Mechanical Behaviors and Energy Absorption Characteristics of Mortise and Tenon Porous Columns under Uniaxial Compressive Loading

-

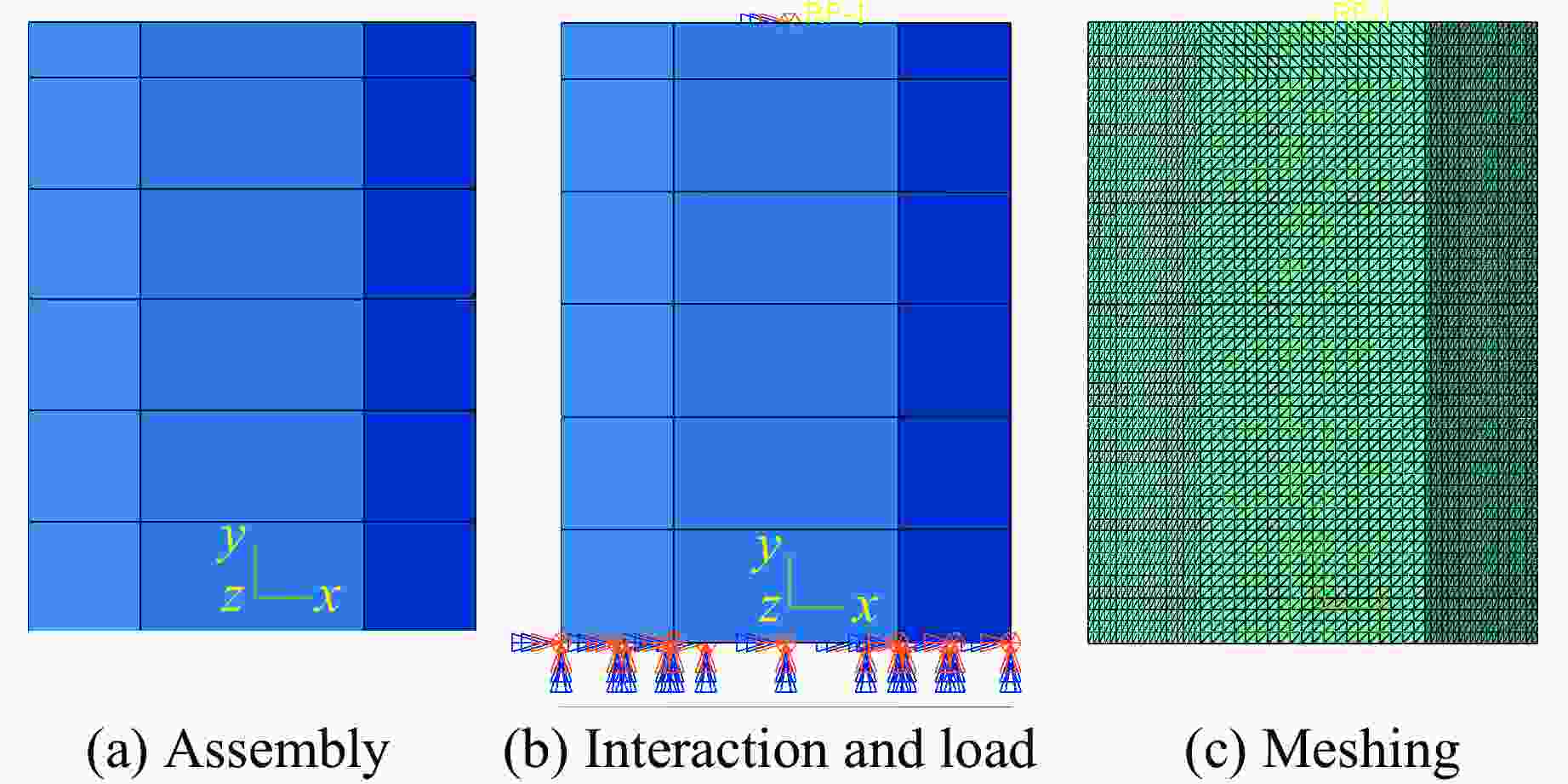

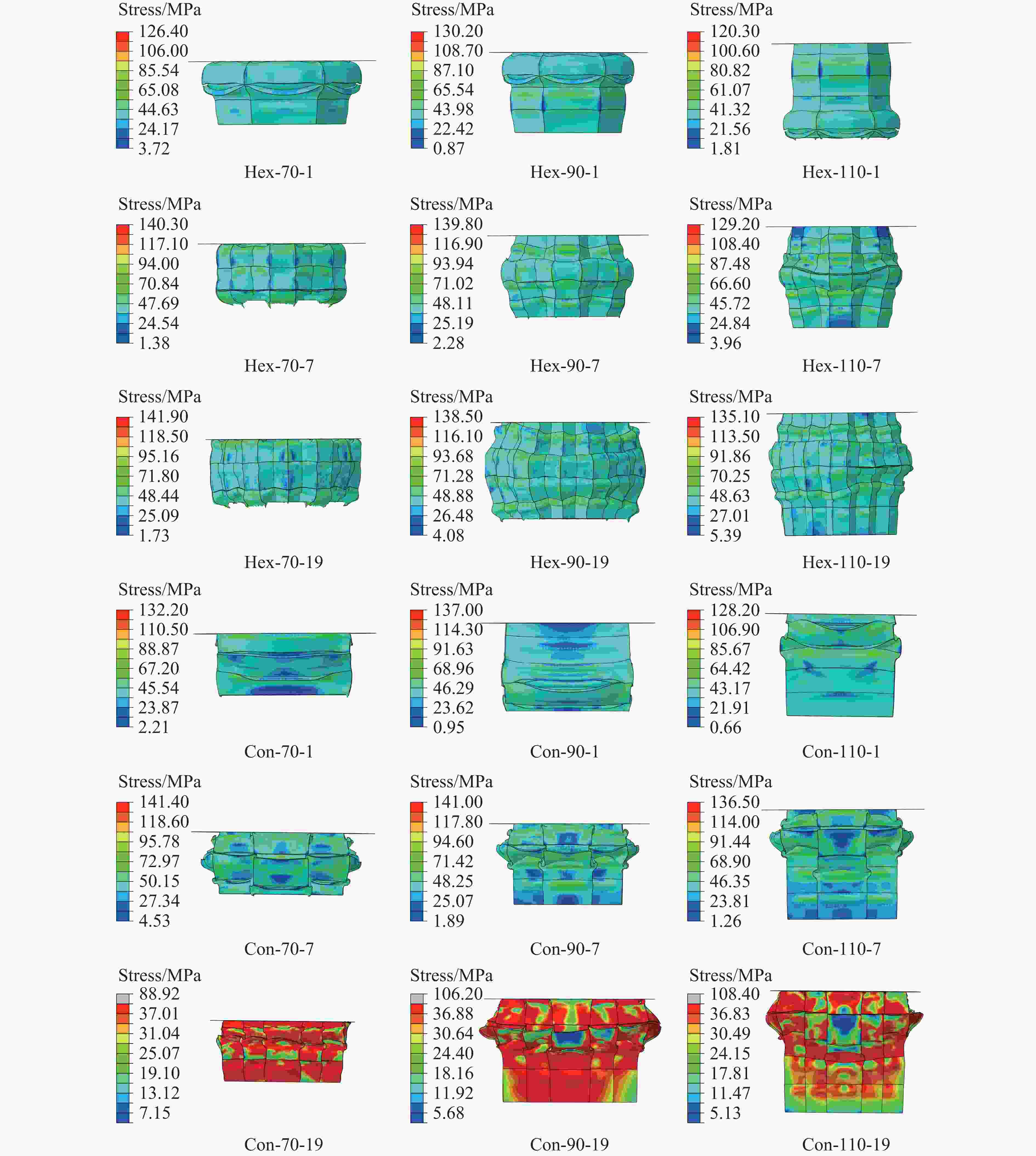

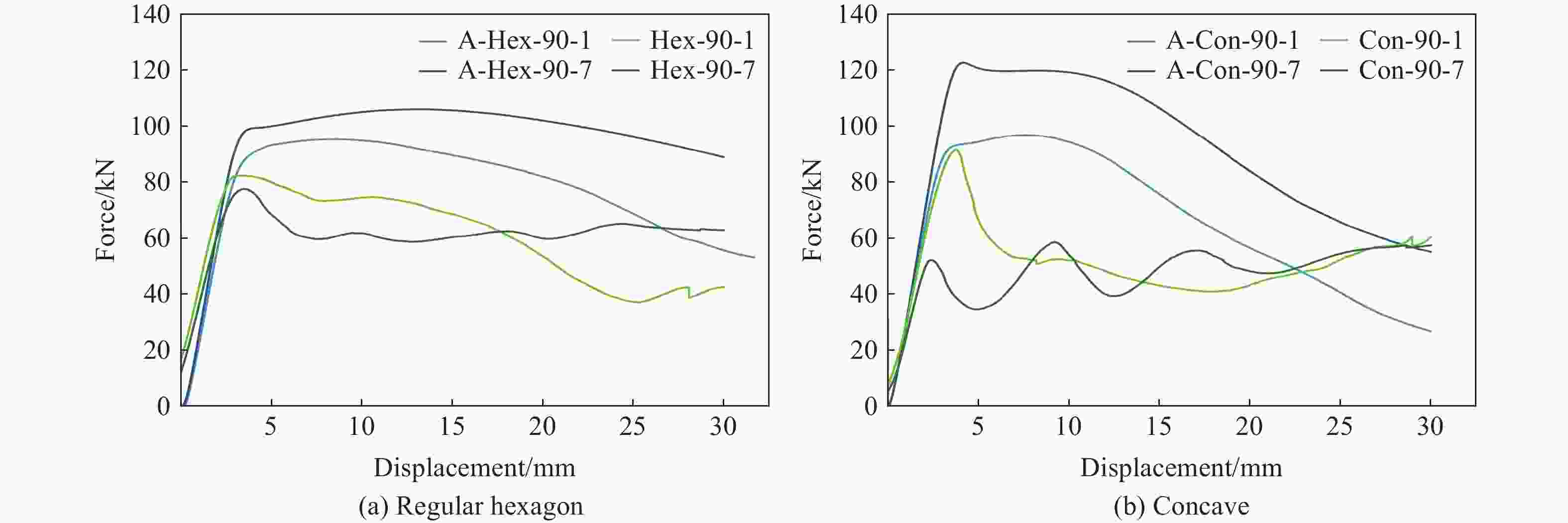

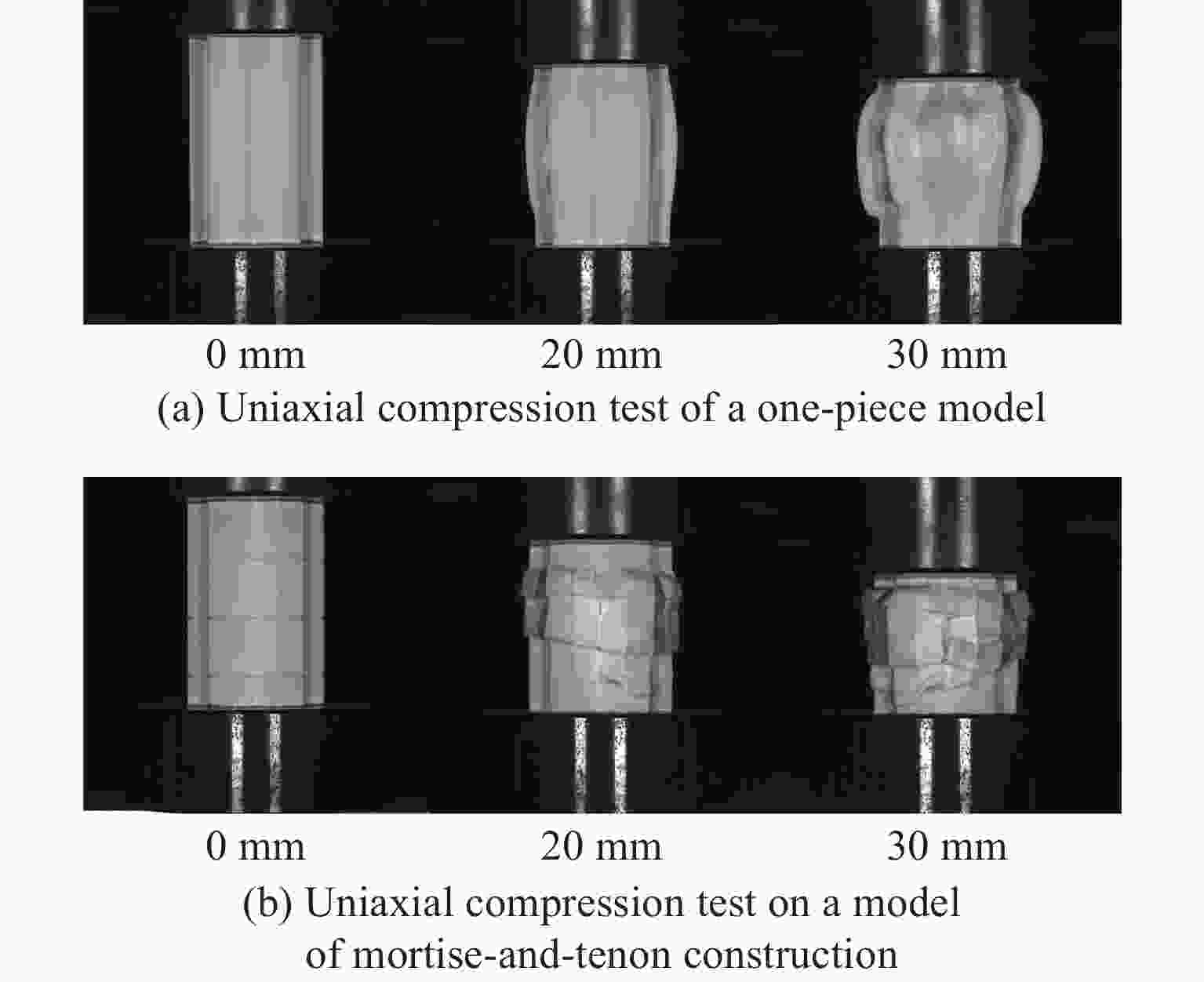

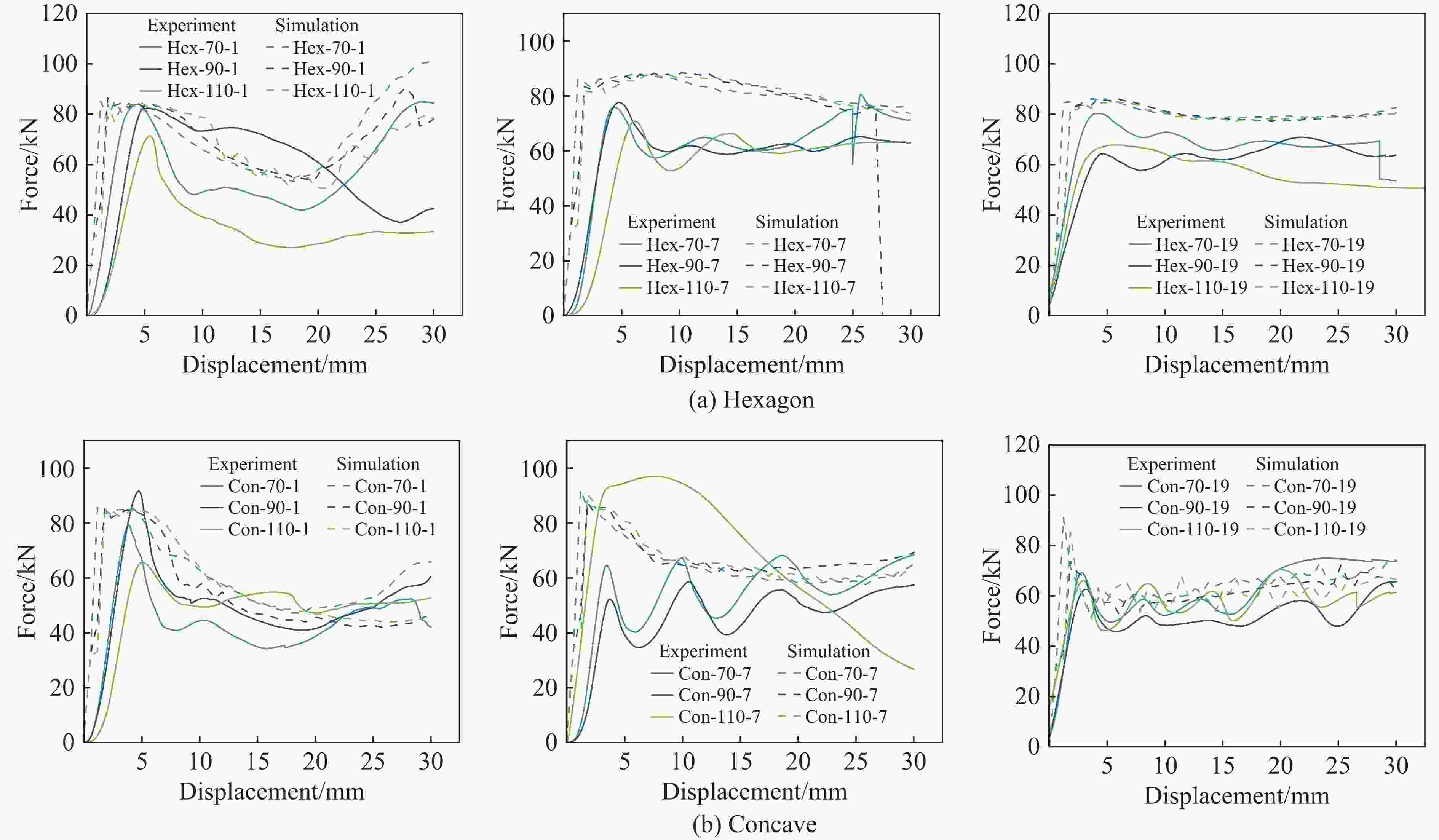

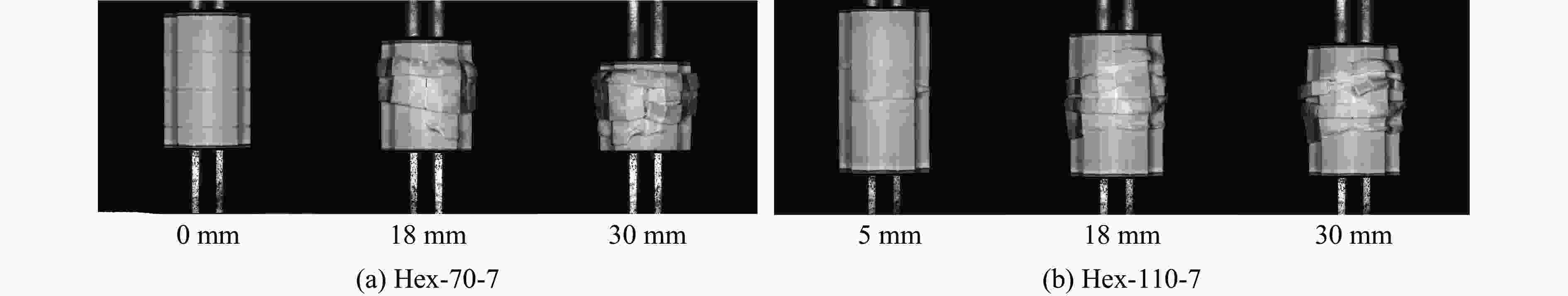

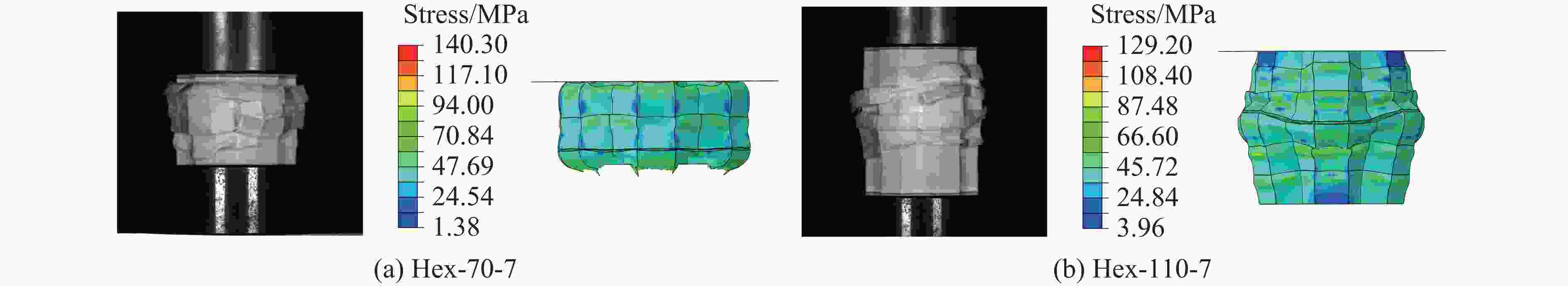

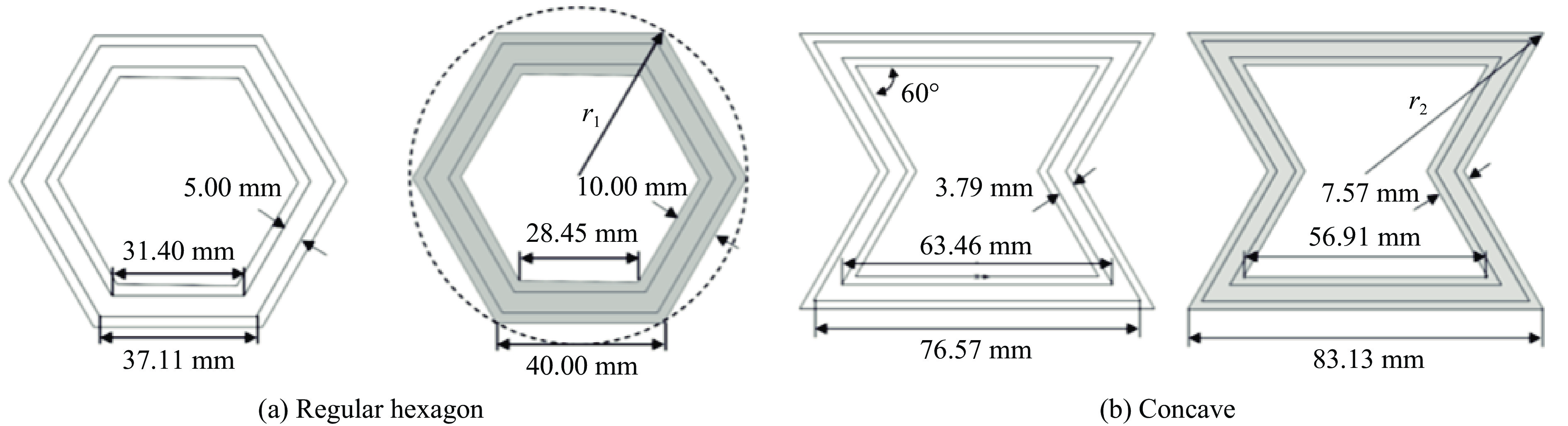

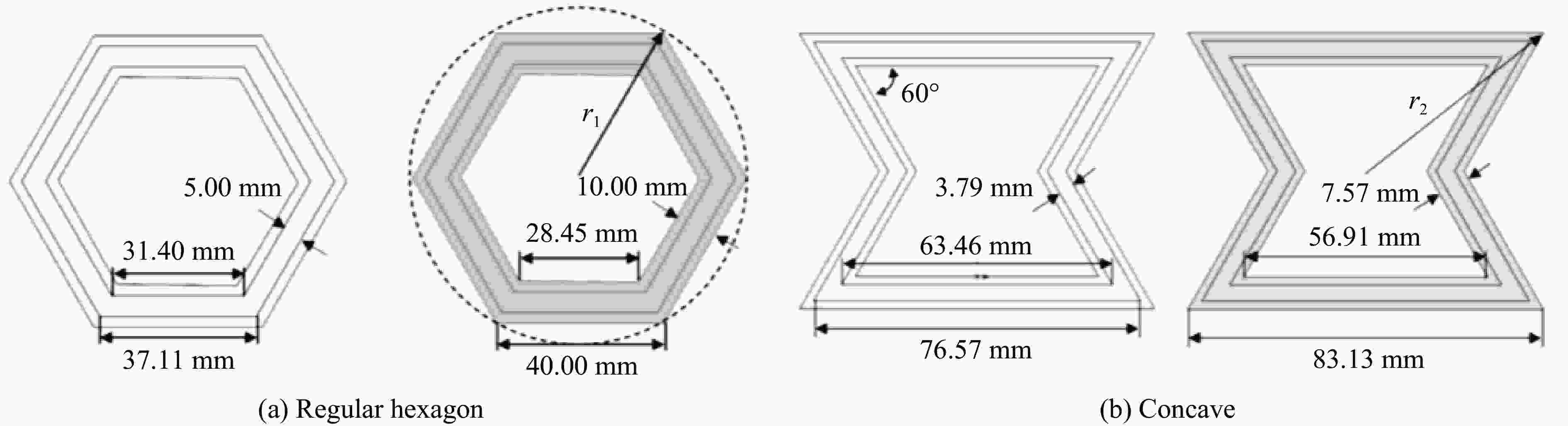

摘要: 将传统木结构建筑的榫卯连接方法引入多孔柱中,在保持多孔柱的孔隙率相同的情况下,探究了连接方式、高度、孔型和孔数对结构力学行为和吸能特性的影响;通过试验测试和有限元模拟计算,研究了多孔柱模型在单轴压缩作用下的力学行为和能量吸收性能。结果表明:榫卯式多孔结构在实现快速装配的同时,内凹形模型的后期承载力较好,六边形孔型模型的承载力和吸能特性较好,单孔模型的承载力较好,多孔模型的吸能特性较好。Abstract: By incorporating the traditional mortise-and-tenon structure commonly used in timber structures into the porous column, and the effects of jointing mode, height, hole shape and number on the mechanical behavior and energy absorption characteristics of the structure are investigated under the condition of maintaining a uniform porosity in the porous columns. The mechanical behaviors and energy absorption performance of the porous column model are studied through tests and finite element simulation under uniaxial compression. The results show that the mortise-and-tenon porous structure has a better load carrying capacity in the later stage of the concave shape while realizing rapid assembly. The hexagonal hole model has better load carrying capacity and energy absorption characteristics. The load carrying capacity of the single hole model is higher, and the energy absorption characteristics of the porous model are better.

-

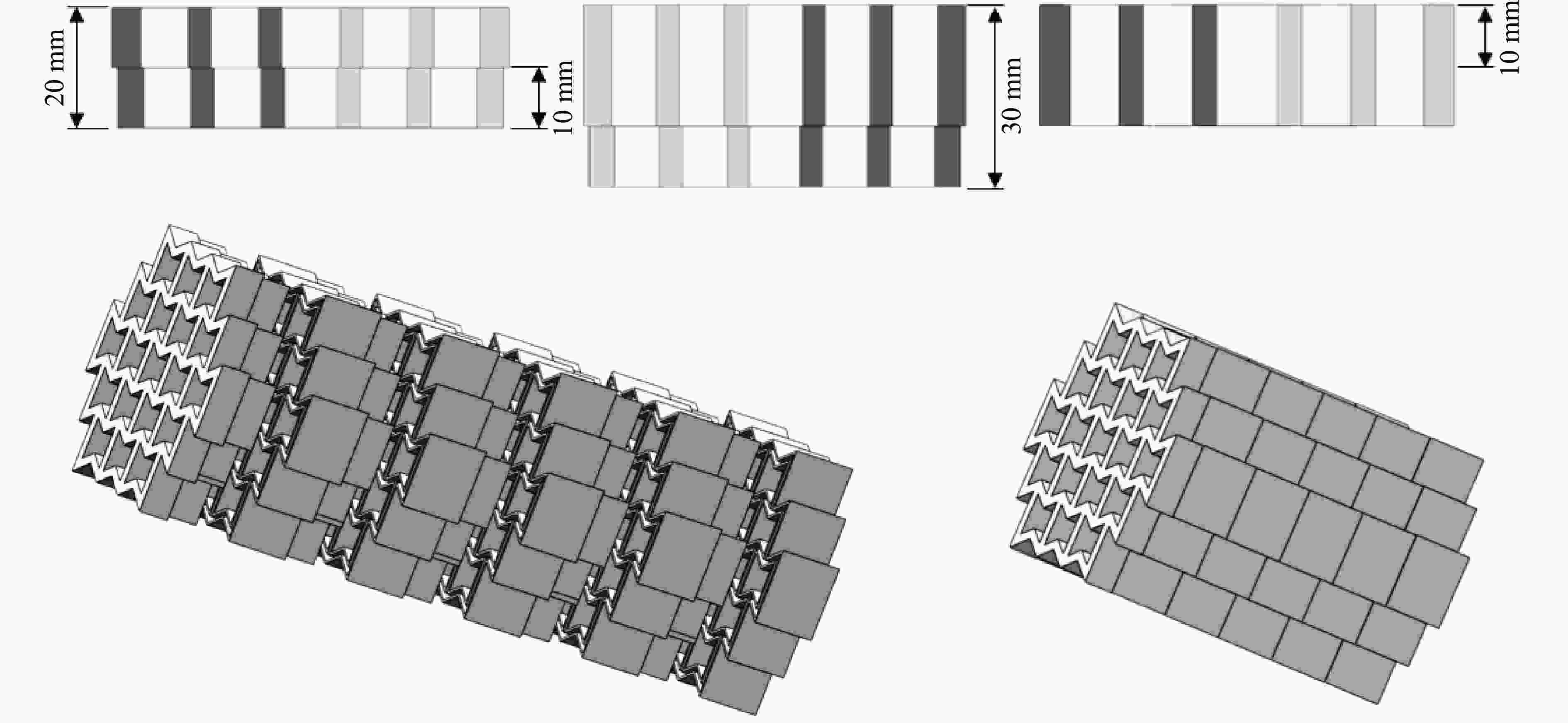

表 1 榫卯式多孔柱模型

Table 1. Mortise-and-tenon porous column model

Hole pattern Height/mm Hole number Model Hole pattern Height/mm Hole number Model Regular hexagon 70 1 Hex-70-1 Concave 70 1 Con-70-1 70 7 Hex-70-7 70 7 Con-70-7 70 19 Hex-70-19 70 19 Con-70-19 90 1 Hex-90-1 90 1 Con-90-1 90 7 Hex-90-7 90 7 Con-90-7 90 19 Hex-90-19 90 19 Con-90-19 110 1 Hex-110-1 110 1 Con-110-1 110 7 Hex-110-7 110 7 Con-110-7 110 19 Hex-110-19 110 19 Con-110-19 表 2 采取不同连接方式的模型的试验数据

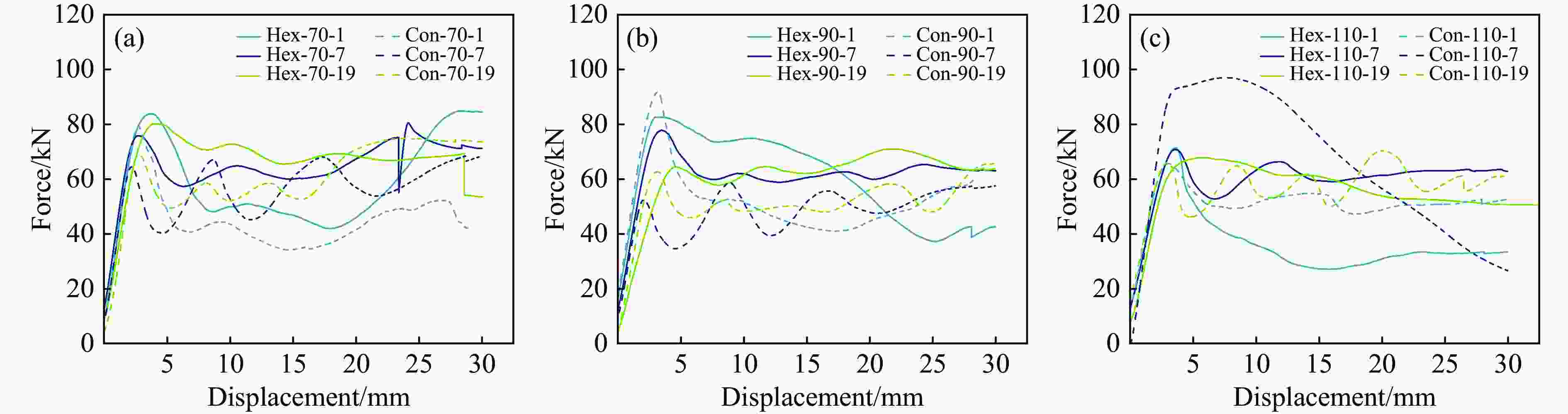

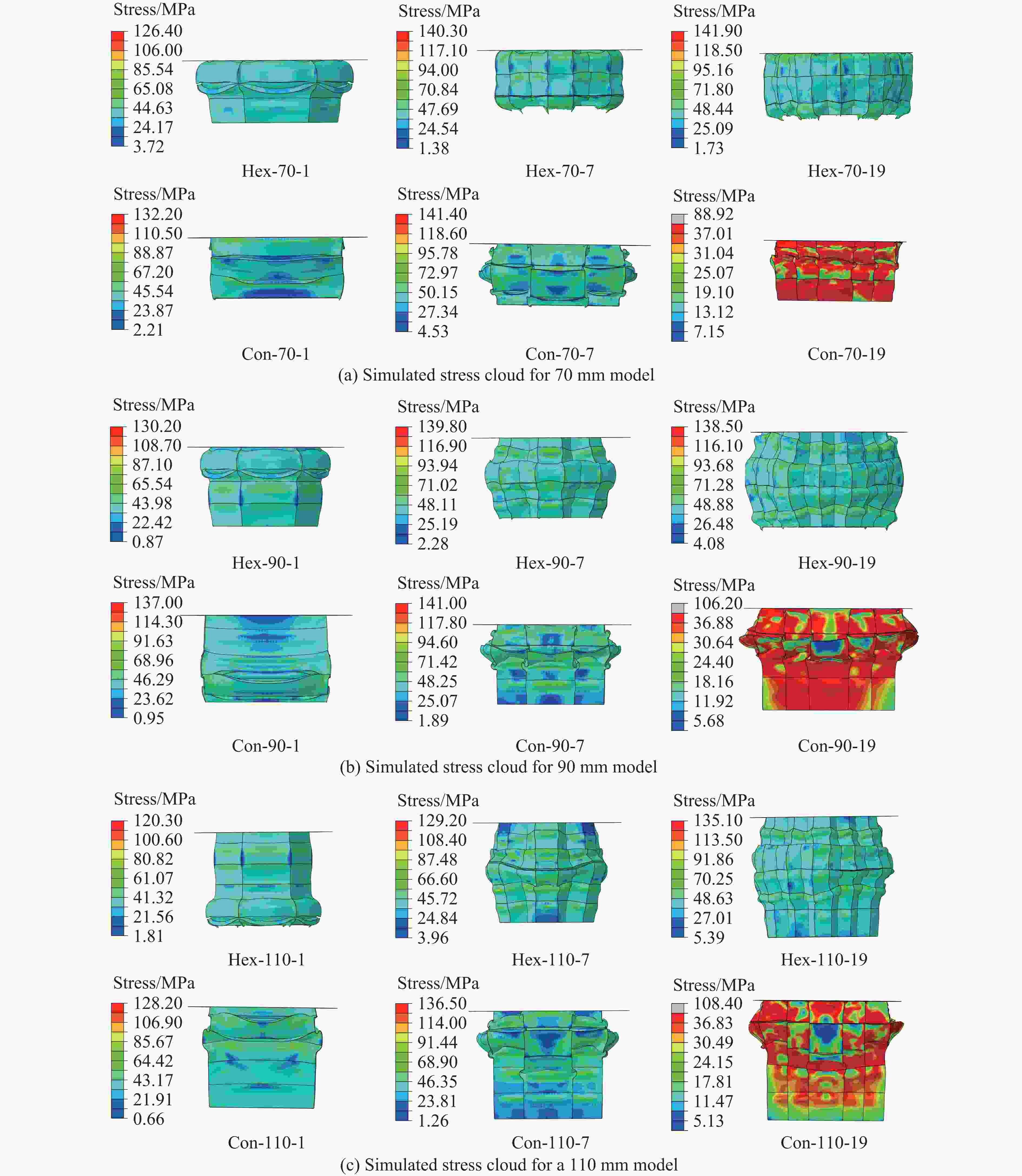

Table 2. Test data of models with different connection modes

Model Maximum force/kN Displacement/mm Model Maximum force/kN Displacement/mm Hex-90-1 82.35 2.94 Con-90-1 91.51 3.77 A-Hex-90-1 95.51 8.25 A-Con-90-1 96.94 7.71 Hex-90-7 77.62 3.51 Con-90-7 58.59 9.17 A-Hex-90-7 106.13 12.99 A-Con-90-7 122.27 4.13 表 3 采用不同连接方式的模型的能量吸收数据

Table 3. Energy absorption data of models with different jointing modes

Model Ea/kJ Fm/kN Model Ea/kJ Fm/kN Hex-90-1 1.80 60.00 Con-90-1 1.54 51.33 A-Hex-90-1 2.44 81.33 A-Con-90-1 1.97 65.67 Hex-90-7 1.84 61.33 Con-90-7 1.43 47.67 A-Hex-90-7 2.85 95.00 A-Con-90-7 2.70 90.00 表 4 模型下压30 mm的试验结果

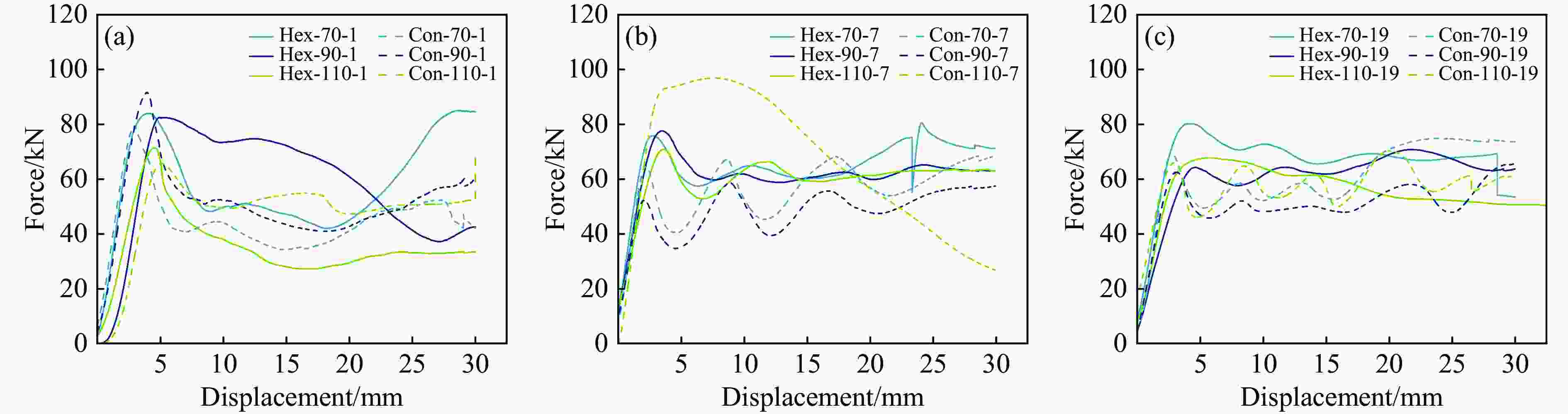

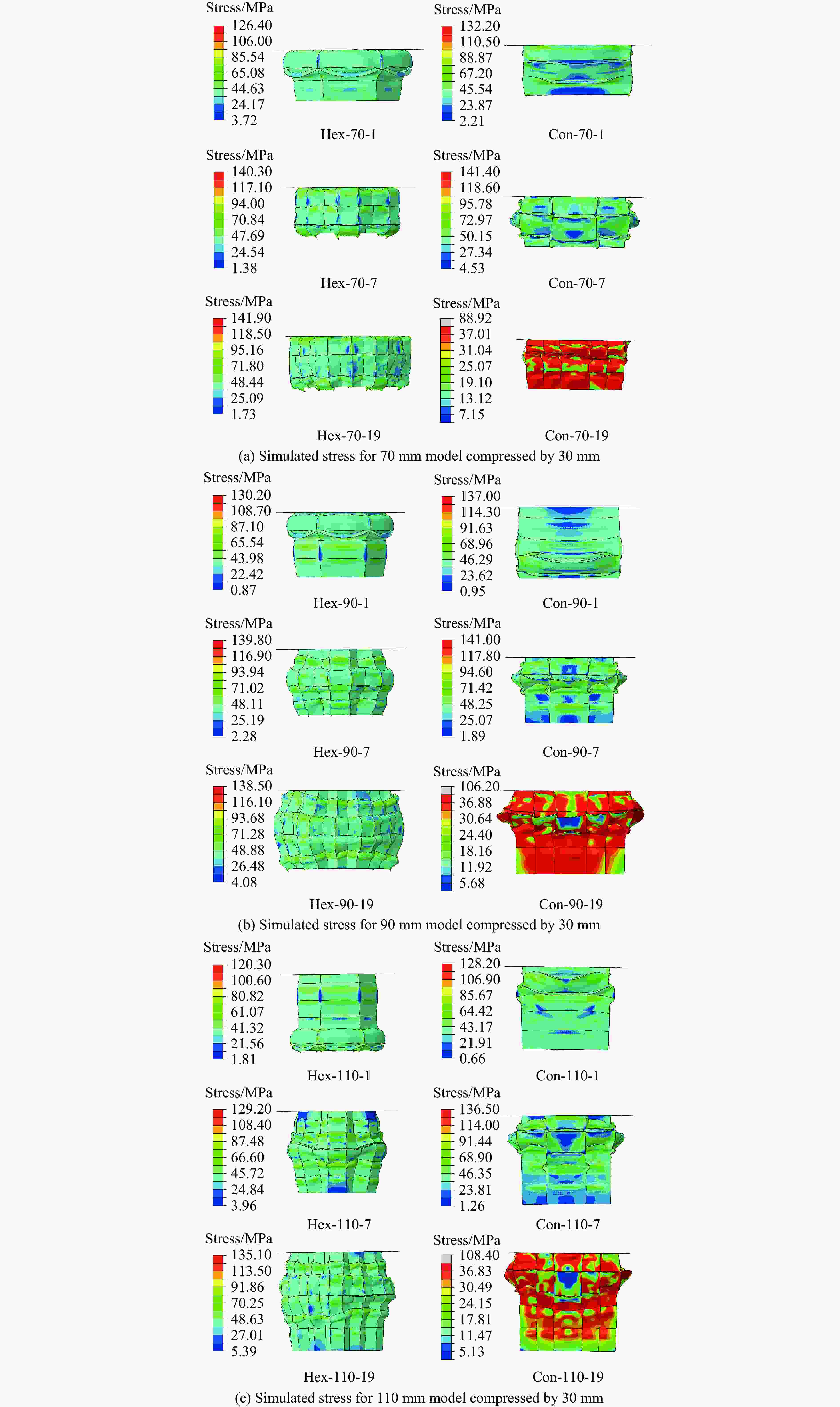

Table 4. Test results of models compressed by 30 mm

Model Maximum force/kN Displacement/mm Model Maximum force/kN Displacement/mm Hex-70-1 83.90 4.48 Con-70-1 79.14 3.90 Hex-90-1 82.42 4.90 Con-90-1 91.57 4.78 Hex-110-1 71.41 5.45 Con-110-1 65.71 5.11 Hex-70-7 75.85 4.33 Con-70-7 68.23 29.80 Hex-90-7 77.64 4.78 Con-90-7 58.60 10.60 Hex-110-7 70.76 6.13 Con-110-7 96.94 7.75 Hex-70-19 80.24 3.95 Con-70-19 74.76 24.88 Hex-90-19 70.80 21.75 Con-90-19 65.60 29.97 Hex-110-19 67.76 5.53 Con-110-19 70.34 20.03 表 5 模型下压30 mm的能量吸收数据

Table 5. Energy absorption of models compressed by 30 mm

Model Ea/kJ Fm/kN Model Ea/kJ Fm/kN Hex-70-1 1.70 56.67 Con-70-1 1.30 43.33 Hex-90-1 1.73 57.67 Con-90-1 1.48 49.33 Hex-110-1 1.03 34.33 Con-110-1 1.43 47.67 Hex-70-7 1.84 61.33 Con-70-7 1.60 53.33 Hex-90-7 1.76 58.67 Con-90-7 1.36 45.33 Hex-110-7 1.64 54.67 Con-110-7 1.97 65.67 Hex-70-19 2.00 66.67 Con-70-19 1.82 60.67 Hex-90-19 1.82 60.67 Con-90-19 1.53 51.00 Hex-110-19 2.20 73.33 Con-110-19 1.71 57.00 表 6 多元线性回归分析结果

Table 6. Results of the multiple linear regression analysis

Implicit variable R2/% P B Height Hole patten Hole number Constant Force 19.3 0.375 20.833 –3 888.889 –559.524 85 160.714 Energy uptake 38.4 0.072 2 083.333 –222 222.222 11 111.111 1 734 722.222 -

[1] LI S C, ZHOU Z C, LUO H Z, et al. Behavior of traditional Chinese mortise-tenon joints: experimental and numerical insight for coupled vertical and reversed cyclic horizontal loads [J]. Journal of Building Engineering, 2020, 30: 101257. doi: 10.1016/j.jobe.2020.101257 [2] ZHU Z G, WU F Q, HAO J. Mechanical behavior of a novel precast concrete beam-column joint using the mortise-tenon connection [J]. Sustainability, 2023, 15(19): 14586. doi: 10.3390/su151914586 [3] 王星, 张献. 榫卯式毂节点半刚性单层球面网壳稳定性及地震响应分析 [J]. 土木工程学报, 2024, 57(10): 1–10.WANG X, ZHANG X. Stability and dynamic performance analysis of semi-rigid single-layer spherical reticulated shell with triodetic joints [J]. China Civil Engineering Journal, 2024, 57(10): 1–10. [4] ZHANG B Z, XIE Q F, LIU Y J, et al. Effects of gaps on the seismic performance of traditional timber frames with straight mortise-tenon joint: experimental tests, energy dissipation mechanism and hysteretic model [J]. Journal of Building Engineering, 2022, 58: 105019. doi: 10.1016/j.jobe.2022.105019 [5] PANOUTSOPOULOU L, MOUZAKIS C. Experimental investigation of the behavior of traditional timber mortise-tenon T-joints under monotonic and cyclic loading [J]. Construction and Building Materials, 2022, 348: 128655. doi: 10.1016/j.conbuildmat.2022.128655 [6] ZHANG H H, ZHANG P, ZHANG W K. A high-output performance mortise and Tenon structure triboelectric nanogenerator for human motion sensing [J]. Nano Energy, 2021, 84: 105933. doi: 10.1016/j.nanoen.2021.105933 [7] 张武昆, 谭永华, 高玉闪, 等. 周期性轻质多孔结构在能量吸收和振动方面的研究进展 [J]. 振动与冲击, 2023, 42(8): 1–19.ZHANG W K, TAN Y H, GAO Y S, et al. Research progress on energy absorption properties and vibration of periodic lightweight porous structures [J]. Journal of Vibration and Shock, 2023, 42(8): 1–19. [8] LI Q Q, GAN W J, HU L, et al. Spherical porous structures for axial compression [J]. International Journal of Mechanical Sciences, 2024, 261: 108681. doi: 10.1016/j.ijmecsci.2023.108681 [9] YIN H F, ZHENG X J, WEN G L, et al. Design optimization of a novel bio-inspired 3D porous structure for crashworthiness [J]. Composite Structures, 2021, 255: 112897. doi: 10.1016/j.compstruct.2020.112897 [10] 杜义贤, 李荣, 田启华, 等. 具有吸能和承载特性的多孔结构拓扑优化 [J]. 华中科技大学学报(自然科学版), 2019, 47(8): 108–113.DU Y X, LI R, TIAN Q H, et al. Topological optimization of porous structure with energy absorption and loading capability [J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2019, 47(8): 108–113. [11] 黄浩, 崔海林, 田晓丽, 等. 多孔结构对冲击波的衰减影响研究 [J]. 机械设计与制造工程, 2024, 53(1): 11–15. doi: 10.3969/j.issn.2095-509X.2024.01.003HUANG H, CUI H L, TIAN X L, et al. Study on the effect of porous structure on shock wave attenuation [J]. Machine Design and Manufacturing Engineering, 2024, 53(1): 11–15. doi: 10.3969/j.issn.2095-509X.2024.01.003 [12] GAO J S, WANG X, TONG J W, et al. Large size translucent wood fiber reinforced PMMA porous composites with excellent thermal, acoustic and energy absorption properties [J]. Composites Communications, 2022, 30: 101059. doi: 10.1016/j.coco.2022.101059 [13] YAN L L, ZHU K Y, CHEN N, et al. Energy-absorption characteristics of tube-reinforced absorbent honeycomb sandwich structure [J]. Composite Structures, 2021, 255: 112946. doi: 10.1016/j.compstruct.2020.112946 [14] 杜晓晓. 木质衍生碳复合电极在微型超级电容器中的应用研究 [D]. 青岛: 青岛科技大学, 2023.DU X X. Research on the application of wood derived carbon composite electrode in micro-supercapacitors [D]. Qingdao: Qingdao University of Science and Technology, 2023. [15] 成瑶. “预埋种子-外延生长”策略制备无机-有机复合材料及其性能研究 [D]. 北京: 北京化工大学, 2019.CHENG Y. Study of preparation and application of inorganic-organic materials by “seeds embedded epitaxial growth” strategy [D]. Beijing: Beijing University of Chemical Technology, 2019. [16] 张宽, 郭晓宁, 张晓晶. 夹层结构榫卯T型接头弯曲破坏机理试验研究 [J]. 复合材料科学与工程, 2021(8): 95–99.ZHANG K, GUO X N, ZHANG X J. Experimental study on failure mechanism of sandwich T-joint by tenon-and-mortise subjected to flexure [J]. Composites Science and Engineering, 2021(8): 95–99. [17] 李腾, 邓庆田, 李新波, 等. 多孔柱准静态压缩力学行为和吸能特性分析 [J]. 塑性工程学报, 2022, 29(2): 204–211. doi: 10.3969/j.issn.1007-2012.2022.02.029LI T, DENG Q T, LI X B, et al. Analysis of quasi-static compression mechanical behavior and energy absorption characteristics of porous columns [J]. Journal of Plasticity Engineering, 2022, 29(2): 204–211. doi: 10.3969/j.issn.1007-2012.2022.02.029 -

下载:

下载: