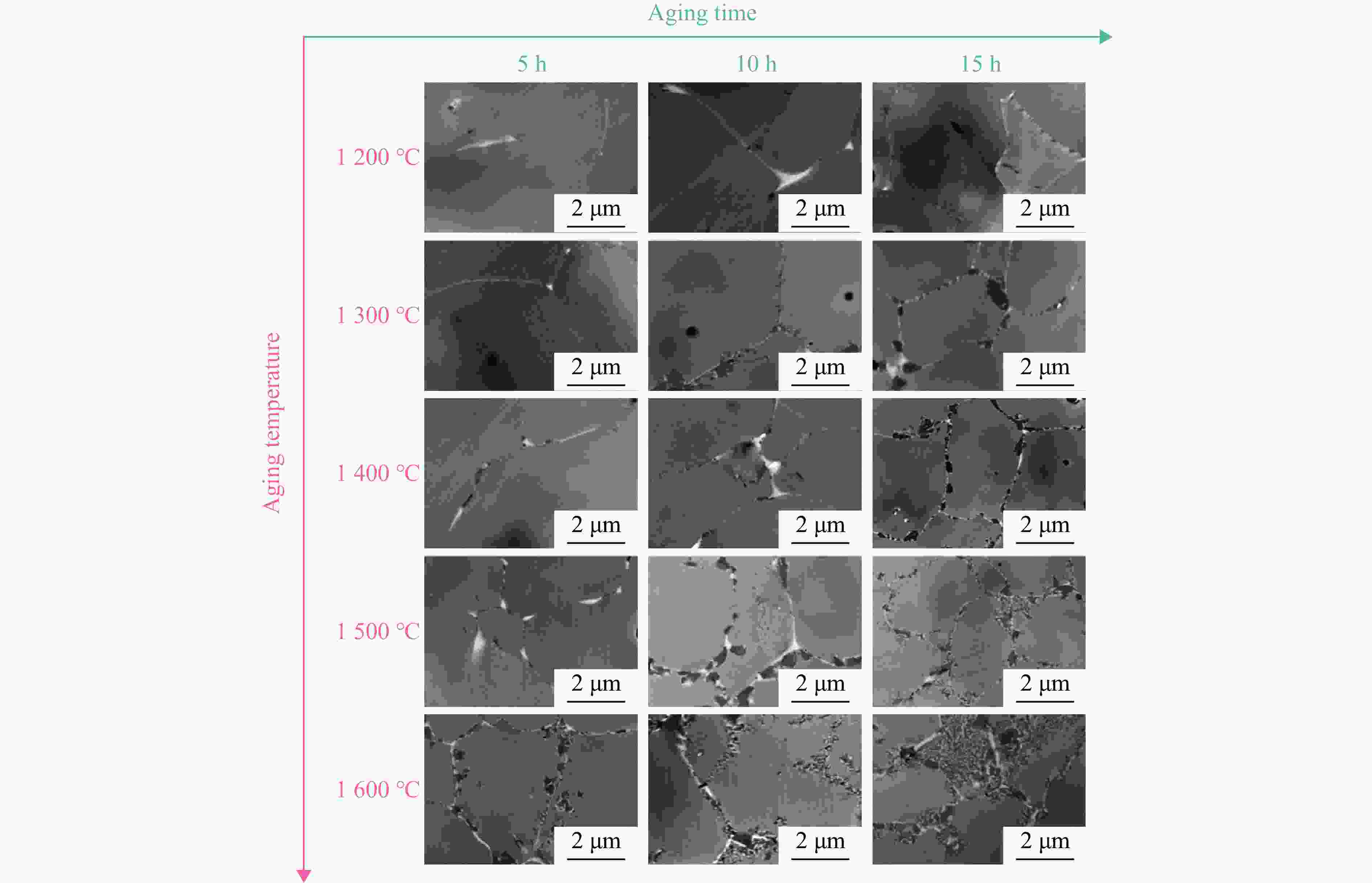

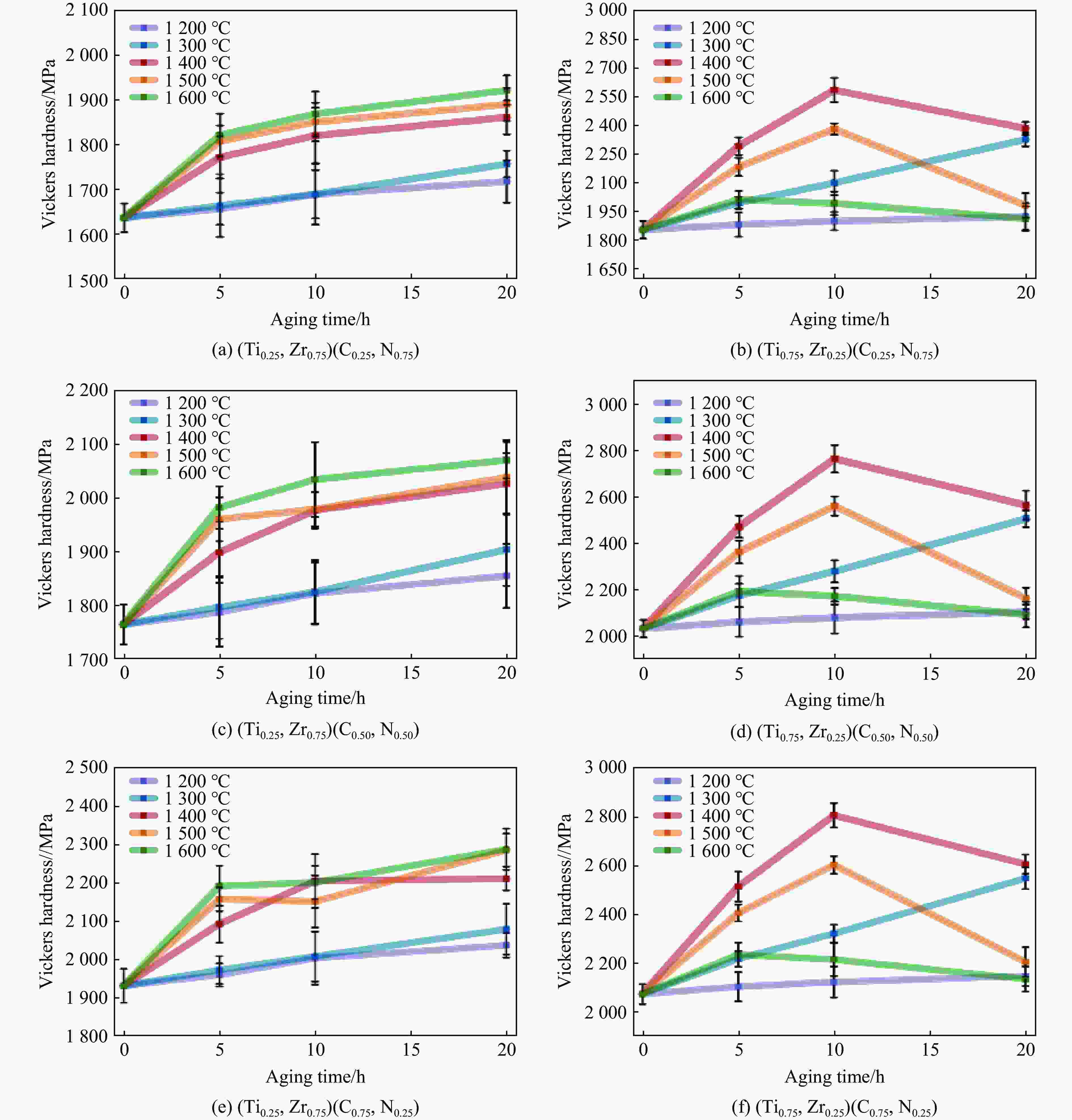

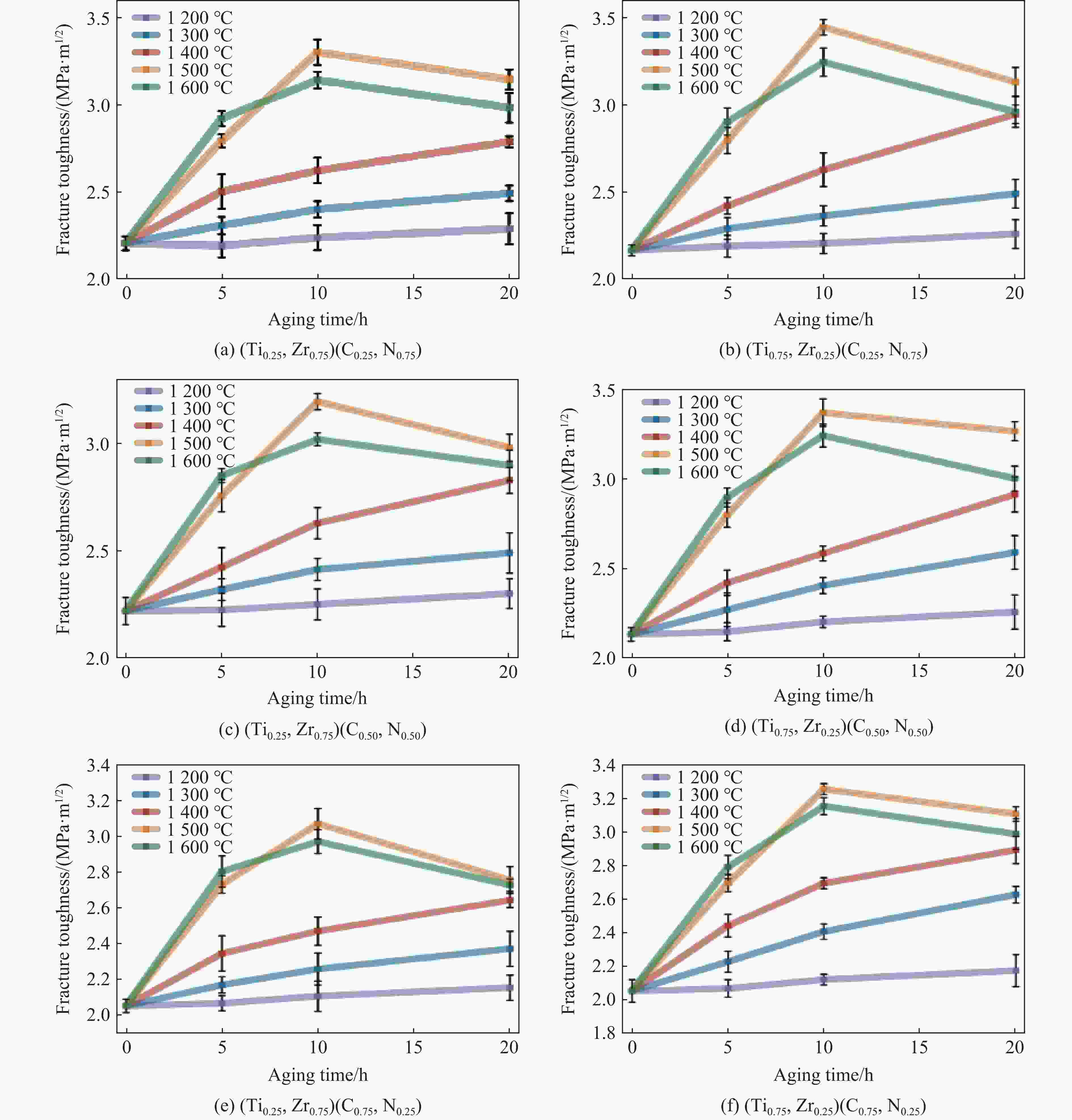

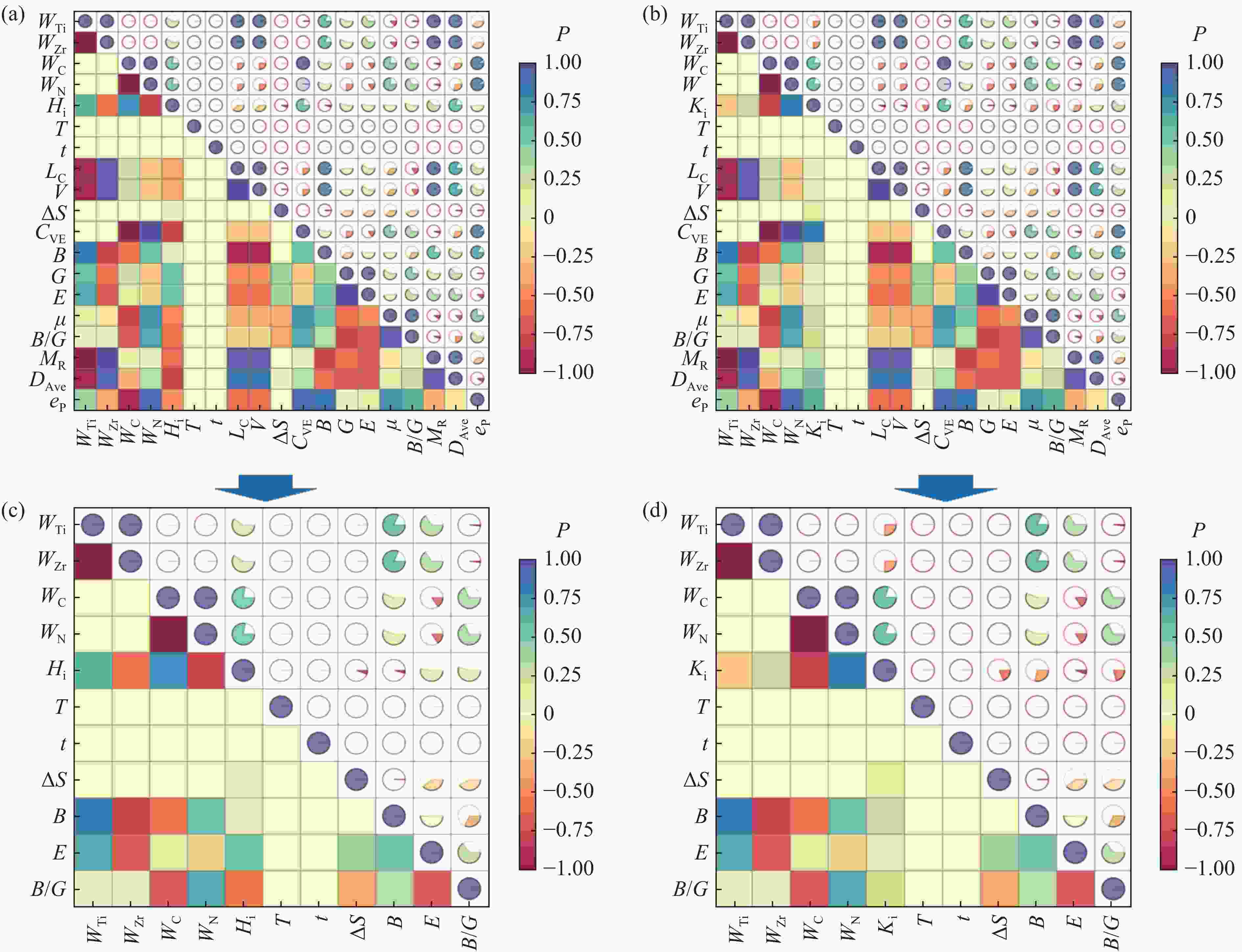

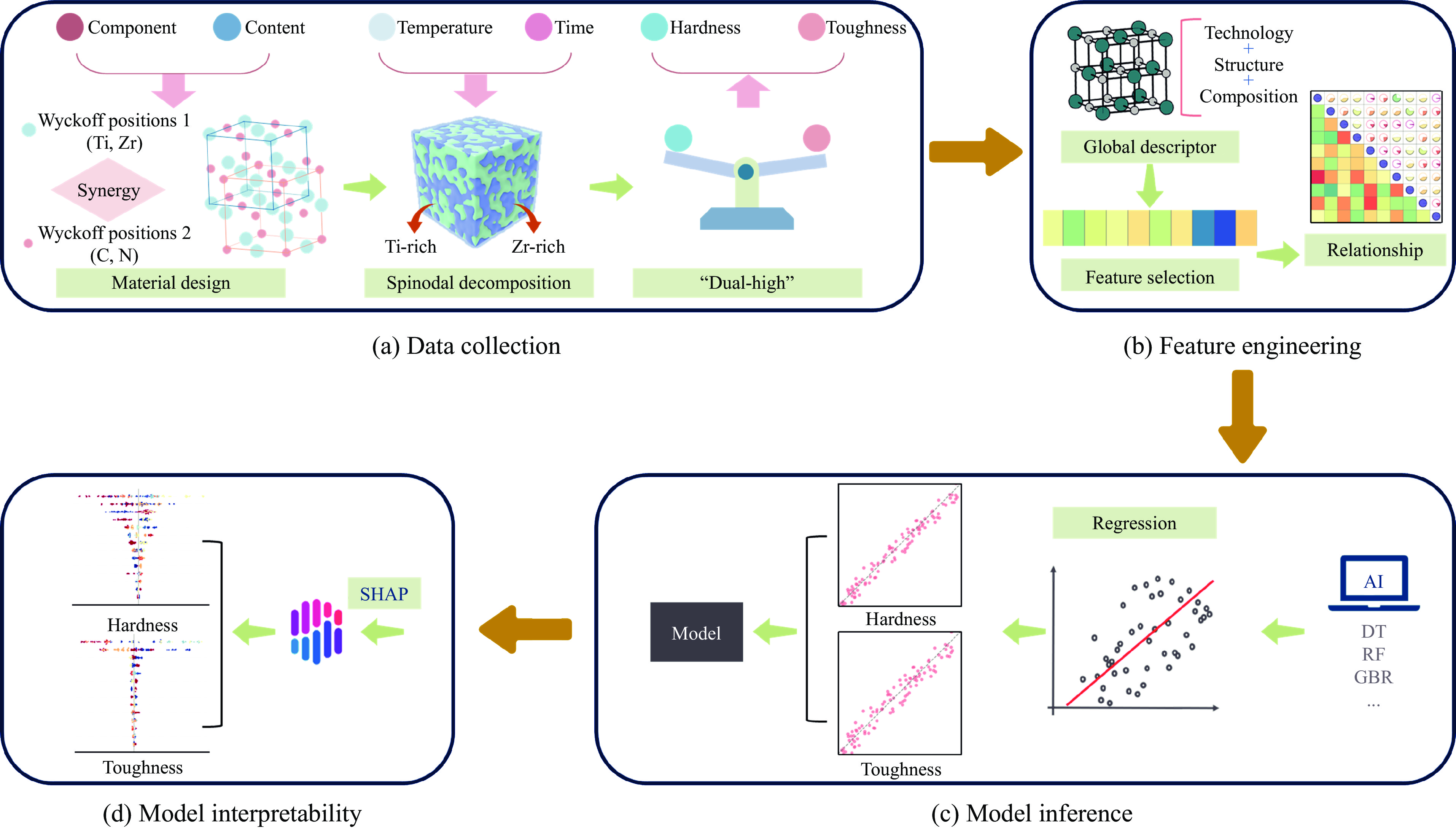

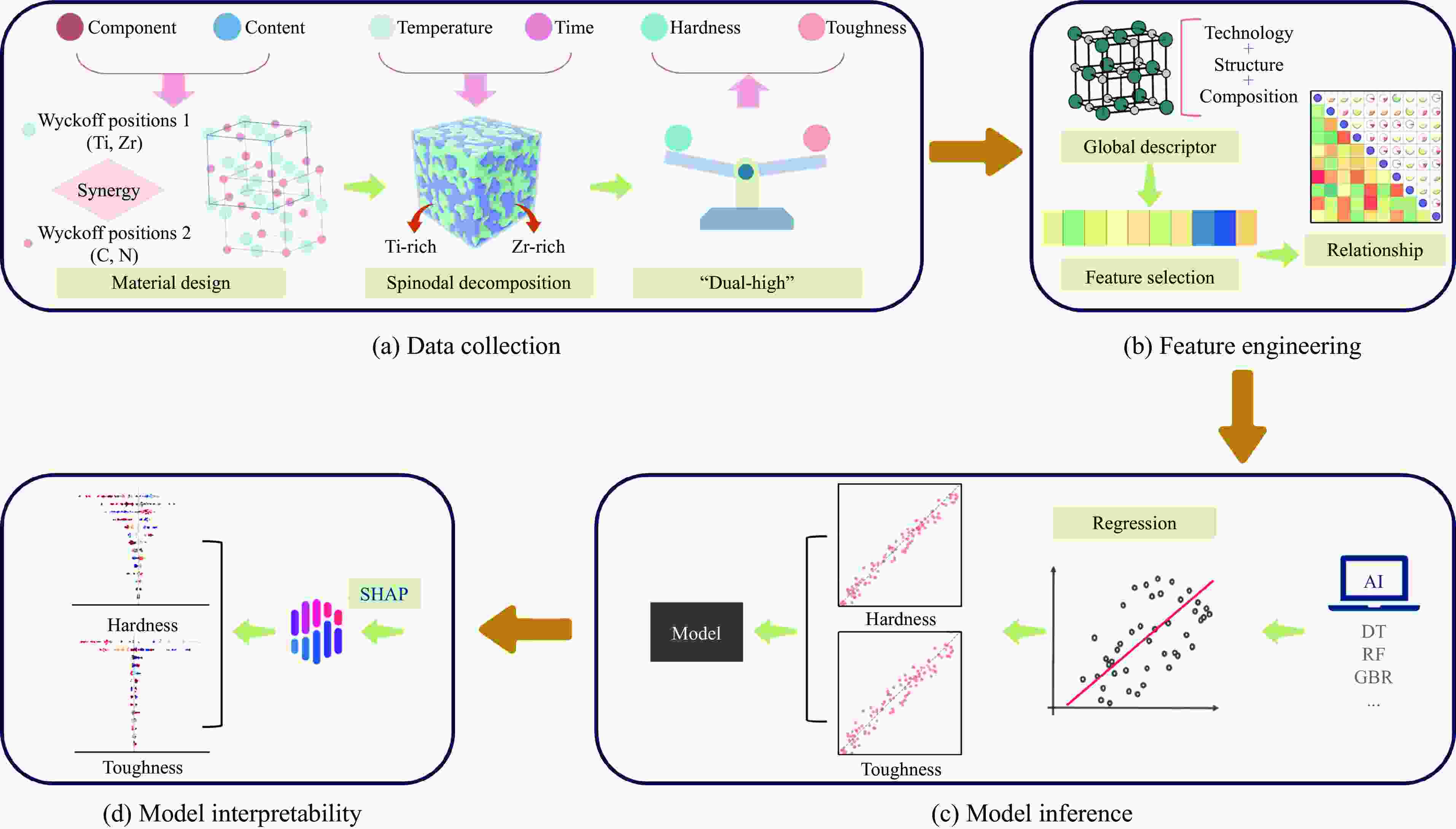

摘要: 传统过渡金属碳化物和氮化物陶瓷的寿命常因硬度与韧性之间的固有权衡关系以及磨损、腐蚀和高温等严苛服役条件而显著缩短。为此,提出了一种通过调幅分解诱导相分离的策略,旨在协同提升(Ti, Zr)(C, N)碳氮化物陶瓷的硬度和韧性。基于热力学计算指导的成分设计,合成了多种不同成分的(Ti, Zr)(C, N)陶瓷样品,系统研究了时效温度和时长对调幅分解过程中显微组织演化的影响。实验结果表明,调幅分解可诱导形成纳米相分离组织,形成纳米级强化网络,从而实现了材料的硬度与韧性的协同提升。此外,结合机器学习模型,构建了成分配比、微观组织与力学性能之间的定量关联,实现了碳氮化物陶瓷的高效筛选和优化。研究结果不仅揭示了调幅分解提升陶瓷力学性能的内在机理,更为极端环境下高性能陶瓷材料的理性设计提供了数据驱动框架。

-

关键词:

- 机器学习 /

- (Ti, Zr)(C, N) /

- 调幅分解 /

- 成分设计

Abstract: Traditional transition-metal carbide and nitride ceramics often exhibit a trade-off between hardness and toughness, leading to significantly reduced service life under severe conditions such as wear, corrosion, and high temperature. In this study, a spinodal decomposition-induced phasese paration strategy was employed to simultaneously enhance the hardness and toughness of (Ti, Zr)(C, N) carbonitride ceramics. Guided by thermodynamic calculations, a series of compositional variants of (Ti, Zr)(C, N) ceramics were synthesized, and the effects of aging temperature and duration on the microstructural evolution were systematically investigated. The experimental results demonstrate that spinodal decomposition induces the formation of a nanoscale phase-separated network, which strengthens the material while preserving fracture resistance. Furthermore, machine-learning models were developed to quantitatively correlate composition, microstructural features, and mechanical properties, enabling efficient screening and optimization of carbonitride ceramics. This work not only elucidates the intrinsic mechanisms by which spinodal decomposition enhances ceramic mechanical performance but also provides a data-driven framework for the rational design of high-performance ceramics for extreme environments.-

Key words:

- machine learning /

- (Ti, Zr)(C, N) /

- spinodal decomposition /

- composition design

-

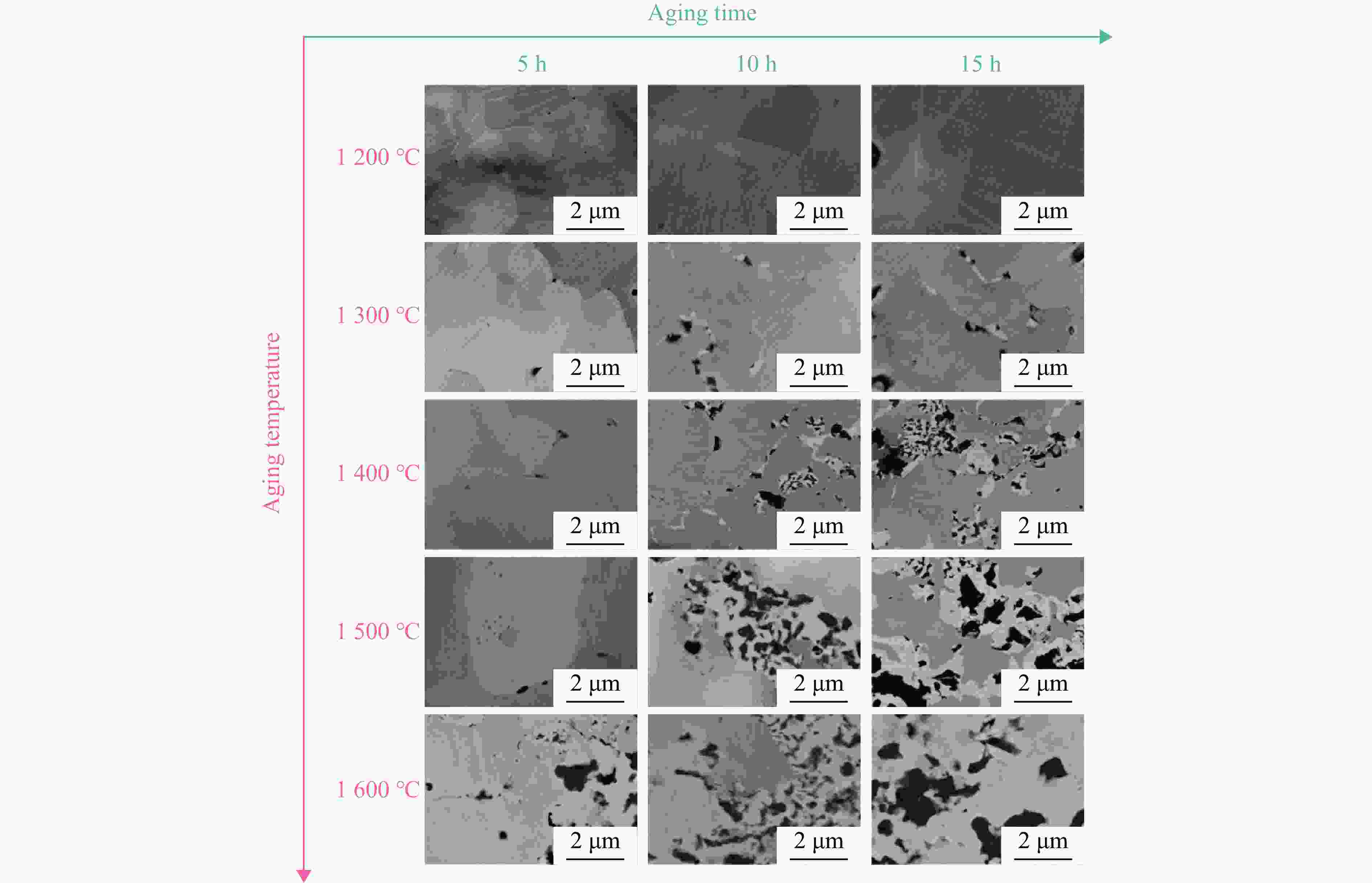

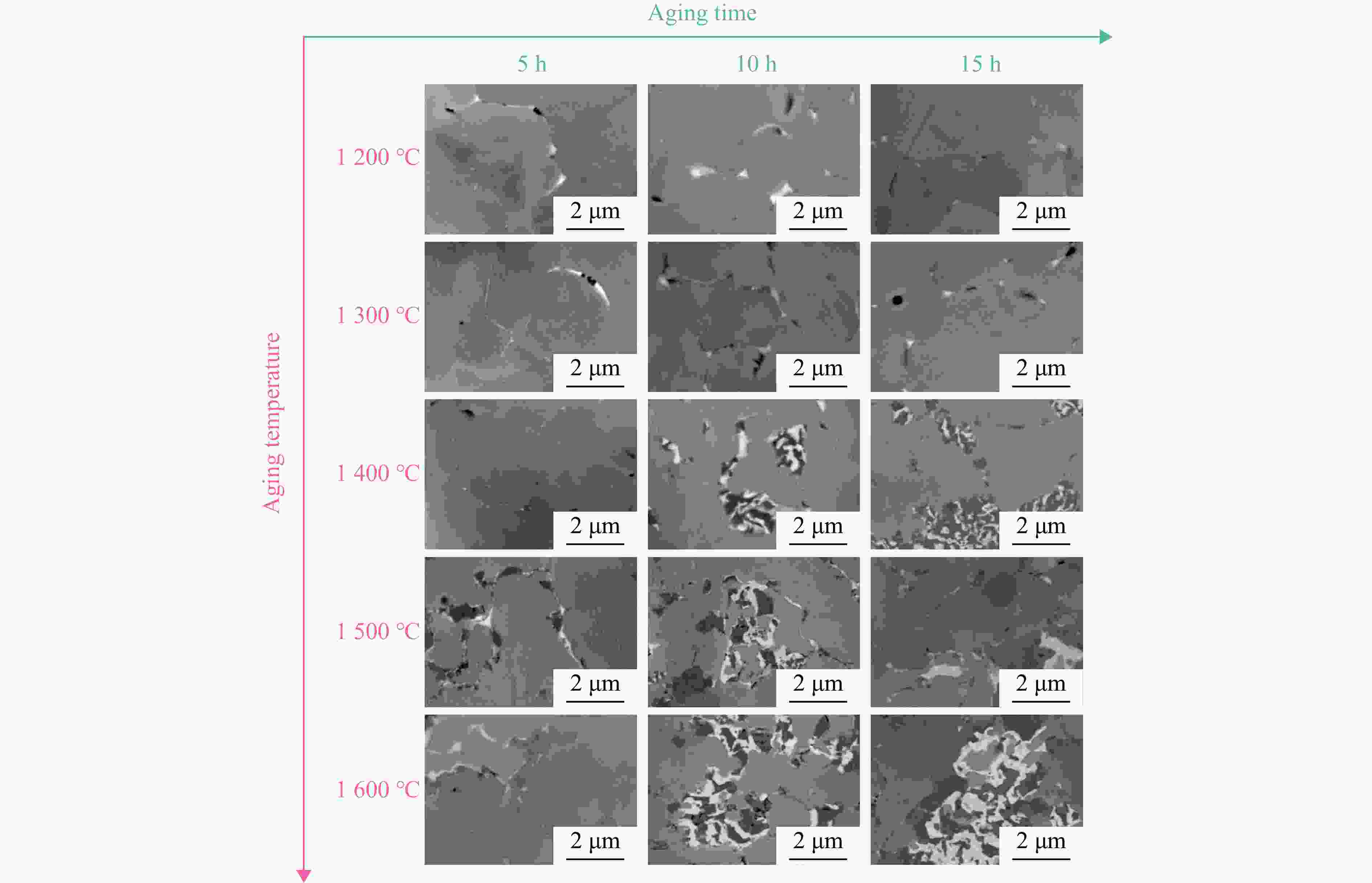

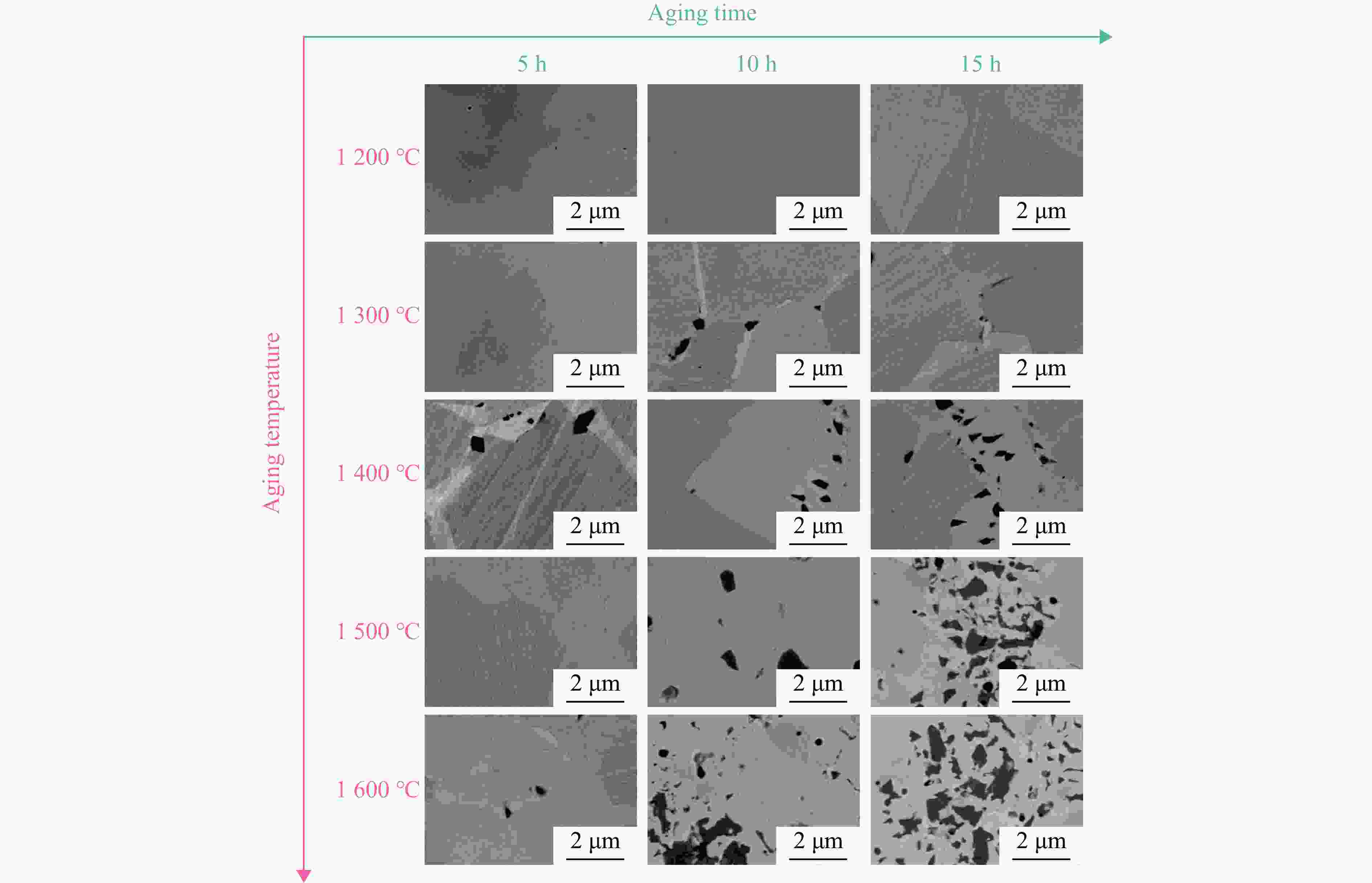

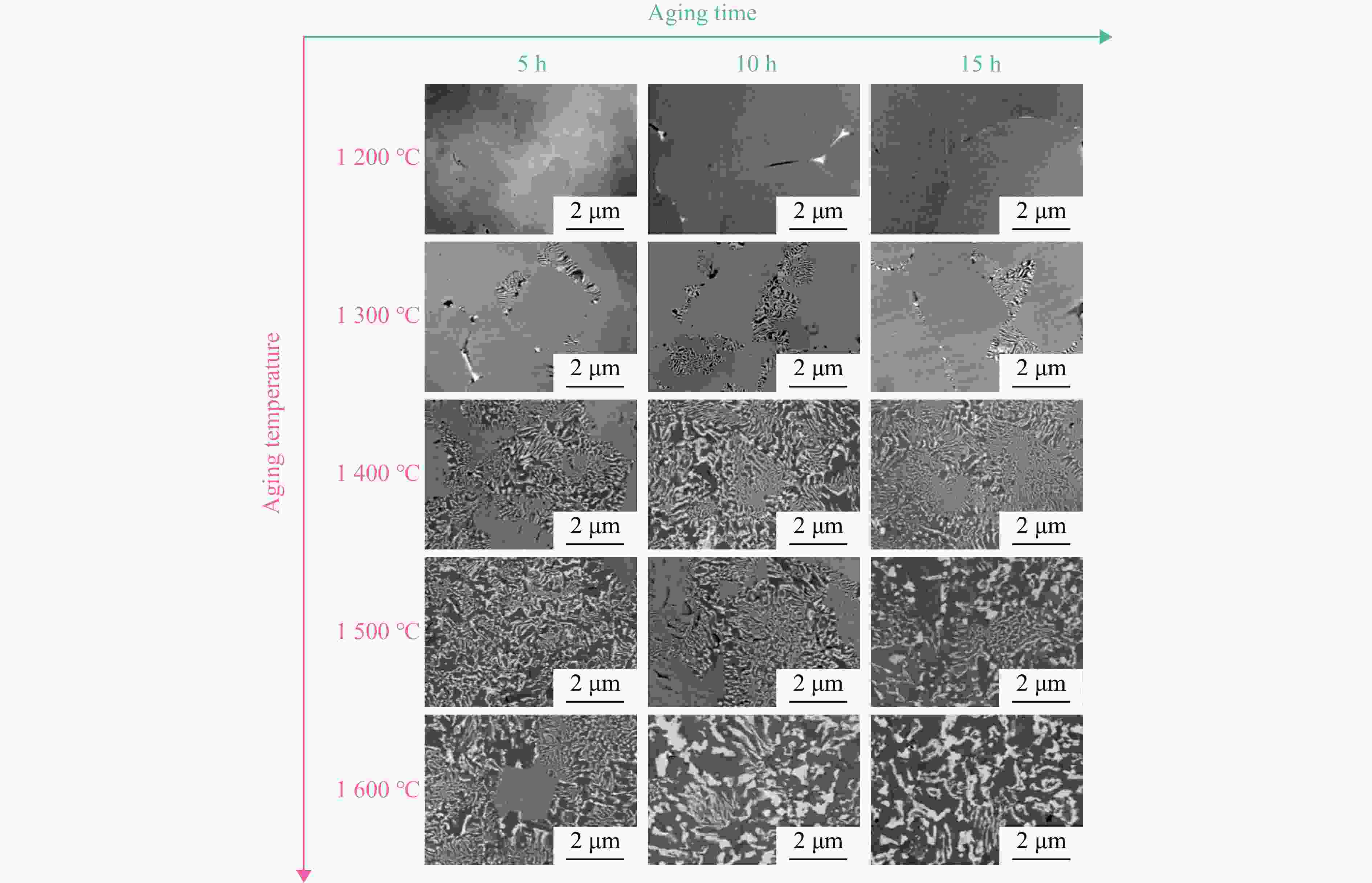

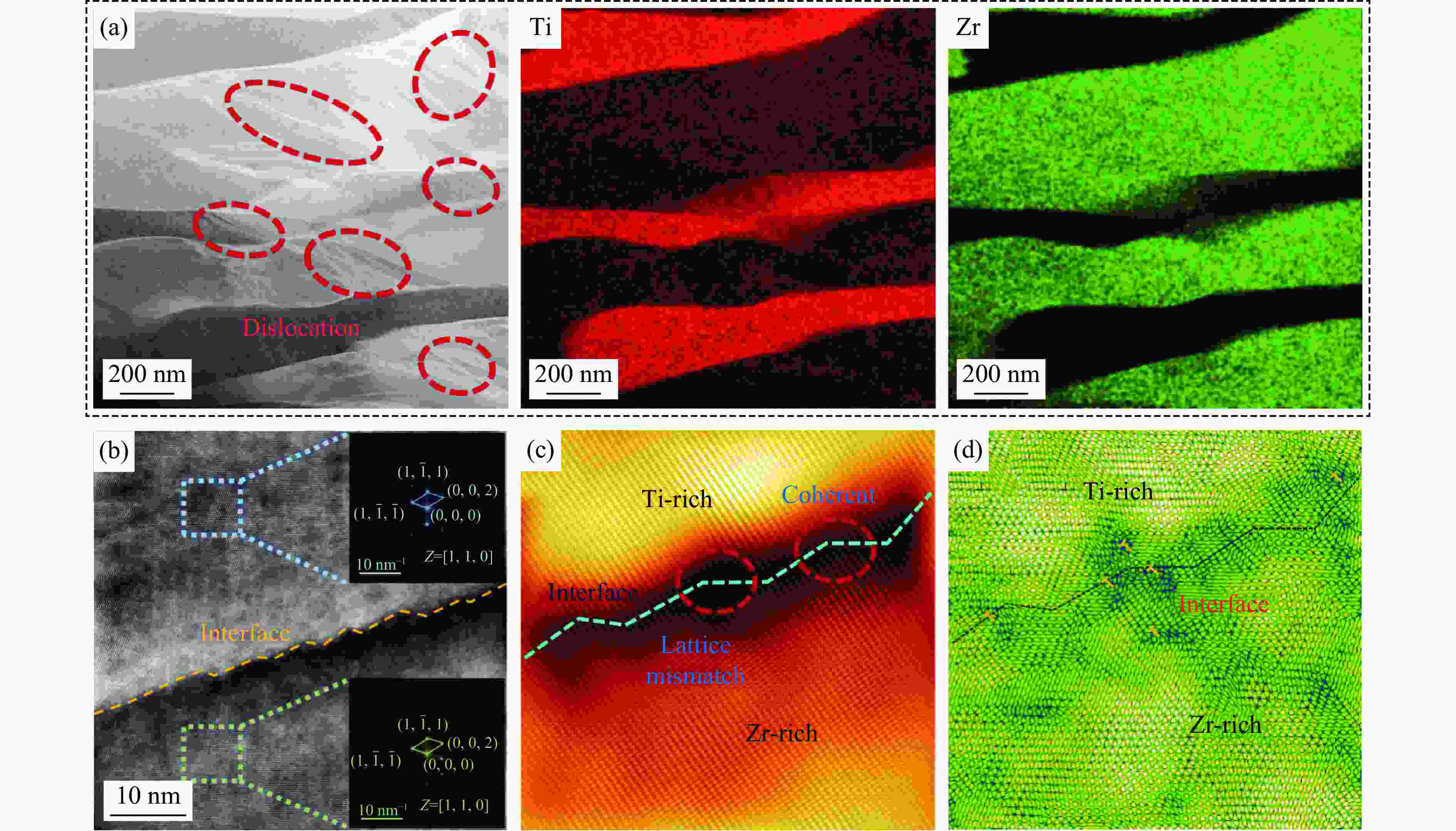

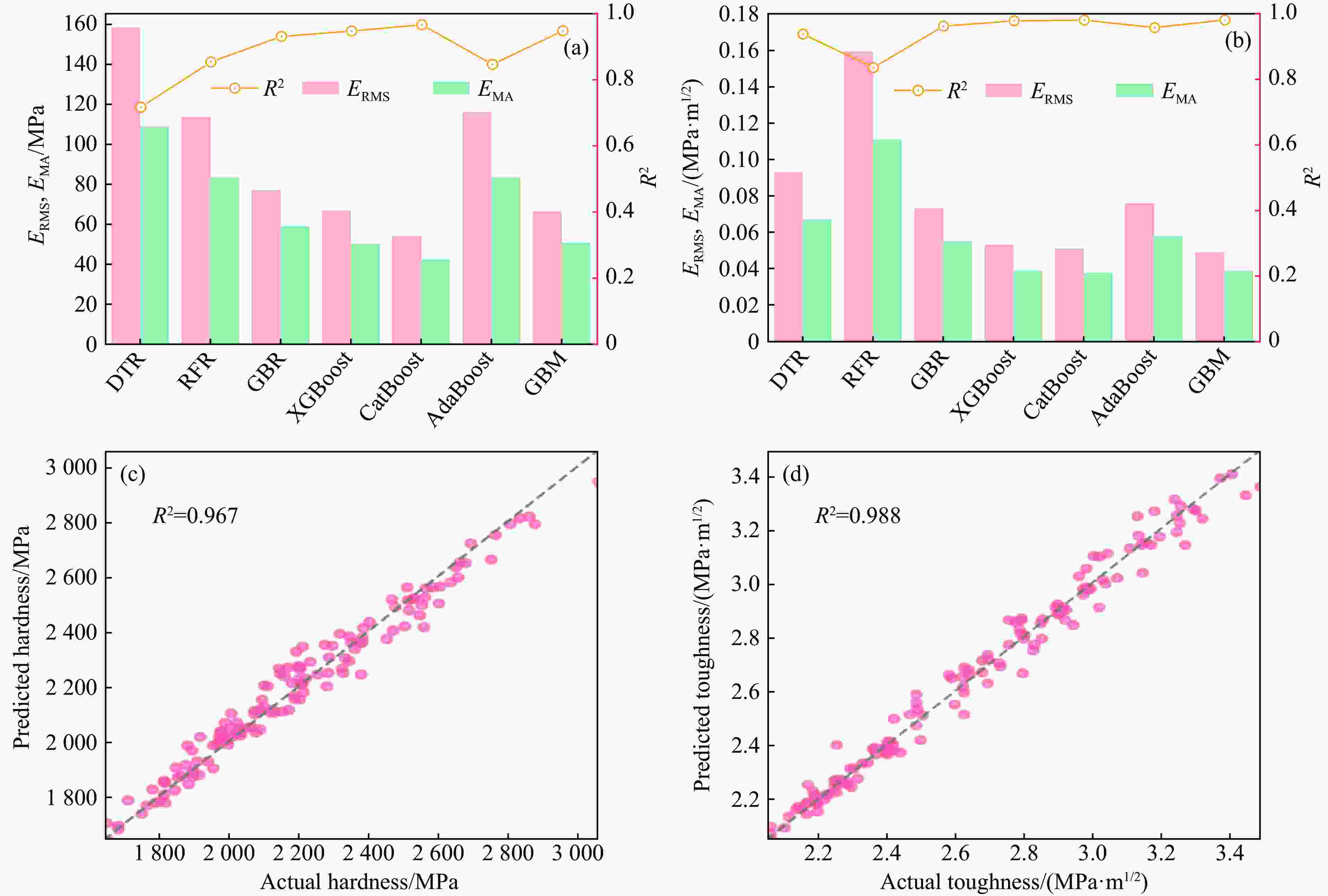

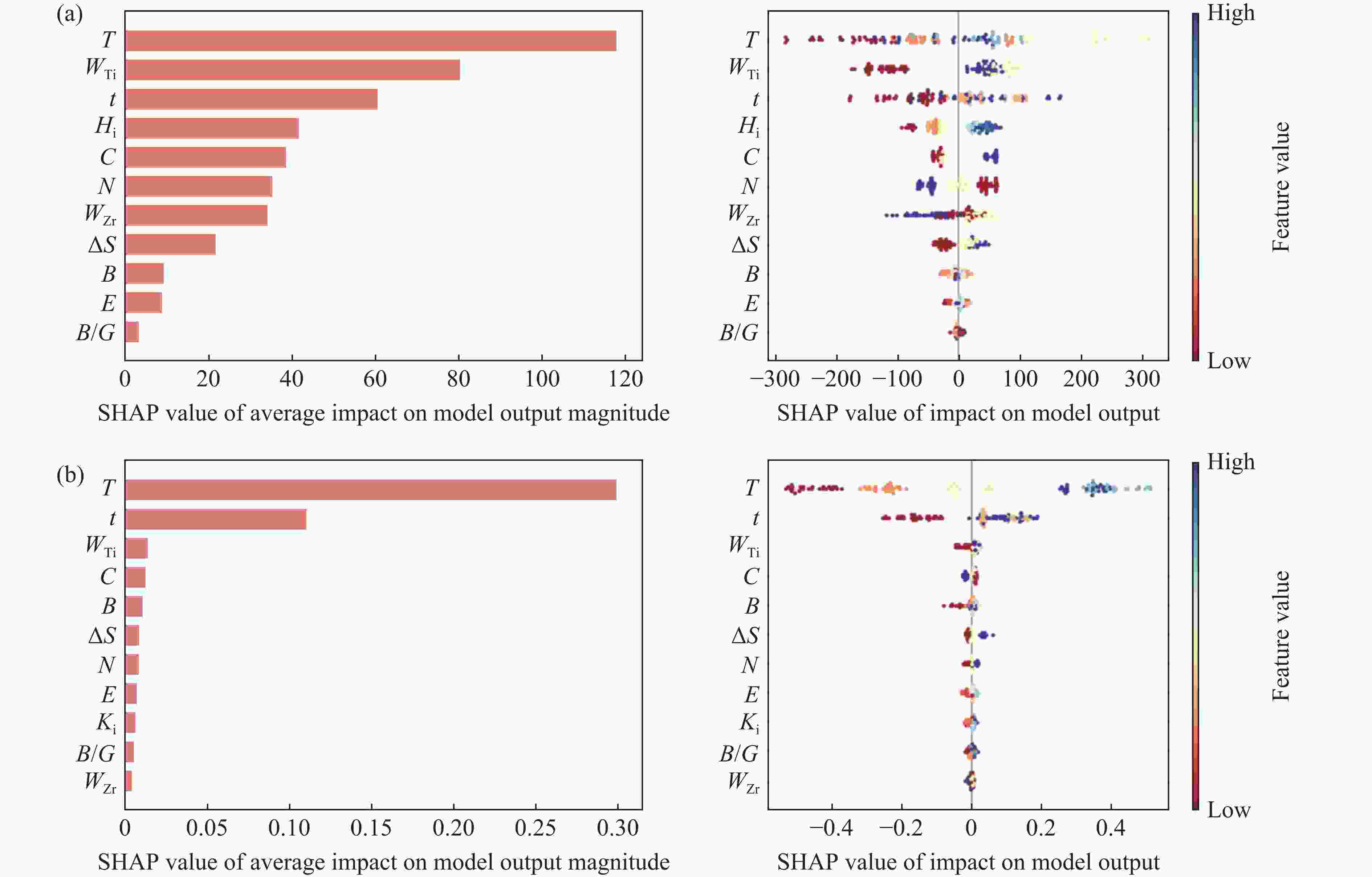

图 10

1500 ℃、10 h下(Ti0.75, Zr0.25)(C0.75, N0.25)的TEM图像:(a) 样品的形貌及EDS图(中间和右侧),(b) 高分辨率图,(c)~(d) 傅里叶逆变换图Figure 10. TEM images of the (Ti0.75, Zr0.25)(C0.75, N0.25) at

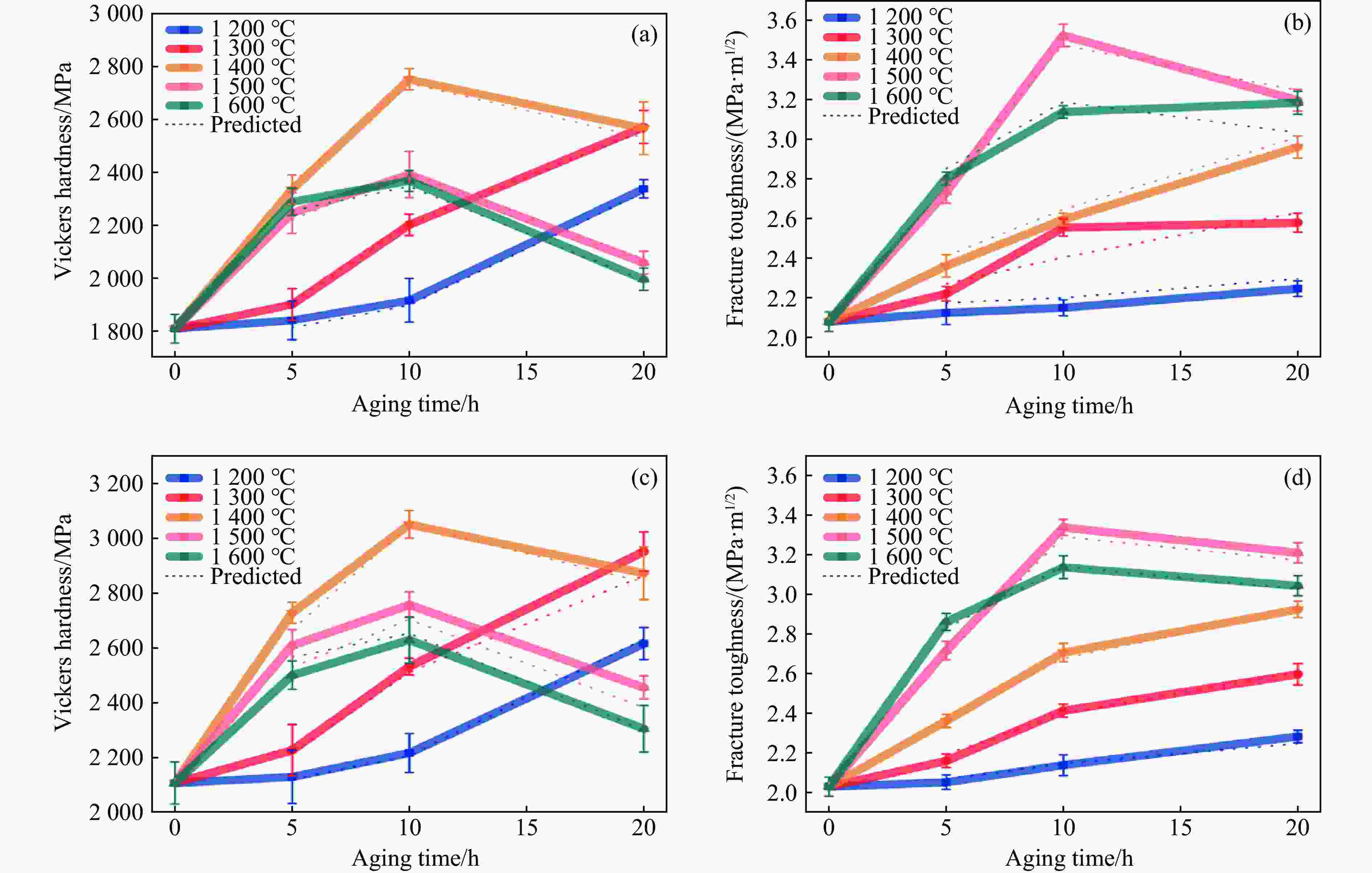

1500 ℃ and 10 h: (a) overview morphology and EDS images (middle and right) of the sample; (b) high-resolution TEM image; (c)–(d) inverse Fourier-transformed images图 16 机器学习的材料性能预测:样品(Ti0.60, Zr0.40)(C0.30, N0.70)的(a)硬度和(b)韧性,样品(Ti0.60, Zr0.40)(C0.75, N0.25)的(c)硬度和(d)韧性

Figure 16. Machine learning prediction of material properties: (a) hardness and (b) toughness of the (Ti0.60, Zr0.40)(C0.30, N0.70), (c) hardness and (d) toughness of the (Ti0.60, Zr0.40)(C0.75, N0.25)

表 1 样品制备所需原料的质量及配比

Table 1. Mass and proportions of raw materials required for sample preparation

Sample Mass/g TiC ZrC TiN ZrN (Ti0.25, Zr0.75)(C0.25, N0.75) 0 2.575 1.550 5.250 (Ti0.75, Zr0.25)(C0.25, N0.75) 0 2.575 4.650 0 (Ti0.25, Zr0.75)(C0.5, N0.5) 1.500 2.575 0 5.250 (Ti0.75, Zr0.25)(C0.5, N0.5) 3.000 0 1.550 2.625 (Ti0.25, Zr0.75)(C0.75, N0.25) 0 7.725 1.550 0 (Ti0.75, Zr0.25)(C0.75, N0.25) 3.000 2.575 1.550 0 -

[1] WANG Q, DENG Y M, DAI M Y, et al. Multiphase ceramic SiBCN-ZrO2/ZrC/ZrB2/SiC with ultra-wide bandwidth electromagnetic absorption [J]. Chemical Engineering Journal, 2024, 498: 155392. doi: 10.1016/j.cej.2024.155392 [2] CAI F Y, NI D W, BAO W C, et al. Ablation behavior and mechanisms of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiC high-entropy ceramic matrix composites [J]. Composites Part B: Engineering, 2022, 243: 110177. doi: 10.1016/j.compositesb.2022.110177 [3] KONG Q Y, ZHANG R, CHEN L, et al. Phase transition of multi-component (TiZrVNb)C ceramics—part Ⅰ: phase decomposition induced by carbon content [J]. Journal of Advanced Ceramics, 2024, 13(5): 679–688. doi: 10.26599/JAC.2024.9220888 [4] BABU R P, MA T R, HEDSTRÖM P, et al. A transmission electron microscopy study of discontinuous precipitation in the high misfit system (Ti, Zr)C [J]. Materials Today Communications, 2020, 25: 101281. doi: 10.1016/j.mtcomm.2020.101281 [5] GILLI N, WATTS J, FAHRENHOLTZ W G, et al. Design of ultra-high temperature ceramic nano-composites from multi-scale length microstructure approach [J]. Composites Part B: Engineering, 2021, 226: 109344. doi: 10.1016/j.compositesb.2021.109344 [6] VALLAURI D, ATÍAS ADRIAN I C, CHRYSANTHOU A. TiC-TiB2 composites: a review of phase relationships, processing and properties [J]. Journal of the European Ceramic Society, 2008, 28(8): 1697–1713. doi: 10.1016/j.jeurceramsoc.2007.11.011 [7] WANG X G, GUO W M, KAN Y M, et al. Densification behavior and properties of hot-pressed ZrC ceramics with Zr and graphite additives [J]. Journal of the European Ceramic Society, 2011, 31(6): 1103–1111. doi: 10.1016/j.jeurceramsoc.2011.01.005 [8] GUO Z Q, WANG K, CUI B, et al. Ultrastrong and ductile Al-Mg alloy matrix composites via composition-modulated precipitation induced by intragranular ceramic nanoparticles [J]. Composites Part B: Engineering, 2025, 291: 112012. doi: 10.1016/j.compositesb.2024.112012 [9] LI Y, KATSUI H, GOTO T. Effect of heat treatment on the decomposition of TiC-ZrC solid solutions by spark plasma sintering [J]. Journal of the European Ceramic Society, 2016, 36(15): 3795–3800. doi: 10.1016/j.jeurceramsoc.2016.01.039 [10] HOLLECK H. Ternäre carbidsysteme der actinoiden mit den übergangsmetallen der 4. bis 8. gruppe [J]. Journal of Nuclear Materials, 1984, 124: 129–146. doi: 10.1016/0022-3115(84)90017-5 [11] XU L, GUO W M, ZOU J, et al. Low-temperature densification of high entropy diboride based composites with fine grains and excellent mechanical properties [J]. Composites Part B: Engineering, 2022, 247: 110331. doi: 10.1016/j.compositesb.2022.110331 [12] TANG Y P, GOTO W, HIROSAWA S, et al. Concurrent strengthening of ultrafine-grained age-hardenable Al-Mg alloy by means of high-pressure torsion and spinodal decomposition [J]. Acta Materialia, 2017, 131: 57–64. doi: 10.1016/j.actamat.2017.04.002 [13] XIAO X P, YI Z Y, CHEN T T, et al. Suppressing spinodal decomposition by adding Co into Cu-Ni-Si alloy [J]. Journal of Alloys and Compounds, 2016, 660: 178–183. doi: 10.1016/j.jallcom.2015.11.103 [14] MIYAMOTO G, TATEYAMA Y, UESUGI T, et al. Solute cluster-induced precipitation and resultant surface hardening during nitriding of Fe-Al-V alloys [J]. Scripta Materialia, 2021, 203: 114121. doi: 10.1016/j.scriptamat.2021.114121 [15] RIOS O, EBRAHIMI F. Spinodal decomposition of the γ-phase upon quenching in the Ti-Al-Nb ternary alloy system [J]. Intermetallics, 2011, 19(1): 93–98. doi: 10.1016/j.intermet.2010.09.014 [16] XIE W J, WANG W H, LIU Y H. On the application of high-throughput experimentation and data-driven approaches in metallic glasses [J]. Materials Genome Engineering Advances, 2023, 1(1): e8. doi: 10.1002/mgea.8 [17] HAN X Q, LIN N, LI A Q, et al. Microstructure and characterization of (Ti, V, Nb, Ta)(C, N) high-entropy ceramic [J]. Ceramics International, 2021, 47(24): 35105–35110. doi: 10.1016/j.ceramint.2021.09.053 [18] LI R, LUO R Y, LIN N, et al. A novel strategy for fabricating (Ti, Ta, Nb, Zr, W)(C, N) high-entropy ceramic reinforced with in situ synthesized W2C particles [J]. Ceramics International, 2022, 48(21): 32540–32545. doi: 10.1016/j.ceramint.2022.07.242 [19] WANG H Y, BI J Q, YANG Y, et al. Preparation, characterization and performance of high-entropy carbonitride ceramics [J]. Ceramics International, 2024, 50(2): 3034–3040. doi: 10.1016/j.ceramint.2023.11.051 [20] HE L, LIU L J, PENG F, et al. Host lattice and solid solution formation in an octal-cation (NbTaZrTiHfVWMo)C high entropy carbide ceramic [J]. Journal of the European Ceramic Society, 2023, 43(14): 5792–5801. doi: 10.1016/j.jeurceramsoc.2023.06.061 [21] ZHANG W B, CUPID D M, GOTCU P, et al. High-throughput description of infinite composition-structure-property-performance relationships of lithium-manganese oxide spinel cathodes [J]. Chemistry of Materials, 2018, 30(7): 2287–2298. doi: 10.1021/acs.chemmater.7b05068 [22] YILDIZ A B, YIXUAN H, BABU R P, et al. Design, synthesis, structure, and stability of novel multi-principal element (Ti, Zr, Hf, W)C ceramic with a miscibility gap [J]. Journal of the European Ceramic Society, 2022, 42(11): 4429–4435. doi: 10.1016/j.jeurceramsoc.2022.04.029 [23] ZHANG W, LI K X, CHEN L, et al. The phase decomposition in non-equimolar (ZrHfVNbMoW)Cx complex concentrated carbides via carbon content regulation [J]. Journal of the European Ceramic Society, 2024, 44(3): 1396–1403. doi: 10.1016/j.jeurceramsoc.2023.10.050 [24] LV J S, LI W, LI T, et al. Ablation behavior of high-entropy boride (Hf-Zr-Ta-Ti)B2 coating fabricated via supersonic atmospheric plasma spraying for carbon/carbon composites [J]. Composites Part B: Engineering, 2024, 270: 111137. doi: 10.1016/j.compositesb.2023.111137 [25] WANG Y Y, WANG J R, CAO Z L, et al. Molecular contrastive learning of representations via graph neural networks [J]. Nature Machine Intelligence, 2022, 4(3): 279–287. doi: 10.1038/s42256-022-00447-x [26] CHEN S, JUNG Y. A generalized-template-based graph neural network for accurate organic reactivity prediction [J]. Nature Machine Intelligence, 2022, 4(9): 772–780. doi: 10.1038/s42256-022-00526-z [27] RAO J H, ZHENG S J, LU Y T, et al. Quantitative evaluation of explainable graph neural networks for molecular property prediction [J]. Patterns, 2022, 3(12): 100628. doi: 10.1016/j.patter.2022.100628 [28] KAR K, KORNBLITH S, FEDORENKO E. Interpretability of artificial neural network models in artificial intelligence versus neuroscience [J]. Nature Machine Intelligence, 2022, 4(12): 1065–1067. doi: 10.1038/s42256-022-00592-3 [29] WU Z X, WANG J K, DU H Y, et al. Chemistry-intuitive explanation of graph neural networks for molecular property prediction with substructure masking [J]. Nature Communications, 2023, 14(1): 2585. doi: 10.1038/s41467-023-38192-3 [30] ZHANG R Z, YUAN Y, WANG X H, et al. Machine learning-assisted rapid electromagnetic design of flexible graphene-based absorptive composites [J]. Chemical Engineering Journal, 2025, 511: 161634. doi: 10.1016/j.cej.2025.161634 [31] WU Z X, KANG L R, HUANG T C, et al. Elevating perovskite efficiency via machine learning-assisted screening of passivators [J]. Chemical Engineering Journal, 2024, 499: 156391. doi: 10.1016/j.cej.2024.156391 [32] SCHMIDT J, MARQUES M R G, BOTTI S, et al. Recent advances and applications of machine learning in solid-state materials science [J]. NPJ Computational Materials, 2019, 5(1): 83. doi: 10.1038/s41524-019-0221-0 [33] JABLONKA K M, ONGARI D, MOOSAVI S M, et al. Big-data science in porous materials: materials genomics and machine learning [J]. Chemical Reviews, 2020, 120(16): 8066–8129. doi: 10.1021/acs.chemrev.0c00004 [34] CHEN C, ZUO Y X, YE W K, et al. A critical review of machine learning of energy materials [J]. Advanced Energy Materials, 2020, 10(8): 1903242. doi: 10.1002/aenm.201903242 [35] LIU H, FU Z P, YANG K, et al. Machine learning for glass science and engineering: a review [J]. Journal of Non-Crystalline Solids, 2021, 557: 119419. doi: 10.1016/j.jnoncrysol.2019.04.039 [36] HART G L W, MUELLER T, TOHER C, et al. Machine learning for alloys [J]. Nature Reviews Materials, 2021, 6(8): 730–755. doi: 10.1038/s41578-021-00340-w [37] SHANG Y, XIONG Z Y, AN K, et al. Materials genome engineering accelerates the research and development of organic and perovskite photovoltaics [J]. Materials Genome Engineering Advances, 2024, 2(1): e28. doi: 10.1002/mgea.28 [38] JIN X Z, LUO H, WANG X F, et al. Data mining accelerated the design strategy of high-entropy alloys with the largest hardness based on genetic algorithm optimization [J]. Materials Genome Engineering Advances, 2024, 2(2): e49. doi: 10.1002/mgea.49 [39] WANG W H, MINAMI T, SHENG Y X, et al. Intelligent quantitative recognition of SARS-CoV-2 using machine learning-based ratiometric fluorescent paper sensors of metal-organic framework Al3+/Au NCs@ZIF-90 [J]. Chemical Engineering Journal, 2025, 506: 159933. doi: 10.1016/j.cej.2025.159933 [40] WAN Y, WEI Q, SUN H, et al. Machine learning assisted biomimetic flexible SERS sensor from seashells for pesticide classification and concentration prediction [J]. Chemical Engineering Journal, 2025, 507: 160813. doi: 10.1016/j.cej.2025.160813 [41] QIU X R, LI H, VER STEEG G, et al. Advances in AI for protein structure prediction: implications for cancer drug discovery and development [J]. Biomolecules, 2024, 14(3): 339. doi: 10.3390/biom14030339 [42] CHANDRA A, TÜNNERMANN L, LÖFSTEDT T, et al. Transformer-based deep learning for predicting protein properties in the life sciences [J]. eLife, 2023, 12: e82819. doi: 10.7554/eLife.82819 [43] PAKHRIN S C, SHRESTHA B, ADHIKARI B, et al. Deep learning-based advances in protein structure prediction [J]. International Journal of Molecular Sciences, 2021, 22(11): 5553. doi: 10.3390/ijms22115553 [44] CHEN L L, LI C H, XU K, et al. Data-driven prediction of phase formation in graphene-metal systems based on phase diagram insights [J]. Materials Genome Engineering Advances, 2025, 3(1): e81. doi: 10.1002/MGEA.81 [45] LIU M Q, HU H Y, CUI Y J, et al. Modeling and analysis of droplet generation in microchannels using interpretable machine learning methods [J]. Chemical Engineering Journal, 2025, 511: 161972. doi: 10.1016/j.cej.2025.161972 [46] PENG Y B, DU Y, ZHOU P, et al. CSUTDCC1—a thermodynamic database for multicomponent cemented carbides [J]. International Journal of Refractory Metals and Hard Materials, 2014, 42: 57–70. doi: 10.1016/j.ijrmhm.2013.10.005 [47] LUKAS H L, FRIES S G, SUNDMAN B. Computational thermodynamics: the Calphad method [M]. Cambridge: Cambridge University Press, 2007. [48] SUNDMAN B, JANSSON B, ANDERSSON J O. The Thermo-Calc databank system [J]. Calphad, 1985, 9(2): 153–190. doi: 10.1016/0364-5916(85)90021-5 [49] POPE C G. X-ray diffraction and the Bragg equation [J]. Journal of Chemical Education, 1997, 74(1): 129. doi: 10.1021/ed074p129 [50] KONG Q Y, CHEN L, HUO S J, et al. Phase transition of multi-component (TiZrVNb)C ceramics—part Ⅱ: from single phase to multiple phases via adjusting V content [J]. Journal of Advanced Ceramics, 2024, 13(5): 689–698. doi: 10.26599/JAC.2024.9220889 [51] KIM H I, KIM T W, KIM Y O, et al. Age-hardenability and related microstructural changes during and after phase transformation in an Au-Ag-Cu-based dental alloy [J]. Materials Research, 2013, 16(1): 71–78. doi: 10.1590/S1516-14392012005000169 [52] ZHANG Z, ZHANG Z, CHANG G, et al. Nitrogen-induced stacking fault energy reduction enables spinodal-decomposition-driven toughening in (Ti, Zr)C ceramics [J]. Journal of Advanced Ceramics, 2025. [53] TAN S T, WANG R K, SONG G K, et al. Machine learning and shapley additive explanation-based interpretable prediction of the electrocatalytic performance of N-doped carbon materials [J]. Fuel, 2024, 355: 129469. doi: 10.1016/j.fuel.2023.129469 [54] KRZYWINSKI M, ALTMAN N. Classification and regression trees [J]. Nature Methods, 2017, 14(8): 757–758. doi: 10.1038/nmeth.4370 [55] ANTONIADIS A, LAMBERT-LACROIX S, POGGI J M. Random forests for global sensitivity analysis: a selective review [J]. Reliability Engineering & System Safety, 2021, 206: 107312. doi: 10.1016/j.ress.2020.107312 [56] SIGRIST F. Gradient and Newton boosting for classification and regression [J]. Expert Systems with Applications, 2021, 167: 114080. doi: 10.1016/j.eswa.2020.114080 [57] CHEN T Q, GUESTRIN C. XGBoost: a scalable tree boosting system [C]//Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining. San Francisco: ACM, 2016: 785–794. [58] PROKHORENKOVA L, GUSEV G, VOROBEV A, et al. CatBoost: unbiased boosting with categorical features [C]//Proceedings of the 32nd International Conference on Neural Information Processing Systems. Montréal: Curran Associates Inc., 2018: 6639−6649. [59] ZHANG P. An optimized AdaBoost algorithm based on k-means clustering [J]. Journal of Physics: Conference Series, 2021, 1856(1): 012021. doi: 10.1088/1742-6596/1856/1/012021 [60] NATEKIN A, KNOLL A. Gradient boosting machines, a tutorial [J]. Frontiers in Neurorobotics, 2013, 7: 21. doi: 10.3389/fnbot.2013.00021 [61] JEON J, SEO N, SON S B, et al. Application of machine learning algorithms and SHAP for prediction and feature analysis of tempered martensite hardness in low-alloy steels [J]. Metals, 2021, 11(8): 1159. doi: 10.3390/met11081159 -

下载:

下载: