| [1] |

朱万成, 唐春安, 左宇军. 深部岩体动态损伤与破裂过程 [M]. 北京: 科学出版社, 2014: 1−3.ZHU W C, TANG C A, ZUO Y J. Dynamic damage and fracture process of deep rock mass [M]. Beijing: Science Press, 2014: 1−3.

|

| [2] |

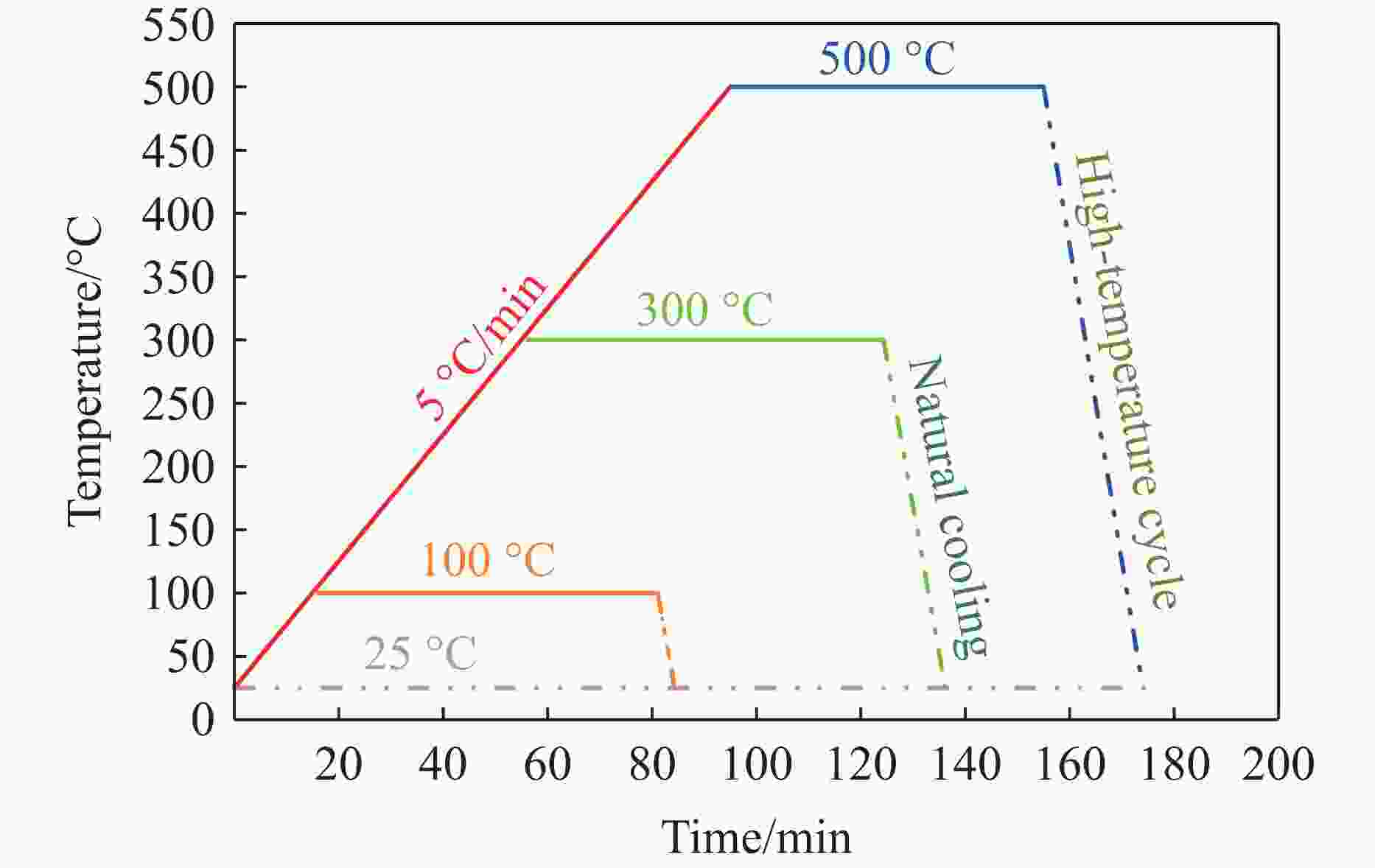

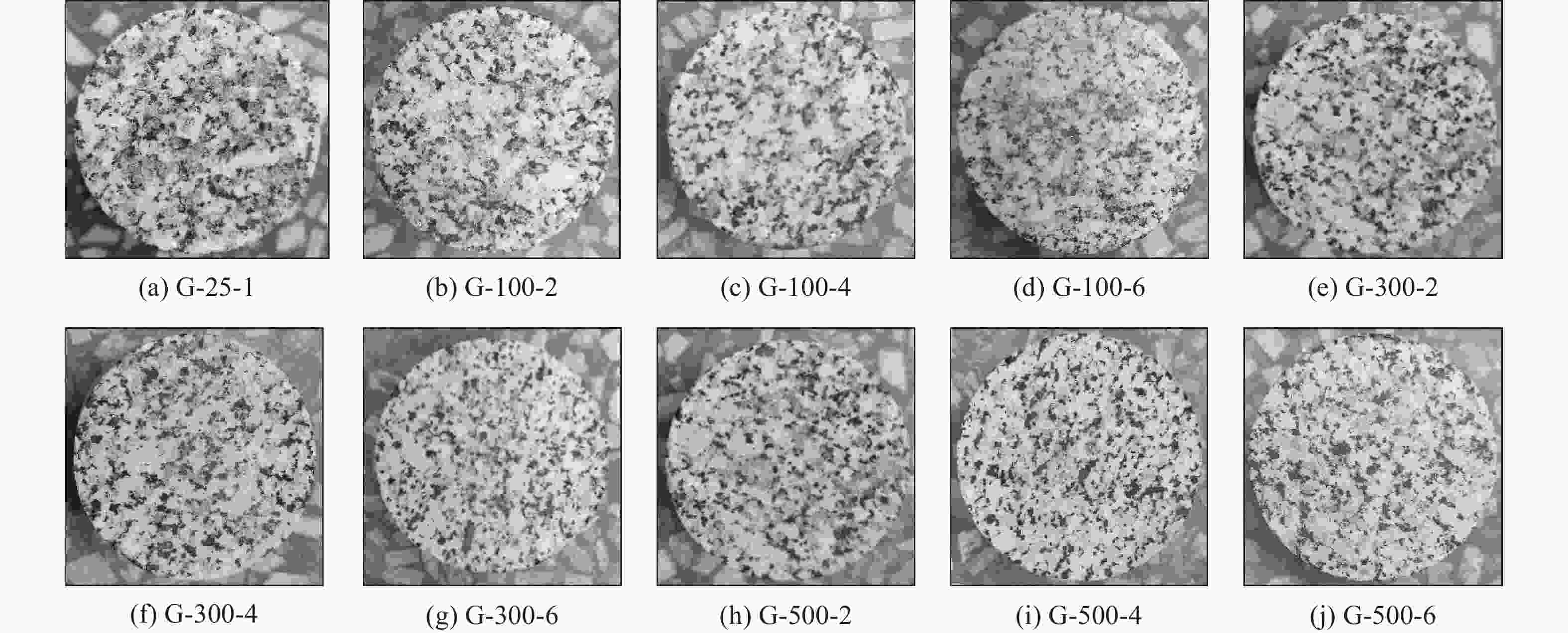

张鸿忠. 热冷循环后花岗岩物理参数演化规律与动态压缩性能研究 [D]. 长沙: 中南大学, 2023: 1−2.ZHANG H Z. Study on the evolution of physical parameters and dynamic compression properties of granite after heating and cooling cycles [D]. Changsha: Central South University, 2023: 1−2.

|

| [3] |

谢和平. 深部岩体力学与开采理论研究进展 [J]. 煤炭学报, 2019, 44(5): 1283–1305. doi: 10.13225/j.cnki.jccs.2019.6038XIE H P. Research review of the state key research development program of China: deep rock mechanics and mining theory [J]. Journal of China Coal Society, 2019, 44(5): 1283–1305. doi: 10.13225/j.cnki.jccs.2019.6038

|

| [4] |

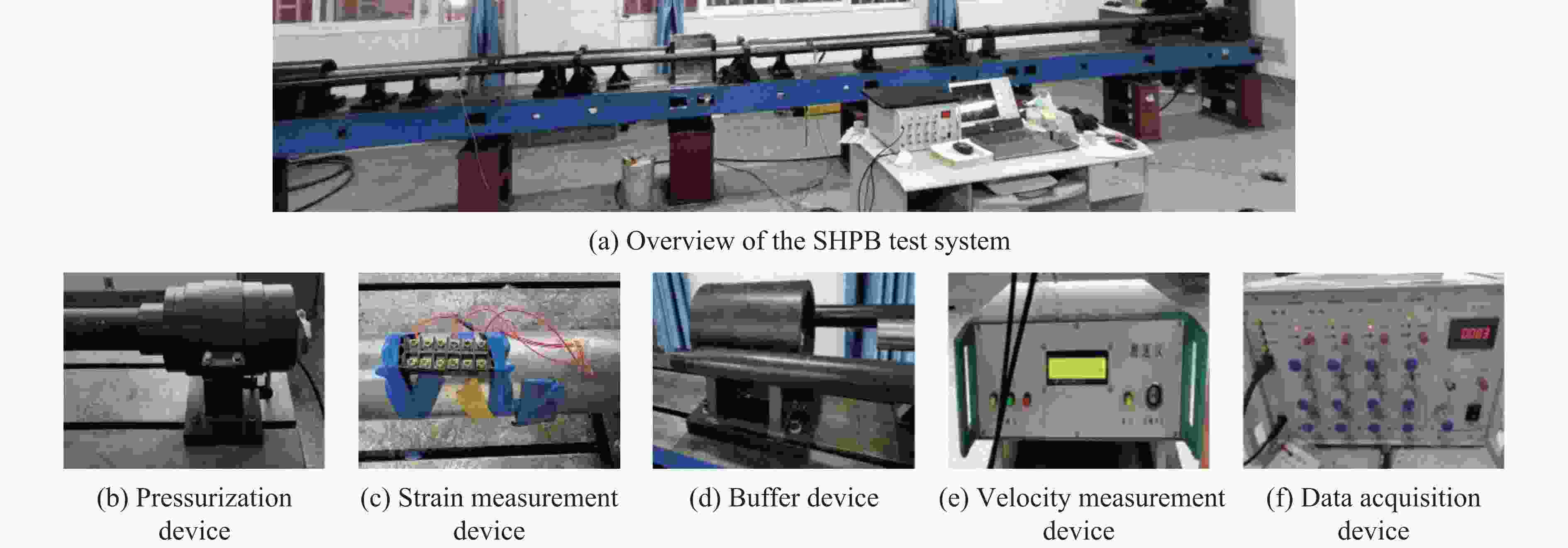

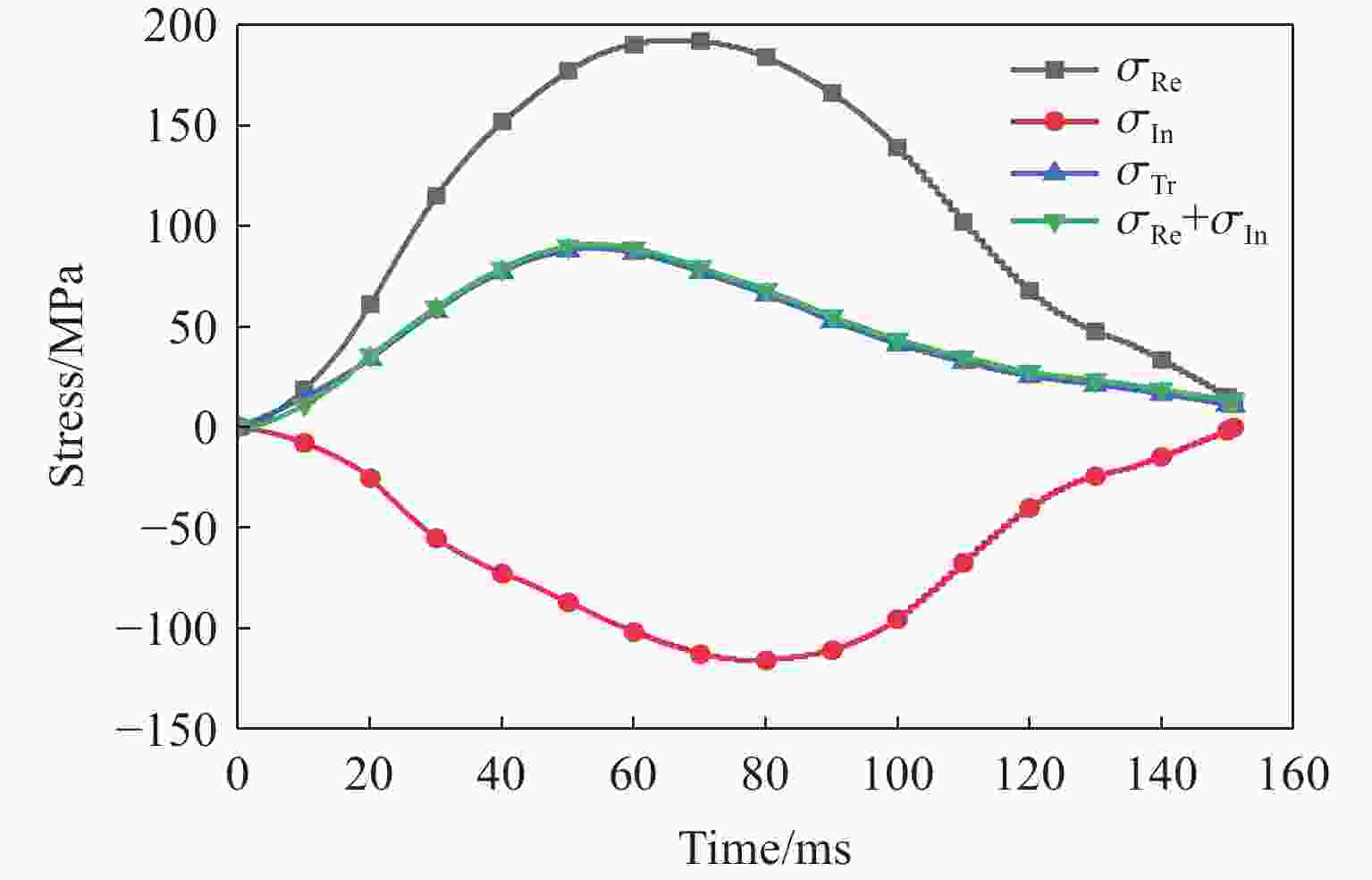

XIA K W, YAO W. Dynamic rock tests using split Hopkinson (Kolsky) bar system—a review [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2015, 7(1): 27–59. doi: 10.1016/j.jrmge.2014.07.008

|

| [5] |

XIE H P, ZHANG K, ZHOU C T, et al. Dynamic response of rock mass subjected to blasting disturbance during tunnel shaft excavation: a field study [J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2022, 8(2): 52. doi: 10.1007/s40948-022-00358-6

|

| [6] |

XIE H P, ZHU J B, ZHOU T, et al. Novel three-dimensional rock dynamic tests using the true triaxial electromagnetic Hopkinson bar system [J]. Rock Mechanics and Rock Engineering, 2021, 54(4): 2079–2086. doi: 10.1007/s00603-020-02344-4

|

| [7] |

谢和平, 周宏伟, 薛东杰, 等. 煤炭深部开采与极限开采深度的研究与思考 [J]. 煤炭学报, 2012, 37(4): 535–542. doi: 10.13225/j.cnki.jccs.2012.04.011XIE H P, ZHOU H W, XUE D J, et al. Research and consideration on deep coal mining and critical mining depth [J]. Journal of China Coal Society, 2012, 37(4): 535–542. doi: 10.13225/j.cnki.jccs.2012.04.011

|

| [8] |

田诺成. 循环荷载作用下花岗岩动力学性能与累积损伤演化规律研究 [D]. 合肥: 合肥工业大学, 2021: 1−3.TIAN N C. Research on dynamic properties and evolution law of cumulative damage of granite under cyclic loading [D]. Hefei: Hefei University of Technology, 2021: 1−3.

|

| [9] |

CHEN B, ZHANG S C, SHEN B T, et al. Mechanical properties and failure characteristics of granite treated with a combined water-air cooling cycle [J]. Case Studies in Thermal Engineering, 2022, 34: 101964. doi: 10.1016/j.csite.2022.101964

|

| [10] |

RONG G, SHA S, LI B W, et al. Experimental investigation on physical and mechanical properties of granite subjected to cyclic heating and liquid nitrogen cooling [J]. Rock Mechanics and Rock Engineering, 2021, 54(5): 2383–2403. doi: 10.1007/s00603-021-02390-6

|

| [11] |

BRAUNAGEL M J, GRIFFITH W A. A split Hopkinson pressure bar method for controlled rapid stress cycling using an oscillating double striker bar [J]. Rock Mechanics and Rock Engineering, 2020, 53: 3845–3851.

|

| [12] |

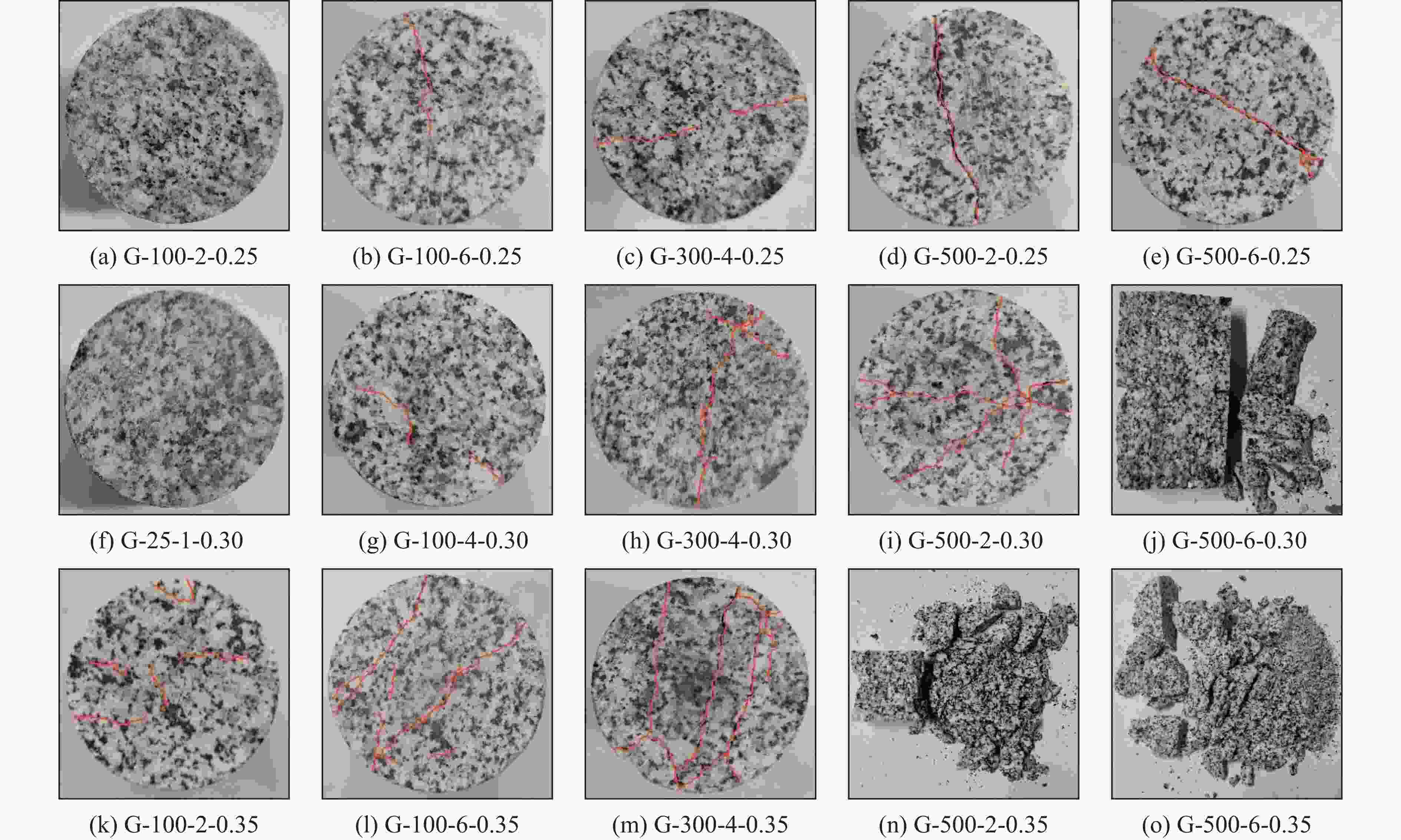

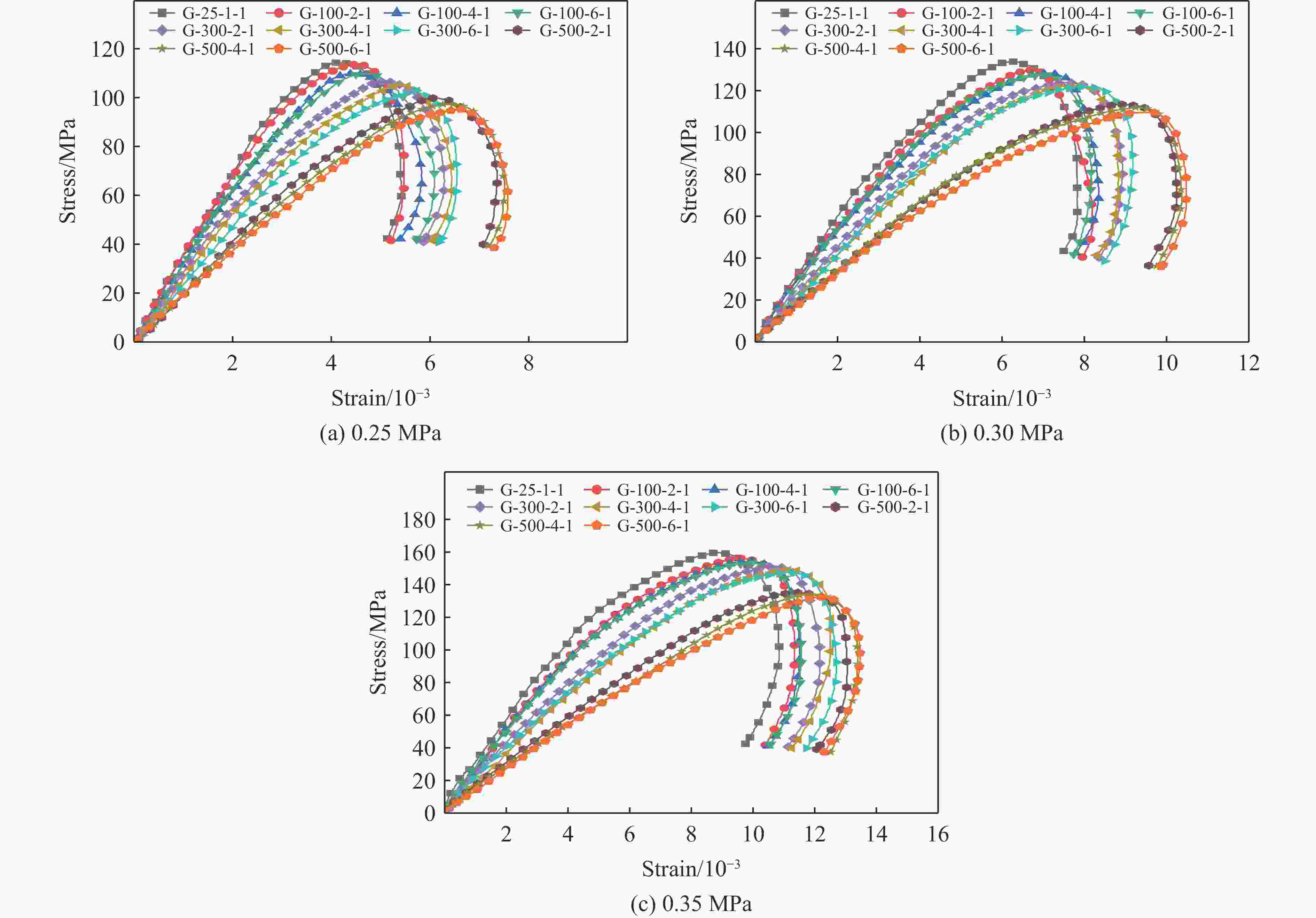

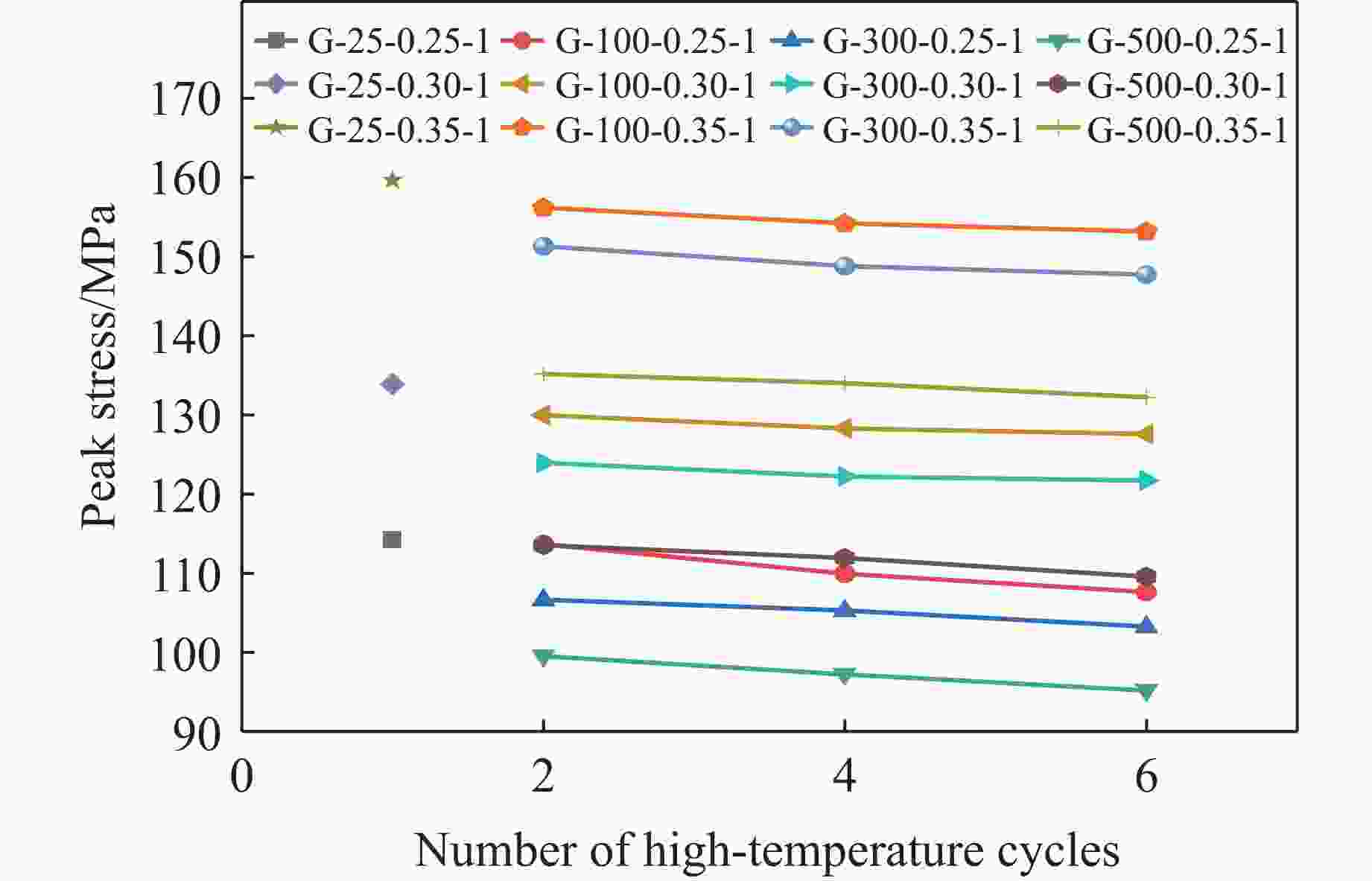

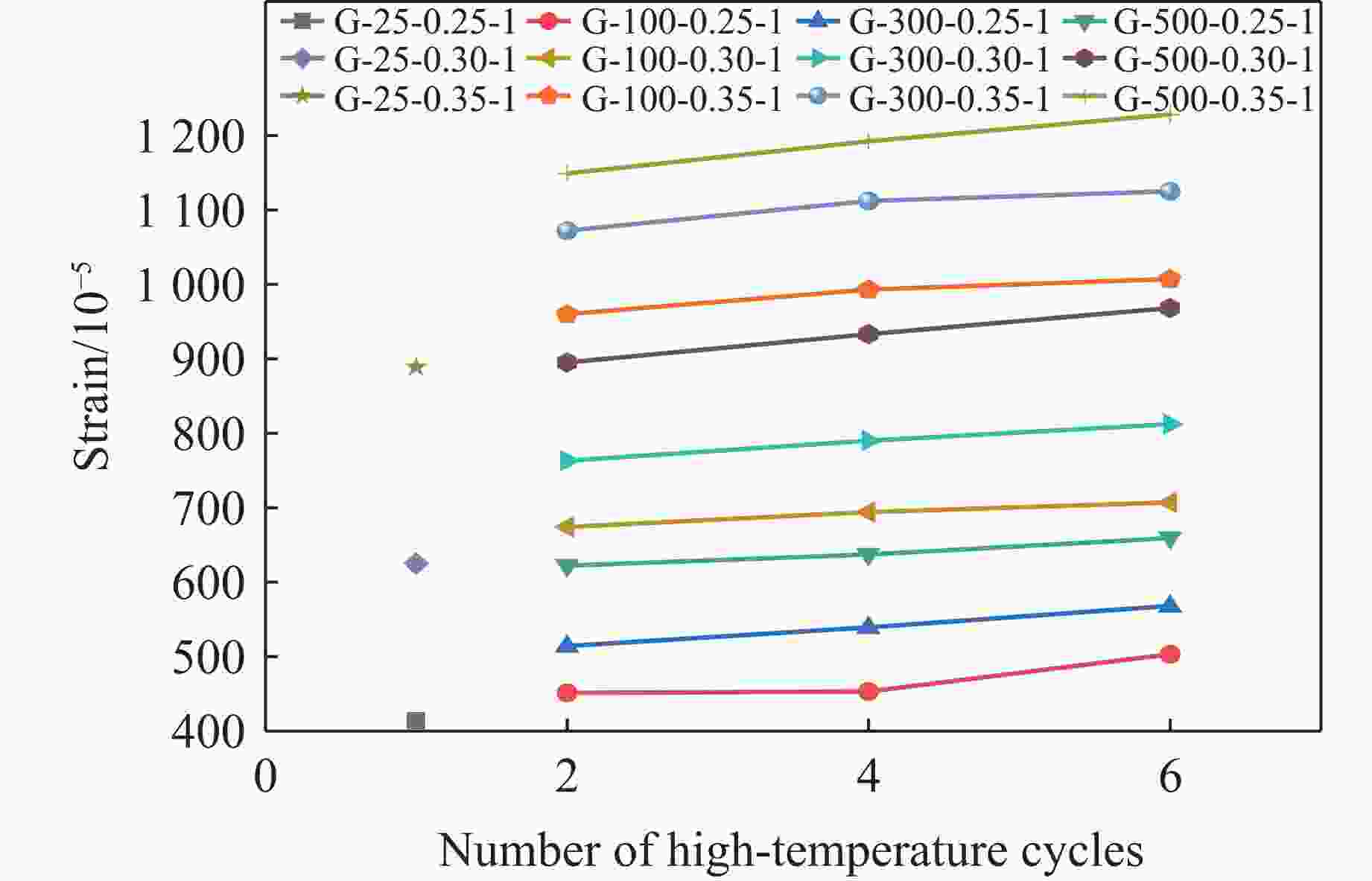

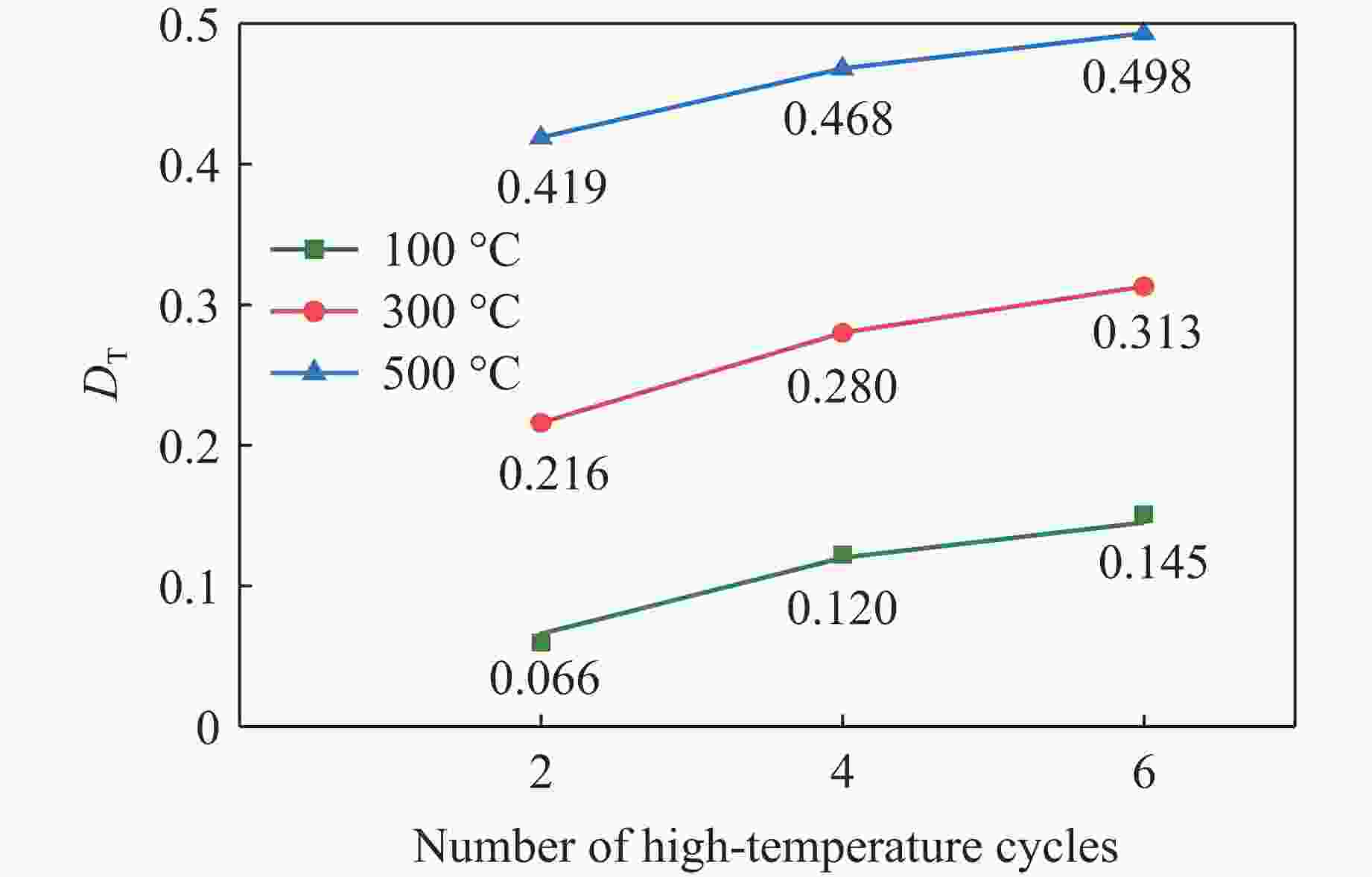

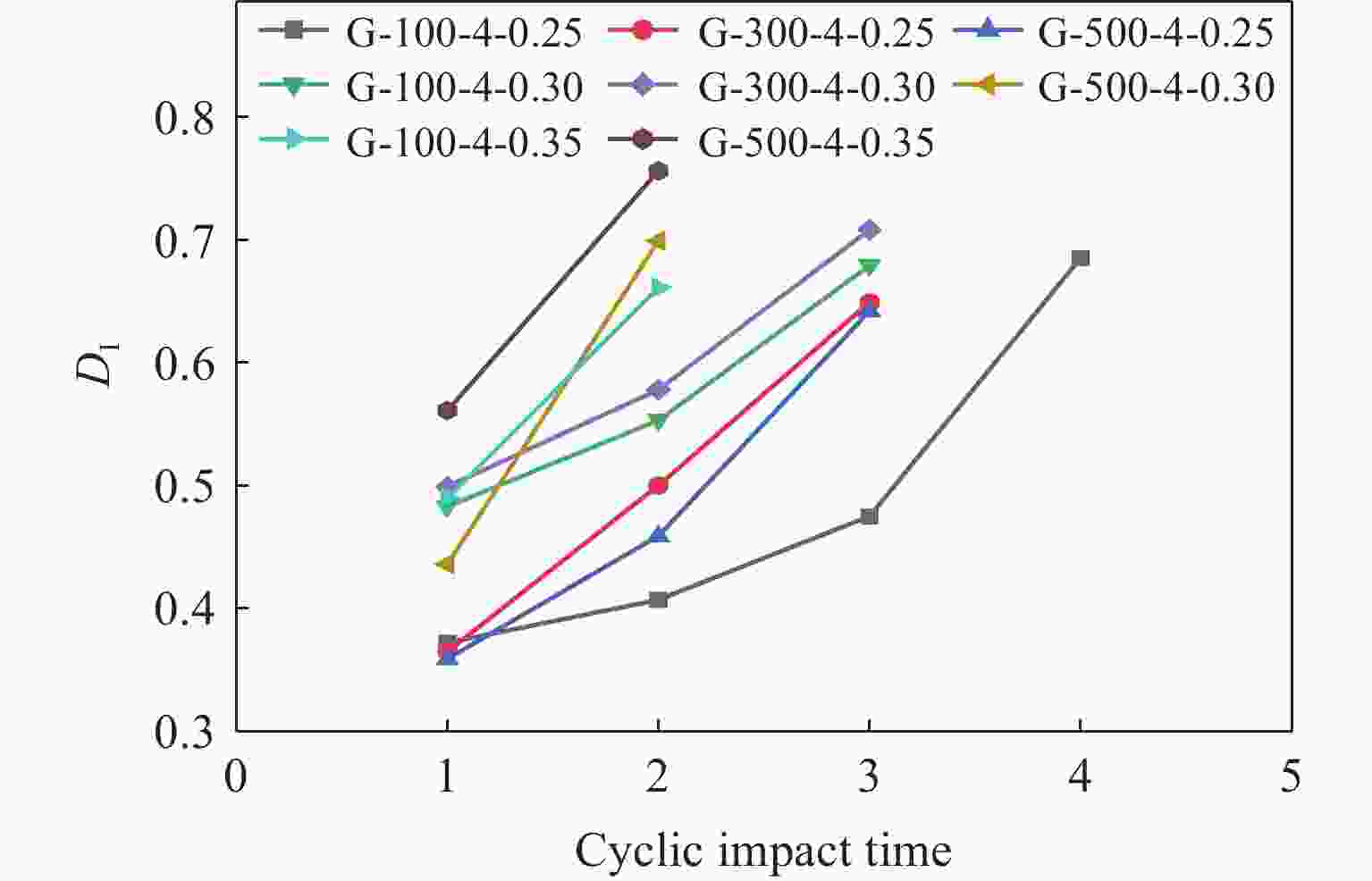

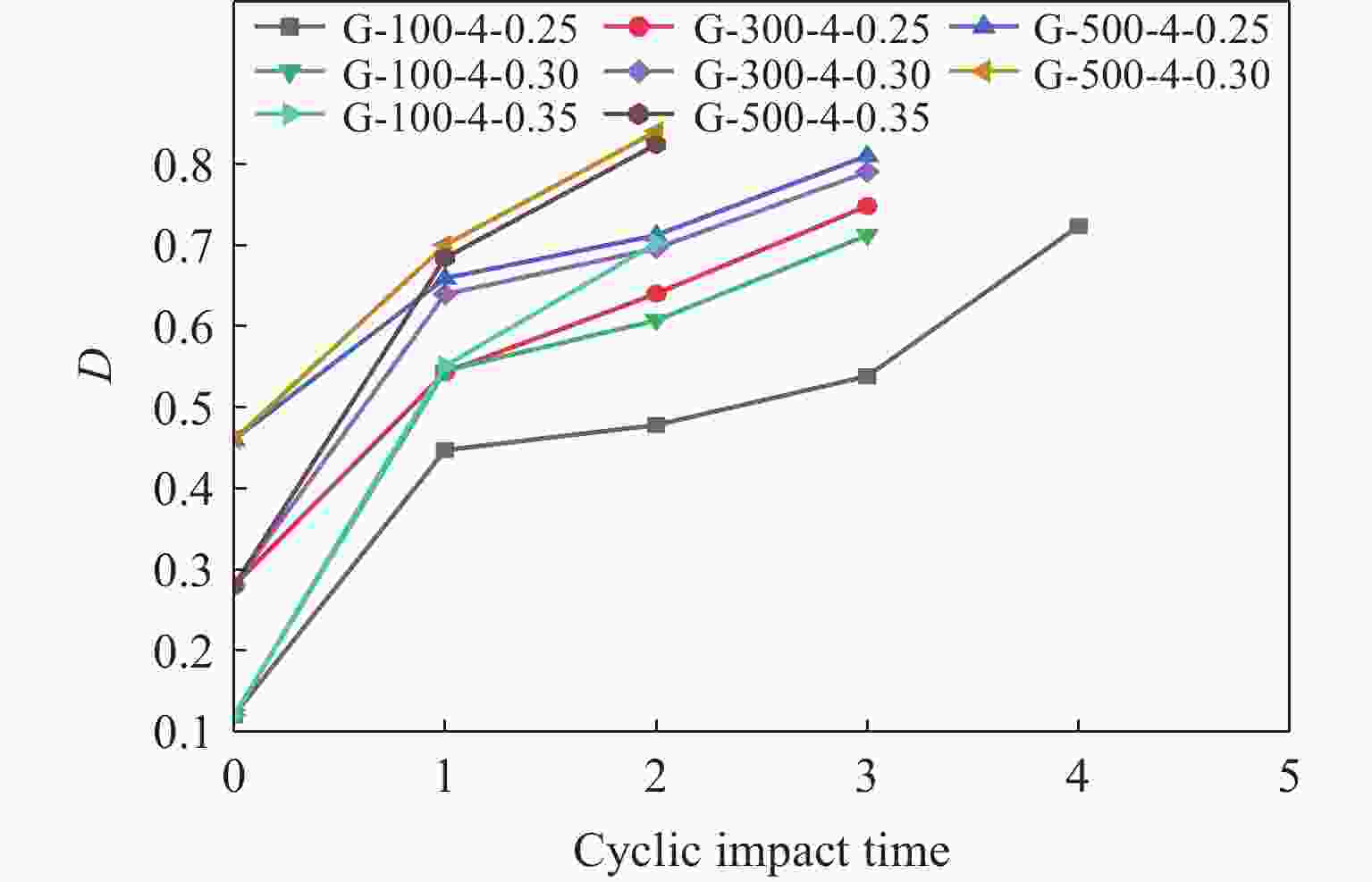

詹金武, 周亚来, 王雨, 等. 高温-冷却-冲击循环下花岗岩物理损伤及力学劣化试验研究 [J]. 岩土力学, 2024, 45(8): 2362–2372, 2386. doi: 10.16285/j.rsm.2023.1429ZHAN J W, ZHOU Y L, WANG Y, et al. Experimental study on physical damage and mechanical degradation of granite subjected to high-temperature cooling impact cycling [J]. Rock and Soil Mechanics, 2024, 45(8): 2362–2372, 2386. doi: 10.16285/j.rsm.2023.1429

|

| [13] |

余莉, 彭海旺, 李国伟, 等. 花岗岩高温-水冷循环作用下的试验研究 [J]. 岩土力学, 2021, 42(4): 1025–1035. doi: 10.16285/j.rsm.2020.1154YU L, PENG H W, LI G W, et al. Experimental study on granite under high temperature-water cooling cycle [J]. Rock and Soil Mechanics, 2021, 42(4): 1025–1035. doi: 10.16285/j.rsm.2020.1154

|

| [14] |

王志亮, 杨辉, 田诺成. 单轴循环冲击下花岗岩力学特性与损伤演化机理 [J]. 哈尔滨工业大学学报, 2020, 52(2): 59–66. doi: 10.11918/201811085WANG Z L, YANG H, TIAN N C. Mechanical property and damage evolution mechanism of granite under uniaxial cyclic impact [J]. Journal of Harbin Institute of Technology, 2020, 52(2): 59–66. doi: 10.11918/201811085

|

| [15] |

齐文超, 蔡勇智, 何童, 等. 高温水冷循环后玄武岩静态压缩力学特性及宏微观损伤演化规律 [J]. 长江科学院院报, 2025, 42(2): 145–154. doi: 10.11988/ckyyb.20230920QI W C, CAI Y Z, HE T, et al. Mechanical characteristics and macromicro damage evolution of basalt under static compression after high temperature water cooling cycles [J]. Journal of Yangtze River Scientific Research Institute, 2025, 42(2): 145–154. doi: 10.11988/ckyyb.20230920

|

| [16] |

刘康琦, 刘红岩, 周月智, 等. 循环冲击荷载作用下单节理岩体的动态力学行为 [J]. 爆炸与冲击, 2025, 45(6): 061423. doi: 10.11883/bzycj-2024-0353LIU K Q, LIU H Y, ZHOU Y Z, et al. Dynamic mechanical behaviors of single-jointed rock mass under cyclic impact loadings [J]. Explosion and Shock Waves, 2025, 45(6): 061423. doi: 10.11883/bzycj-2024-0353

|

| [17] |

王伟, 刘泽, 牛庆合, 等. 循环冲击作用下砂岩裂缝扩展及渗透率响应特征 [J]. 爆炸与冲击, 2025, 45(6): 061421. doi: 10.11883/bzycj-2024-0346WANG W, LIU Z, NIU Q H, et al. Characteristics of fracture propagation and permeability response of sandstone under cyclic impact effect [J]. Explosion and Shock Waves, 2025, 45(6): 061421. doi: 10.11883/bzycj-2024-0346

|

| [18] |

杨逾, 魏珂, 刘文洲. 基于Lemaitre原理改进砂岩蠕变损伤模型研究 [J]. 力学季刊, 2018, 39(1): 164–170.YANG Y, WEI K, LIU W Z. Study on the creep damage model of sandstone based on the principle of lemaitre improvement [J]. Chinese Quarterly of Mechanics, 2018, 39(1): 164–170.

|

| [19] |

ZHOU Y X, XIA K, LI X B, et al. Suggested methods for determining the dynamic strength parameters and mode-Ⅰ fracture toughness of rock materials [J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 49: 105–112. doi: 10.1016/j.ijrmms.2011.10.004

|

| [20] |

HUDSON J A, HARRISON J P. Rock dynamics and time-dependent aspects [M]//HUDSON J A, HARRISON J P. Engineering Rock Mechanics: An Introduction to the Principles. Amsterdam: Elsevier, 1997: 207−221.

|

| [21] |

FAIRHURST C E, HUDSON J A. Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 1999, 36(3): 281–289. doi: 10.1016/S0148-9062(99)00006-6

|

| [22] |

杨科, 刘文杰, 马衍坤, 等. 煤岩组合体冲击动力学特征试验研究 [J]. 煤炭学报, 2022, 47(7): 2569–2581. doi: 10.13225/j.cnki.jccs.2021.1279YANG K, LIU W J, MA Y K, et al. Experimental research on dynamic characteristics of coal-rock combined specimen [J]. Journal of China Coal Society, 2022, 47(7): 2569–2581. doi: 10.13225/j.cnki.jccs.2021.1279

|

| [23] |

王倩倩. 基于不同循环静载的损伤砂岩静动态力学性能研究 [D]. 淮南: 安徽理工大学, 2021: 55−56.WANG Q Q. Study on static and dynamic mechanical properties of damaged sandstone under different cyclic static loads [D]. Huainan: Anhui University of Science and Technology, 2021: 55−56.

|

| [24] |

张蓉蓉, 沈永辉, 马冬冬, 等. 循环冲击作用下冻融红砂岩动力学特性与损伤机理 [J]. 爆炸与冲击, 2024, 44(8): 081443. doi: 10.11883/bzycj-2023-0449ZHANG R R, SHEN Y H, MA D D, et al. Dynamic characteristics and damage mechanism of freeze-thaw treated red sandstone under cyclic impact [J]. Explosion and Shock Waves, 2024, 44(8): 081443. doi: 10.11883/bzycj-2023-0449

|

| [25] |

中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 煤和岩石物理力学性质测定方法 第8部分: 煤和岩石变形参数测定方法: GB/T 23561.8—2009 [S]. 北京: 中国标准出版社, 2009.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Methods for determining the physical and mechanical properties of coal and rock—part 8: methods for determining the deformation parameters of coal and rock: GB/T 23561.8—2009 [S]. Beijing: Standards Press of China, 2009.

|

| [26] |

ASTM. Standard test methods for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures: ASTM D7012-14e1 [S]. Pennsylvania: ASTM International, 2014.

|

| [27] |

MA D D, XIANG H S, MA Q Y, et al. Dynamic damage constitutive model of frozen silty soil with prefabricated crack under uniaxial load [J]. Journal of Engineering Mechanics, 2021, 147(6): 04021033. doi: 10.1061/(ASCE)EM.1943-7889.0001933

|

下载:

下载: