Phase Transition and Mechanical Property Modulation of Silicon Nitride at High Temperature and High Pressure

-

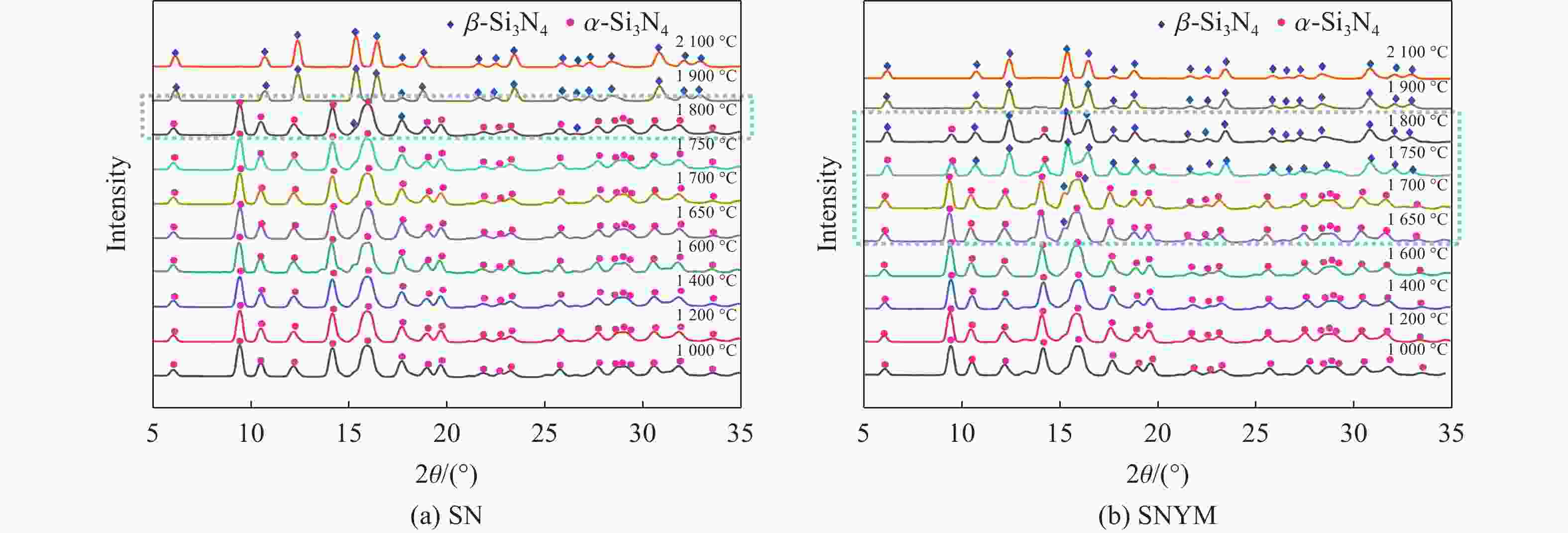

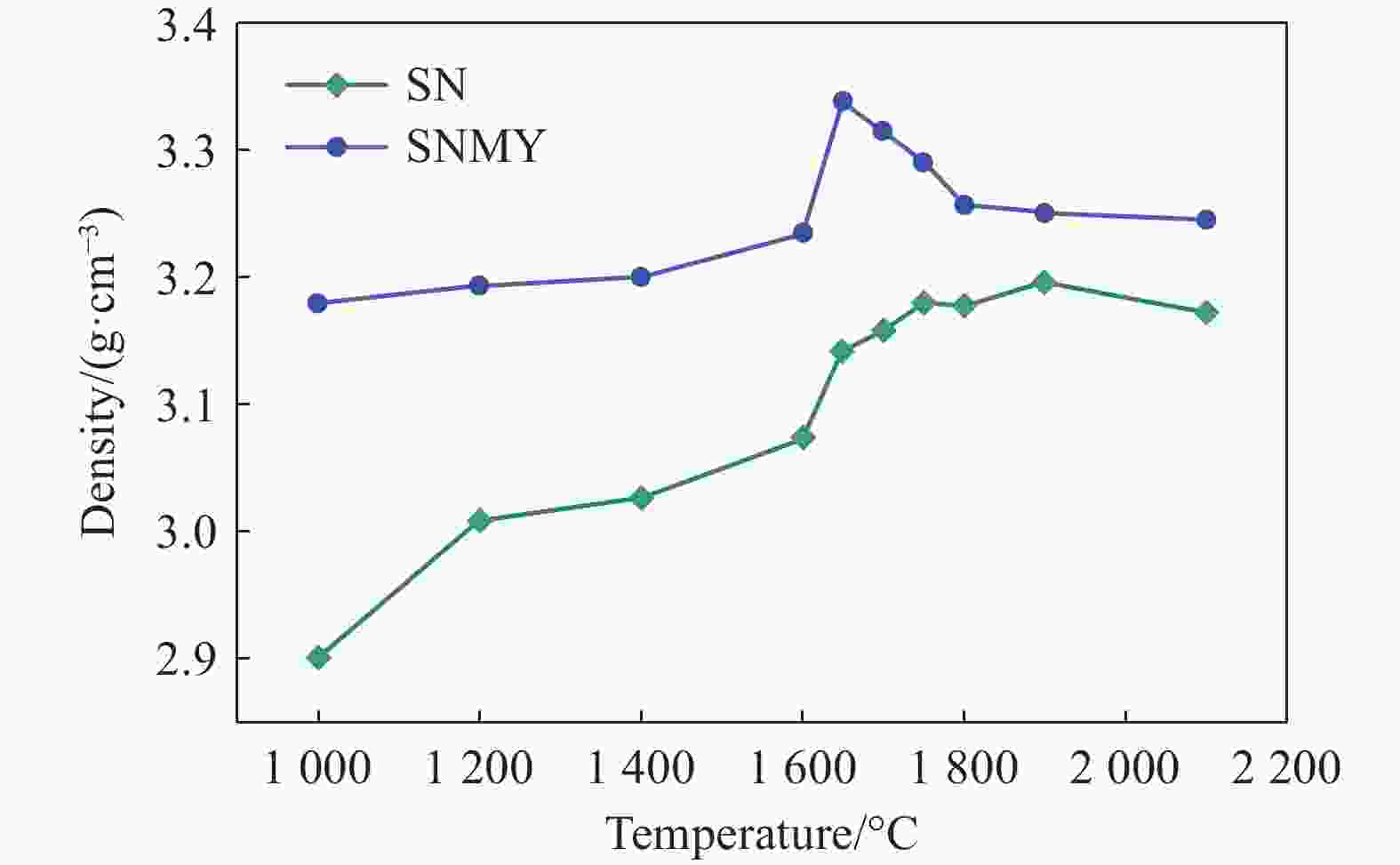

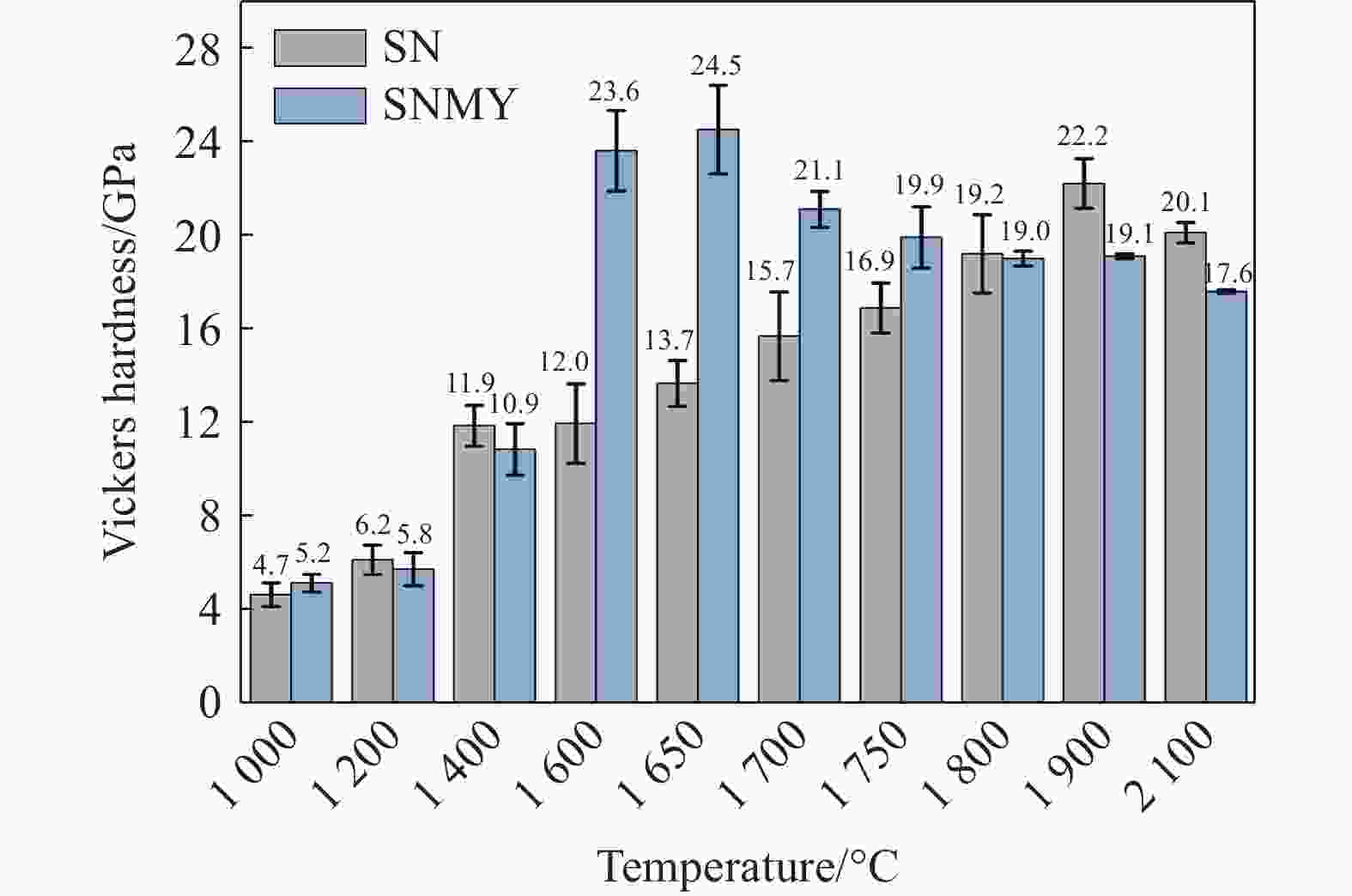

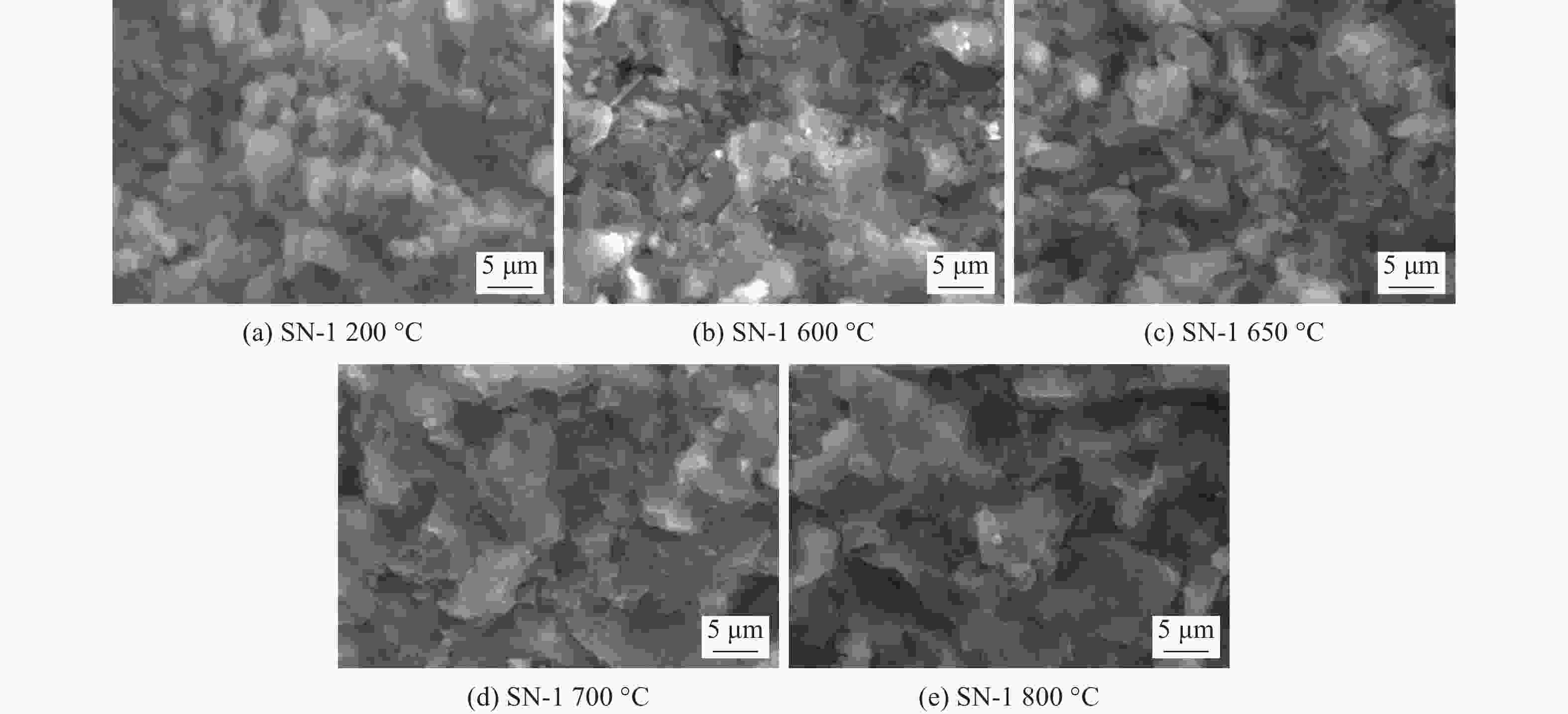

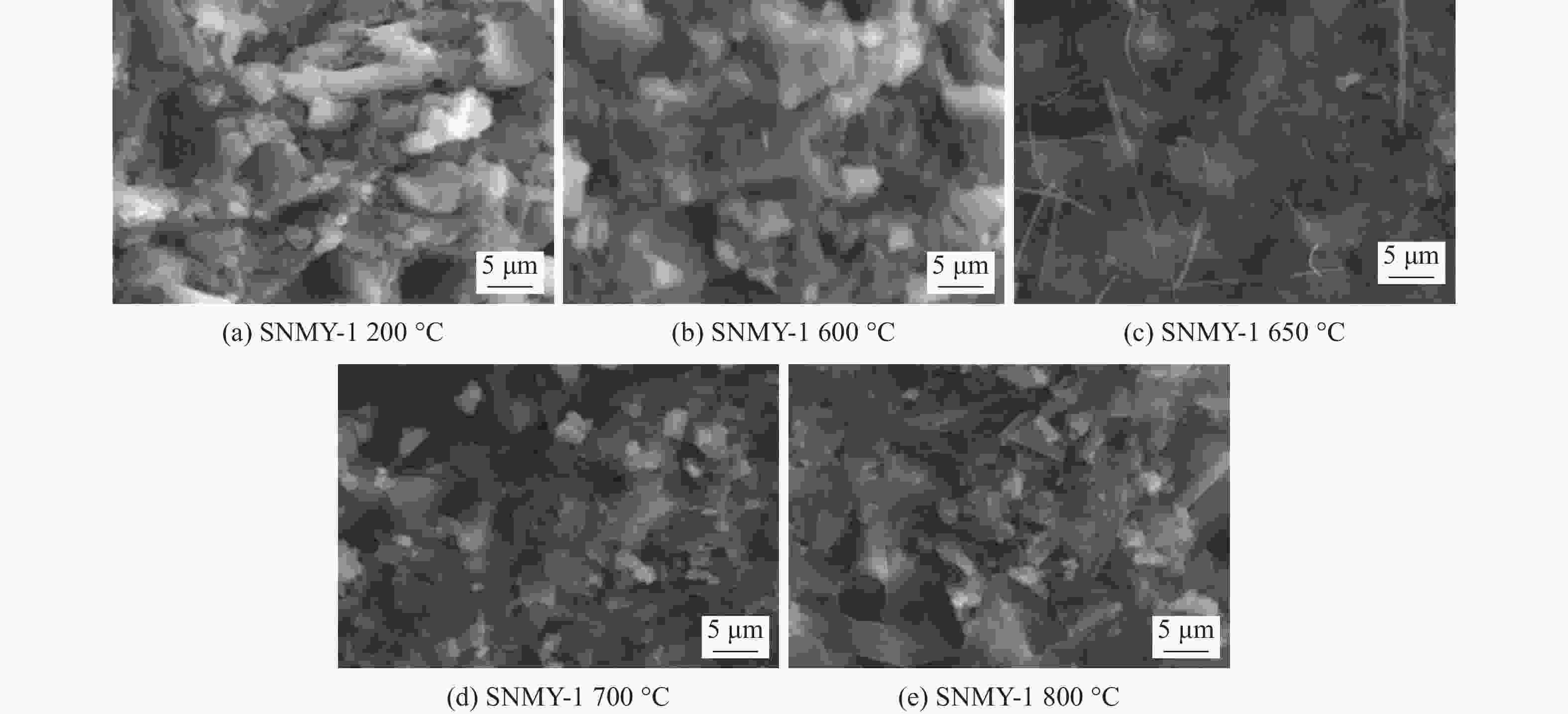

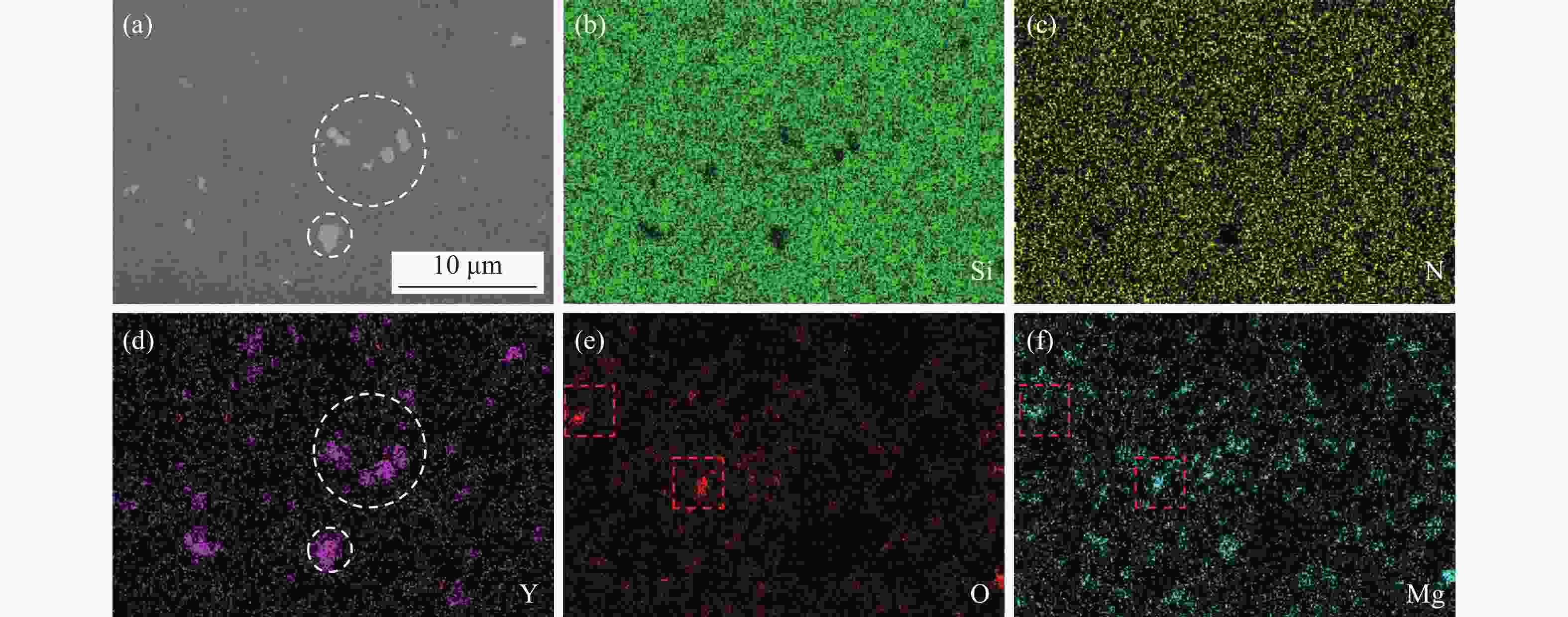

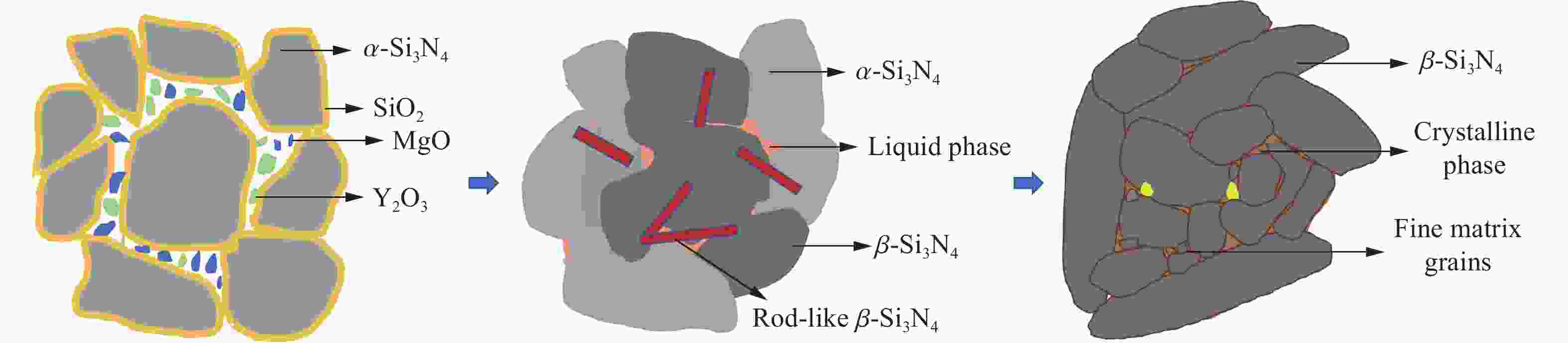

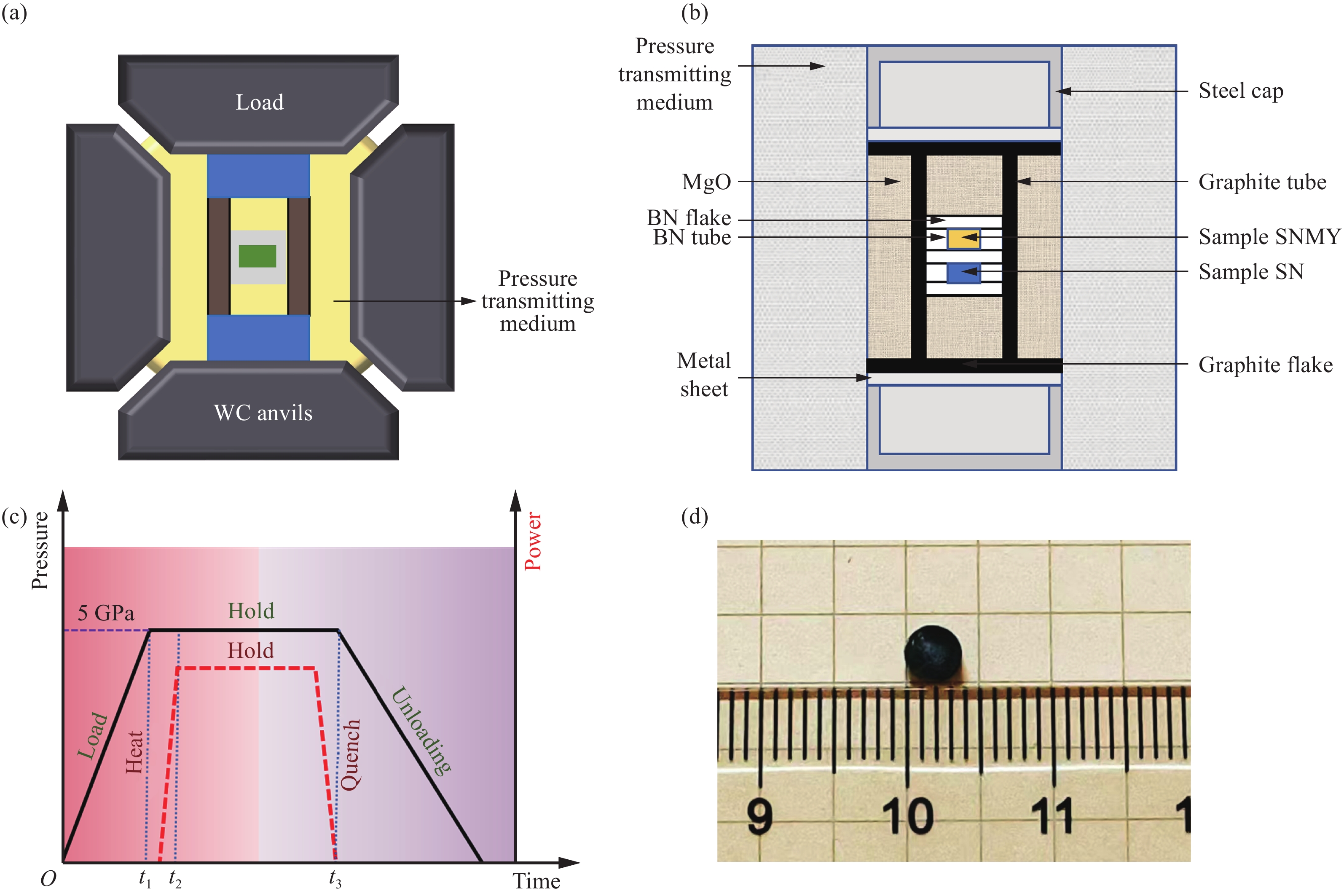

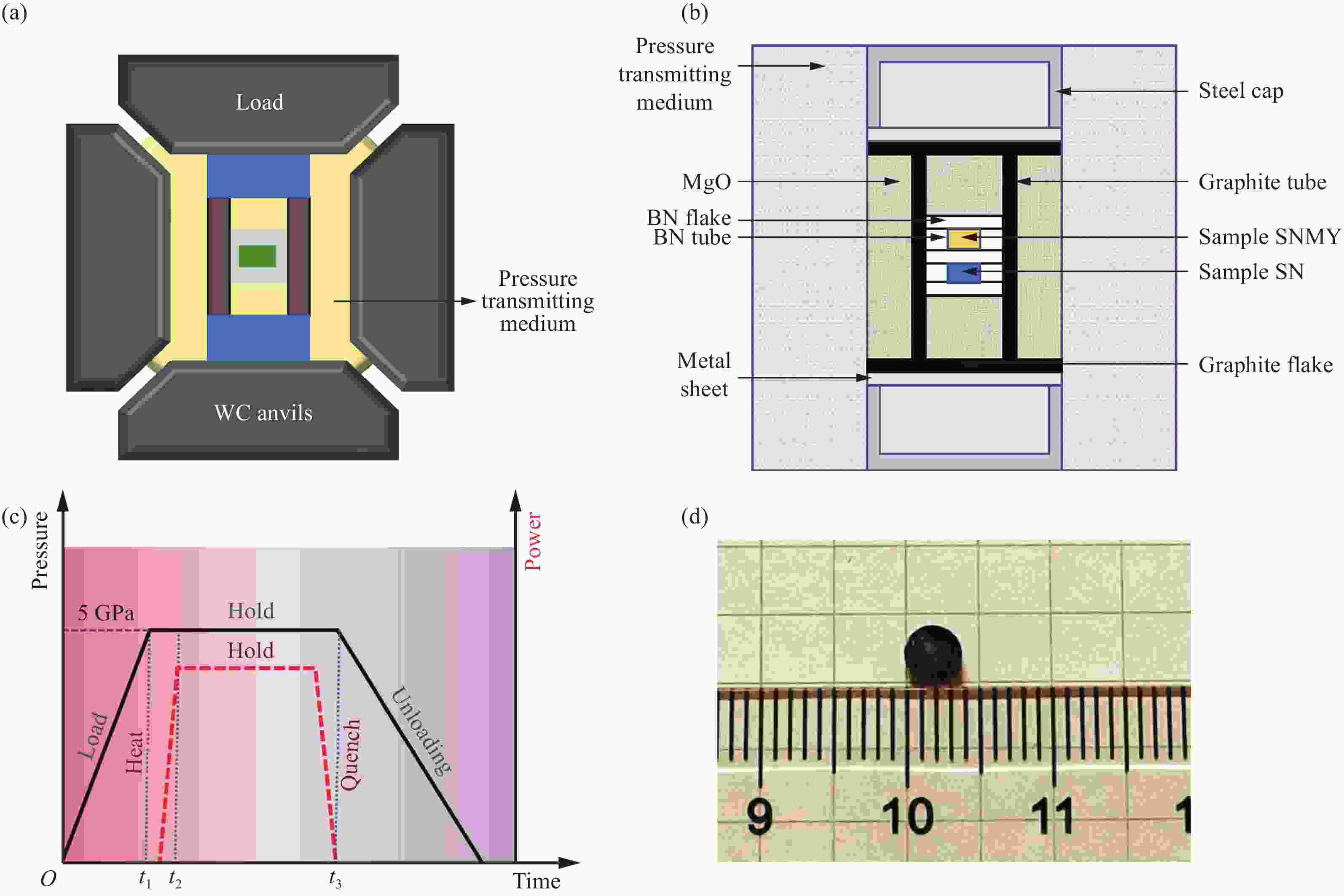

摘要: 氮化硅(Si3N4)陶瓷因其独特的物理和化学特性,被认为是一种兼具高可靠性与经济性的新型结构陶瓷。然而,Si3N4具有强共价键,导致传统烧结难以使其致密化。为此,将高温高压烧结技术与MgO-Y2O3双元烧结助剂(Si3N4、MgO、Y2O3的质量比为94∶3∶3)相结合,实现了高温高压与液相协同烧结。通过设计双层对比实验组装,确保烧结温度相同,进而系统研究了双元烧结助剂对高压下Si3N4的烧结过程、相变行为、微观形貌和力学性能的影响。结果表明:MgO-Y2O3在烧结过程中形成液相,加速了α-Si3N4→β-Si3N4的转变,使Si3N4相变的起始温度从

1800 ℃降低至1650 ℃;同时,高压促进晶粒重排与烧结,成功制备出高致密的Si3N4陶瓷,其中,最优样品的维氏硬度达(24.5±1.9) GPa。研究工作为优化Si3N4陶瓷烧结工艺提供了新的有效策略。Abstract: Silicon nitride (Si3N4) ceramics are a novel category of structural ceramics, exhibiting both high reliability and economy value due to their unique physical and chemical properties. However, their strong covalent bonds make densification challenging, and phase transition control remains an issue. In this study, high temperature and high pressure (HTHP) sintering was utilized in combination with MgO-Y2O3 binary additives (mass ratio Si3N4∶MgO∶Y2O3 = 94∶3∶3) to achieve a synergistic sintering process involving both high pressure and liquid-phase formation. The effects of binary sintering additives on the sintering process, phase transition behavior, microscopic morphology and mechanical properties of Si3N4 under high pressure were systematically investigated by designing a two-layer comparative experimental assembly to ensure the same sintering temperature. The results show that the MgO-Y2O3 promotes the α→β phase transformation of Si3N4 through liquid phase formation, which reduces the phase transition onset temperature from1800 ℃ to1650 ℃. Furthermore, high pressure enhances grain rearrangement and densification. As a result, highly dense Si3N4 ceramics with an optimal Vickers hardness up to (24.5±1.9) GPa were successfully synthesized. These findings provide an effective strategy for preparing high-performance Si3N4 ceramics and hold significant implications for advancements in physics and material science. -

表 1 不同温度下Si3N4(SN)和Si3N4-MgO-Y2O3(SNMY)样品中β-Si3N4的质量分数

Table 1. Mass fractions of β-Si3N4 in Si3N4 (SN) and Si3N4-MgO-Y2O3 (SNMY) samples under different temperatures

SN samples $w_{\beta \text{-}{\mathrm{Si_3N_4}}} $/% SNMY samples $w_{\beta \text{-}{\mathrm{Si_3N_4}}} $/% SN- 1000 ℃16.8 SNMY- 1000 ℃22.2 SN- 1200 ℃16.9 SNMY- 1200 ℃23.0 SN- 1400 ℃20.0 SNMY- 1400 ℃23.2 SN- 1600 ℃21.2 SNMY- 1600 ℃19.8 SN- 1650 ℃18.6 SNMY- 1650 ℃29.4 SN- 1700 ℃20.3 SNMY- 1700 ℃30.7 SN- 1750 ℃21.7 SNMY- 1750 ℃67.0 SN- 1800 ℃21.2 SNMY- 1800 ℃74.3 SN- 1900 ℃96.3 SNMY- 1900 ℃81.5 SN- 2100 ℃96.3 SNMY- 2100 ℃82.5 -

[1] RILEY F L. Silicon nitride and related materials [J]. Journal of the American Ceramic Society, 2000, 83(2): 245–265. doi: 10.1111/j.1151-2916.2000.tb01182.x [2] ZHANG Y, WANG H J, ZHANG W, et al. Preparation and study of porous Si3N4 ceramics with high strength [J]. Rare Metal Materials and Engineering, 2004, 33(6): 655–658. [3] ZHOU Y, HYUGA H, KUSANO D, et al. A tough silicon nitride ceramic with high thermal conductivity [J]. Advanced Materials, 2011, 23(39): 4563–4567. doi: 10.1002/adma.201102462 [4] 肖桂凤, 唐志平, 周昌国, 等. 氮化硅陶瓷层裂强度的研究 [J]. 高压物理学报, 2005, 19(3): 219–224. doi: 10.11858/gywlxb.2005.03.005XIAO G F, TANG Z P, ZHOU C G, et al. A study on the spallation behavior of silicon nitride [J]. Chinese Journal of High Pressure Physics, 2005, 19(3): 219–224. doi: 10.11858/gywlxb.2005.03.005 [5] SOMIYA S. Hydrothermal corrosion of nitride and carbide of silicon [J]. Materials Chemistry and Physics, 2001, 67(1/2/3): 157–164. doi: 10.1016/S0254-0584(00)00434-X [6] DINIZ A E, GILES FERRER J A. A comparison between silicon nitride-based ceramic and coated carbide tools in the face milling of irregular surfaces [J]. Journal of Materials Processing Technology, 2008, 206(1/2/3): 294–304. doi: 10.1016/j.jmatprotec.2007.12.035 [7] KAWAI N, TSURUI K, SHINDO D, et al. Fracture behavior of silicon nitride ceramics subjected to hypervelocity impact [J]. International Journal of Impact Engineering, 2011, 38(7): 542–545. doi: 10.1016/j.ijimpeng.2011.01.003 [8] KONDO N, HYUGA H, KITA H. Joining of silicon nitride with silicon slurry via reaction bonding and post sintering [J]. Journal of the Ceramic Society of Japan, 2010, 118(1373): 9–12. doi: 10.2109/jcersj2.118.9 [9] LIN Y D, YONG Z, LUO X S, et al. Monolithically integrated, broadband, high-efficiency silicon nitride-on-silicon waveguide photodetectors in a visible-light integrated photonics platform [J]. Nature Communications, 2022, 13(1): 6362. doi: 10.1038/s41467-022-34100-3 [10] WANG L, SNIDLE R W, GU L. Rolling contact silicon nitride bearing technology: a review of recent research [J]. Wear, 2000, 246(1/2): 159–173. doi: 10.1016/S0043-1648(00)00504-4 [11] PASUPULETI S, PEDDETTI R, SANTHANAM S, et al. The effect of nano-sized sintering aids on toughening behavior of silicon nitride [J]. Journal of Materials Science, 2008, 43(8): 2799–2805. doi: 10.1007/s10853-008-2543-z [12] MAZDIYASNI K S, COOKE C M. Consolidation, microstructure, and mechanical properties of Si3N4 doped with rare-earth oxides [J]. Journal of the American Ceramic Society, 1974, 57(12): 536–537. doi: 10.1111/j.1151-2916.1974.tb10806.x [13] ZHOU Y, HYUGA H, KUSANO D, et al. Effects of yttria and magnesia on densification and thermal conductivity of sintered reaction-bonded silicon nitrides [J]. Journal of the American Ceramic Society, 2019, 102(4): 1579–1588. doi: 10.1111/jace.16015 [14] LI S S, CHEN H B, WANG W D, et al. Effects of Y2O3/MgO ratio on mechanical properties and thermal conductivity of silicon nitride ceramics [J]. International Journal of Applied Ceramic Technology, 2022, 19(5): 2873–2882. doi: 10.1111/ijac.14067 [15] LI Y S, KIM H N, WU H B, et al. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: the effects of Y2O3 additive content [J]. Journal of the European Ceramic Society, 2021, 41(1): 274–283. doi: 10.1016/j.jeurceramsoc.2020.08.035 [16] ZHU X W, HAYASHI H, ZHOU Y, et al. Influence of additive composition on thermal and mechanical properties of β-Si3N4 ceramics [J]. Journal of Materials Research, 2004, 19(11): 3270–3278. doi: 10.1557/JMR.2004.0416 [17] 侯领, 沈维霞, 房超, 等. 高导热金刚石/铝复合材料的高温高压制备 [J]. 高压物理学报, 2020, 34(5): 053101. doi: 10.11858/gywlxb.20200514HOU L, SHEN W X, FANG C, et al. High thermal conductivity of diamond/Al composites via high pressure and high temperature sintering [J]. Chinese Journal of High Pressure Physics, 2020, 34(5): 053101. doi: 10.11858/gywlxb.20200514 [18] 邓雯丽, 邓福铭, 张鹏, 等. 纯PCBN高压烧结行为与工艺规律 [J]. 高压物理学报, 2018, 32(2): 023303. doi: 10.11858/gywlxb.20170617DENG W L, DENG F M, ZHANG P, et al. Sintering behavior and technical rule of pure PCBN synthesized under high pressure [J]. Chinese Journal of High Pressure Physics, 2018, 32(2): 023303. doi: 10.11858/gywlxb.20170617 [19] HE P H, HE Y L, LIANG W J, et al. Sintering polycrystalline silicon carbide composite ceramics with ultra-high hardness under high pressure [J]. International Journal of Refractory Metals and Hard Materials, 2024, 125: 106918. doi: 10.1016/j.ijrmhm.2024.106918 [20] 吴颖, 湛炎霞, 马锋杰, 等. 高压下超导氢化物研究进展 [J]. 中国科学: 物理学 力学 天文学, 2022, 52(7): 270006.WU Y, ZHAN Y X, MA F J, et al. New progress in superconducting hydrides under high pressure [J]. Scientia Sinica Physica, Mechanica & Astronomica, 2022, 52(7): 270006. [21] FILGUEIRA M, NASCIMENTOÁ L N, OLIVEIRA M P, et al. HTHP sintering of binderless Si3N4: structure, microstructure, mechanical properties and machining behavior [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018, 40(3): 118. doi: 10.1007/s40430-018-1035-6 [22] CHEN W, XU E G, LIU X Y, et al. Study on a novel Si3N4-based composite with the incorporation of N-GQDs produced from nano-lignin [J]. Ceramics International, 2024, 50(11): 19534–19542. doi: 10.1016/j.ceramint.2024.03.052 [23] TONG Z W, JI H M, LI X L, et al. Microstructure control and optimization of low temperature pressureless sintered silicon nitride-barium aluminosilicate composites [J]. Journal of the European Ceramic Society, 2020, 40(12): 4177–4183. doi: 10.1016/j.jeurceramsoc.2020.05.009 [24] HU J B, ZHANG B, LI C, et al. Fabrication of Si3N4 ceramics with high thermal conductivity and flexural strength via novel two-step gas-pressure sintering [J]. Journal of the European Ceramic Society, 2022, 42(12): 4846–4854. doi: 10.1016/j.jeurceramsoc.2022.04.049 [25] TIEGS T N, MONTGOMERY F C, SCHROEDER J L, et al. Effect of powder characteristics on the α- to β-Si3N4 transformation kinetics [M]//SINGH J P. Proceedings of the 21st Annual Conference on Composites, Advanced Ceramics, Materials, and Structures B: Ceramic Engineering and Science Proceedings. Westerville: The American Ceramic Society, 1997. [26] BOCANEGRA-BERNAL M H, MATOVIC B. Dense and near-net-shape fabrication of Si3N4 ceramics [J]. Materials Science and Engineering: A, 2009, 500(1/2): 130–149. doi: 10.1016/j.msea.2008.09.015 -

下载:

下载: