The Rate-Temperature Dependent Compressive Mechanical Behavior and Deformation Mechanism of CrCoNiSi0.3 Medium Entropy Alloy

-

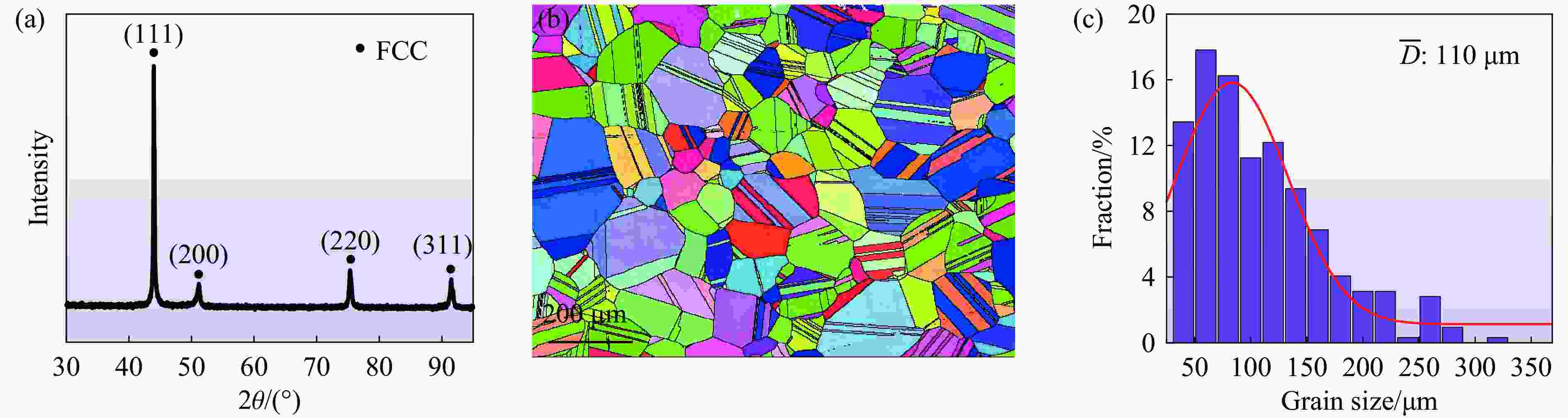

摘要: CrCoNiSi0.3中熵合金在准静态加载下展现出优异的强韧协同力学行为,温度和应变率对合金力学行为的影响亟待研究。通过霍普金森压杆装置,对CrCoNiSi0.3中熵合金进行了室温(20 ℃)动态压缩(

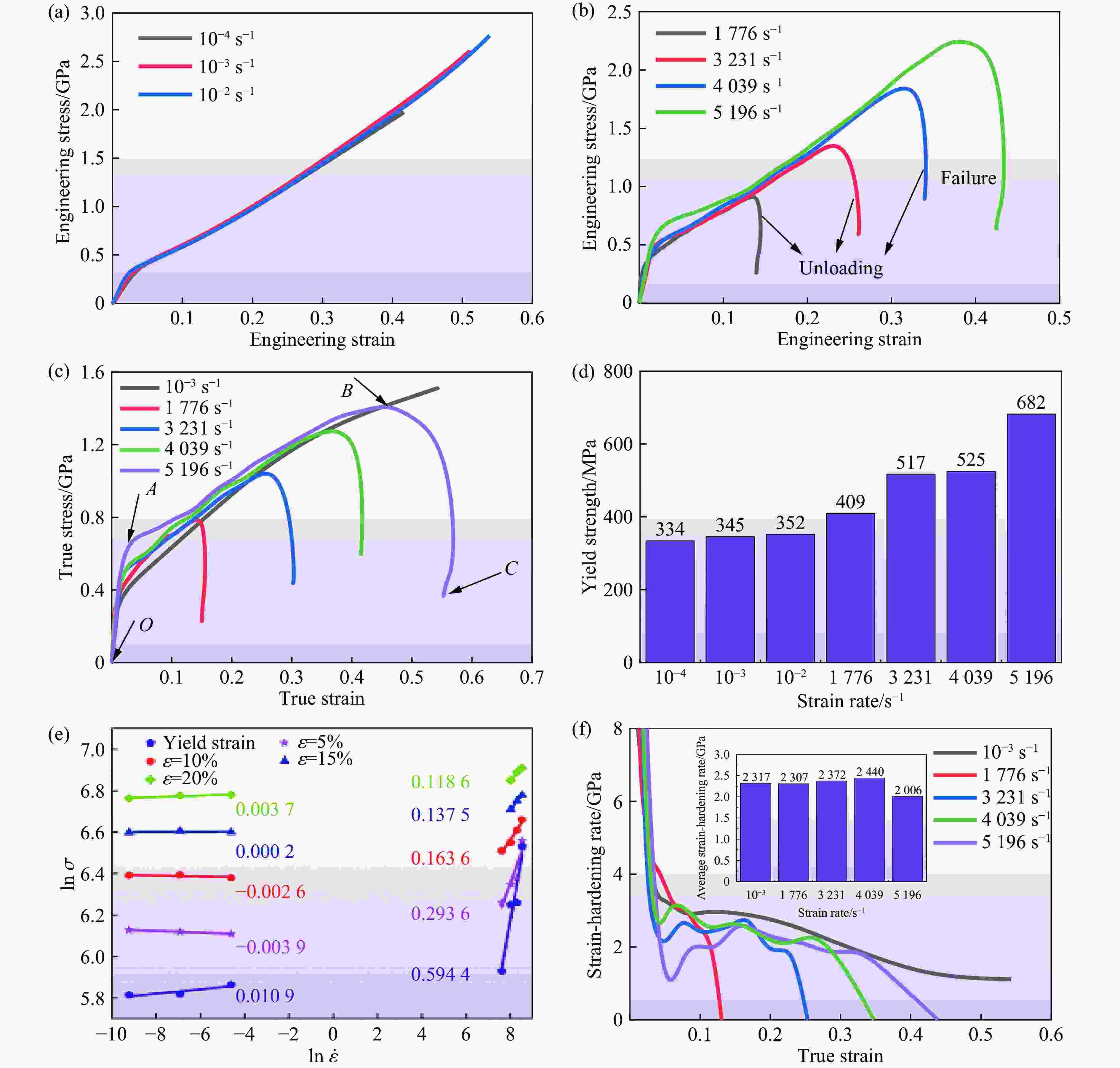

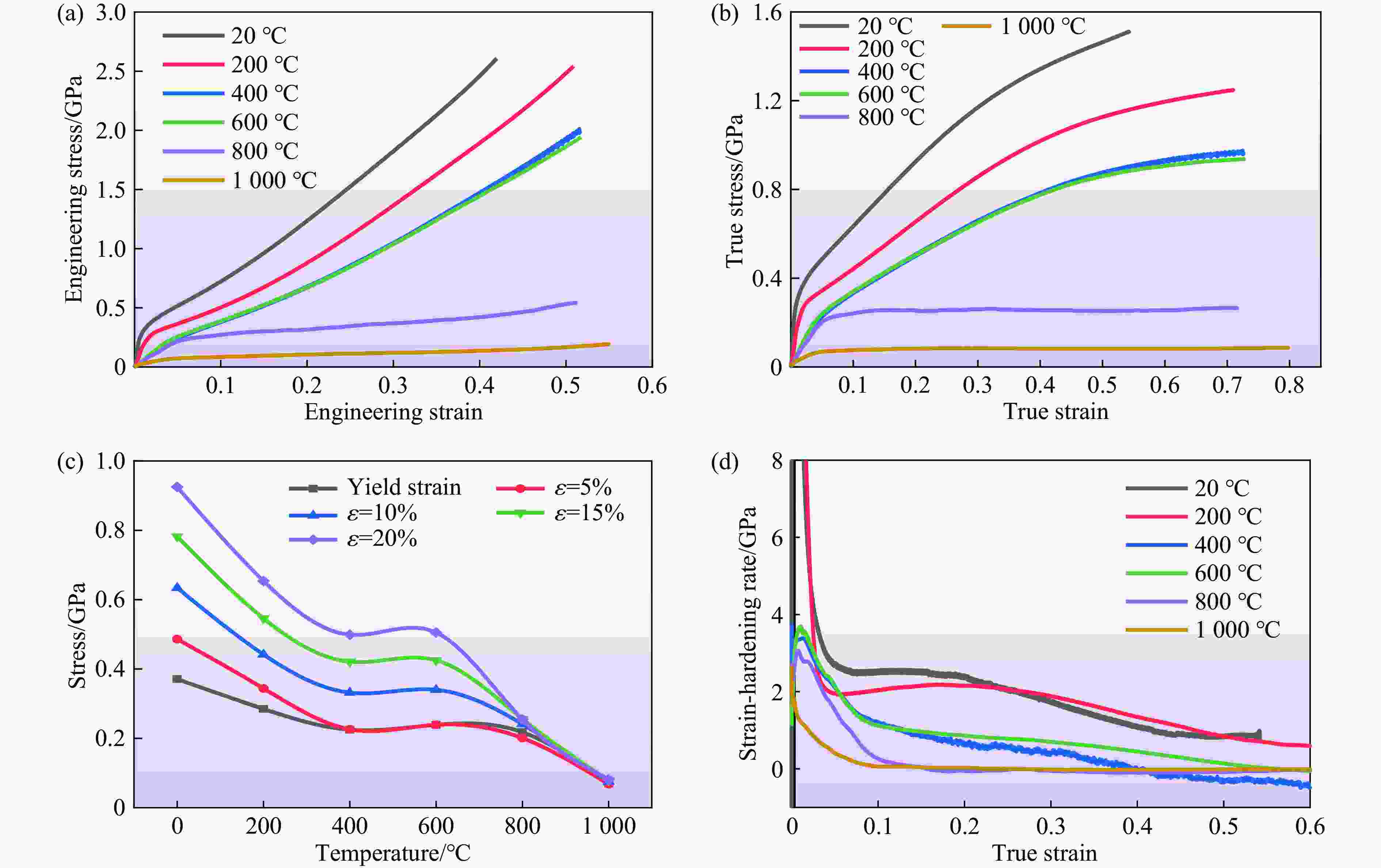

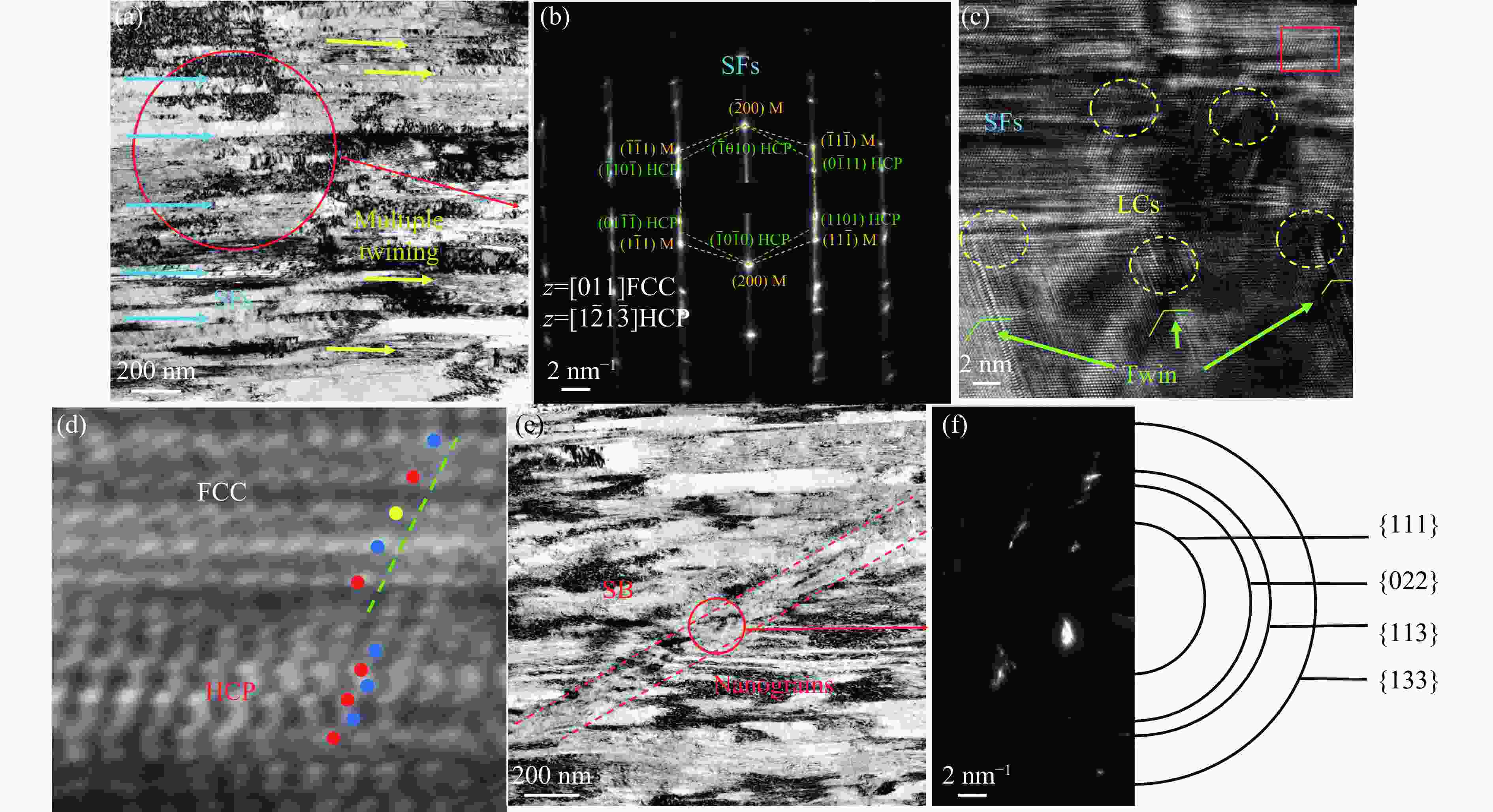

1776 ~5196 s−1)实验和高温(20~1000 ℃)准静态压缩实验,系统研究了CrCoNiSi0.3中熵合金在不同应变率和温度下的力学行为和变形机理。结果表明:在动态加载下,CrCoNiSi0.3中熵合金的屈服强度随着应变率的升高而增大,表现出较高的应变率敏感性,该现象源于随着应变率增大而增加的层错、变形孪晶和面心立方到密排六方相变;平均应变硬化率随着应变率的升高先略有上升,当应变率达到约5196 s−1时,由于剪切带形成,平均应变硬化率下降。随着温度的升高,压缩屈服应力和应变硬化能力下降,但直至1000 ℃仍未表现出明显的应变软化现象;在600 ℃下合金有高密度层错和位错锁,表现出与400 ℃时基本一致的屈服强度和流动应力。针对应变硬化随应变率升高而降低的力学行为,在模型中引入应变硬化函数,建立了修正的Johnson-Cook本构模型,该模型可以较好地预测CrCoNiSi0.3中熵合金的力学行为。Abstract: The CrCoNiSi0.3 medium entropy alloy exhibits excellent synergistic mechanical behavior of strength and toughness under quasi-static loading. However, the influences of temperature and strain rate on the mechanical behavior of the alloy urgently need to be studied. Through the split Hopkinson pressure bar (SHPB), dynamic compression experiments at room temperature (20 ℃) with strain rates ranging from1776 s−1 to5196 s−1 and quasi-static compression experiments at high temperatures (from 20 ℃ to1000 ℃) were carried out on the CrCoNiSi0.3 medium entropy alloy. The strain rate and temperature-dependent mechanical behavior and deformation mechanism of the CrCoNiSi0.3 medium entropy alloy were systematically investigated. The results show that under dynamic loading, the yield strength of the CrCoNiSi0.3 medium entropy alloy increases with the increase of the strain rate, exhibiting a high strain rate sensitivity. This is attributed to the comprehensive mechanism of stacking faults, deformation twins, and the phase transformation from face-centered cubic to hexagonal close packed, which increase as the strain rate increases. The average work hardening rate increases slightly at first with the increase of the strain rate. When the strain rate reaches about5196 s−1, the average work hardening rate decreases due to the formation of shear bands. As the temperature rises, the compressive yield stress and work hardening ability of the alloy gradually decrease. However, there is still no work softening phenomenon at a temperature of1000 ℃. Due to the high density of stacking faults and dislocation locks in the alloy at 600 ℃, it shows almost the same yield strength and flow stress as at 400 ℃. Aiming at the mechanical behavior that the strain hardening shows a decrease with the increase of the strain rate, a strain hardening function was introduced into the model, and a modified Johnson-Cook constitutive model was established, which can predict the mechanical behavior of the CrCoNiSi0.3 medium entropy alloy quite well.-

Key words:

- medium entropy alloy /

- mechanical behavior /

- strain rate /

- strain hardening /

- deformation mechanism

-

图 3 室温不同应变率压缩下CrCoNiSi0.3的准静态工程应力-工程应变曲线(a)、动态工程应力-工程应变曲线(b)、真实应力-真实应变曲线(c)、屈服应力柱状图(d)、应力-应变率双对数曲线(应力和应变率的单位分别为MPa和s−1)(e)和应变硬化率-真实应变曲线(f)

Figure 3. Quasi-static engineering stress-strain curves (a), dynamic engineering stress-strain curves (b), true stress-strain curves (c), yield stress histogram (d), double-log stress-strain rate curves (The units of stress and strain rate are MPa and s−1, respectively.) (e), strain-hardening rate-true strain curves (f) of CrCoNiSi0.3 under compression at different strain rates at room temperature

图 4 不同温度、准静态(10−3 s−1)压缩下试样的工程应力-工程应变曲线(a)、真实应力-真实应变曲线(b)、不同应变下压缩屈服应力随温度的变化(c)和应变硬化率-真实应变曲线(d)

Figure 4. Engineering stress-strain curves (a), true stress-strain curves (b), yield stress-temperature curves at different strains (c), and strain-hardening rate-true strain curves (d) of specimens under quasi-static compression (10−3 s−1) at different temperatures

图 5 室温压缩至应变为45.8%时试样的TEM形貌(a)、红色圆形区域(图5(a))的衍射花样(b)和高分辨图像(c)、红色方框区域(图5(c))的放大图(d)、剪切带形貌(e)以及红色圆形区域剪切带(图5(e))的衍射斑点图像(f)

Figure 5. (a) TEM images of the specimen when compressed to a strain of 45.8% at room temperature; (b)−(c) diffraction pattern and high-resolution images in the circular region of Fig. 5(a), (d) enlarged image for the red rectangular area of Fig. 5(c), (e) shear band topography, and (f) diffraction spots in the circular region of Fig. 5(e), respectively

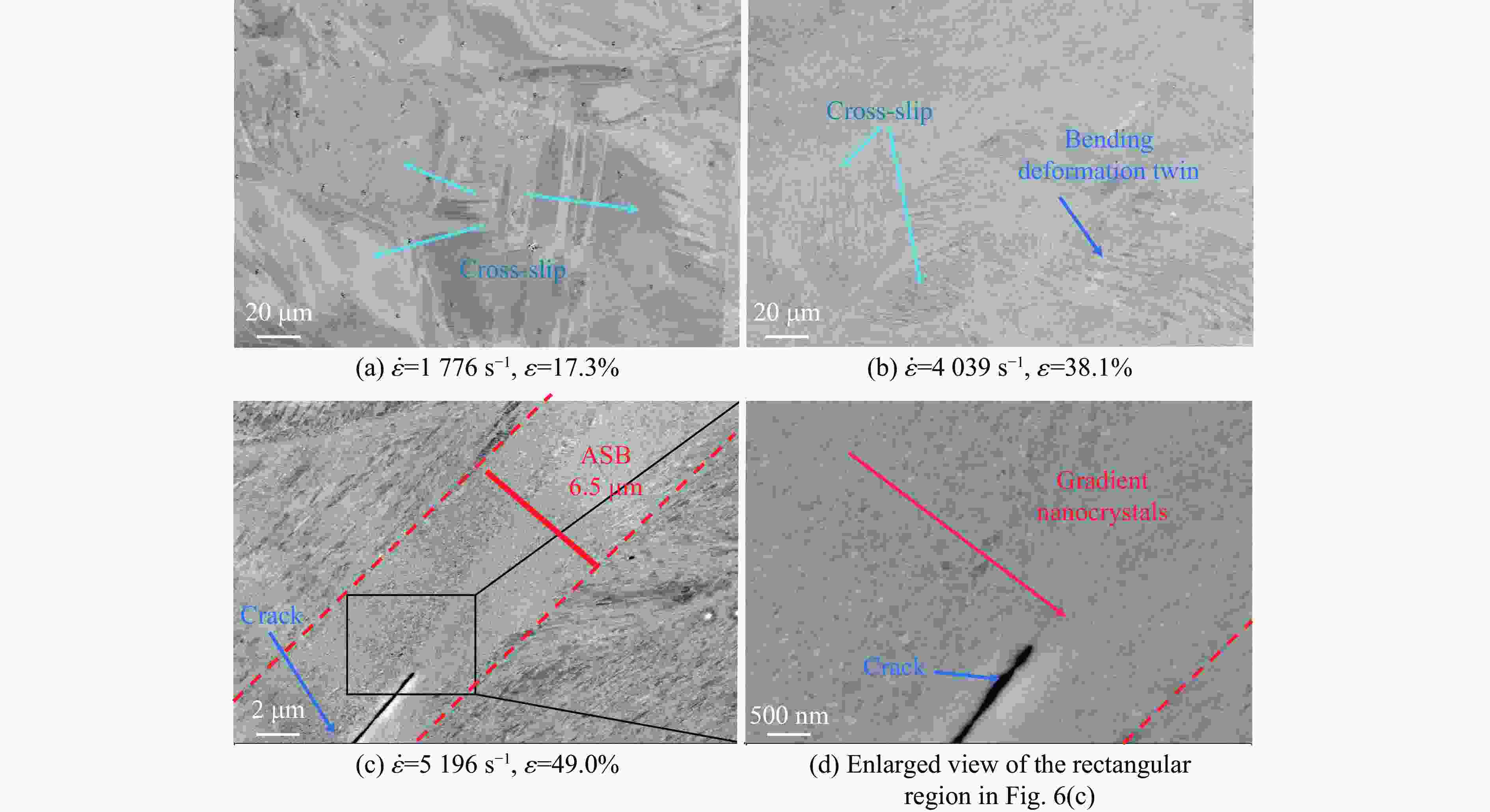

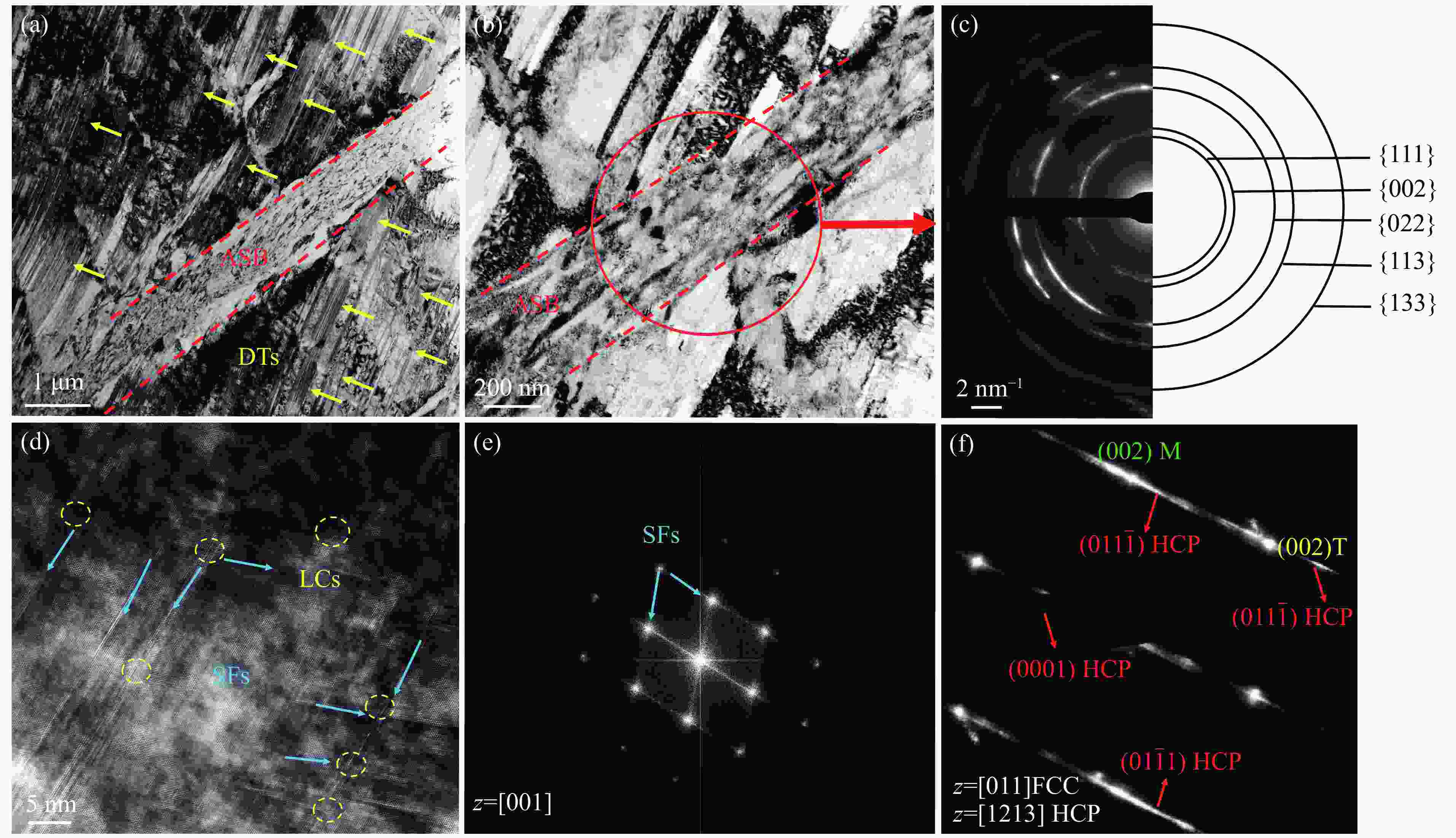

图 7 应变率为

5196 s−1的动态压缩后试样的TEM图像(a)~(b)、剪切带内部衍射斑点(c)、剪切带附近区域高分辨图像(d)及衍射斑点(e)~(f)Figure 7. TEM images of the specimen after dynamic compression with the strain rate of

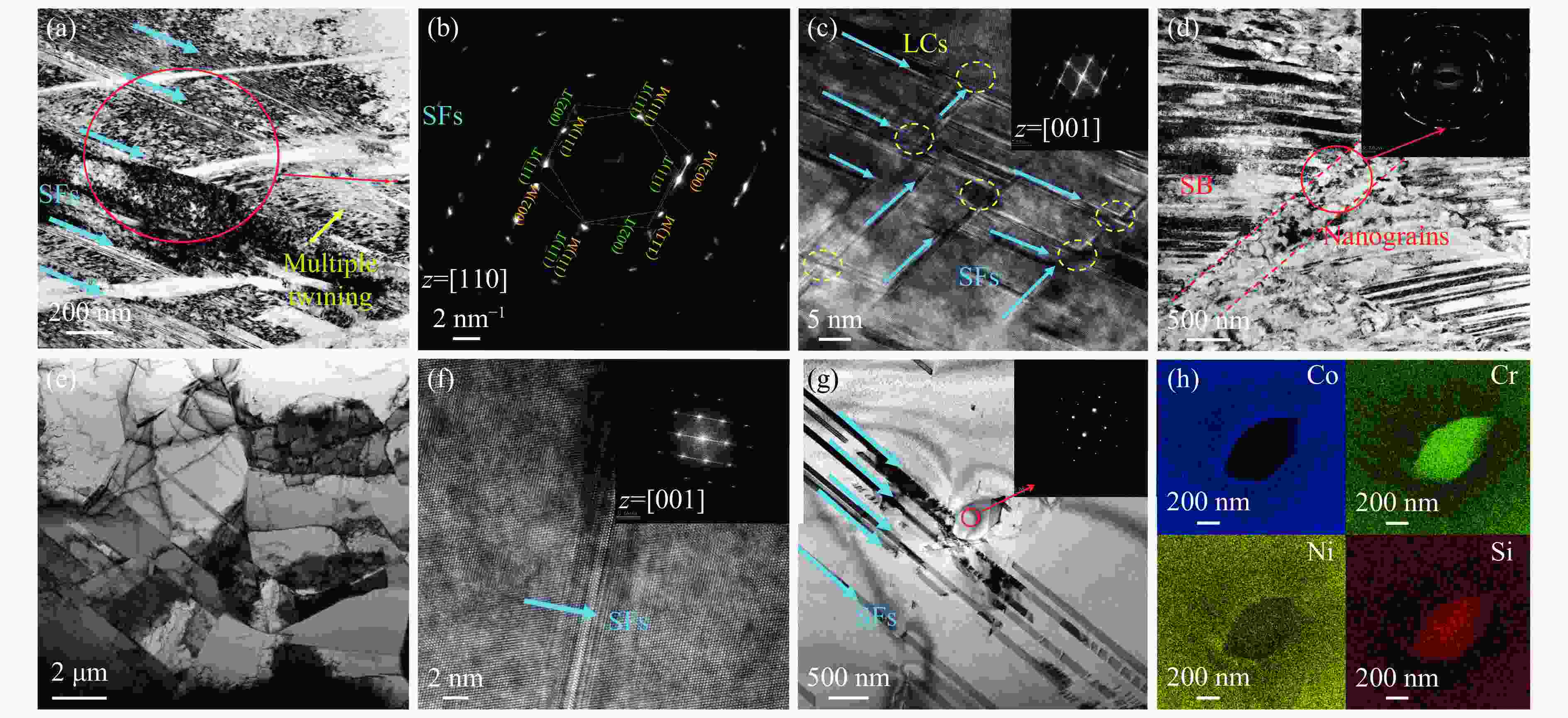

5196 s−1 (a)−(b), diffraction spots inside the shear band (c), high-resolution images of areas near the shear band (d) and diffraction spots (e)−(f)图 8 600 ℃准静态压缩后试样的(a) 形貌、(b)~(c) 图8(a)中红色圆形区域对应的衍射斑点和高分辨图像、(d) 剪切带形貌以及

1000 ℃高温准静态压缩后试样的(e) 形貌、(f)~(g) 高分辨图像、(h) 图8(g)中析出相的面扫图Figure 8. TEM images of specimens after high-temperature quasi-static compression experiment at 600 ℃ ((a)−(d)) and

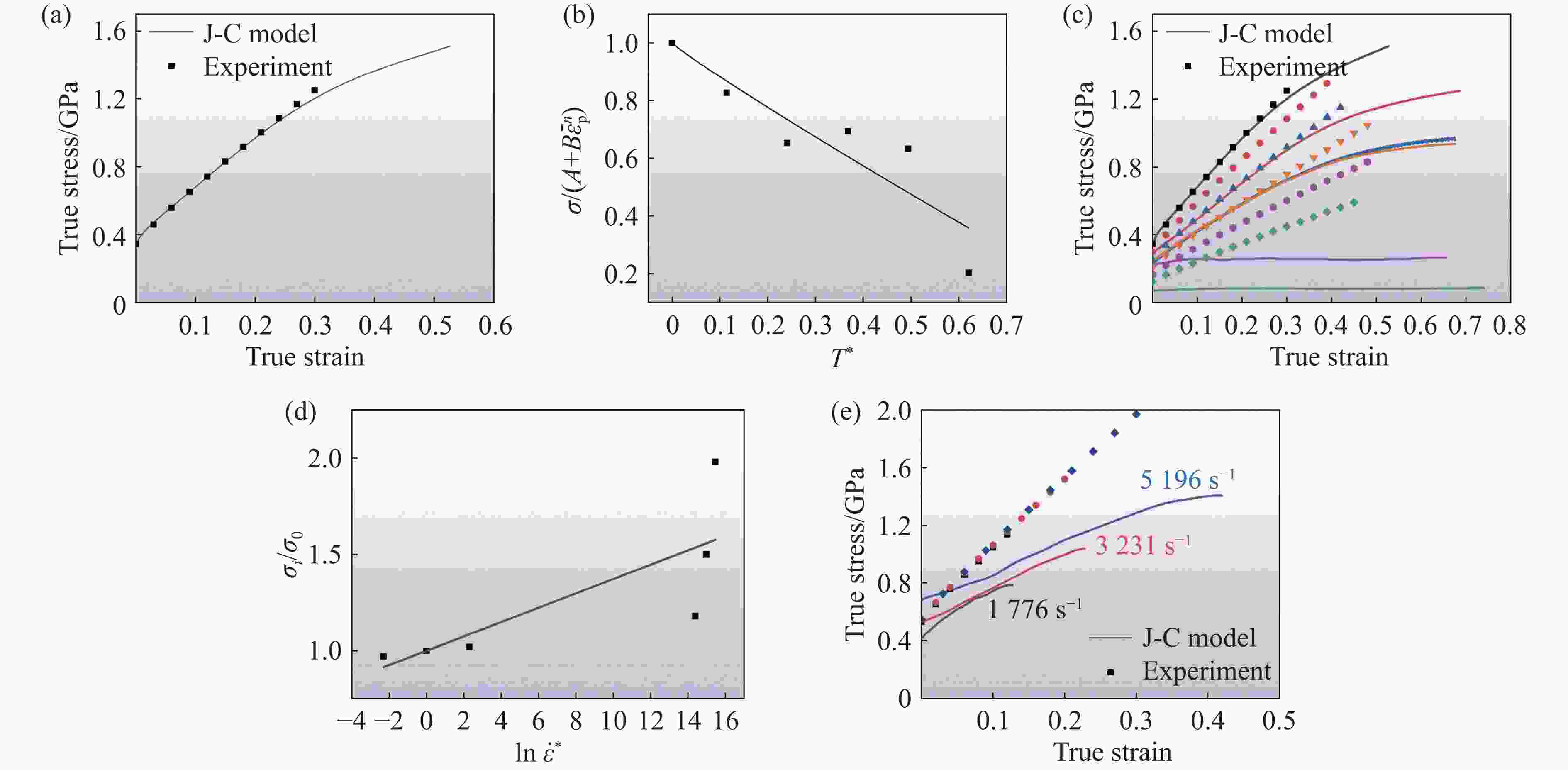

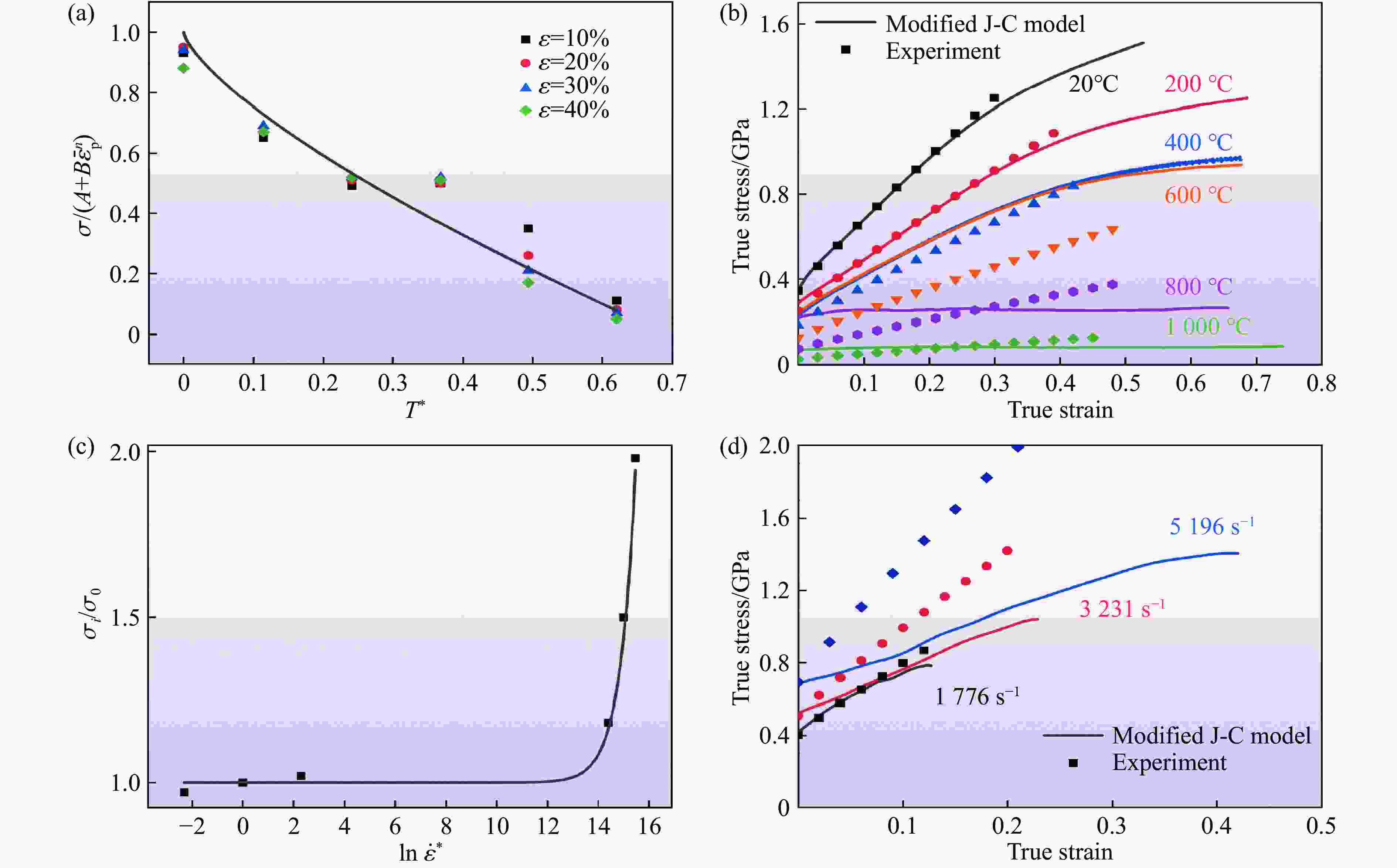

1000 ℃ ((e)−(h)): (a) the topography; (b)−(c) diffraction spots and high-resolution images of circular region in Fig. 8(a); (d) the shear band; (e) topography images, (f)−(g) high-resolution images; (h) the surface map of the precipitated phase of Fig. 8(g)图 9 (a)室温准静态($ {T}_{\mathrm{r}}=20 $ ℃,$ \dot{\varepsilon }={10}^{-3} $s−1)压缩下试样的真实应力-真实应变曲线,(b) 高温准静态加载下$ \sigma /(A+B{\overline{\varepsilon }}_{\mathrm{p}}^{n}) $与T*的拟合曲线,(c) 高温准静态加载下真实应力-真实应变曲线,(d) $ {\sigma }_{i}/{\sigma }_{0} $-$ \mathrm{ln}\,{\dot{\varepsilon }}^{*} $拟合曲线,(e) 室温动态加载下试样的真实应力-真实应变曲线

Figure 9. (a) True stress-strain curve of the specimen under quasi-static compression at room temperature ($ {T}_{\mathrm{r}}=20 $ ℃, $ \dot{\varepsilon }={10}^{-3} $s−1); (b) $ \sigma /(A+B{\overline{\varepsilon }}_{\mathrm{p}}^{n}) $ - T* curve of the specimen under quasi-static compression at high temperature; (c) true stress-strain curves of the specimen under quasi-static compression at high temperature; (d) $ {\sigma }_{i}/{\sigma }_{0} $-$ \mathrm{ln}\,{\dot{\varepsilon }}^{*} $ fitting curves; (e) true stress-strain curves of specimens under dynamic compression at room temperature

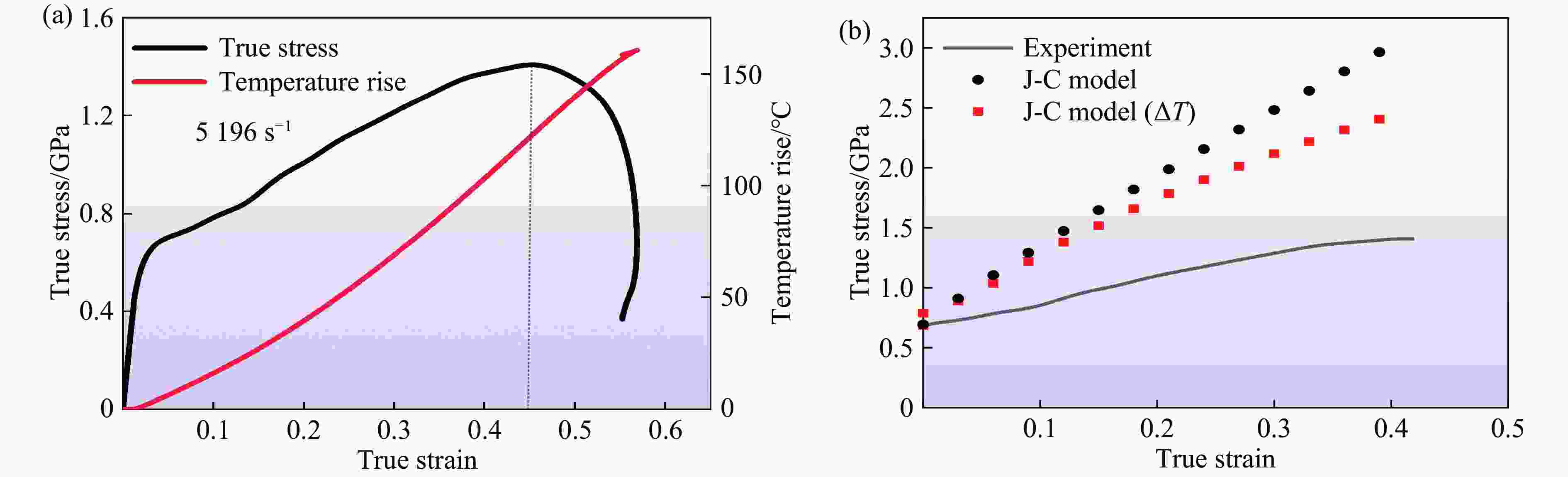

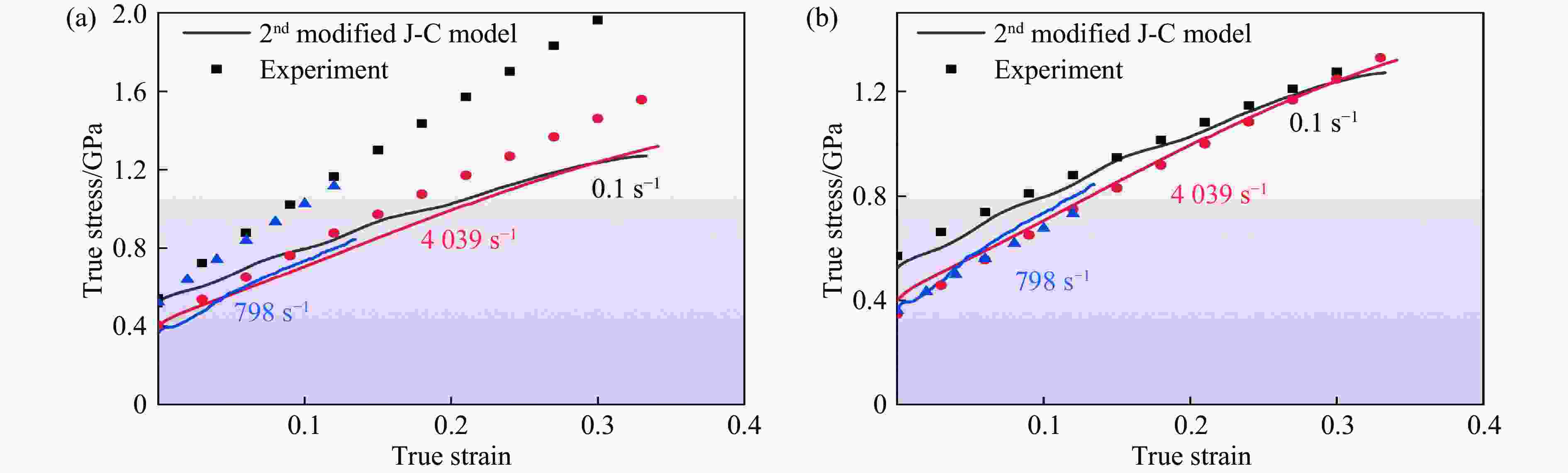

图 10 第1次修正后的拟合结果:(a) 高温准静态压缩下不同应变试样的$ \sigma /(A+B{\overline{\varepsilon }}_{\mathrm{p}}^{n}) $- T*拟合曲线,(b) 高温准静态压缩下的真实应力-真实应变曲线,(c) $ {\sigma }_{i}/{\sigma }_{0} $-$ \mathrm{ln}\,{\dot{\varepsilon }}^{*} $拟合曲线,(d) 室温动态加载下试样的真实应力-真实应变曲线

Figure 10. Fitting results after the first revision: (a) $ \sigma /(A+B{\overline{\varepsilon }}_{\mathrm{p}}^{n}) $ - T* curve of the specimen under quasi-static compression at high temperature; (b) true stress-strain curves of specimens under quasi-static compression at high temperature; (c) $ {\sigma }_{i}/{\sigma }_{0} $-$ \mathrm{ln}\,{\dot{\varepsilon }}^{*} $ fitting curves; (d) true stress-strain curves of specimens under dynamic compression at room temperature

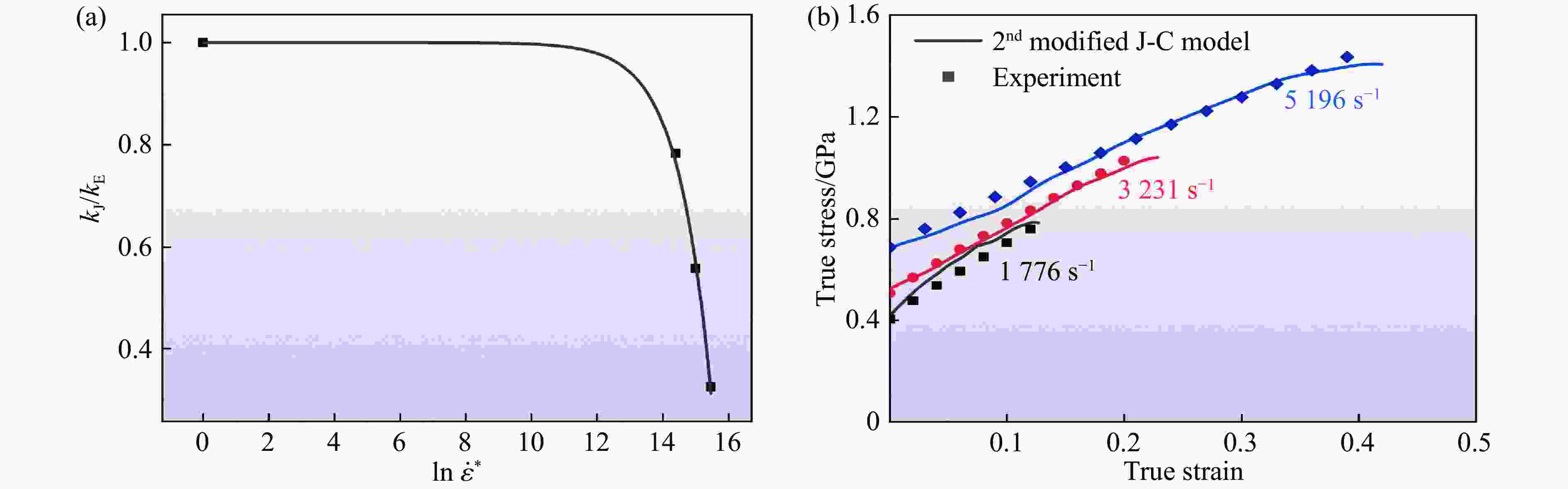

图 11 (a)

5196 s−1应变率下真实应力和温升随真实应变的变化,(b) 真实应力-真实应变实验数据与是否引入温度因素的J-C模型计算结果对比Figure 11. (a) Changes of true stress and temperature rise with true strain at a strain rate of

5196 s−1; (b) comparison of true stress-strain between the experimental data and the J-C model results with and without considering the temperature图 12 (a) 不同应变率和参考应变率下真实应力-真实应变曲线屈服段斜率之比$ {k}_{\mathrm{J}}/{k}_{\mathrm{E}} $,(b) 第2次修正J-C模型得到的室温动态加载下试样的真实应力-真实应变拟合曲线

Figure 12. (a) Ratio of the slope in the yield stage of true stress-strain curves under different strain rates to that under the reference strain rate $ {k}_{\mathrm{J}}/{k}_{\mathrm{E}} $; (b) true stress-strain fitting curves of specimens under dynamic loading at room temperature obtained by the J-C model with second modification

-

[1] CAI P C, LIU J H, LUAN J, et al. Local chemical fluctuation-tailored hierarchical heterostructure overcomes strength-ductility trade-off in high entropy alloys [J]. Journal of Materials Science & Technology, 2025, 214: 74–86. doi: 10.1016/j.jmst.2024.06.033 [2] SALIFU S, OLUBAMBI PA. Microstructural and nanoindentation study of spark plasma sintered high entropy alloy reinforced aluminium matrix composites [J]. Journal of Alloys and Compounds, 2024, 999: 175021. doi: 10.1016/j.jallcom.2024.175021 [3] EZATPOUR H R, JALALABADI M, HUO Y, et al. Microstructure, mechanical and tribological properties of Mg/CoCrFeNiMoTi high entropy alloy composites produced via FSP [J]. Engineering Failure Analysis, 2024, 161: 108281. doi: 10.1016/j.engfailanal.2024.108281 [4] MA Y, YUAN F P, YANG M X, et al. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures [J]. Acta Materialia, 2018, 148: 407–418. doi: 10.1016/j.actamat.2018.02.016 [5] CHANG H, ZHANG T W, MA S G, et al. Novel Si-added CrCoNi medium entropy alloys achieving the break through of strength-ductility trade-off [J]. Materials & Design, 2021, 197: 109202. doi: 10.1016/j.matdes.2020.109202 [6] WU X L, YANG M X, JIANG P, et al. Deformation nanotwins suppress shear banding during impact test of CrCoNi medium-entropy alloy [J]. Scripta Materialia, 2020, 178: 452–456. doi: 10.1016/j.scriptamat.2019.12.017 [7] 樊谦璐. Al、Ti对CoCrNi多主元合金微观组织及力学性能的影响[D]. 武汉: 华中科技大学, 2017.FAN Q L. Effects of Al and Ti on microstructures and mechanical properties of CoCrNi multi-principal-element alloy [D]. Wuhan: Huazhong University of Science and Technology, 2017. [8] 赵佳琪. CoCrNix (x=0.5~1)和CoCrNiTix (x=0.1~1)中熵合金的计算与模拟[D]. 太原: 太原理工大学, 2020.ZHAO J Q. Calculation and simulation of CoCrNix (x=0.5–1) and CoCrNiTix (x=0.1–1) medium entropy alloys [D]. Taiyuan: Taiyuan University of Technology, 2020. [9] ZHANG L K, AMAR A, ZHANG M Y, et al. Enhanced strength-ductility synergy in a brittle CoCrNi2 (V3B2Si)0.2 eutectic high-entropy alloy by spheroidized M3B2 and recrystallized FCC [J]. Science China Materials, 2023, 66(11): 4197–4206. doi: 10.1007/s40843-023-2520-1 [10] GE S F, LIN S F, FU H M, et al. High-temperature mechanical properties and dynamic recrystallization mechanism of in situ silicide-reinforced MoNbTaTiVSi refractory high-entropy alloy composite [J]. Acta Metallurgica Sinica, 2022, 35(10): 1617–1630. doi: 10.1007/s40195-022-01394-7 [11] 张驰, 石国梁, 张奎, 等. 添加Si和Zn对VW75镁合金显微组织、力学性能和弹性模量的影响 [J]. 稀有金属, 2024, 48(6): 796–807. doi: 10.13373/j.cnki.cjrm.XY21090006ZHANG C, SHI G L, ZHANG K, et al. Microstructure, mechanical properties and elastic modulus of VW75 magnesium alloy with Si and Zn addition [J]. Chinese Journal of Rare Metals, 2024, 48(6): 796–807. doi: 10.13373/j.cnki.cjrm.XY21090006 [12] PARK J M, MOON J, BAE J W, et al. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy [J]. Materials Science and Engineering: A, 2018, 719: 155–163. doi: 10.1016/j.msea.2018.02.031 [13] 严犇. CoCrFeNiAl0.1RE高熵合金热变形行为研究[D]. 镇江: 江苏科技大学, 2019.YAN B. Hot deformation behaviors of CoCrFeNiAl0.1RE high-entropy alloy [D]. Zhenjiang: Jiangsu University of Science and Technology, 2019. [14] 王璐, 马胜国, 赵聃, 等. AlCoCrFeNi高熵合金在冲击载荷下的动态力学性能 [J]. 热加工工艺, 2018, 47(24): 86–89. doi: 10.14158/j.cnki.1001-3814.2018.24.021WANG L, MA S G, ZHAO D, et al. Dynamic mechanical properties of AlCoCrFeNi high-entropy alloys under impact load [J]. Hot Working Technology, 2018, 47(24): 86–89. doi: 10.14158/j.cnki.1001-3814.2018.24.021 [15] 王平. CrCoNiSi0.3中熵合金动态剪切行为研究 [D]. 太原: 太原理工大学, 2022.WANG P. Dynamic shear behavior of CrCoNiSi0.3 medium entropy alloy [D]. Taiyuan: Taiyuan University of Technology, 2022. [16] BERGHAU S D. Numerical methods for experimental mechanics [M]. New York: Springer, 2001. [17] LI Z, ZHAO S, DIAO H, et al. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: remarkable resistance to shear failure [J]. Science Letter, 2017, 7(1): 42742. doi: 10.1038/srep42742 [18] 杜时雨. L12相强化中熵合金率温相关的力学行为及绝热剪切局域化研究[D]. 太原: 太原理工大学, 2024.DU S Y. Research on the rate-temperature dependent mechanical behavior and adiabatic shear localization of L12 phase-strengthened medium-entropy alloys [D]. Taiyuan: Taiyuan University of Technology, 2024. [19] LI X L, ZHAO E L, LIU Z T, et al. Experimental study on multiple propagation characteristics of stress wave and surface displacement behavior in coal based on SHPB and DIC [J]. Bulletin of Engineering Geology and the Environment, 2023, 82(7): 246. doi: 10.1007/S10064-023-03272-7 [20] ZHENG Z J, WANG C F, YU J L, et al. Dynamic stress-strain states for metal foams using a 3D cellular model [J]. Journal of the Mechanics and Physics of Solids, 2014, 72: 93–114. doi: 10.1016/j.jmps.2014.07.013 [21] QIAO L, ZHU J C. Constitutive modeling of hot deformation behavior of AlCrFeNi multi-component alloy [J]. Vacuum, 2022, 201: 111059. doi: 10.1016/J.VACUUM.2022.111059 [22] ANNASAMY M, HAGHDADI N, TAYLOR A, et al. Dynamic recrystallization behaviour of AlxCoCrFeNi high entropy alloys during high-temperature plane strain compression [J]. Materials Science and Engineering: A, 2019, 745: 90–106. doi: 10.1016/j.msea.2018.12.102 [23] YU Z X, XIE B J, ZHU Z W, et al. High-temperature deformation behavior and processing maps of a novel AlNbTi3VZr1.5 refractory high entropy alloy [J]. Journal of Alloys and Compounds, 2022, 912: 165220. doi: 10.1016/j.jallcom.2022.165220 [24] MUHAMMAD A, SHEN J H, SHI W D, et al. Critical temperature-dependent shear band formation in CoCrNi alloy under high-temperature dynamic compression [J]. Journal of Alloys and Compounds, 2024, 1000: 175028. doi: 10.1016/j.jallcom.2024.175028 [25] 王建军, 袁康博, 张晓琼, 等. 第三型应变时效的提出与研究进展 [J]. 爆炸与冲击, 2021, 41(5): 051101. doi: 10.11883/bzycj-2020-0422WANG J J, YUAN K B, ZHANG X Q, et al. Proposition and research progress of the third-type strain aging [J]. Explosion and Shock Waves, 2021, 41(5): 051101. doi: 10.11883/bzycj-2020-0422 [26] MEYERS M A, LI Z Z, ZHAO S T, et al. Shear localization of fcc high-entropy alloys [J]. EPJ Web of Conferences, 2018, 183: 03028. doi: 10.1051/epjconf/201818303028 [27] WANG Z Q, BEYERLEIN I J, LESAR R. Dislocation motion in high strain-rate deformation [J]. Philosophical Magazine, 2007, 87(16): 2263–2279. doi: 10.1080/14786430601153422 [28] DONG J L, ZHANG X P, WANG G J, et al. Mechanical responses and crystal plasticity model of CoCrNi medium-entropy alloy under ramp wave compression [J]. Matter and Radiation at Extremes, 2024, 9(5): 057802. doi: 10.1063/5.0206773 [29] ZHANG J L, ZHANG Y Q, LI H M, et al. Determination of critical dynamic recrystallization conditions and mechanism analysis of Ti600 high-temperature titanium alloy [J]. Journal of Materials Engineering and Performance, 2021, 30(1): 229–238. doi: 10.1007/s11665-020-05270-2 [30] 马建强, 闫宏伟, 汪洋, 等. Cu-Sn合金的高温热模拟压缩晶界组织分析 [J]. 热加工工艺, 2019, 48(6): 55–57. doi: 10.14158/j.cnki.1001-3814.2019.06.013MA J Q, YAN H W, WANG Y, et al. Analysis on grain boundary microstructure of high temperature thermal simulation compression of Cu-Sn alloy [J]. Hot Working Technology, 2019, 48(6): 55–57. doi: 10.14158/j.cnki.1001-3814.2019.06.013 [31] 黄西成, 胡文军. Johnson-Cook本构参数的确定方法[C]//第六届全国爆炸力学实验技术学术会议论文集. 长沙: 中国力学学会爆炸力学专业委员会实验技术专业组, 2010: 8.HUANG X C, HU W J. Determination method of Johnson-Cook constitutive parameters [C]//Proceedings of the 6th National Academic Conference on Experimental Technology of Explosion Mechanics. Changsha: Experimental Technology Professional Group, Committee on Explosion Mechanics, Chinese Society of Theoretical and Applied Mechanics, 2010: 8. [32] 贾宝华, 刘思勇, 李革, 等. 基于J-C模型的TC18钛合金动态本构方程构建 [J]. 钛工业进展, 2018, 35(5): 24–28. doi: 10.13567/j.cnki.issn1009-9964.2018.05.005JIA B H, LIU S Y, LI G, et al. Establishment of dynamic constitutive equation for TC18 titanium alloy based on J-C model [J]. Titanium Industry Progress, 2018, 35(5): 24–28. doi: 10.13567/j.cnki.issn1009-9964.2018.05.005 [33] GAO C, IWAMOTO T. Instrumented Taylor impact test for measuring stress-strain curve through single trial [J]. International Journal of Impact Engineering, 2021, 157: 103980. doi: 10.1016/j.ijimpeng.2021.103980 [34] VOLLHÜTER J, BEZOLD A, KARPSTEIN N, et al. Strain rate-dependent anomalous work hardening of a single-crystalline CoNi-base superalloy [J]. Metallurgical and Materials Transactions A, 2023, 54(5): 1608–1619. doi: 10.1007/s11661-023-06966-5 -

下载:

下载: