Sintering and Characterizing of WC-5Co Cemented Carbide under High Temperature and High Pressure

-

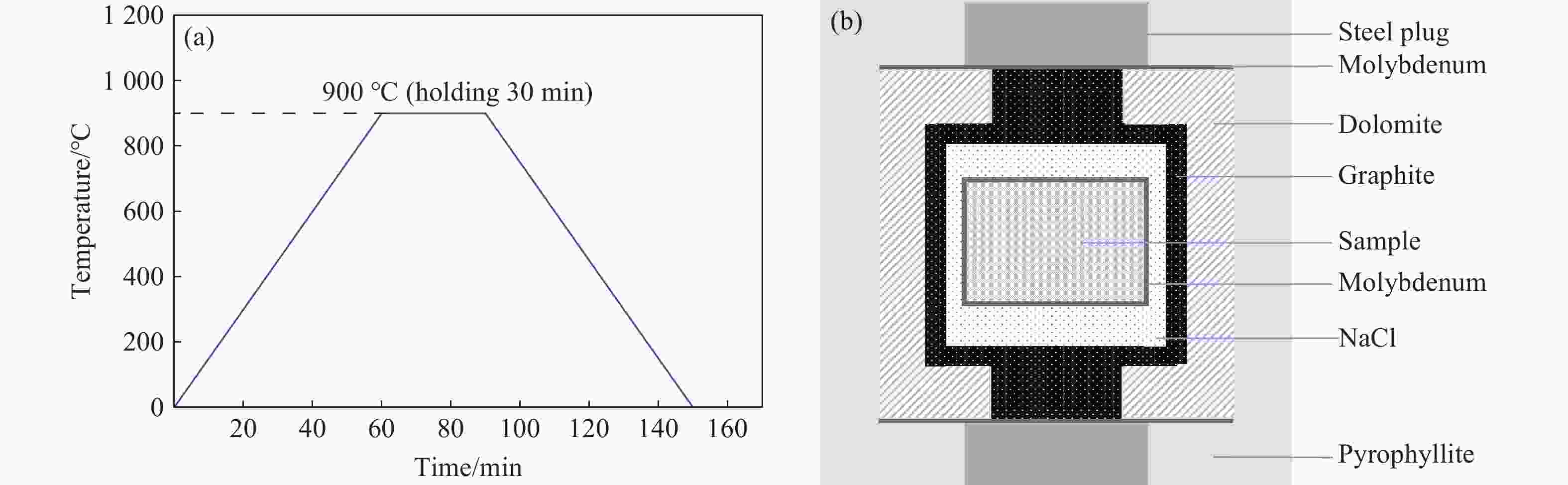

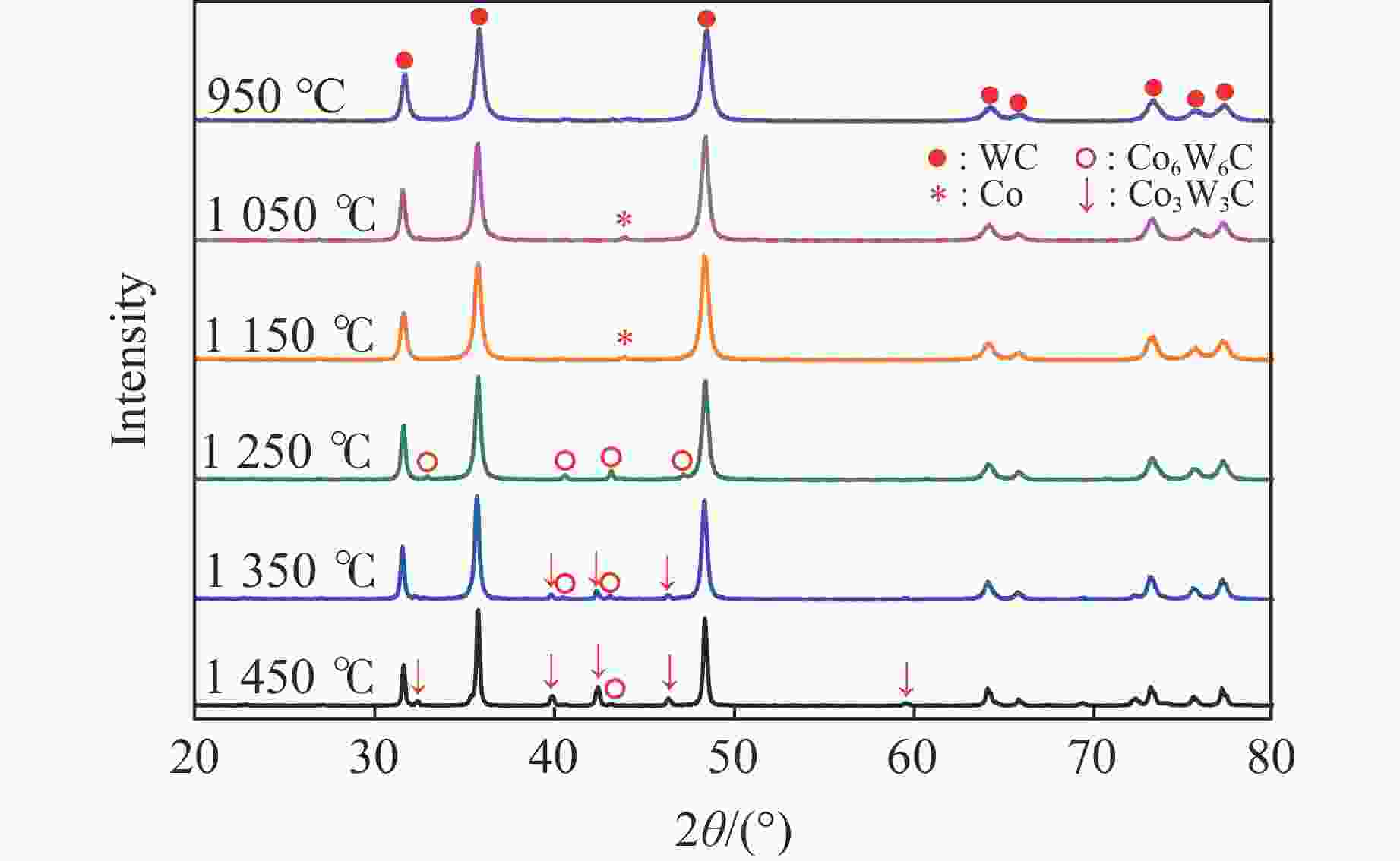

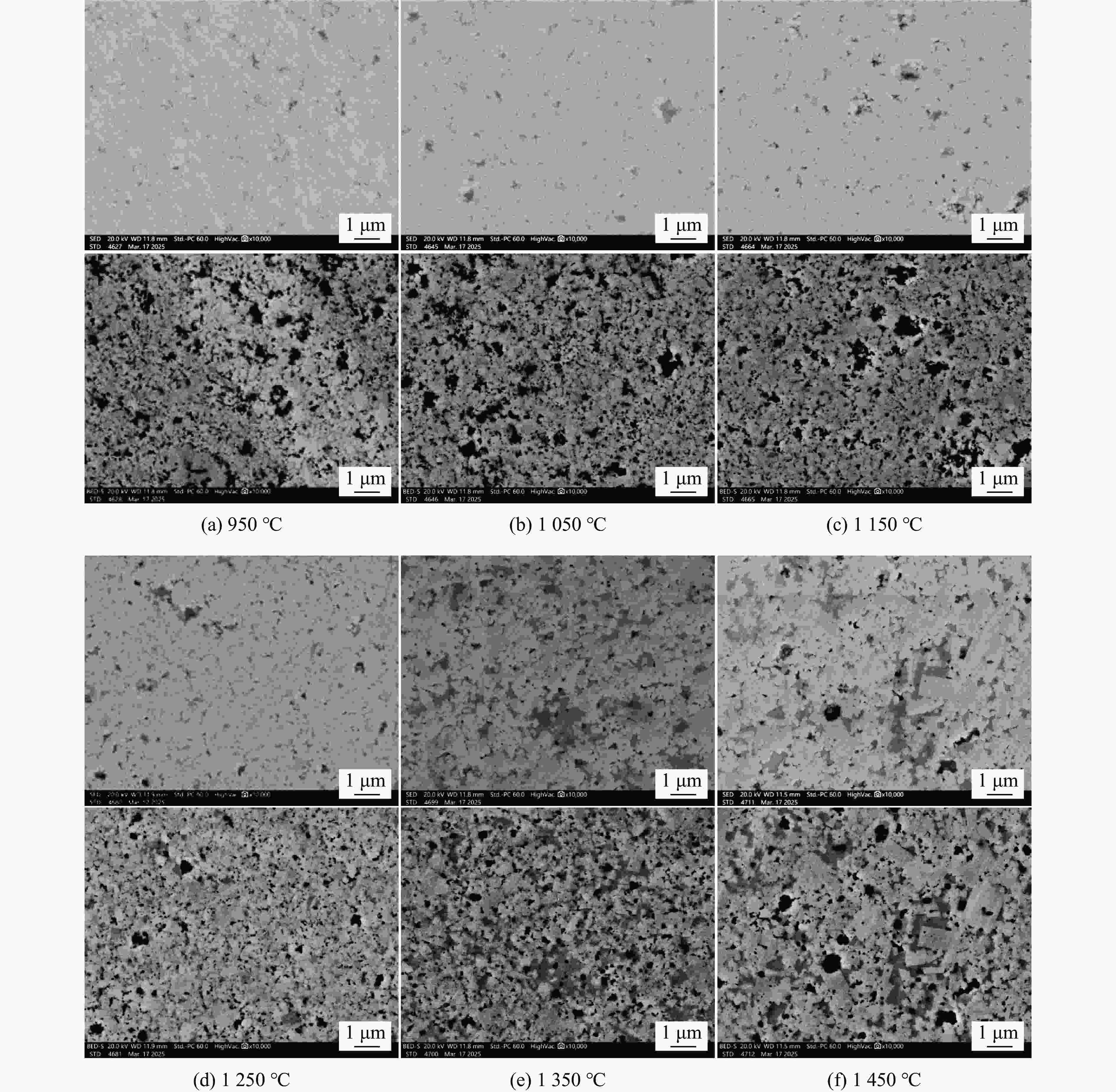

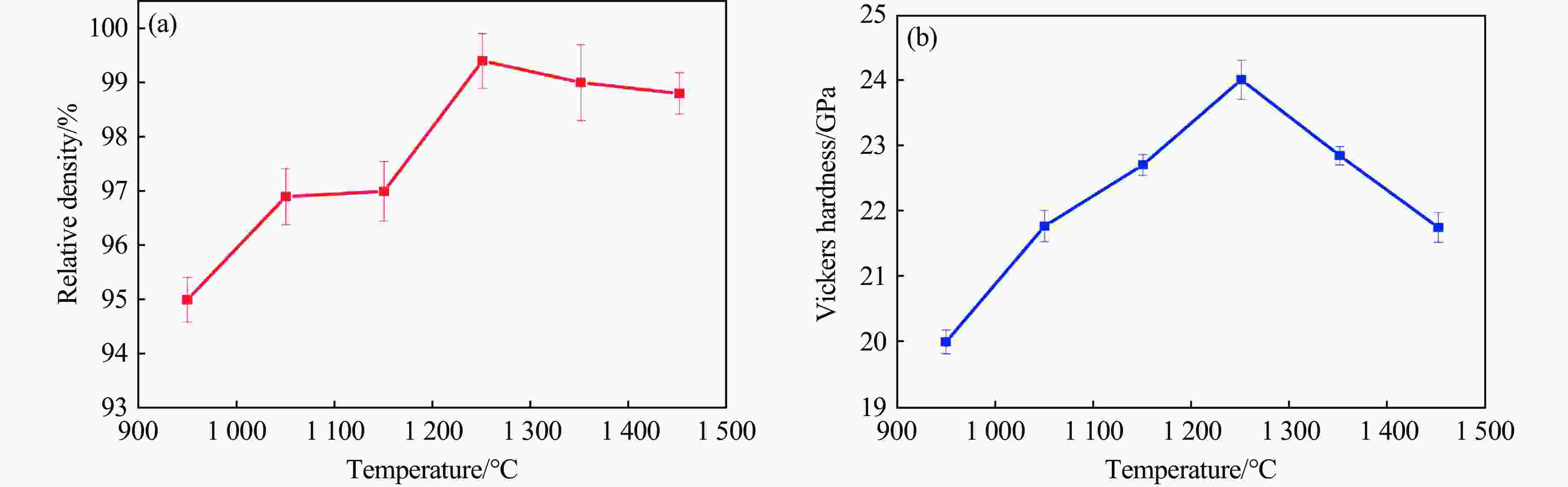

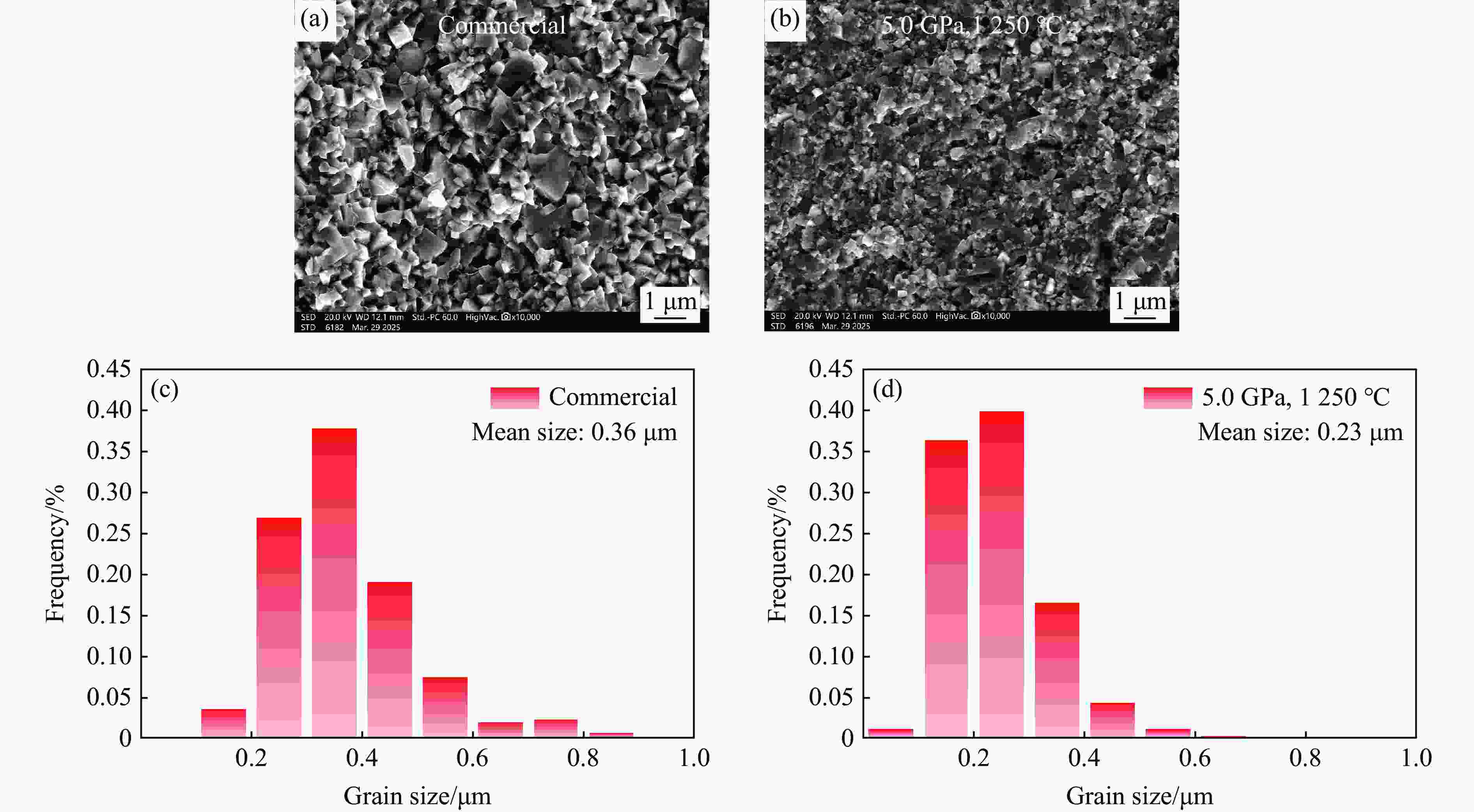

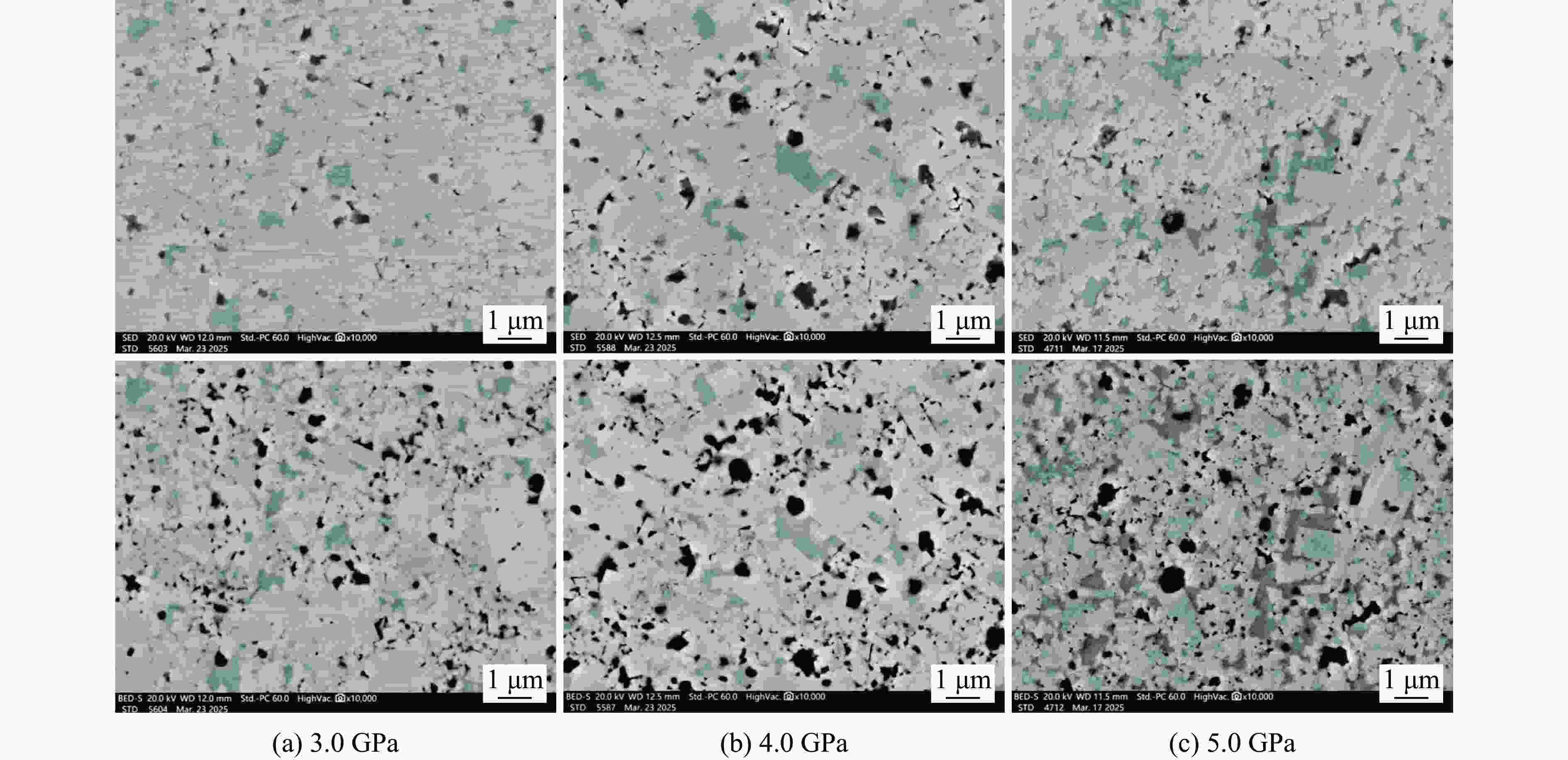

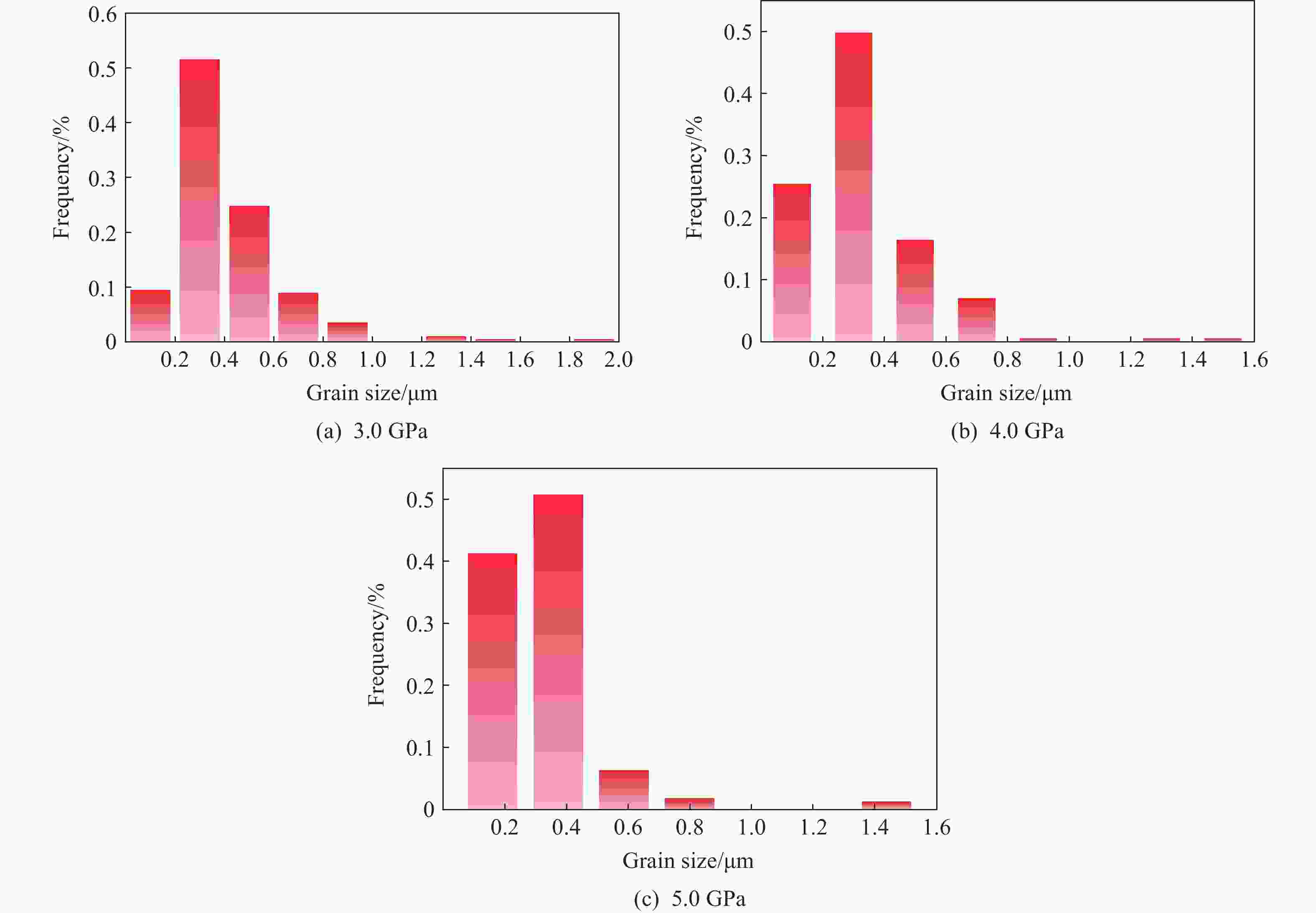

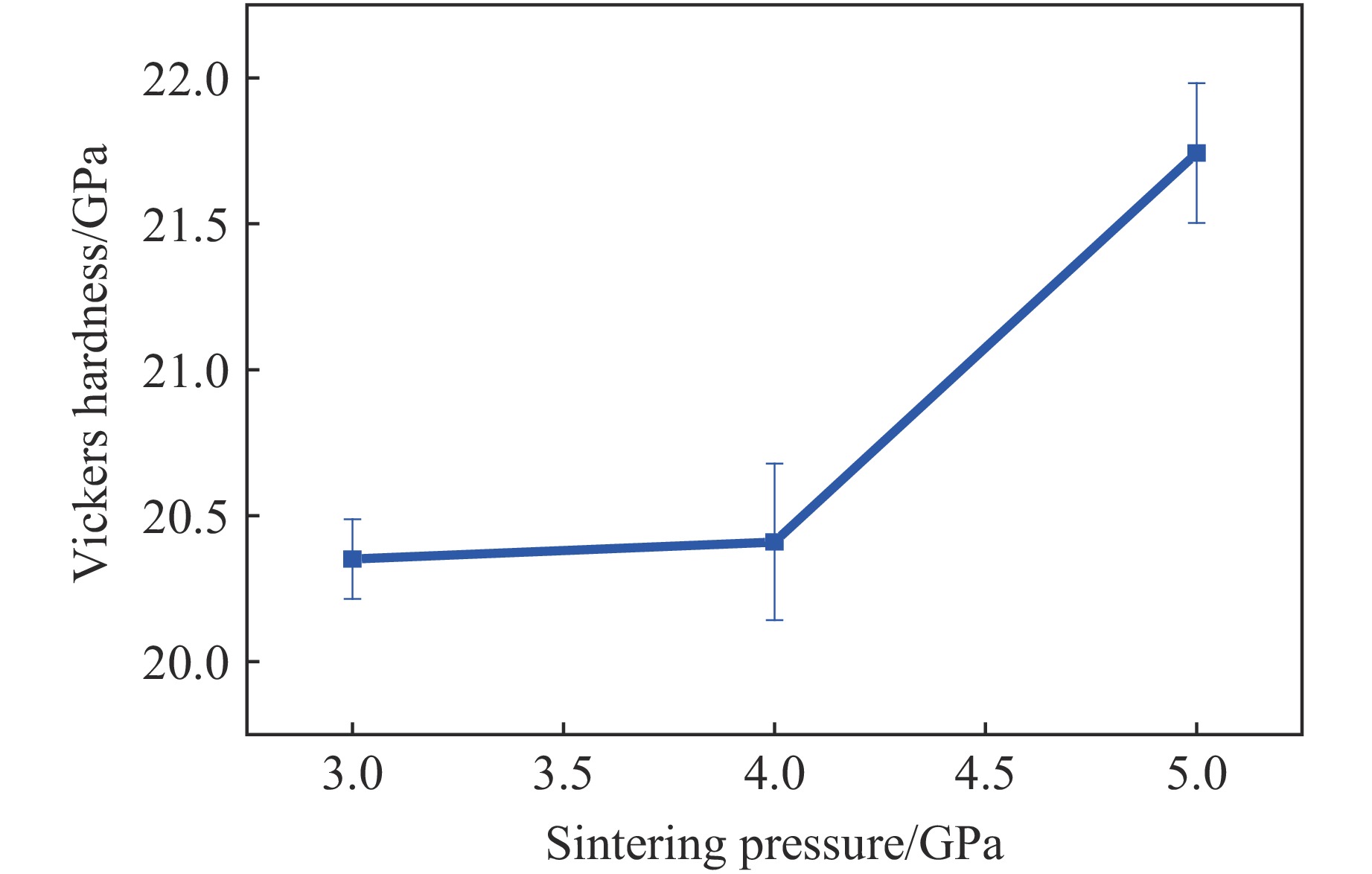

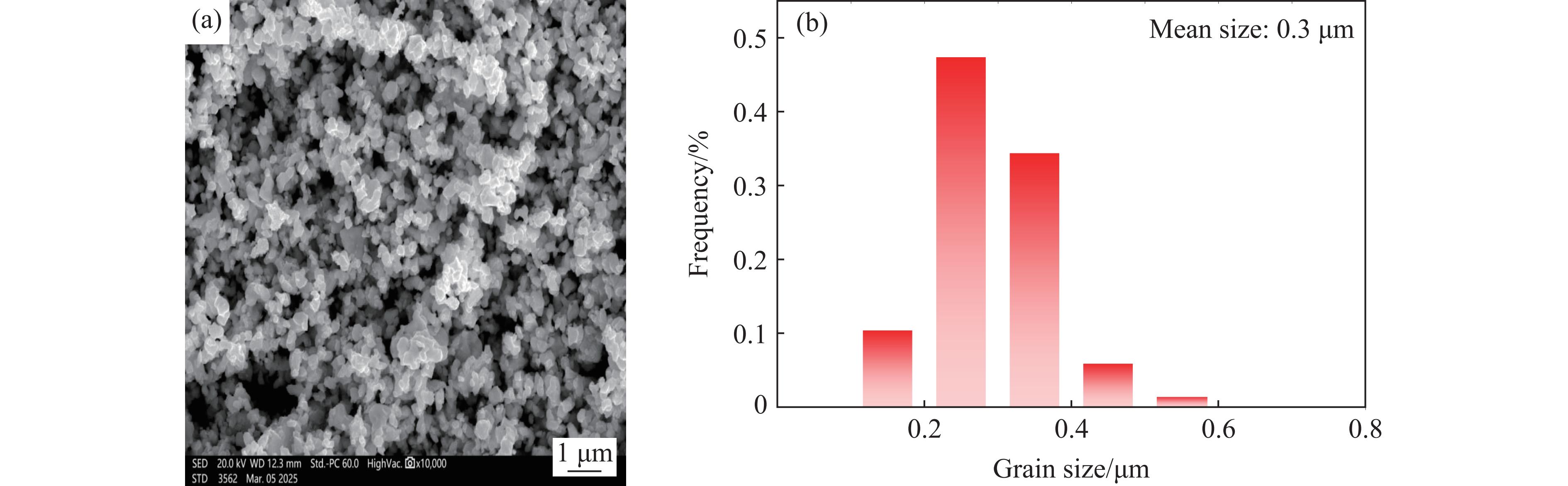

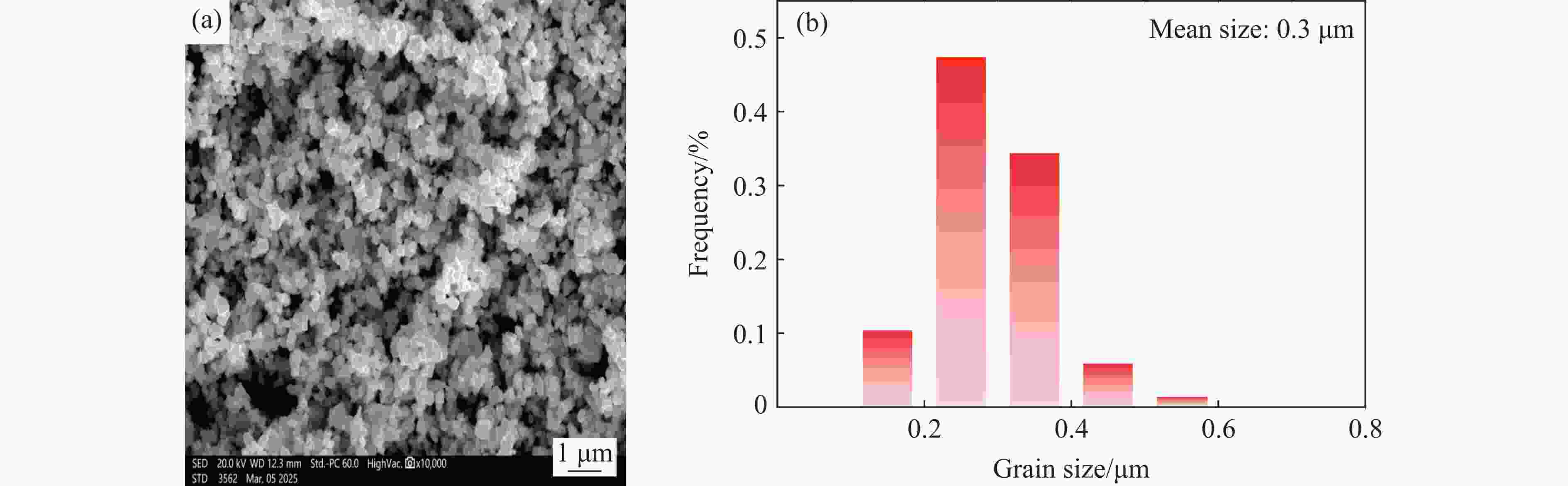

摘要: 碳化钨-钴(WC-Co)硬质合金作为一种重要的粉末冶金制品,被广泛应用于众多工业领域。传统烧结方法存在烧结温度高、时间长、晶粒粗化等问题,难以满足高强度细晶硬质合金的制备需求。采用高温高压法,对亚微米WC-5Co(钴的质量分数为5%)硬质合金进行了烧结行为研究。实验结果表明,在5.0 GPa、1 250 ℃的制备条件下,烧结体的致密度可达99.4%,维氏硬度为(24.0±0.3) GPa,明显优于放电等离子体烧结法和真空烧结法所制备的同组分硬质合金。与相同初始粉料的商用硬质合金相比,高温高压条件下烧结样品中WC的平均晶粒尺寸减小了约36%,维氏硬度提升了约10%。相较于传统烧结方法,高温高压烧结法有效降低了烧结温度,缩短了烧结时间,提升了烧结效率。此外,高压能够有效抑制固相烧结阶段WC晶粒的异常生长,在液相烧结过程中(1 450 ℃),随着烧结压力的升高,WC晶粒有明显的细化现象,当烧结压力从3.0 GPa提升至5.0 GPa时,样品的维氏硬度提升了约7%。Abstract: As an important type of powder metallurgy products, tungsten carbide-cobalt (WC-Co) cemented carbides are widely applied in numerous industrial fields. Traditional sintering methods suffer from high sintering temperatures, long sintering times, and grain coarsening, which make it difficult to meet the requirements for the preparation of high-strength fine-grained cemented carbides. In this study, the sintering behavior of the sub-micron WC-5Co (with a mass fraction of cobalt of 5%) cemented carbides was investigated using the high-temperature and high-pressure (HTHP) method. The experimental results show that the sintered body can achieve a relative density of 99.4% and a Vickers hardness value of (24.0±0.3) GPa under the treatment conditions of 5.0 GPa and 1 250 ℃, which is significantly better than that of the same composition of cemented carbides prepared by spark plasma sintering (SPS) and vacuum sintering methods. In comparison with the commercial cemented carbides with the same initial powder, the average grain size of WC in the sintered samples under high-temperature and high-pressure conditions is reduced by about 36%, and the Vickers hardness is increased by about 10%. In comparison with traditional sintering methods, the HTHP sintering method effectively reduces the sintering temperature, shortens the sintering time, and enhances sintering efficiency. Moreover, high pressure can effectively inhibit the abnormal growth of the WC grains during solid-state sintering. During liquid-phase sintering (at 1 450 ℃), an increase in sintering pressure results in significant refinement of the WC grains. When the sintering pressure is increased from 3.0 GPa to 5.0 GPa, the Vickers hardness of the samples is increased by about 7%.

-

表 1 5.0 GPa、不同烧结温度下样品的平均晶粒尺寸

Table 1. Average size of grain in samples sintered at 5.0 GPa under different temperatures

Temperature/℃ Grain size/μm 950 0.21±0.08 1 050 0.22±0.09 1 150 0.23±0.09 1 250 0.23±0.10 1 350 0.25±0.11 1 450 0.34±0.16 表 2 商用硬质合金及高温高压烧结样品的残余应力及WC的晶格常数

Table 2. Residual stress and WC lattice parameters for commercial cemented carbides and HTHP sintered samples

Samples Residual stress/MPa Lattice parameter a/Å c/Å Unit cell volume/Å3 Commercial 644 2.907 025 2.834 347 20.74 HTHP sintered (5.0 GPa, 1 250 ℃) 974 2.903 636 2.836 092 20.71 -

[1] KAWAKAMI M. Cemented carbide tools and moulds for wear-resistant applications in Japan [J]. International Journal of Refractory Metals and Hard Materials, 2024, 118: 106477. doi: 10.1016/j.ijrmhm.2023.106477 [2] KOUADRI S, NECIB K, ATLATI S, et al. Quantification of the chip segmentation in metal machining: application to machining the aeronautical aluminium alloy AA2024-T351 with cemented carbide tools WC-Co [J]. International Journal of Machine Tools and Manufacture, 2013, 64: 102–113. doi: 10.1016/j.ijmachtools.2012.08.006 [3] NIE H B, ZHANG T Q. Development of manufacturing technology on WC-Co hardmetals [J]. Tungsten, 2019, 1(3): 198–212. doi: 10.1007/s42864-019-00025-6 [4] WOOD R J K, ROY M. Tribology of thermal-sprayed coatings [M]//ROY M. Surface Engineering for Enhanced Performance Against Wear. Vienna: Springer, 2013: 1–43. [5] ROEBUCK B. Temperature dependent properties of Co-W-C alloys [J]. International Journal of Refractory Metals and Hard Materials, 2023, 111: 106073. doi: 10.1016/j.ijrmhm.2022.106073 [6] CHANG S H, CHANG P Y. Investigation into the sintered behavior and properties of nanostructured WC-Co-Ni-Fe hard metal alloys [J]. Materials Science and Engineering: A, 2014, 606: 150–156. doi: 10.1016/j.msea.2014.03.096 [7] BERTALAN C, MOSELEY S, PEREIRA L, et al. Influence of sintering parameters on the microstructure and mechanical properties of WC-Co hardmetals [J]. International Journal of Refractory Metals and Hard Materials, 2024, 118: 106439. doi: 10.1016/j.ijrmhm.2023.106439 [8] ZHOU P F, XIAO D H, YUAN T C. Comparison between ultrafine-grained WC-Co and WC-HEA-cemented carbides [J]. Powder Metallurgy, 2017, 60(1): 1–6. doi: 10.1080/00325899.2016.1260903 [9] NAIK S N, WALLEY S M. The Hall-Petch and inverse Hall-Petch relations and the hardness of nanocrystalline metals [J]. Journal of Materials Science, 2020, 55(7): 2661–2681. doi: 10.1007/s10853-019-04160-w [10] WANG Y, XIANG F M, YUAN X B, et al. Effects of processing parameters on the microstructure and mechanical properties of nanoscaled WC-10Co cemented carbide [J]. Materials, 2022, 15(13): 4472. doi: 10.3390/ma15134472 [11] 李萌, 弓满锋, 张程煜, 等. 超细、纳米晶WC-Co硬质合金烧结技术的研究现状 [J]. 材料导报, 2020, 34(15): 15138–15144. doi: 10.11896/cldb.19050188LI M, GONG M F, ZHANG C Y, et al. Research progress of sintering technique of ultrafine and nano WC-Co cemented carbides [J]. Materials Reports, 2020, 34(15): 15138–15144. doi: 10.11896/cldb.19050188 [12] 李云飞, 高鑫, 陈鹏万, 等. TiB2/B4C复相陶瓷自蔓延热爆炸烧结与性能表征 [J]. 兵工学报, 2024, 45(1): 26–34. doi: 10.12382/bgxb.2023.0078LI Y F, GAO X, CHEN P W, et al. SHS-assisted shock sintering and characterization of TiB2/B4C composite ceramics [J]. Acta Armamentarii, 2024, 45(1): 26–34. doi: 10.12382/bgxb.2023.0078 [13] WANG X, FANG Z Z, SOHN H Y. Grain growth during the early stage of sintering of nanosized WC-Co powder [J]. International Journal of Refractory Metals and Hard Materials, 2008, 26(3): 232–241. doi: 10.1016/j.ijrmhm.2007.04.006 [14] GU J F, ZOU J, LIU J H, et al. Sintering highly dense ultra-high temperature ceramics with suppressed grain growth [J]. Journal of the European Ceramic Society, 2020, 40(4): 1086–1092. doi: 10.1016/j.jeurceramsoc.2019.11.056 [15] CHEN J, PENG F, WANG Y P, et al. Mechanisms and mechanical properties of high-temperature high-pressure sintered vanadium carbide ceramics [J]. International Journal of Refractory Metals and Hard Materials, 2024, 118: 106483. doi: 10.1016/j.ijrmhm.2023.106483 [16] WANG W Q, PENG F, LIANG H, et al. Synthesis and sintering of tungsten tetraboride and tantalum-bearing tungsten tetraboride under ultra high temperature and high pressure [J]. International Journal of Refractory Metals and Hard Materials, 2022, 102: 105701. doi: 10.1016/j.ijrmhm.2021.105701 [17] KARIMI M M, GOMES U U, OLIVEIRA M P, et al. High pressure assisted WC/Co hardmetal sintering—effect of sintering temperature [J]. AIP Conference Proceedings, 2017, 1809(1): 020025. doi: 10.1063/1.4975440 [18] WANG Y P, KOU Z L, ZHANG J W, et al. A new pressurization-insulation and pre-sealing system to improve pressure in cubic press from 6 GPa to 12 GPa [J]. Review of Scientific Instruments, 2020, 91(3): 035119. doi: 10.1063/5.0001958 [19] MORIYOSHI Y, AKAISHI M, FUKUNAGA O. The microstructure of WC and WC-4.3wt% Co sintered at high pressure [J]. Journal of Materials Science, 1986, 21(12): 4250–4256. doi: 10.1007/BF01106538 [20] ZHANG Y F, KOU Z L, WANG Z W, et al. Magic high-pressure strengthening in tungsten carbide system [J]. Ceramics International, 2019, 45(7): 8721–8726. doi: 10.1016/j.ceramint.2019.01.195 [21] HE D W, AKAISHI M, TANAKA T. High pressure synthesis of cubic boron nitride from Si-hBN system [J]. Diamond and Related Materials, 2001, 10(8): 1465–1469. doi: 10.1016/S0925-9635(00)00581-1 [22] ISONISHI K. Synthesis and characteristics of WC-Co alloy fabricated by mechanical alloying and pressure sintering [J]. Journal of Solid Mechanics and Materials Engineering, 2009, 3(2): 178–186. doi: 10.1299/jmmp.3.178 [23] KURLOV A S, REMPEL A A. Effect of WC nanoparticle size on the sintering temperature, density, and microhardness of WC-8wt% Co alloys [J]. Inorganic Materials, 2009, 45(4): 380–385. doi: 10.1134/S0020168509040098 [24] 屈广林, 颜练武, 张卫兵, 等. 碳化钨和碳化钒在固相钴中的固溶研究 [J]. 硬质合金, 2014, 31(1): 8–14.QU G L, YAN L W, ZHANG W B, et al. Research on solution of tungsten carbide and vanadium carbide in solid phase of cobalt [J]. Cemented Carbide, 2014, 31(1): 8–14. [25] VENGRENOVITCH R D. On the Ostwald ripening theory [J]. Acta Metallurgica, 1982, 30(6): 1079–1086. doi: 10.1016/0001-6160(82)90004-9 [26] ZHONG Y, SHAW L L. Growth mechanisms of WC in WC-5.75wt% Co [J]. Ceramics International, 2011, 37(8): 3591–3597. doi: 10.1016/j.ceramint.2011.06.016 [27] CHAIM R. Grain coalescence by grain rotation in nano-ceramics [J]. Scripta Materialia, 2012, 66(5): 269–271. doi: 10.1016/j.scriptamat.2011.11.007 [28] 王洪涛, 王旭, 余永宁. 纳米WC/Co硬质合金粉末烧结早期的晶粒长大研究 [J]. 稀有金属与硬质合金, 2005, 33(1): 18–21. doi: 10.3969/j.issn.1004-0536.2005.01.006WANG H T, WANG X, YU Y N. Study of grain growth of nanocrystalline WC/Co powder in the early stage of sintering [J]. Rare Metals and Cemented Carbides, 2005, 33(1): 18–21. doi: 10.3969/j.issn.1004-0536.2005.01.006 [29] HAHN H, GLEITER H. The effect of pressure on grain growth and boundary mobility [J]. Scripta Metallurgica, 1979, 13(1): 3–6. doi: 10.1016/0036-9748(79)90378-8 [30] 何伟锋, 杨宇辉, 王珂玮, 等. 真空烧结温度对WC-Co硬质合金微观组织及性能的影响 [J]. 热加工工艺, 2023, 52(22): 72–77. doi: 10.14158/j.cnki.1001-3814.20212263HE W F, YANG Y H, WANG K W, et al. Effect of vacuum sintering temperature on microstructure and properties of WC-Co cemented carbide [J]. Hot Working Technology, 2023, 52(22): 72–77. doi: 10.14158/j.cnki.1001-3814.20212263 [31] 李壮, 王家君, 林晨光, 等. WC-Co超细硬质合金微观结构对其性能的影响 [J]. 硬质合金, 2009, 26(3): 188–193. doi: 10.3969/j.issn.1003-7292.2009.03.011LI Z, WANG J J, LIN C G, et al. Estimation of influence on microstructure and properties of ultrafine WC-Co cemented carbide [J]. Cemented Carbide, 2009, 26(3): 188–193. doi: 10.3969/j.issn.1003-7292.2009.03.011 [32] SIWAK P, GARBIEC D. WC-5Co cemented carbides fabricated by SPS [J]. Archives of Metallurgy and Materials, 2018, 63(4): 2031–2037. doi: 10.24425/amm.2018.125140 [33] 周书助, 谭锦灏, 胡茂中, 等. SPS烧结WC-5%Co纳米复合粉硬质合金 [J]. 硬质合金, 2010, 27(1): 14–17. doi: 10.3969/j.issn.1003-7292.2010.01.004ZHOU S Z, TAN J H, HU M Z, et al. Spark plasma sintering of ultrafine WC-5%Co cemented carbide composite powders [J]. Cemented Carbide, 2010, 27(1): 14–17. doi: 10.3969/j.issn.1003-7292.2010.01.004 [34] NOYAN I C, COHEN J B. Residual stress: measurement by diffraction and interpretation [M]. New York: Springer, 2013. [35] 李小雷, 王红亮, 曹新鑫, 等. 高压烧结AlN陶瓷的残余应力研究 [J]. 功能材料, 2018, 49(7): 7121–7124. doi: 10.3969/j.issn.1001-9731.2018.07.020LI X L, WANG H L, CAO X X, et al. Residual stress of aluminum nitride ceramics sintered at high pressure [J]. Journal of Functional Materials, 2018, 49(7): 7121–7124. doi: 10.3969/j.issn.1001-9731.2018.07.020 [36] LASALMONIE A, STRUDEL J L. Influence of grain size on the mechanical behaviour of some high strength materials [J]. Journal of Materials Science, 1986, 21(6): 1837–1852. doi: 10.1007/BF00547918 [37] MA D J, KOU Z L, LIU Y J, et al. Sub-micron binderless tungsten carbide sintering behavior under high pressure and high temperature [J]. International Journal of Refractory Metals and Hard Materials, 2016, 54: 427–432. doi: 10.1016/j.ijrmhm.2015.10.001 -

下载:

下载: