Analysis and Modeling of Plastic Deformation Characteristics of Sheet Metal under the Combined Action of Overpressure and Impulse

-

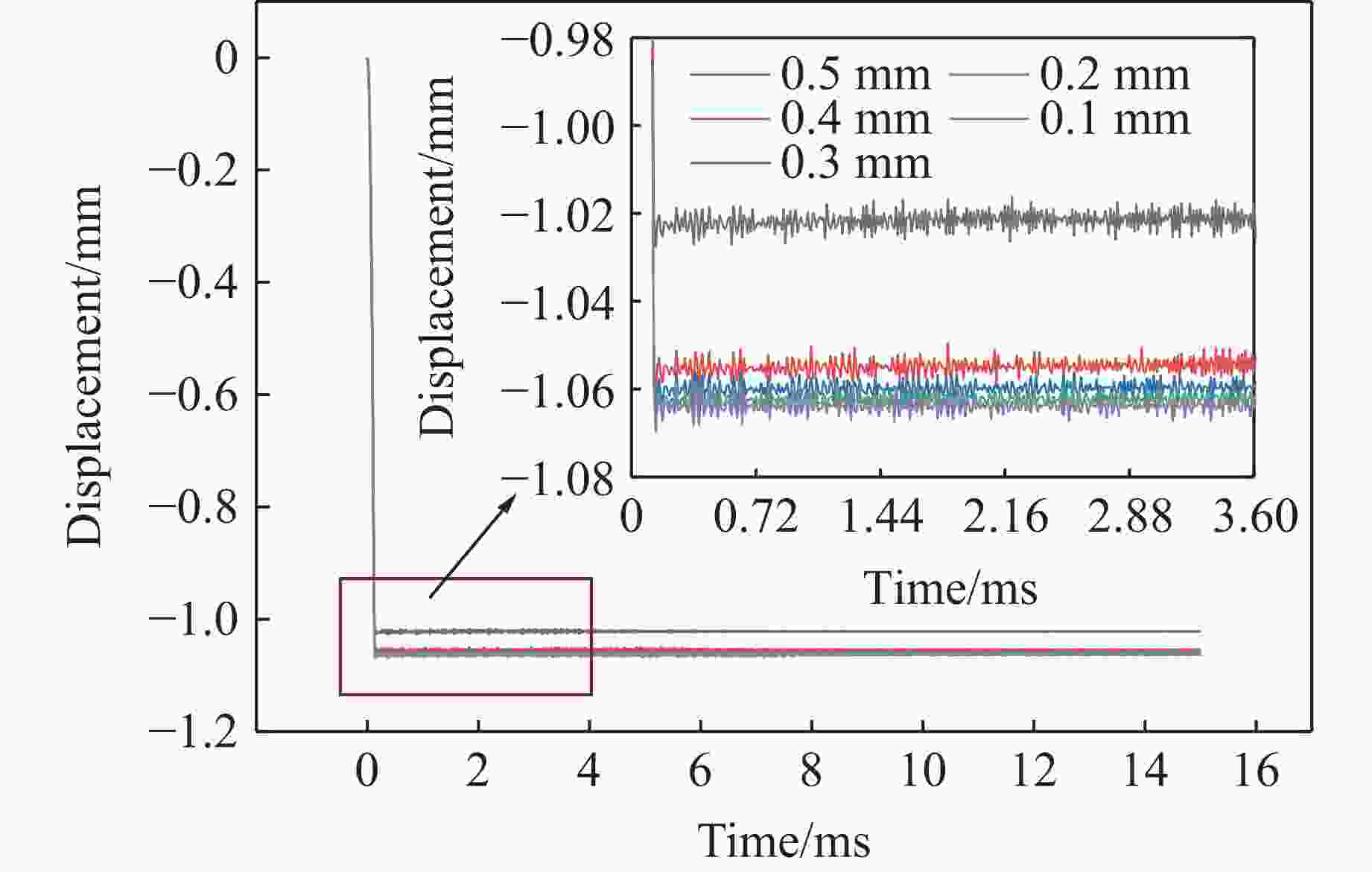

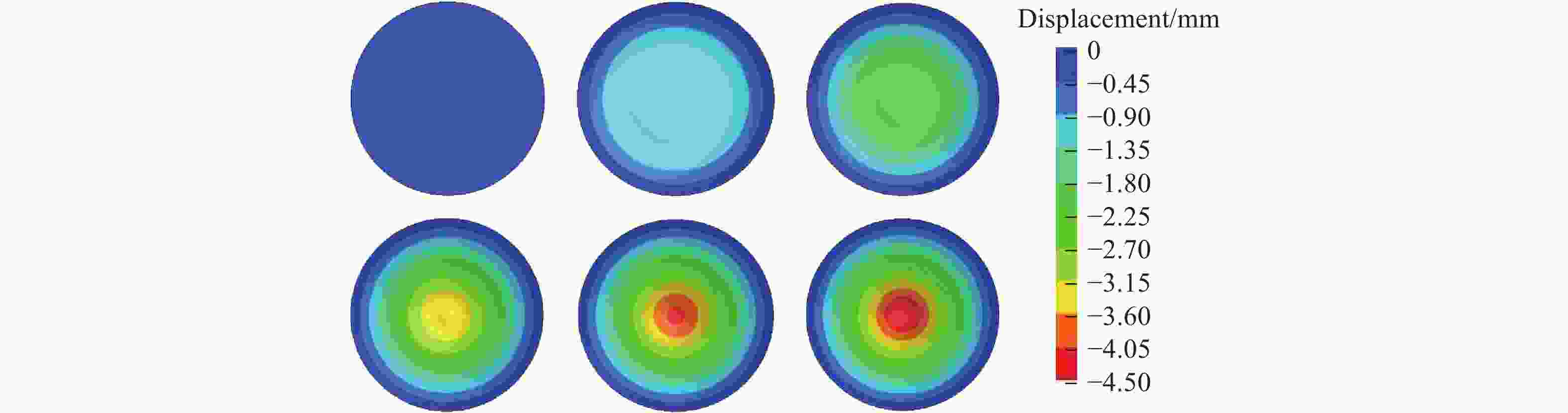

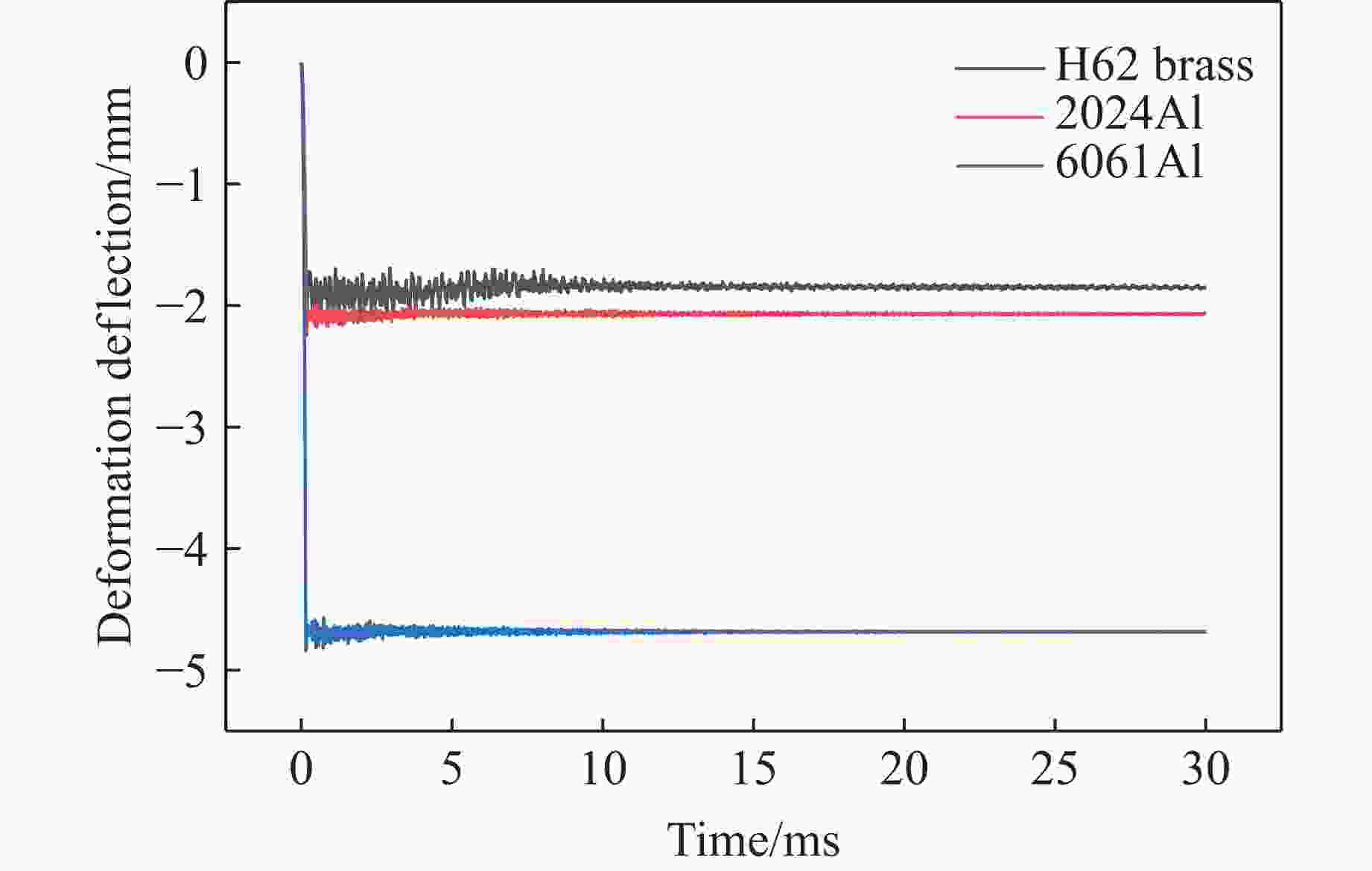

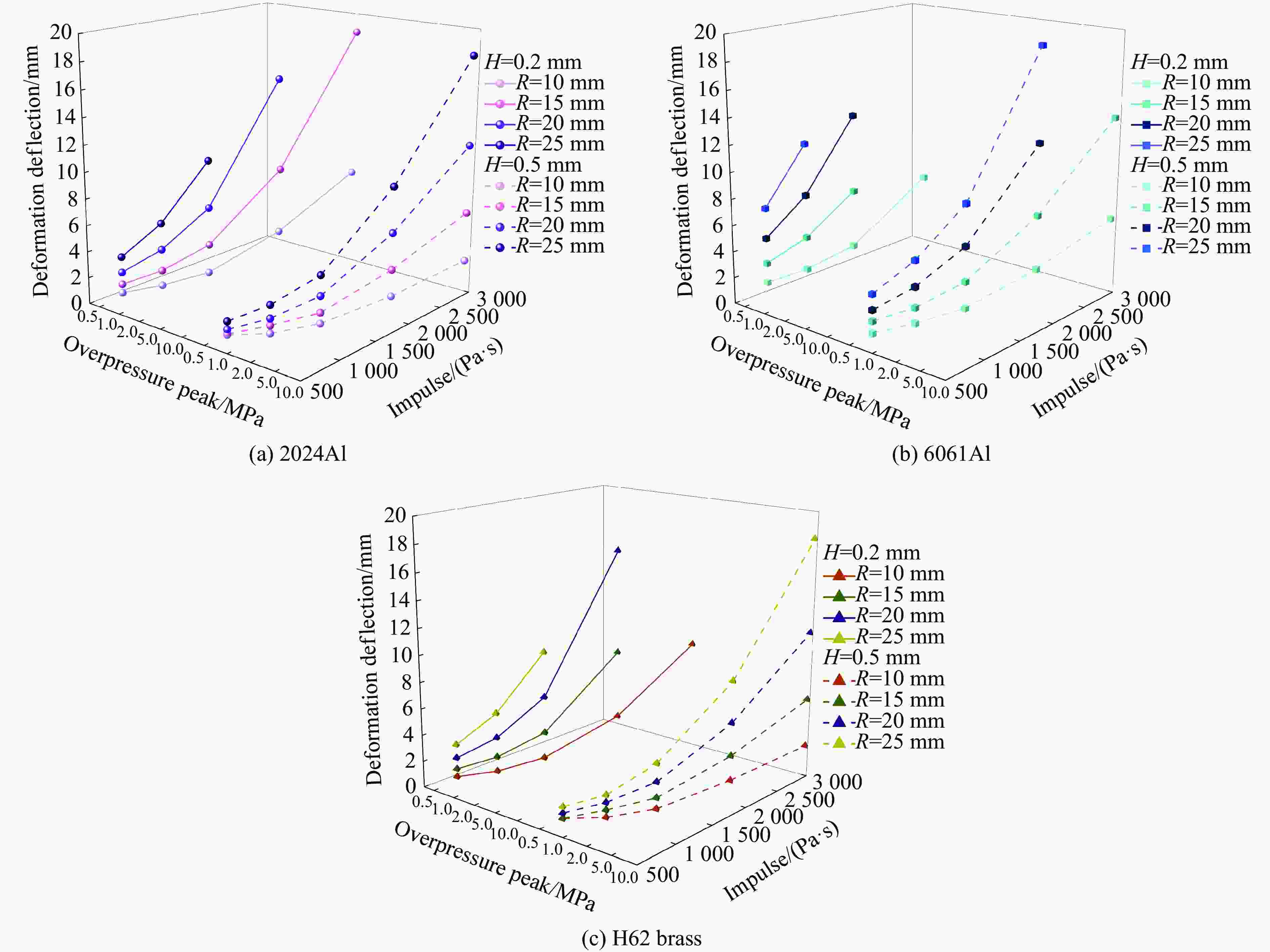

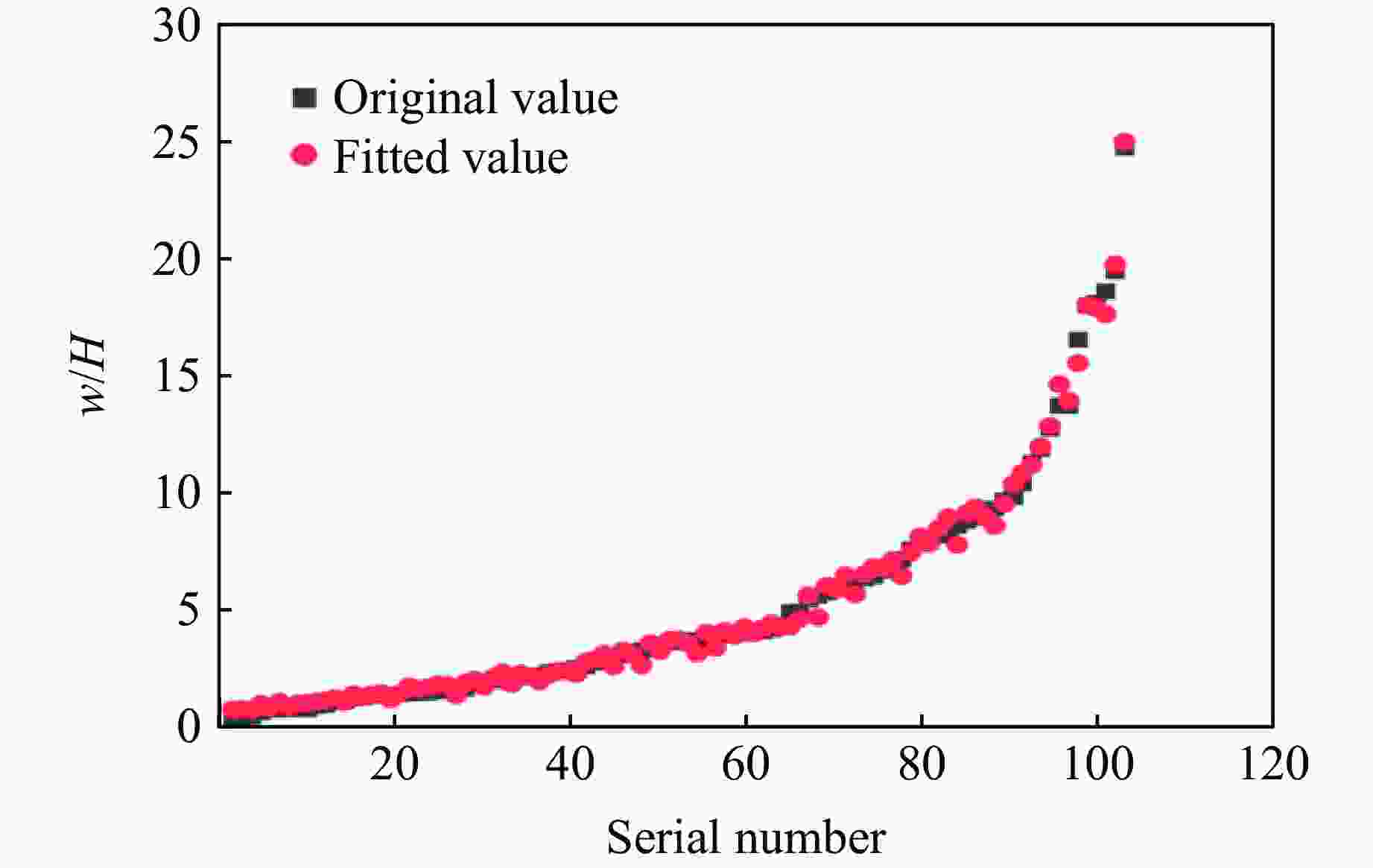

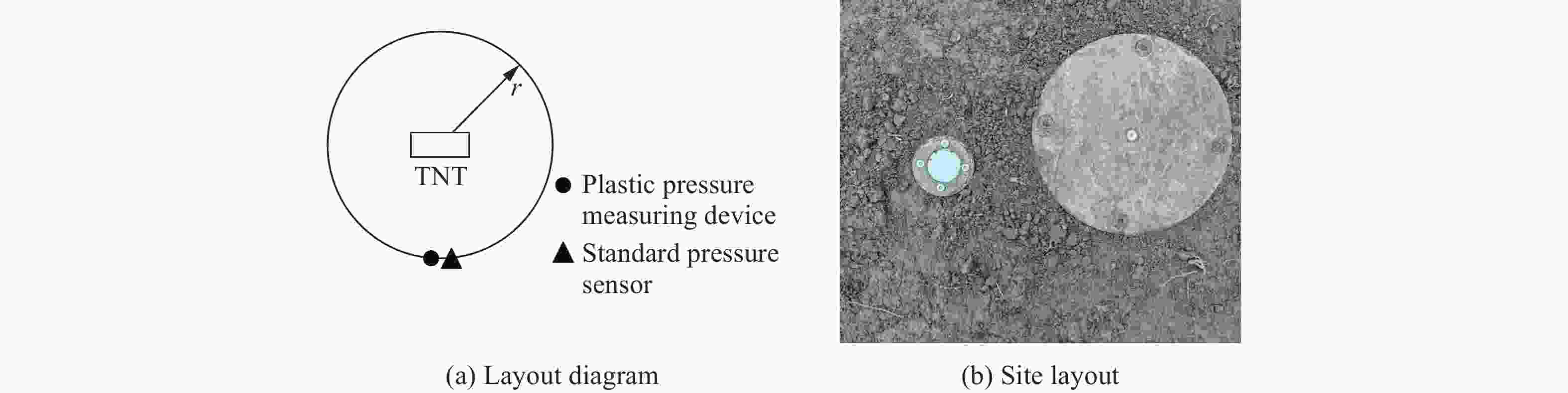

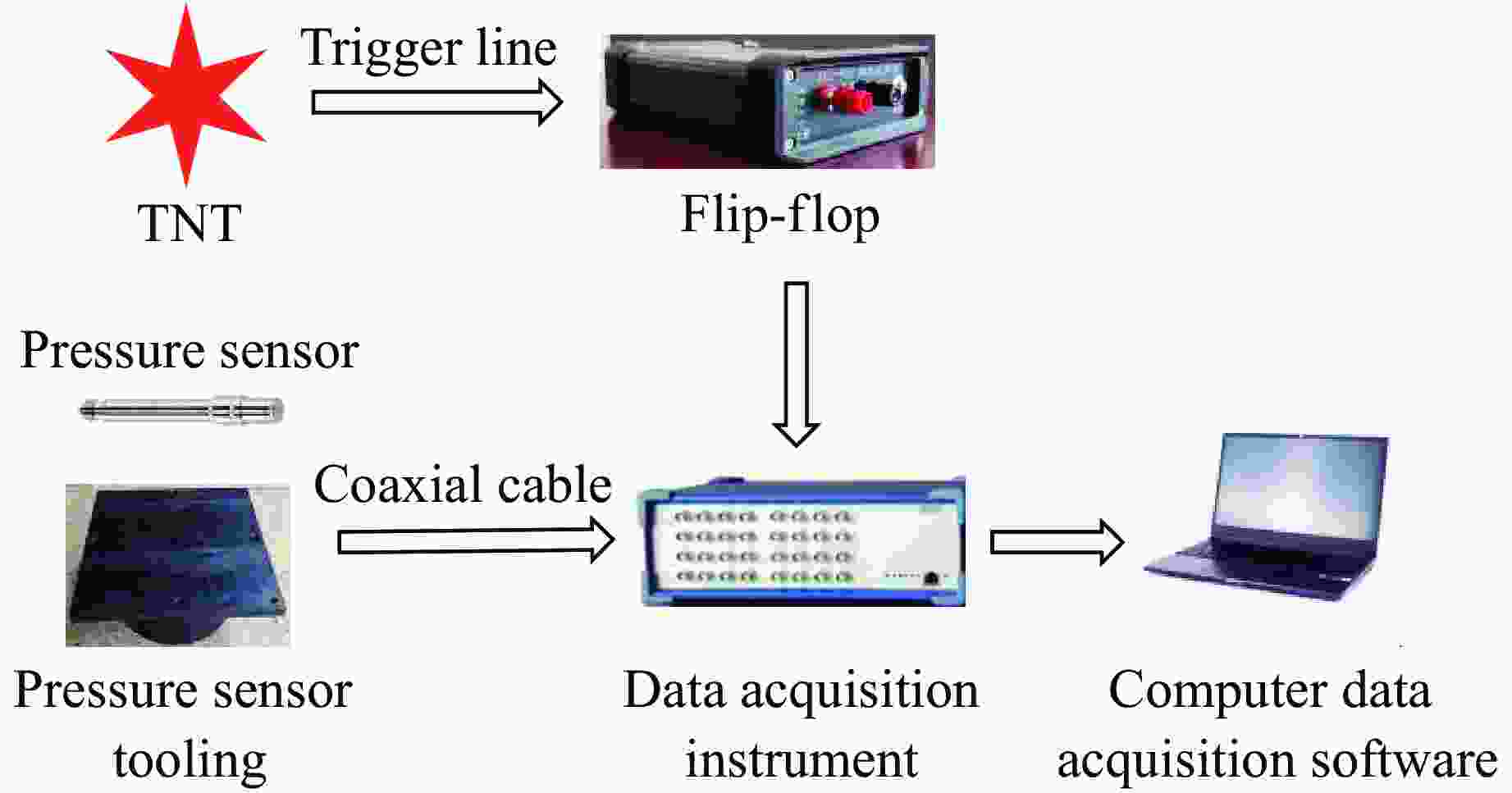

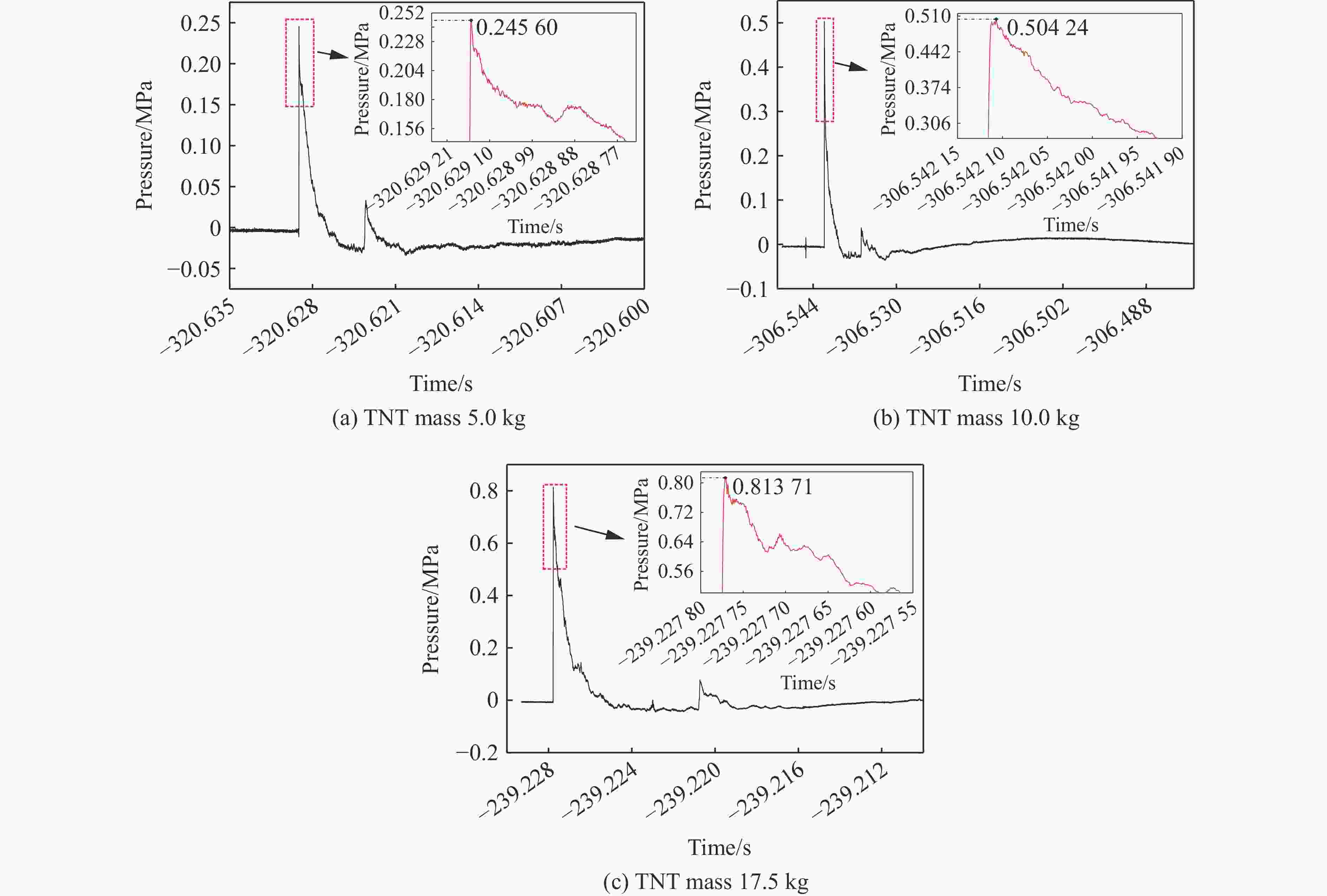

摘要: 当前,基于塑性变形的冲击波压力测试研究往往忽视了超压峰值与冲量对金属薄板的共同作用,导致构建的模型应用范围受限。针对上述问题,开展了不同厚度和直径的3种典型金属圆板在不同冲击载荷作用下的数值模拟分析,揭示了圆板变形量与超压、冲量、直径及厚度的正负相关性。综合考虑超压与冲量共同作用对薄板变形的影响,使用量纲分析方法建立了“圆板变形挠度-超压/冲量”关系模型。试验数据表明,模型的平均误差为4.84%,满足爆炸场测试精度要求,可用于实际冲击波测试。研究成果可为高能战斗部冲击波毁伤威力测试评估提供测试手段及数据支撑。Abstract: The current research of shock wave pressure testing based on plastic deformation neglects the combined effect of overpressure peak and impulse on metal sheet, and the application range of the model is limited. To solve the above problems, the simulation analysis of three typical metal plates with different thicknesses and diameters under different impact loads is carried out, and the positive and negative correlations between the deformation of the plates and overpressure, impulse, diameter and thickness are revealed. Considering the influence of overpressure and impulse on thin plate deformation, the relationship model of deflection of circular plate deformation-overpressure/impulse is established by using dimensional analysis method. The verification test data show that the average error of the model is 4.84%, which meets the requirement of test accuracy in explosion field and can be used for actual shock wave test. The research provides an effective test method and accurate data support for the evaluation of shock wave damage power of high energy warhead.

-

Key words:

- shock wave pressure test /

- metal sheet /

- plastic deformation /

- dimensional analysis

-

表 1 材料参数

Table 1. Material parameters

Material ρ/(kg·m−3) E/GPa ν A/MPa B/MPa n C 2024Al 2 780 69.77 0.33 294.06 481.10 0.881 0 0.008 3 6061Al 2 700 74.31 0.33 96.49 341.11 0.626 6 0.015 0 H62 brass 8 520 101.78 0.31 288.87 167.24 0.435 1 0.017 0 表 2 冲击载荷作用下圆板大变形问题中变量的量纲系数排序

Table 2. Dimensional coefficients of variables in large deformation of circular plates under impact loads

Dimension $ \rho $ $ H $ $ E $ $ A $ $ B $ $ n $ $ R $ $ p $ $ I $ $ w $ M 1 0 1 1 1 0 0 1 1 0 L −3 1 −1 −1 −1 0 1 −1 −1 1 T 0 0 −2 −2 −2 0 0 −2 −1 0 表 3 初等变换后冲击载荷作用下圆板大变形问题中变量的量纲系数

Table 3. Dimensional coefficients of variables in large deformation of circular plates under impact loads after elementary transformations

Dimension $ \rho $ $ H $ $ E $ $ A $ $ B $ $ n $ $ R $ $ p $ $ I $ $ w $ M 1 0 0 0 0 0 0 0 1/2 0 L 0 1 0 0 0 0 1 0 1 1 T 0 0 1 1 1 0 0 1 1/2 0 表 4 动态试验与模型计算结果的对比

Table 4. Comparison of the dynamic test results with the calculated results of the relational model

TNT mass/kg pm/MPa I/(Pa·s) Deformation deflection Test/mm Calc./mm Relative error/% 5.0 0.246 178.32 0.174 0.163 6.32 10.0 0.504 295.87 0.338 0.325 3.85 17.5 0.816 485.45 0.550 0.526 4.36 -

[1] 库尔P. 水下爆炸 [M]. 罗耀杰, 韩润泽, 官信, 等, 译. 北京: 国防工业出版社, 1960.KUHL P. Underwater explosion [M]. Translated by LUO Y J, HAN R Z, GUAN X, et al. Beijing: National Defense Industry Press, 1960. [2] JONES N. Impulsive loading of a simply supported circular rigid plastic plate [J]. Journal of Applied Mechanics, 1968, 35(1): 59–65. [3] FLORENCE A L. Circular plate under a uniformly distributed impulse [J]. International Journal of Solids and Structures, 1966, 2(1): 37–47. [4] TABATA O, KAWAHATA K, SUGIYAMA S, et al. Mechanical property measurements of thin films using load-deflection of composite rectangular membrane [C]//IEEE Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines & Robots. Salt Lake City: IEEE, 1989: 152–156. [5] 余同希, 陈发良. 用“膜力因子法”分析简支刚塑性圆板的大挠度动力响应 [J]. 力学学报, 1990, 22(5): 555–565.YU T X, CHEN F L. Analysis of the large deflection dynamic response of simply-supported circular plates by the “membrane factor method” [J]. Chinese Journal of Theoretical and Applied Mechanics, 1990, 22(5): 555–565. [6] 陈发良, 余同希. 计入膜力塑性耗散效应的矩形板塑性动力响应 [J]. 爆炸与冲击, 2005, 25(3): 200–206.CHEN F L, YU T X. Dynamic plastic response of rectangular plates with plastic energy dissipation by membrane force [J]. Explosion and Shock Waves, 2005, 25(3): 200–206. [7] WIERZBICKI T, NURICK G N. Large deformation of thin plates under localised impulsive loading [J]. International Journal of Impact Engineering, 1996, 18(7/8): 899–918. [8] 李家文. 爆炸冲击波作用下结构瞬态响应分析 [D]. 长沙: 国防科学技术大学, 2006.LI J W. Transient response analysis of structures under blast wave [D]. Changsha: National University of Defense Technology, 2006. [9] BRILL A, ME-BAR Y, SADOT O, et al. A method for measuring the impulse on structural foundations due to a blast wave [J]. International Journal of Impact Engineering, 2012, 49: 214–221. [10] 傅辉刚, 孔德仁, 李丽萍, 等. 基于效应靶法评价爆炸冲击波毁伤的数值仿真 [J]. 测试技术学报, 2015, 29(4): 326–331. doi: 10.3969/j.issn.1671-7449.2015.04.010FU H G, KONG D R, LI L P, et al. Numerical simulation of assessing the damage of explosive blast wave base on effective target’s method [J]. Journal of Test and Measurement Technology, 2015, 29(4): 326–331. doi: 10.3969/j.issn.1671-7449.2015.04.010 [11] 李丽萍. 破片战斗部毁伤威力测试关键技术研究 [D]. 南京: 南京理工大学, 2017.LI L P. Investigation on some key measuring technologies of fragment warhead power field [D]. Nanjing: Nanjing University of Science and Technology, 2017. [12] 荣吉利, 刘东兵, 赵自通, 等. 圆支圆板在动爆冲击波作用下的动力响应 [J]. 北京理工大学学报, 2021, 41(5): 474–479.RONG J L, LIU D B, ZHAO Z T, et al. Dynamic response of fixed circular plate subjected to dynamic explosion shock wave [J]. Transactions of Beijing Institute of Technology, 2021, 41(5): 474–479. [13] 吴迪, 米国, 郭香华, 等. 空爆载荷作用下固支弹塑性圆板的动力学模型 [J]. 高压物理学报, 2022, 36(5): 054202.WU D, MI G, GUO X H, et al. Dynamic model of elastoplastic circular plate with fixed support under air explosion load [J]. Chinese Journal of High Pressure Physics, 2022, 36(5): 054202. [14] 翟红波, 李尚青, 毛伯永, 等. 周边固支效应靶薄板冲击响应的稳健性分析 [J]. 振动、测试与诊断, 2023, 43(5): 1026–1032, 1045.ZHAI H B, LI S Q, MAO B Y, et al. Analysis of shock response robustness for effect target sheet with peripheral fixed support [J]. Journal of Vibration, Measurement & Diagnosis, 2023, 43(5): 1026–1032, 1045. [15] 郭佳凯, 朱春晓, 施锐, 等. 冲击波作用下变形圆板表面载荷研究 [J]. 舰船科学技术, 2024, 46(5): 21–26.GUO J K, ZHU C X, SHI R, et al. Research on surface load of deformation circular plate under blast wave [J]. Ship Science and Technology, 2024, 46(5): 21–26. [16] SIRIGIRI V K R, GUDIGA V Y, GATTU U S, et al. A review on Johnson Cook material model [J]. Materials Today: Proceedings, 2022, 62: 3450–3456. [17] SHIRBHATE P A, GOEL M D. Investigation of effect of perforations in honeycomb sandwich structure for enhanced blast load mitigation [J]. Mechanics of Advanced Materials and Structures, 2023, 30(17): 3463–3478. [18] JACOB N, NURICK G N, LANGDON G S. The effect of stand-off distance on the failure of fully clamped circular mild steel plates subjected to blast loads [J]. Engineering Structures, 2007, 29(10): 2723–2736. [19] GHARABABAEI H, DARVIZEH A, DARVIZEH M. Analytical and experimental studies for deformation of circular plates subjected to blast loading [J]. Journal of Mechanical Science and Technology, 2010, 24(9): 1855–1864. [20] GHARABABAEI H, DARVIZEH A. Experimental and analytical investigation of large deformation of thin circular plates subjected to localized and uniform impulsive loading# [J]. Mechanics Based Design of Structures and Machines, 2010, 38(2): 171–189. -

下载:

下载: