Anti-Scour Characteristics of Multi-Cell Tube Energy-Absorbing Column Filled with Aluminum Foam

-

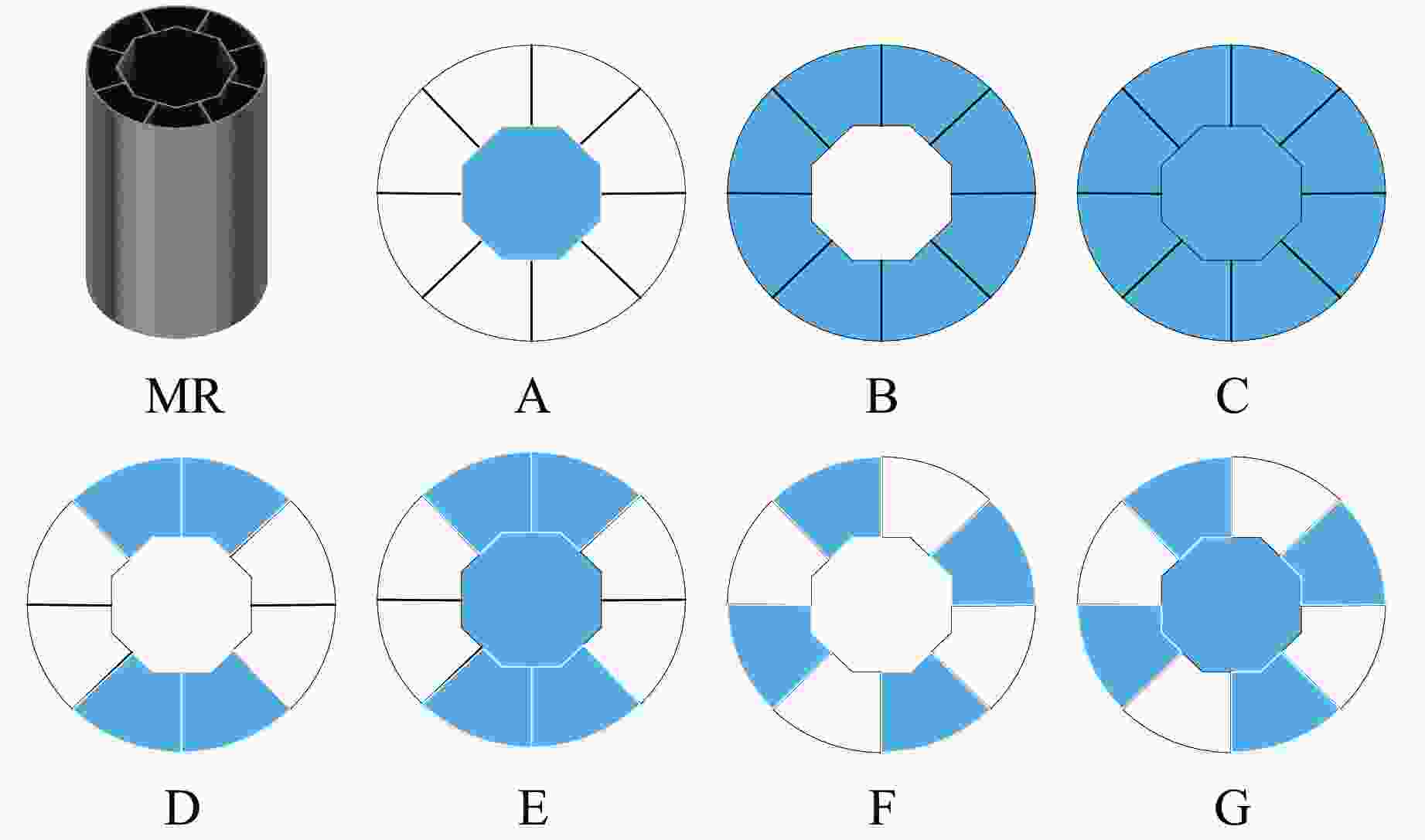

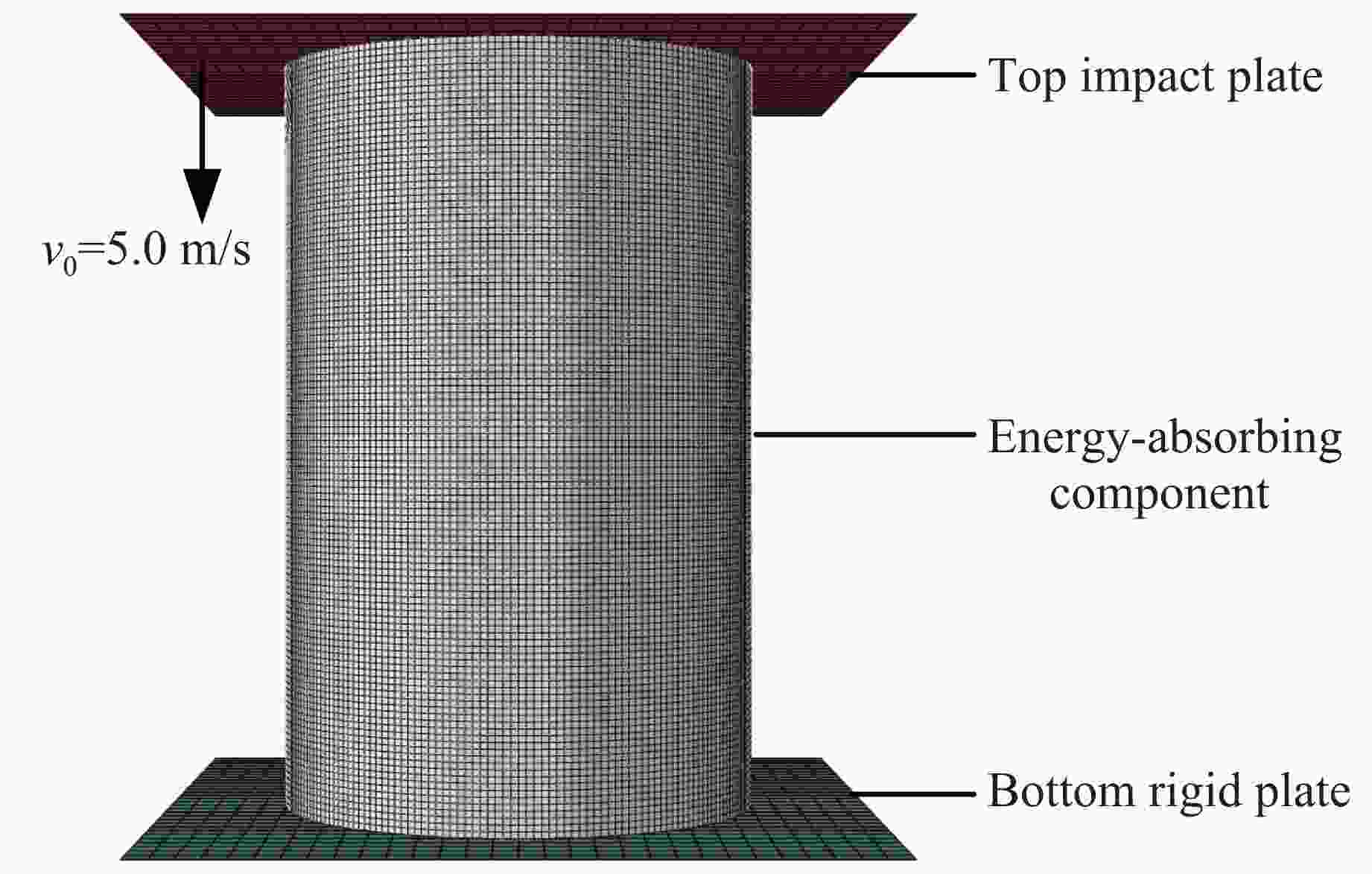

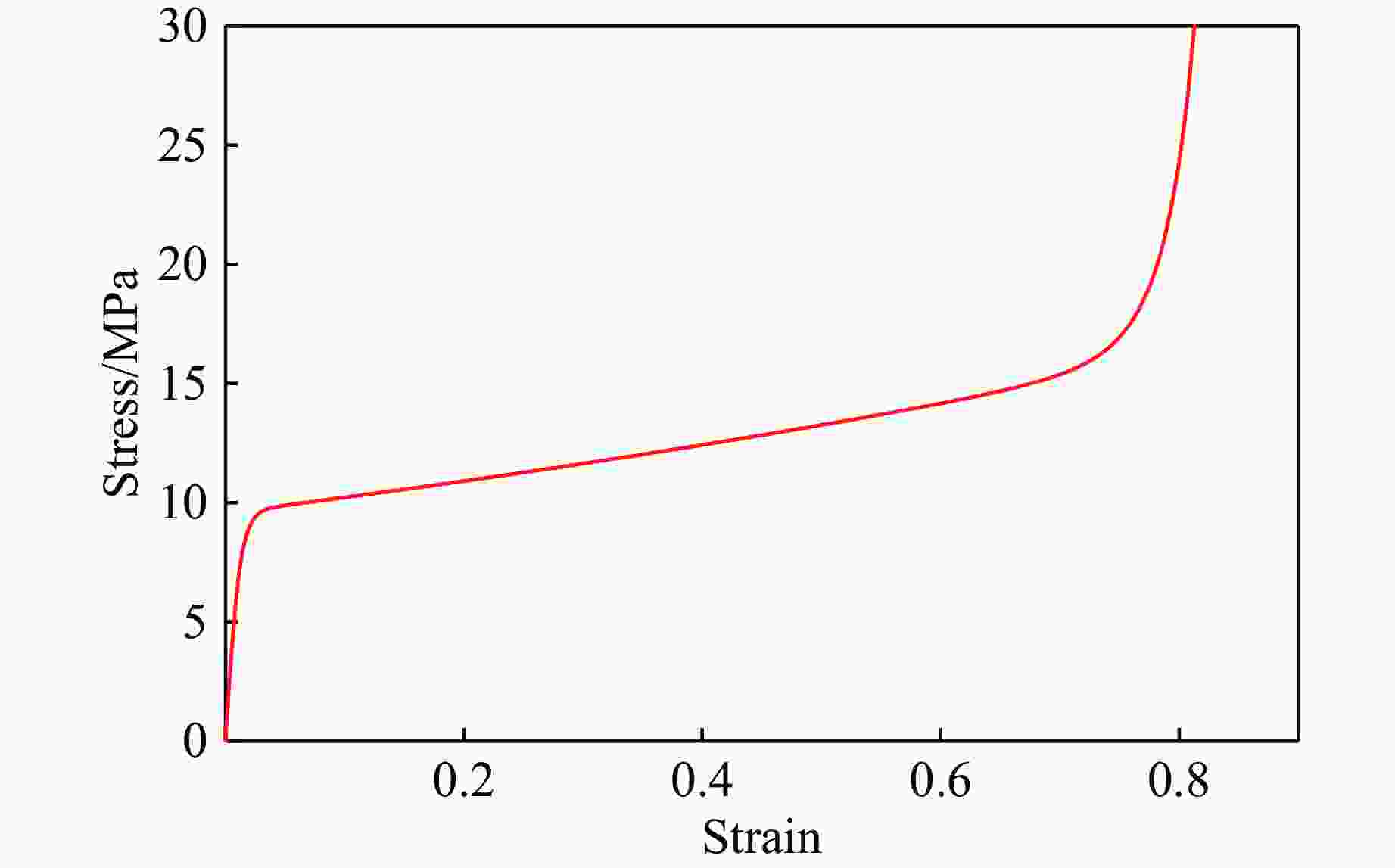

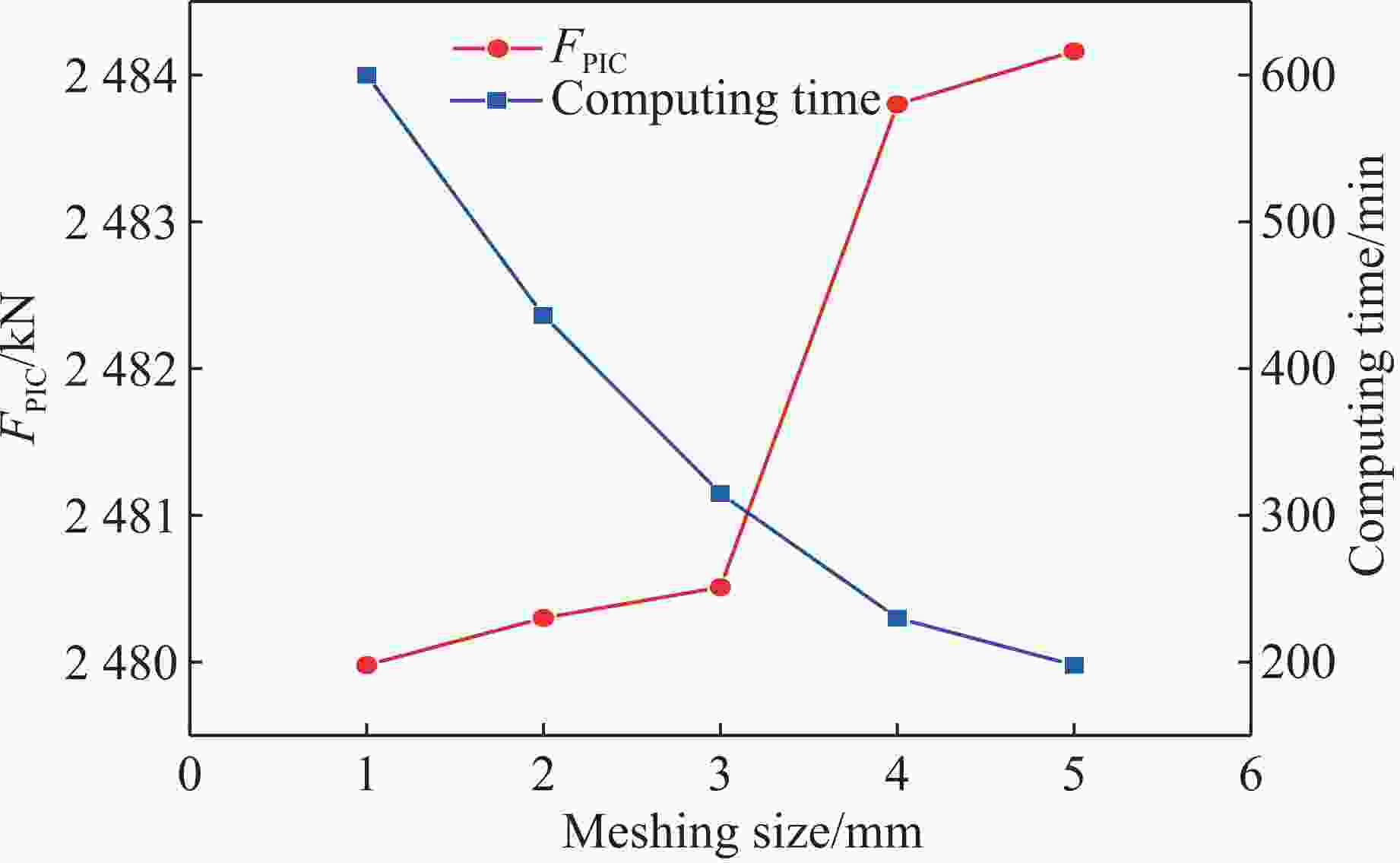

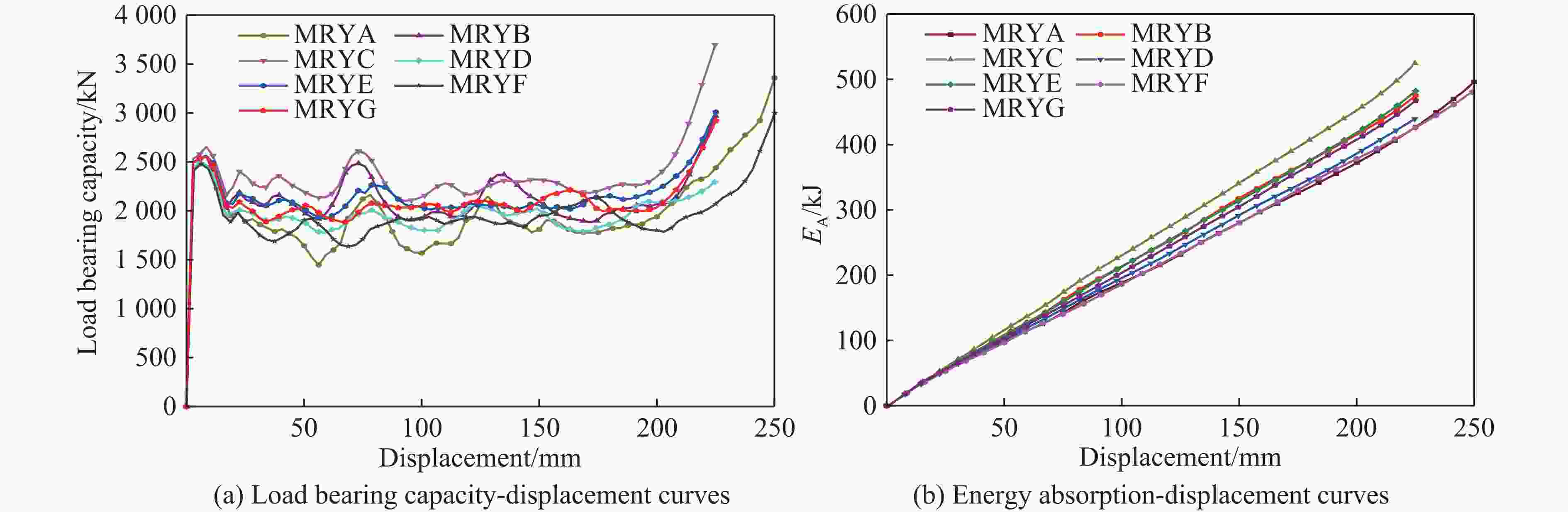

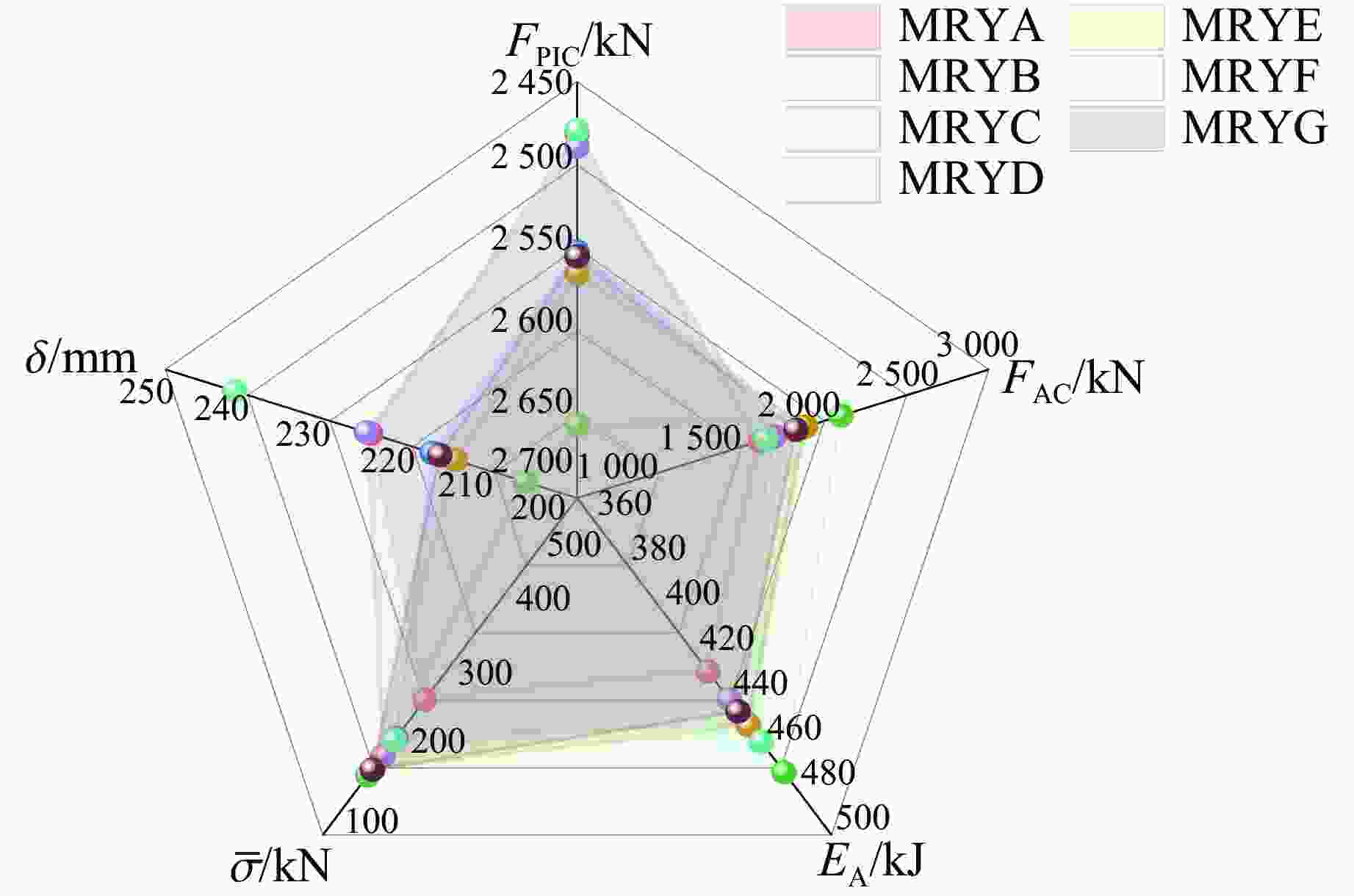

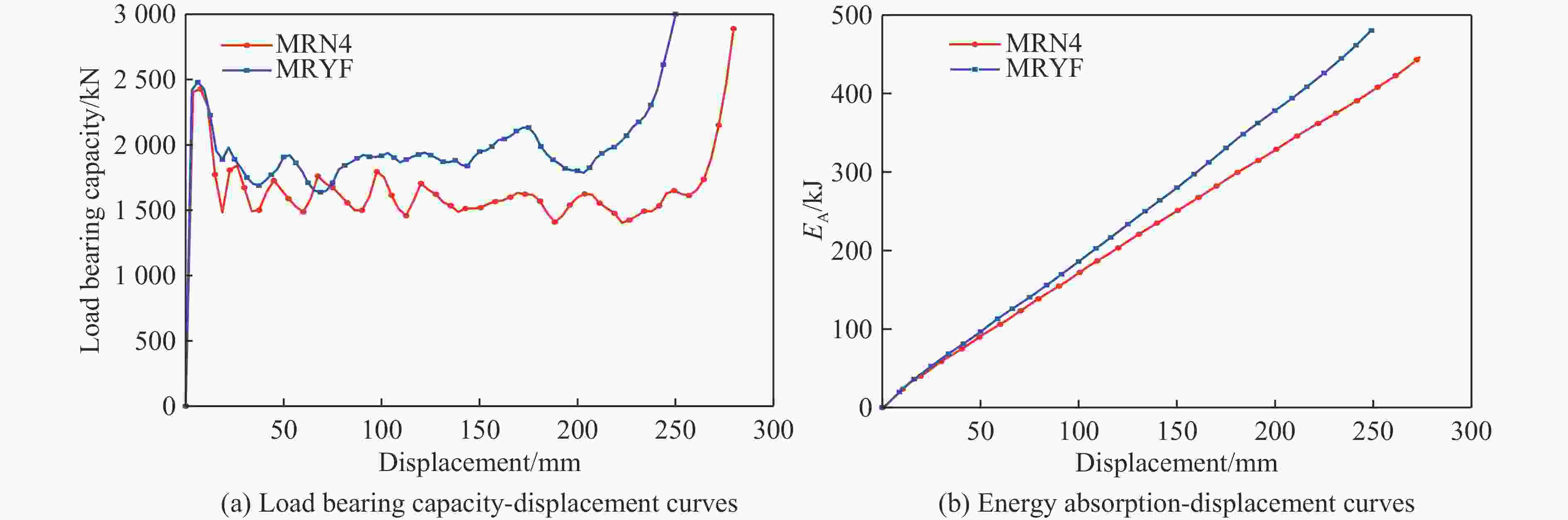

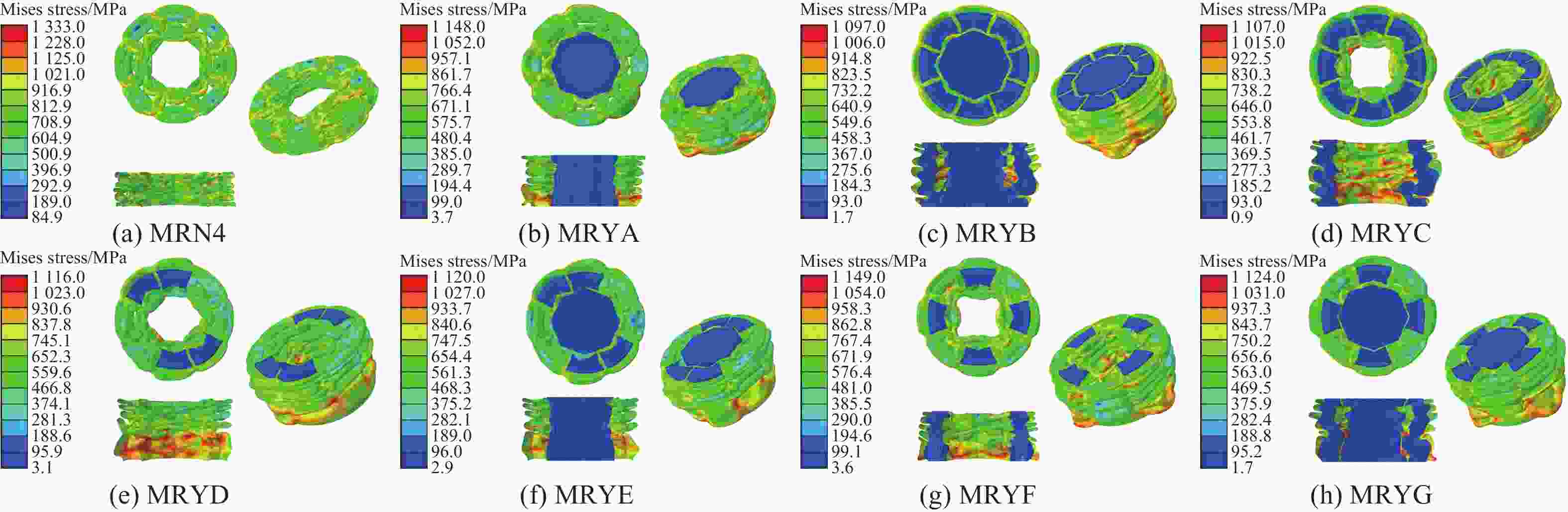

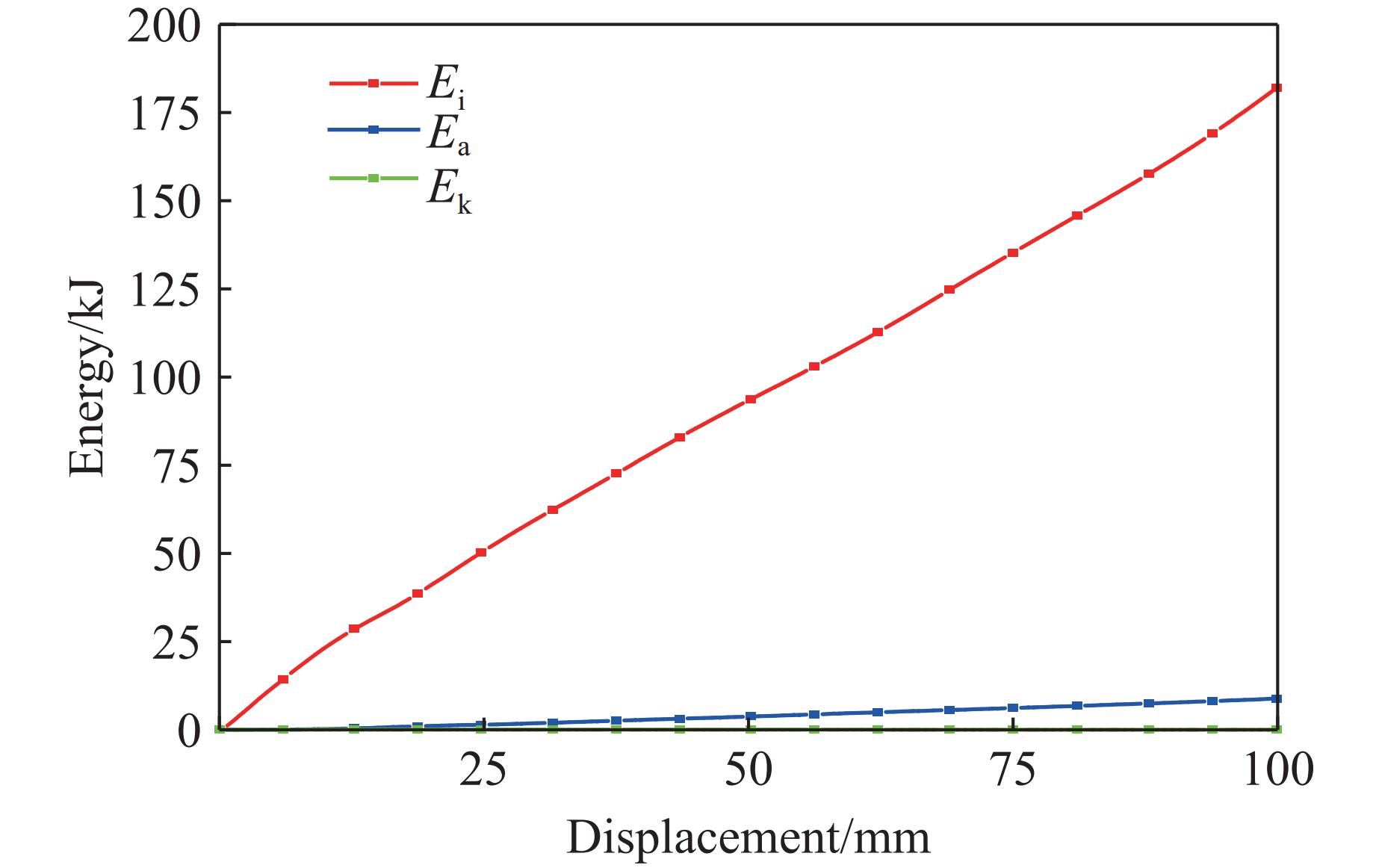

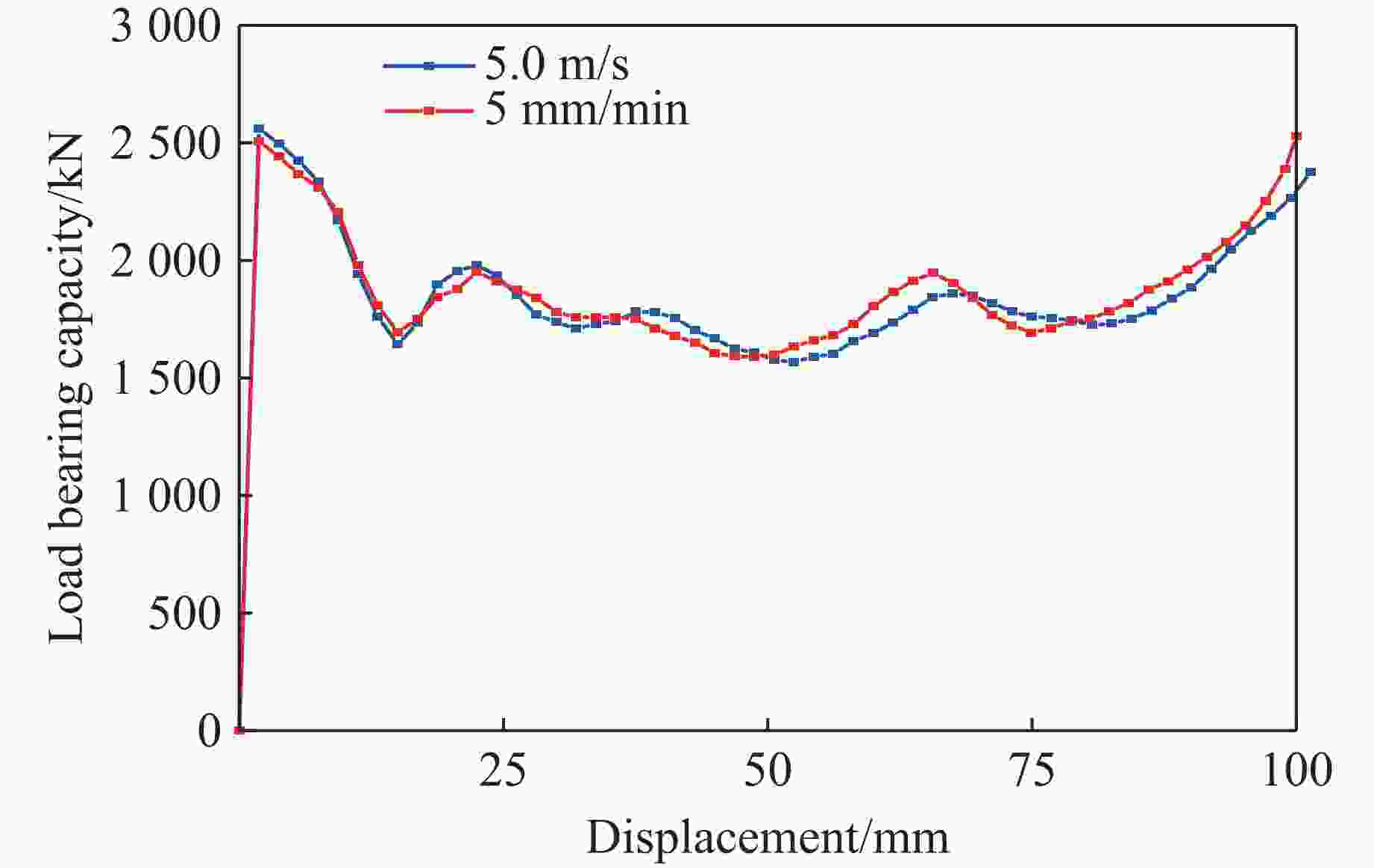

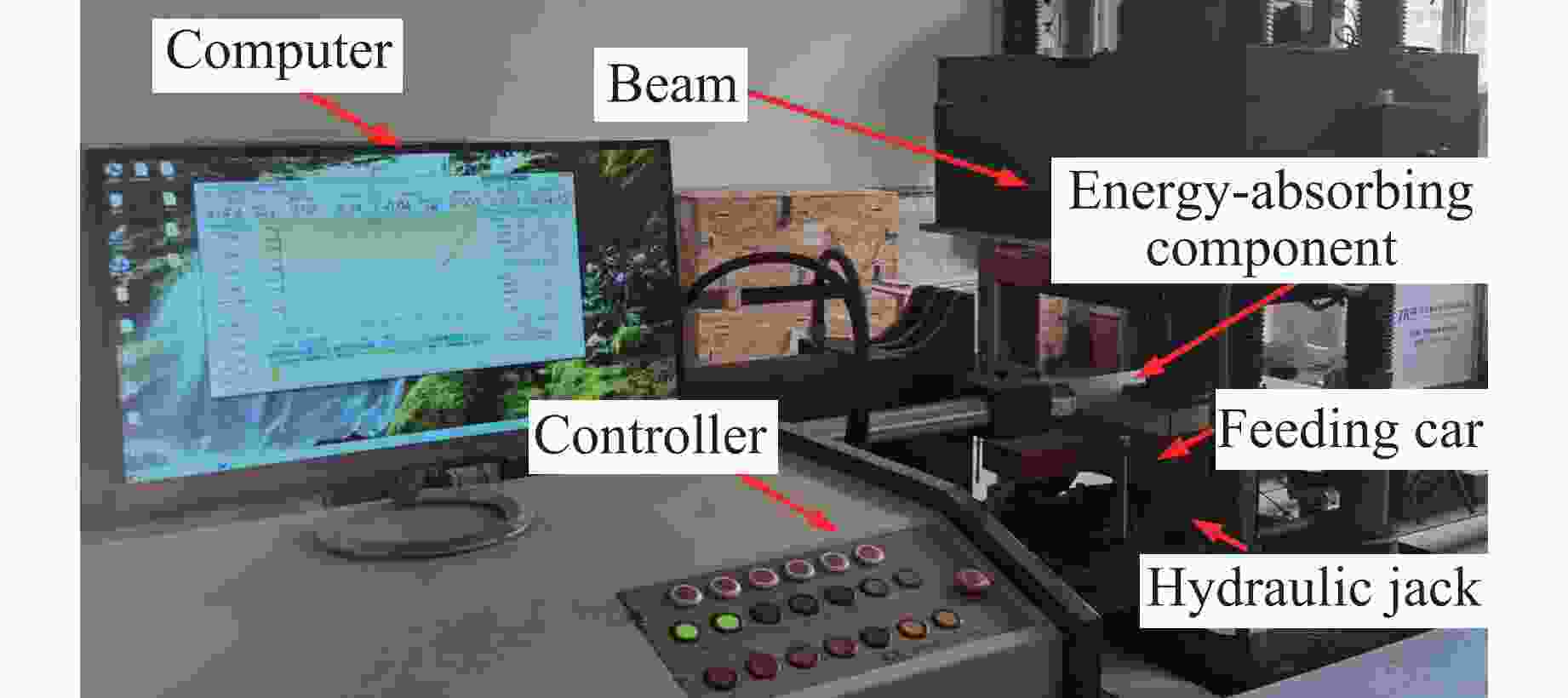

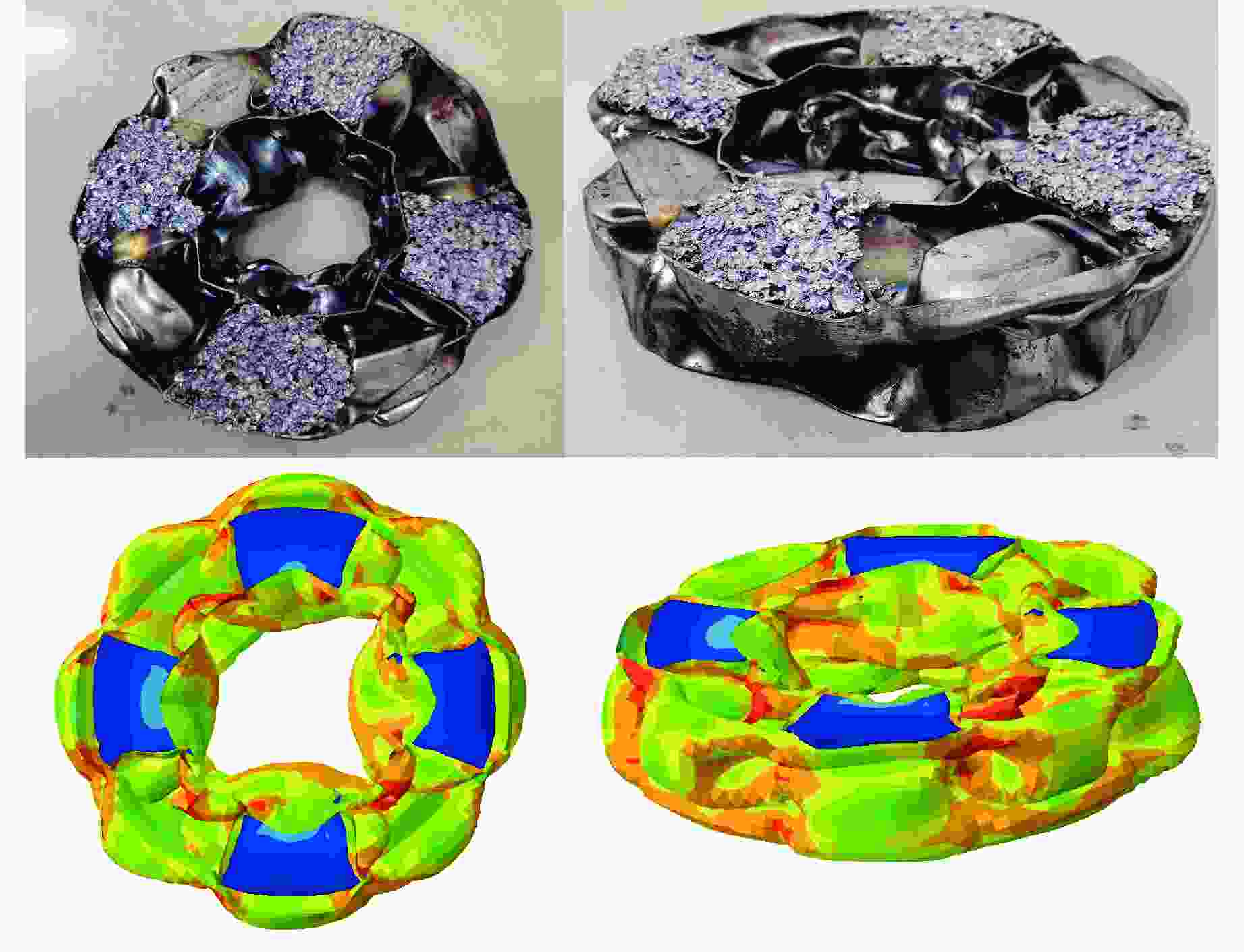

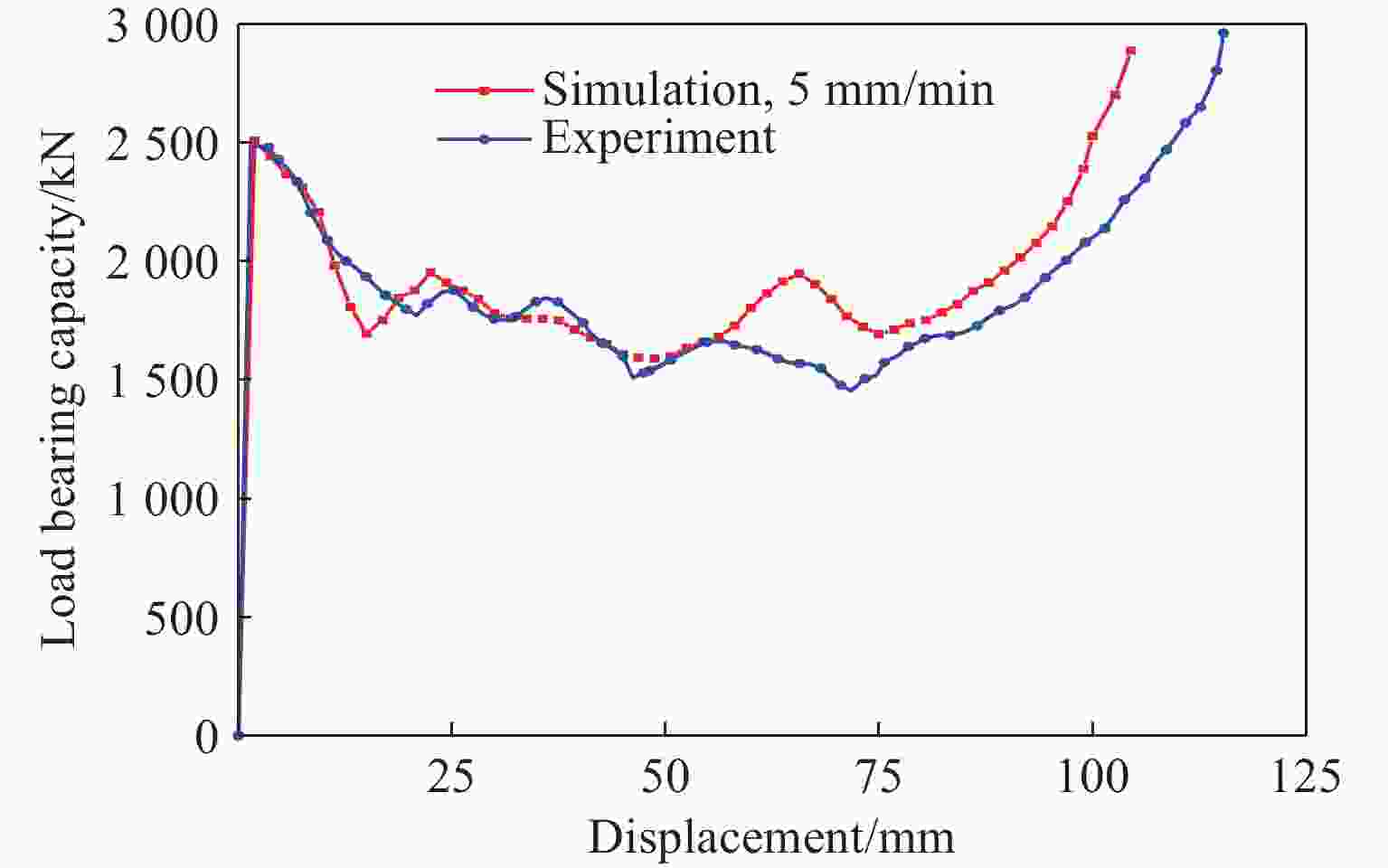

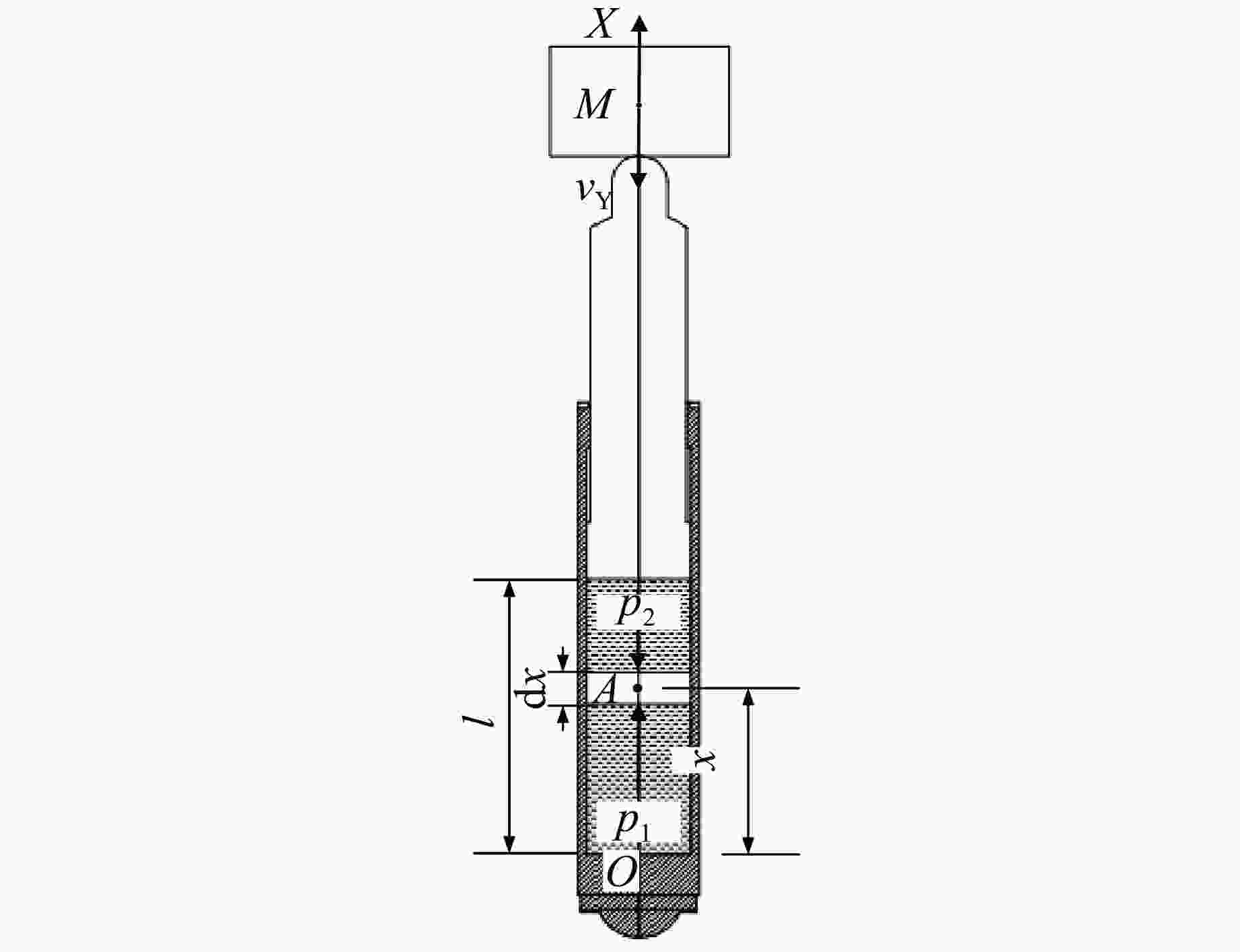

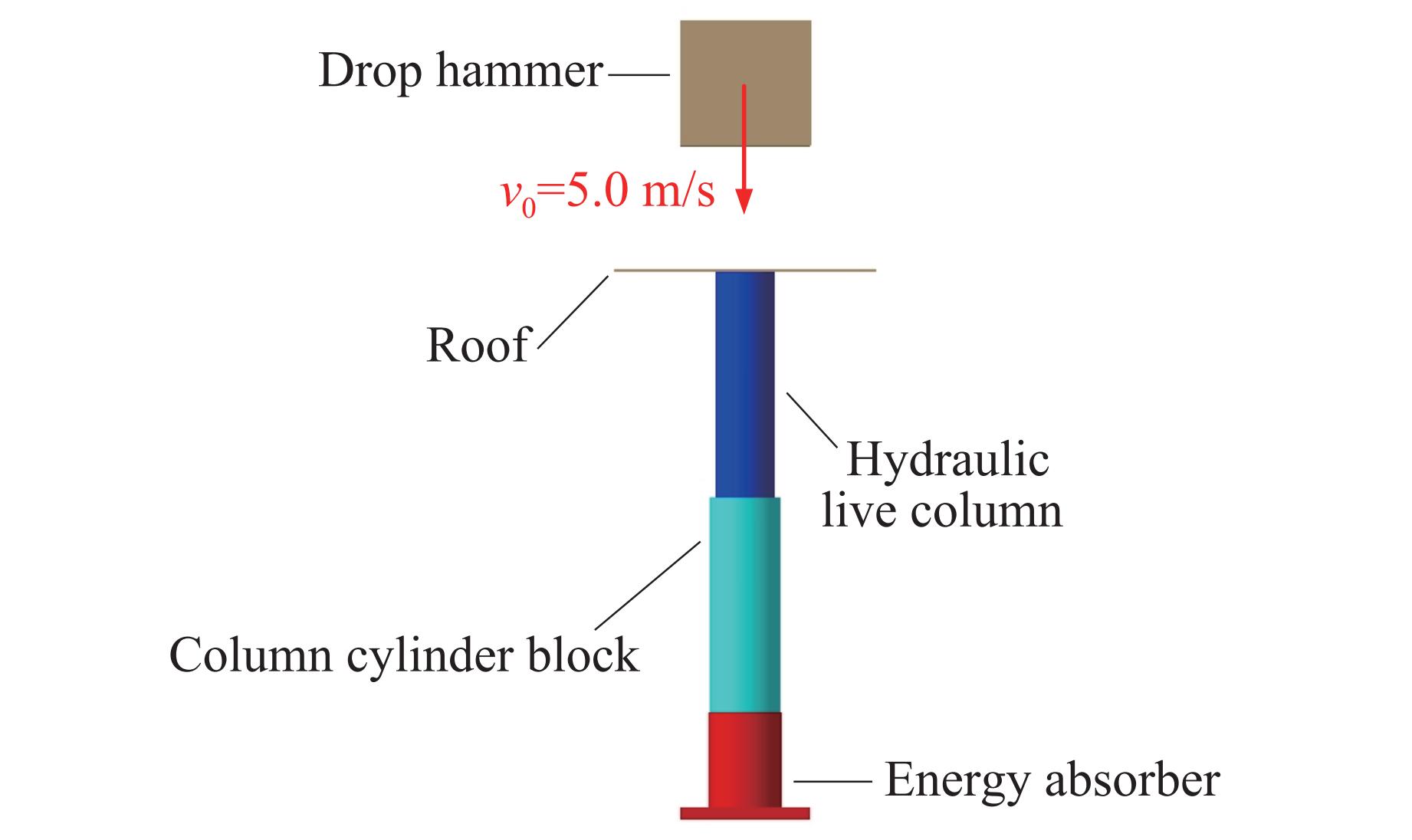

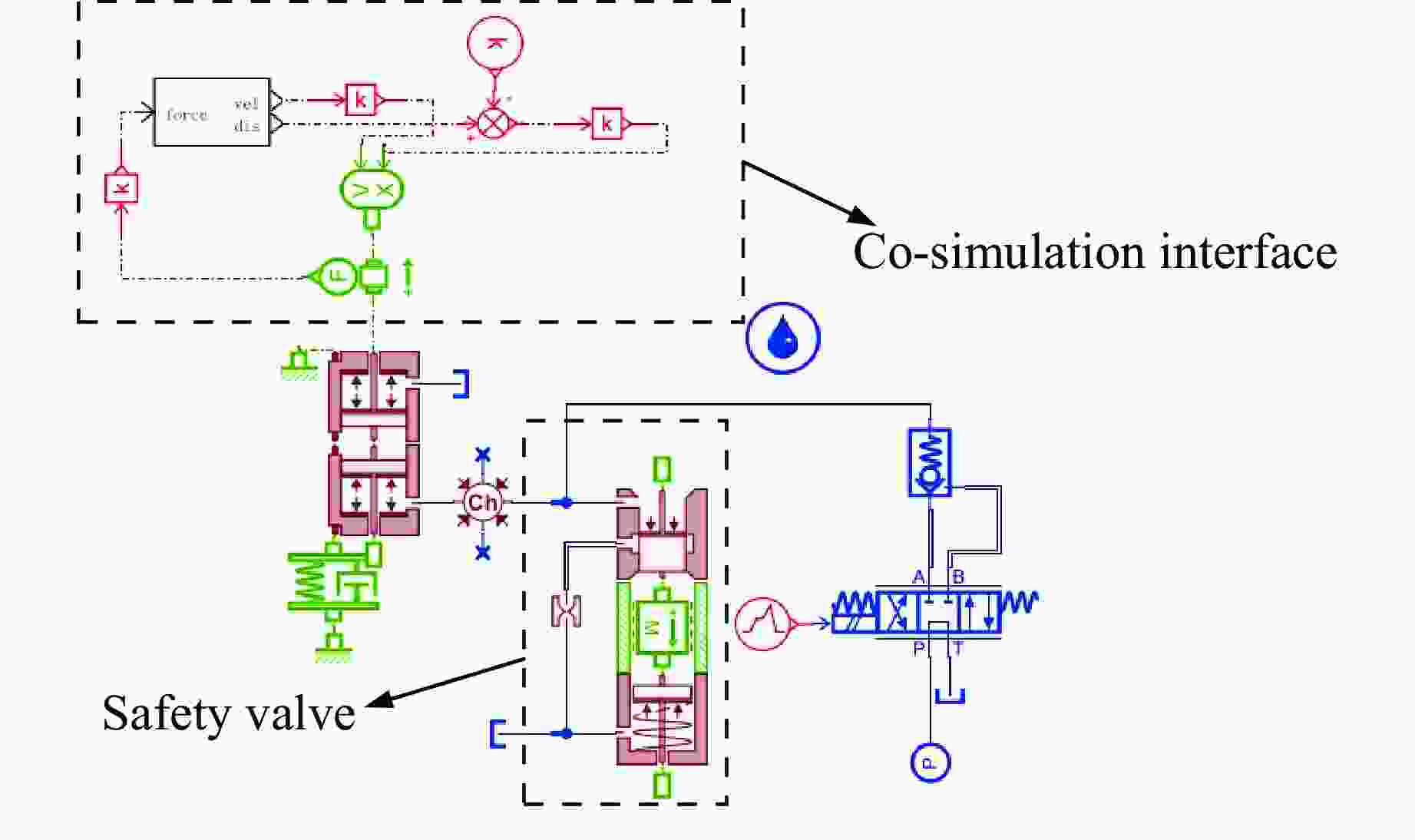

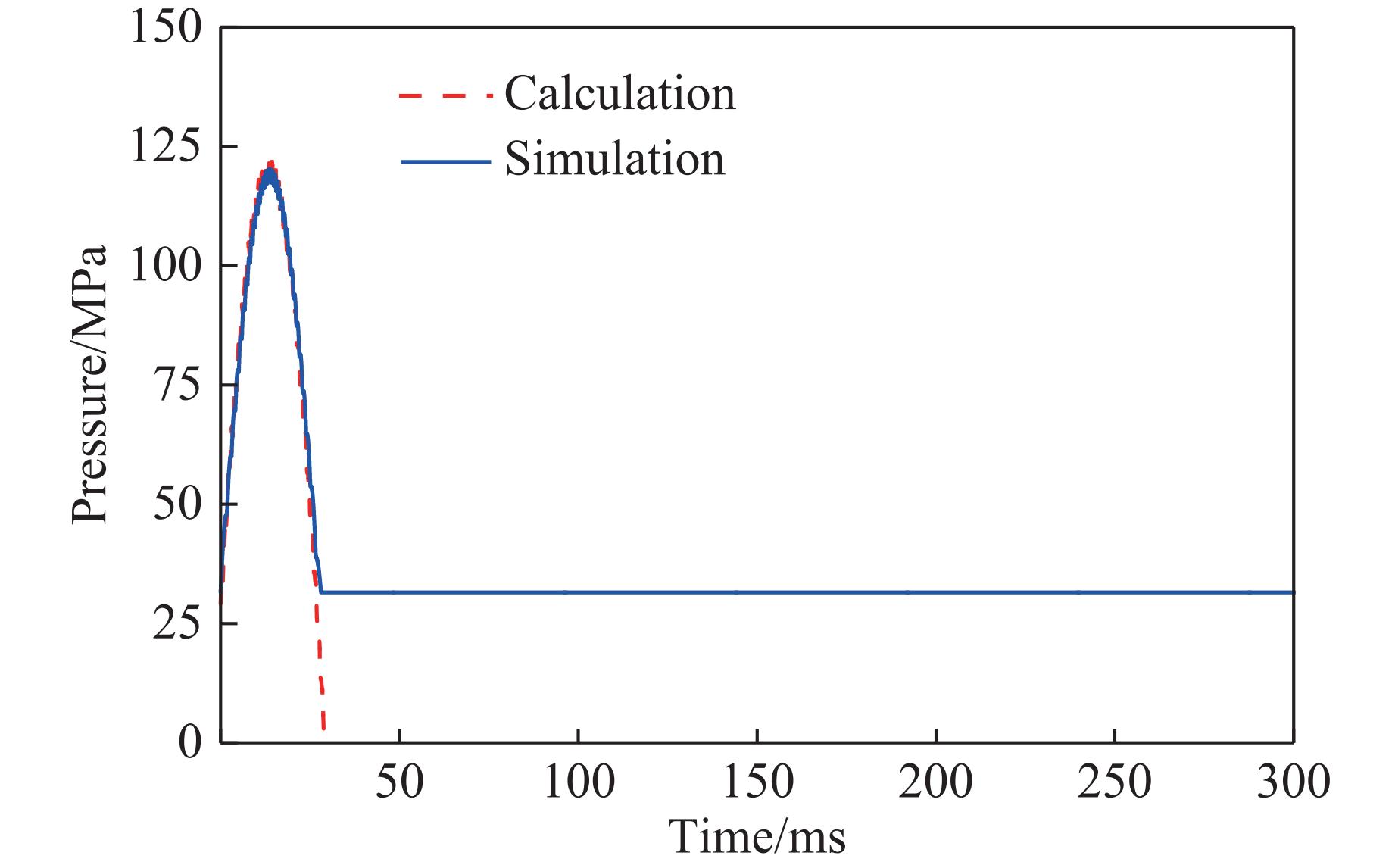

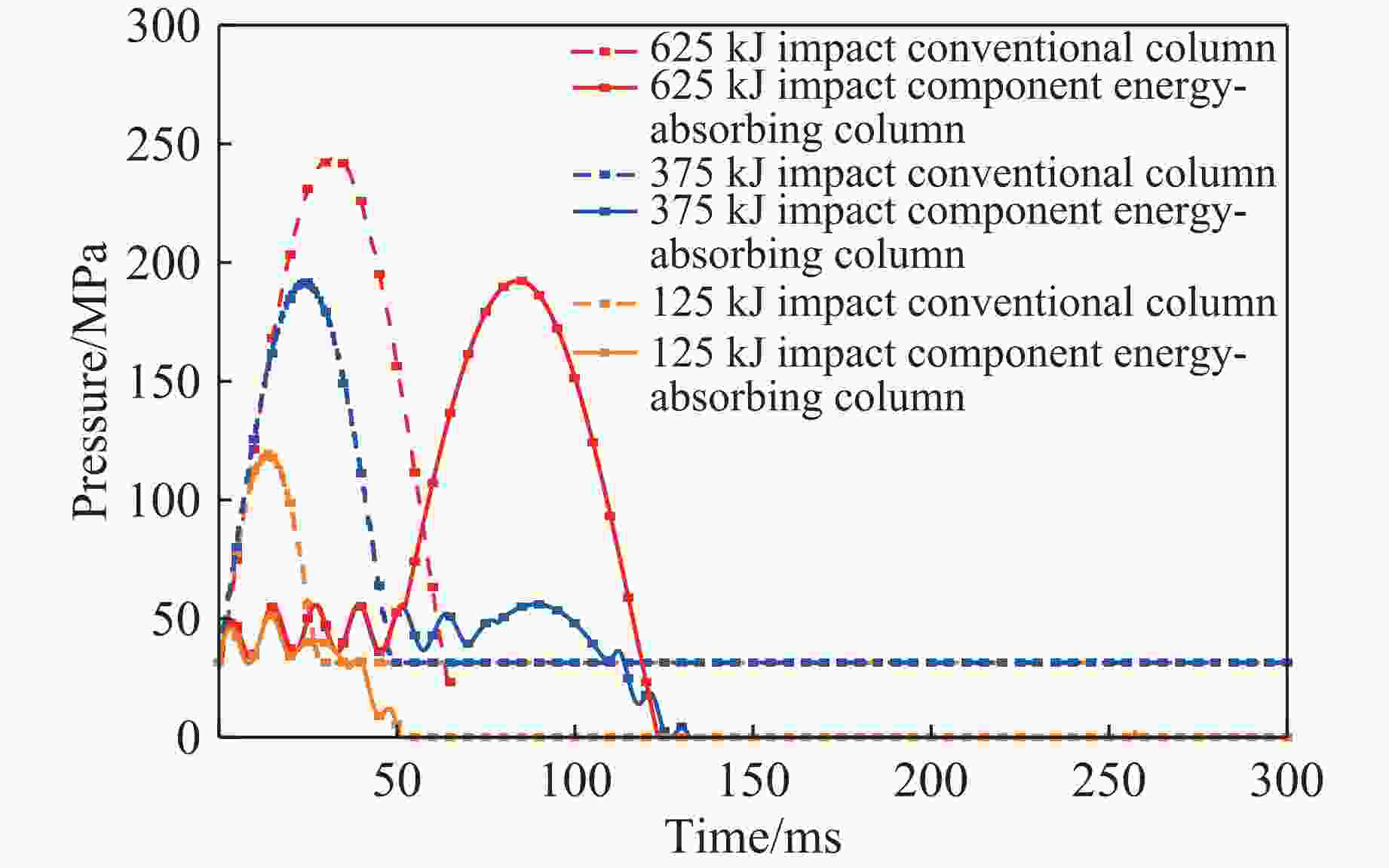

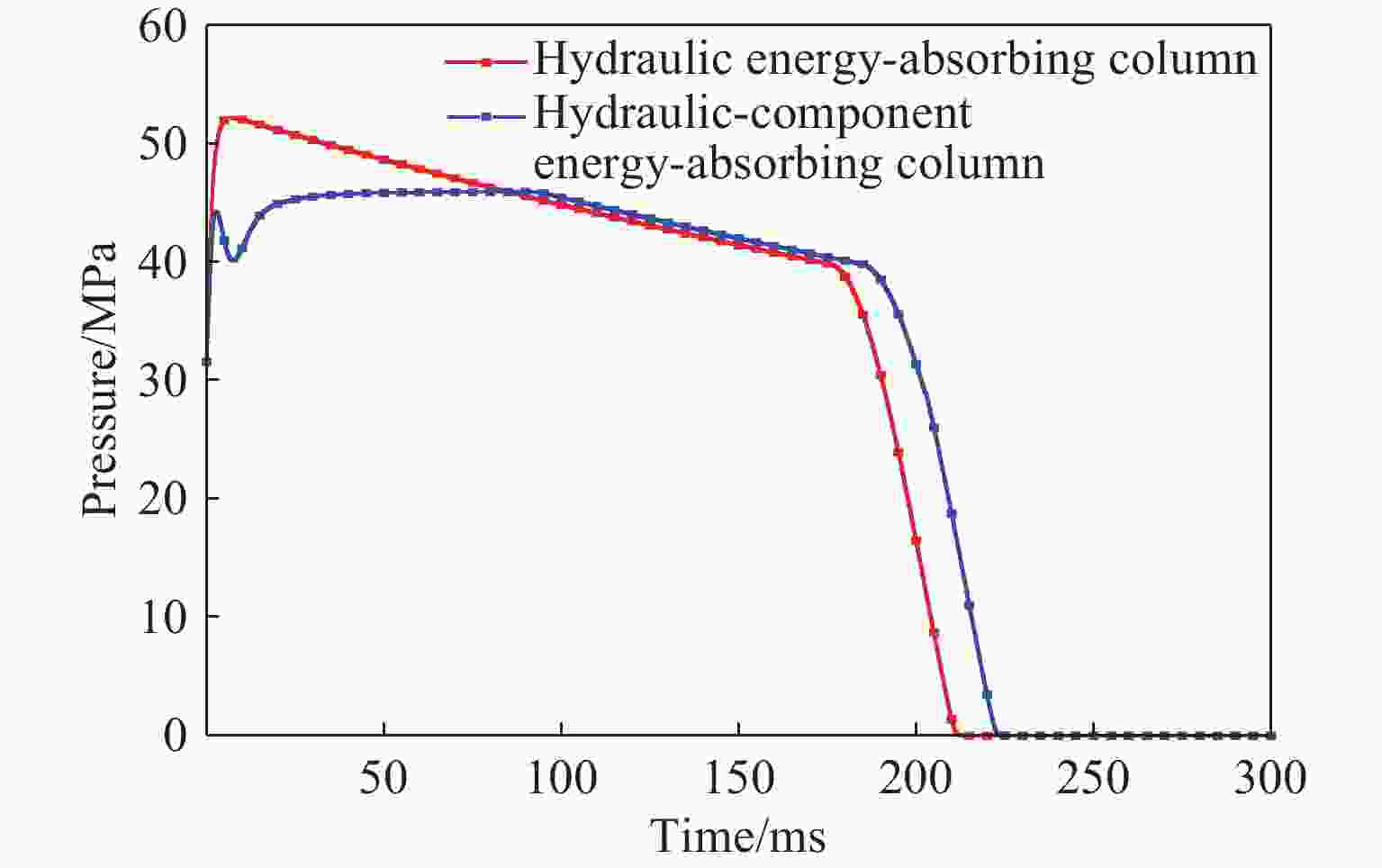

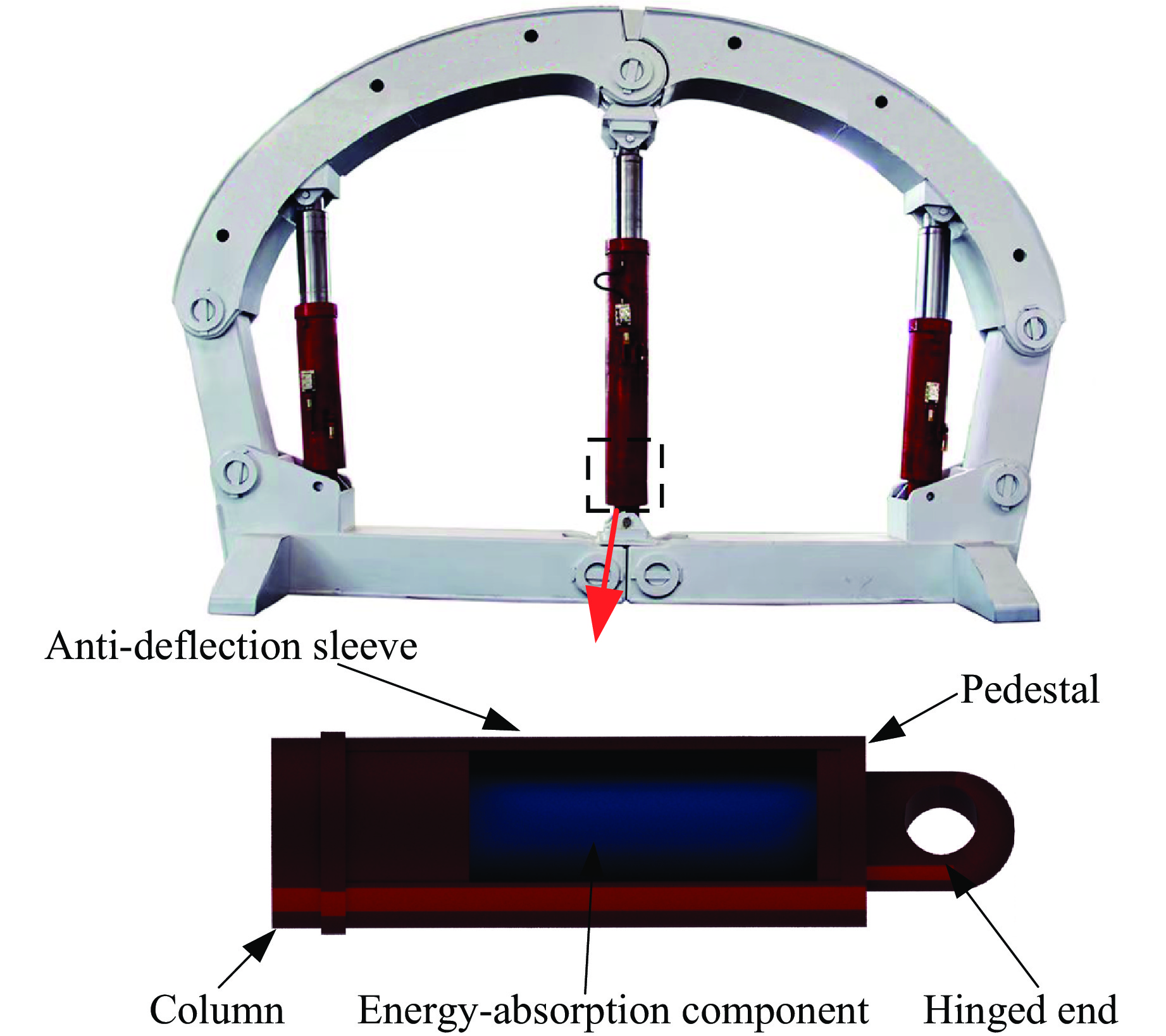

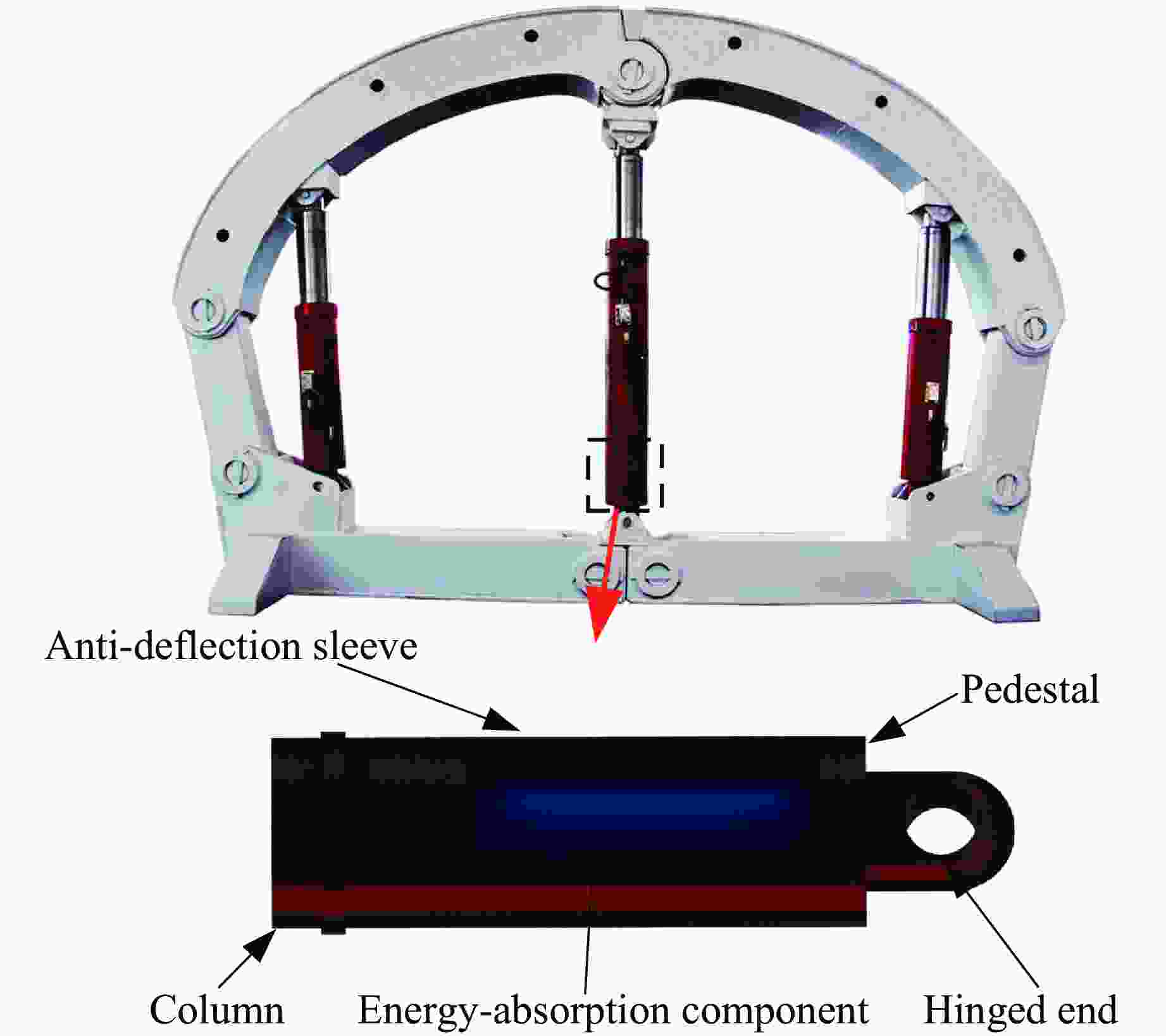

摘要: 了解液压支架的防冲性能是防治巷道冲击地压的关键。基于在吸能构件研究方面的基础,针对现有液压支架缓冲吸能性能不足的问题,提出了一种泡沫铝填充新型吸能构件,并开展了防冲立柱的吸能特性研究。通过数值模拟方法在不同壁厚多胞圆管中选择吸能性能最优的管件,进行了7种不同方式的泡沫铝填充,并通过准静态压溃实验验证数值模拟的准确性,分析得出吸能性能较优的吸能构件填充类型(MRYF类型)。通过落锤冲击液压系统耦合数值模拟方法,对不同冲击能量作用下的常规立柱(无安全阀作用)和构件吸能立柱(MRYF类型吸能构件单独作用)的冲击特性进行分析,进而比较强冲击能量作用下液压吸能立柱(安全阀单独作用)和液压-构件吸能立柱(MRYF类型吸能构件与安全阀共同作用)的吸能特性。结果表明:新型吸能构件的平均承载力增加18.11%,吸能量提升7.64%,载荷均方差减小10.75%,变形模式更规律,综合吸能性能更优异;不同冲击能量下,吸能立柱内的液体压力峰值均明显减小;强冲击能量作用下,液压-构件吸能立柱内的液体压力峰值相对于液压吸能立柱降低6.28 MPa,立柱内液体压力更加平稳;新型吸能构件的加入可实现让缩吸能,有效降低冲击载荷下立柱内的最大液体压力,并减少对安全阀施加的总冲击能量,提高安全阀对不同冲击载荷的适应性以及冲击载荷作用下支架立柱的抗冲击性能。Abstract: The anti-scour performance of hydraulic support is the key to prevent roadway rock burst. Based on the research foundation of energy absorption components, this paper proposes a new type of energy absorption component filled with aluminum foam, and studies the energy absorption characteristics of the anti-shock column. Through the numerical simulation method, the optimal energy-absorbing performance of the multi-cell tube with different wall thicknesses was selected for seven different ways of aluminum foam filling. The simulation was verified by quasi-static crushing tests, and the filling type of the energy-absorbing component with better energy-absorbing performance (MRYF type) was analyzed. Through the coupling simulation method of drop hammer impact hydraulic system, the impact characteristics of conventional column (no safety valve function) and component energy absorption column (MRYF type energy absorption component function alone) under different impact energy were analyzed. Then the energy absorption characteristics of hydraulic energy absorption column (safety valve acting alone) with hydraulic-component energy absorption column (MRYF type energy absorption component and safety valve acting together) under the action of strong impact energy were compared. The results show that the average bearing capacity of the new energy-absorbing component is increased by 18.11%, the energy absorption is increased by 7.64%, the load mean square error is reduced by 10.75%, the deformation mode is more regular, and the comprehensive energy-absorbing performance is better. Under different impact energy, the peak value of liquid pressure in energy-absorbing column decreases obviously. Under the action of strong impact energy, the peak value of liquid pressure in the hydraulic-component energy absorbing column is reduced by 6.28 MPa compared with the hydraulic energy absorbing column, and the liquid pressure in the column is more stable. Adding new energy absorbing components can reduce energy absorption and the maximum liquid pressure inside the support column under impact load. At the same time, it can reduce the total impact energy applied to the safety valve and improve the adaptability of the safety valve to different impact loads. Further, it improves the impact resistance of the support column under impact load and provides theoretical basis for the design of anti-impact support.

-

Key words:

- energy-absorbing components /

- foam aluminum filling /

- impact resistance /

- safety valve

-

表 1 构件结构尺寸

Table 1. Structural dimensions of the component

Serial No. D/mm h/mm d/mm θ/mm Type MRN1 200 350 120 2.0 Poly cellular tubular MRN2 200 350 120 2.2 Poly cellular tubular MRN3 200 350 120 2.4 Poly cellular tubular MRN4 200 350 120 2.6 Poly cellular tubular MRN5 200 350 120 2.8 Poly cellular tubular MRN6 200 350 120 3.0 Poly cellular tubular MRYA 200 350 120 2.6 A MRYB 200 350 120 2.6 B MRYC 200 350 120 2.6 C MRYD 200 350 120 2.6 D MRYE 200 350 120 2.6 E MRYF 200 350 120 2.6 F MRYG 200 350 120 2.6 G 表 2 材料物理参数和本构模型参数

Table 2. Physical parameters and constitutive model parameters of materials

Material ρ/(kg·m−3) E/GPa μ A/MPa B/MPa C n m 45 steel 7 800 210 0.3 507 320 0.064 0.28 1.06 表 3 不同壁厚构件吸能性能参数

Table 3. Energy absorption performance parameters of components with different wall thicknesses

Serial No. FPIC/kN FAC/kN EA/kJ $\overline\sigma $/kN δ/mm MRN1 1 835 1 044 287.40 164.36 273.97 MRN2 2 024 1 225 332.47 191.55 270.35 MRN3 2 221 1 387 380.76 197.97 275.11 MRN4 2 427 1 623 447.01 216.67 274.91 MRN5 2 656 1 823 503.79 218.96 275.73 MRN6 2 878 2 005 560.26 246.91 278.46 -

[1] 潘一山, 王凯兴, 肖永惠. 基于摆型波理论的防冲支护设计 [J]. 岩石力学与工程学报, 2013, 32(8): 1537–1543.PAN Y S, WANG K X, XIAO Y H. Design of anti-scour support based on theory of pendulum-type wave [J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(8): 1537–1543. [2] 肖永惠, 潘一山, 陈建强, 等. 巷道防冲支架吸能构件屈曲吸能可靠性研究 [J]. 采矿与安全工程学报, 2022, 39(2): 317–327. doi: 10.13545/j.cnki.jmse.2021.0495XIAO Y H, PAN Y S, CHEN J Q, et al. Buckling energy absorption reliability of energy absorption component of roadway rockburst preventing support [J]. Journal of Mining & Safety Engineering, 2022, 39(2): 317–327. doi: 10.13545/j.cnki.jmse.2021.0495 [3] 王春华, 安达, 韩冲, 等. 冲击地压新型加肋板圆管式吸能防冲构件的仿真与试验 [J]. 振动与冲击, 2019, 38(11): 203–210, 241. doi: 10.13465/j.cnki.jvs.2019.11.030WANG C H, AN D, HAN C, et al. Simulation and tests for new tubular type energy-absorbing and anti-impact members with stiffened plate under rock burst [J]. Journal of Vibration and Shock, 2019, 38(11): 203–210, 241. doi: 10.13465/j.cnki.jvs.2019.11.030 [4] HA N S, PHAM T M, HAO H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing [J]. International Journal of Mechanical Sciences, 2021, 201: 106464. doi: 10.1016/j.ijmecsci.2021.106464 [5] ALBAK E İ. Crashworthiness design for multi-cell circumferentially corrugated thin-walled tubes with sub-sections under multiple loading conditions [J]. Thin-Walled Structures, 2021, 164: 107886. doi: 10.1016/j.tws.2021.107886 [6] NAGARJUN J, KUMAR A P, REDDY K Y, et al. Dynamic crushing and energy absorption performance of newly designed multitubular structures [J]. Materials Today: Proceedings, 2020, 27: 1928–1933. doi: 10.1016/j.matpr.2020.04.103 [7] ZHANG Y, HE N, HOU Y B. Crashworthiness optimization of a vertex fractal hexagonal structure [J]. International Journal of Computational Methods, 2020, 17(7): 1950031. doi: 10.1142/S0219876219500312 [8] BUYALICH G D, BUYALICH K G, VOYEVODIN V V. Radial deformations of working cylinder of hydraulic legs depending on their extension [J]. IOP Conference Series: Materials Science and Engineering, 2015, 91(1): 012087. doi: 10.1088/1757-899X/91/1/012087 [9] 刘欣科, 赵忠辉, 赵锐. 冲击载荷作用下液压支架立柱动态特性研究 [J]. 煤炭科学技术, 2012, 40(12): 66–70. doi: 10.13199/j.cst.2012.12.72.liuxk.028LIU X K, ZHAO Z H, ZHAO R. Study on dynamic features of leg applied to hydraulic powered support under bumping load [J]. Coal Science and Technology, 2012, 40(12): 66–70. doi: 10.13199/j.cst.2012.12.72.liuxk.028 [10] 张建卓, 张佳林. 吸能型防冲立柱液体冲击问题研究 [J]. 振动与冲击, 2020, 39(8): 51–57. doi: 10.13465/j.cnki.jvs.2020.08.008ZHANG J Z, ZHANG J L. A study on liquid shock of energy-absorbing anti-impact hydraulic column [J]. Journal of Vibration and Shock, 2020, 39(8): 51–57. doi: 10.13465/j.cnki.jvs.2020.08.008 [11] 肖晓春, 朱恒, 徐军, 等. 含泡沫铝填充多胞方管吸能立柱防冲特性数值研究 [J]. 煤炭科学技术, 2023, 51(10): 302–311. doi: 10.13199/j.cnki.cst.2022-1608XIAO X C, ZHU H, XU J, et al. Numerical study on anti-impact characteristics of energy absorbing column with multicellular square tube filled with aluminum foam [J]. Coal Science and Technology, 2023, 51(10): 302–311. doi: 10.13199/j.cnki.cst.2022-1608 [12] 田立勇, 周禹鹏, 孙业新, 等. 防冲支架立柱多胞薄壁吸能构件能量吸收性能 [J]. 煤炭学报, 2023, 48(5): 2224–2235. doi: 10.13225/j.cnki.jccs.2022.0903TIAN L Y, ZHOU Y P, SUN Y X, et al. Energy absorption performance of multicellular thin-walled energy-absorbing components of anti-shock support columns [J]. Journal of China Coal Society, 2023, 48(5): 2224–2235. doi: 10.13225/j.cnki.jccs.2022.0903 [13] 张煜航, 武晓东, 庄大杰, 等. 泡沫铝填充半球壳结构动力学特性研究 [J]. 兵器装备工程学报, 2023, 44(6): 65–73. doi: 10.11809/bqzbgcxb2023.06.009ZHANG Y H, WU X D, ZHUANG D J, et al. Study on dynamic characteristics of aluminum foam-filled hemisphere shell [J]. Journal of Ordnance Equipment Engineering, 2023, 44(6): 65–73. doi: 10.11809/bqzbgcxb2023.06.009 [14] 张佳林. 吸能型防冲液压立柱抗冲击特性研究 [D]. 阜新: 辽宁工程技术大学, 2019.ZHANG J L. Study on impact resistance of energy-absorbing anti-impact hydraulic column [D]. Fuxin: Liaoning Technical University, 2019. [15] CHEN W G, WIERZBICKI T. Relative merits of single-cell, multi-cell and foam-filled thin-walled structures in energy absorption [J]. Thin-Walled Structures, 2001, 39(4): 287–306. doi: 10.1016/S0263-8231(01)00006-4 [16] 田立勇, 于晓涵, 周禹鹏, 等. 液压支架立柱防冲吸能构件优化仿真及压溃实验研究 [J]. 煤炭学报, 2024, 49(6): 2924–2936. doi: 10.13225/j.cnki.jccs.2023.0676TIAN L Y, YU X H, ZHOU Y P, et al. Optimization simulation and crushing experiment of anti-impact energy absorption component of hydraulic support column [J]. Journal of China Coal Society, 2024, 49(6): 2924–2936. doi: 10.13225/j.cnki.jccs.2023.0676 [17] 潘一山, 肖永惠, 李国臻. 巷道防冲液压支架研究及应用 [J]. 煤炭学报, 2020, 45(1): 90–99. doi: 10.13225/j.cnki.jccs.YG19.1762PAN Y S, XIAO Y H, LI G Z. Roadway hydraulic support for rockburst prevention in coal mine and its application [J]. Journal of China Coal Society, 2020, 45(1): 90–99. doi: 10.13225/j.cnki.jccs.YG19.1762 [18] 吴明泽, 张晓伟, 张庆明. 材料和内边界约束对薄壁圆管轴向压缩吸能特性的影响研究 [J]. 应用力学学报, 2020, 37(4): 1415–1421. doi: 10.11776/cjam.37.04.D037WU M Z, ZHANG X W, ZHANG Q M. Effects of material properties and inner-constraints on the energy absorption of thin-walled circular tube under axial compression [J]. Chinese Journal of Applied Mechanics, 2020, 37(4): 1415–1421. doi: 10.11776/cjam.37.04.D037 [19] 杜常赞. 闭孔泡沫铝压缩性能实验与仿真研究 [D]. 哈尔滨: 哈尔滨工业大学, 2021.DU C Z. Experimental and simulation study on compression performance of closed cell aluminum foam [D]. Harbin: Harbin Institute of Technology, 2021. [20] 曹梦真, 邱田伟, 安钰坤. 泡沫铝有限元仿真模型研究现状 [J]. 中国材料进展, 2024, 43(4): 323–330. doi: 10.7502/j.issn.1674-3962.202210016CAO M Z, QIU T W, AN Y K. Research status of finite element simulation model of aluminum foams [J]. Materials China, 2024, 43(4): 323–330. doi: 10.7502/j.issn.1674-3962.202210016 [21] LI W W, LUO Y H, LI M, et al. A more weight-efficient hierarchical hexagonal multi-cell tubular absorber [J]. International Journal of Mechanical Sciences, 2018, 140: 241–249. doi: 10.1016/j.ijmecsci.2018.03.006 [22] MOU H L, ZOU T C, FENG Z Y, et al. Crashworthiness analysis and evaluation of fuselage section with sub-floor composite sinusoidal specimens [J]. Latin American Journal of Solids and Structures, 2016, 13(6): 1186–1202. doi: 10.1590/1679-78252446 [23] 周颖, 潘一山, 张建卓, 等. 高压大流量安全阀卸荷过程模型构建及仿真分析 [J]. 辽宁工程技术大学学报(自然科学版), 2018, 37(1): 136–140. doi: 10.11956/j.issn.1008-0562.2018.01.024ZHOU Y, PAN Y S, ZHANG J Z, et al. Model building for unloading process of high pressure large flow relief valve and its simulation analysis [J]. Journal of Liaoning Technical University (Natural Science), 2018, 37(1): 136–140. doi: 10.11956/j.issn.1008-0562.2018.01.024 [24] 赵怀志, 王晓东. 液压支架大流量安全阀冲击特性影响因素仿真分析 [J]. 液压与气动, 2022, 46(2): 131–137. doi: 10.11832/j.issn.1000-4858.2022.02.017ZHAO H Z, WANG X D. Simulation analysis of influencing factors on impact characteristics of large flow safety valve for hydraulic support [J]. Chinese Hydraulics & Pneumatics, 2022, 46(2): 131–137. doi: 10.11832/j.issn.1000-4858.2022.02.017 -

下载:

下载: