Investigations on the Stick-Slip Behavior and Dynamic Interface Friction Mechanisms of Fiber Winding

-

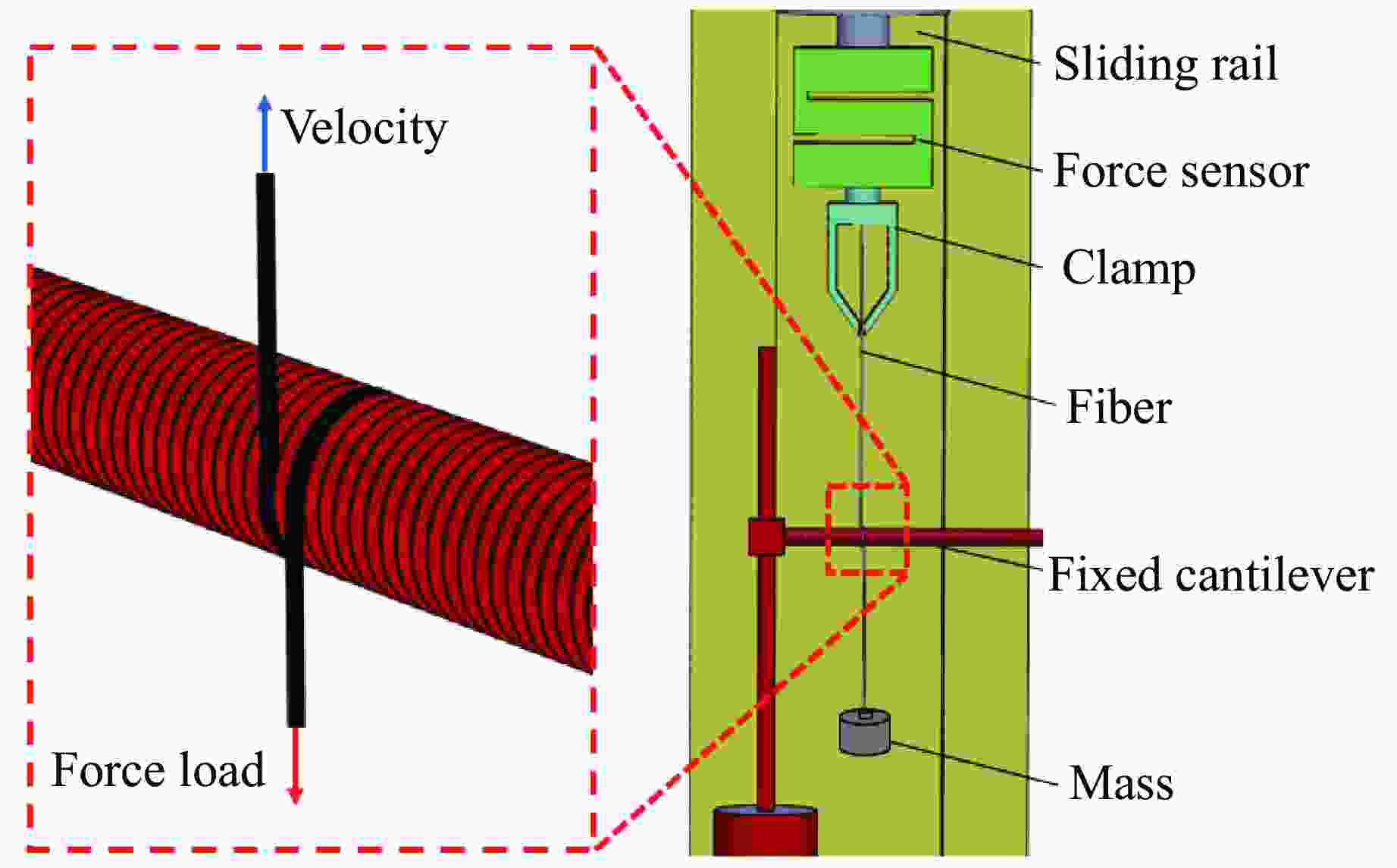

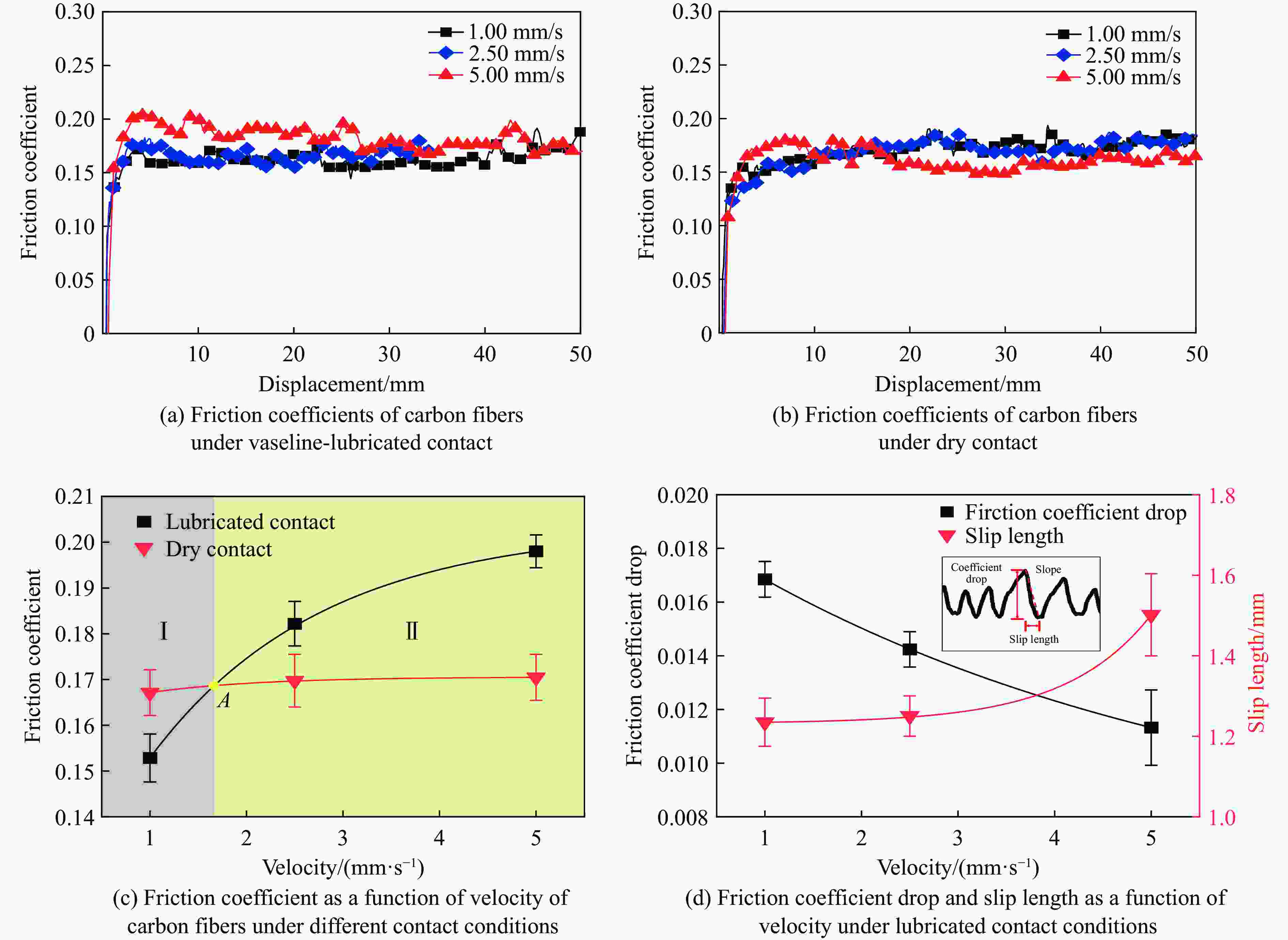

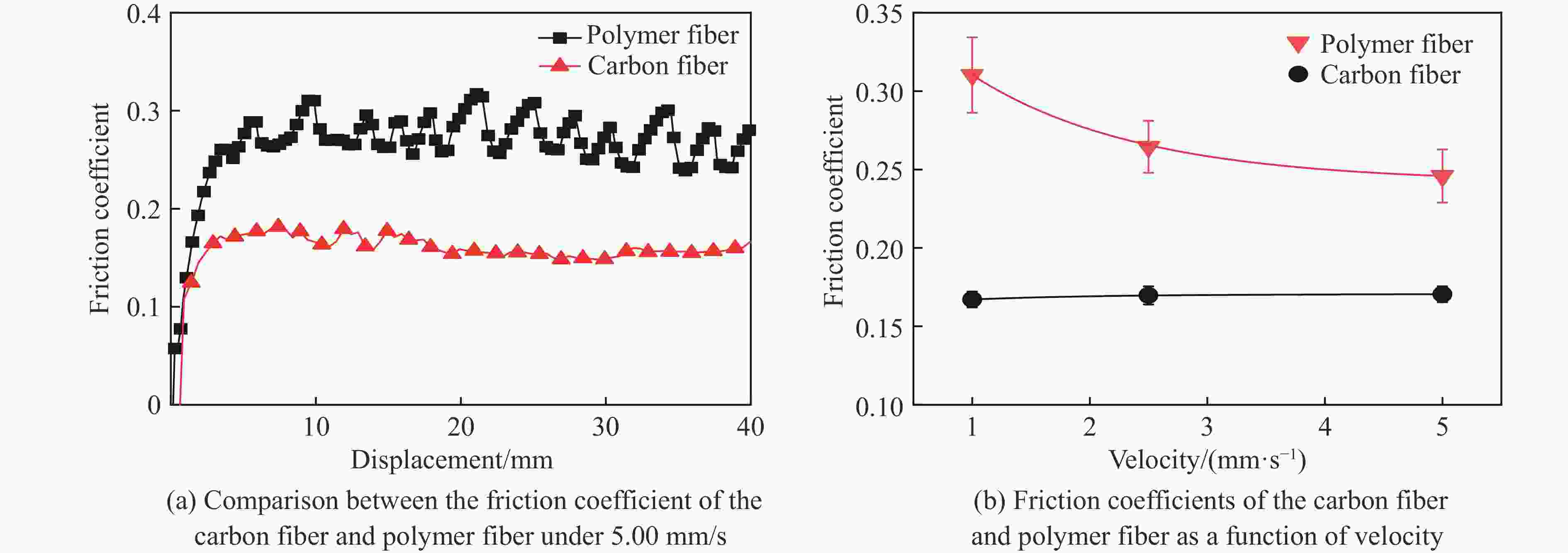

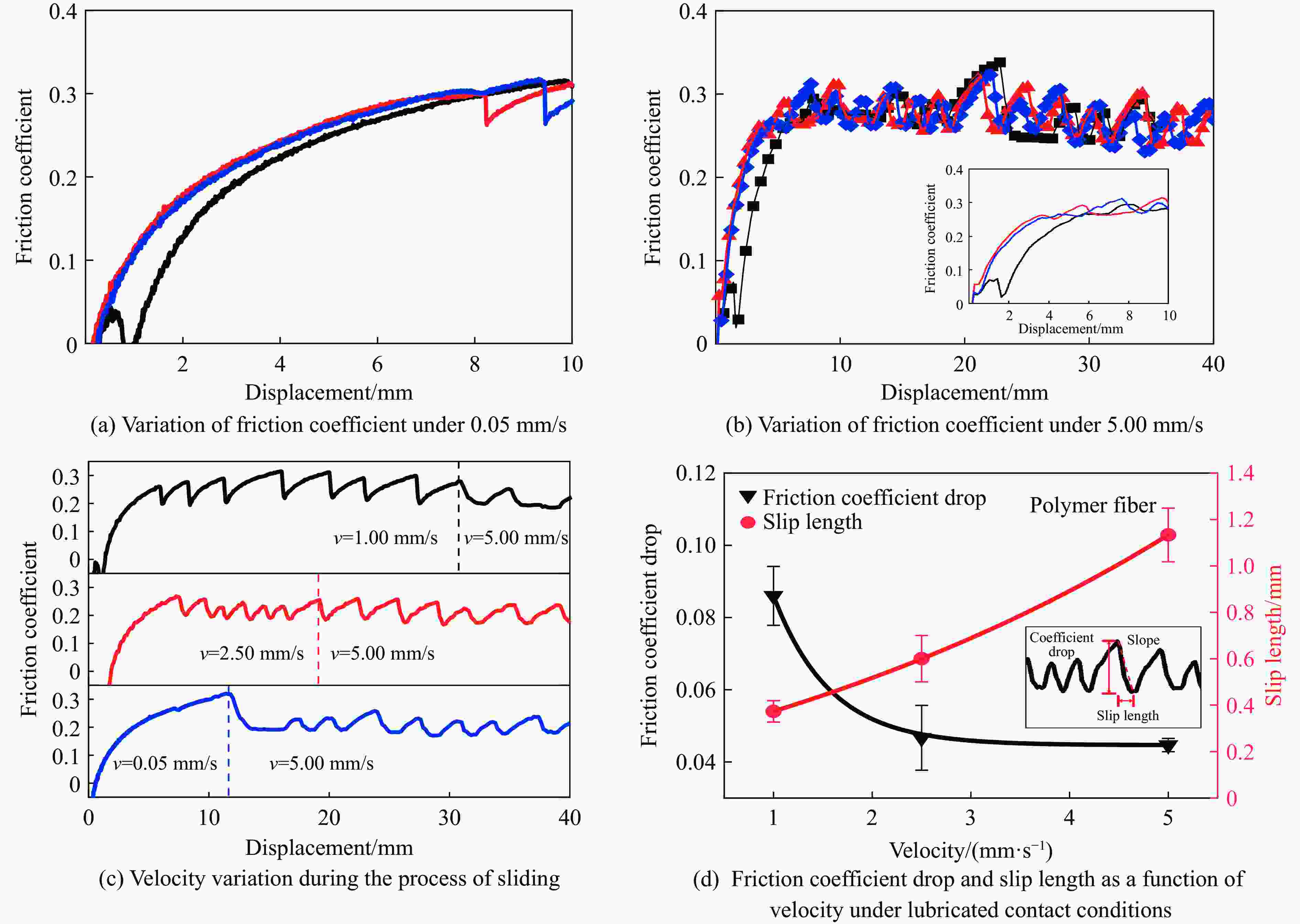

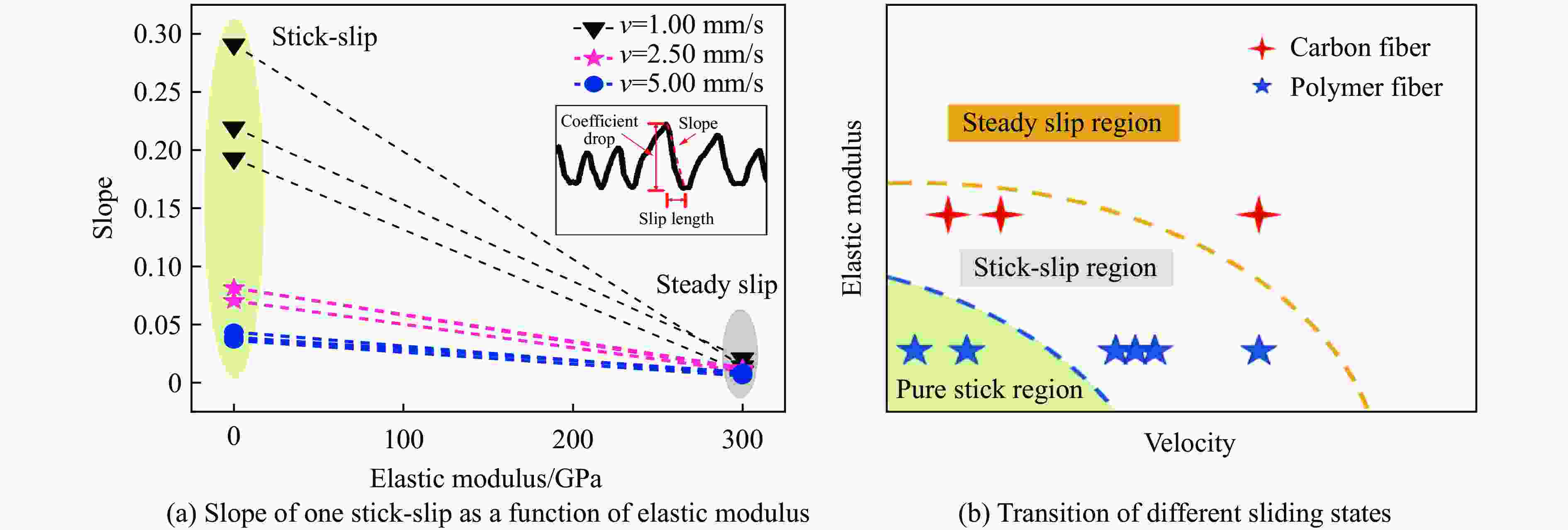

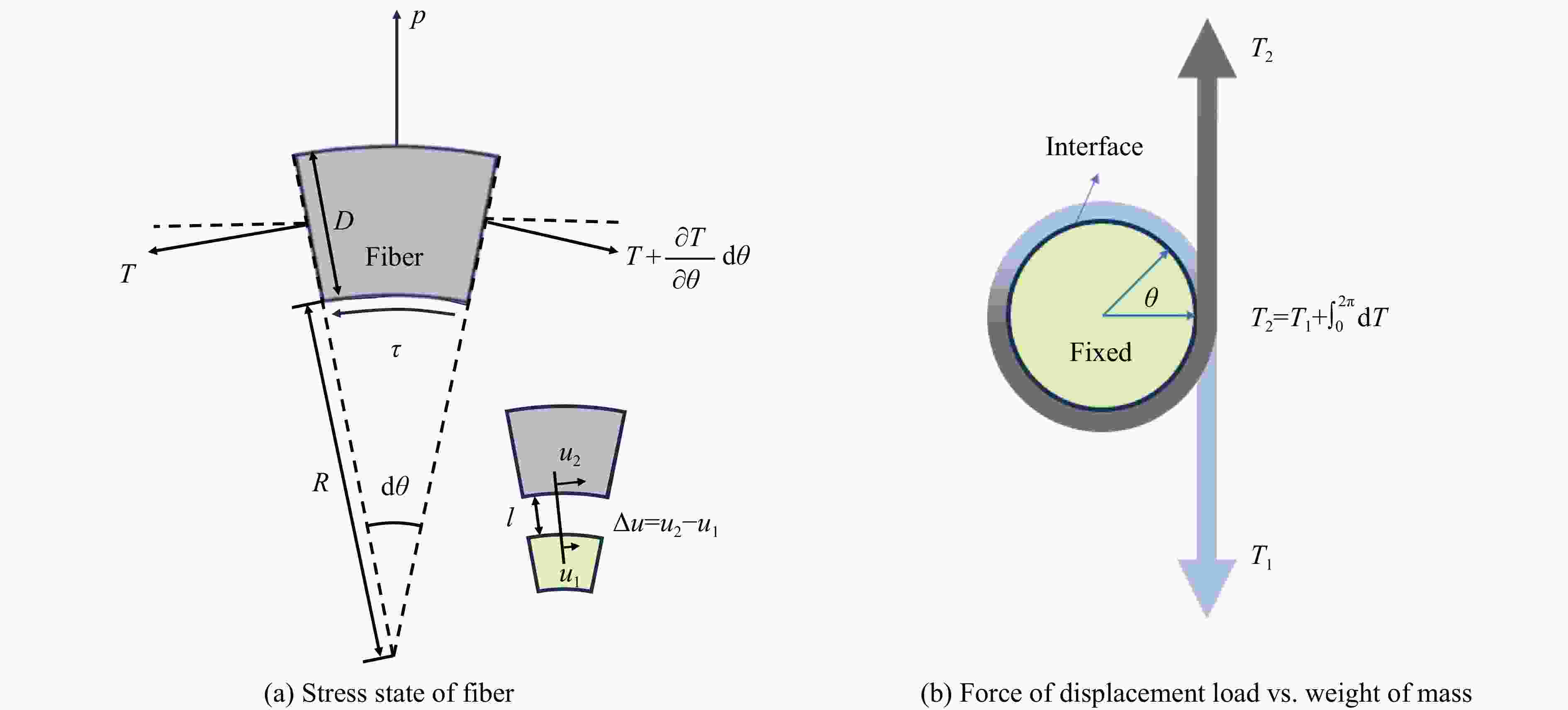

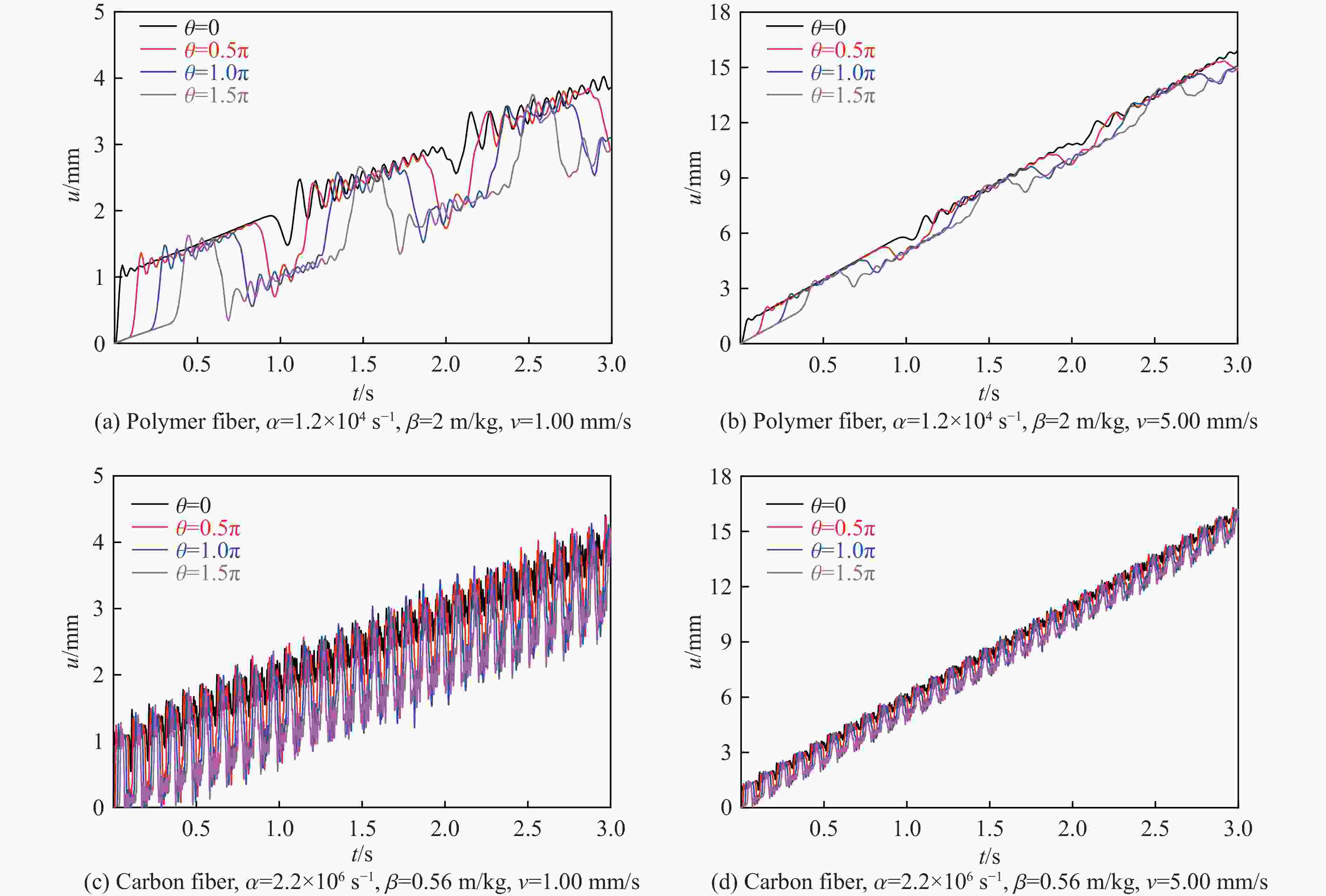

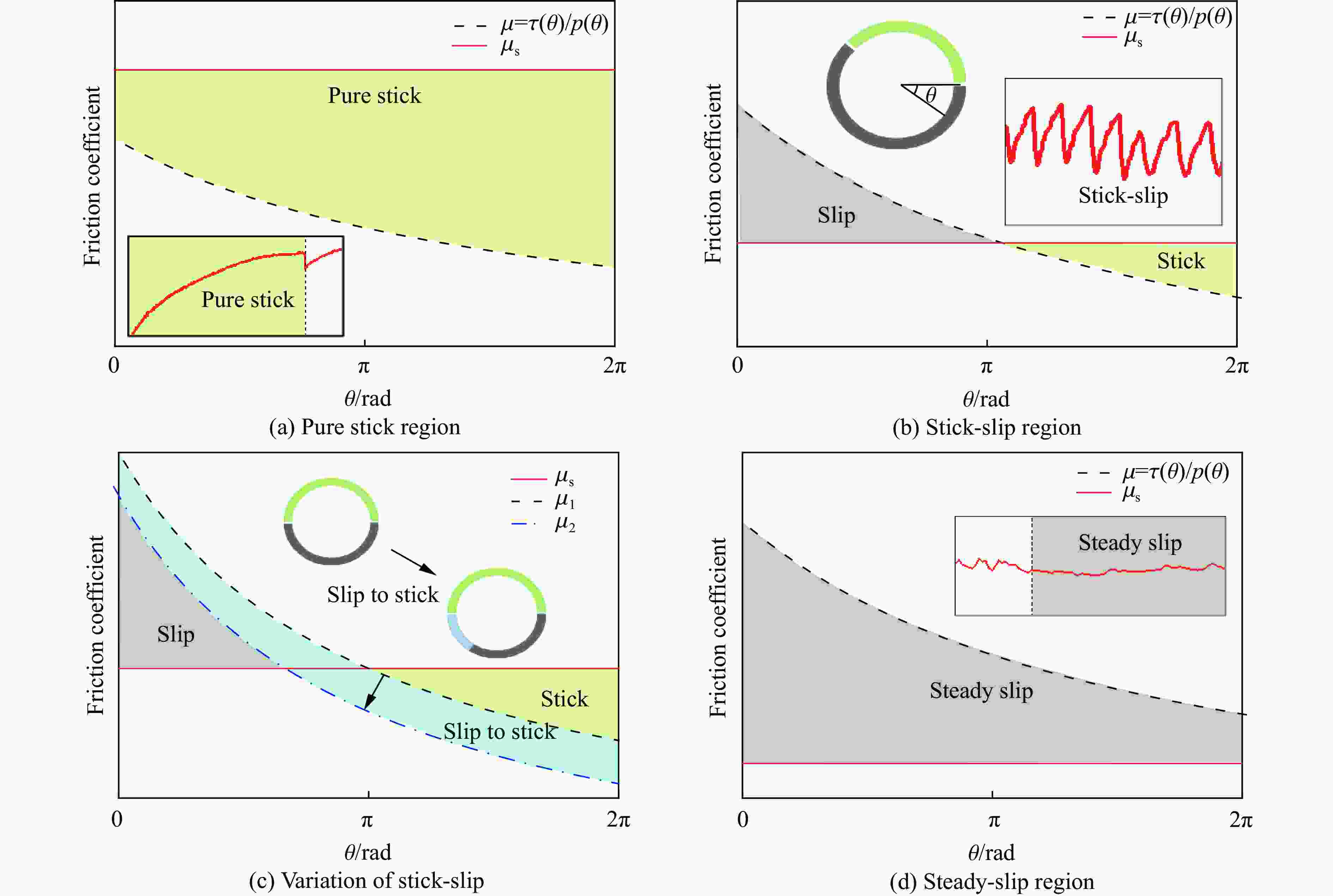

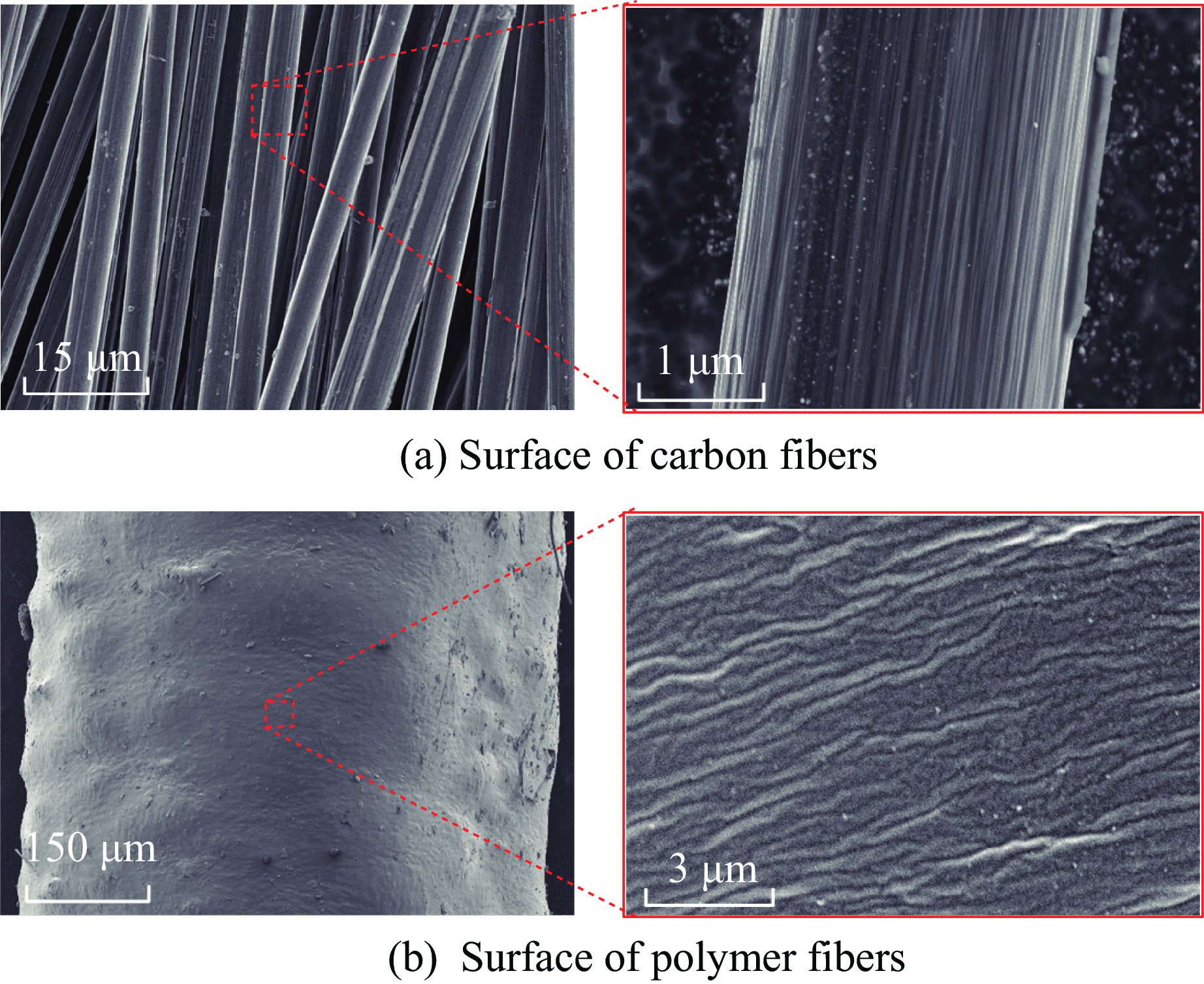

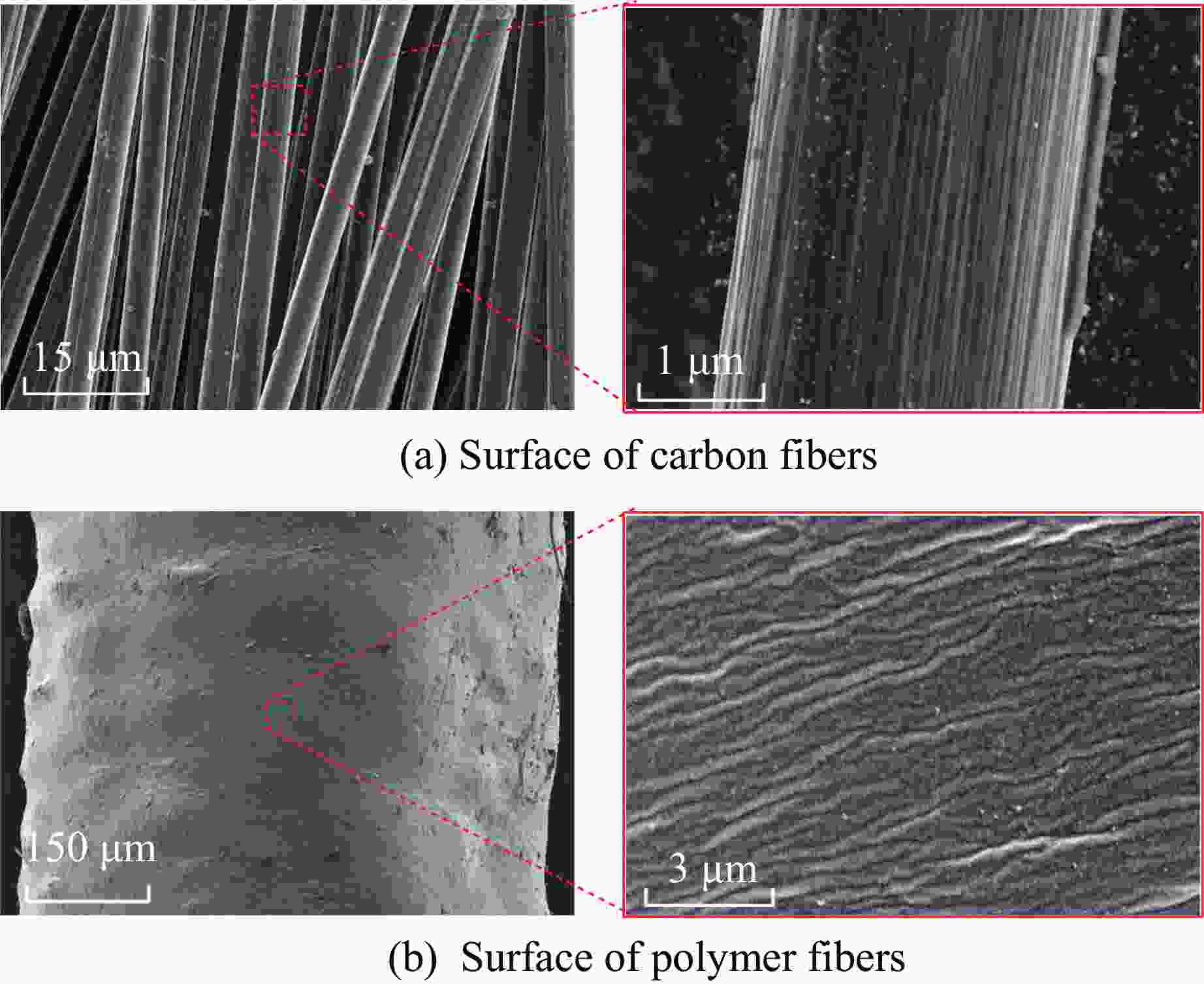

摘要: 通过缠绕方式可以增加绳索界面的接触摩擦系数,进而提升其应用的安全性和稳定性。然而,当前关于纤维缠绕的黏滑特性及动摩擦力学行为研究尚存在不足,特别是其与速度相关的黏-滑转换机制仍很欠缺。为此,设计了纤维缠绕的界面黏滑实验,研究了具有高弹性模量的碳纤维以及具有低弹性模量的聚合物纤维在不同加载条件下的界面动摩擦力学性能,探讨了不同加载速度以及界面润滑条件对2种纤维滑移的影响规律。结果表明,界面间的滑动状态主要由材料的弹性模量以及界面间滑移速度共同决定,高弹性模量材料相较于低弹性模量材料更容易脱离黏滑状态进入纯滑动状态。润滑状态下界面摩擦系数的速度敏感性更高。理论结果表明,初始阶段纤维缠绕的界面摩擦系数分布并不均匀,与缠绕角度成反比关系,且弹性模量较高的纤维界面滑移状态的同步性更强。研究结果可为纤维缠绕的界面摩擦与安全使用提供理论和技术支撑。Abstract: Fiber winding can enhance the friction coefficient at the interface of ropes, thereby improving the security and stability of the entire mechanical system. Nevertheless, specific mechanisms underlying this phenomenon remain unclear, particularly concerning the velocity-dependent stick-slip model. An experimental system focused on the stick-slip behavior from fiber winding was designed to unveil principles governing two types of fiber sliding with different fiber types, contact conditions and loading velocities. The results indicate that the fiber elastic modulus and sliding velocity jointly determine the sliding state of the interface. Specifically, brittle fibers with a high elastic modulus exhibit an easier transition from a stick-slip state to a steady-slip state. The variation in the friction coefficient at different sliding velocities is more pronounced under lubricated conditions. Theoretical results indicate that the friction coefficient appears non-uniform across the interface, and is inversely proportional to the angle of entanglement. For high-modulus fibers, the sliding state exhibits stronger synchronization throughout the entire interface. This study provides theoretical and technical support for manipulating interface friction and improving the safe use of fiber winding.

-

Key words:

- interface /

- stick-slip /

- dynamic friction /

- fiber winding

-

表 1 聚合物纤维和碳纤维的材料参数

Table 1. Material parameters of polymer fibers and carbon fibers

Material ρ/(kg·m−3) E/MPa D/mm R/mm α/s−1 β/(m·kg−1) τ/Pa Polymer fibers 500 2 1 5 1.2×104 2 6.6×103 Carbon fibers 1800 2.3×105 1 5 2.2×106 0.56 1.6×104 -

[1] CAPOZZA R, RUBINSTEIN S M, BAREL I, et al. Stabilizing stick-slip friction [J]. Physical Review Letters, 2011, 107(2): 024301. doi: 10.1103/PhysRevLett.107.024301 [2] LU Y X, HAN D, FU Q D, et al. Experimental investigation of stick-slip behaviors in dry sliding friction [J]. Tribology International, 2025, 201: 110221. doi: 10.1016/j.triboint.2024.110221 [3] OBERST S, LAI J C S. Nonlinear transient and chaotic interactions in disc brake squeal [J]. Journal of Sound and Vibration, 2015, 342: 272–289. doi: 10.1016/j.jsv.2015.01.005 [4] PARK J, LEE Y. The evaluation of noise based on the frictional phenomena using automotive interior materials [J]. Tribology Transactions, 2021, 64(5): 777–783. doi: 10.1080/10402004.2020.1869359 [5] YONGTAO M, PENGYUN G, LIN C, et al. Research on squeak noise from polypropylene in frictional contact with leather for automotive interior assembly [J]. Tribology Transactions, 2021, 64(2): 313–324. doi: 10.1080/10402004.2020.1836298 [6] WANG Q, WANG Z W, MO J L, et al. Nonlinear behaviors of the disc brake system under the effect of wheel-rail adhesion [J]. Tribology International, 2022, 165: 107263. doi: 10.1016/j.triboint.2021.107263 [7] SONG Y, WANG Z W, LIU Z G, et al. A spatial coupling model to study dynamic performance of pantograph-catenary with vehicle-track excitation [J]. Mechanical Systems and Signal Processing, 2021, 151: 107336. doi: 10.1016/j.ymssp.2020.107336 [8] MARUI E, ENDO H, HASHIMOTO M, et al. Some considerations of slideway friction characteristics by observing stick-slip vibration [J]. Tribology International, 1996, 29(3): 251–262. doi: 10.1016/0301-679X(96)83204-X [9] SINOU J J, DEREURE O, MAZET G B, et al. Friction-induced vibration for an aircraft brake system—part 1: experimental approach and stability analysis [J]. International Journal of Mechanical Sciences, 2006, 48(5): 536–554. doi: 10.1016/j.ijmecsci.2005.12.002 [10] LORANG X, FOY-MARGIOCCHI F, NGUYEN Q S, et al. TGV disc brake squeal [J]. Journal of Sound and Vibration, 2006, 293(3/4/5): 735–746. doi: 10.1016/j.jsv.2005.12.006 [11] OUYANG H, MOTTERSHEAD J E, CARTMELL M P, et al. Friction-induced parametric resonances in discs: effect of a negative friction-velocity relationship [J]. Journal of Sound and Vibration, 1998, 209(2): 251–264. doi: 10.1006/jsvi.1997.1261 [12] YAN C S, CHEN H Y, LAI P Y, et al. Statistical laws of stick-slip friction at mesoscale [J]. Nature Communications, 2023, 14(1): 6221. doi: 10.1038/s41467-023-41850-1 [13] BEN-DAVID O, RUBINSTEIN S M, FINEBERG J. Slip-stick and the evolution of frictional strength [J]. Nature, 2010, 463(7277): 76–79. doi: 10.1038/nature08676 [14] WON H I, LEE B, CHUNG J. Stick-slip vibration of a cantilever beam subjected to harmonic base excitation [J]. Nonlinear Dynamics, 2018, 92(4): 1815–1828. doi: 10.1007/s11071-018-4164-7 [15] CUBILLO A, URIONDO A, PERINPANAYAGAM S. Computational mixed TEHL model and Stribeck curve of a journal bearing [J]. Tribology Transactions, 2017, 60(6): 1053–1062. doi: 10.1080/10402004.2016.1245456 [16] LIU X B, VLAJIC N, LONG X H, et al. Nonlinear motions of a flexible rotor with a drill bit: stick-slip and delay effects [J]. Nonlinear Dynamics, 2013, 72(1): 61–77. doi: 10.1007/s11071-012-0690-x [17] HE Y Y, FU Y H, WANG H, et al. Inhibiting mechanism of micro dimples on the stick-slip of sliding guideway: combined numerical analysis with tribological tests [J]. Tribology International, 2021, 162: 107144. doi: 10.1016/j.triboint.2021.107144 [18] 陈美多, 张祥林, 袁良柱, 等. 岩石界面的动态剪切扩散行为 [J]. 爆炸与冲击, 2024, 44(8): 081422. doi: 10.11883/bzycj-2023-0469CHEN M D, ZHANG X L, YUAN L Z, et al. Dynamic shear diffusion behavior at rock interfaces [J]. Explosion and Shock Waves, 2024, 44(8): 081422. doi: 10.11883/bzycj-2023-0469 [19] LEINE R I, VAN CAMPEN D H, DE KRAKER A, et al. Stick-slip vibrations induced by alternate friction models [J]. Nonlinear Dynamics, 1998, 16(1): 41–54. doi: 10.1023/A:1008289604683 [20] FEENY B, GURAN A, HINRICHS N, et al. A historical review on dry friction and stick-slip phenomena [J]. Applied Mechanics Reviews, 1998, 51(5): 321–341. doi: 10.1115/1.3099008 [21] XIE Z L, JIAO J, WRONA S. The fluid-structure interaction lubrication performances of a novel bearing: experimental and numerical study [J]. Tribology International, 2023, 179: 108151. doi: 10.1016/j.triboint.2022.108151 [22] HETZLER H, SCHWARZER D, SEEMANN W. Analytical investigation of steady-state stability and Hopf-bifurcations occurring in sliding friction oscillators with application to low-frequency disc brake noise [J]. Communications in Nonlinear Science and Numerical Simulation, 2007, 12(1): 83–99. doi: 10.1016/j.cnsns.2006.01.007 [23] WANG P F, YANG J L, LI X, et al. Modification of the contact surfaces for improving the puncture resistance of laminar structures [J]. Scientific Reports, 2017, 7(1): 6615. doi: 10.1038/s41598-017-06007-3 [24] WANG P F, ZHANG X, ZHANG H, et al. Energy absorption mechanisms of modified double-aluminum layers under low-velocity impact [J]. International Journal of Applied Mechanics, 2015, 7(6): 1550086. doi: 10.1142/S1758825115500866 [25] WANG P F, JIANG H B, LIU M, et al. Toughening mechanisms for the dynamic perforation behavior of laminar aluminum alloy with lubricated frictional interfaces [J]. Materials & Design, 2022, 224: 111268. doi: 10.1016/j.matdes.2022.111268 [26] 王文帅, 王鹏飞, 田杰, 等. 双层碳纳米管薄膜的侵彻力学性能 [J]. 高压物理学报, 2022, 36(4): 044105. doi: 10.11858/gywlxb.20220508WANG W S, WANG P F, TIAN J, et al. Penetration mechanical properties of double-layer carbon nanotube films [J]. Chinese Journal of High Pressure Physics, 2022, 36(4): 044105. doi: 10.11858/gywlxb.20220508 [27] GWEON J H, JOO B S, JANG H. The effect of short glass fiber dispersion on the friction and vibration of brake friction materials [J]. Wear, 2016, 362/363: 61–67. doi: 10.1016/j.wear.2016.05.004 [28] PARK J S, LEE S M, JOO B S, et al. The effect of material properties on the stick-slip behavior of polymers: a case study with PMMA, PC, PTFE, and PVC [J]. Wear, 2017, 378/379: 11–16. doi: 10.1016/j.wear.2017.01.097 [29] YOON S W, SHIN M W, LEE W G, et al. Effect of surface contact conditions on the stick-slip behavior of brake friction material [J]. Wear, 2012, 294/295: 305–312. doi: 10.1016/j.wear.2012.07.011 [30] WANG X C, MO J L, OUYANG H, et al. An investigation of stick-slip oscillation of Mn-Cu damping alloy as a friction material [J]. Tribology International, 2020, 146: 106024. doi: 10.1016/j.triboint.2019.106024 [31] WANG X C, WANG R L, HUANG B, et al. A study of effect of various normal force loading forms on frictional stick-slip vibration [J]. Journal of Dynamics, Monitoring and Diagnostics, 2022, 1(1): 46–55. doi: 10.37965/jdmd.v2i2.48 [32] GAO H, ZHAO L J, LI L, et al. Effect of wear-induced surface deformation on stick-slip friction of galvanized automotive steels [J]. Langmuir, 2022, 38(37): 11459–11467. doi: 10.1021/acs.langmuir.2c01825 [33] YANG W F, GONG W, CHANG B Y, et al. Scale-bridging mechanics transfer enables ultrabrightmechanoluminescent fiber electronics [J]. ACS Nano, 2024, 18(35): 24404–24413. doi: 10.1021/acsnano.4c07125 -

下载:

下载: