| [1] |

KORONIS G, SILVA A, FONTUL M. Green composites: a review of adequate materials for automotive applications [J]. Composites Part B: Engineering, 2013, 44(1): 120–127. doi: 10.1016/j.compositesb.2012.07.004

|

| [2] |

YAN C Z, HAO L, HUSSEIN A, et al. Evaluations of cellular lattice structures manufactured using selective laser melting [J]. International Journal of Machine Tools and Manufacture, 2012, 62: 32–38. doi: 10.1016/j.ijmachtools.2012.06.002

|

| [3] |

ZHANG L C, ATTAR H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: a review [J]. Advanced Engineering Materials, 2016, 18(4): 463–475. doi: 10.1002/adem.201500419

|

| [4] |

ZHANG J J, LU G X, YOU Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: a review [J]. Composites Part B: Engineering, 2020, 201: 108340. doi: 10.1016/j.compositesb.2020.108340

|

| [5] |

ZHANG H, SUN W F. Mechanical behavior and crashworthiness assessment of corrugated inner rib reinforced tubular structures [J]. Thin-Walled Structures, 2023, 189: 110894. doi: 10.1016/J.TWS.2023.110894

|

| [6] |

EVANS A G, HUTCHINSON J W, FLECK N A, et al. The topological design of multifunctional cellular metals [J]. Progress in Materials Science, 2001, 46(3/4): 309–327. doi: 10.1016/S0079-6425(00)00016-5

|

| [7] |

ASHBY M F. The properties of foams and lattices [J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2006, 364(1838): 15–30. doi: 10.1098/rsta.2005.1678

|

| [8] |

ANDREW J J, VERMA P, KUMAR S. Impact behavior of nanoengineered, 3D printed plate-lattices [J]. Materials & Design, 2021, 202: 109516. doi: 10.1016/j.matdes.2021.109516

|

| [9] |

REN Y, LIU Z F, CAI S Y, et al. Mechanical properties and deformation behaviors of layered-hybrid lattice structure fabricated by selective laser melting [J]. Advanced Engineering Materials, 2024, 26(1): 2301040. doi: 10.1002/ADEM.202301040

|

| [10] |

SUN Z P, GUO Y B, SHIM V P W. Deformation and energy absorption characteristics of additively-manufactured polymeric lattice structures—effects of cell topology and material anisotropy [J]. Thin-Walled Structures, 2021, 169: 108420. doi: 10.1016/j.tws.2021.108420

|

| [11] |

LIU C, LERTTHANASARN J, PHAM M S. The origin of the boundary strengthening in polycrystal-inspired architected materials [J]. Nature Communications, 2021, 12(1): 4600. doi: 10.1038/s41467-021-24886-z

|

| [12] |

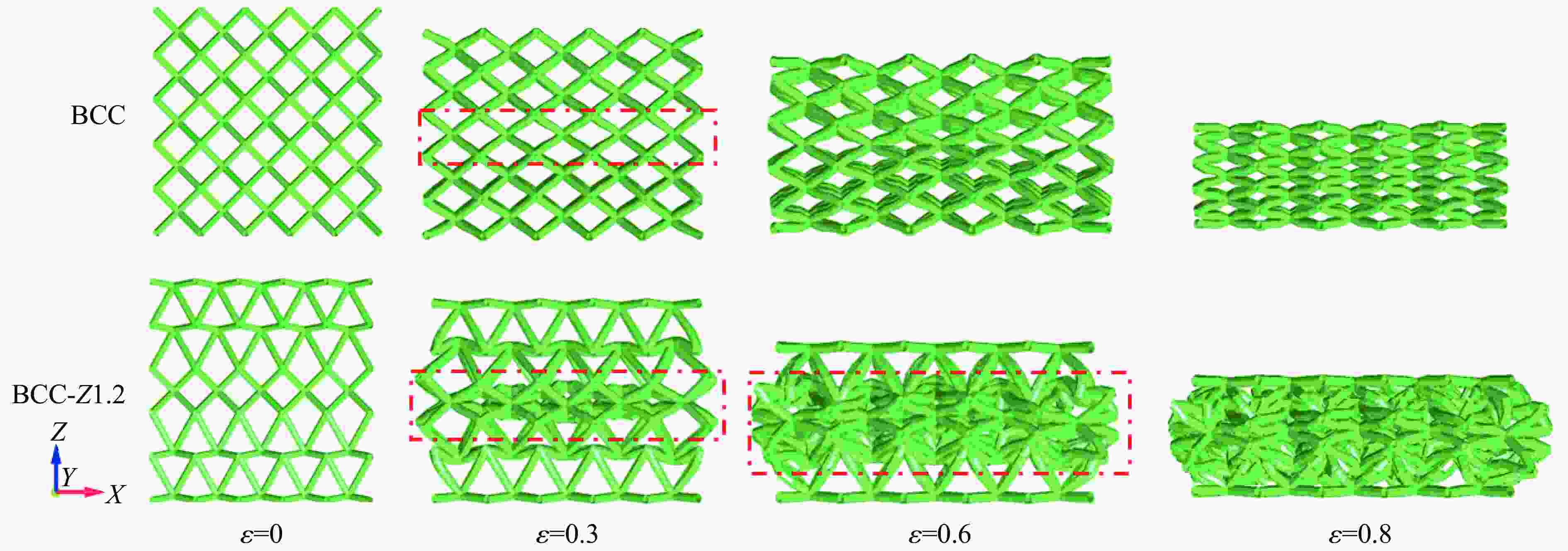

YE J J, SUN Z P, DING Y Y, et al. The deformation mechanism, energy absorption behavior and optimal design of vertical-reinforced lattices [J]. Thin-Walled Structures, 2023, 190: 110988. doi: 10.1016/j.tws.2023.110988

|

| [13] |

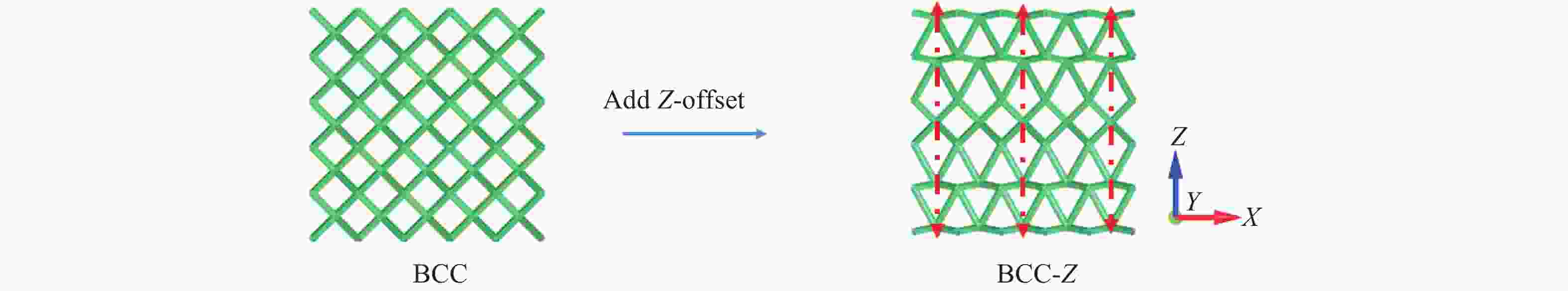

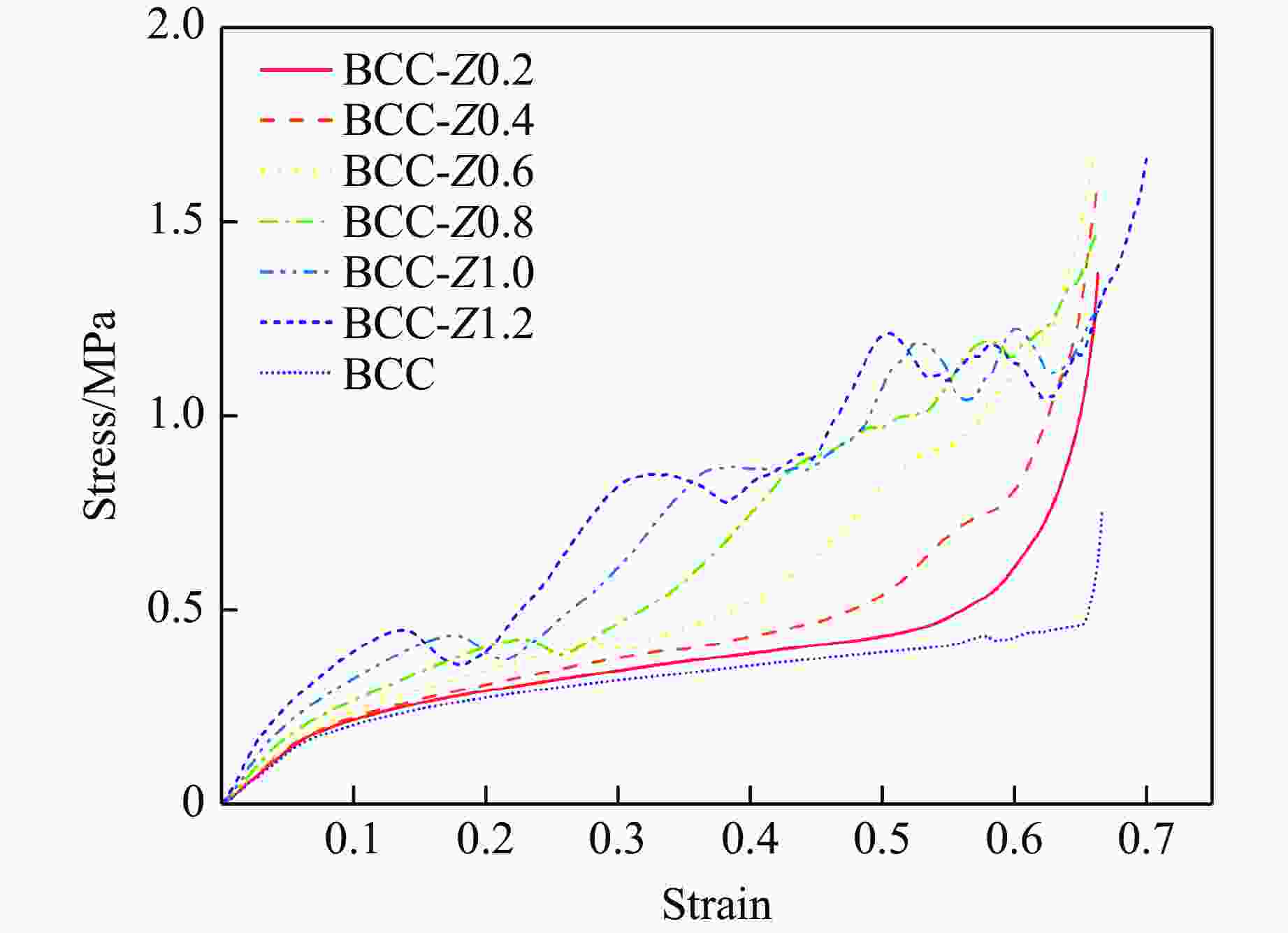

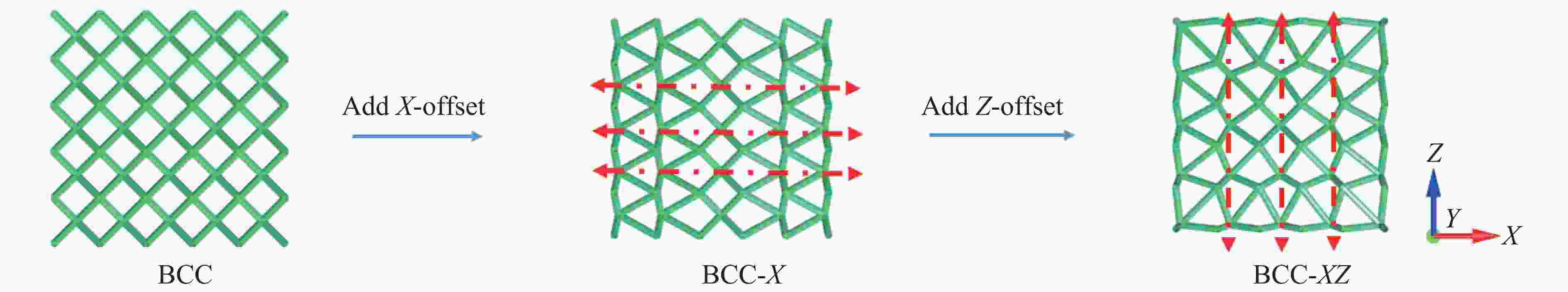

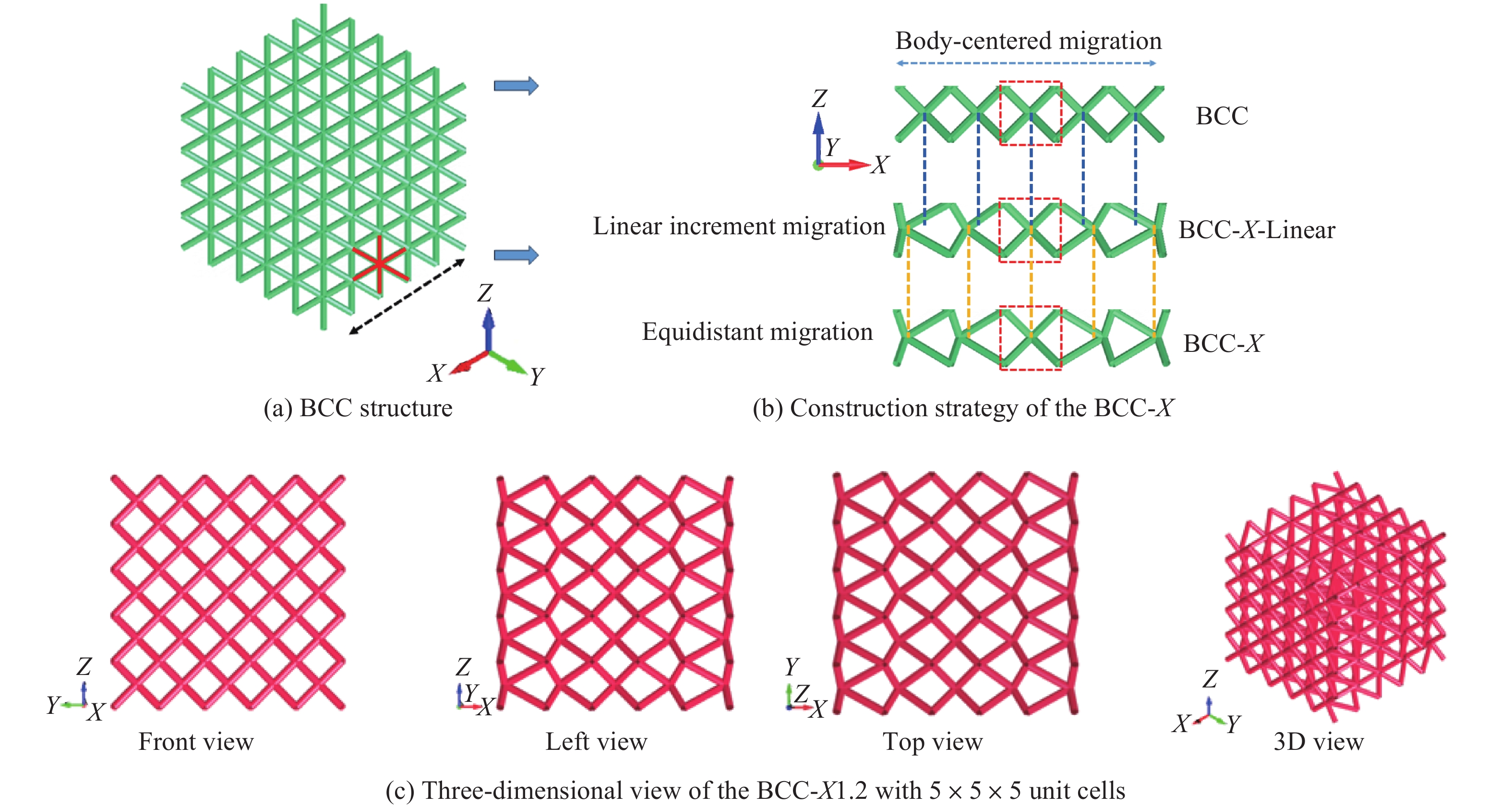

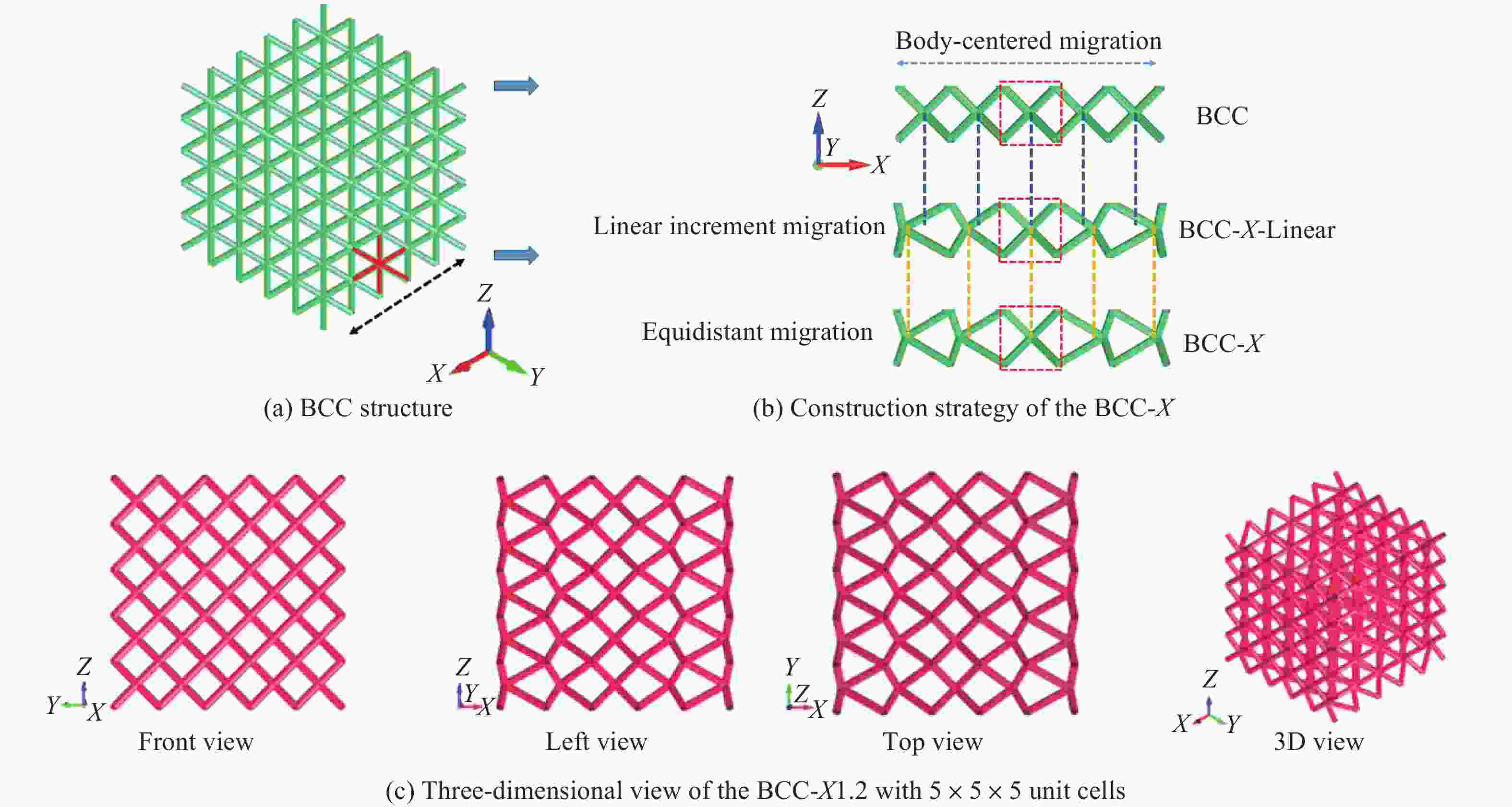

WANG P, YANG F, LU G X, et al. Anisotropic compression behaviors of bio-inspired modified body-centered cubic lattices validated by additive manufacturing [J]. Composites Part B: Engineering, 2022, 234: 109724. doi: 10.1016/j.compositesb.2022.109724

|

| [14] |

王润洲, 张越, 李世强. 组合点阵材料GBCC-BCC变形机制及力学性能分析 [J]. 中国科学: 物理学 力学 天文学, 2023, 53(4): 244611. doi: 10.1360/SSPMA-2022-0314WANG R Z, ZHANG Y, LI S Q. Analysis of the deformation mechanism and mechanical properties of graded body-centered cubic nested body-centered cubic lattice material [J]. SCIENTIA SINICA Physica, Mechanica & Astronomica, 2023, 53(4): 244611. doi: 10.1360/SSPMA-2022-0314

|

| [15] |

MA X D, ZHANG N, ZHANG C L, et al. Mechanical behavior of a novel lattice structure with two-step deformation [J]. Thin-Walled Structures, 2024, 197: 111580. doi: 10.1016/J.TWS.2024.111580

|

| [16] |

GUO S, MA Y W, LIU P, et al. Mechanical properties of lattice structures with a central cube: experiments and simulations [J]. Materials, 2024, 17(6): 1329. doi: 10.3390/MA17061329

|

| [17] |

SMITH M, GUAN Z, CANTWELL W J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique [J]. International Journal of Mechanical Sciences, 2013, 67: 28–41. doi: 10.1016/j.ijmecsci.2012.12.004

|

| [18] |

BAYKASOĞLU A, BAYKASOĞLU C, CETIN E. Multi-objective crashworthiness optimization of lattice structure filled thin-walled tubes [J]. Thin-Walled Structures, 2020, 149: 106630. doi: 10.1016/j.tws.2020.106630

|

| [19] |

ZHANG N, MA X D, CHANG Y J, et al. A lattice structure with adjustable mechanical behavior constructed by rotating triangles translated out of plane and splicing each other [J]. International Journal of Solids and Structures, 2024, 292: 112740. doi: 10.1016/J.IJSOLSTR.2024.112740

|

| [20] |

BIAN Y J, YANG F, ZHANG S Y, et al. Similarities of the mechanical responses of body-centered cubic lattice structures with different constituent materials under compression [J]. JOM, 2022, 74(4): 1774–1783. doi: 10.1007/s11837-021-04926-1

|

| [21] |

DENG X L, QIN S G, HUANG J L. Crashworthiness analysis of gradient hierarchical multicellular columns evolved from the spatial folding [J]. Materials & Design, 2022, 215: 110435. doi: 10.1016/j.matdes.2022.110435

|

| [22] |

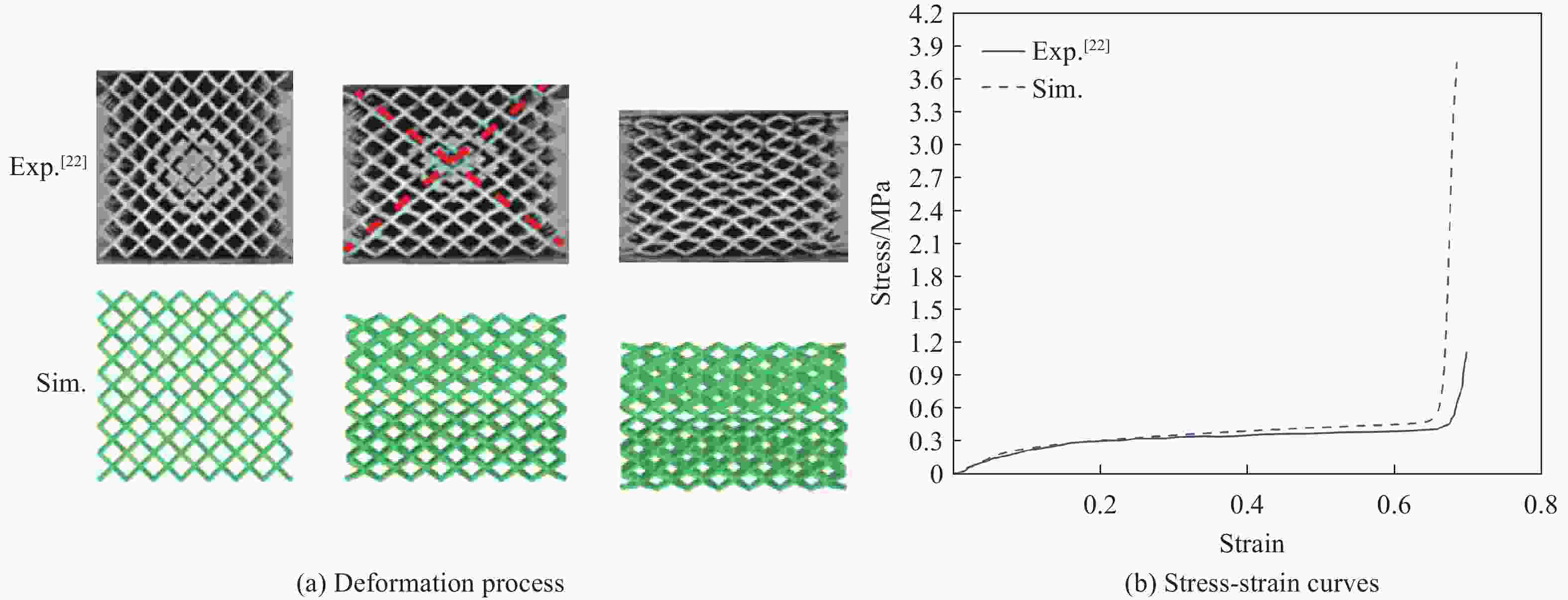

ZHANG S Y, YANG F, LI P H, et al. A topologically gradient body centered lattice design with enhanced stiffness and energy absorption properties [J]. Engineering Structures, 2022, 263: 114384. doi: 10.1016/J.ENGSTRUCT.2022.114384

|

下载:

下载: