Damage and Fractal Analysis of Double-Hole Blasting

-

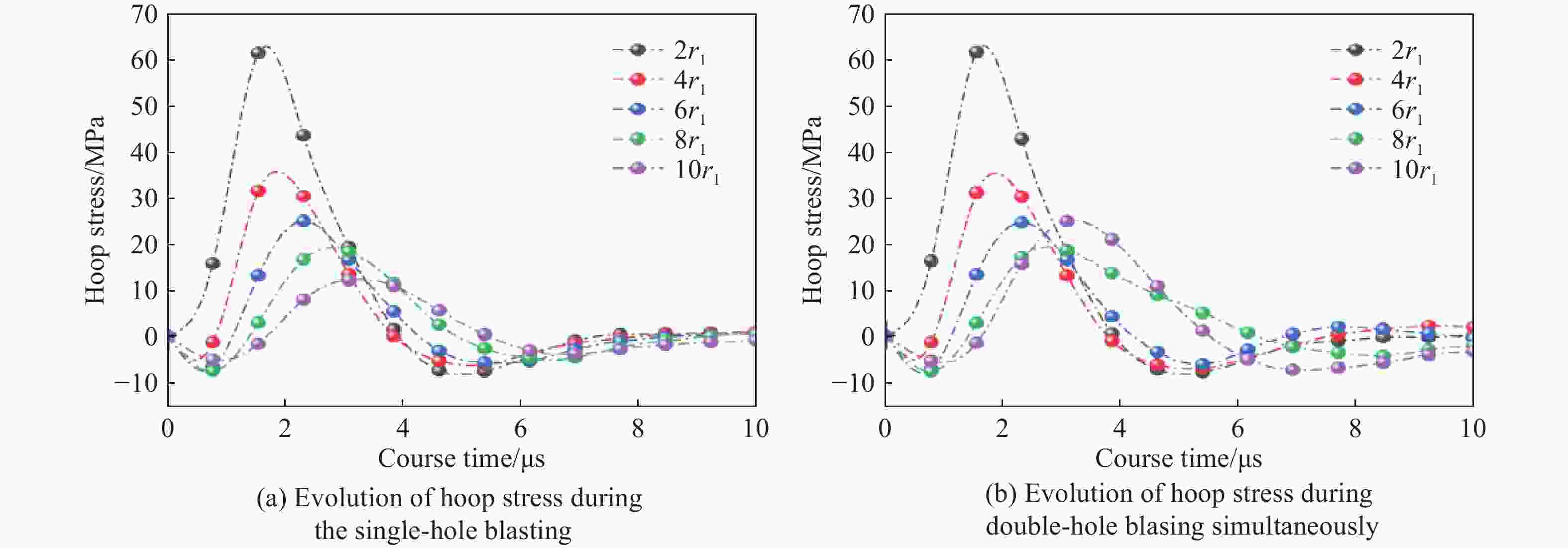

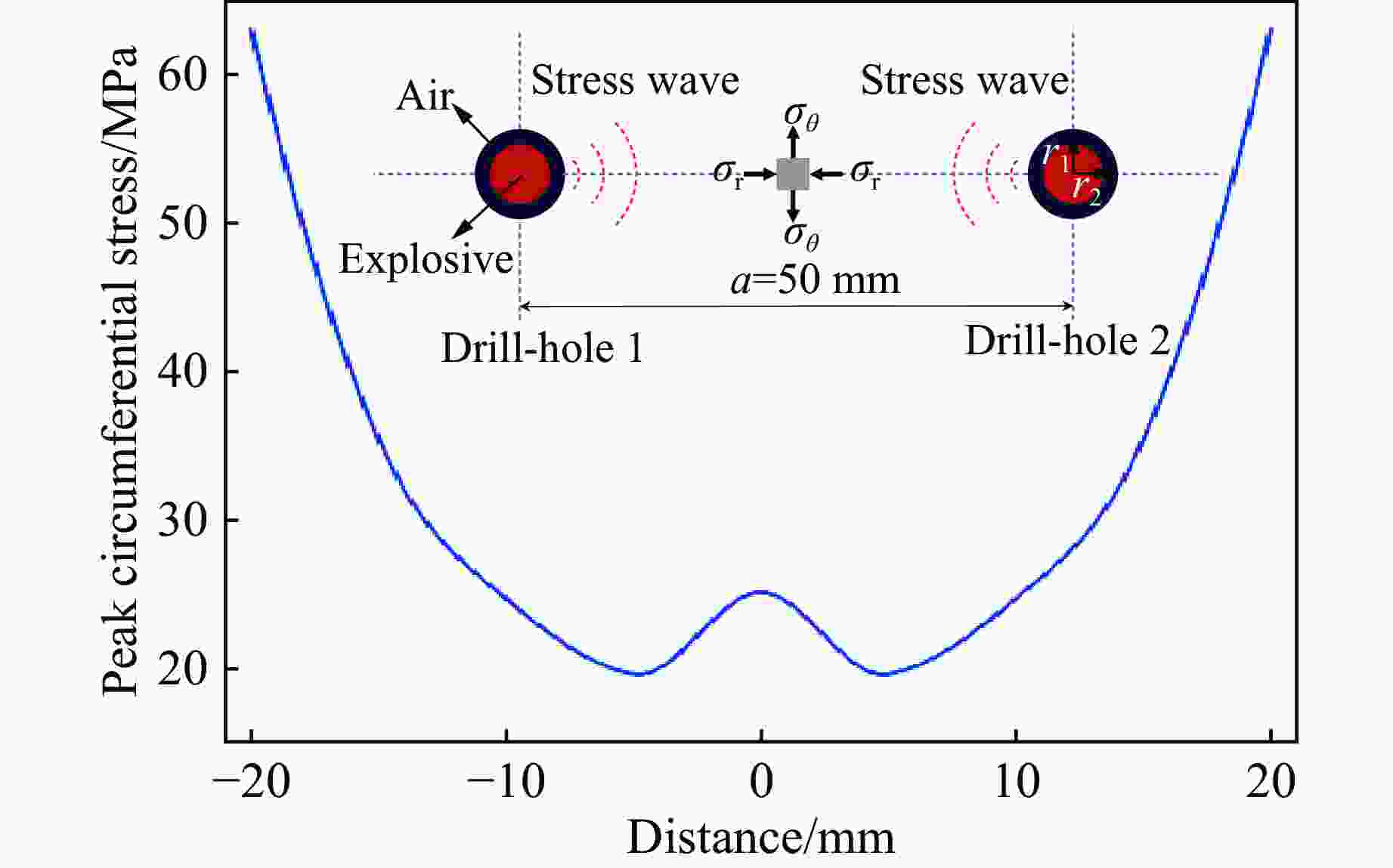

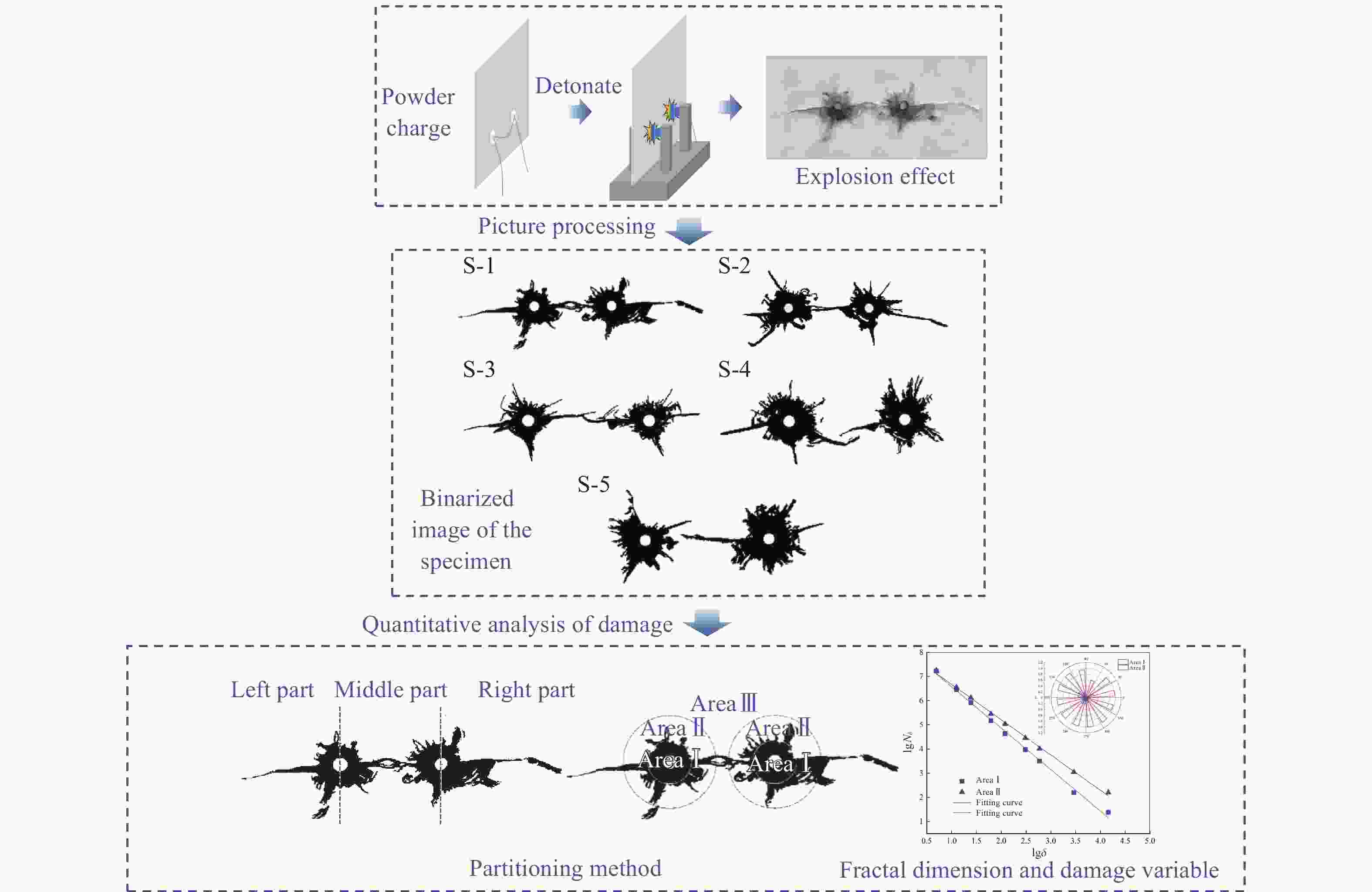

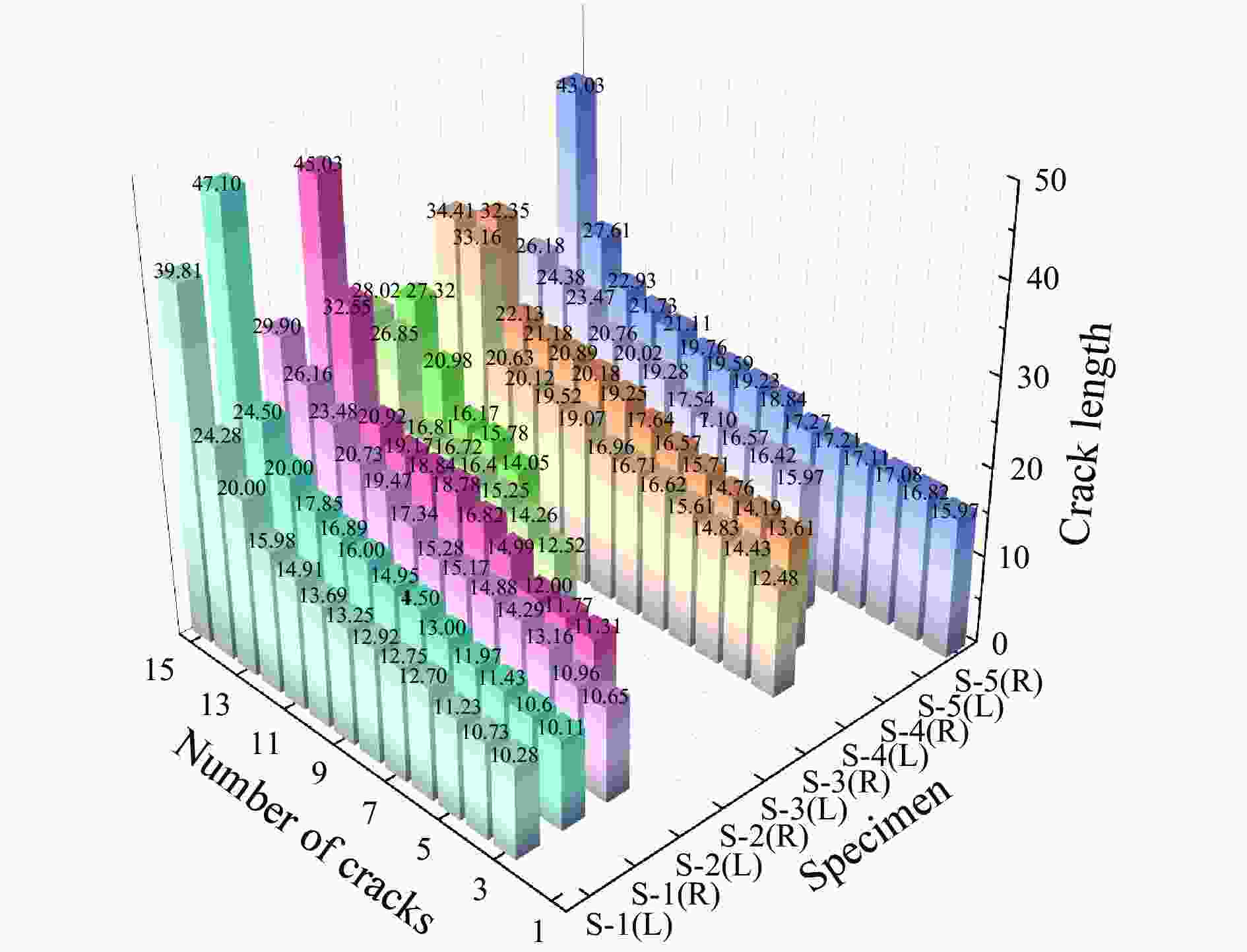

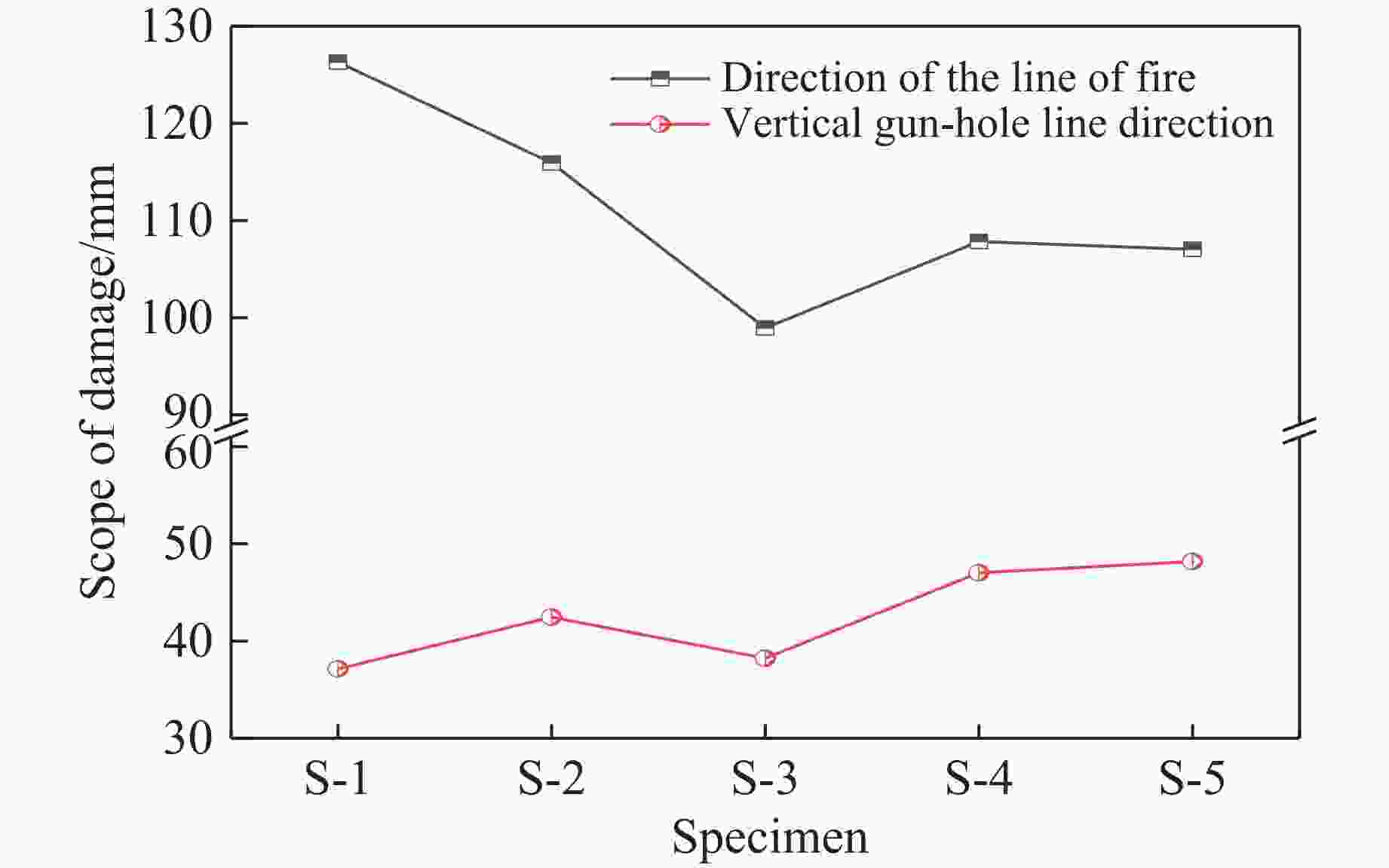

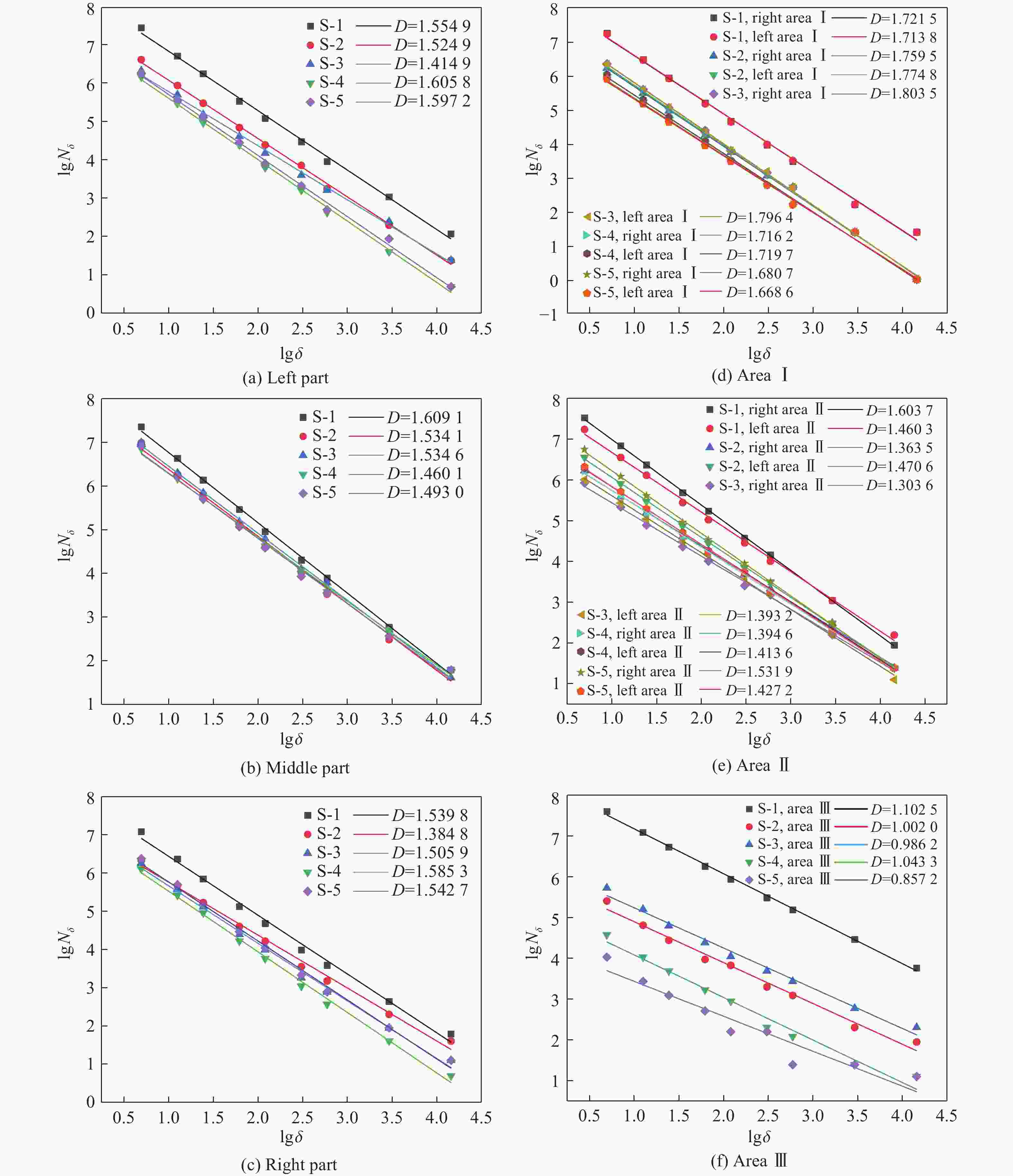

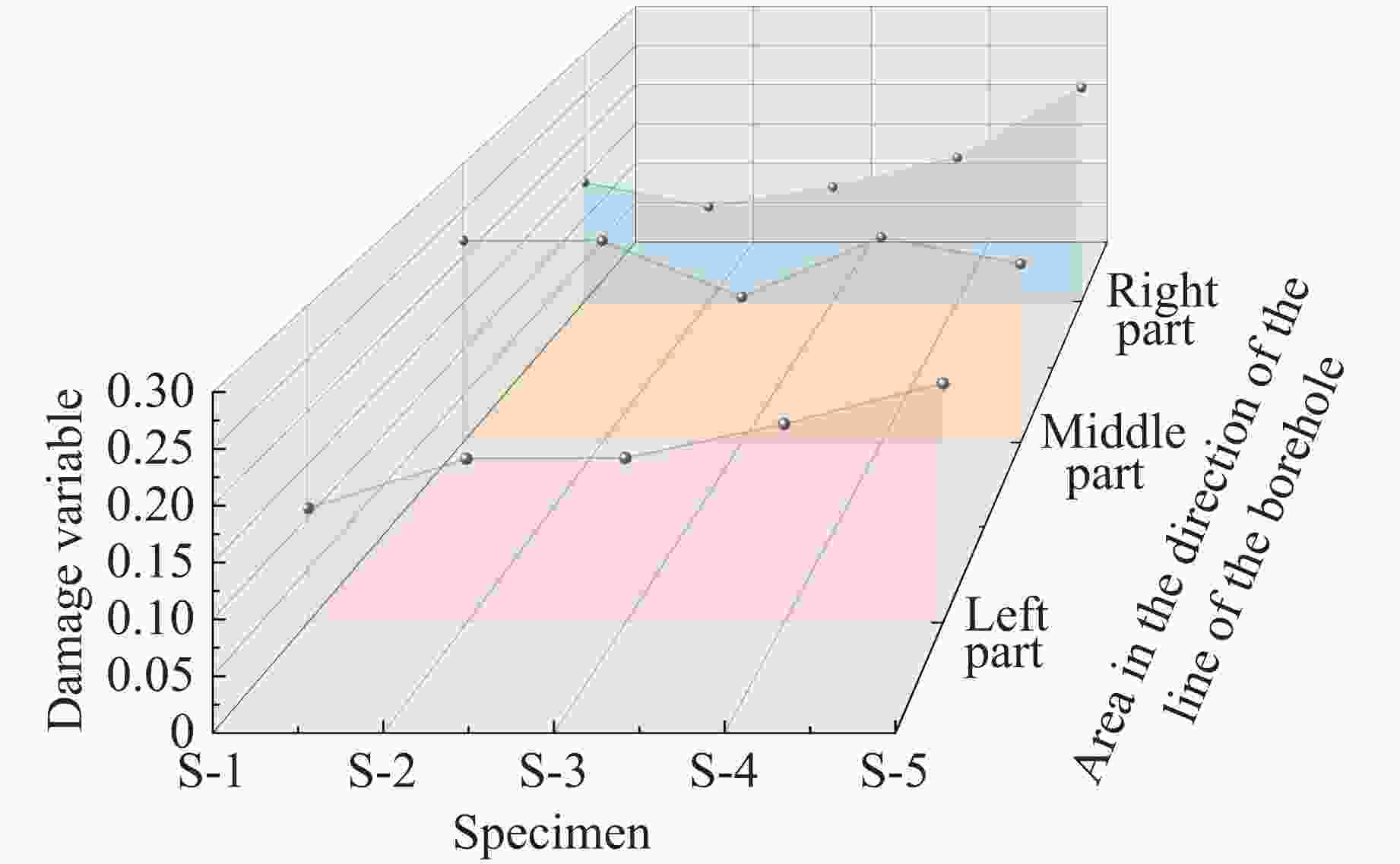

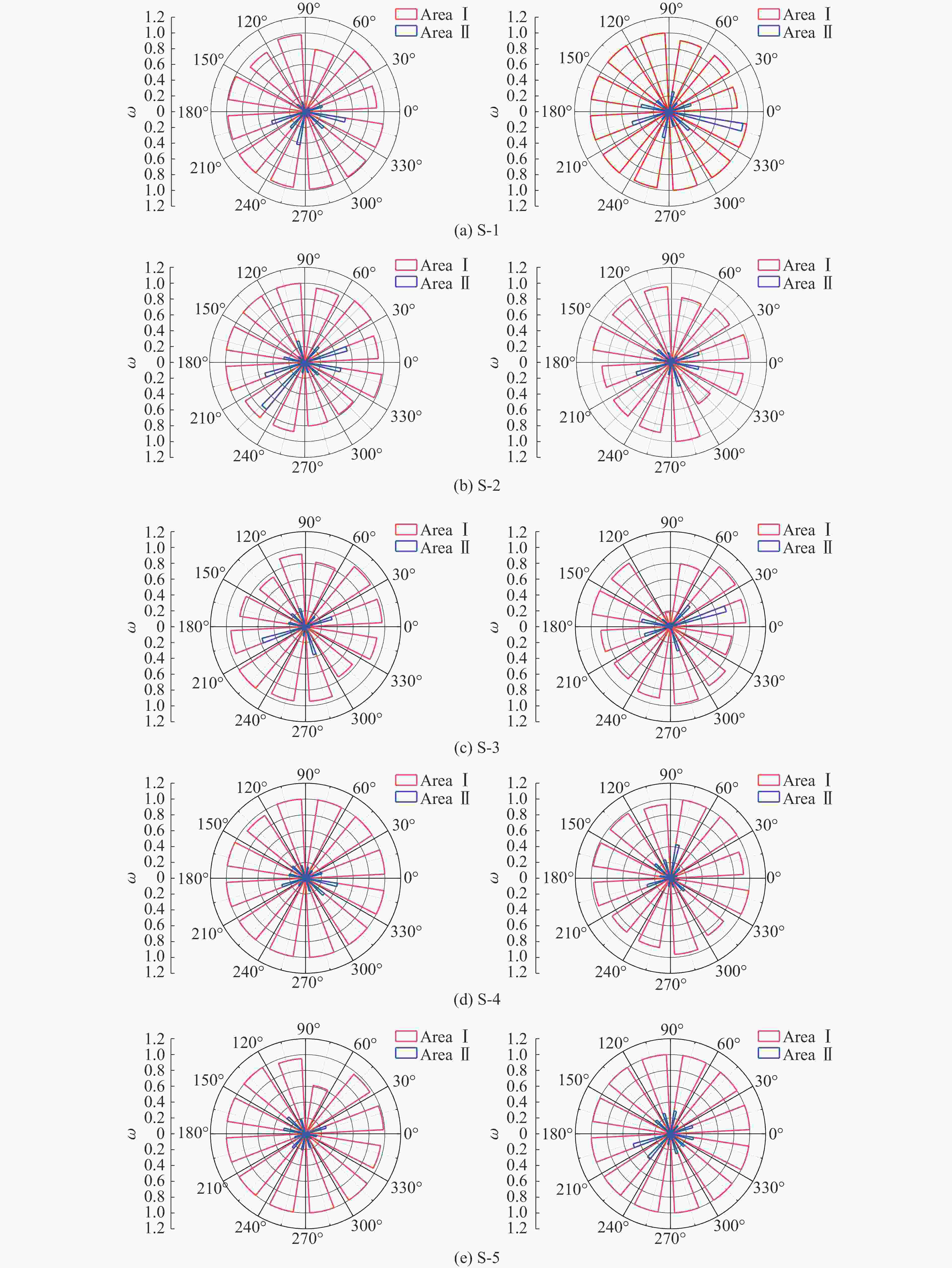

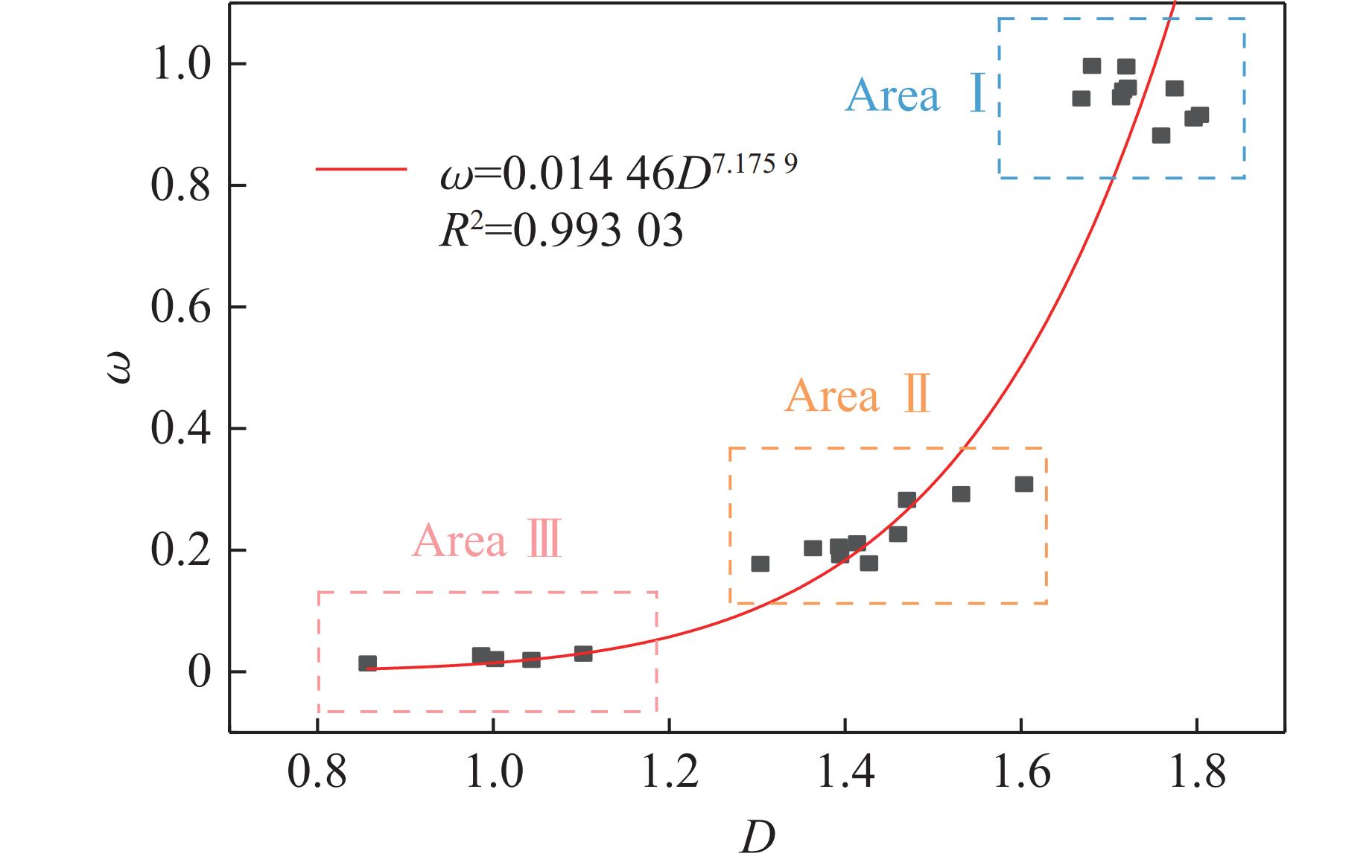

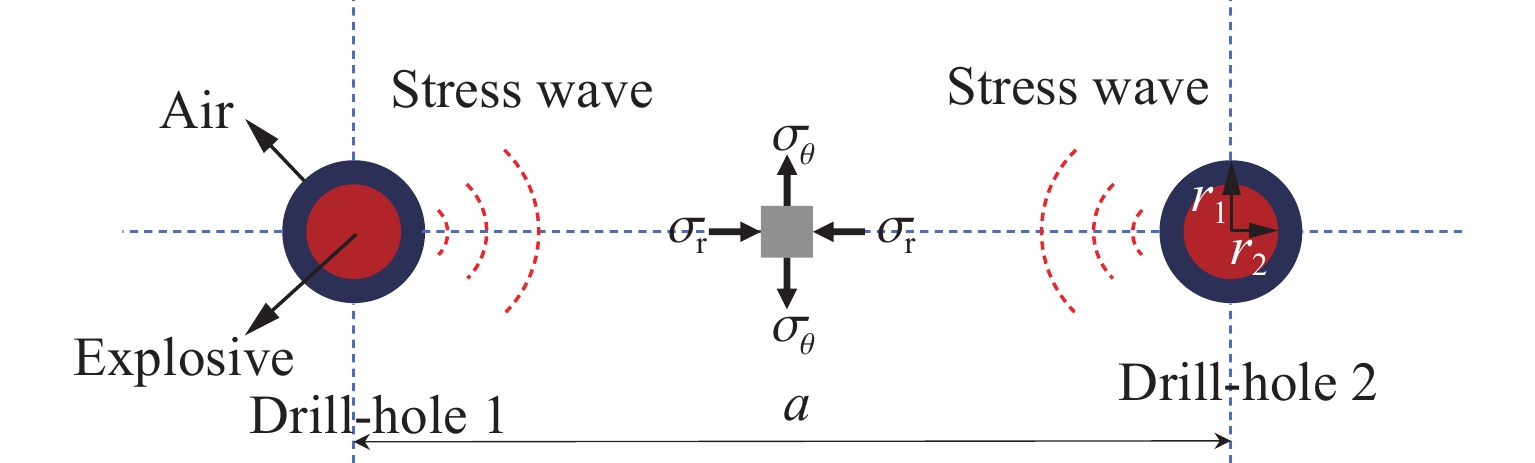

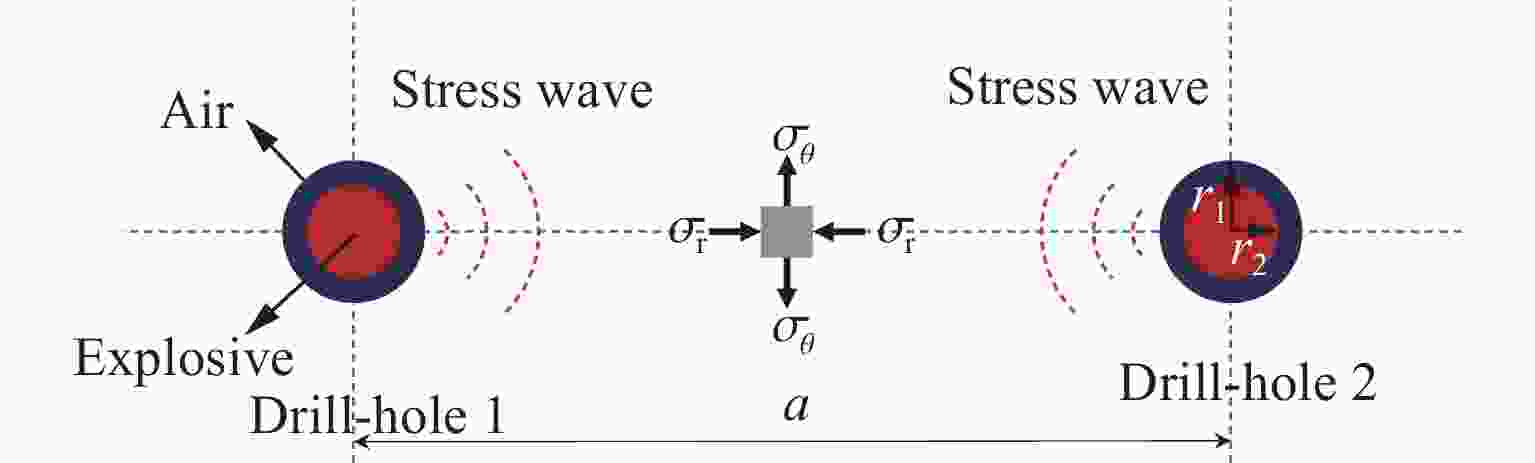

摘要: 采用理论分析和模型试验研究双孔爆破介质的损伤破坏特征,基于双孔爆破模型的弹性力学平面应变问题解析,建立了双孔爆破动态应力场演化的理论模型。通过模型试验研究了不同炮孔间距下双孔爆破的损伤特征,通过分区和分形维数定量表征了炮孔周围不同区域的损伤特征。结果表明:随着炮孔间距的增大,应力波叠加作用降低,压碎区半径增大,裂纹数先减少后增多,主裂纹的平均长度逐渐增大;炮孔连线方向的损伤逐渐减小,垂直于炮孔连线方向的损伤逐渐增大;小孔距有利于裂纹孔间贯穿和沿炮孔连线方向扩展;试件左部和右部区域的损伤变量逐渐增大,中部区域的损伤变量在炮孔间距为50 mm时出现最小值;区域Ⅰ和区域Ⅱ的损伤变量先减小后增大,区域Ⅲ的损伤变量逐渐减小;在极坐标系下,区域Ⅰ的损伤均匀分布,区域Ⅱ的损伤由椭圆形分布逐渐向圆形分布转变。根据损伤区域分形维数与损伤变量的关系,构建了聚甲基丙烯酸甲酯材料双孔爆破分形损伤模型。Abstract: To investigate the damage and failure characteristics of the double-hole blasting medium, theoretical analysis and model experiments are conducted in this study. Based on the analytical solution of the elastic plane strain problem in the double-hole blasting model, a theoretical model is established to study the evolution of the dynamic stress field during double-hole blasting. The damage of double-hole blasting with different blast hole spacing is studied by the model experiment; the damage in different regions around the blast holes is analyzed by partitioned research and fractal dimension quantification. The study shows that as the blast hole spacing increases, the super position effect of stress waves decreases, the radius of the crushing zone and the average length of the main crack gradually increase, the number of cracks decreases first and then increases. Additioanlly, the increase of blast hole spacing lead to gradual decrease of the damage along the direction of the blast hole connection, while the damage perpendicular to the direction of the blast hole connection gradually increases. Small hole spacing is conducive to the penetration of cracks between holes and promotes cracks expansion along the direction of the blast hole connection. With increasing blast hole spacing, the damage variable in the left and right regions of the specimen gradually increases, and reaches a minimum value in the central region when the blast hole spacing is 50 mm. The damage variables in area Ⅰ and area Ⅱ first decrease and then increase, while the damage variable in area Ⅲ gradually decreases. The damage variable distribution in the polar coordinate system shows that area Ⅰ exhibits a uniform damage pattern, and area Ⅱ gradually transitions from an elliptical to a circular distribution. Based on the relationship between the fractal dimension of the damage area and the damage variable, a fractal damage model for double-hole blasting of poly(methyl methacrylate) (PMMA) material is constructed.

-

表 1 试件损伤破坏结果

Table 1. Damage and failure results of specimens

Specimen No. Crack penetration type Radius of crushing zone/mm Number of cracks Average crack

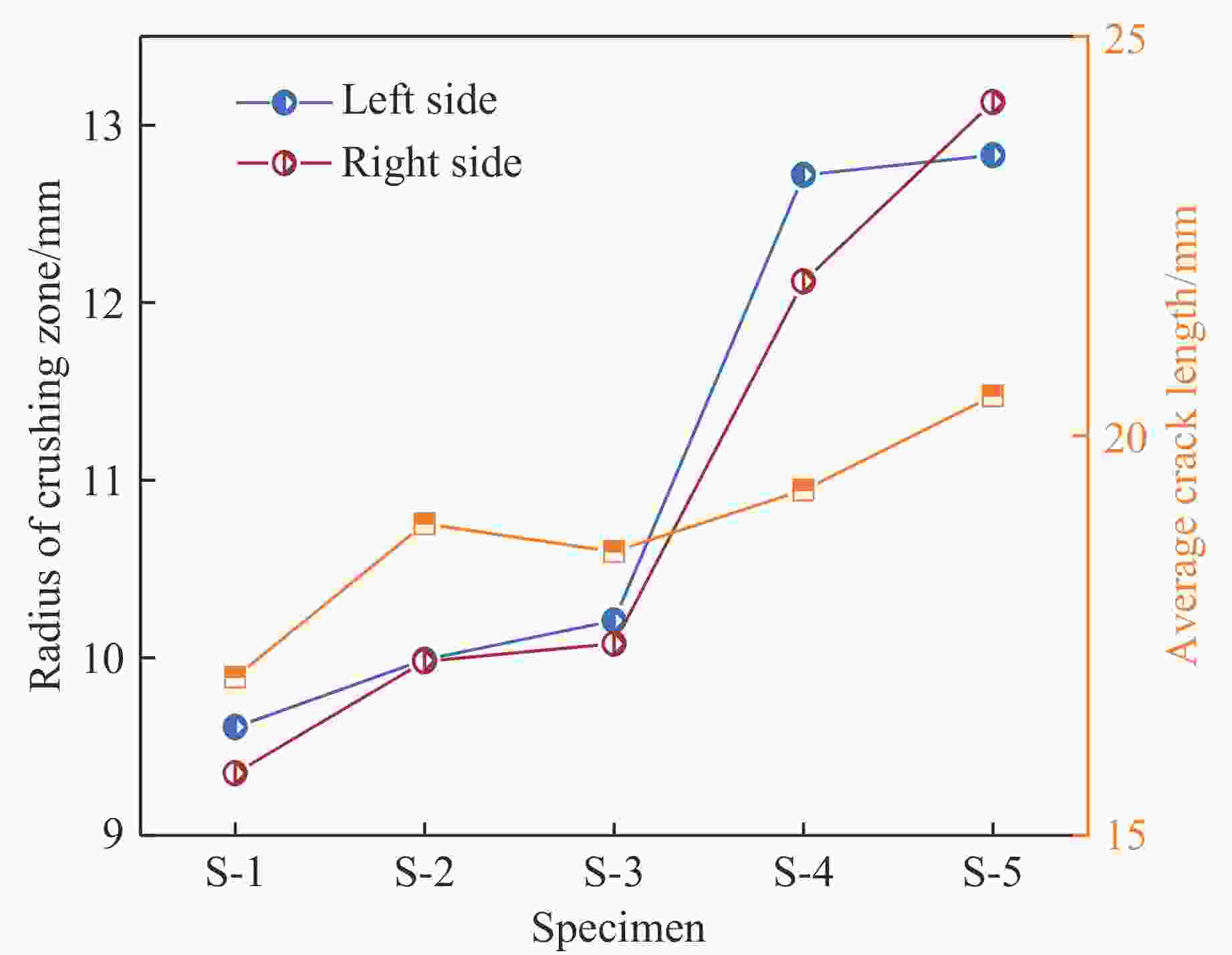

length/mmLeft side Right side Left side Right side S-1 Penetrated 9.61 9.35 13 13 16.98 S-2 Penetrated 9.99 9.98 13 11 18.90 S-3 Penetrated 10.21 10.08 8 5 18.55 S-4 Not penetrated 12.72 12.12 13 12 19.32 S-5 Not penetrated 12.83 13.13 11 15 20.50 表 2 试件不同区域的损伤变量

Table 2. Damage variables in different areas of the specimen

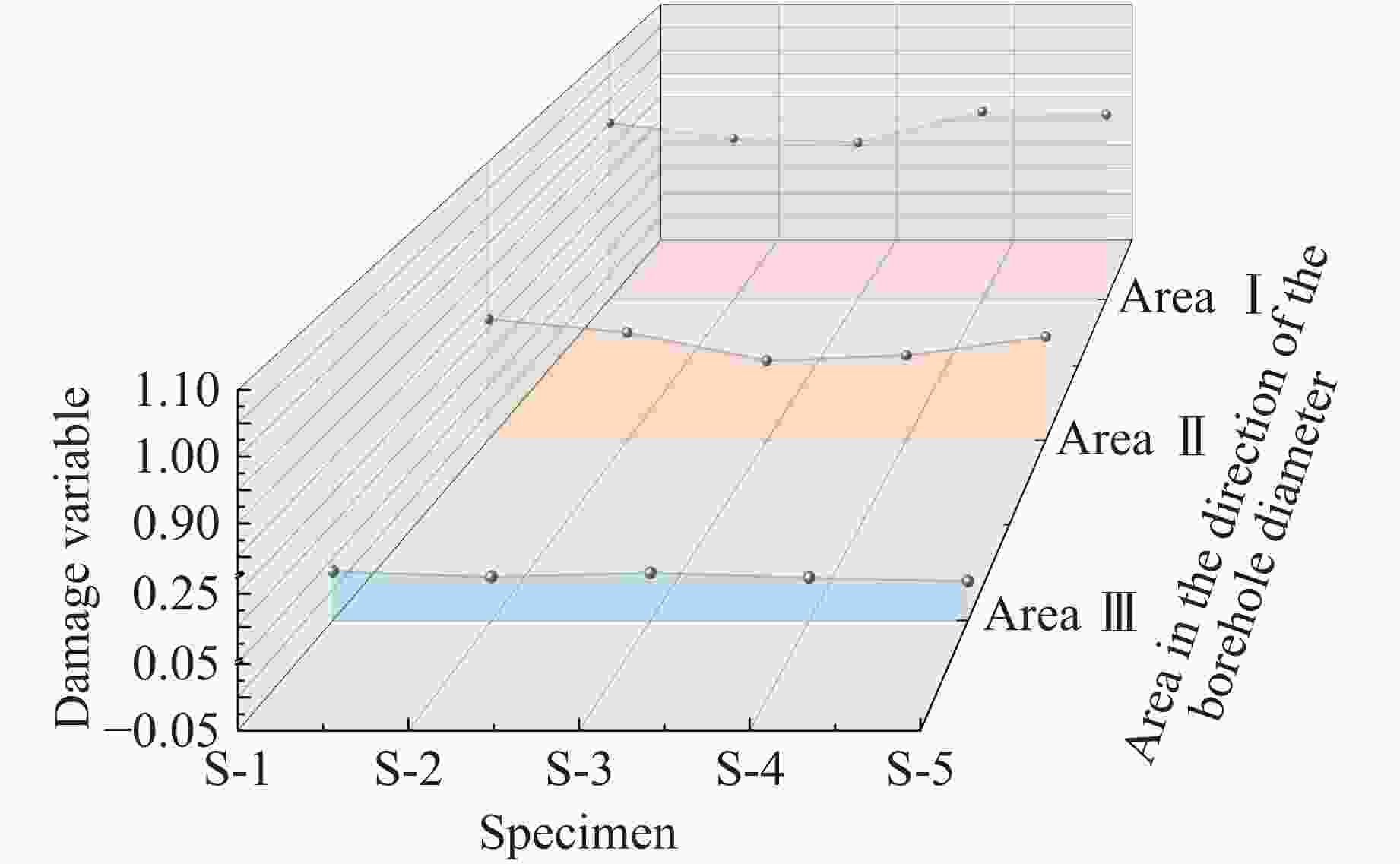

Specimen No. Damage variables in different regions Left part Middle part Right part Left area Ⅰ Right area Ⅰ Left area Ⅱ Right area Ⅱ Area Ⅲ S-1 0.108 41 0.217 40 0.143 84 0.944 65 0.960 75 0.226 13 0.308 11 0.029 32 S-2 0.155 12 0.217 06 0.114 41 0.959 40 0.882 10 0.282 54 0.202 86 0.020 43 S-3 0.155 94 0.156 67 0.138 33 0.909 68 0.916 03 0.205 54 0.177 00 0.026 95 S-4 0.187 96 0.221 13 0.173 87 0.995 47 0.956 00 0.211 06 0.191 31 0.019 31 S-5 0.226 17 0.192 44 0.258 36 0.942 80 0.996 45 0.178 02 0.292 02 0.013 48 -

[1] 杨建华, 彭超, 叶志伟, 等. 深部岩体爆破冲击波能量分布特征 [J]. 兵工学报, 2024, 45(6): 1735–1746. doi: 10.12382/bgxb.2023.0254YANG J H, PENG C, YE Z W, et al. Energy distribution of shock wave in deep rock mass blasting [J]. Acta Armamentarii, 2024, 45(6): 1735–1746. doi: 10.12382/bgxb.2023.0254 [2] 王家来, 徐颖. 应变波对岩体的损伤作用和爆生裂纹传播 [J]. 爆炸与冲击, 1995, 15(3): 212–216. doi: 10.11883/1001-1455(1995)03-0212-5WANG J L, XU Y. Damage effect in rock by strain waves and crack propagation by explosion [J]. Explosion and Shock Waves, 1995, 15(3): 212–216. doi: 10.11883/1001-1455(1995)03-0212-5 [3] 杨小林, 王树仁. 岩石爆破损伤断裂的细观机理 [J]. 爆炸与冲击, 2000, 20(3): 247–252. doi: 10.11883/1001-1455(2000)03-0247-6YANG X L, WANG S R. Meso-mechanism of damage and fracture on rock blasting [J]. Explosion and Shock Waves, 2000, 20(3): 247–252. doi: 10.11883/1001-1455(2000)03-0247-6 [4] SAWMLIANA C. Mechanism of rock breakage by blasting, influences of rock and explosive properties on blast results [J]. TAI Journal, 2012, 1(1): 33–38. [5] 杨仁树, 丁晨曦, 王雁冰, 等. 爆炸应力波与爆生气体对被爆介质作用效应研究 [J]. 岩石力学与工程学报, 2016, 35(Suppl 2): 3501–3506. doi: 10.13722/j.cnki.jrme.2016.0066YANG R S, DING C X, WANG Y B, et al. Action-effect study of medium under loading of explosion stress wave and explosion gas [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(Suppl 2): 3501–3506. doi: 10.13722/j.cnki.jrme.2016.0066 [6] QIU S, ELIASSON V. Interaction and coalescence of multiple simultaneous and non-simultaneous blast waves [J]. Shock Waves, 2016, 26(3): 287–297. doi: 10.1007/s00193-015-0567-2 [7] LI X H, ZHU Z M, WANG M, et al. Numerical study on the behavior of blasting in deep rock masses [J]. Tunnelling and Underground Space Technology, 2021, 113: 103968. doi: 10.1016/j.tust.2021.103968 [8] 范勇, 孙金山, 贾永胜, 等. 高地应力硐室光面爆破孔间应力相互作用与成缝机制 [J]. 岩石力学与工程学报, 2023, 42(6): 1352–1365. doi: 10.13722/j.cnki.jrme.2022.1127FAN Y, SUN J S, JIA Y S, et al. Stress interaction and crack penetration mechanism between smooth blasting holes for tunnel excavation under high in-situ stress [J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(6): 1352–1365. doi: 10.13722/j.cnki.jrme.2022.1127 [9] 马泗洲, 蒋海明, 刘科伟, 等. 地应力对岩体预裂爆破成缝过程的影响 [J]. 爆炸与冲击, 2025, 45(9): 095201.MA S Z, JIANG H M, LIU K W, et al. Effect of in-situ stress on fracture formation process of rock mass in presplit blasting [J]. Explosion and Shock Waves, 2025, 45(9): 095201. [10] 李潜, 李海波, 傅帅旸, 等. 高地应力下双孔爆破成缝最优孔间距研究 [J]. 岩石力学与工程学报, 2025, 44(3): 678–690. doi: 10.3724/1000-6915.jrme.2024.0545LI Q, LI H B, FU S Y, et al. Study on the most optimistic hole spacing for double-hole blasting under high in-situ stresses [J]. Chinese Journal of Rock Mechanics and Engineering, 2025, 44(3): 678–690. doi: 10.3724/1000-6915.jrme.2024.0545 [11] ZHOU Z Q, MA J, WANG J G, et al. Evolution characteristics of strain and displacement fields in double-hole short-delay blasting based on DIC [J]. Processes, 2024, 12(7): 1291. doi: 10.3390/pr12071291 [12] HE C L, YANG J. Experimental and numerical investigations of dynamic failure process in rock under blast loading [J]. Tunnelling and Underground Space Technology, 2019, 83: 552–564. doi: 10.1016/j.tust.2018.08.047 [13] MANDELBROT B B, WHEELER J A. The fractal geometry of nature [J]. American Journal of Physics, 1983, 51(3): 286–287. doi: 10.1119/1.13295 [14] 谢和平. 分形-岩石力学导论 [M]. 北京: 科学出版社, 1996: 129−138.XIE H P. Introduction to fractal-rock mechanics [M]. Beijing: Science Press, 1996: 129−138. [15] 杨军, 王树仁. 岩石爆破分形损伤模型研究 [J]. 爆炸与冲击, 1996, 16(1): 5–10. doi: 10.11883/1001-1455(1996)01-0005-6YANG J, WANG S R. Study on fractal damage model of rock fragmentation by blasting [J]. Explosion and Shock Waves, 1996, 16(1): 5–10. doi: 10.11883/1001-1455(1996)01-0005-6 [16] 祝文化, 明锋, 宋成梓. 爆破荷载作用下岩体损伤破坏的分形研究 [J]. 岩土力学, 2011, 32(10): 3131–3135. doi: 10.3969/j.issn.1000-7598.2011.10.040ZHU W H, MING F, SUN C Z. Fractal study of rock damage under blasting loading [J]. Rock and Soil Mechanics, 2011, 32(10): 3131–3135. doi: 10.3969/j.issn.1000-7598.2011.10.040 [17] 杨仁树, 许鹏. 爆炸作用下介质损伤破坏的分形研究 [J]. 煤炭学报, 2017, 42(12): 3065–3071. doi: 10.13225/j.cnki.jccs.2017.0107YANG R S, XU P. Fractal study of media damage under blasting loading [J]. Journal of China Coal Society, 2017, 42(12): 3065–3071. doi: 10.13225/j.cnki.jccs.2017.0107 [18] 杨仁树, 肖成龙, 李永亮, 等. 不耦合偏心装药结构爆破损伤破坏的分形研究 [J]. 振动与冲击, 2020, 39(12): 129–134. doi: 10.13465/j.cnki.jvs.2020.12.017YANG R S, XIAO C L, LI Y L, et al. A fractal study on blasting damage of an eccentric decouple charge structure [J]. Journal of Vibration and Shock, 2020, 39(12): 129–134. doi: 10.13465/j.cnki.jvs.2020.12.017 [19] DING C X, YANG R S, LEI Z, et al. Fractal damage and crack propagation in decoupled charge blasting [J]. Soil Dynamics and Earthquake Engineering, 2021, 141: 106503. doi: 10.1016/j.soildyn.2020.106503 [20] 马军, 汪旭光, 李祥龙, 等. 不耦合装药刻痕爆破裂纹的动态力学特征及损伤分形规律实验 [J]. 兵工学报, 2023, 44(12): 3676–3686. doi: 10.12382/bgxb.2022.1270MA J, WANG X G, LI X L, et al. Experiment on dynamic mechanical characteristics and damage fractal law of crack in decoupled charge scratch blasting [J]. Acta Armamentarii, 2023, 44(12): 3676–3686. doi: 10.12382/bgxb.2022.1270 [21] 纪哲, 岳文豪, 苏洪, 等. 不同割缝宽度爆生裂纹扩展行为研究 [J]. 高压物理学报, 2024, 38(6): 064107. doi: 10.11858/gywlxb.20240733JI Z, YUE W H, SU H, et al. Study on the behavior of blasting crack propagation under different crack widths [J]. Chinese Journal of High Pressure Physics, 2024, 38(6): 064107. doi: 10.11858/gywlxb.20240733 [22] FAN Y, LU W B, ZHOU Y H, et al. Influence of tunneling methods on the strainburst characteristics during the excavation of deep rock masses [J]. Engineering Geology, 2016, 201: 85–95. doi: 10.1016/j.enggeo.2015.12.015 [23] LI X D, LIU K W, QIU T, et al. Numerical study on fracture control blasting using air-water coupling [J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2023, 9(1): 29. doi: 10.1007/s40948-023-00546-y [24] YILMAZ O, UNLU T. Three dimensional numerical rock damage analysis under blasting load [J]. Tunnelling and Underground Space Technology, 2013, 38: 266–278. doi: 10.1016/j.tust.2013.07.007 [25] ROSSMANITH H P, DAEHNKE A, NASMILLNER R E K, et al. Fracture mechanics applications to drilling and blasting [J]. Fatigue & Fracture of Engineering Materials & Structures, 1997, 20(11): 1617–1636. doi: 10.1111/j.1460-2695.1997.tb01515.x [26] 徐颖, 孟益平, 程玉生. 装药不耦合系数对爆破裂纹控制的试验研究 [J]. 岩石力学与工程学报, 2002, 21(12): 1843–1847. doi: 10.3321/j.issn:1000-6915.2002.12.020XU Y, MENG Y P, CHENG Y S. Study on control of blast crack by decoupling charge index [J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(12): 1843–1847. doi: 10.3321/j.issn:1000-6915.2002.12.020 [27] 侯猛. 巷道掘进光面爆破参数的动焦散实验研究 [D]. 昆明: 昆明理工大学, 2021: 21−22.HOU M. Experimental study of the dynamic focal dispersion of the parameters of surface blasting in roadway excavation [D]. Kunming: Kunming University of Science and Technology, 2021: 21−22. [28] LOPES R, BETROUNI N. Fractal and multifractal analysis: a review [J]. Medical Image Analysis, 2009, 13(4): 634–649. doi: 10.1016/j.media.2009.05.003 [29] SCHNEIDER C A, RASBAND W S, ELICEIRI K W. NIH Image to ImageJ: 25 years of image analysis [J]. Nature Methods, 2012, 9(7): 671–675. doi: 10.1038/nmeth.2089 [30] SHI X, YANG P, GENG X Y, et al. Investigating static properties and microscopic pore structure characteristics of rubberized cement-soil under freeze-thaw cycles [J]. Construction and Building Materials, 2025, 458: 139524. doi: 10.1016/J.CONBUILDMAT.2024.139524 -

下载:

下载: