Influence of Silicon Nitride Content on Explosive Performance of Bulk Emulsion Explosive

-

摘要: 为了提高现场混装乳化炸药的爆炸性能,将氮元素含量丰富的氮化硅引入炸药,通过空中爆炸、爆速和铅柱压缩实验,测定氮化硅含量对现场混装乳化炸药空中冲击波参数、爆速和猛度的影响。实验结果表明,随着氮化硅的质量分数从0%提升至1.2%:炸药密度由1.02 g/cm3提升至1.11 g/cm3,空中冲击波压力峰值由

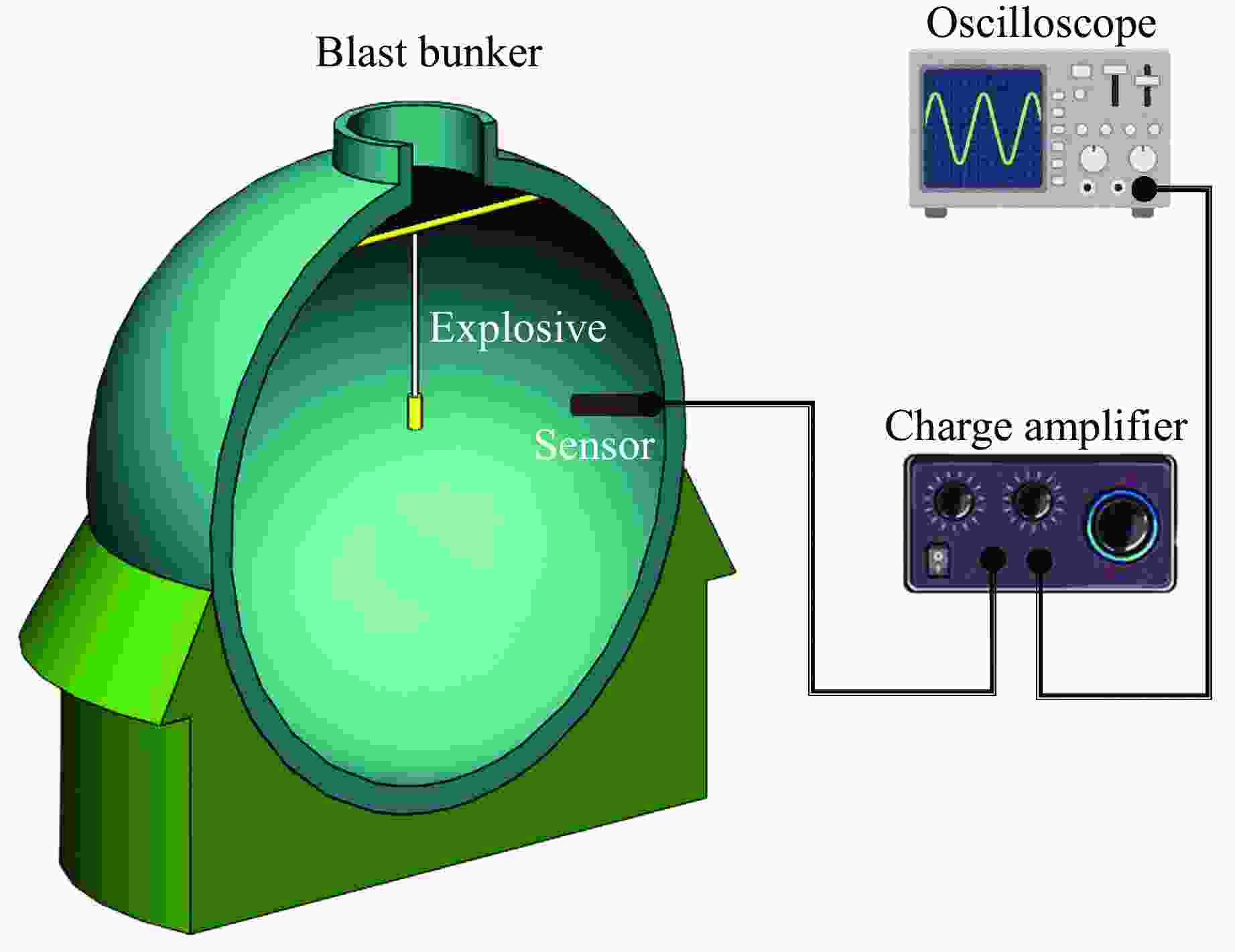

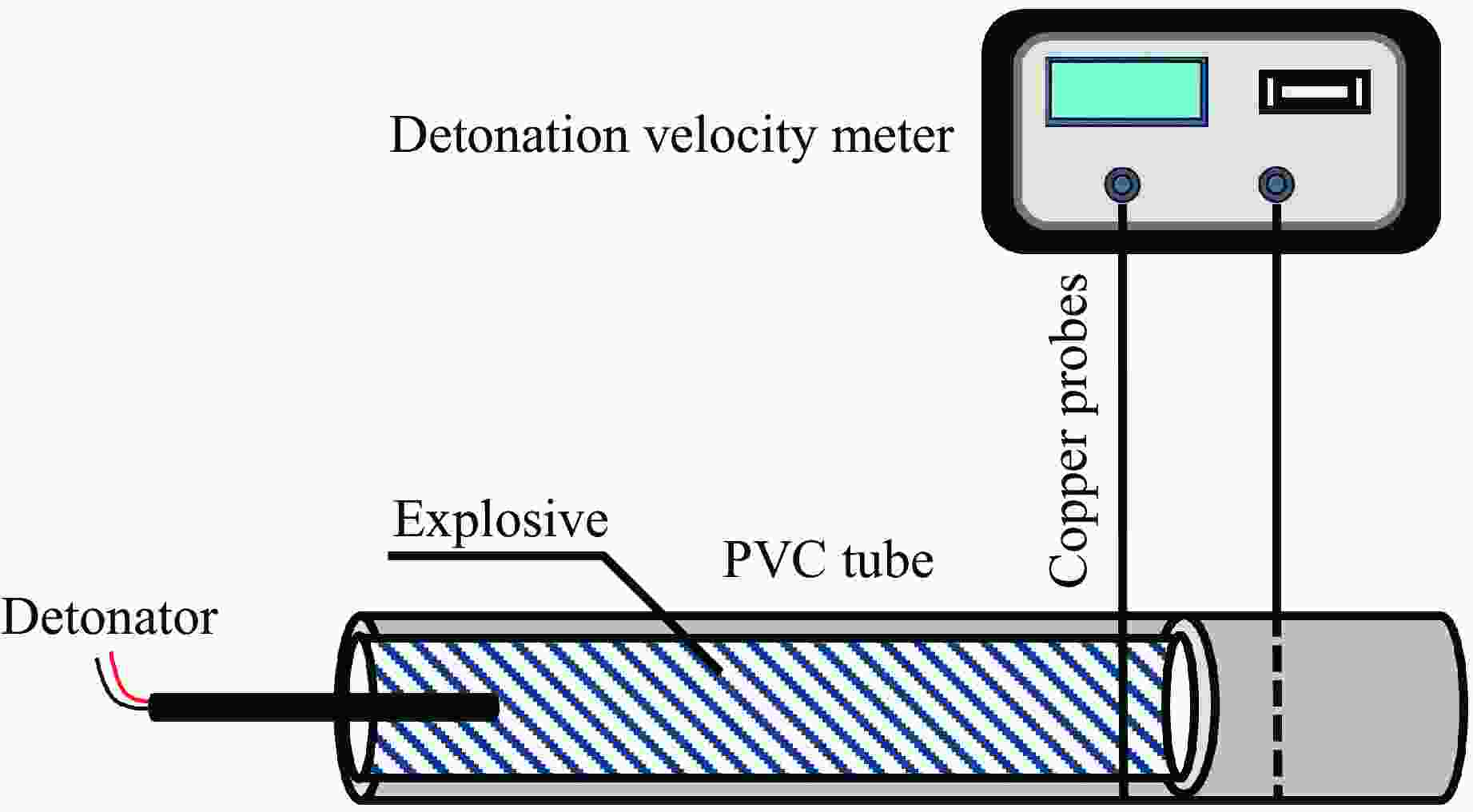

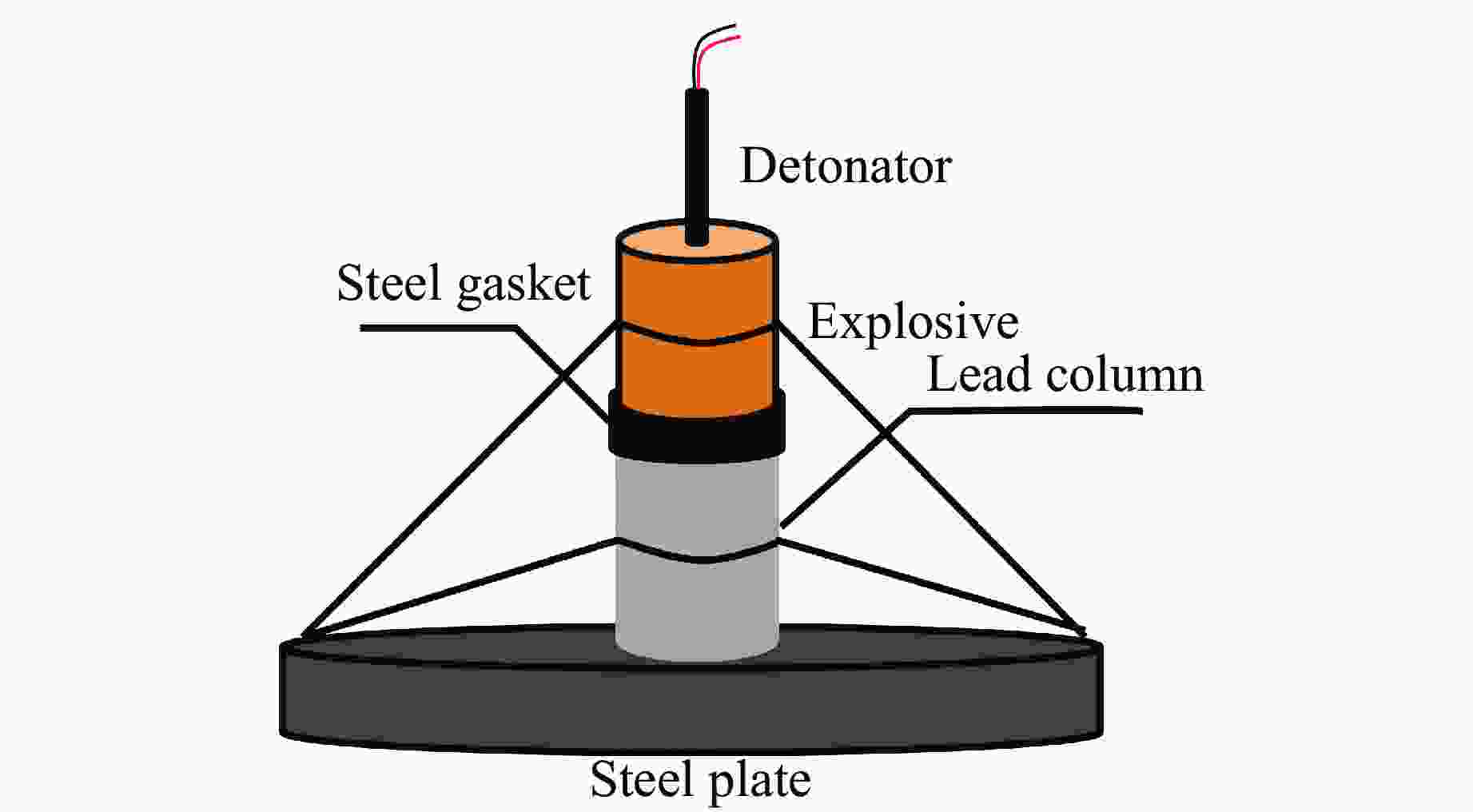

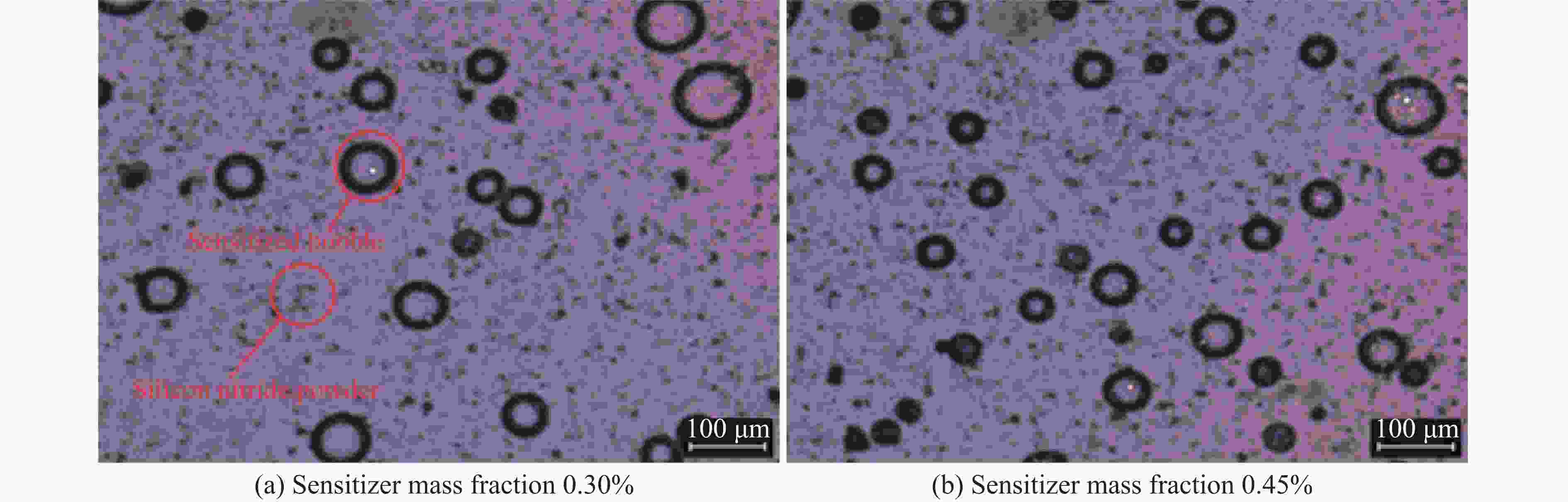

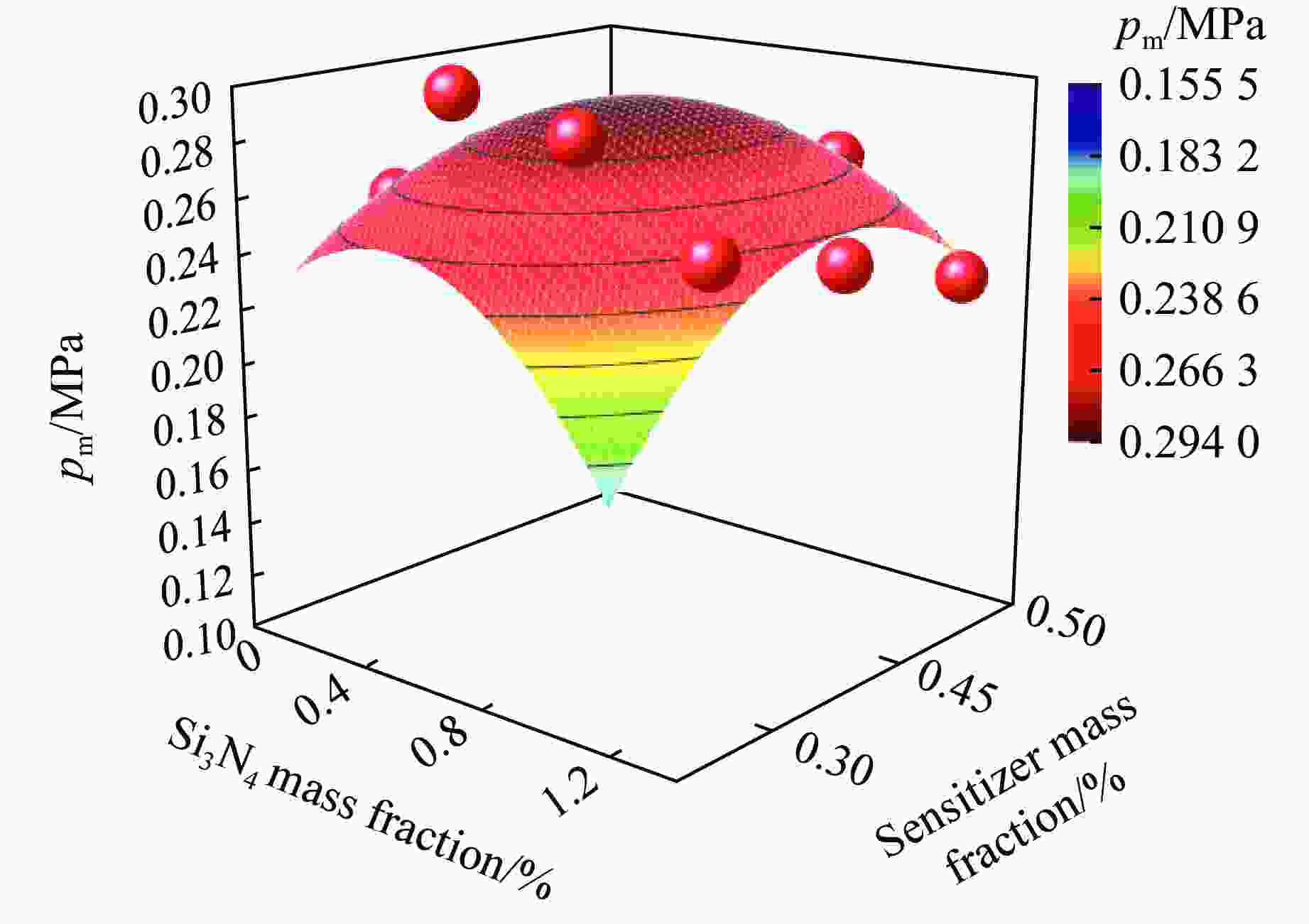

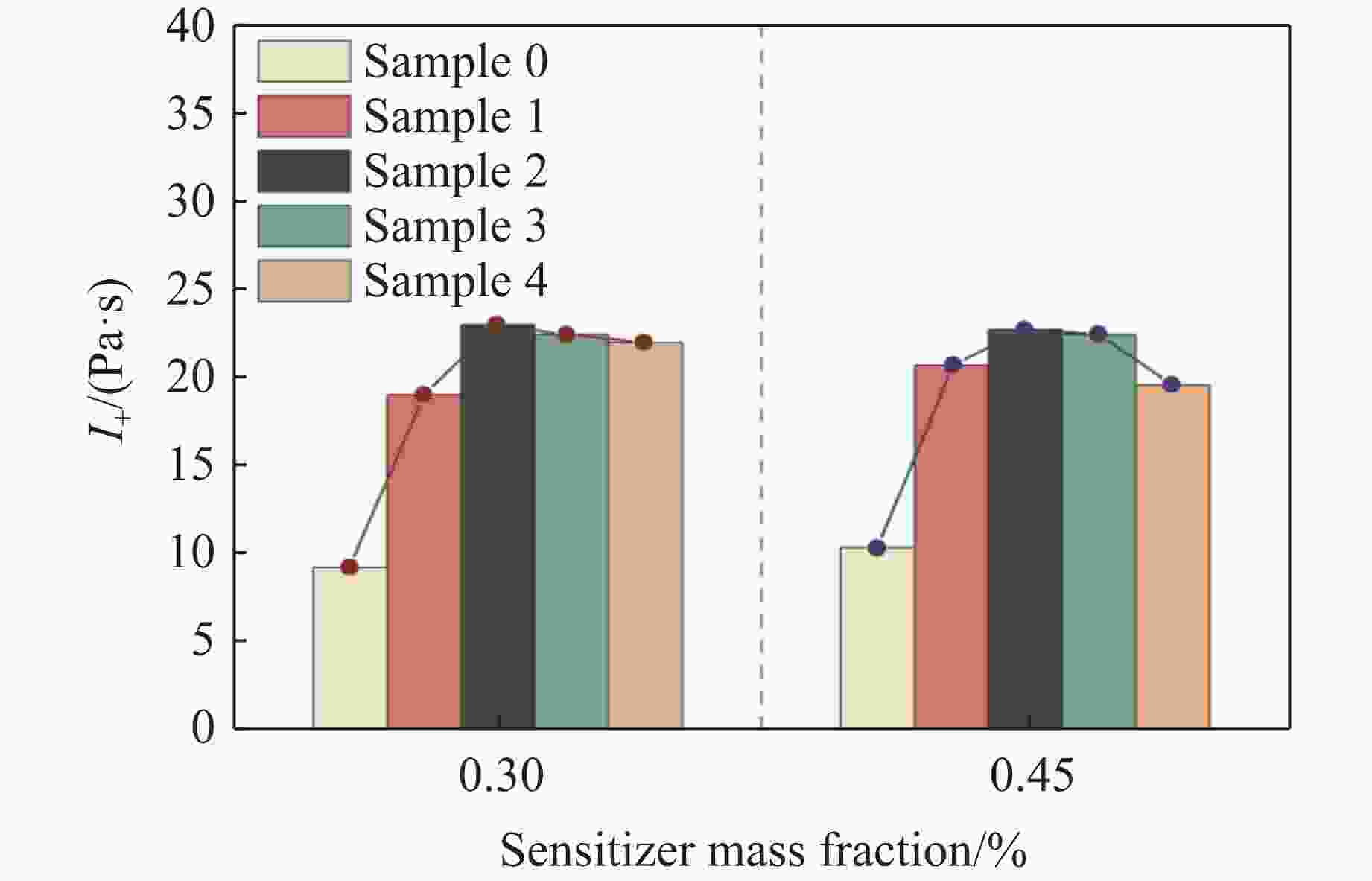

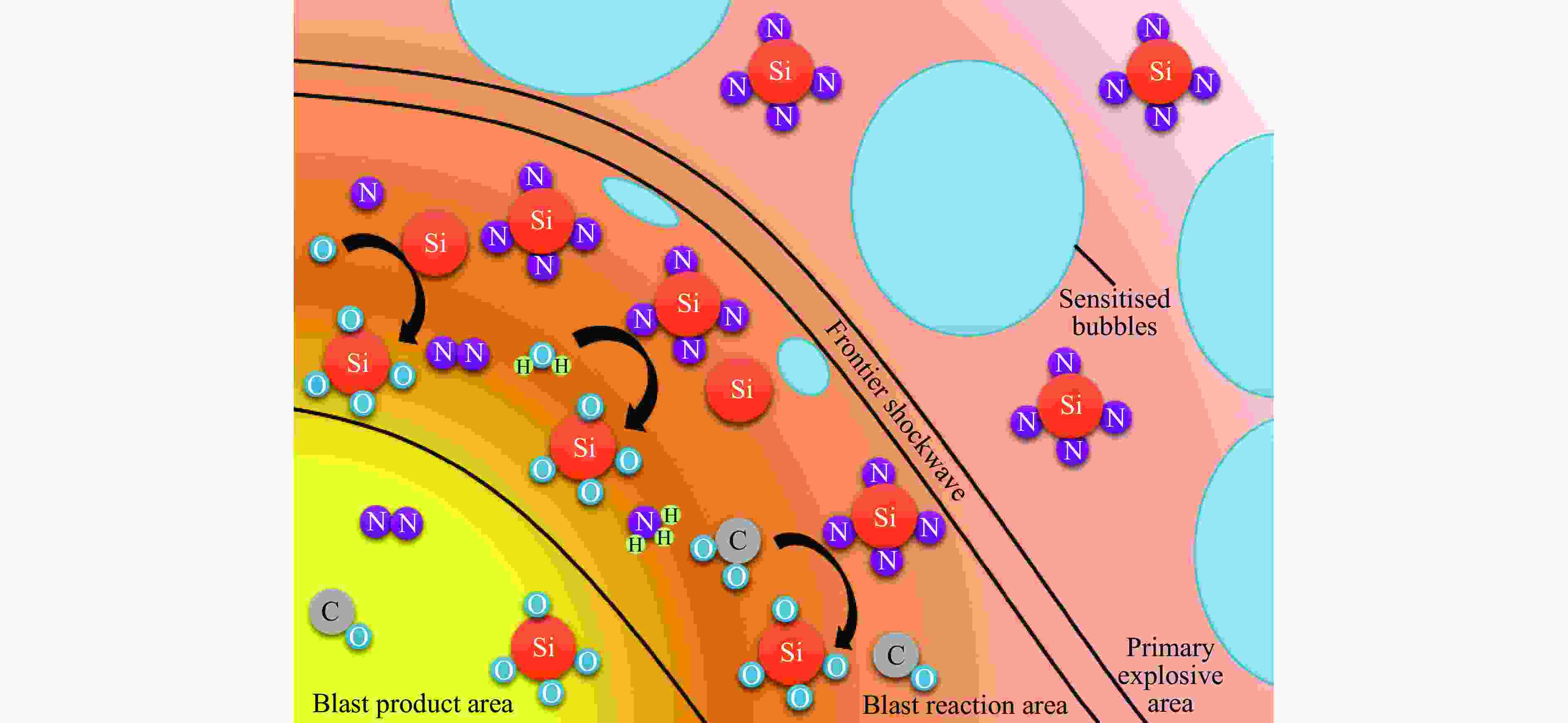

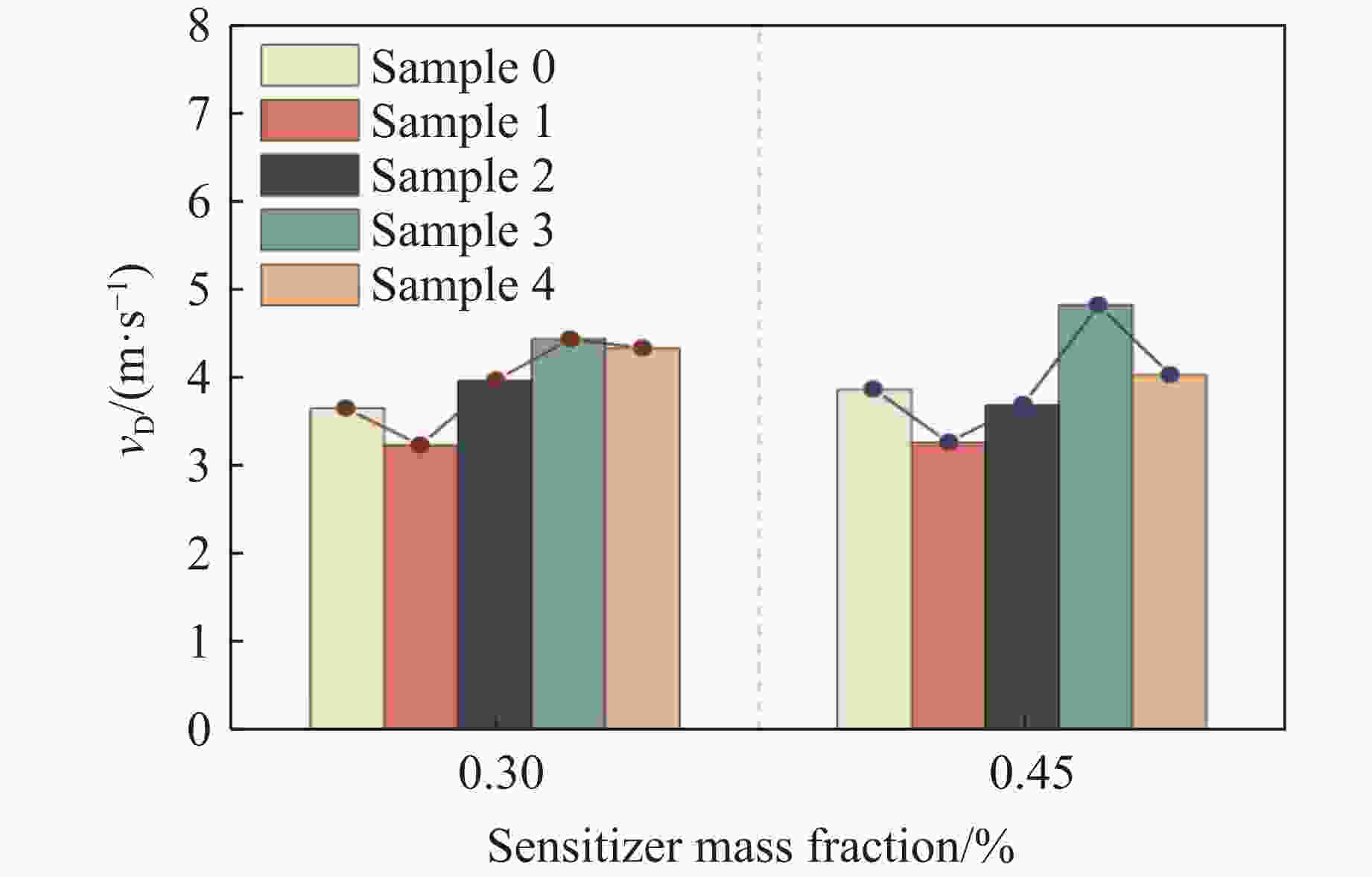

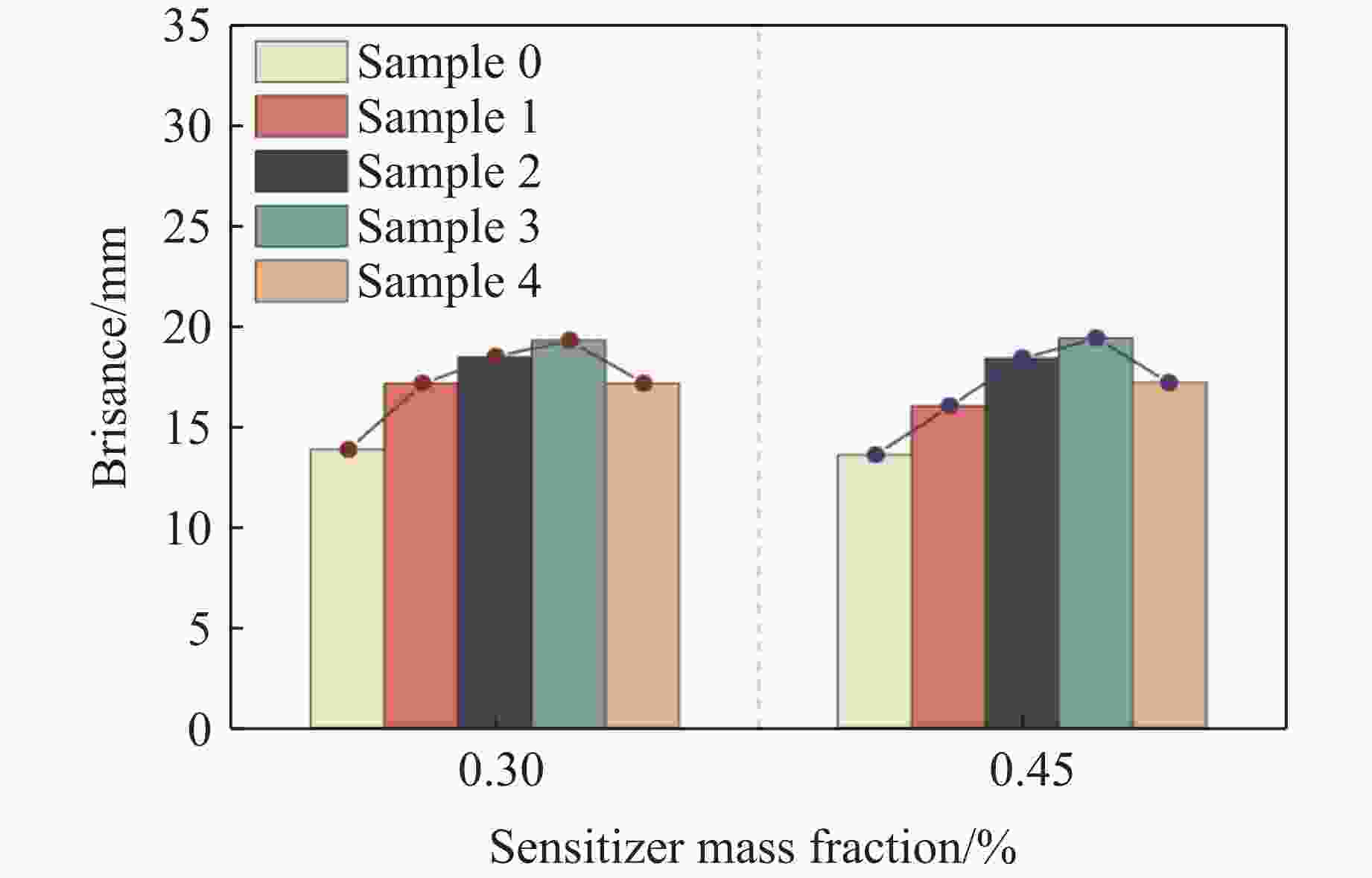

0.1156 MPa提升至0.2977 MPa再下降到0.2408 MPa,最大峰值为最小值的2.58倍;比冲量由9.22 Pa·s提升至23.00 Pa·s,而后下降到19.59 Pa·s,最大比冲量为最小值的2.49倍;爆速则呈现先下降至3265.66 m/s后上升至4830.60 m/s再下降至4541.51 m/s的变化趋势,最大爆速为最小值的1.48倍;猛度由13.86 mm提升至19.40 mm再缩减到17.18 mm,最大猛度为最小值的1.40倍。实验结果显示,氮化硅能够提高现场混装乳化炸药的爆炸性能,对现场混装乳化炸药配方优化设计具有一定的参考意义。Abstract: Silicon nitride, with high nitrogen content, was added to improve the explosive performance of bulk emulsion explosive. The influence of silicon nitride content on the air shock wave parameters, detonation velocity, and brisance was investigated by air blast experiments, detonation velocity tests, and lead column compression experiments. The results showed that: with the silicon nitride mass fraction increasing from 0% to 1.2%, the density of the explosive increased from 1.02 g/cm3 to 1.11 g/cm3, the air shock wave pressure peak increased from0.1156 MPa to0.2977 MPa and then decreased to0.2408 MPa, with the maximum peak value being 2.58 times that of the minimum. The specific impulse increased from 9.22 Pa·s to 23.00 Pa·s and then decreased to 19.59 Pa·s, with the maximum specific impulse being 2.49 times that of the minimum value. The detonation velocity showed a trend of decreasing to3265.66 m/s, then increasing to4830.60 m/s, and finally decreasing to4541.51 m/s, with the maximum detonation velocity being 1.48 times that of the minimum. The brisance increased from 13.86 mm to 19.40 mm and then decreased to 17.18 mm, with the maximum brisance being 1.40 times that of the minimum. From the experimental results, it can be concluded that silicon nitride can improve the explosive performance of bulk emulsion explosives, which is of reference significance for the optimal design of bulk emulsion explosives formulations.-

Key words:

- emulsion explosive /

- on-site mixed /

- silicon nitride /

- detonation performance /

- brisance

-

表 1 现场混装乳化炸药原材料和爆炸产物的物化参数

Table 1. Physicochemical parameters of raw materials and explosive products of field mixed emulsion explosives

Material Relative molecular mass/(g·mol−1) Heat of formation/(kJ·mol−1) Oxygen balance/(g·g−1) NH4NO3 80.04 353.46 0.20 NaNO3 84.99 462.66 0.47 H2O 18.01 286.20 0 C18H38 254.51 558.96 −3.46 C16H32 224.44 661.55 −3.42 C24H44O6 428.63 894.52 −2.39 Si3N4 140.28 751.57 −0.68 SiO2 60.08 910.90 0 N2 28.01 0 0 CO 28.01 111.47 −0.57 CO2 44.01 393.50 0 Na2O 61.98 414.22 0 表 2 爆炸参数理论计算结果

Table 2. Theoretical calculation results of explosion parameters

Sample nOB/(g·g−1) QV/(kJ·kg−1) vD/(m·s−1) p/GPa TB/K 0 − 0.0718 2491.29 4380.92 4.90 2044.30 1 − 0.0732 2519.71 4404.29 4.96 2058.13 2 − 0.0745 2548.13 4427.51 5.01 2071.89 3 − 0.0772 2604.98 4473.51 5.11 2099.19 4 − 0.0800 2661.82 4518.93 5.22 2126.22 表 3 炸药样品的密度

Table 3. Density of explosive samples

Sensitizer mass fraction/% Explosive sample density/(g·cm−3) Sample 0 Sample 1 Sample 2 Sample 3 Sample 4 0.30 1.02 1.03 1.07 1.09 1.11 0.45 0.93 0.95 0.97 1.01 1.05 表 4 不同炸药样品的空中冲击波参数

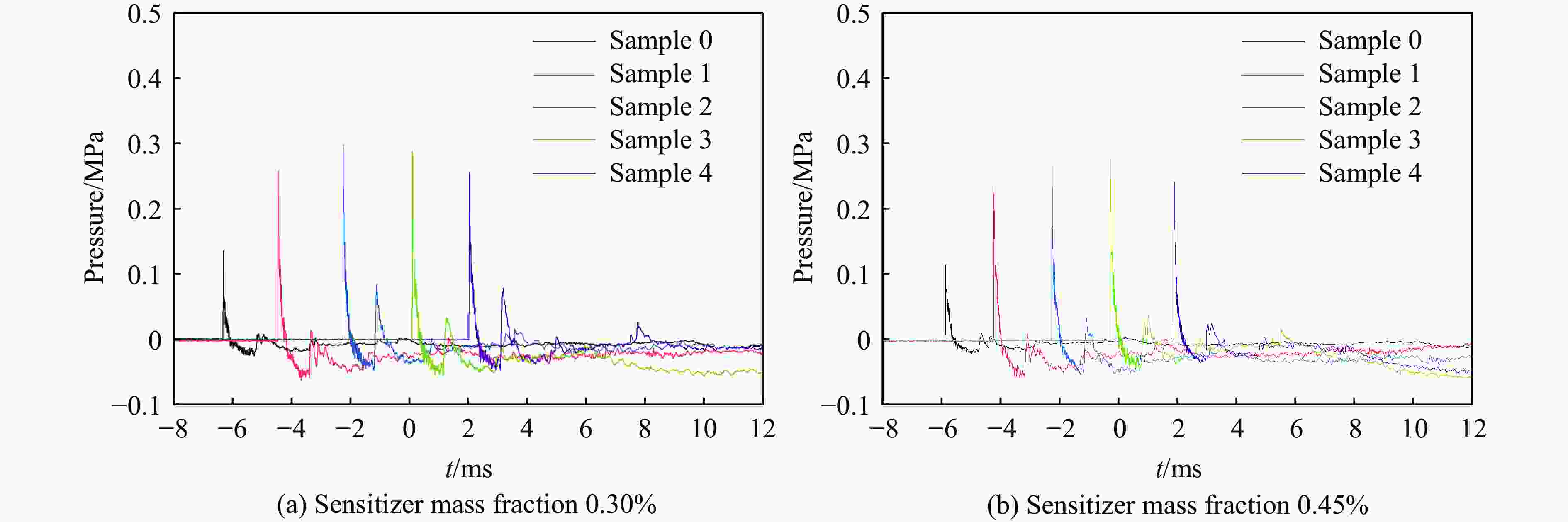

Table 4. Parameters of the airborne shock wave of different explosive samples

Sample Sensitizer mass fraction/% Peak pressure/MPa Positive pressure time/μs Specific impulse/(Pa·s) 0 0.30 0.1364 229.92 9.22 0.45 0.1156 243.37 10.38 1 0.30 0.2576 292.87 19.04 0.45 0.2352 268.97 20.70 2 0.30 0.2977 270.56 23.00 0.45 0.2653 310.34 22.74 3 0.30 0.2888 267.74 22.46 0.45 0.2776 297.31 22.46 4 0.30 0.2558 310.48 21.99 0.45 0.2408 301.37 19.59 表 5 不同炸药样品的爆速

Table 5. Detonation velocity of different explosive samples

Sample Sensitizer mass fraction/% Experimental detonation velocity/(m·s−1) Theoretical detonation velocity/(m·s−1) 0 0.30 3654.62 4380.92 0.45 3867.45 4380.92 1 0.30 3236.24 4404.29 0.45 3265.66 4404.29 2 0.30 3968.25 4427.51 0.45 3692.76 4427.51 3 0.30 4440.50 4473.51 0.45 4830.60 4473.51 4 0.30 4332.76 4518.93 0.45 4541.51 4518.93 表 6 不同炸药样品的猛度

Table 6. Brisance of different explosive samples

Sample Sensitizer mass fraction/% Brisance/mm 0 0.30 13.86 0.45 13.59 1 0.30 17.15 0.45 16.03 2 0.30 18.45 0.45 18.41 3 0.30 19.30 0.45 19.40 4 0.30 17.16 0.45 17.18 -

[1] 汪旭光. 乳化炸药 [M]. 2版. 北京: 冶金工业出版社, 2008.WANG X G. Emulsion explosives [M]. 2nd ed. Beijing: Metallurgical Industry Press, 2008. [2] 钱海. 铝粉对乳化炸药爆炸性能和热安定性的影响 [D]. 淮南: 安徽理工大学, 2017.QIAN H. Effect of aluminum powder on detonation performance and thermal stability of emulsion explosives [D]. Huainan: Anhui University of Science and Technology, 2017. [3] YUNOSHEV A S, PLASTININ A V, VORONIN M S. Effect of aluminum additive on the detonation velocity and acceleration ability of an emulsion explosive [J]. Combustion, Explosion, and Shock Waves, 2021, 57(6): 719–725. doi: 10.1134/S0010508221060113 [4] MISHRA A K, AGRAWAL H, RAUT M. Effect of aluminum content on detonation velocity and density of emulsion explosives [J]. Journal of Molecular Modeling, 2019, 25(3): 70. doi: 10.1007/s00894-019-3961-3 [5] 龚悦, 何杰, 汪旭光, 等. 钛粉对乳化炸药爆轰性能和热分解特性的影响 [J]. 含能材料, 2017, 25(4): 304–308. doi: 10.11943/j.issn.1006-9941.2017.04.006GONG Y, HE J, WANG X G, et al. Influence of titanium powder on detonation performances and thermal decomposition characteristics of emulsion explosive [J]. Chinese Journal of Energetic Materials, 2017, 25(4): 304–308. doi: 10.11943/j.issn.1006-9941.2017.04.006 [6] 程扬帆, 汪泉, 龚悦, 等. MgH2型复合敏化储氢乳化炸药的制备及其爆轰性能 [J]. 化工学报, 2017, 68(4): 1734–1739. doi: 10.11949/j.issn.0438-1157.20161341CHENG Y F, WANG Q, GONG Y, et al. Preparation and detonation properties of MgH2 type of composite sensitized emulsion explosives [J]. CIESC Journal, 2017, 68(4): 1734–1739. doi: 10.11949/j.issn.0438-1157.20161341 [7] 程扬帆, 汪泉, 龚悦, 等. 敏化方式对MgH2型储氢乳化炸药爆轰性能的影响 [J]. 含能材料, 2017, 25(2): 167–172. doi: 10.11943/j.issn.1006-9941.2017.02.013CHENG Y F, WANG Q, GONG Y, et al. Effect of sensitizing methods on the detonation performances of MgH2-based hydrogen storage emulsion explosives [J]. Chinese Journal of Energetic Materials, 2017, 25(2): 167–172. doi: 10.11943/j.issn.1006-9941.2017.02.013 [8] CHENG Y F, MA H H, LIU R, et al. Explosion power and pressure desensitization resisting property of emulsion explosives sensitized by MgH2 [J]. Journal of Energetic Materials, 2014, 32(3): 207–218. doi: 10.1080/07370652.2013.818078 [9] CHENG Y F, MENG X R, FENG C T, et al. The effect of the hydrogen containing material TiH2 on the detonation characteristics of emulsion explosives [J]. Propellants, Explosives, Pyrotechnics, 2017, 42(6): 585–591. doi: 10.1002/prep.201700045 [10] WANG F, MA H H, SHEN Z W. Experimental study on the effect of titanium hydride content on the detonation performance of emulsion explosives [J]. Propellants, Explosives, Pyrotechnics, 2024, 49(2): e202300235. doi: 10.1002/prep.202300235 [11] LIU R, WANG X G, WANG H, et al. Thermal decomposition behaviors and reaction mechanism of emulsion explosive with the addition of TiH2 powders [J]. Case Studies in Thermal Engineering, 2025, 65: 105583. doi: 10.1016/j.csite.2024.105583 [12] 张续, 吴红波, 张洪, 等. 油相材料对现场混装乳化炸药性能的影响 [J]. 安徽化工, 2019, 45(4): 65–67. doi: 10.3969/j.issn.1008-553X.2019.04.021ZHANG X, WU H B, ZHANG H, et al. Effect of oil phase materials on the performance of field mixed emulsion explosive [J]. Anhui Chemical Industry, 2019, 45(4): 65–67. doi: 10.3969/j.issn.1008-553X.2019.04.021 [13] 刘锋, 何祥, 吴攀宇, 等. 内相粒径对现场混装乳化炸药爆炸性能的影响 [J]. 火炸药学报, 2023, 46(9): 825–833. doi: 10.14077/j.issn.1007-7812.202211024LIU F, HE X, WU P Y, et al. Effect of internal phase particle size on explosion performance of on-site mixed emulsion explosive [J]. Chinese Journal of Explosives & Propellants, 2023, 46(9): 825–833. doi: 10.14077/j.issn.1007-7812.202211024 [14] 牛草原, 黄文尧, 刘小辉, 等. 多孔粒状硝酸铵质量分数对现场混装乳化炸药的性能影响 [J]. 火炸药学报, 2023, 46(11): 999–1006. doi: 10.14077/j.issn.1007-7812.202302017NIU C Y, HUANG W Y, LIU X H, et al. Influence of porous granular ammonium nitrate content on the performance of field mixed emulsion explosive [J]. Chinese Journal of Explosives & Propellants, 2023, 46(11): 999–1006. doi: 10.14077/j.issn.1007-7812.202302017 [15] 匡照. 氮化铝质量分数对现场混装乳化炸药性能的影响 [D]. 淮南: 安徽理工大学, 2024.KUANG Z. Effect of aluminum nitride content on the performance of field-mixed emulsion explosives [D]. Huainan: Anhui University of Science and Technology, 2024. [16] 郇昌天, 李强, 蒋丹宇. 氮化硅陶瓷的应用和酸腐蚀研究进展 [J]. 现代技术陶瓷, 2011, 32(3): 3–8. doi: 10.3969/j.issn.1005-1198.2011.03.002HUAN C T, LI Q, JIANG D Y. Application of Si3N4 and research progress on corrosion behavior [J]. Advanced Ceramics, 2011, 32(3): 3–8. doi: 10.3969/j.issn.1005-1198.2011.03.002 [17] 陈思员, 姜贵庆, 俞继军, 等. 氮化硅的氧化机制研究 [J]. 宇航材料工艺, 2010, 40(1): 28–31. doi: 10.3969/j.issn.1007-2330.2010.01.007CHEN S Y, JIANG G Q, YU J J, et al. Oxidation mechanism study of silicon nitride [J]. Aerospace Materials & Technology, 2010, 40(1): 28–31. doi: 10.3969/j.issn.1007-2330.2010.01.007 [18] 刘胜, 王营营, 满延进, 等. 氮化硅粉改性及其陶瓷高温摩擦磨损性能研究 [J]. 陶瓷学报, 2024, 45(1): 139–149. doi: 10.13957/j.cnki.tcxb.2024.01.014LIU S, WANG Y Y, MAN Y J, et al. Modification of silicon nitride powders and friction and wear properties of ceramics at high temperature [J]. Journal of Ceramics, 2024, 45(1): 139–149. doi: 10.13957/j.cnki.tcxb.2024.01.014 [19] 黄勇, 代建清, 许兴利, 等. 氮化硅粉体的表面化学性质和水中的胶体特性 [J]. 硅酸盐通报, 2000, 19(2): 35–42, 28. doi: 10.3969/j.issn.1001-1625.2000.02.011HUANG Y, DAI J Q, XU X L, et al. Surface characteristics and aqueous colloidal chemistry of silicon nitride powder [J]. Bulletin of the Chinese Ceramic Society, 2000, 19(2): 35–42, 28. doi: 10.3969/j.issn.1001-1625.2000.02.011 [20] 王月隆. 氮化硅粉体合成及其高导热陶瓷的组织与性能研究 [D]. 北京: 北京科技大学, 2022.WANG Y L. Research on powder preparation and microstructure and properties of silicon nitride ceramics with high thermal conductivity [D]. Beijing: University of Science and Technology Beijing, 2022. [21] 黄寅生. 炸药理论 [M]. 北京: 北京理工大学出版社, 2016.HUANG Y S. Explosives theory [M]. Beijing: Beijing Institute of Technology Press, 2016. [22] 刘锋, 匡照, 吴攀宇, 等. 内相粒径对现场混装乳化炸药热感度的影响 [J]. 火炸药学报, 2022, 45(5): 697–702. doi: 10.14077/j.issn.1007-7812.202204018LIU F, KUANG Z, WU P Y, et al. Effect of internal phase particle size on thermal sensitivity of on-site mixed emulsion explosive [J]. Chinese Journal of Explosives & Propellants, 2022, 45(5): 697–702. doi: 10.14077/j.issn.1007-7812.202204018 [23] 崔雪峰, 刘万义, 孟祥宇, 等. 乳化炸药的配方设计与应用评价 [J]. 采矿技术, 2021, 21(1): 27–29, 36. doi: 10.3969/j.issn.1671-2900.2021.01.009CUI X F, LIU W Y, MENG X Y, et al. Formulation design and application evaluation of emulsion explosive [J]. Mining Technology, 2021, 21(1): 27–29, 36. doi: 10.3969/j.issn.1671-2900.2021.01.009 [24] 崔鑫. 乳化炸药热稳定性研究 [D]. 淮南: 安徽理工大学, 2007.CUI X. Study of thermal stability of emulsion explosive [D]. Huainan: Anhui University of Science and Technology, 2007. [25] 刘锋, 汪全, 吴攀宇, 等. 内相粒径对现场混装乳化炸药基质抗振动性能的影响 [J]. 化工学报, 2022, 73(9): 4217–4225. doi: 10.11949/0438-1157.20220742LIU F, WANG Q, WU P Y, et al. Effect of internal phase particle size on vibration resistance of on-site mixed emulsion explosive matrix [J]. CIESC Journal, 2022, 73(9): 4217–4225. doi: 10.11949/0438-1157.20220742 [26] 国家技术监督局. 炸药猛度试验铅柱压缩法: GB/T 12440—1990 [S]. 北京: 中国标准出版社, 1990. [27] CALIFANO V, CALABRIA R, MASSOLI P. Experimental evaluation of the effect of emulsion stability on micro-explosion phenomena for water-in-oil emulsions [J]. Fuel, 2014, 117: 87–94. doi: 10.1016/j.fuel.2013.08.073 [28] HAMPSHIRE S, POMEROY M J. Silicon nitride grain boundary glasses: chemistry, structure and properties [J]. Key Engineering Materials, 2011, 484: 46–51. doi: 10.4028/www.scientific.net/KEM.484.46 [29] 隋智通. 硅氮化反应的平衡及动力学研究 [J]. 东北工学院学报, 1980(1): 31–38.SUI Z T. Equilibrations and kinetics of silicon nitridation [J]. Journal of Northeast Institute of Technology, 1980(1): 31–38. [30] 向茂乔, 耿玉琦, 朱庆山. 氮化硅粉体制备技术及粉体质量研究进展 [J]. 化工学报, 2022, 73(1): 73–84. doi: 10.11949/0438-1157.20210866XIANG M Q, GENG Y Q, ZHU Q S. Research advances in preparation technology and quality of silicon nitride powder [J]. CIESC Journal, 2022, 73(1): 73–84. doi: 10.11949/0438-1157.20210866 [31] 黄文尧, 颜事龙. 炸药化学与制造 [M]. 北京: 冶金工业出版社, 2009.HUANG W Y, YAN S L. Explosives chemistry and production [M]. Beijing: Metallurgical Industry Press, 2009. [32] 杨胜晖, 郑波. 含铝温压炸药的爆炸能量结构研究 [J]. 爆破器材, 2019, 48(2): 20–24. doi: 10.3969/j.issn.1001-8352.2019.02.004YANG S H, ZHENG B. Explosion energy structure of aluminized thermobaric explosive [J]. Explosive Materials, 2019, 48(2): 20–24. doi: 10.3969/j.issn.1001-8352.2019.02.004 [33] 许祖熙, 段卫东, 刘瑞, 等. 铝粉质量分数及颗粒度对乳化炸药做功能力的影响 [J]. 工程爆破, 2017, 23(6): 86–90. doi: 10.3969/j.issn.1006-7051.2017.06.019XU Z X, DUAN W D, LIU R, et al. The effect of aluminum content and granularity on workability of emulsion explosives [J]. Engineering Blasting, 2017, 23(6): 86–90. doi: 10.3969/j.issn.1006-7051.2017.06.019 [34] XIE R J, MITOMO M, HUANG L P, et al. Joining of silicon nitride ceramics for high-temperature applications [J]. Journal of Materials Research, 2000, 15(1): 136–141. doi: 10.1557/JMR.2000.0023 [35] NARUSHIMA T, GOTO T, HAGIWARA J, et al. High-temperature oxidation of chemically vapor-deposited silicon nitride in a carbon monoxide-carbon dioxide atmosphere [J]. Journal of the American Ceramic Society, 1994, 77(11): 2921–2925. doi: 10.1111/j.1151-2916.1994.tb04525.x [36] 何志伟, 朱文宇, 葛玉强, 等. 铝灰替代含铝乳化炸药中铝粉的可行性研究 [J]. 爆破器材, 2023, 52(2): 32–38. doi: 10.3969/j.issn.1001-8352.2023.02.006HE Z W, ZHU W Y, GE Y Q, et al. Feasibility study on substitution of aluminum powder in aluminized emulsion explosive with aluminum ash [J]. Explosive Materials, 2023, 52(2): 32–38. doi: 10.3969/j.issn.1001-8352.2023.02.006 [37] WANG Y X, MA H H, SHEN Z W, et al. Detonation characteristics of emulsion explosives sensitized by hydrogen-storage glass microballoons [J]. Propellants, Explosives, Pyrotechnics, 2018, 43(9): 939–947. doi: 10.1002/prep.201800044 [38] CHENG Y F, YAO Y L, LI D Y, et al. Effects of boron powders on the detonation performance of emulsion explosives [J]. Propellants, Explosives, Pyrotechnics, 2023, 48(3): e202200277. doi: 10.1002/prep.202200277 -

下载:

下载: