| [1] |

CUI X T, ZHANG H W, WANG S X, et al. Design of lightweight multi-material automotive bodies using new material performance indices of thin-walled beams for the material selection with crashworthiness consideration [J]. Materials & Design, 2011, 32(2): 815–821.

|

| [2] |

EVANS A G. Lightweight materials and structures [J]. MRS Bulletin, 2001, 26(10): 790–797. doi: 10.1557/mrs2001.206

|

| [3] |

WANG D F, LI S H. Material selection decision-making method for multi-material lightweight automotive body driven by performance [J]. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2022, 236(4): 730–746. doi: 10.1177/14644207211055661

|

| [4] |

XIONG F, WANG D F, MA Z D, et al. Structure-material integrated multi-objective lightweight design of the front end structure of automobile body [J]. Structural and Multidisciplinary Optimization, 2018, 57(2): 829–847. doi: 10.1007/s00158-017-1778-1

|

| [5] |

LI Z M, TASAN C C, PRADEEP K G, et al. A TRIP-assisted dual-phase high-entropy alloy: grain size and phase fraction effects on deformation behavior [J]. Acta Materialia, 2017, 131: 323–335. doi: 10.1016/j.actamat.2017.03.069

|

| [6] |

TASAN C C, DIEHL M, YAN D, et al. An overview of dual-phase steels: advances in microstructure-oriented processing and micromechanically guided design [J]. Annual Review of Materials Research, 2015, 45: 391–431. doi: 10.1146/annurev-matsci-070214-021103

|

| [7] |

HUA X J, HU P, XING H R, et al. Development and property tuning of refractory high-entropy alloys: a review [J]. Acta Metallurgica Sinica (English Letters), 2022, 35(8): 1231–1265. doi: 10.1007/s40195-022-01382-x

|

| [8] |

ZHOU J L, CHENG Y H, CHEN Y X, et al. Composition design and preparation process of refractory high-entropy alloys: a review [J]. International Journal of Refractory Metals and Hard Materials, 2022, 105: 105836. doi: 10.1016/j.ijrmhm.2022.105836

|

| [9] |

LIU K, WANG J Y, LI X, et al. A new lightweight Al2.7TiVCrCu high entropy alloy with excellent strength and toughness after homogenization treatment [J]. Materials Science and Engineering: A, 2023, 869: 144779. doi: 10.1016/j.msea.2023.144779

|

| [10] |

FAN X J, QU R T, ZHANG Z F. Remarkably high fracture toughness of HfNbTaTiZr refractory high-entropy alloy [J]. Journal of Materials Science & Technology, 2022, 123: 70–77.

|

| [11] |

JIANG W T, WANG X H, KANG H J, et al. Microstructure and mechanical properties of AlNbTiVZr system refractory high entropy alloys [J]. Journal of Alloys and Compounds, 2022, 925: 166767. doi: 10.1016/j.jallcom.2022.166767

|

| [12] |

ZHANG Y S, WANG H M, ZHU Y Y, et al. High specific yield strength and superior ductility of a lightweight refractory high-entropy alloy prepared by laser additive manufacturing [J]. Additive Manufacturing, 2023, 77: 103813. doi: 10.1016/j.addma.2023.103813

|

| [13] |

申会鹏, 张天宇, 李行雨, 等. 点阵结构单元力学性能及在结构轻量化设计中的应用 [J]. 机电工程, 2024, 41(7): 1276–1284. doi: 10.3969/j.issn.1001-4551.2024.07.016SHEN H P, ZHANG T Y, LI H Y, et al. Mechanical performance of lattice structure units and its application in lightweight design of structures [J]. Journal of Mechanical & Electrical Engineering, 2024, 41(7): 1276–1284. doi: 10.3969/j.issn.1001-4551.2024.07.016

|

| [14] |

王鹏欢, 汤名锴, 王森林. 激光选区熔化成形多层级Gyroid点阵结构的力学性能研究 [J]. 力学学报, 2024, 57(1): 148–161.WANG P H, TANG M K, WANG S L. Mechanical properties of multi-level Gyroid lattice structures fabricated by selective laser melting [J]. Chinese Journal of Theoretical and Applied Mechanics, 2025, 57(1): 148–161.

|

| [15] |

常超, 马桢, 褚井泉, 等. 基于增材制造空心点阵结构的压缩变形研究 [J]. 高压物理学报, 2022, 36(2): 024101. doi: 10.11858/gywlxb.20210885CHANG C, MA Z, CHU J Q, et al. Research on compression deformation of hollow lattice structure based on additive manufacturing [J]. Chinese Journal of High Pressure Physics, 2022, 36(2): 024101. doi: 10.11858/gywlxb.20210885

|

| [16] |

王向明, 苏亚东, 吴斌, 等. 微桁架点阵结构在飞机结构/功能一体化中的应用 [J]. 航空制造技术, 2018, 61(10): 16–25.WANG X M, SU Y D, WU B, et al. Application for additive manufacturing of lattice materials on integrated aircraft structures and functions [J]. Aeronautical Manufacturing Technology, 2018, 61(10): 16–25.

|

| [17] |

顾晓春, 刘亚波, 钱远宏, 等. 含缺陷点阵结构的力学性能影响研究 [J]. 失效分析与预防, 2020, 15(2): 91–96. doi: 10.3969/j.issn.1673-6214.2020.02.005GU X C, LIU Y B, QIAN Y H, et al. Study on mechanical properties of lattice structure with defects [J]. Failure Analysis and Prevention, 2020, 15(2): 91–96. doi: 10.3969/j.issn.1673-6214.2020.02.005

|

| [18] |

陈昇声, 张旭. 不同热处理方式对AlSi10Mg点阵结构压缩性能的影响 [J]. 材料科学, 2024, 14(6): 946–956. doi: 10.12677/ms.2024.146107CHEN S S, ZHANG X. The influence of different heat treatment methods on the compressive performance of AlSi10Mg lattice structure [J]. Material Sciences, 2024, 14(6): 946–956. doi: 10.12677/ms.2024.146107

|

| [19] |

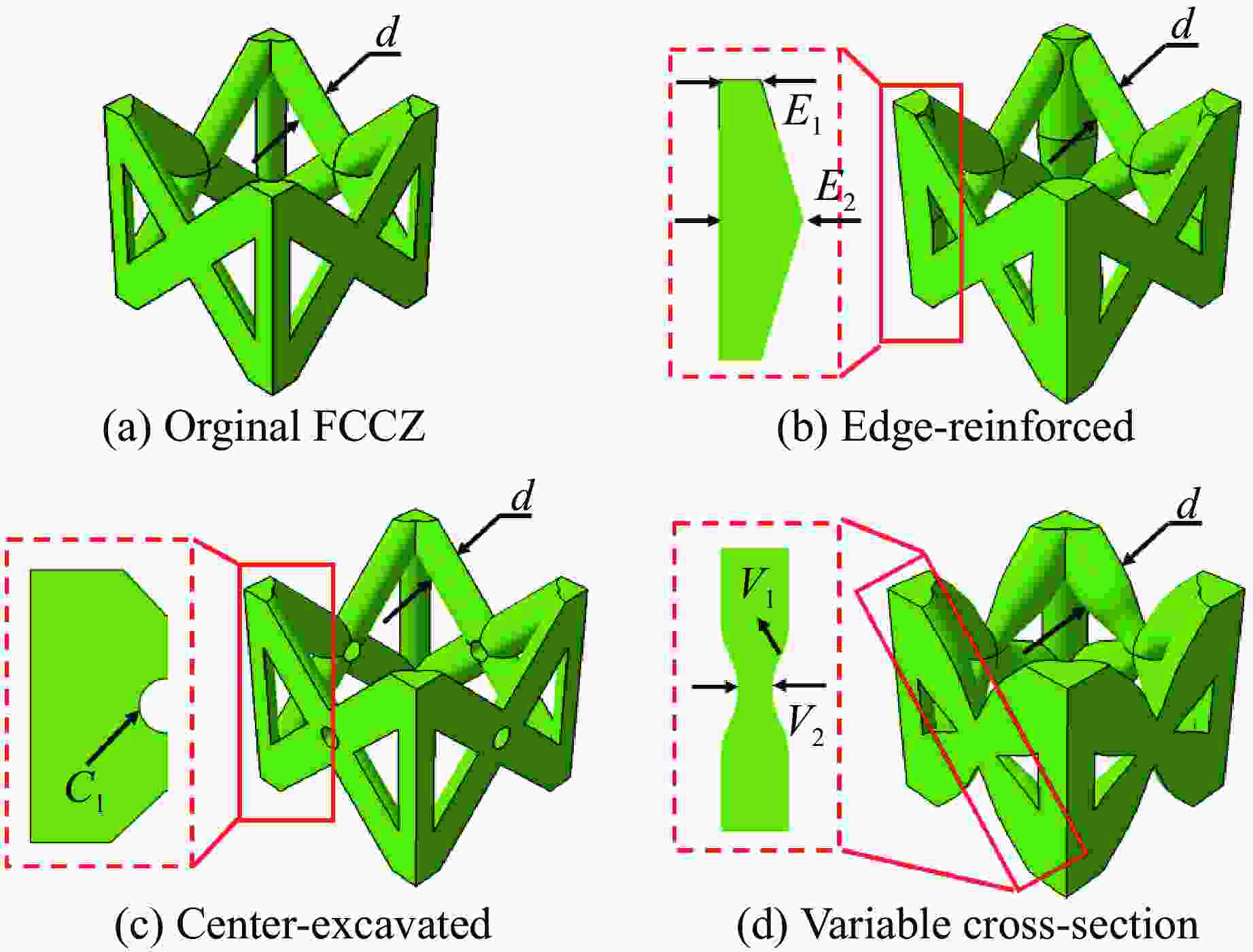

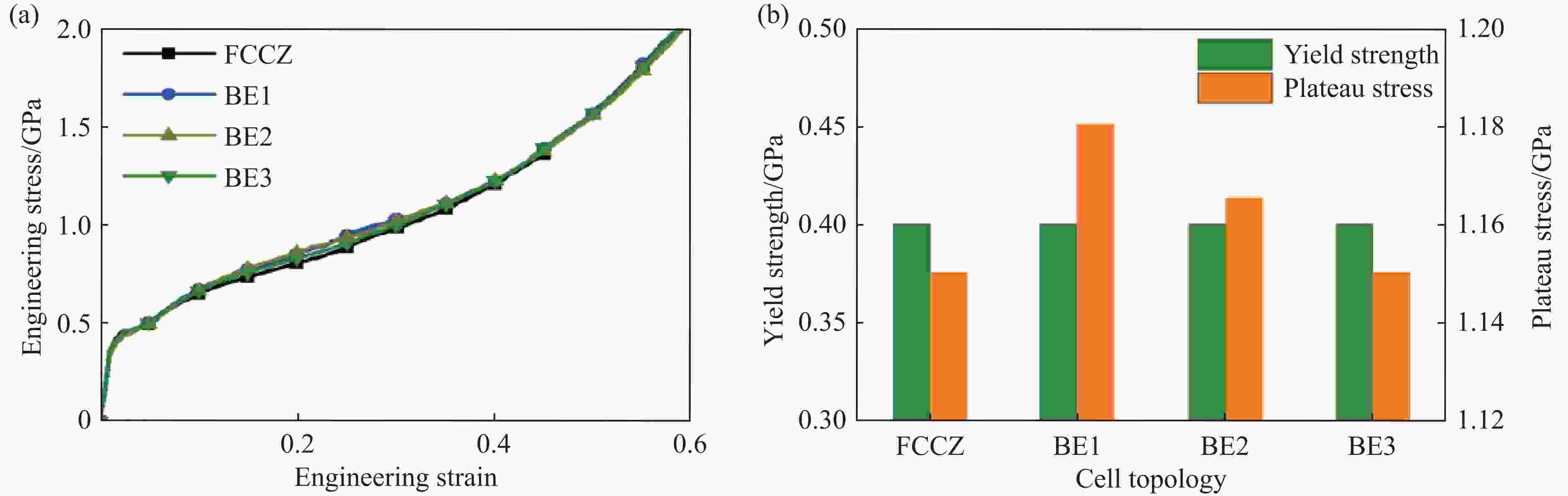

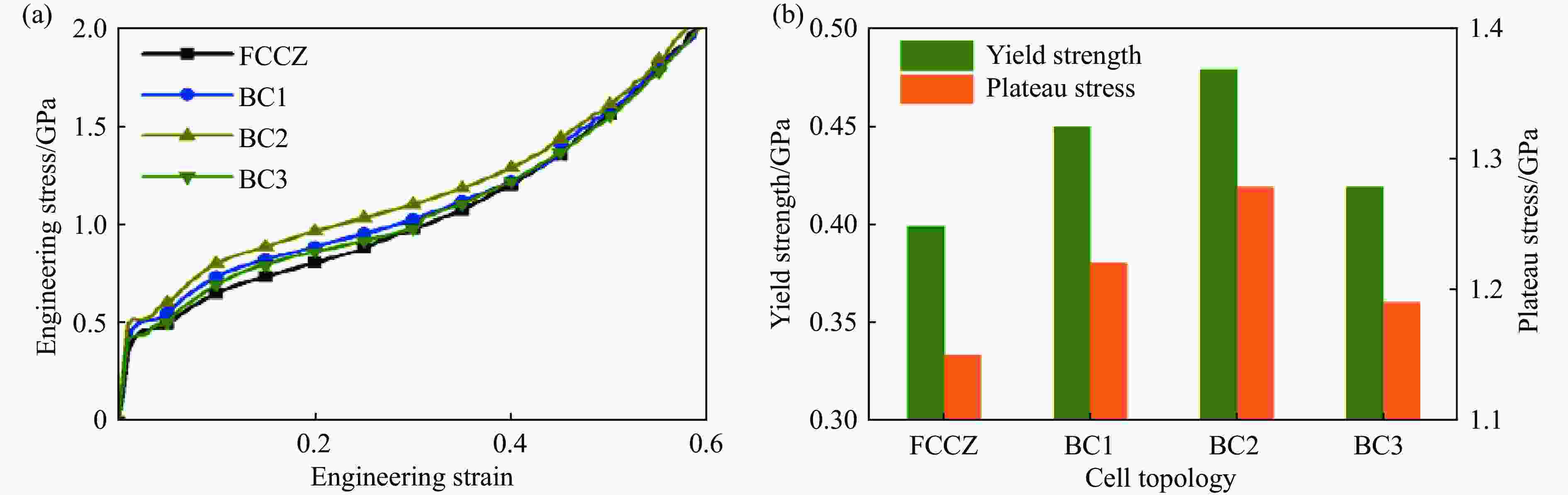

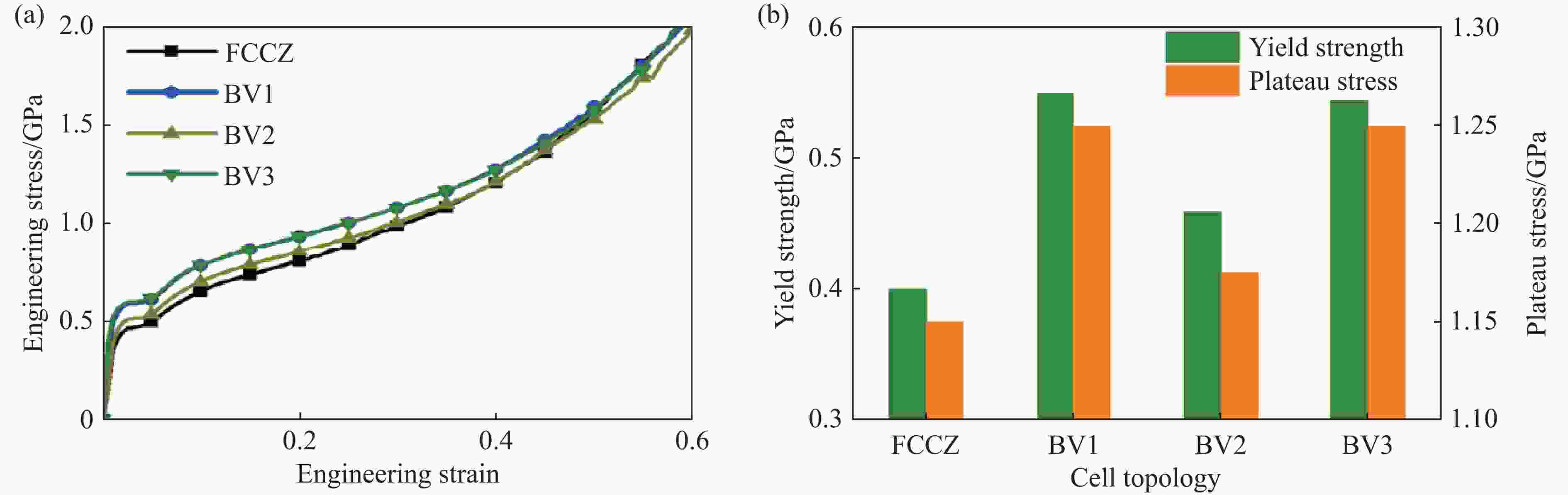

郭璐, 刘志芳, 李世强, 等. 改进型FCC晶格材料设计与吸能特性 [J]. 高压物理学报, 2022, 36(1): 014206. doi: 10.11858/gywlxb.20210853GUO L, LIU Z F, LI S Q, et al. Design and energy absorption characteristic of improved FCC lattice materials [J]. Chinese Journal of High Pressure Physics, 2022, 36(1): 014206. doi: 10.11858/gywlxb.20210853

|

| [20] |

李腾, 张晨帆, 邓庆田, 等. 基于TPU材料层级结构的优化设计及吸能特性 [J]. 高压物理学报, 2022, 36(6): 064104. doi: 10.11858/gywlxb.20220542LI T, ZHANG C F, DENG Q T, et al. Optimized design and energy absorption of TPU material based on hierarchical structure [J]. Chinese Journal of High Pressure Physics, 2022, 36(6): 064104. doi: 10.11858/gywlxb.20220542

|

| [21] |

辛春亮, 薛再清, 涂建, 等. 有限元分析常用材料参数手册 [M]. 北京: 机械工业出版社, 2020: 90–95.XIN C L, XUE Z Q, TU J, et al. Finite element analysis handbook of common material parameters [M]. Beijing: China Machine Press, 2020: 90–95.

|

| [22] |

ZHOU X, QU C, LUO Y, et al. Compression behavior and impact energy absorption characteristics of 3D printed polymer lattices and their hybrid sandwich structures [J]. Journal of Materials Engineering and Performance, 2021, 30(12): 8763–8770. doi: 10.1007/s11665-021-06242-w

|

| [23] |

张武昆, 赵剑, 谭永华, 等. 不同增强方向的带支柱体心立方点阵及其填充结构的压缩力学性能分析 [J]. 中国机械工程, 2024, 35(9): 1642–1652. doi: 10.3969/j.issn.1004-132X.2024.09.014ZHANG W K, ZHAO J, TAN Y H, et al. Analysis of compressive mechanics properties of body centered cubic lattice with pillars in different reinforcement directions and their filling structures [J]. China Mechanical Engineering, 2024, 35(9): 1642–1652. doi: 10.3969/j.issn.1004-132X.2024.09.014

|

| [24] |

YANG Y, WANG S, YAN S, et al. Enhancing the mechanical performance of additively manufactured lattice structure via locally reinforcing struts: coupled influence of structure and microstructure [J]. Materials Science and Engineering: A, 2025, 927: 147989. doi: 10.1016/j.msea.2025.147989

|

| [25] |

CAO X F, XIAO D B, LI Y, et al. Dynamic compressive behavior of a modified additively manufactured rhombic dodecahedron 316L stainless steel lattice structure [J]. Thin-Walled Structures, 2020, 148: 106586. doi: 10.1016/j.tws.2019.106586

|

| [26] |

FAN X J, TANG Q, FENG Q X, et al. Design, mechanical properties and energy absorption capability of graded-thickness triply periodic minimal surface structures fabricated by selective laser melting [J]. International Journal of Mechanical Sciences, 2021, 204: 106586. doi: 10.1016/j.ijmecsci.2021.106586

|

| [27] |

XU S C, CHEN N, QIN H Y, et al. Biomimetic study of a honeycomb energy absorption structure based on straw micro-porous structure [J]. Biomimetics, 2024, 9(1): 60. doi: 10.3390/biomimetics9010060

|

| [28] |

ZHAO X J, LI Z Z, ZOU Y P, et al. Compressive characteristics and energy absorption capacity of automobile energy-absorbing box with filled porous TPMS structures [J]. Applied Sciences, 2024, 14(9): 3790. doi: 10.3390/app14093790

|

| [29] |

WANG H, TAN D W, LIU Z P, et al. On crashworthiness of novel porous structure based on composite TPMS structures [J]. Engineering Structures, 2022, 252: 113640. doi: 10.1016/j.engstruct.2021.113640

|

| [30] |

王春国, 文安松, 范子豪, 等. 泡沫增强复合材料点阵夹芯梁抗冲击性能 [J]. 高压物理学报, 2022, 36(1): 014201. doi: 10.11858/gywlxb.20210807WANG C G, WEN A S, FAN Z H, et al. Dynamic failure of foam-reinforce composite lattice sandwich beam to local impulsive load [J]. Chinese Journal of High Pressure Physics, 2022, 36(1): 014201. doi: 10.11858/gywlxb.20210807

|

| [31] |

杨帆, 卞奕杰, 王鹏, 等. 界面增强多晶点阵结构的耐撞吸能性能 [J]. 高压物理学报, 2022, 36(2): 024201. doi: 10.11858/gywlxb.20210827YANG F, BIAN Y J, WANG P, et al. Crashworthiness and energy absorption properties of polycrystal-like lattice structures strengthened by interfaces [J]. Chinese Journal of High Pressure Physics, 2022, 36(2): 024201. doi: 10.11858/gywlxb.20210827

|

下载:

下载: