Damage of a New Shaped Warhead to Water-Containing Composite Structure

-

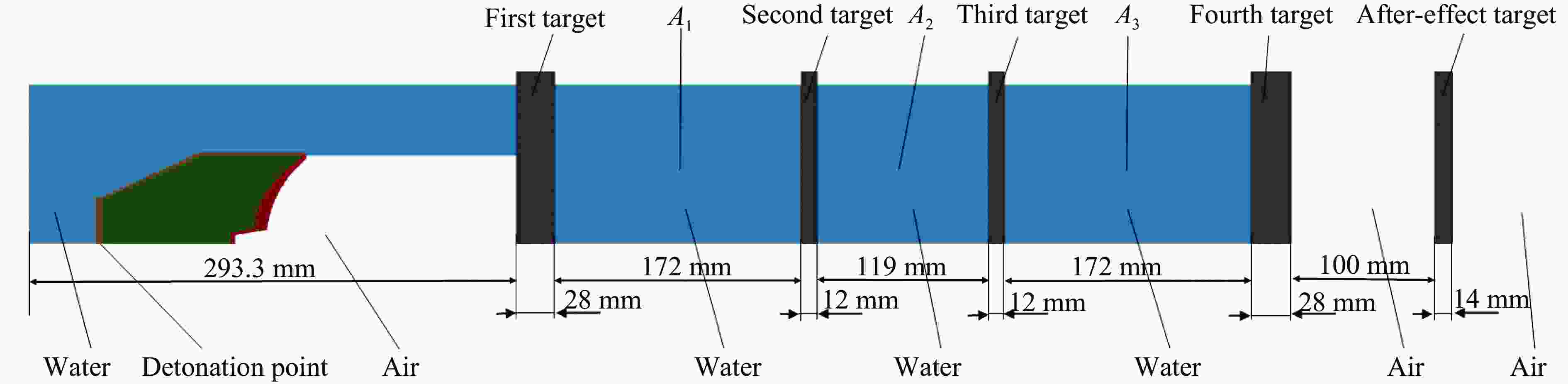

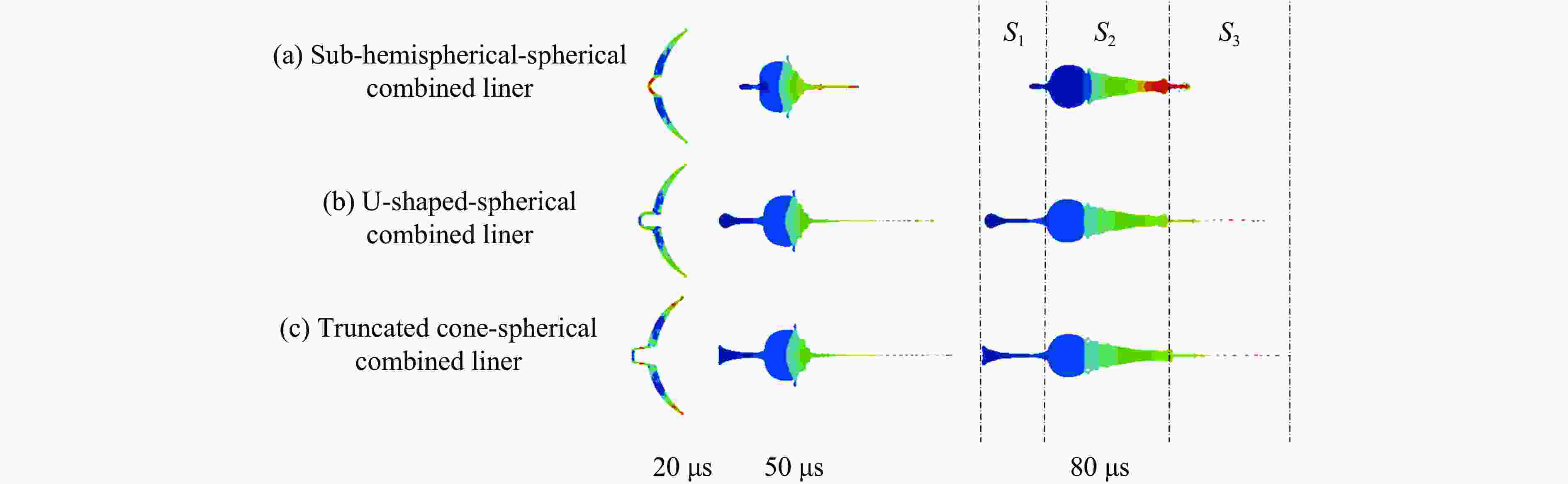

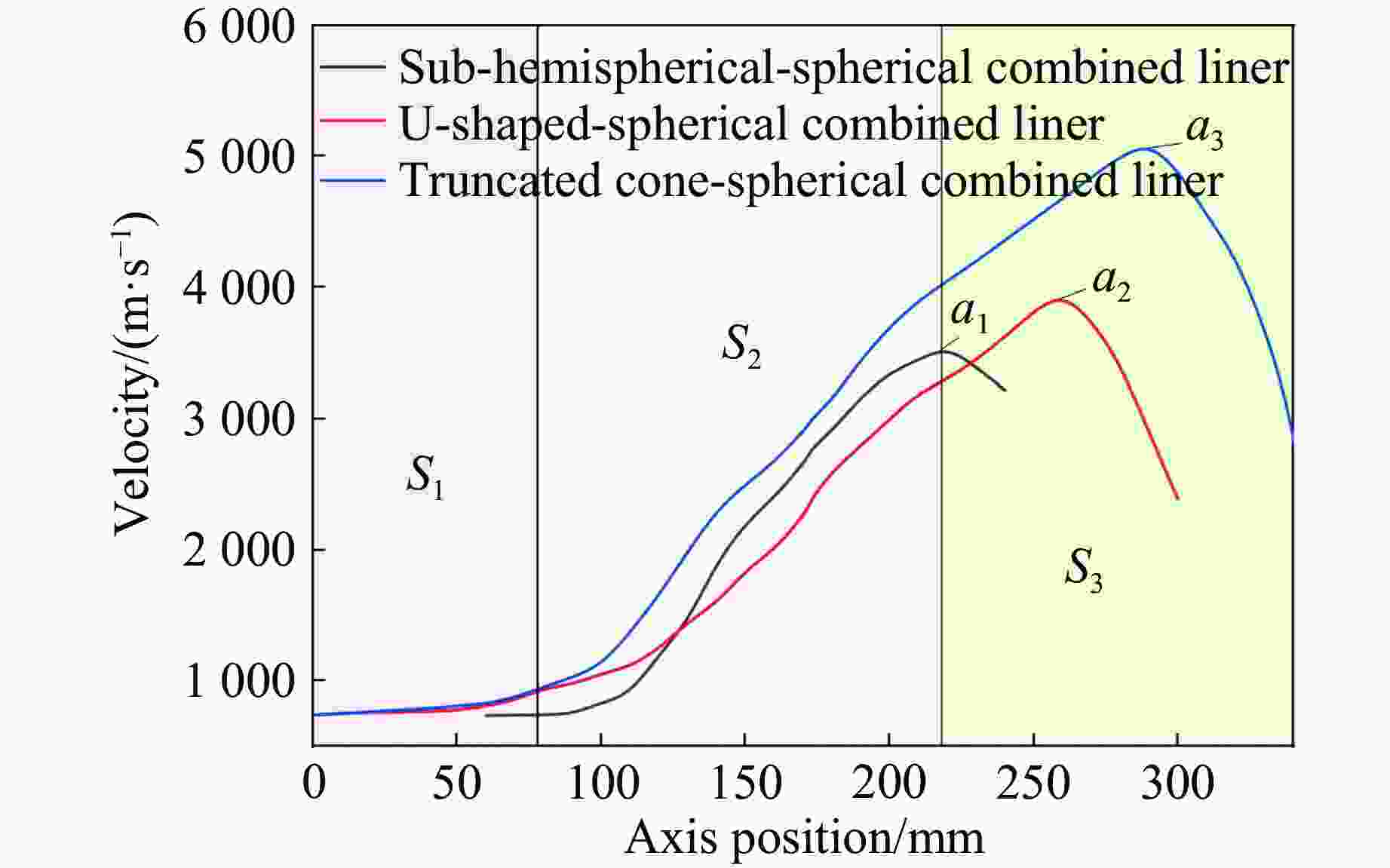

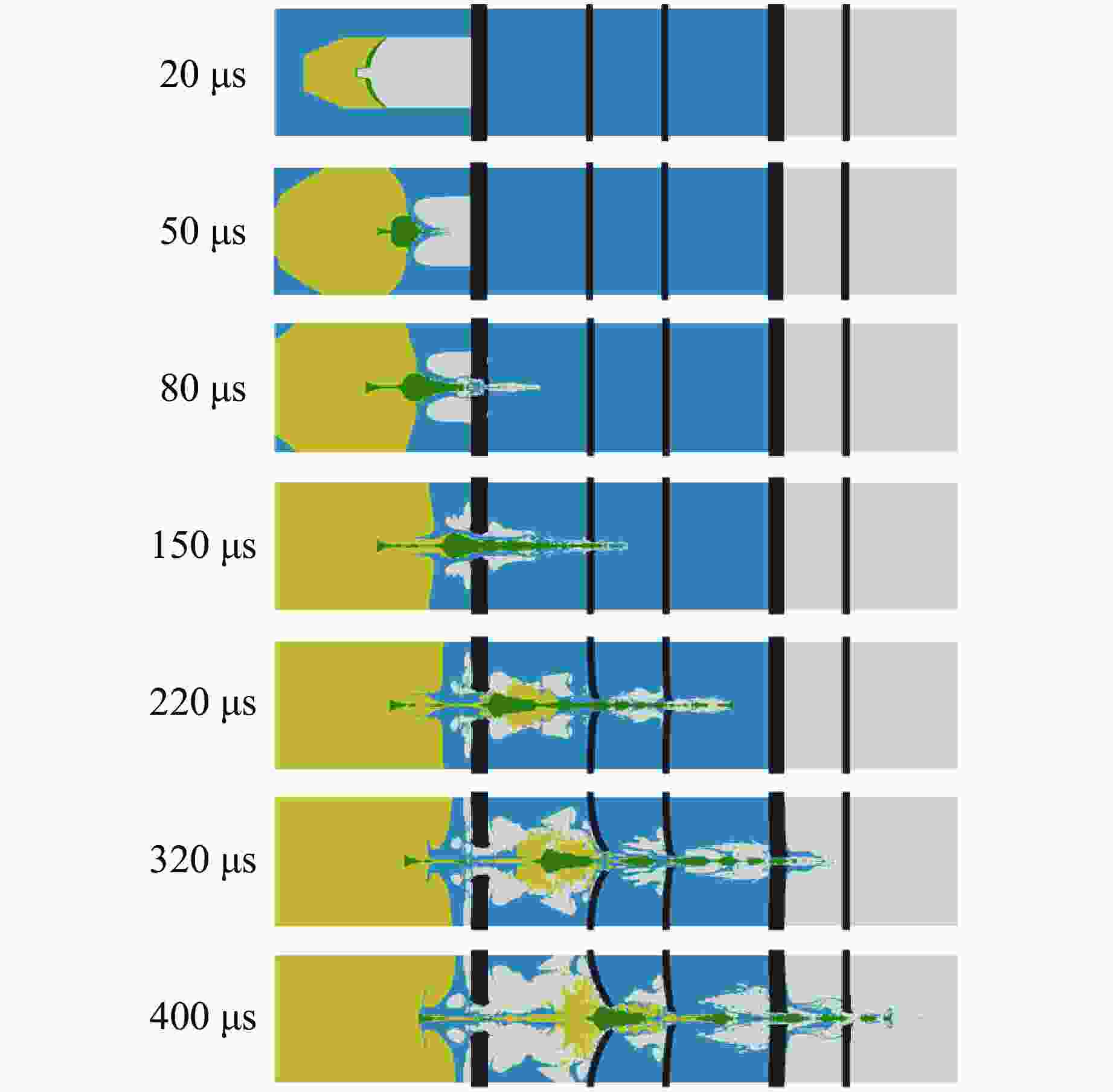

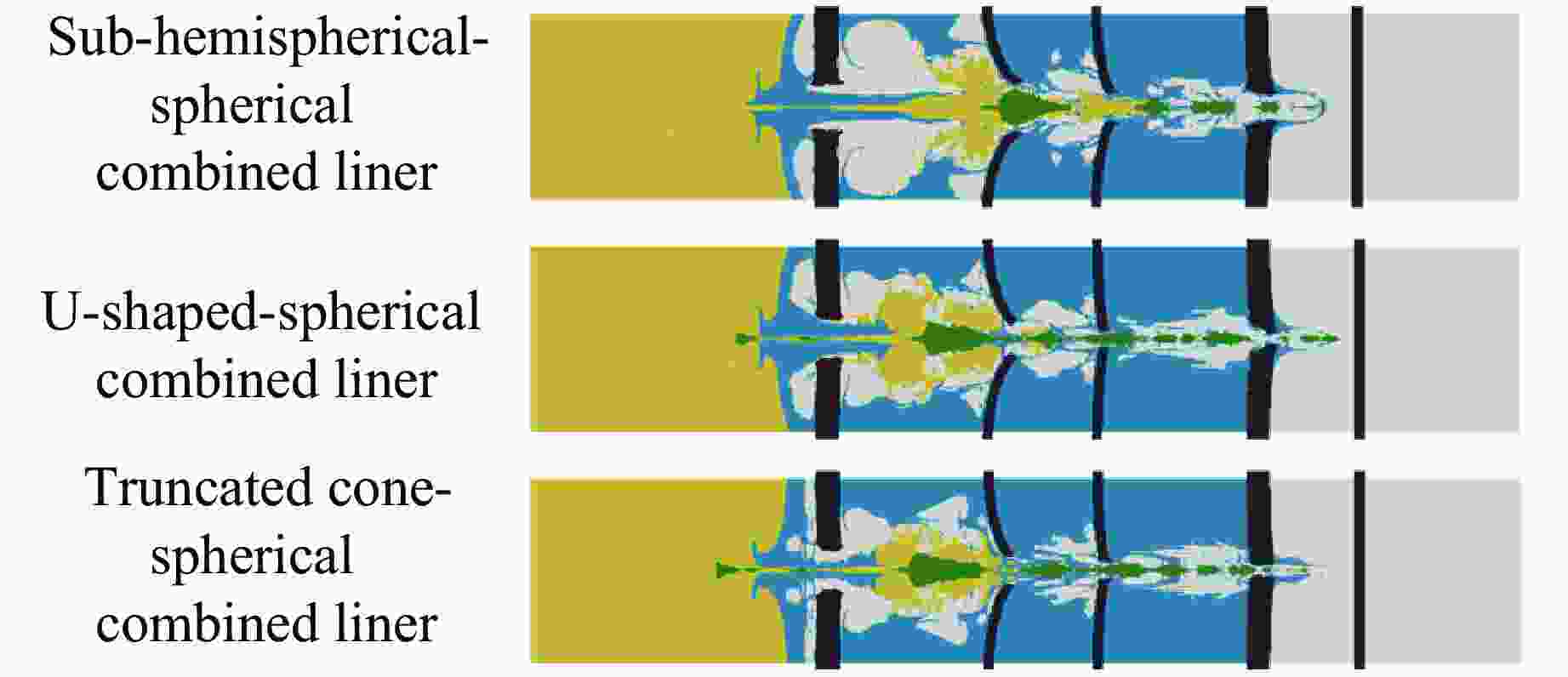

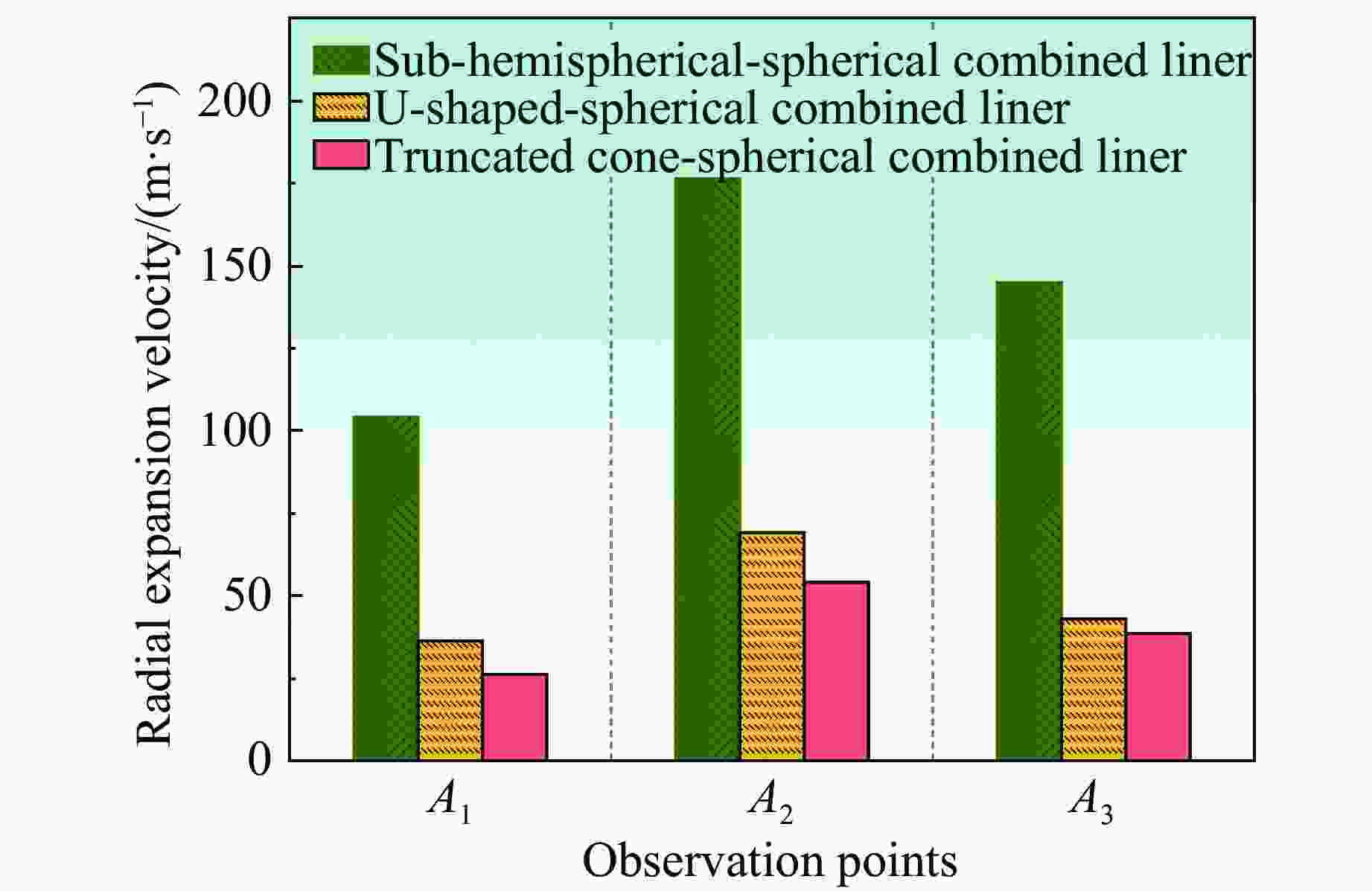

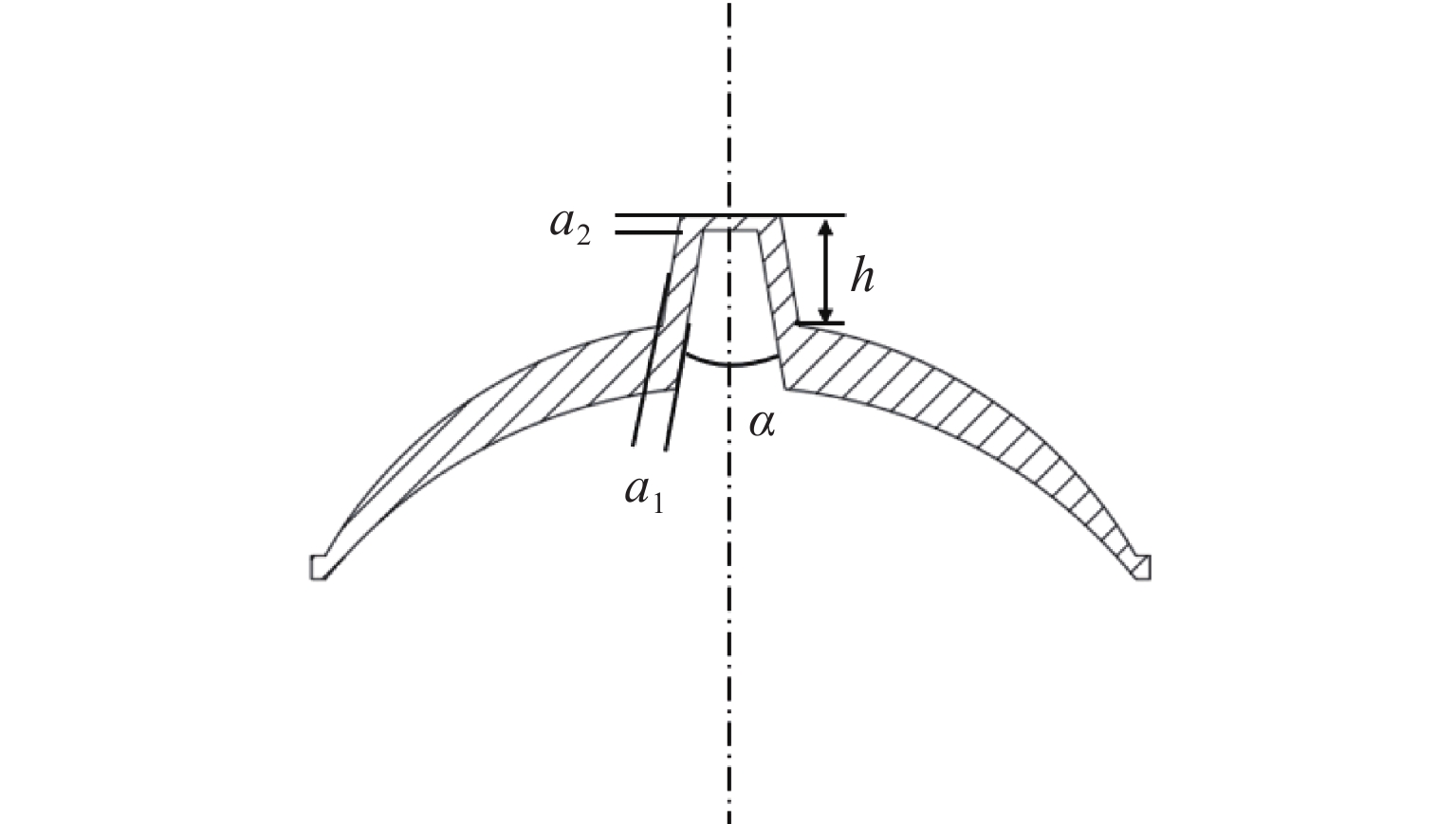

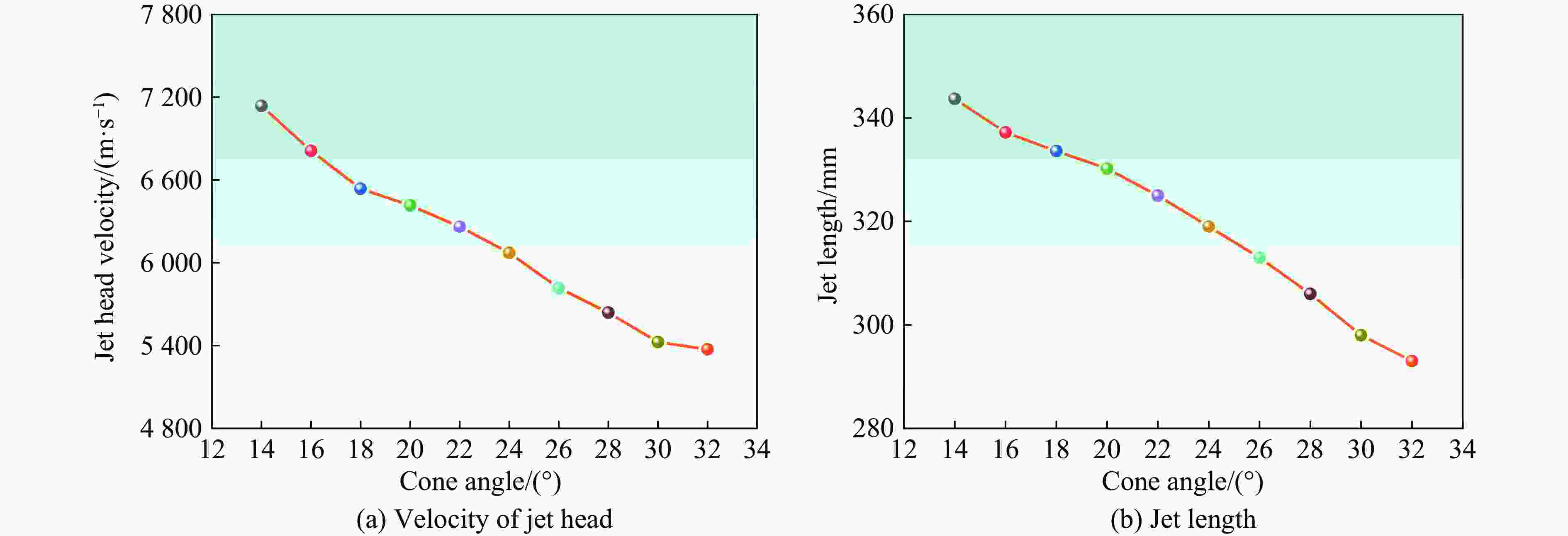

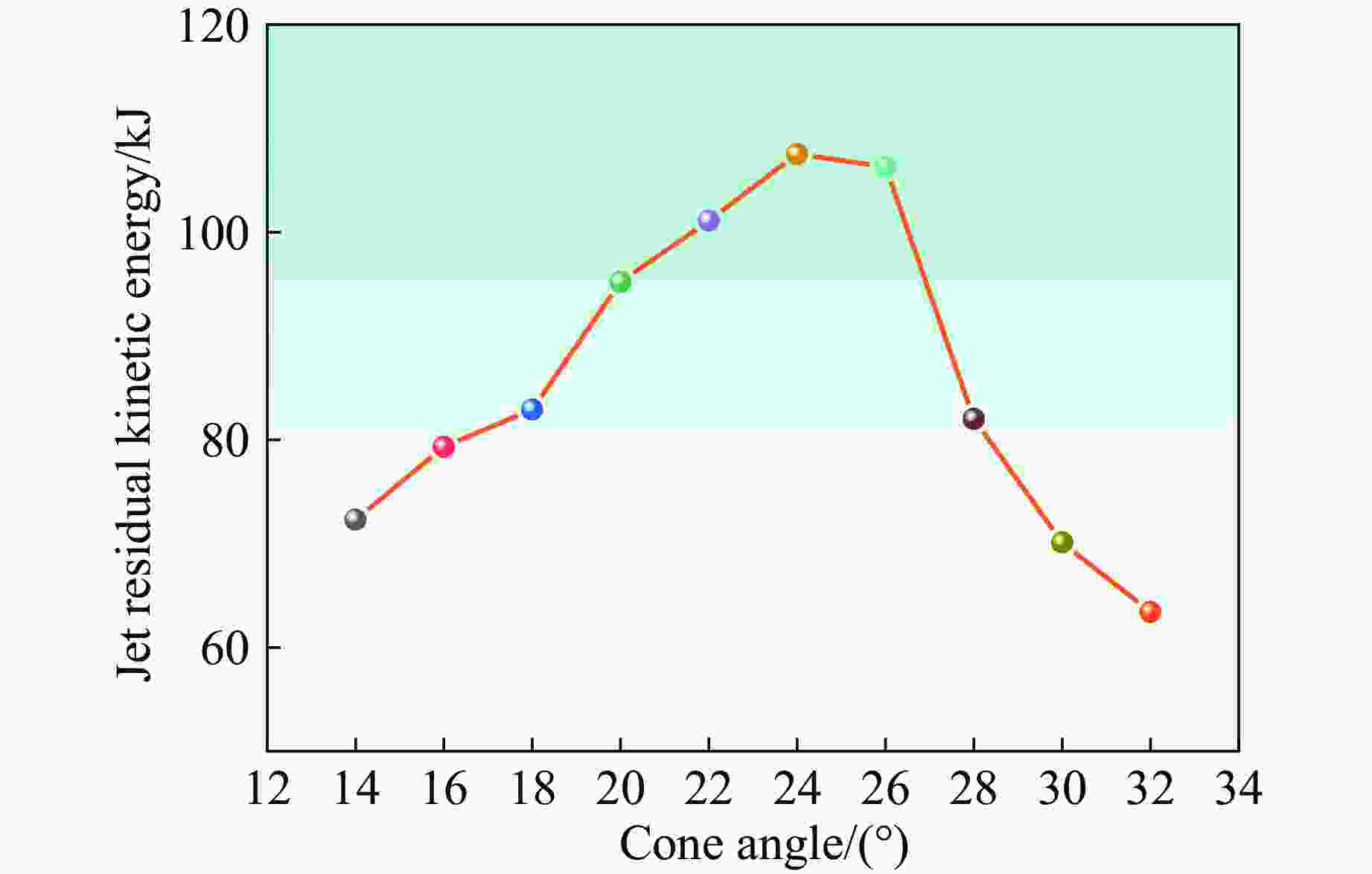

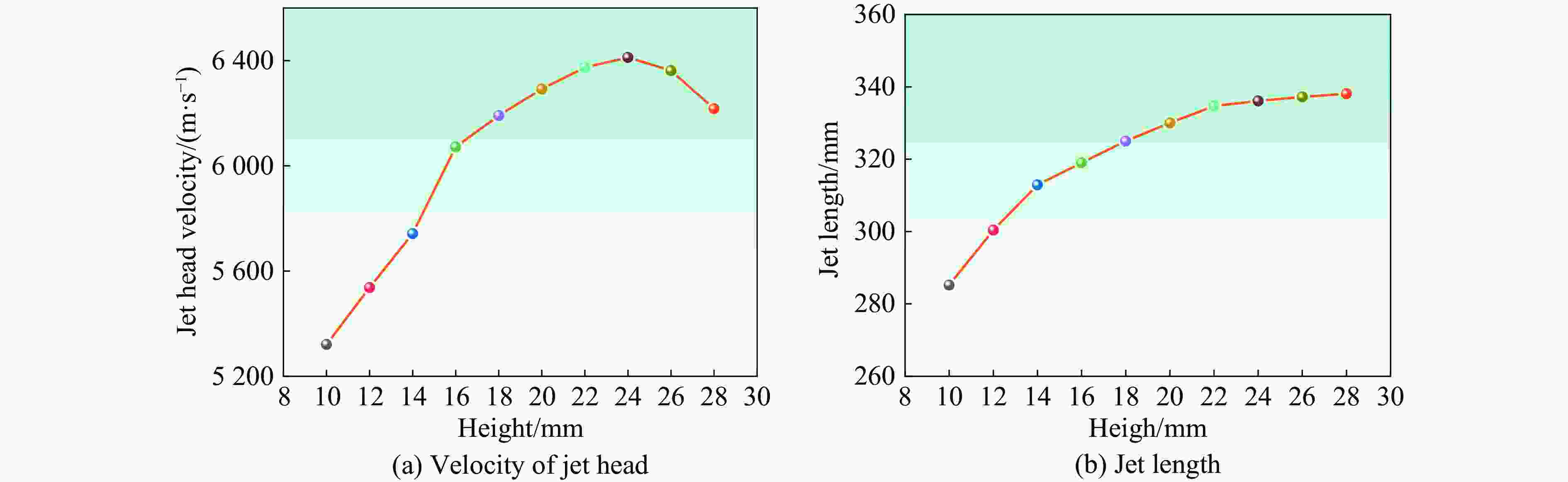

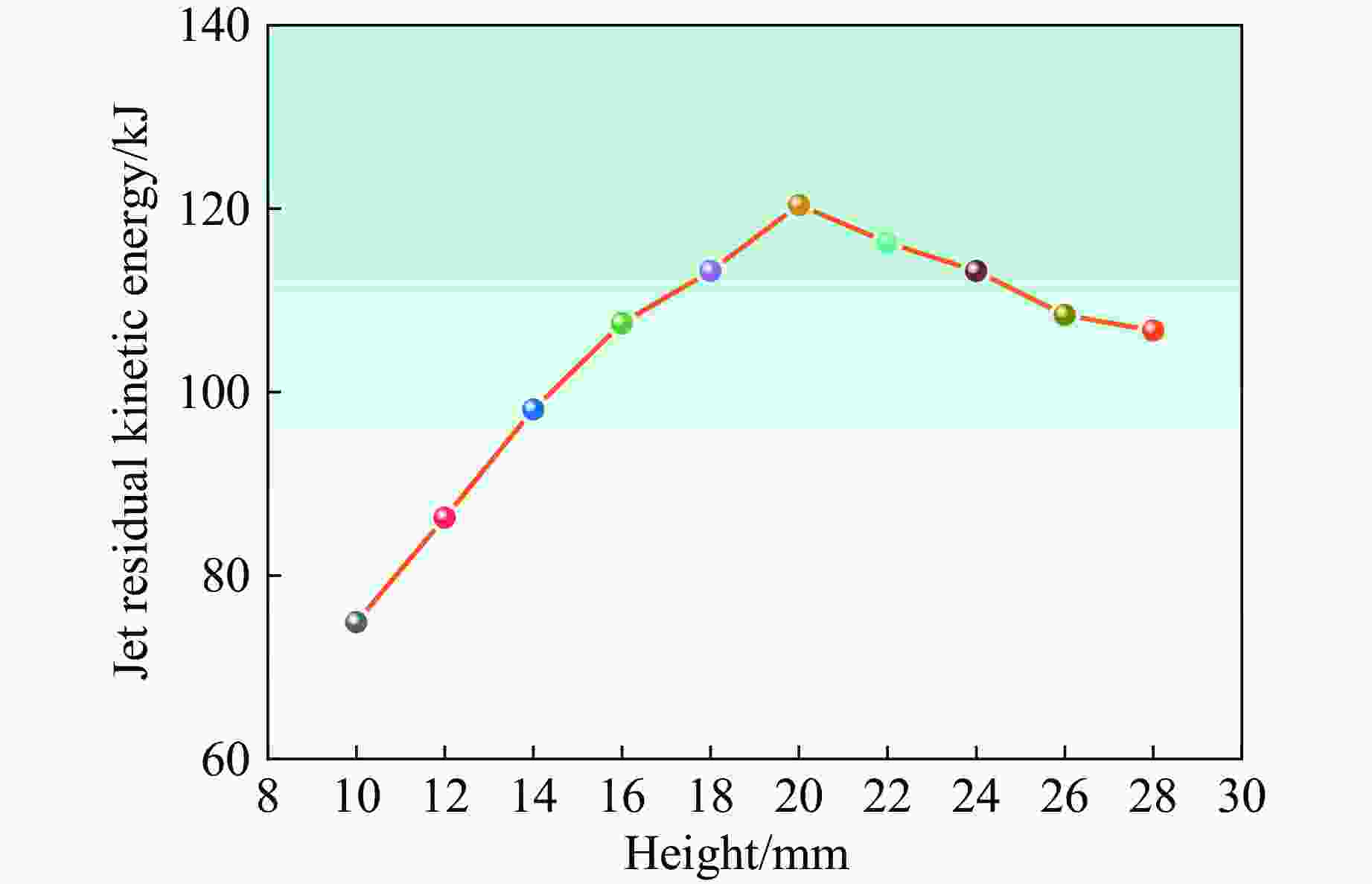

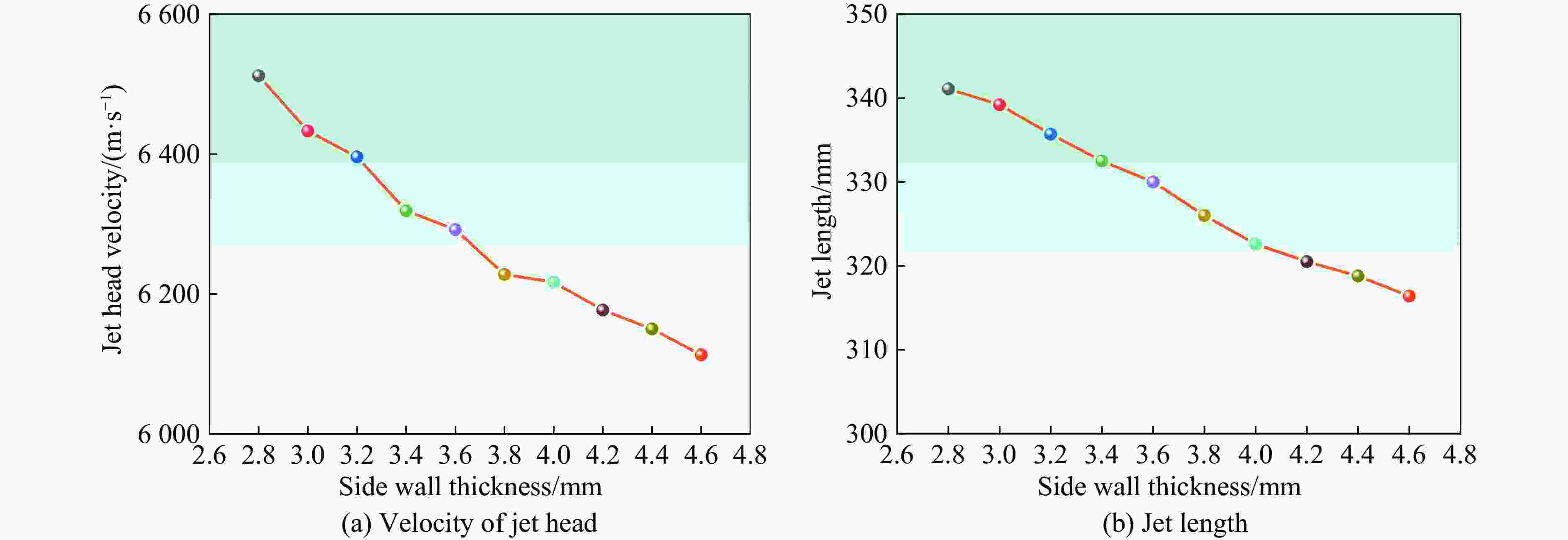

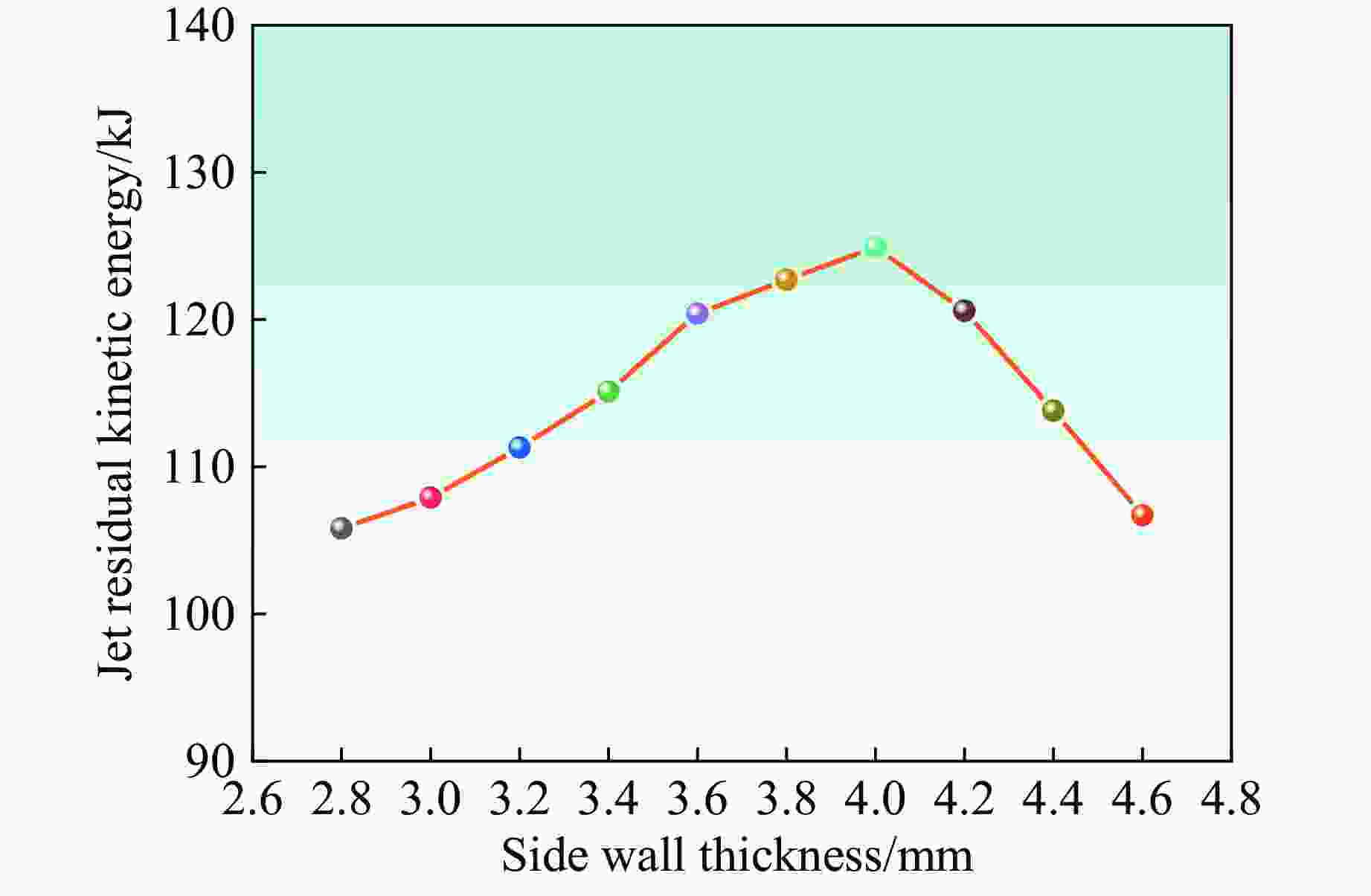

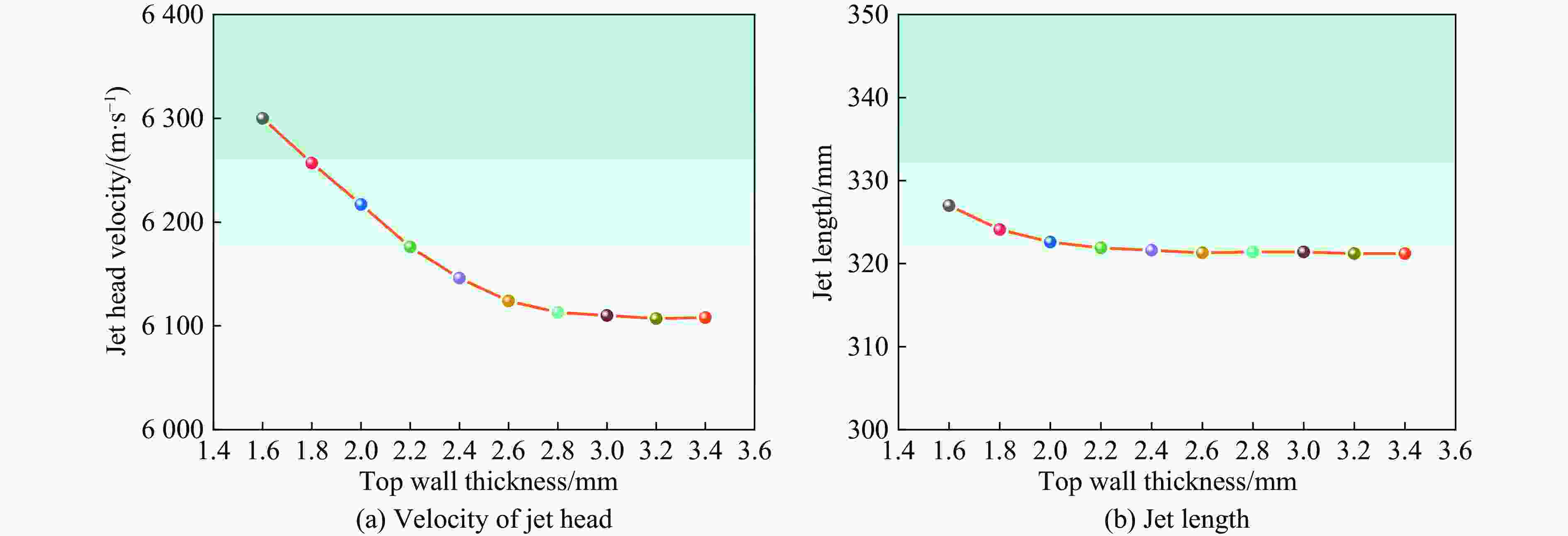

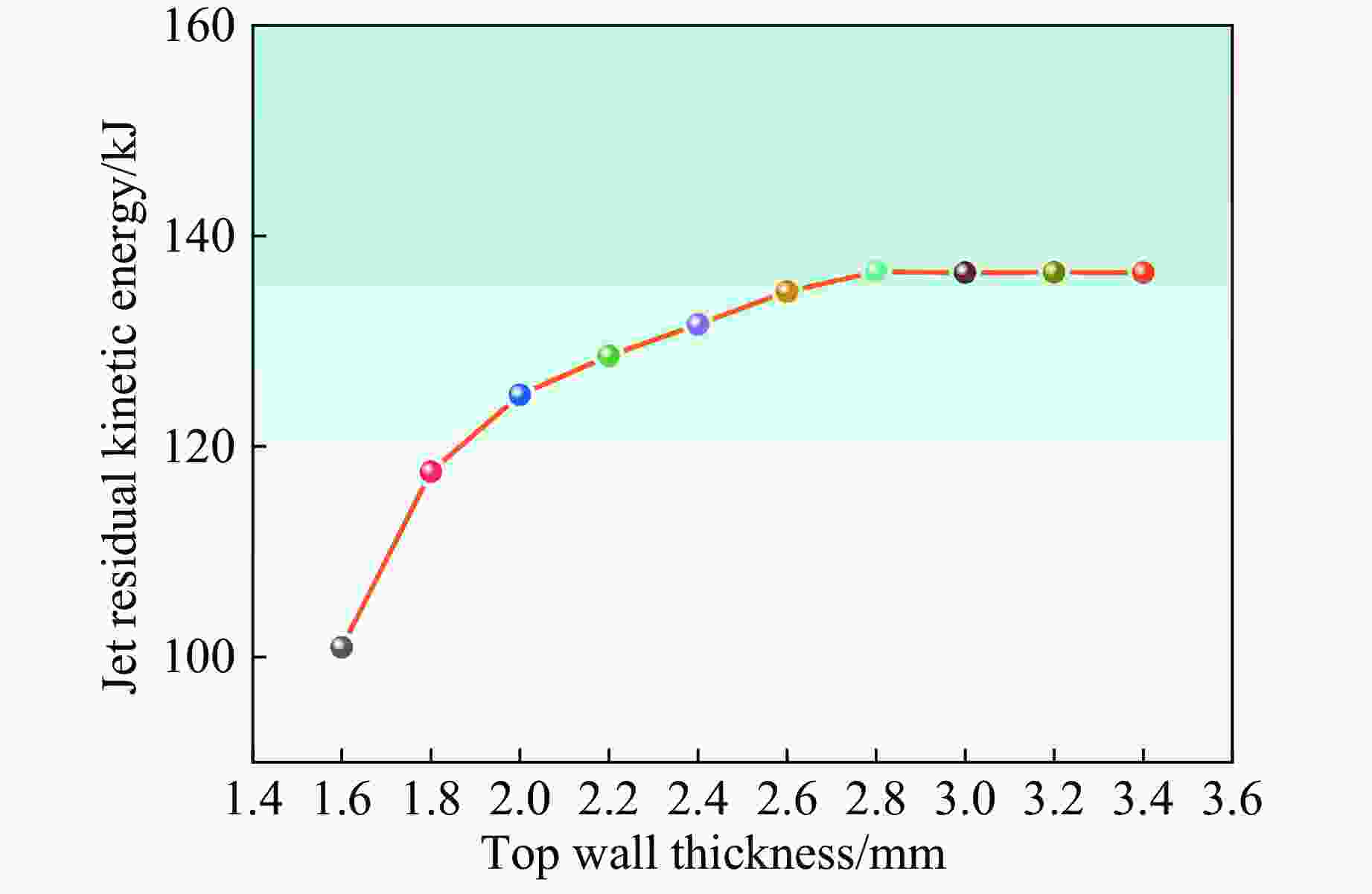

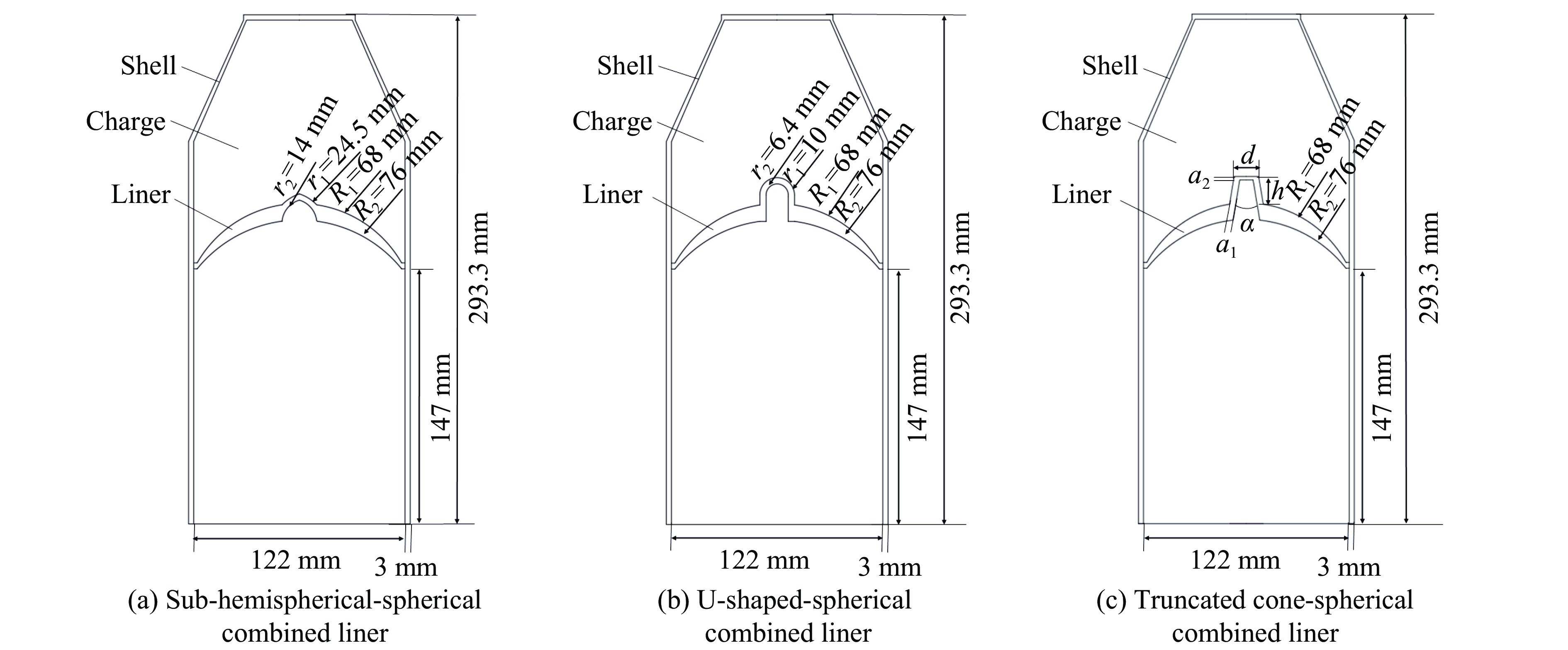

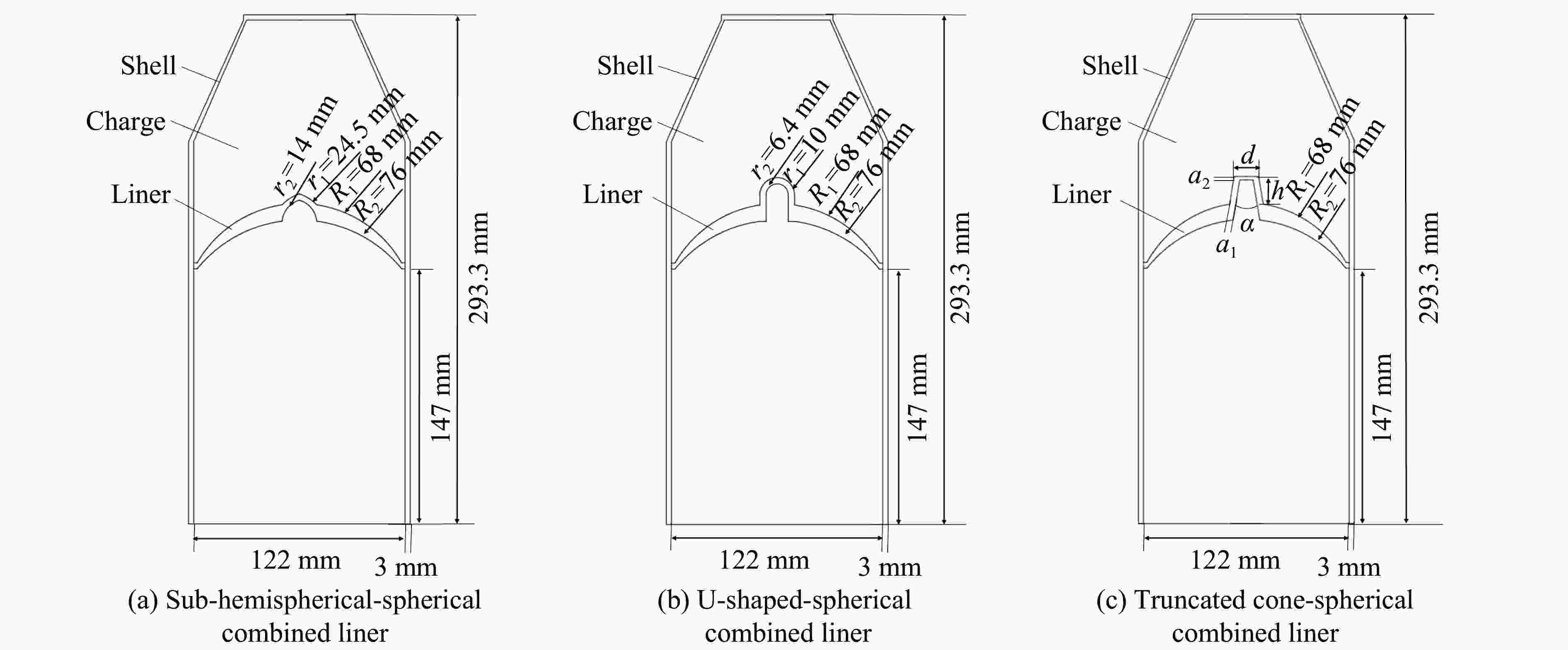

摘要: 为提高聚能战斗部对含水复合结构的侵彻能力,设计了一种截锥-球缺组合罩,并通过数值模拟探究了其在水介质中的射流成型运动规律和对含水复合结构的毁伤性能。研究发现:在侵彻含水复合结构的过程中,相比于亚半球-球缺组合罩和U形-球缺组合罩,截锥-球缺组合罩形成的射流长度更大,射流头部速度更高,在水介质中形成的空腔通道、水介质径向扩展速度均最小,击穿后效靶板后的射流剩余动能以及射流剩余速度最大。利用数值模拟技术探究了截锥-球缺组合罩中截锥罩的锥角、高度、侧壁壁厚、顶壁壁厚等结构参数对射流形态及侵彻性能的影响,并对其进行了正交优化试验设计,结果表明:结构参数对射流侵彻性能的影响由大到小依次为截锥罩的锥角、高度、侧壁壁厚、顶壁壁厚;当锥角为26°、高度为22 mm、侧壁壁厚为4.0 mm、顶壁壁厚为3.2 mm时,截锥-球缺组合罩的侵彻性能较优,穿透后效靶板时的射流剩余动能为136.2 kJ。该研究对聚能型鱼雷战斗部的设计以及提高鱼雷战斗部毁伤威力具有一定的参考价值。Abstract: In order to improve the penetration capability of the shaped charge warhead to the water-containing composite structure, a truncated cone-sphere combined liner was designed, and its jet forming motion law in the water medium and the damage performance to the water-containing composite structure were explored by numerical simulation. It is found that in the process of penetrating the water-containing composite structure, the truncated cone-sphere combined liner has a larger jet length and a higher jet head velocity compared with the sub-hemisphere-sphere combined liner and the U-shaped-sphere combined liner. It also has the smallest cavity channel formed in the water medium and the radial expansion velocity of the water medium and the largest residual kinetic energy and jet velocity after the penetrated target plate. The influence of structural parameters such as cone angle α, height h, side wall thickness a1 and top wall thickness a2 on the jet shape and penetration performance of the truncated cone-spherical combined liner was investigated by simulation, and a orthogonal optimization test was designed. It is found that the influence of these structural parameters on the jet penetration performance decreases in the order of: the cone angle α, height h, side wall thickness a1, and top wall thickness a2. When α=26°, h=22 mm, a1=4.0 mm, and a2=3.2 mm, the penetration performance of the truncated cone-sphere combined liner is superior, and the residual kinetic energy of the jet in penetrating the aftereffect target is 136.2 kJ. This study provides a valuable reference for the design of shaped torpedo warhead and the improvement of torpedo warhead damage power.

-

表 1 8701炸药材料参数

Table 1. Material parameters of 8701 explosive

ρ/(g·cm−3) D/(m·s−1) pCJ/GPa A/GPa B/GPa R1 R2 ω E/GPa 1.717 8700 29.6 854.5 20.493 4.6 1.35 0.25 8.5 表 2 金属材料参数

Table 2. Material parameters of metal

Material ρ/(g·cm−3) A0/MPa B0/MPa C Tr/K Tm/K m n Al 2.797 265 426 0.015 300 775 1.00 0.34 45 steel 7.830 350 300 0.014 294 1760 0.26 1.03 Copper 8.960 90 292 0.025 293 1236 1.09 0.31 表 3 空气材料参数

Table 3. Material parameters of air

ρ/(g·cm−3) C0/(km·s−1) S1 S2 S3 ωm Ea/MPa V0 1.25×10−3 3.440 0 0 0 1.4 0.25 0 表 4 水介质材料参数

Table 4. Material parameters of water

ρ/(g·cm−3) C0/(km·s−1) S1 S2 S3 a Ew/MPa V0 1.02 1.510 1.92 −0.096 0 0 0 0 表 5 试验与模拟结果的对比

Table 5. Comparison of test and simulation results

Target Perforation diameter/mm Deviation/% Test Simulation First layer 50 47.8 4.4 Second layer 37 37.8 2.1 Third layer 40 42.3 5.7 Fourth layer 41 43.1 5.1 After-effect target 49 48.3 1.4 表 6 靶板穿孔的对比

Table 6. Comparison of perforations of target plates

First floor Second floor Third floor Fourth floor After-effect target

表 7 空腔通道面积的对比

Table 7. Comparison of the cavity channel area

Type of liner Cavity channel area/cm2 Proportion of aqueous media/% Sub-hemispherical-spherical combined liner 147.12 34.2 U-shaped-spherical combined liner 113.60 26.4 Truncated cone-spherical combined liner 100.90 23.4 表 8 射流剩余动能和射流剩余速度

Table 8. Residual kinetic energy and residual velocity of the jet

Type of liner Residual kinetic energy/kJ Residual velocity/(m·s−1) Sub-hemispherical-spherical combined liner 53.5 972 U-shaped-spherical combined liner 77.4 1 389 Truncated cone-spherical combined liner 98.2 1 752 表 9 各个因素水平

Table 9. Level settings of the factors

Level Factor α/(°) h/mm a1/mm a2/mm 1 18 14 3.2 2.0 2 22 18 3.6 2.4 3 26 22 4.0 2.8 4 30 26 4.4 3.2 表 10 正交优化方案

Table 10. Orthogonal optimization schemes

Scheme α/(°) h/mm a1/mm a2/mm Ek/kJ 1 18 14 3.2 2.0 82.1 2 18 18 3.6 2.4 87.8 3 18 22 4.0 2.8 98.9 4 18 26 4.4 3.2 93.4 5 22 14 3.6 2.8 107.1 6 22 18 3.2 3.2 109.3 7 22 22 4.4 2.0 113.1 8 22 26 4.0 2.4 109.8 9 26 14 4.0 3.2 120.6 10 26 18 4.4 2.8 124.2 11 26 22 3.2 2.4 131.5 12 26 26 3.6 2.0 126.1 13 30 14 4.4 2.4 97.3 14 30 18 4.0 2.0 100.7 15 30 22 3.6 3.2 103.3 16 30 26 3.2 2.8 93.7 表 11 极差分析

Table 11. Range analysis

Factor Ek/kJ R K1 K2 K3 K4 α 90.55 109.83 125.60 98.75 35.05 h 101.77 105.50 111.70 105.75 9.93 a1 104.15 106.08 107.50 107.00 3.35 a2 105.50 106.60 105.97 106.65 1.15 -

[1] 汪玉, 华宏星. 舰船现代冲击理论及应用 [M]. 北京: 科学出版社, 2005: 7−9.WANG Y, HUA H X. Modern impact theory and application of ships [M]. Beijing: Science Press, 2005: 7−9. [2] 郑宇. 双层药型罩毁伤元形成机理研究 [D]. 南京: 南京理工大学, 2008: 1−11.ZHENG Y. Study on the formation mechanism of kill element from shaped charge with double layer liners [D]. Nanjing: Nanjing University of Science and Technology, 2008: 1−11. [3] 郭雁潮. 聚能装药对舰船典型靶板的毁伤特性研究 [D]. 太原: 中北大学, 2020: 2−4.GUO Y C. Research on the damage efficiency of shaped charge to warship typical target plates [D]. Taiyuan: North China University, 2020: 2−4. [4] TOSELLO R. Tandem shaped charges for underwater applications [C]//Proceedings of the 5th International Symposium on Ballistics. Jerusalem, Israel: Israel Institute of Technology/Faculty of Mechanical Engineering, 1995: 359−368. [5] PUGH E M, EICHELBERGER R J, ROSTOKER N. Theory of jet formation by charges with lined conical cavities [J]. Journal of Applied Physics, 1952, 23(5): 532–536. doi: 10.1063/1.1702246 [6] JANZON S G, CHICK M, BUSSEL T J. Penetration and failure of explosive formed penetrators i-n water [C]//14th International Symposium on Ballistics. Quebec, Canada: Canadian Defence Preparedness Association, 1993: 611−617. [7] 刘念念, 宋丹丹, 金辉, 等. 半球形聚能装药对复合靶板结构的毁伤数值仿真与试验研究 [J]. 振动与冲击, 2018, 37(4): 153–159. doi: 10.13465/j.cnki.jvs.2018.04.023LIU N N, SONG D D, JIN H, et al. Numerical simulation and experimental study on the damage characteristics of hemispherical shaped charge on composite armor [J]. Journal of Vibration and Shock, 2018, 37(4): 153–159. doi: 10.13465/j.cnki.jvs.2018.04.023 [8] 杨珊, 王树山, 王韫泽, 等. 成型装药水下大炸高对多层间隔靶的侵彻威力 [J]. 火炸药学报, 2022, 45(2): 243–248. doi: 10.14077/j.issn.1007-7812.202111001YANG S, WANG S S, WANG Y Z, et al. Penetration power of large underwater explosion height of shaped charge to multi-layer spacer target [J]. Chinese Journal of Explosives & Propellants, 2022, 45(2): 243–248. doi: 10.14077/j.issn.1007-7812.202111001 [9] 王海福, 江增荣, 李向荣. 药型罩参数对聚能装药水下作用效应的影响 [J]. 北京理工大学学报, 2006, 26(5): 405–409. doi: 10.3969/j.issn.1001-0645.2006.05.007WANG H F, JIANG Z R, LI X R. Influences of liner parameters on the effects of shaped charge operating underwater [J]. Transactions of Beijing Institute of Technology, 2006, 26(5): 405–409. doi: 10.3969/j.issn.1001-0645.2006.05.007 [10] 赵鑫, 徐永杰, 董方栋, 等. 组合药型罩聚能装药对轻装甲侵彻仿真研究 [J]. 兵器装备工程学报, 2022, 43(10): 90–95. doi: 10.11809/bqzbgcxb2022.10.013ZHAO X, XU Y J, DONG F D, et al. Simulation study on penetration of light armor by compound liner shaped charge [J]. Journal of Ordnance Equipment Engineering, 2022, 43(10): 90–95. doi: 10.11809/bqzbgcxb2022.10.013 [11] 白晶, 张国伟, 李岩, 等. 圆柱-球缺组合型药型罩结构优化研究 [J]. 中北大学学报(自然科学版), 2023, 44(2): 122–127, 153.BAI J, ZHANG G W, LI Y, et al. Research on the structural optimization of cylindrical-spherical lacking composite liner [J]. Journal of North University of China (Natural Science Edition), 2023, 44(2): 122–127, 153. [12] 赵海平, 刘天生, 石军磊, 等. 双锥结合罩射流特性影响因素的模拟研究 [J]. 火工品, 2018(2): 35–39. doi: 10.3969/j.issn.1003-1480.2018.02.010ZHAO H P, LIU T S, SHI J L, et al. Numerical simulation of impacts on jet formation properties of dual-cone shaped charge [J]. Initiators & Pyrotechnics, 2018(2): 35–39. doi: 10.3969/j.issn.1003-1480.2018.02.010 [13] 李明星, 王志军, 伊建亚, 等. 不同聚能装药水下作用效果的对比分析 [J]. 兵器材料科学与工程, 2017, 40(5): 95–99. doi: 10.14024/j.cnki.1004-244x.20170911.002LI M X, WANG Z J, YI J Y, et al. Comparative analysis of underwater effect for different shaped charge [J]. Ordnance Material Science and Engineering, 2017, 40(5): 95–99. doi: 10.14024/j.cnki.1004-244x.20170911.002 [14] 潘乾坤, 袁浩, 任凯, 等. 不同组合式聚能战斗部对水下目标的毁伤研究 [J]. 兵器装备工程学报, 2024, 45(5): 173–179. doi: 10.11809/bqzbgcxb2024.05.025PAN Q K, YUAN H, REN K, et al. Research on damage to underwater targets by different combined shaped charge warhead [J]. Journal of Ordnance Equipment Engineering, 2024, 45(5): 173–179. doi: 10.11809/bqzbgcxb2024.05.025 [15] 张春辉, 张斐, 王志军, 等. 复合材质杆式射流侵彻水下目标的数值模拟 [J]. 爆破器材, 2019, 48(1): 8–14. doi: 10.3969/j.issn.1001-8352.2019.01.002ZHANG C H, ZHANG F, WANG Z J, et al. Numerical simulation of composite-material rod-like jet penetrating underwater targets [J]. Explosive Materials, 2019, 48(1): 8–14. doi: 10.3969/j.issn.1001-8352.2019.01.002 [16] 王志凯, 梁永辉, 戴伯达, 等. 近自由液面聚能战斗部水下爆炸威力场 [J]. 现代应用物理, 2024, 15(2): 021005. doi: 10.12061/j.issn.2095-6223.2024.021005WANG Z K, LIANG Y H, DAI B D, et al. Underwater explosion power field of near-free surface shaped charge warhead [J]. Modern Applied Physics, 2024, 15(2): 021005. doi: 10.12061/j.issn.2095-6223.2024.021005 [17] 黄洪. 聚能装药水下爆炸对目标的毁伤特性研究 [D]. 沈阳: 沈阳理工大学, 2021: 176−185, 192.HUANG H. Damage characteristics of shaped charge underwater explosion to target [D]. Shenyang: Shenyang University of Technology, 2021: 176−185, 192. [18] 周方毅, 詹发民, 黄雪峰, 等. 全尺寸圆锥-球缺组合药型罩聚能战斗部毁伤试验 [J]. 兵工学报, 2024, 45(Suppl 2): 251–258. doi: 10.12382/bgxb.2024.0084ZHOU F Y, ZHAN F M, HUANG X F, et al. Test research on damage effect of full-size shaped charge warhead with conical-spherical combined liner [J]. Acta Armamentarii, 2024, 45(Suppl 2): 251–258. doi: 10.12382/bgxb.2024.0084 [19] 张军, 李裕春, 黄骏逸, 等. 水下爆破聚能装药结构正交优化设计 [J]. 兵器装备工程学报, 2021, 42(2): 52–57. doi: 10.11809/bqzbgcxb2021.02.010ZHANG J, LI Y C, HUANG J Y, et al. Orthogonal optimization design of shaped charge structure for underwater blasting [J]. Journal of Ordnance Equipment Engineering, 2021, 42(2): 52–57. doi: 10.11809/bqzbgcxb2021.02.010 [20] 李兵, 刘念念, 陈高杰, 等. 水中聚能战斗部毁伤双层圆柱壳的数值模拟与试验研究 [J]. 兵工学报, 2018, 39(1): 38–45. doi: 10.3969/j.issn.1000-1093.2018.01.004LI B, LIU N N, CHEN G J, et al. Numerical simulation and experimental research on damage of shaped charge warhead to double-layer columniform shell [J]. Acta Armamentarii, 2018, 39(1): 38–45. doi: 10.3969/j.issn.1000-1093.2018.01.004 [21] 蒋文灿, 程祥珍, 梁斌, 等. 一种组合药型罩聚能装药战斗部对含水复合结构毁伤的数值模拟及试验研究 [J]. 爆炸与冲击, 2022, 42(8): 083303. doi: 10.11883/bzycj-2021-0389JIANG W C, CHENG X Z, LIANG B, et al. Numerical simulation and experimental study on the damage of water partitioned structure by a shaped charge warhead with a combined charge liner [J]. Explosion and Shock Waves, 2022, 42(8): 083303. doi: 10.11883/bzycj-2021-0389 [22] 徐鹤峰. 组合药型罩水中毁伤元形成及侵彻性能研究 [D]. 沈阳: 沈阳理工大学, 2022: 24−26.XU H F. Study on formation and penetration performance of damage elements in water of composite liner [D]. Shenyang: Shenyang University of Technology, 2022: 24−26. [23] 徐小棣, 梁增友, 盛鹏, 等. 带隔板组合药型罩对反应装甲侵彻后效作用研究 [J]. 火炮发射与控制学报, 2025, 46(3): 98–106. doi: 10.19323/j.issn.1673-6524.202405014XU X D, LIANG Z Y, SHENG P, et al. Study on after-effect of penetrating explosive reactive armor by combination liner with wave-shaper [J]. Journal of Gun Launch & Control, 2025, 46(3): 98–106. doi: 10.19323/j.issn.1673-6524.202405014 [24] 车龙, 郭策安, 潘琳琳, 等. 爆炸冲击作用下反坦克三角锥混凝土的毁伤特性数值模拟分析 [J]. 火炮发射与控制学报, 2025, 46(2): 53–59. doi: 10.19323/j.issn.1673-6524.202410006CHE L, GUO C A, PAN L L, et al. Numerical simulation analysis of damage characteristics of anti-tank triangular cone concrete under explosive impact [J]. Journal of Gun Launch & Control, 2025, 46(2): 53–59. doi: 10.19323/j.issn.1673-6524.202410006 -

下载:

下载: