Dynamic Response Characteristics of Bridge Pile Foundation Structure Subjected to Blasting Vibration of Canal Excavation

-

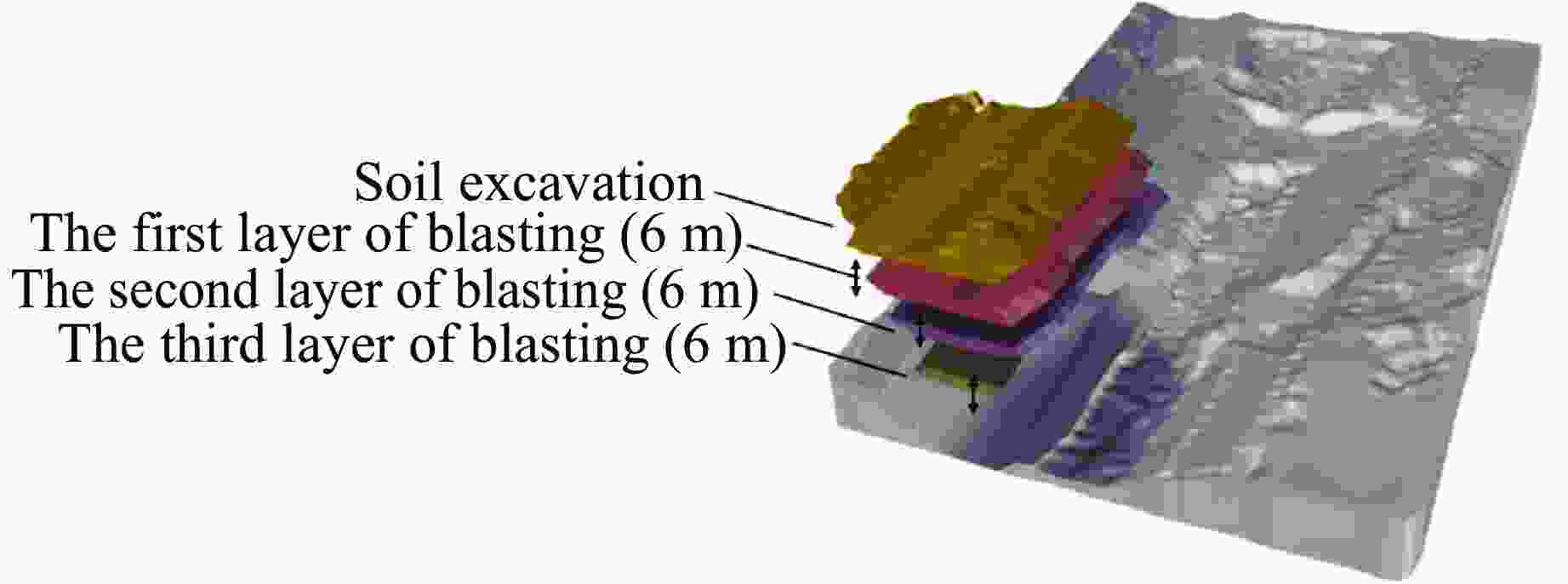

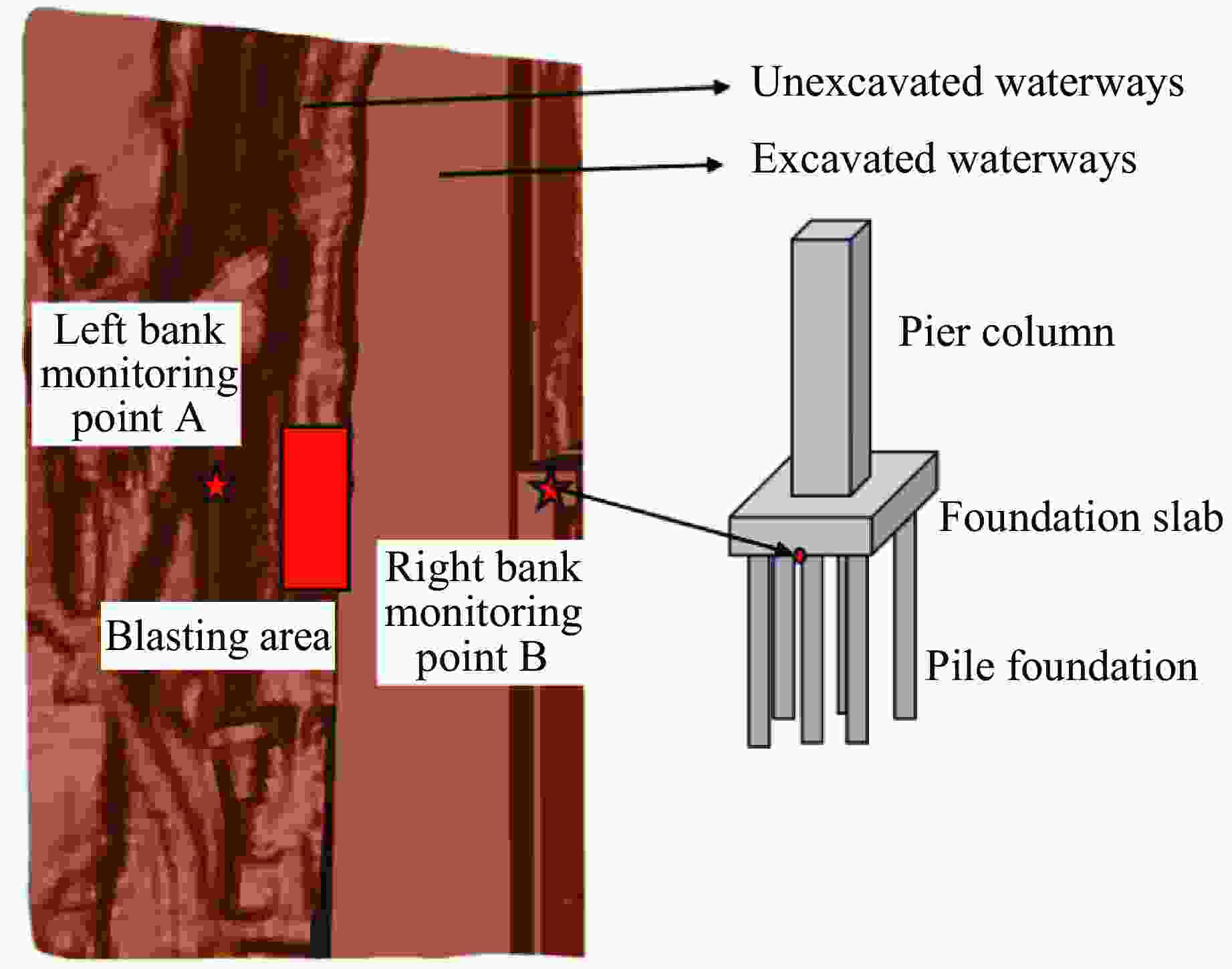

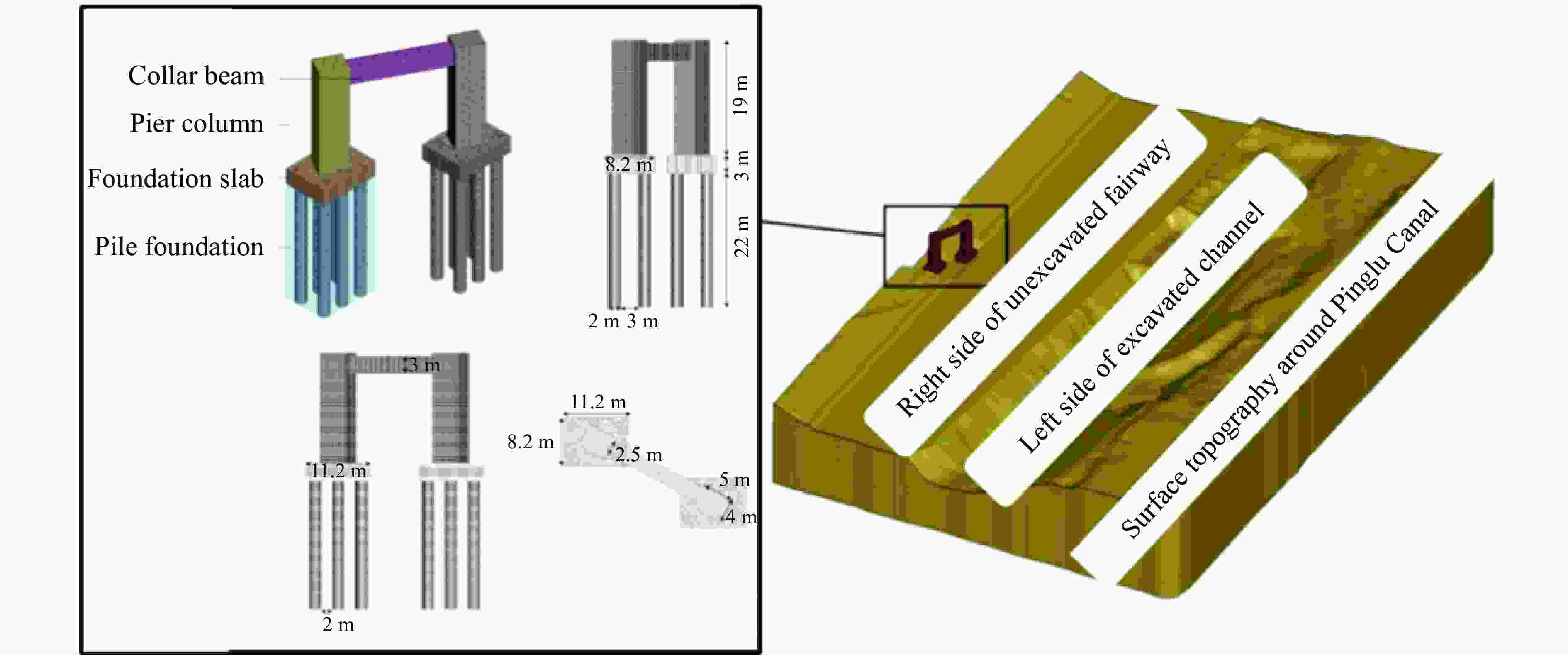

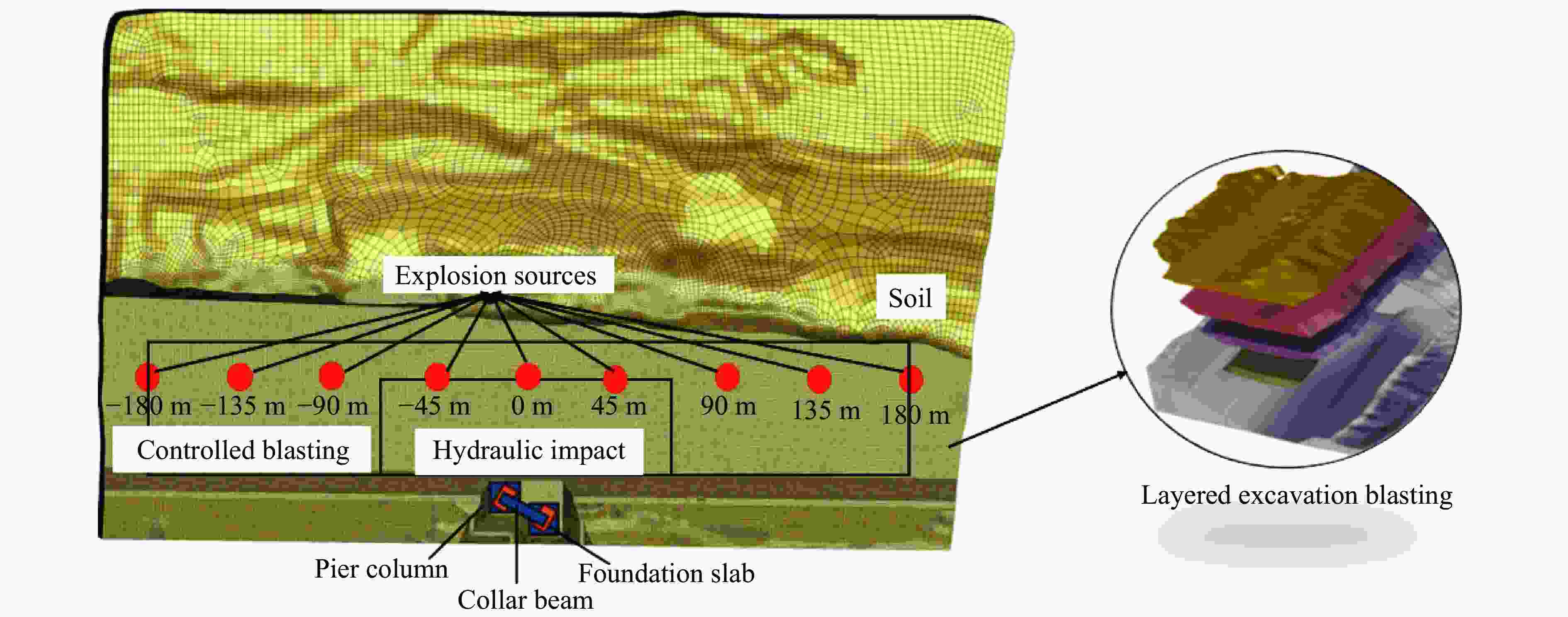

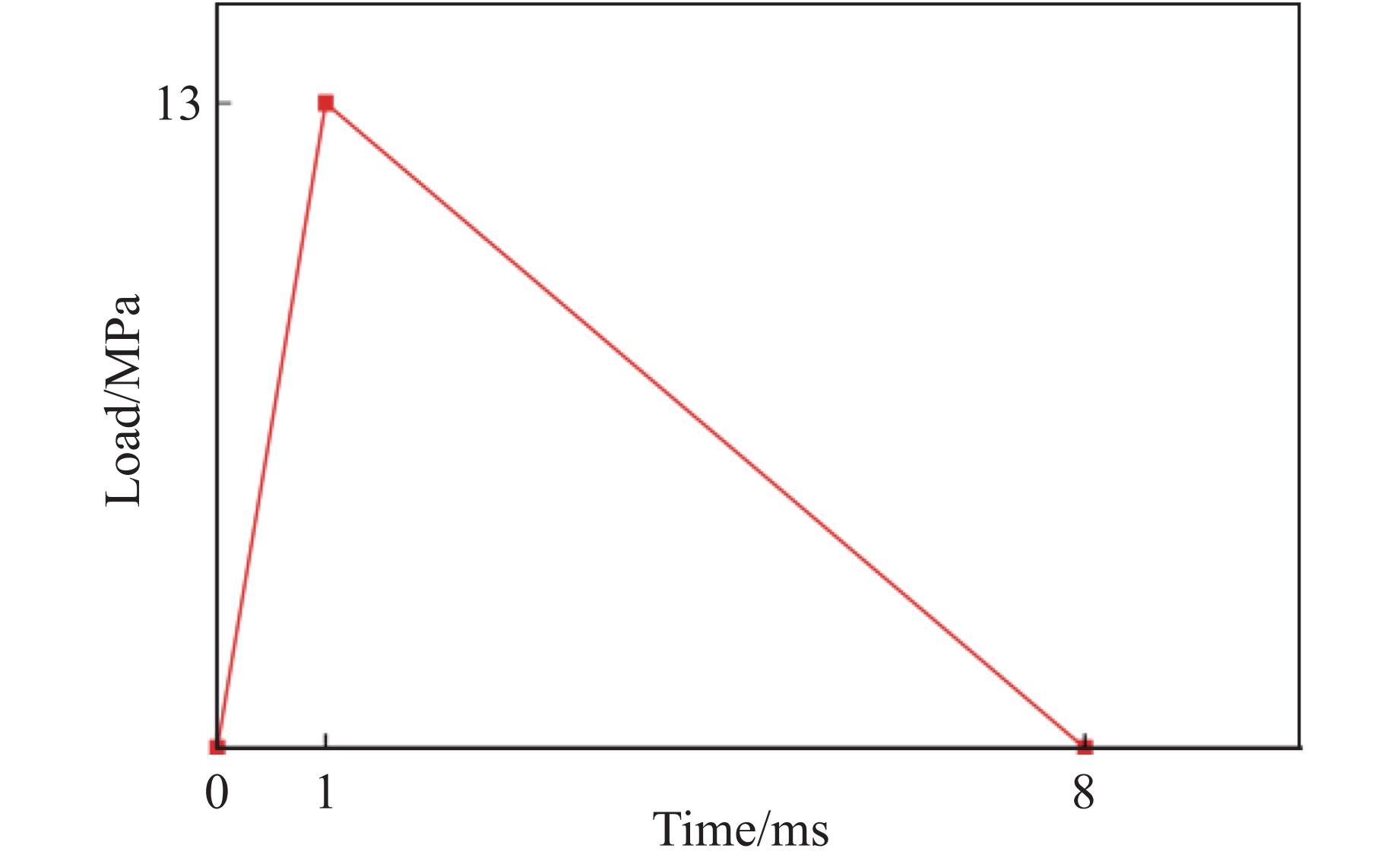

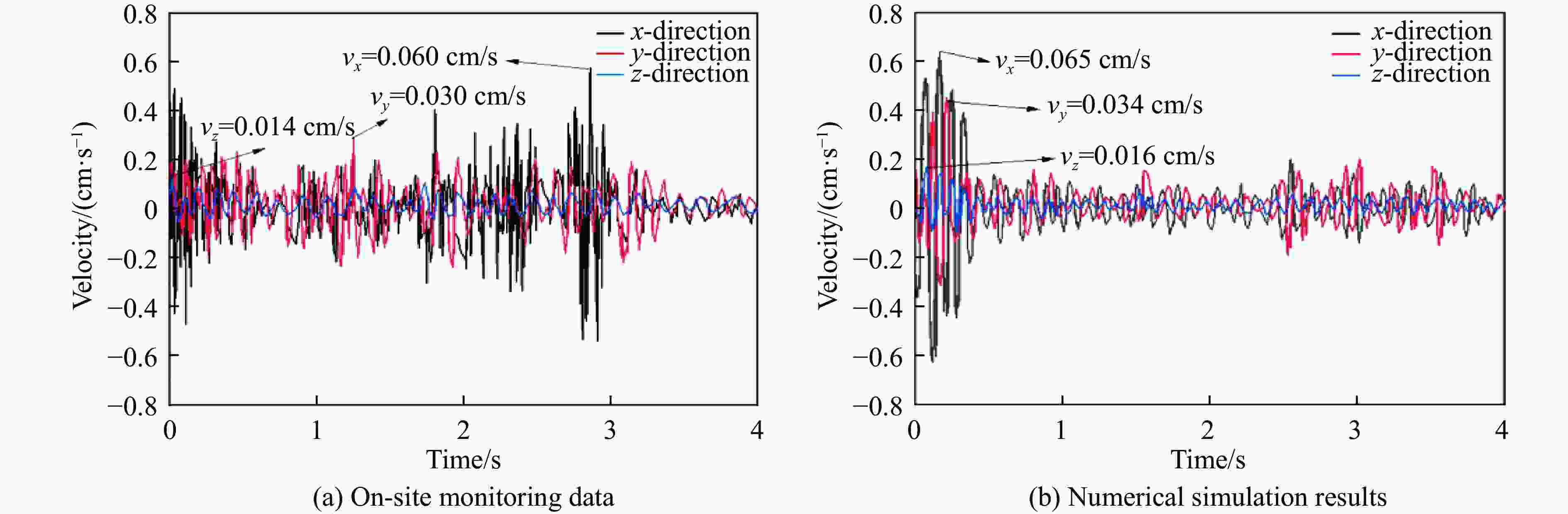

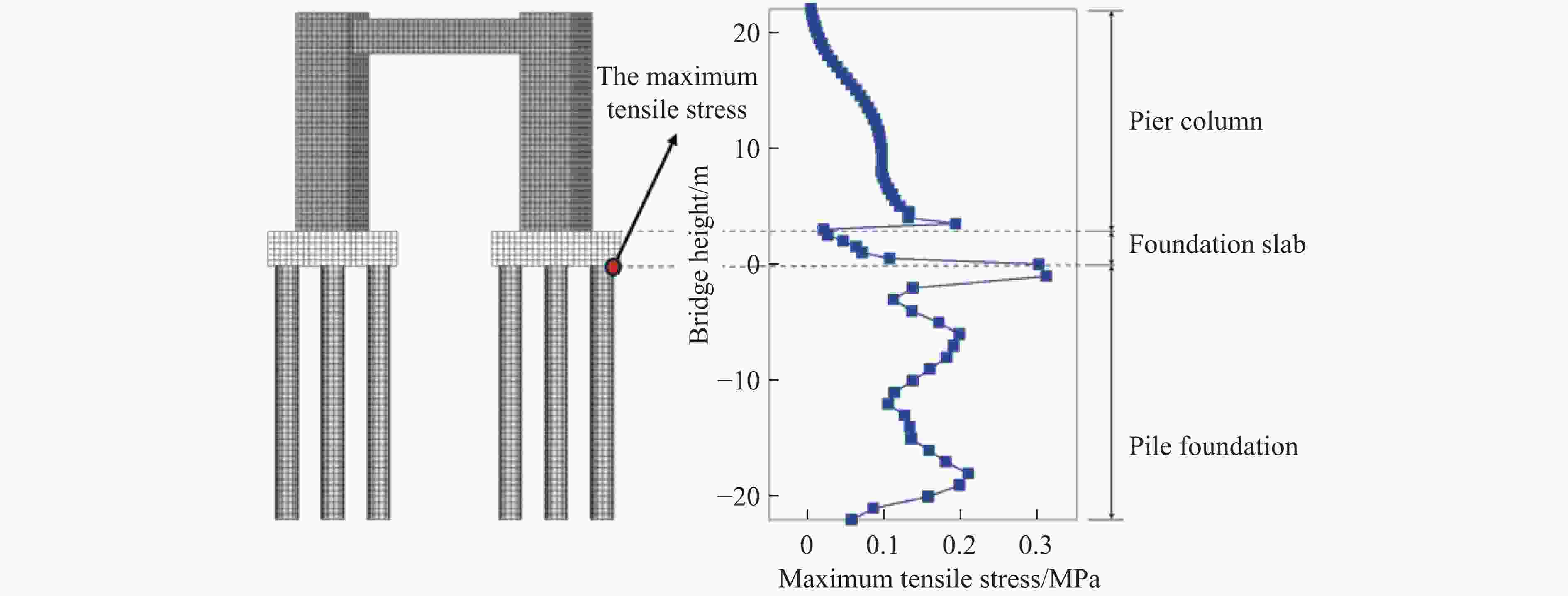

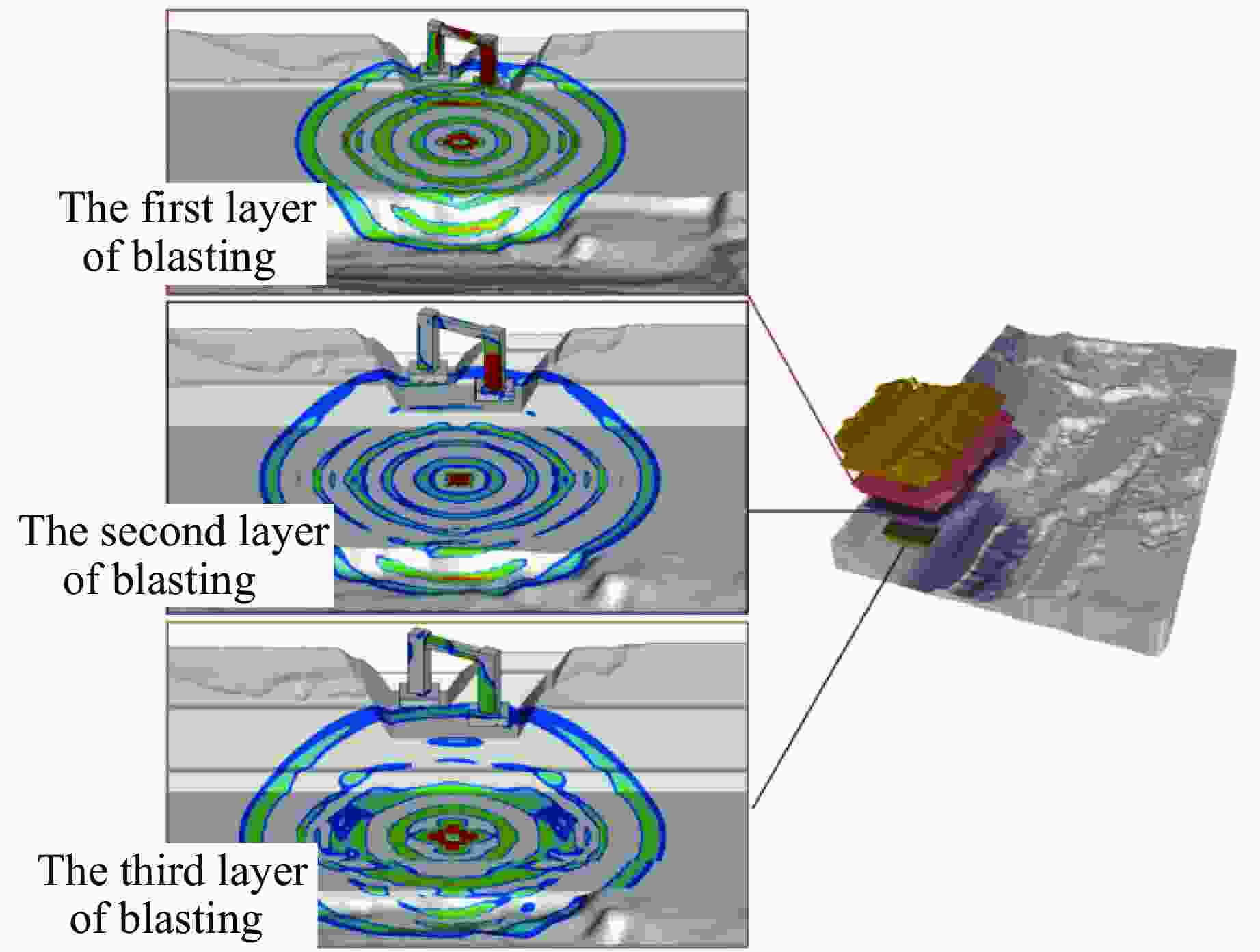

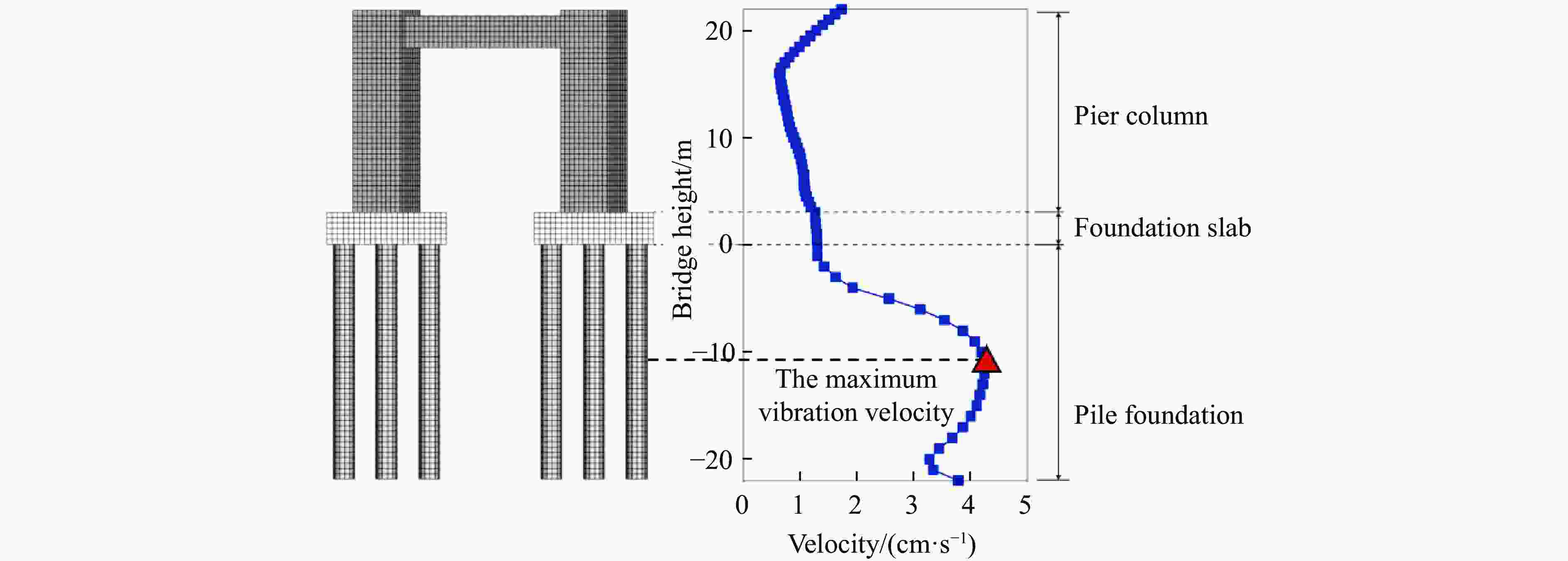

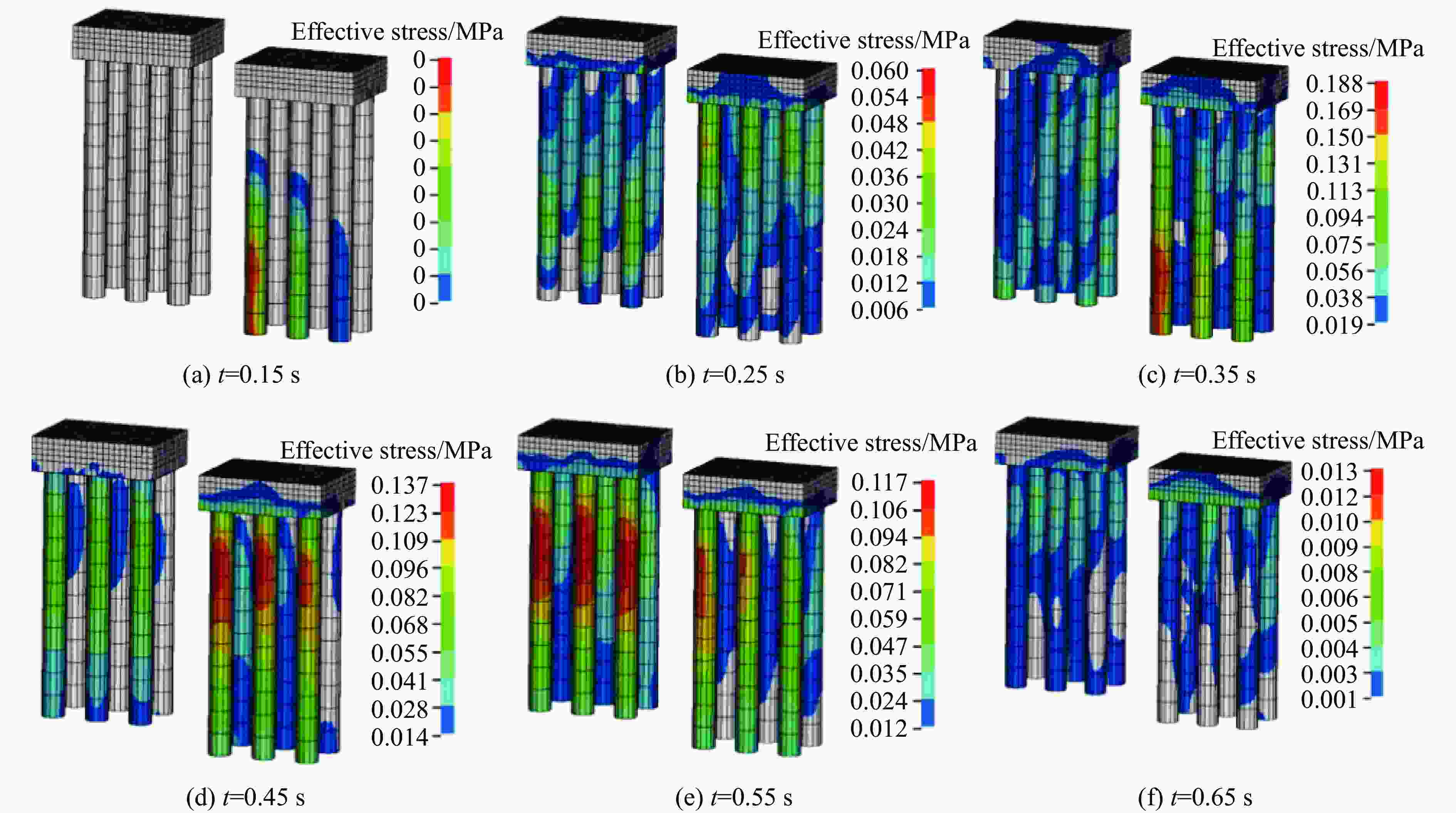

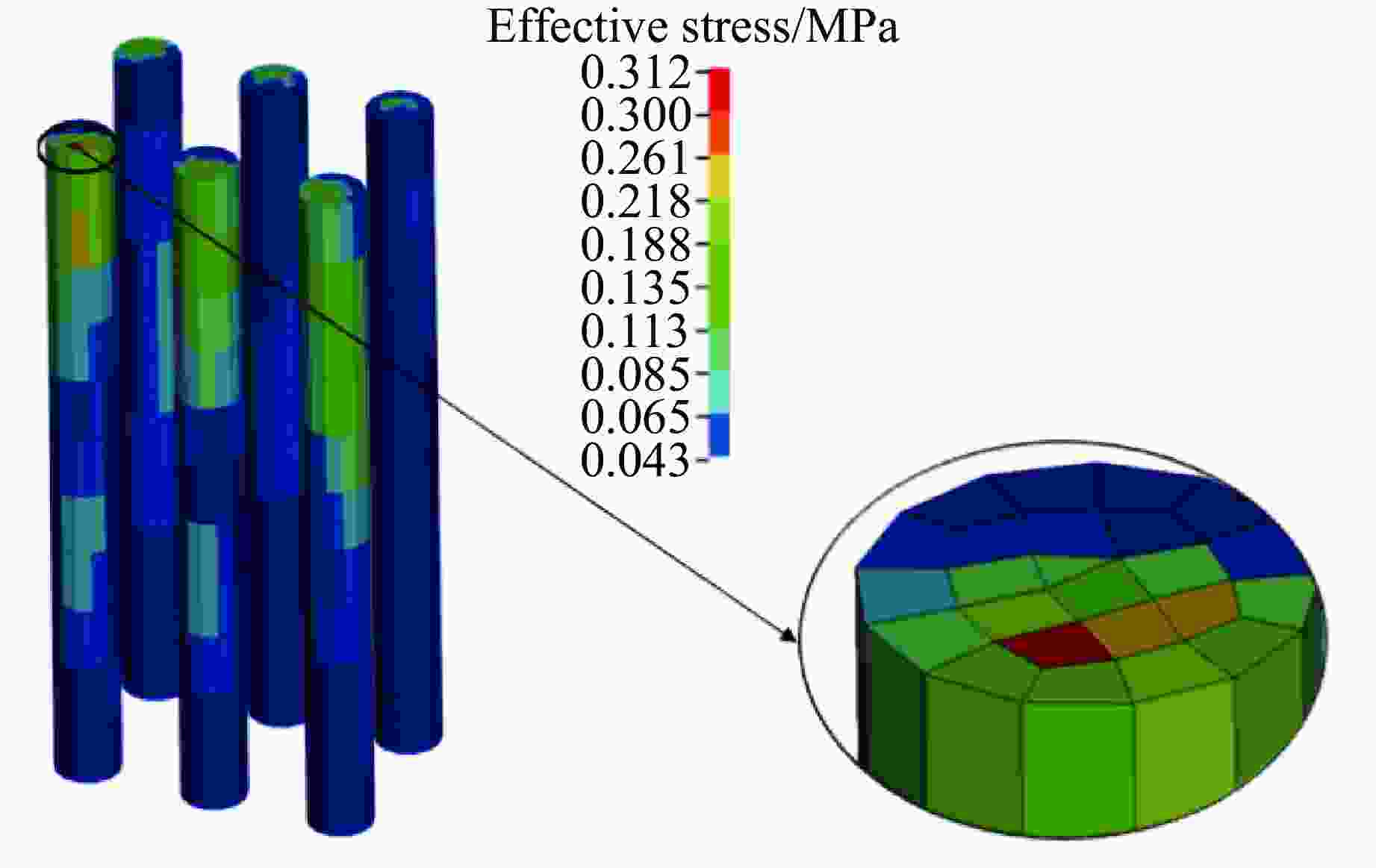

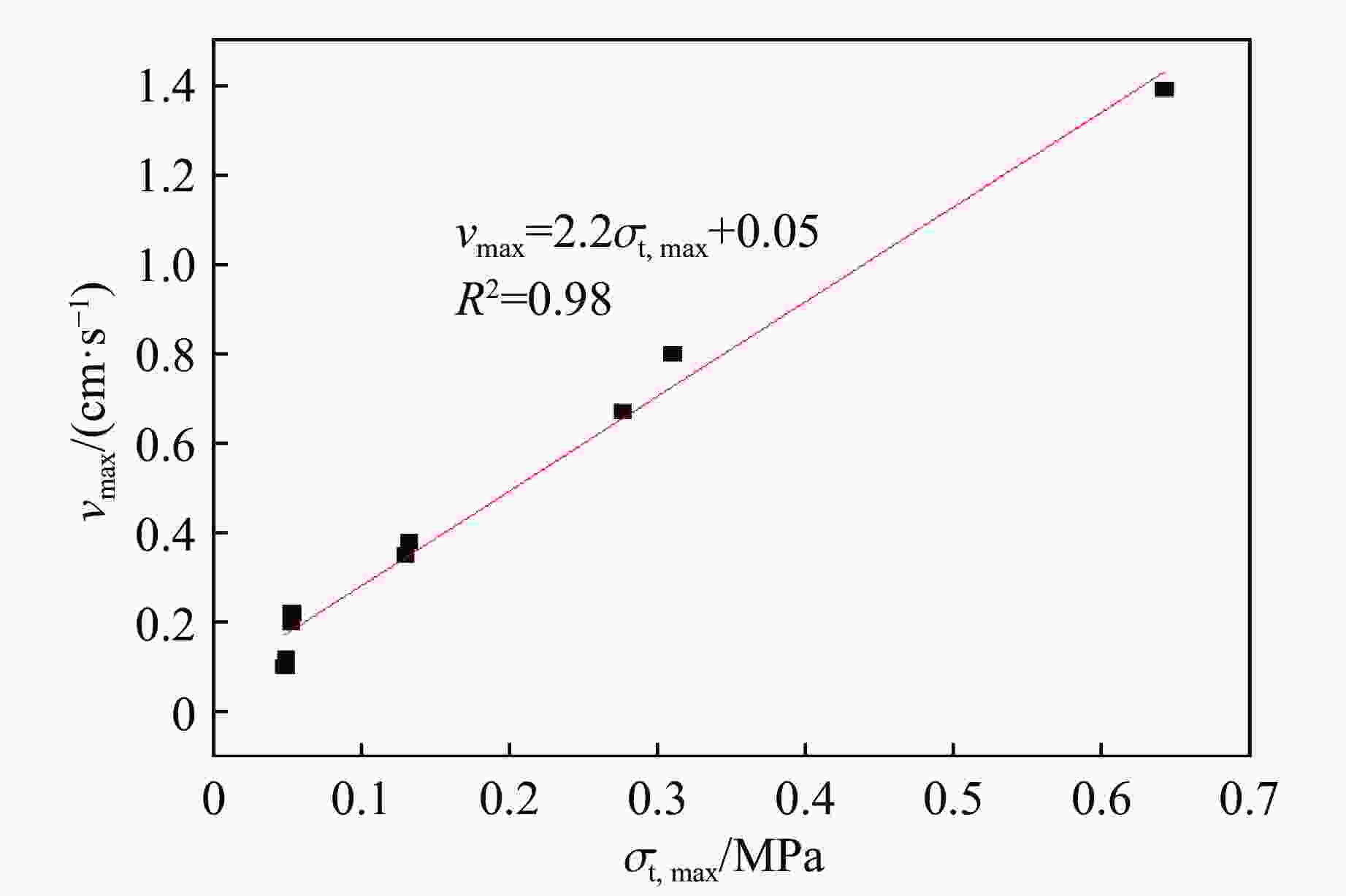

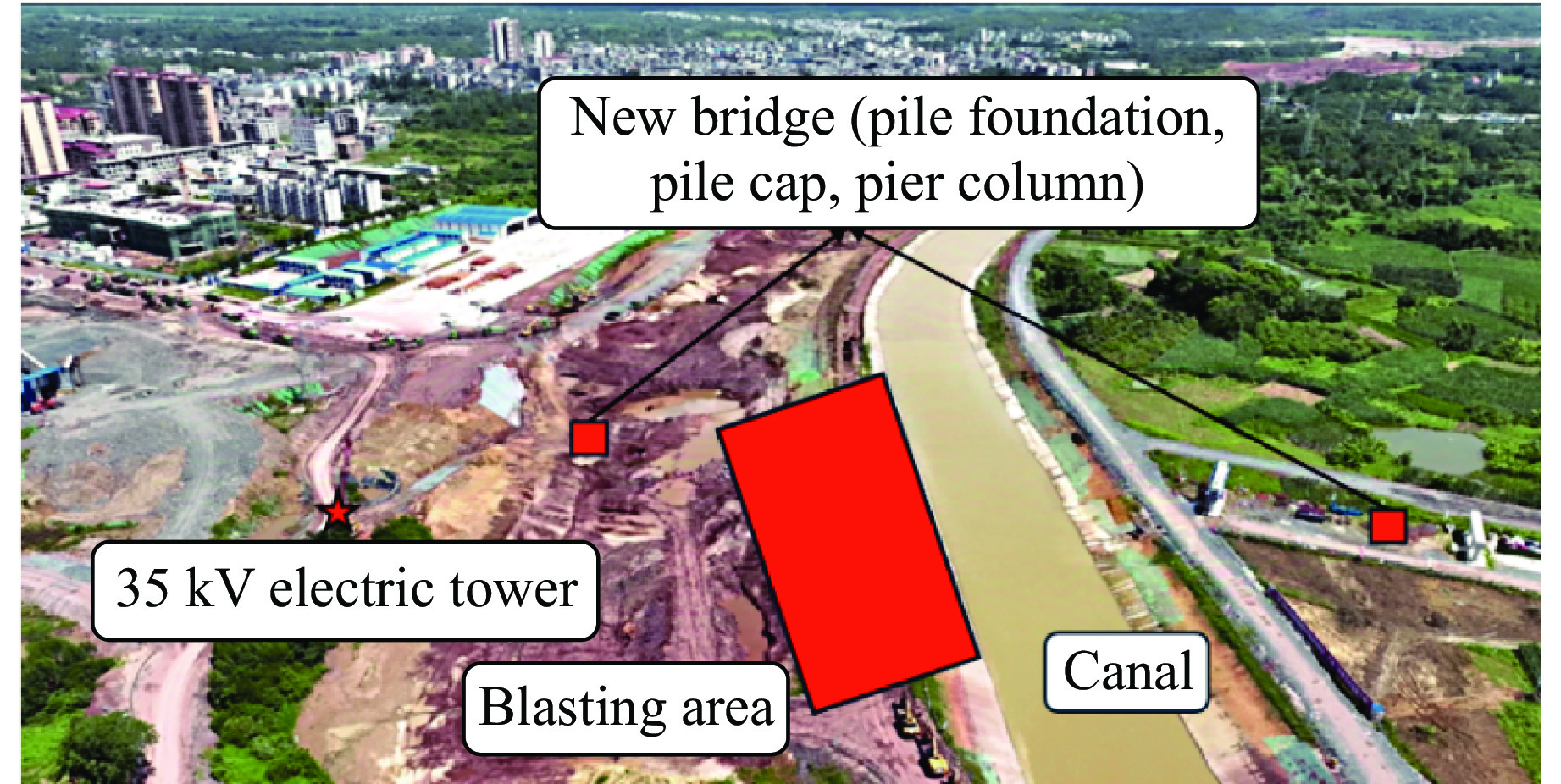

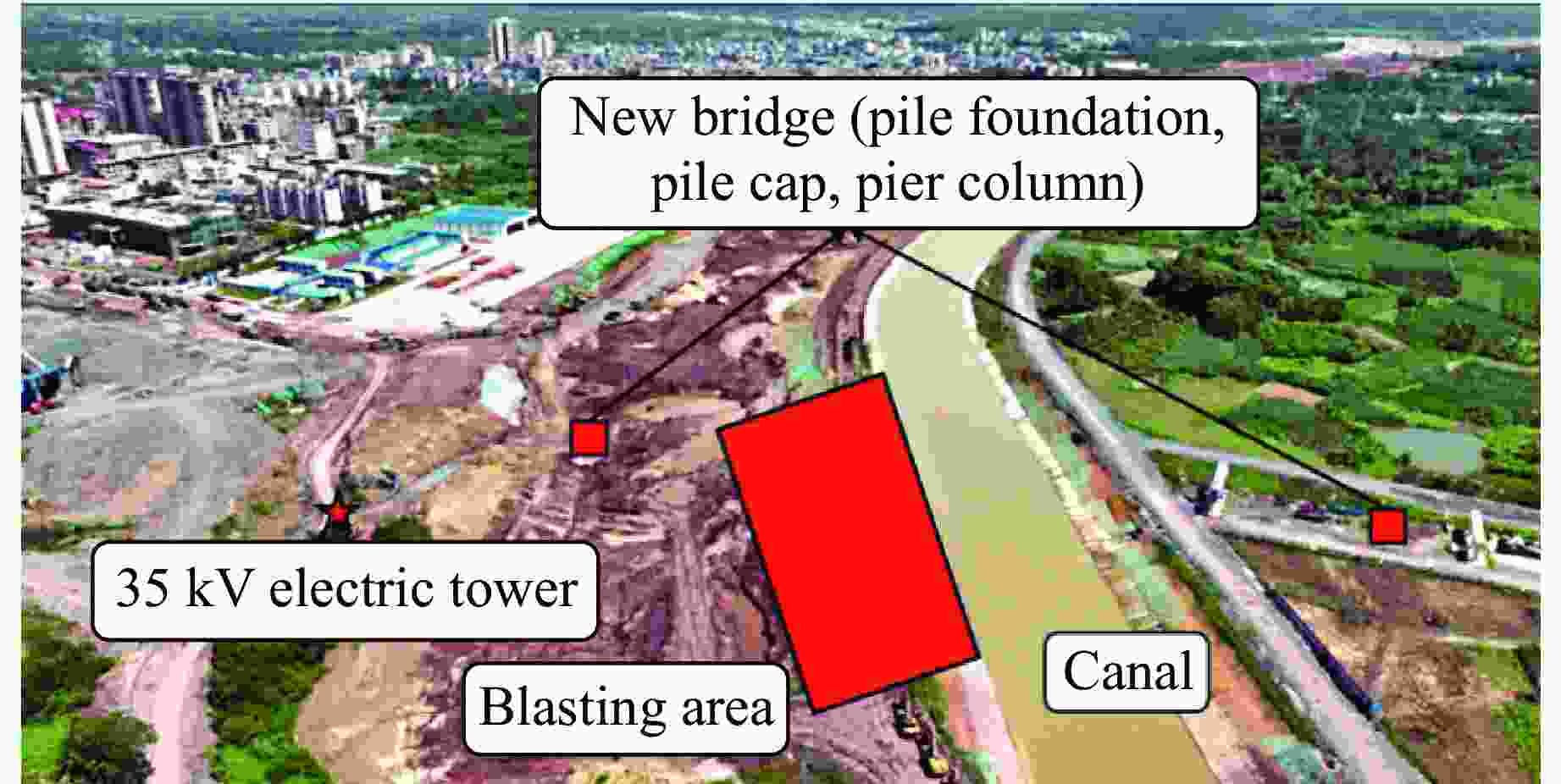

摘要: 爆破开挖是提升运河航道扩挖效率的重要施工方法,但其引起的爆破振动效应可能对既有水道的桥梁下部结构产生不利影响。为阐明桥梁下部结构在爆破开挖振动作用下的动力响应特性,依托平陆运河航道扩挖爆破工程,结合经现场测试验证的有限元模拟方法,分析了爆破影响下邻近桥梁下部结构的应力和振速分布特征,基于最大拉应力准则,提出了桥梁下部结构的安全振速阈值。结果表明:在运河爆破开挖振动作用下,桥梁桩基与承台交接处产生最大拉应力;下部结构振动较大的部位主要位于桩基;以承台为监测点的桥梁下部结构的安全允许振速为3.2 cm/s。Abstract: Blasting excavation is a critical construction method for enhancing the canal channel expansion efficiency. However, the induced blasting vibration may adversely affect the substructure of existing waterway bridges. To clarify the dynamic response characteristics of the bridge substructure subjected to blasting-induced vibration, this study analyzed the stress and vibration velocity distributions in the adjacent bridge substructure during the Pinglu Canal channel expansion project. A finite element numerical simulation method, validated by field test, was employed to establish the safe vibration velocity threshold for the substructure based on the maximum tensile stress criterion. The results show that the maximum tensile stress occurs at the interface between the bridge pile foundation and the pile cap during canal blasting excavation. The most significant vibrations in the substructure are concentrated in the pile foundation. The allowable vibration velocity for the bridge substructure, with the pile cap as the monitoring point, is 3.2 cm/s.

-

Key words:

- blasting vibration /

- bridge pile foundation /

- finite element method /

- dynamic response

-

表 1 工程爆破设计方案

Table 1. Engineering blasting design scheme

Layer Total number of

blasts conductedBlasting

elevation/mTotal blasting

area/m2Single blasting

area/m2Single blasting

volume/m31 15 13.0−19.0 18 184 1 200 7 200 2 13 7.0−13.0 16 386 1 150 6 800 2 13 1.4−7.0 15 360 1 000 6 000 表 2 台阶爆破参数

Table 2. Parameters of bench blasting

Step

height/mDip angle/

(°)Deep/m Borehole

length/mHole

spacing/mRow

spacing/mCharge per blast hole/kg Charge

length/mStemming

length/mFront row Back row 6 90 0.6 6.6 3.0 2.5 13.5 15.0 3.6 3.0 表 3 监测点爆破峰值振动速度与主频

Table 3. Peak particle velocity and dominant frequency of monitoring points

Working condition Measuring point position v/(cm·s−1) f/Hz x y z x y z 1 Left bank 0.060 0.030 0.014 13.70 14.55 12.86 2 Right bank 0.043 0.023 0.033 17.54 9.59 20.62 表 4 各材料的物理力学参数

Table 4. Physical and mechanical parameters of each material

Materials ρ/(g·cm−3) E/GPa μ σY/MPa $ \varphi $/(°) c/kPa Concrete 2.4 30 0.20 20 Steel 7.9 210 0.25 235 Silt clay 1.8 5 0.35 20 20 Fully weathered silty mudstone 2.0 0.5 0.35 25 30 Strongly weathered silty mudstone 2.2 3 0.30 30 100 Medium weathered silty mudstone 2.4 10 0.25 35 200 表 5 数值计算和监测点A的现场实验数据

Table 5. Numerical simulation results and field monitoring data for monitoring point A

vx vy vz Exp./(cm·s−1) Sim./(cm·s−1) δx/% Exp./(cm·s−1) Sim./(cm·s−1) δy/% Exp./(cm·s−1) Sim./(cm·s−1) δz/% 0.060 0.065 7.6 0.030 0.034 11.7 0.014 0.016 12.5 表 6 多种爆源振动影响下下部结构的最大拉应力和最大振速

Table 6. Maximum tensile stress and maximum vibration velocity of substructure under multiple blasting source vibrations

d/m σt,max/MPa vmax/(cm·s−1) d/m σt,max/MPa vmax/(cm·s−1) d/m σt,max/MPa vmax/(cm·s−1) −200 0.048 0.10 −50 0.310 0.80 100 0.130 0.35 −150 0.052 0.20 0 0.642 1.39 150 0.053 0.22 −100 0.132 0.38 50 0.276 0.67 200 0.049 0.12 -

[1] 梁轩. 考虑动水作用和冲刷效应的深水桥梁桩基地震动力响应研究 [D]. 上海: 同济大学, 2022.LIANG X. Seismic analysis of deep water bridge pile foundation considering hydrodynamic pressure and scour effect [D]. Shanghai: Tongji University, 2022. [2] 胡春林, 杨小卫. 上部结构刚度对桩基地震动力响应的影响 [J]. 土工基础, 2007, 21(2): 21–24. doi: 10.3969/j.issn.1004-3152.2007.02.008HU C L, YANG X W. Influence of seisimic responseon pile due to stiffness variation of superstructure [J]. Soil Engineering and Foundation, 2007, 21(2): 21–24. doi: 10.3969/j.issn.1004-3152.2007.02.008 [3] 罗川, 占昌宝, 楼云锋, 等. 地震激励下桩-土非线性耦合作用对桩基动力响应特性的影响 [J]. 振动与冲击, 2017, 36(3): 20–26. doi: 10.13465/j.cnki.jvs.2017.03.004LUO C, ZHAN C B, LOU Y F, et al. Effects of pile-soil nonlinear coupling actions on dynamic response features of pile foundation under earthquake [J]. Journal of Vibration and Shock, 2017, 36(3): 20–26. doi: 10.13465/j.cnki.jvs.2017.03.004 [4] YAO A J, ZHANG J T, ZHOU Y J. Study on the dynamic response of the steel pipe pile foundation during construction of neighborhood deep excavation [J]. Procedia Engineering, 2016, 165: 58–68. doi: 10.1016/j.proeng.2016.11.735 [5] 陈海兵, 梁发云. 群桩基础水平动力响应简化边界元频域解答 [J]. 岩土工程学报, 2014, 36(6): 1057–1063. doi: 10.11779/CJGE201406010CHEN H B, LIANG F Y. Simplified boundary element method for lateral vibration response of pile groups in frequency domain [J]. Chinese Journal of Geotechnical Engineering, 2014, 36(6): 1057–1063. doi: 10.11779/CJGE201406010 [6] 王文剑, 楼梦麟, 马恒春, 等. 上部结构对桩基础地震应力影响的模型试验研究 [J]. 地震工程与工程振动, 2001, 21(2): 103–108. doi: 10.3969/j.issn.1000-1301.2001.02.019WANG W J, LOU M L, MA H C, et al. Study on efffects of superstructure on pile foundation seismic stresses by model test [J]. Earthquake Engineering and Engineering Dynamics, 2001, 21(2): 103–108. doi: 10.3969/j.issn.1000-1301.2001.02.019 [7] 夏宇磬. 城区钻爆法隧道爆破邻近桩基振动效应研究 [D]. 武汉: 中国地质大学, 2023.XIA Y Q. Dynamic behavior of pile foundations subjected to urban subway tunnel blasting excavation [D]. Wuhan: China University of Geosciences, 2023. [8] HUANG W H, LIU J K, WANG H, et al. Study on dynamic response of inclined pile group foundation under earthquake action [J]. Buildings, 2023, 13(10): 2416. doi: 10.3390/BUILDINGS13102416 [9] LIANG W W, LENG L Y, TIAN H, et al. Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake [J]. Nonlinear Engineering, 2022, 11(1): 485–493. doi: 10.1515/nleng-2022-0228 [10] 尹平保, 陆帆, 贺炜, 等. 考虑斜坡效应的桥梁桩基动力响应特性及地震易损性分析 [J]. 土木工程学报, 2025, 58(7): 66–76.YIN P B, LU F, HE W, et al. Dynamic response characteristics and seismic fragility analysis of bridge pile foundation considering of slope effect [J]. China Civil Engineering Journal, 2025, 58(7): 66–76. [11] HUANG Y, CHEN X G, CHENG L J, et al. Dynamic response analysis of pile group foundation of super-giant sewage treatment structure on hydraulic fill foundation [J]. Shock and Vibration, 2022, 2022(1): 1440477. doi: 10.1155/2022/1440477 [12] MESSIOUD S, DIAS D, SBARTAI B. Influence of the pile toe condition on the dynamic response of a group of pile foundations [J]. International Journal of Advanced Structural Engineering, 2019, 11(1): 55–66. doi: 10.1007/s40091-019-0217-5 [13] WEN H, JIE C, QIAN S, et al. Dynamic response of cross-sea bridge pile foundation under the coaction of wave and current [J]. International Journal of Earth Sciences and Engineering, 2016, 9(4): 1383–1387. [14] 王福兴, 张宾, 曹寰宇, 等. 敏感条件下隧道爆破施工中邻近桩基的振动响应分析 [J]. 煤矿爆破, 2024, 42(4): 12–18. doi: 10.3969/j.issn.1674-3970.2024.04.003WANG F X, ZHANG B, CAO H Y, et al. Vibration response analysis of adjacent pile foundations during tunnel blasting construction under sensitive conditions [J]. Coal Mine Blasting, 2024, 42(4): 12–18. doi: 10.3969/j.issn.1674-3970.2024.04.003 [15] 刘闯, 冯忠居, 张福强, 等. 地震作用下特大型桥梁嵌岩桩基础动力响应 [J]. 交通运输工程学报, 2018, 18(4): 53–62. doi: 10.19818/j.cnki.1671-1637.2018.04.006LIU C, FENG Z J, ZHANG F Q, et al. Dynamic response of rock-socketed pile foundation for extra-large bridge under earthquake action [J]. Journal of Traffic and Transportation Engineering, 2018, 18(4): 53–62. doi: 10.19818/j.cnki.1671-1637.2018.04.006 [16] 杨建华, 卢文波, 陈明, 等. 岩石爆破开挖诱发振动的等效模拟方法 [J]. 爆炸与冲击, 2012, 32(2): 157–163. doi: 10.3969/j.issn.1001-1455.2012.02.007YANG J H, LU W B, CHEN M, et al. An equivalent simulation method for blasting vibration of surrounding rock [J]. Explosion and Shock Waves, 2012, 32(2): 157–163. doi: 10.3969/j.issn.1001-1455.2012.02.007 [17] 姚金宝. 露天矿山开采逐孔爆破总装药量大小对爆破振动影响的研究 [J]. 煤矿爆破, 2023, 41(3): 31–34. doi: 10.3969/j.issn.1674-3970.2023.03.006YAO J B. Study on the effect of total charge amount of hole-by-hole blasting on blasting vibration in open-pit mining [J]. Coal Mine Blasting, 2023, 41(3): 31–34. doi: 10.3969/j.issn.1674-3970.2023.03.006 [18] 梁悦. 不同爆破方式下地下洞室围岩动态响应的数值计算分析 [D]. 南京: 东南大学, 2022.LIANG Y. Numerical analysis of dynamic response of underground cavern surrounding rock masses under different blasting parameters [D]. Nanjing: Southeast University, 2022. [19] 易长平. 爆破振动对地下洞室的影响研究 [D]. 武汉: 武汉大学, 2005.YI C P. The influence of blasting vibration on underground chambers [D]. Wuhan: Wuhan University, 2005. -

下载:

下载: