Energy Conversion Characteristics and Temperature Field Simulation of Ignition Resistors for Industrial Electronic Detonators

-

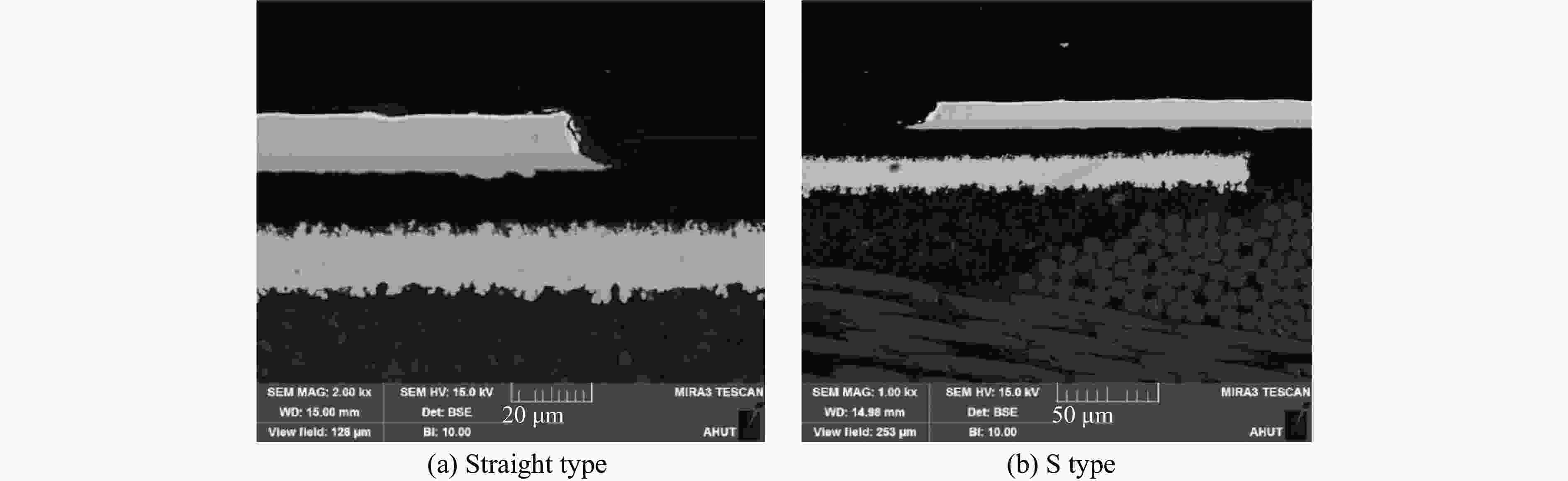

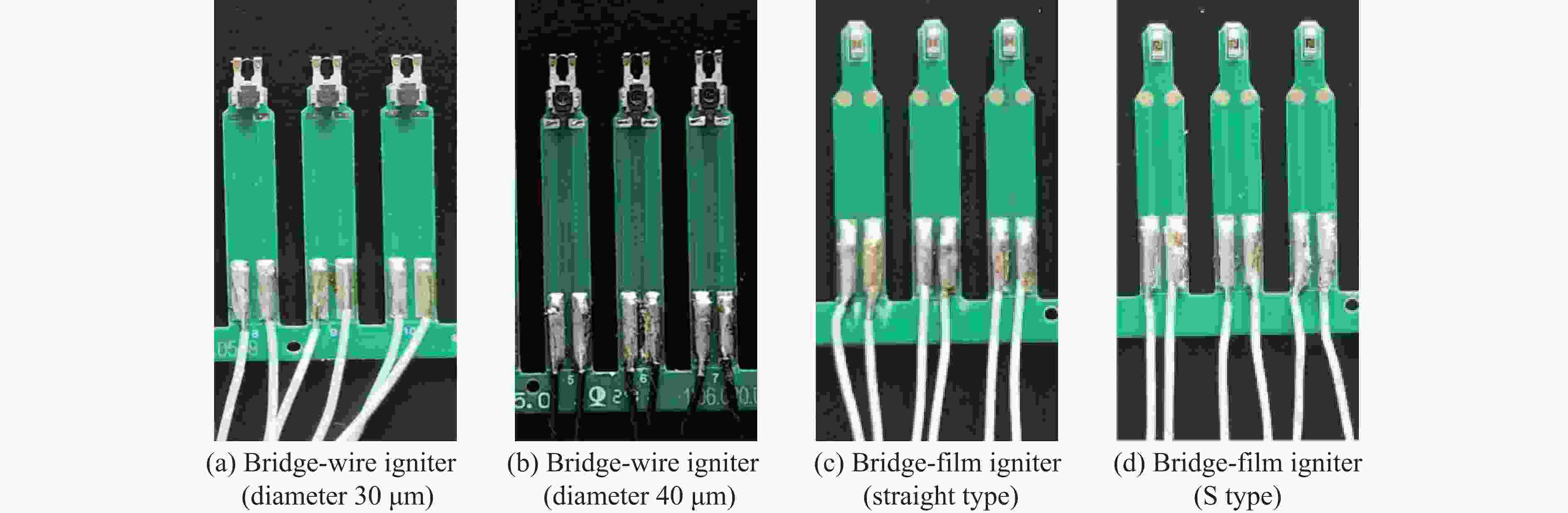

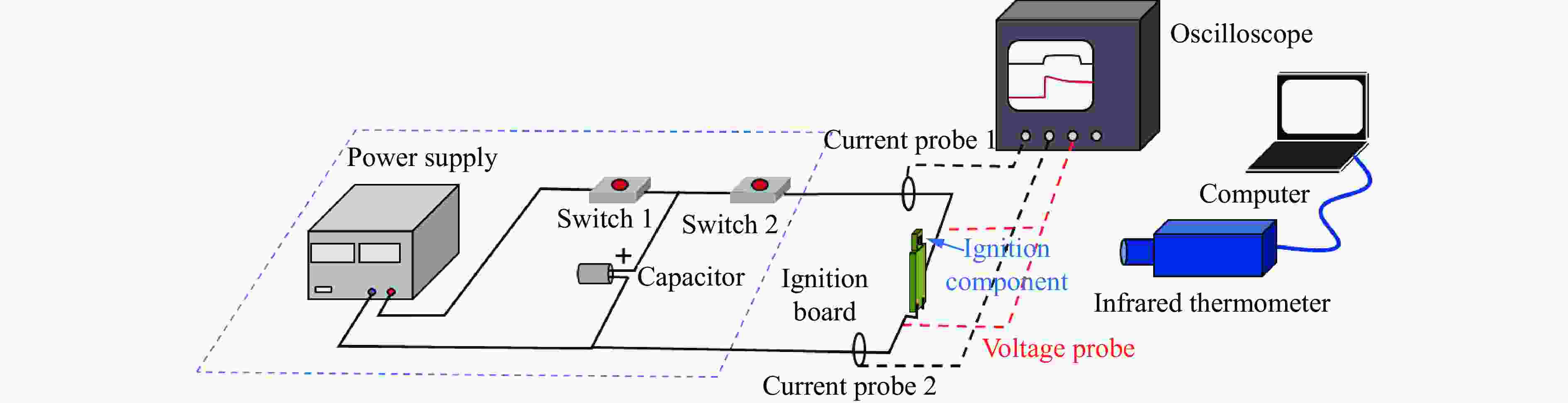

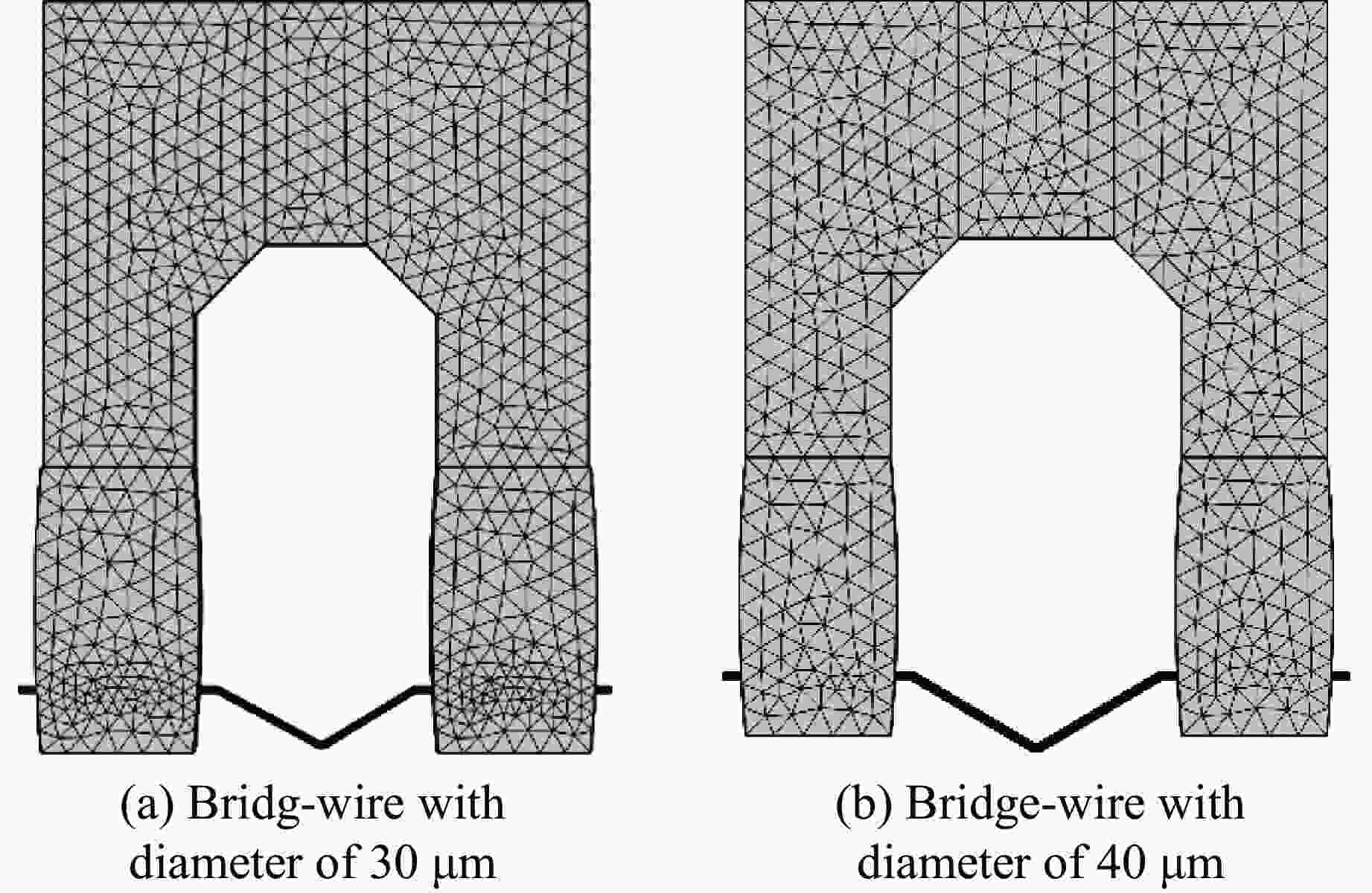

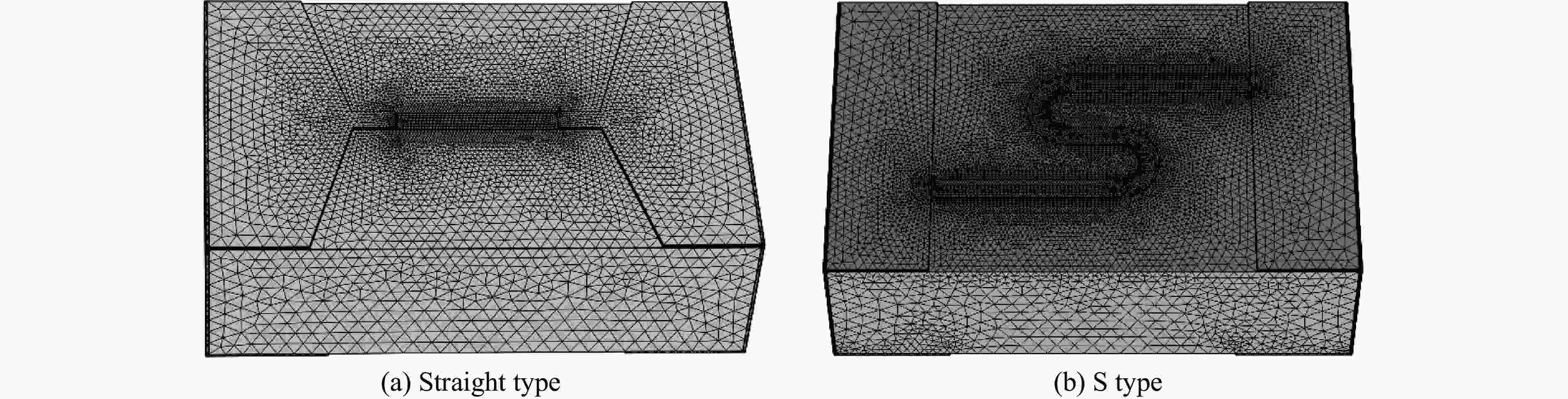

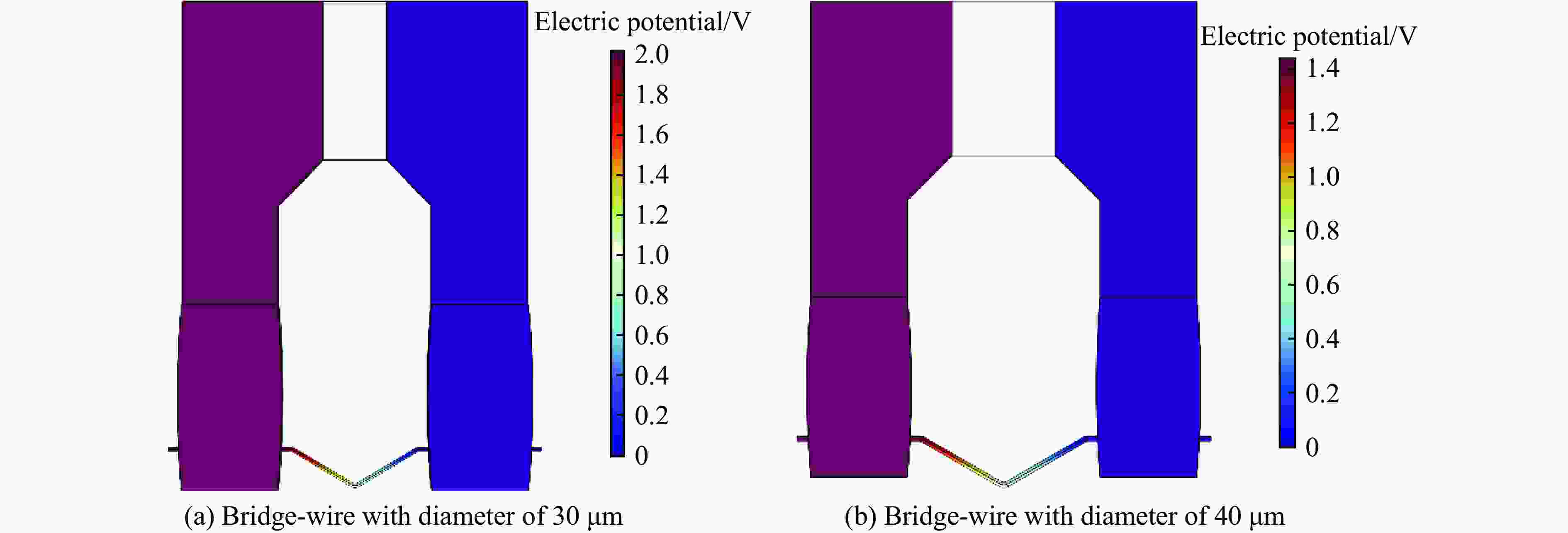

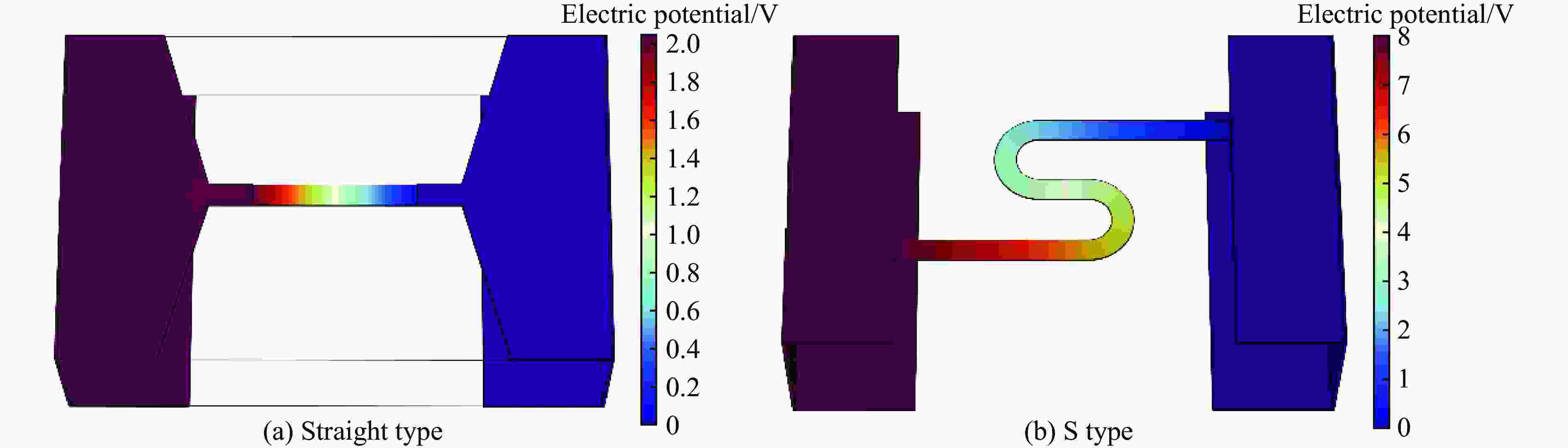

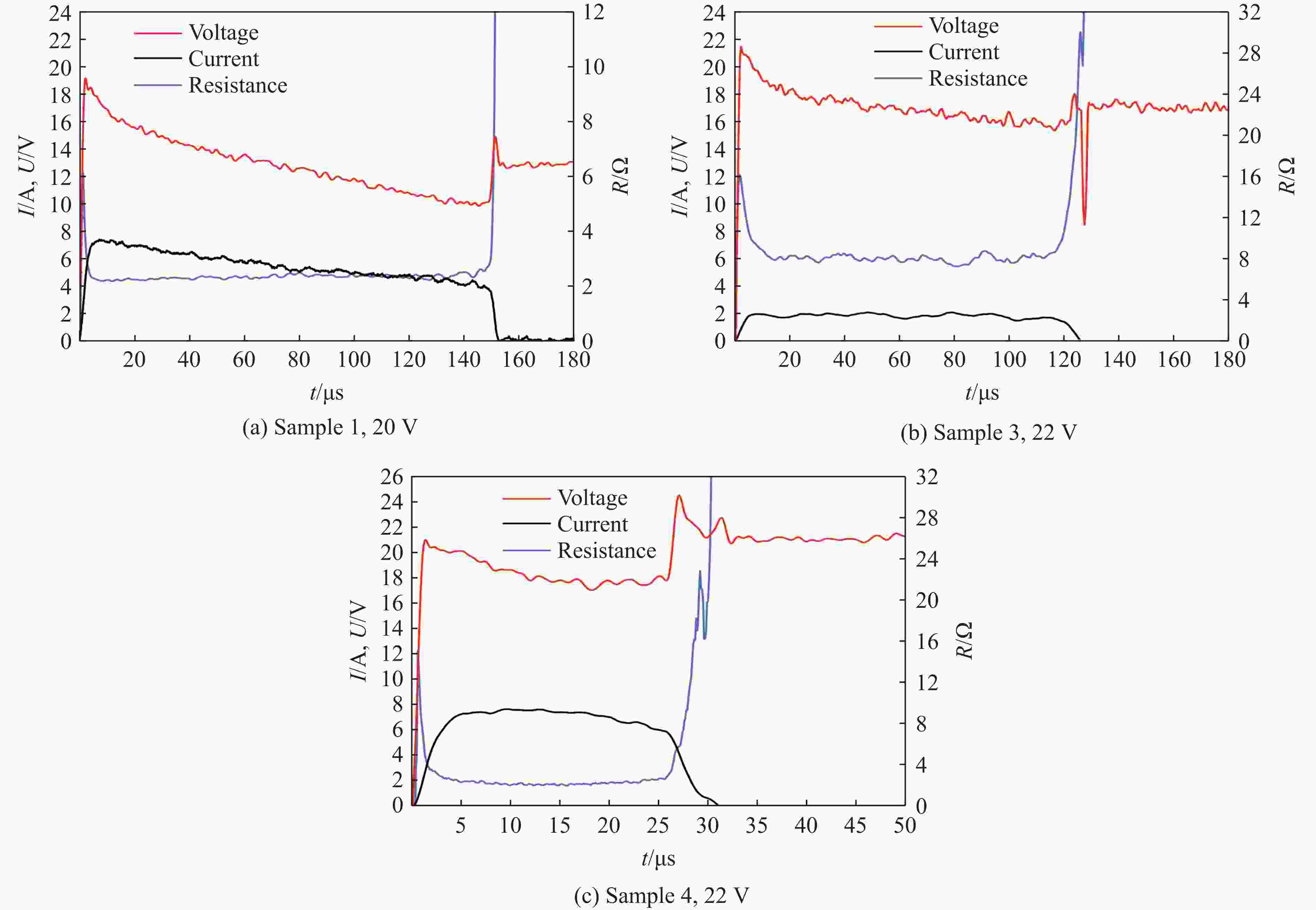

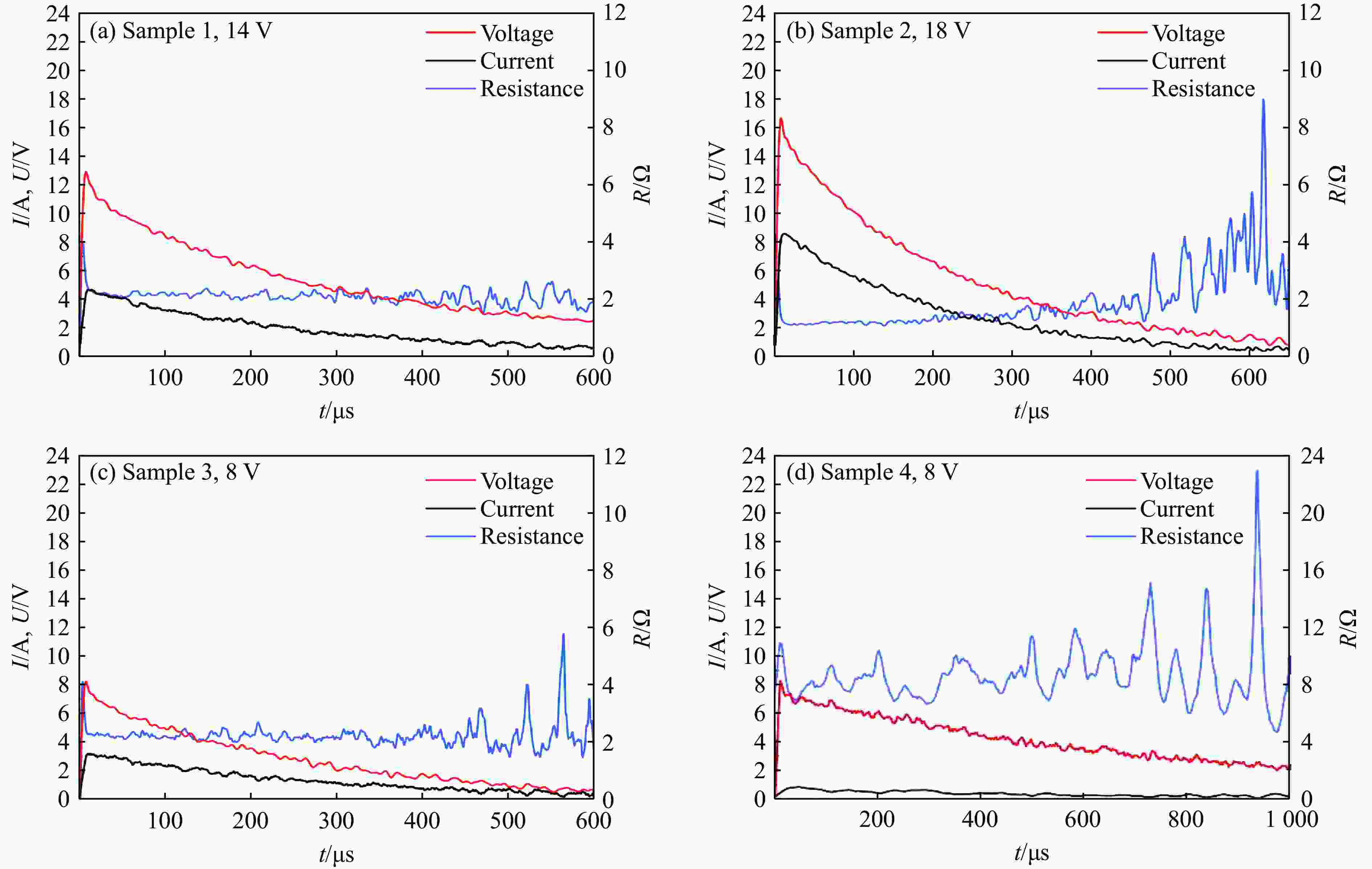

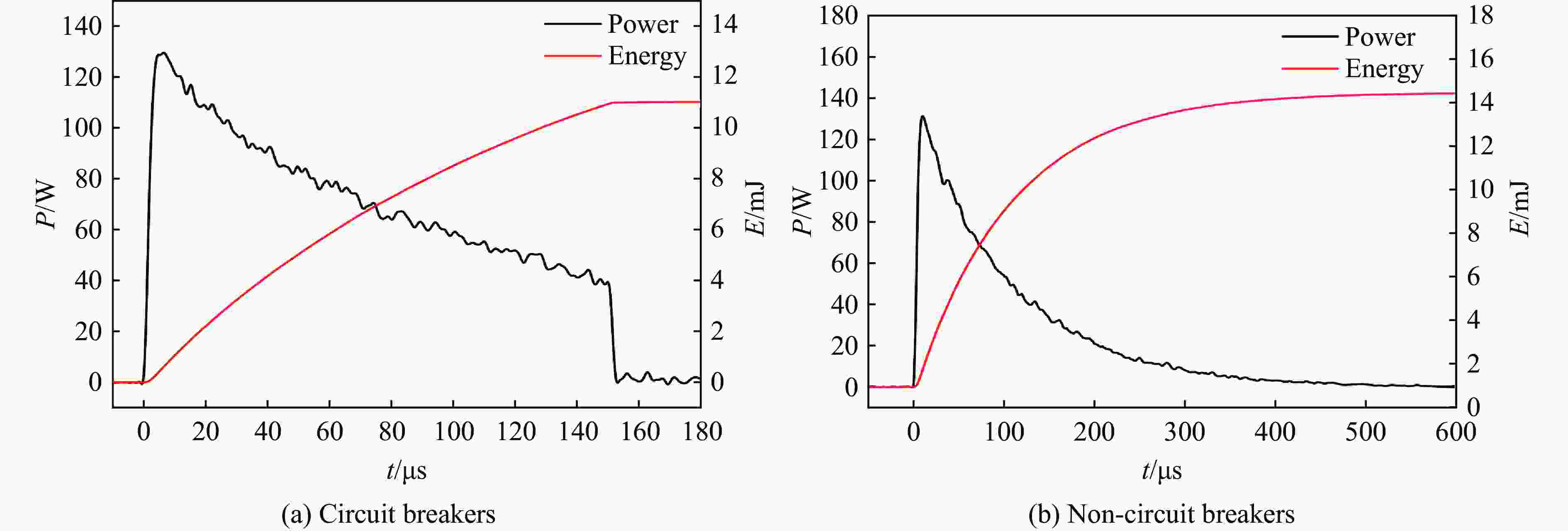

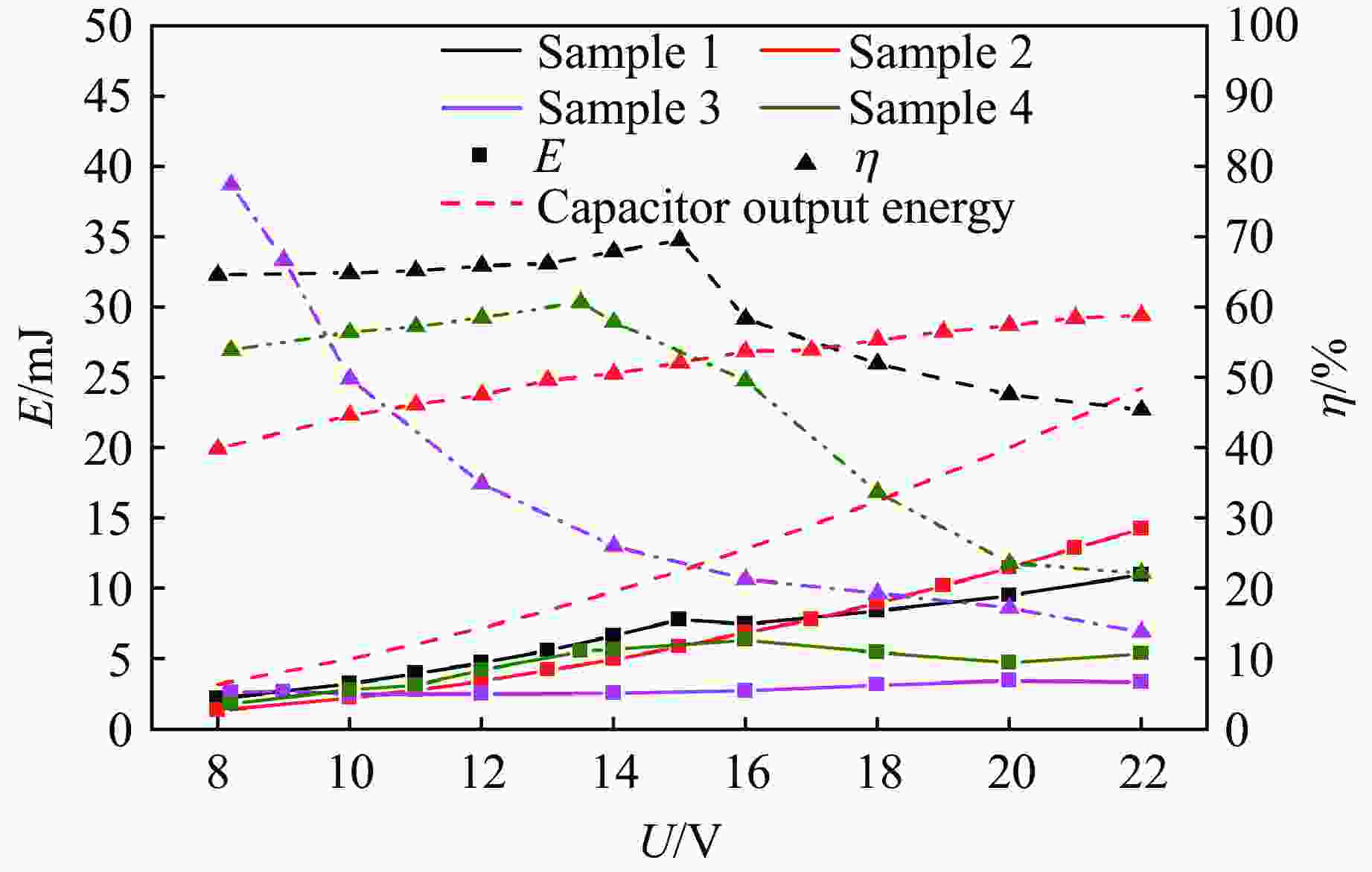

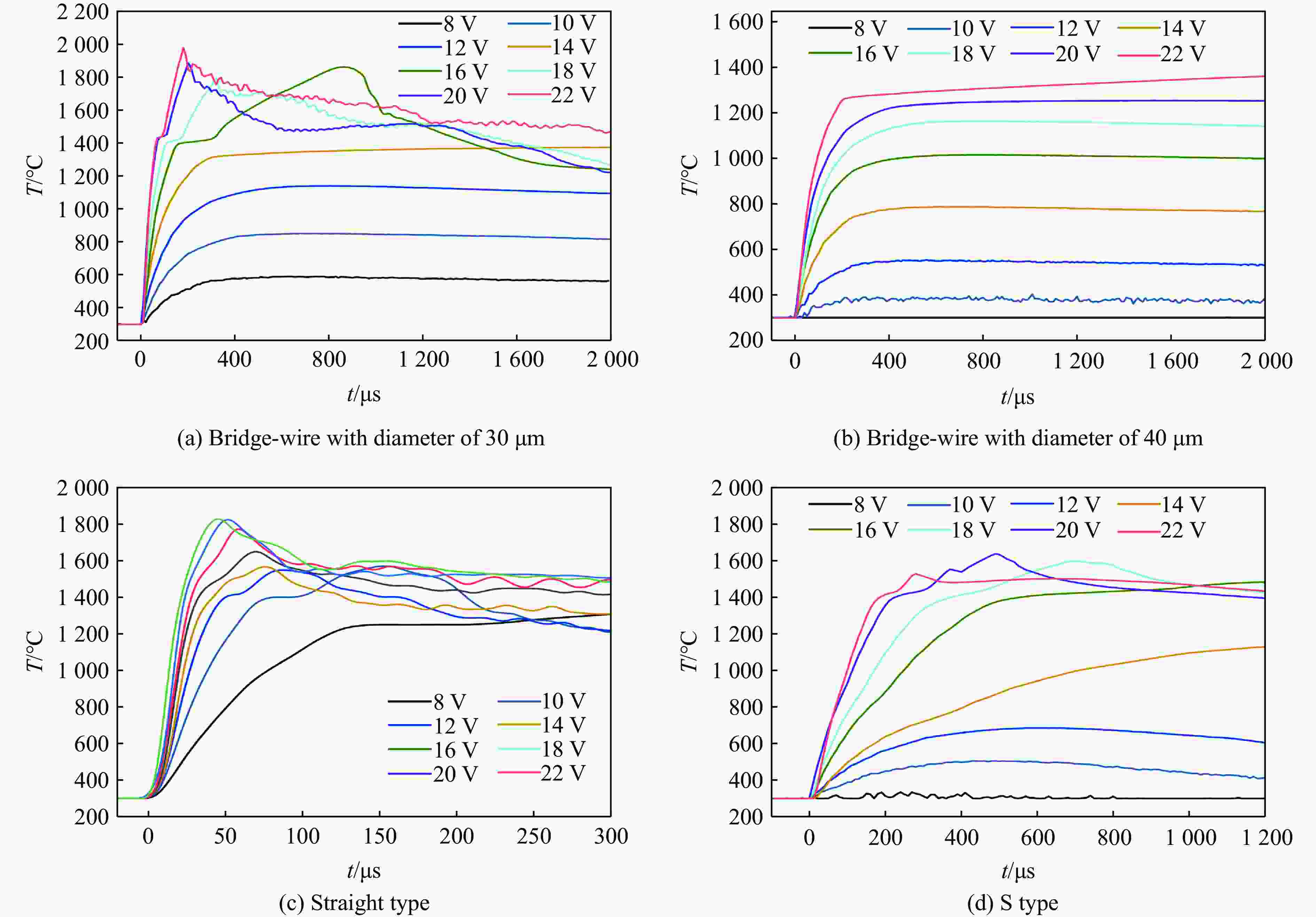

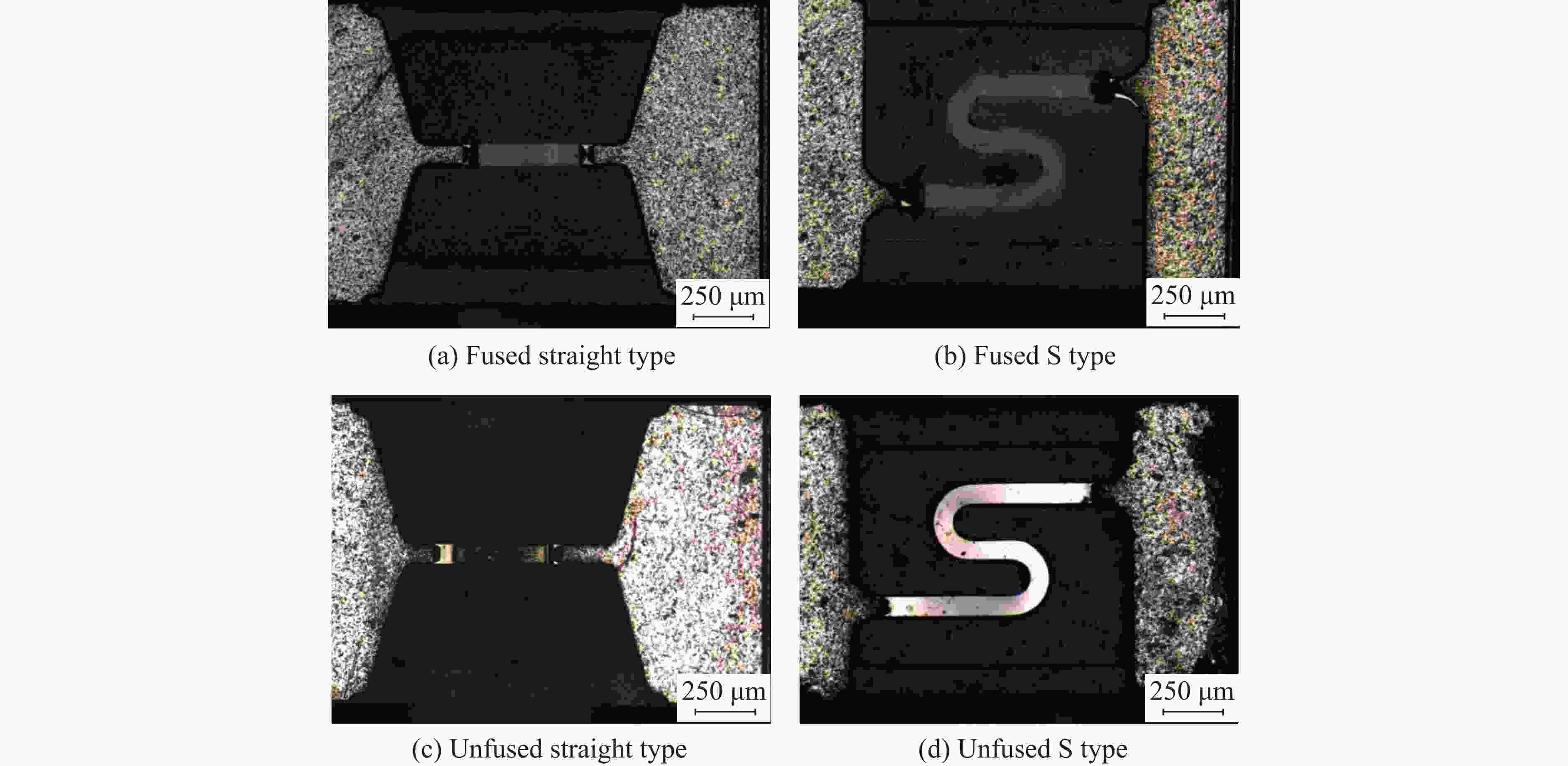

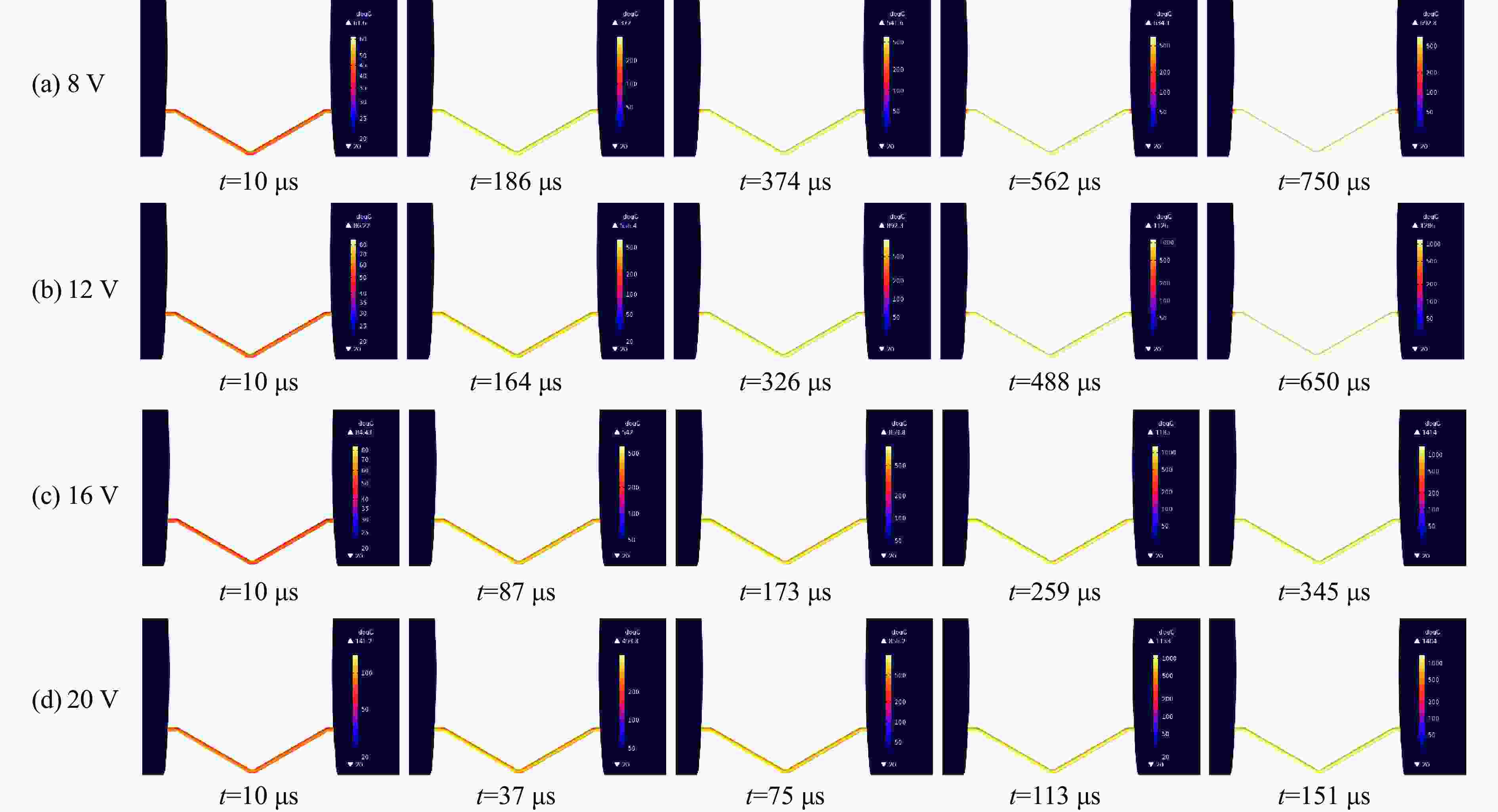

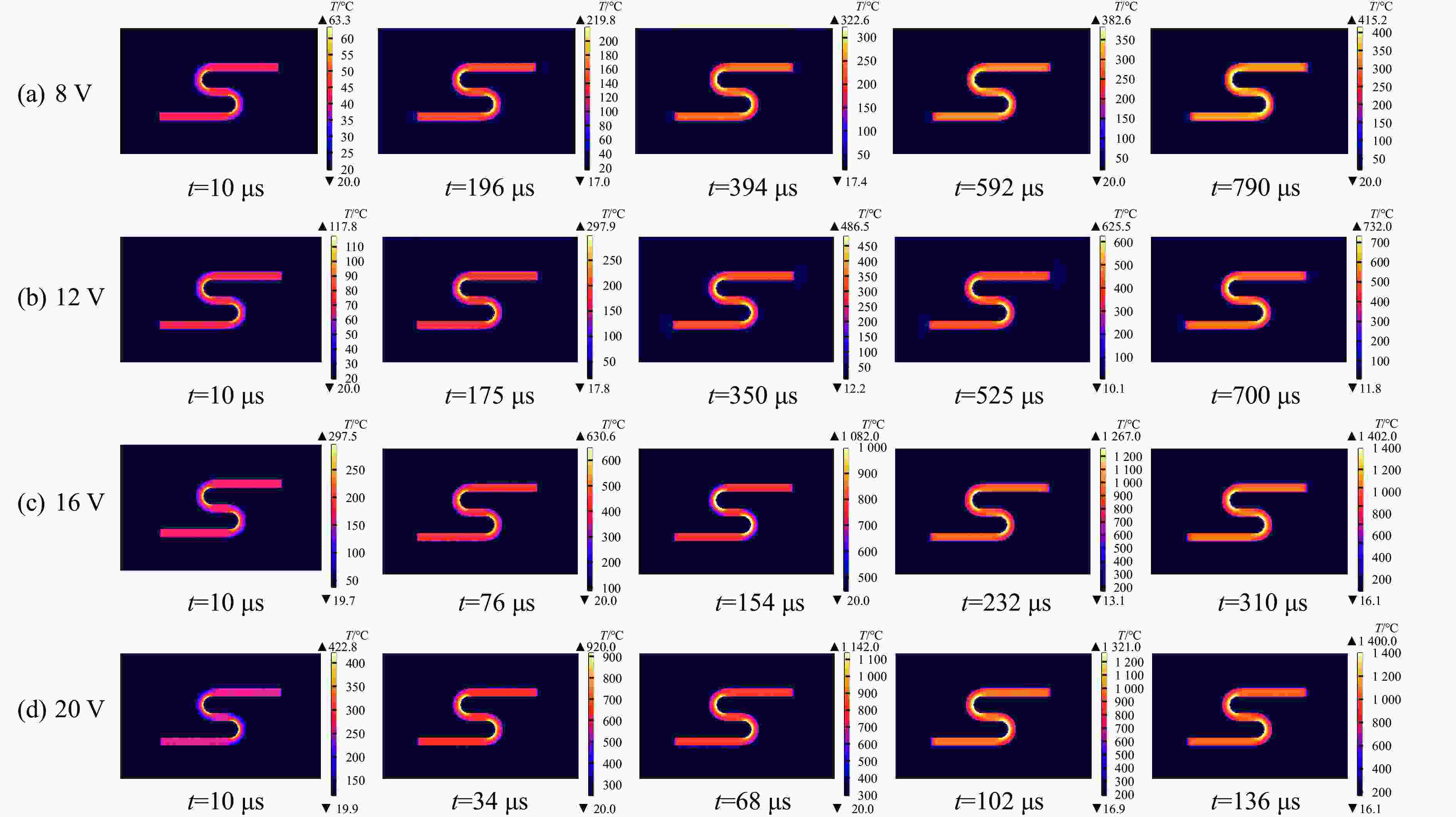

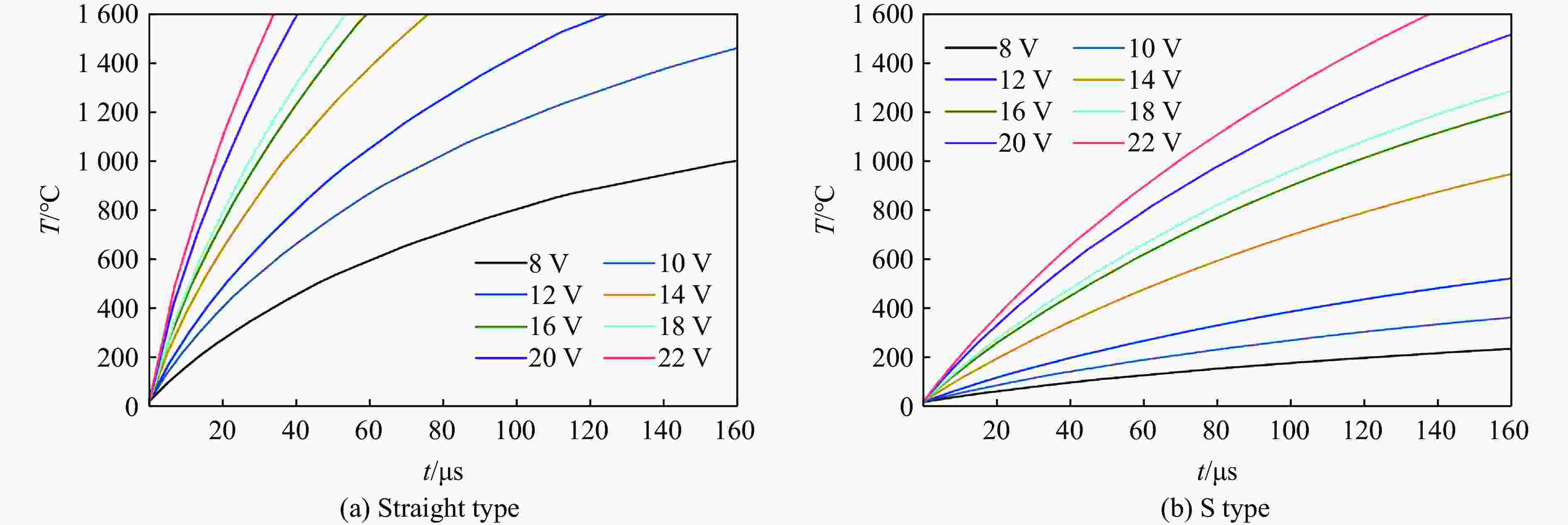

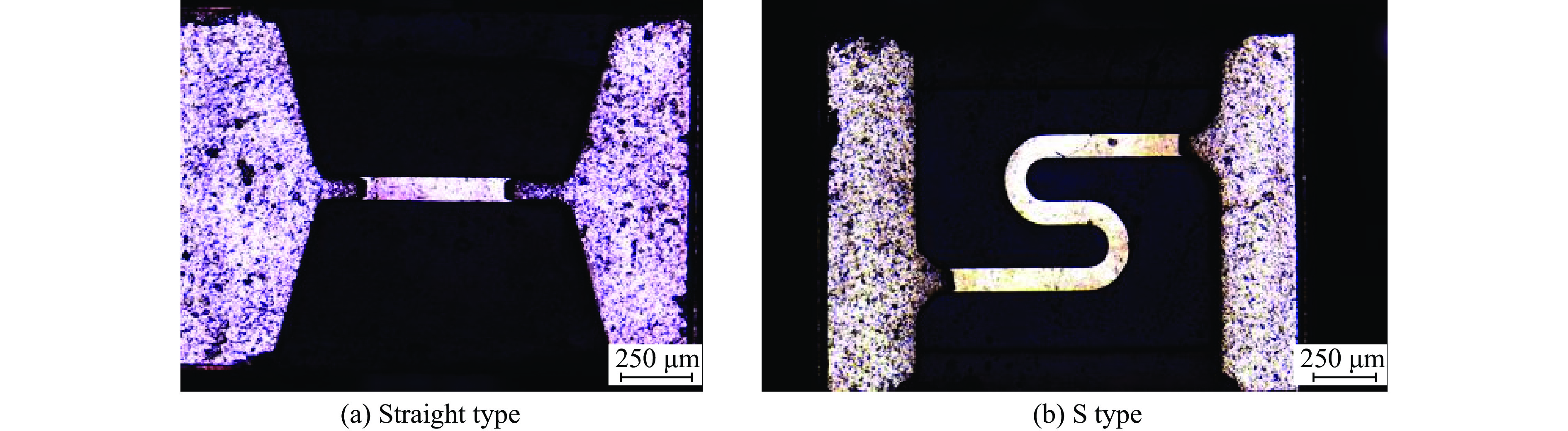

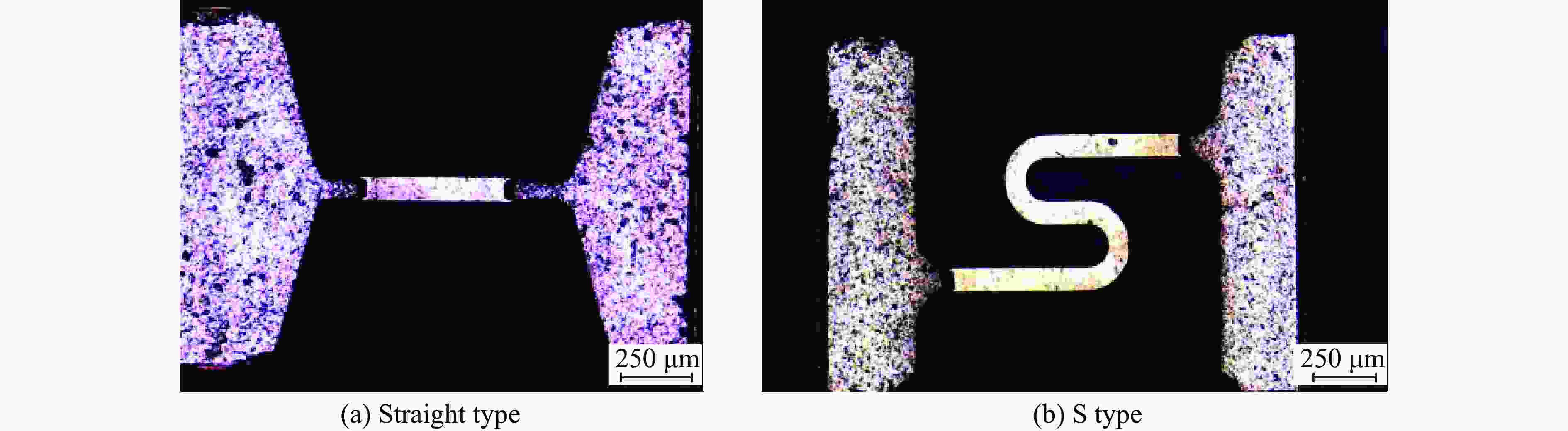

摘要: 为了研究点火电阻发火过程中温度的动态变化,解决储能电容-点火电阻体系的匹配性问题,通过电热实验、红外温度测量和数值模拟方法,对不同电容放电电压下点火电阻的电压-电流变化和温度变化进行测量,并结合未熔断样品的表面情况,确定点火电阻的临界熔断电压,得出点火电阻的电特性规律和温度变化规律。结果表明:在相同电压下,桥膜式直线型点火电阻的熔断时间最短;相同阻值下,桥膜式点火电阻的熔断时间和升温时间比桥丝式更短,能达到的最高温度也更高。数值仿真结果与实验数据吻合良好,验证了模型的准确性,同时揭示了桥丝式和桥膜式S型点火电阻在通电过程中热量易在拐角处积累并率先发生相变的规律。Abstract: In order to study the dynamic changes of temperature during the ignition process of the ignition resistor and solve the matching problem of the energy storage capacitor-ignition resistor system, this study measures the voltage-current changes and temperature changes of the ignition resistor under different capacitor discharge voltages through electrothermal experiments, infrared temperature measurement and numerical simulation methods. Combined with the surface conditions of the unmelted samples, the critical fuse voltage of the ignition resistor was determined, and the law of the electrical characteristic curve and the temperature variation law of the ignition resistor were obtained. The results show that under the same voltage, the bridge membrane straight type has the shortest melting time. Under the same resistance value, the melting time and heating time of the bridge-film ignition resistor are shorter than those of the bridge-wire type, and the maximum temperature it can reach is also higher. For the bridge-wire type and bridge-film S type ignition resistors, heat is prone to accumulate at the corners and phase change occurs first during the power-on process.

-

Key words:

- electronic detonator /

- ignition resistor /

- Joule heat /

- fuse voltage /

- temperature distribution /

- COMSOL

-

表 1 实验方案

Table 1. Experimental scheme

Sample Igniter type Dimension Capacitor Capacitor charging voltage/V 1 Bridge-wire igniter $\varnothing $30 μm Liquid aluminum

capacitor8, 10, 12, 14, 16, 18, 20, 22 2 Bridge-wire igniter $\varnothing $40 μm 3 Bridge-film igniter Straight type 4 Bridge-film igniter S type 表 2 材料参数

Table 2. Material parameters

Materials ρb/(kg·m−3) cp/(J·kg−1·K−1) k/(W·m−1·K−1) ε ρ0/(Ω·m) a/K−1 Copper 8960 385 400.0 6.5 5.998×10−2 5.4×10−3 Ni-Cr alloy 8400 1.0 1.090×10−6 3.5×10−4 FR-4 substrate 1900 1369 0.3 4.5 表 3 桥丝式点火电阻的主要尺寸

Table 3. Main dimensions of bridge-wire ignition resistor

Bridge-wire diameter/μm Bridge-wire length/mm Bridge spacing/mm 30 1.31 1.2 40 1.67 1.5 表 4 桥膜式点火电阻的主要尺寸

Table 4. Main dimensions of bridge-film ignition resistors

Type Length/μm Width/μm Thickness/μm Spacing/μm Straight type 590 80 4 S type 2350 80 4 170 表 5 点火元件熔断结果

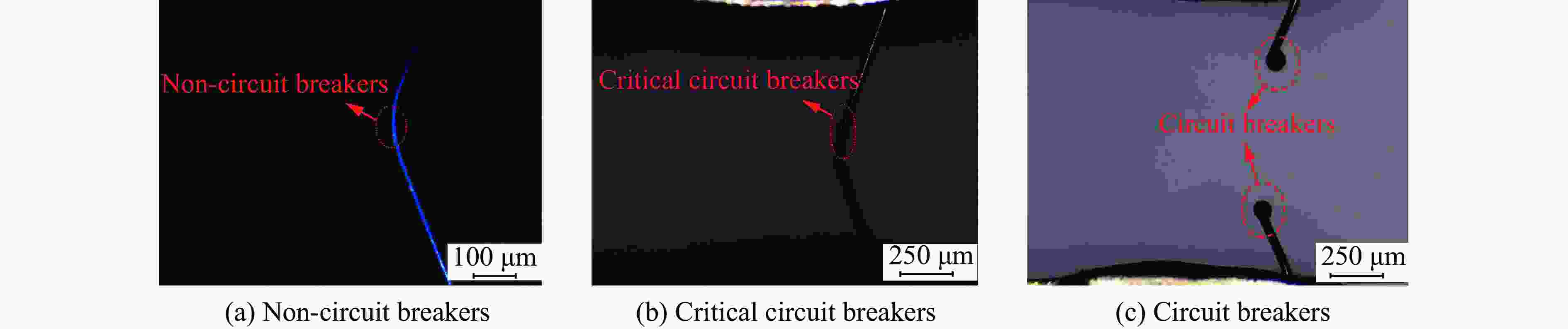

Table 5. Fusing results of ignition elements

Voltage/V Bridge-wire igniter Bridge-film igniter Sample 1 Sample 2 Sample 3 Sample 4 8 Not fused Not fused Not fused Not fused 10 Not fused Not fused Fusing Not fused 12 Not fused Not fused Fusing Not fused 14 Not fused Not fused Fusing Fusing 16 Fusing Not fused Fusing Fusing 18 Fusing Not fused Fusing Fusing 20 Fusing Not fused Fusing Fusing 22 Fusing Not fused Fusing Fusing 表 6 临界熔断电压

Table 6. Critical fuse voltage

Sample Resistance value/Ω Experimental value/V 1 2.03 15.28 2 Not fused Not fused 3 1.92 8.35 4 7.89 13.62 表 7 点火电阻的平均熔断时间

Table 7. Average fusing time of ignition resistor

Voltage/V Fusing time of bridge-wire ignition resistor/μs Fusing time of bridge-film ignition resistor/μs Sample 1 Sample 2 Sample 3 Sample 4 8 Not fused Not fused Not fused Not fused 10 Not fused Not fused 153.0 Not fused 12 Not fused Not fused 103.2 Not fused 14 Not fused Not fused 65.6 373.6 16 645.7 Not fused 52.3 329.3 18 213.5 Not fused 47.6 205.7 20 166.2 Not fused 36.6 155.6 22 152.2 Not fused 31.1 129.2 表 8 点火电阻的发火性能参数

Table 8. Ignition performance parameters of ignition resistors

Voltage/V Q/mJ Sample 1 Sample 2 Sample 3 Sample 4 E/mJ η/% E/mJ η/% E/mJ η/% E/mJ η/% 8 3.20 2.17 64.54 1.34 39.86 2.60 77.33 1.81 53.84 10 5.00 3.24 64.80 2.23 44.60 2.49 49.80 2.82 56.40 12 7.20 4.74 65.83 3.42 47.50 2.51 34.86 4.21 58.47 14 9.80 6.65 67.86 4.95 50.51 2.55 26.02 5.67 57.86 16 12.80 7.47 58.36 6.87 53.67 2.73 21.33 6.34 49.53 18 16.20 8.41 51.91 8.96 55.31 3.13 19.32 5.46 33.70 20 20.00 9.51 47.55 11.47 57.35 3.45 17.25 4.72 23.60 22 24.20 10.98 45.37 14.23 58.76 3.34 13.80 5.37 22.19 表 9 点火电阻温度测试结果统计

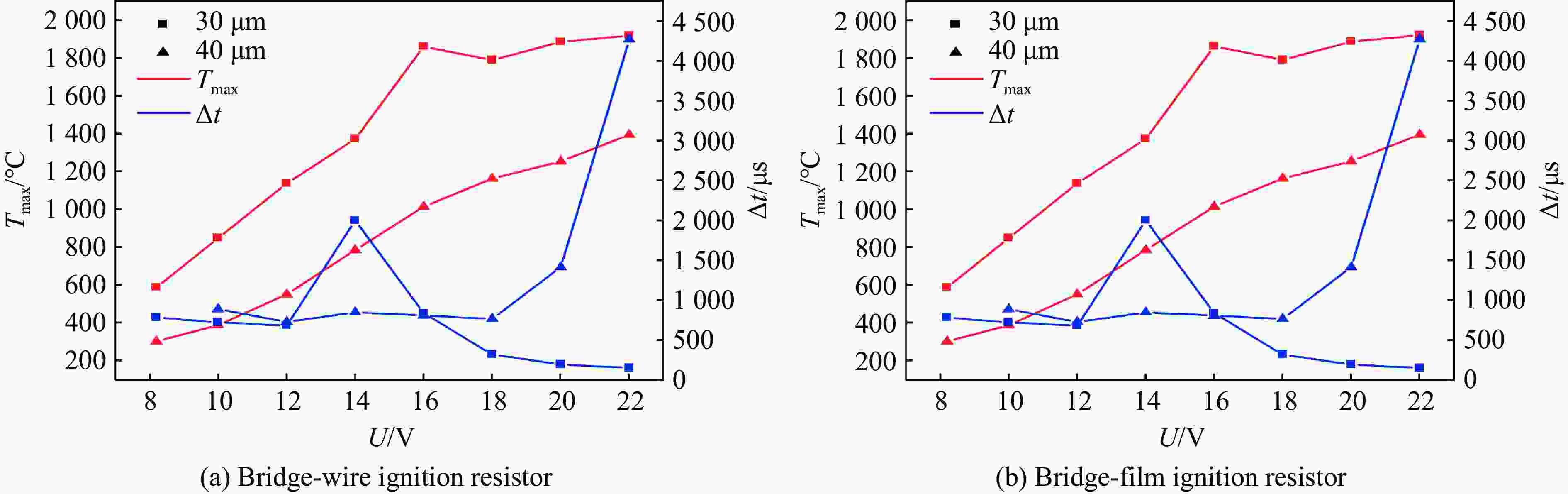

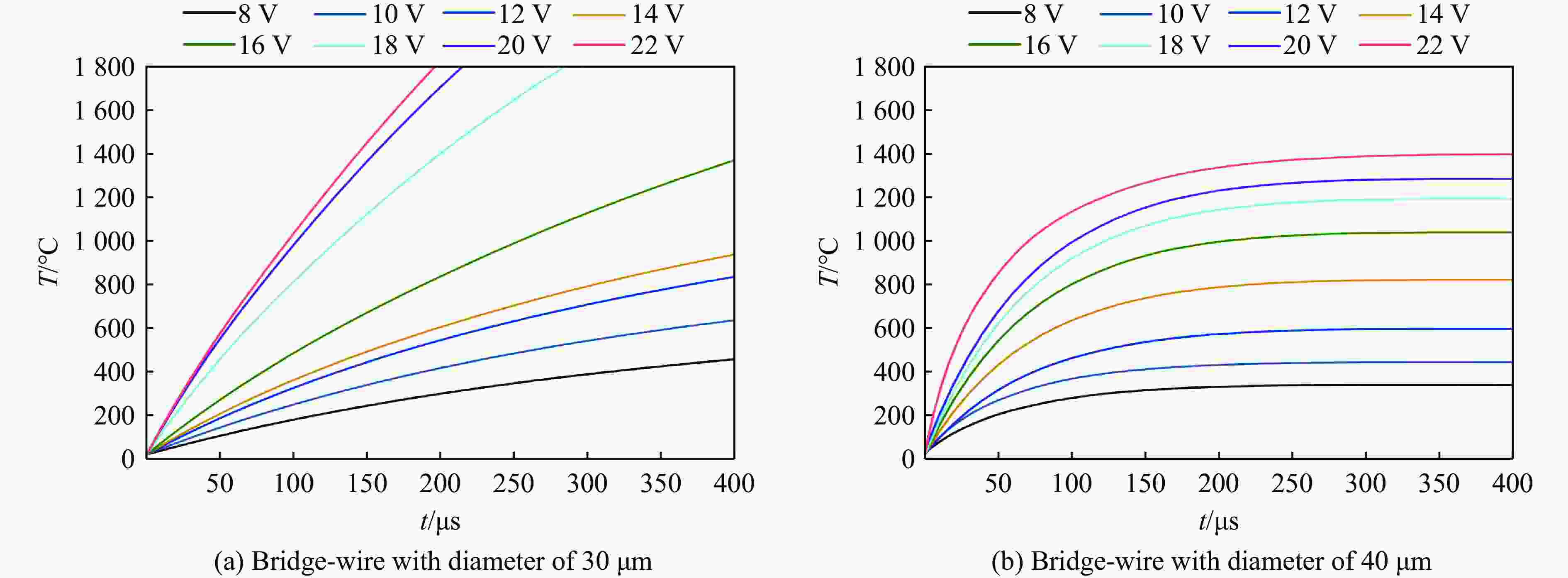

Table 9. Statistics of ignition resistor temperature test results

Voltage/V Sample 1 Sample 2 Sample 3 Sample 4 Tmax/℃ Δt/μs Tmax/℃ Δt/μs Tmax/℃ Δt/μs Tmax/℃ Δt/μs 8 589.13 786.67 305.00 1322.50 380.00 366.36 10 849.15 723.33 390.24 650.00 1572.57 163.33 504.63 460.00 12 1137.10 683.33 552.75 570.00 1548.86 86.67 685.38 600.00 14 1372.34 2000.00 786.70 670.00 1573.82 76.67 1161.89 1793.33 16 1859.50 843.33 1015.09 676.67 1622.65 66.67 1489.12 1540.00 18 1788.21 320.00 1163.21 573.33 1810.25 53.33 1596.17 700.00 20 1884.61 196.67 1253.71 470.00 1858.31 50.00 1636.78 490.00 22 1918.36 150.00 1394.04 220.00 1860.95 40.00 1528.09 250.00 表 10 桥丝熔断时间的实验值与仿真值的对比

Table 10. Comparison between the experimental and simulated values of the bridge-wire fusing time

Voltage/V Fusing time Exp./μs Sim./μs Deviation/% 16 645.7 350.3 −45.75 18 213.5 201.1 −5.81 20 166.2 155.8 −6.26 22 152.2 141.4 −7.10 表 11 桥膜熔断时间的实验值与仿真值对比

Table 11. Comparison of experimental and simulated values of bridge-film fusing time

Voltage/V Experimental fusing time/μs Simulated fusing time/μs Deviation/% Straight type S type Straight type S type Straight type S type 10 153.0 145.9 −4.64 12 103.2 96.2 −6.78 14 65.6 373.6 61.7 351.9 −5.95 −5.81 16 52.3 329.3 48.3 313.8 −7.65 −4.71 18 47.6 205.7 43.5 187.7 −8.61 −8.75 20 36.6 155.6 33.0 139.7 −9.84 −10.22 22 31.1 129.2 28.2 113.5 −9.32 −12.15 -

[1] 任小明, 姚洪志, 解瑞珍, 等. 镍铬硅薄膜换能元的制备及其发火性能研究 [J]. 火工品, 2024(5): 42–45. doi: 10.3969/j.issn.1003-1480.2024.05.006REN X M, YAO H Z, XIE R Z, et al. Study on the preparation and firing property of Ni-Cr-Si thin film transducers [J]. Initiators & Pyrotechnics, 2024(5): 42–45. doi: 10.3969/j.issn.1003-1480.2024.05.006 [2] 解瑞珍, 薛艳, 任小明, 等. 桥区参数对Ni-Cr薄膜换能元发火性能的影响 [J]. 火工品, 2012(1): 18–20. doi: 10.3969/j.issn.1003-1480.2012.01.006XIE R Z, XUE Y, REN X M, et al. Effect of bridge parameters on the firing sensitivity of Ni-Cr alloy thin film transducer elements [J]. Initiators & Pyrotechnics, 2012(1): 18–20. doi: 10.3969/j.issn.1003-1480.2012.01.006 [3] 任小明, 解瑞珍, 薛艳, 等. Ni-Cr薄膜换能元点火性能研究 [J]. 火工品, 2011(2): 4–6. doi: 10.3969/j.issn.1003-1480.2011.02.002REN X M, XIE R Z, XUE Y, et al. Study on firing performance of Ni-Cr film igniting resistor [J]. Initiators & Pyrotechnics, 2011(2): 4–6. doi: 10.3969/j.issn.1003-1480.2011.02.002 [4] 付帅, 沈瑞琪, 朱朋, 等. 多层Al/Ni含能薄膜在电容放电激励下的能量释放特性和规律 [J]. 含能材料, 2019, 27(2): 155–161. doi: 10.11943/CJEM2018173FU S, SHEN R Q, ZHU P, et al. Characteristics and laws of energy release for multilayer Al/Ni RMFs under capacitive discharge excitation [J]. Chinese Journal of Energetic Materials, 2019, 27(2): 155–161. doi: 10.11943/CJEM2018173 [5] 成一, 陈守文. 电点火头发火过程的时间结构的研究 [J]. 爆破器材, 2001, 30(5): 22–24. doi: 10.3969/j.issn.1001-8352.2001.05.006CHENG Y, CHEN S W. Study on the time structure of electric ignition process in fuse head [J]. Explosive Materials, 2001, 30(5): 22–24. doi: 10.3969/j.issn.1001-8352.2001.05.006 [6] LYU X X, WEI G H, DU X, et al. Numerical simulation of the ignition law for a hot bridge wire electroexplosive device [J]. Measurement Science and Technology, 2023, 34(3): 035014. doi: 10.1088/1361-6501/acf604 [7] 王科伟, 杨正才, 刘海旭, 等. 钝感Ni-Cr金属桥膜换能元的制备及性能 [J]. 含能材料, 2014, 22(6): 819–823. doi: 10.11943/j.issn.1006-9941.2014.06.020WANG K W, YANG Z C, LIU H X, et al. Preparation and characterization of insensitive Ni-Cr metal film igniting component [J]. Chinese Journal of Energetic Materials, 2014, 22(6): 819–823. doi: 10.11943/j.issn.1006-9941.2014.06.020 [8] LI S, ZHANG L, YUAN C H, et al. The ignition performance of metal film bridge [J]. IOP Conference Series: Earth and Environmental Science, 2021, 692: 022072. doi: 10.1088/1755-1315/692/2/022072 [9] 焦清介, 赵婉君, 常英珂, 等. 电爆桥膜换能元设计研究 [J]. 火工品, 2023(6): 14–20. doi: 10.3969/j.issn.1003-1480.2023.06.003JIAO Q J, ZHAO W J, CHANG Y K, et al. Research on the design of exploding bridge film energy convertor [J]. Initiators & Pyrotechnics, 2023(6): 14–20. doi: 10.3969/j.issn.1003-1480.2023.06.003 [10] 汪佩兰, 曾象志, 张松正. 灼热桥式火工品桥温的数值模拟 [J]. 北京理工大学学报, 1994, 14(Suppl 1): 66–70.WANG P L, ZENG X Z, ZHANG S Z. Numerical simulation of bridge wire temperature in hot bridge wire explosive initiator [J]. Journal of Beijing Institute of Technology, 1994, 14(Suppl 1): 66–70. [11] XU Q, YANG Z Q, ZHANG Q H, et al. Simulation and characterization of a thin film Au/Ni micro hot bridge-wire ignition element under capacitor discharging [J]. International Journal of Thermal Sciences, 2016, 102: 100–110. doi: 10.1016/j.ijthermalsci.2015.11.009 [12] 李慧, 白颖伟, 任炜, 等. 火工品换能元直流激励下温度响应特性仿真研究 [J]. 兵工学报, 2016, 37(Suppl 2): 138–143.LI H, BAI Y W, REN W, et al. Simulation research on temperature response characteristics of initiating device transformer under DC excitation [J]. Acta Armamentarii, 2016, 37(Suppl 2): 138–143. [13] 闫守阳, 赵河明, 韩晶, 等. 基于电热特性分析的微桥膜设计 [J]. 火工品, 2021(6): 1–5. doi: 10.3969/j.issn.1003-1480.2021.06.001YAN S Y, ZHAO H M, HAN J, et al. Design of micro-bridge membrane based on electrothermal analysis [J]. Initiators & Pyrotechnics, 2021(6): 1–5. doi: 10.3969/j.issn.1003-1480.2021.06.001 [14] 张树养. 影响红外测温的主要因素分析研究 [J]. 工业计量, 2023, 33(5): 16–20. doi: 10.13228/j.boyuan.issn1002-1183.2022.0281ZHANG S Y. Analysis and research on the main factorsaffecting infrared temperature measurement [J]. Industrial Metrology, 2023, 33(5): 16–20. doi: 10.13228/j.boyuan.issn1002-1183.2022.0281 [15] 孙秋香, 宋庆军, 卢慧粉, 等. 扫描电镜能谱仪谱峰鉴别方法 [J]. 理化检验-物理分册, 2018, 54(10): 754–756. doi: 10.11973/lhjy-wl201810009SUN Q X, SONG Q J, LU H F, et al. Spectral peak identification method of energy dispersive spectrometer in scanning electron microscope [J]. Physical Testing and Chemical Analysis (Part A: Physical Testing), 2018, 54(10): 754–756. doi: 10.11973/lhjy-wl201810009 [16] 底才翔, 孙艳军, 王菲, 等. 激光切割碳纤维复合材料的温度场仿真 [J]. 激光技术, 2020, 44(5): 628–632. doi: 10.7510/jgjs.issn.1001-3806.2020.05.017DI C X, SUN Y J, WANG F, et al. Temperature field simulation of laser cut carbon fiber reinforced plastics [J]. Laser Technology, 2020, 44(5): 628–632. doi: 10.7510/jgjs.issn.1001-3806.2020.05.017 [17] 周庆, 焦清介. Ni-Cr桥丝式电火工品发火规律 [J]. 四川兵工学报, 2015, 36(4): 144–147. doi: 10.11809/scbgxb2015.04.039ZHOU Q, JIAO Q J. Study on firing property of Ni-Cr electric hot wire initiating devices [J]. Journal of Ordnance Equipment Engineering, 2015, 36(4): 144–147. doi: 10.11809/scbgxb2015.04.039 [18] AKAGI H, WATANABE E H, AREDES M. Instantaneous power theory and applications to power conditioning [M]. Hoboken: John Wiley & Sons, 2017: 19–111. -

下载:

下载: