Dynamic Response of Prefabricated Wall Panels for a Whole-Indoor Substation under Blast Loading Based on Finite Element Simulation

-

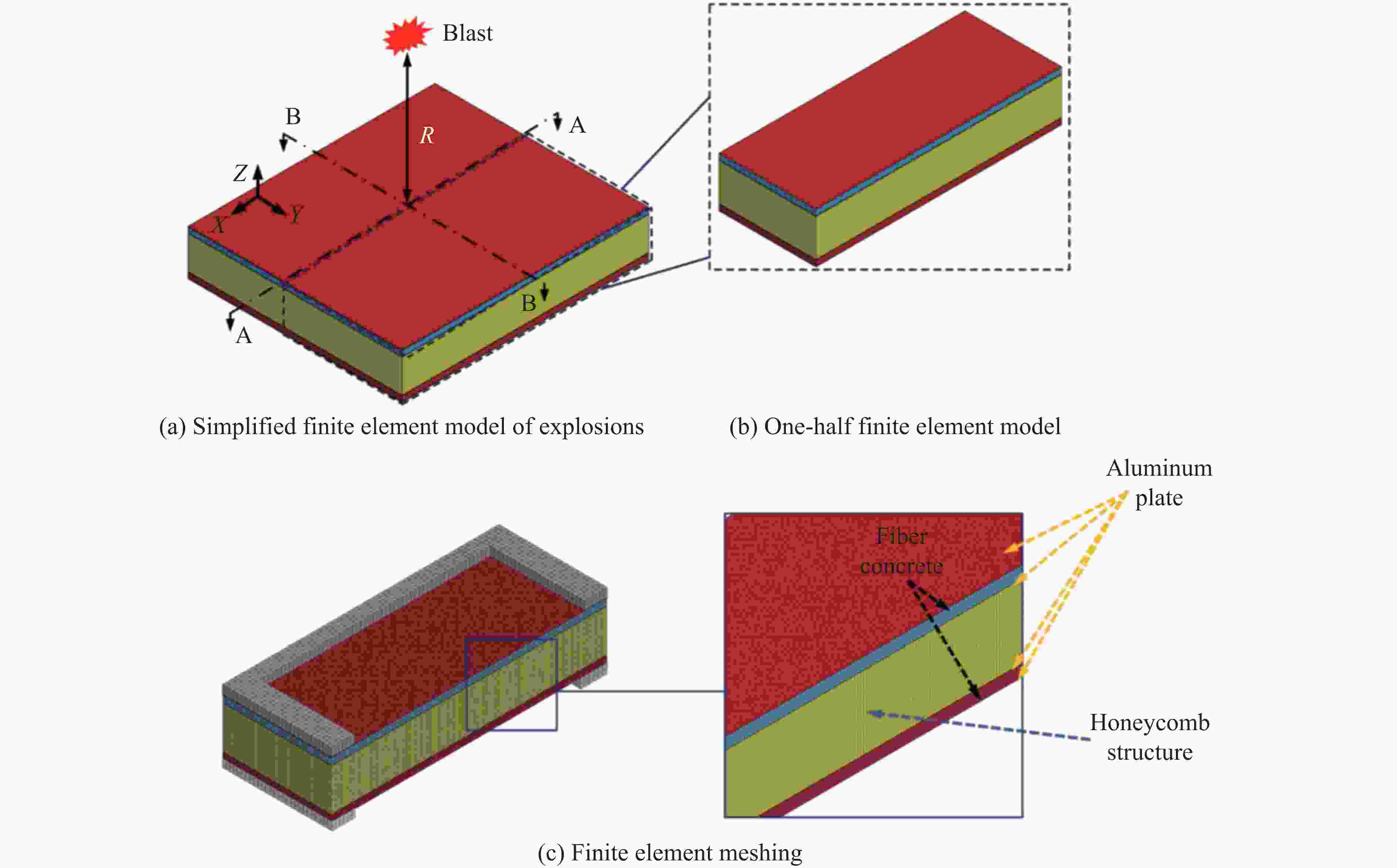

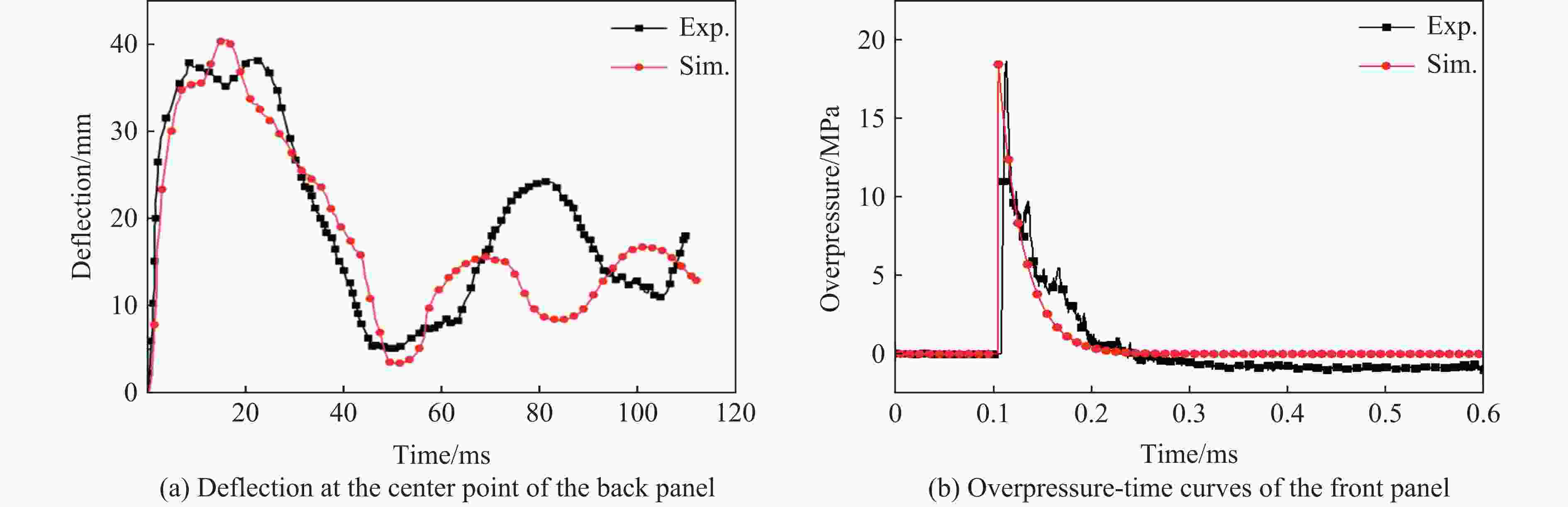

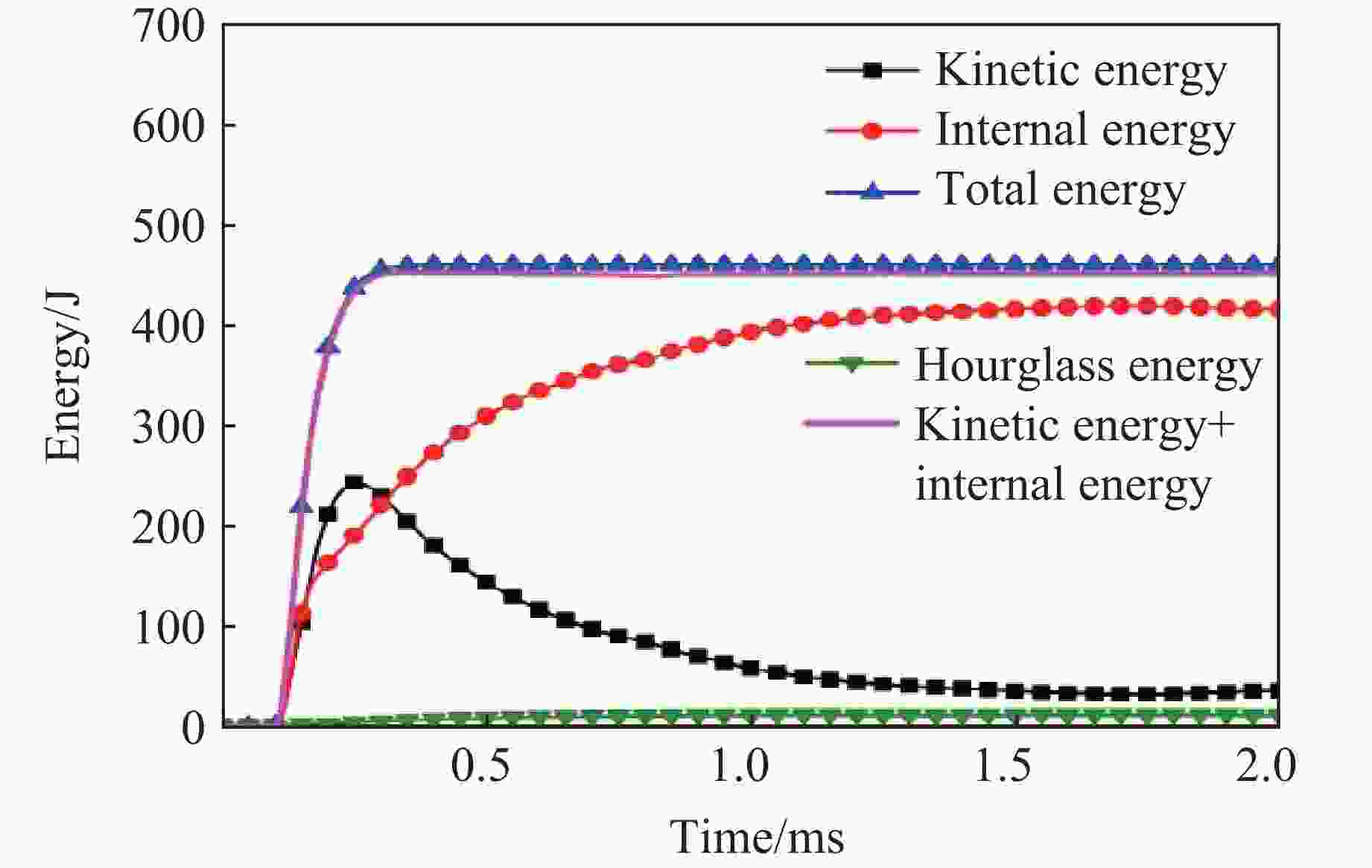

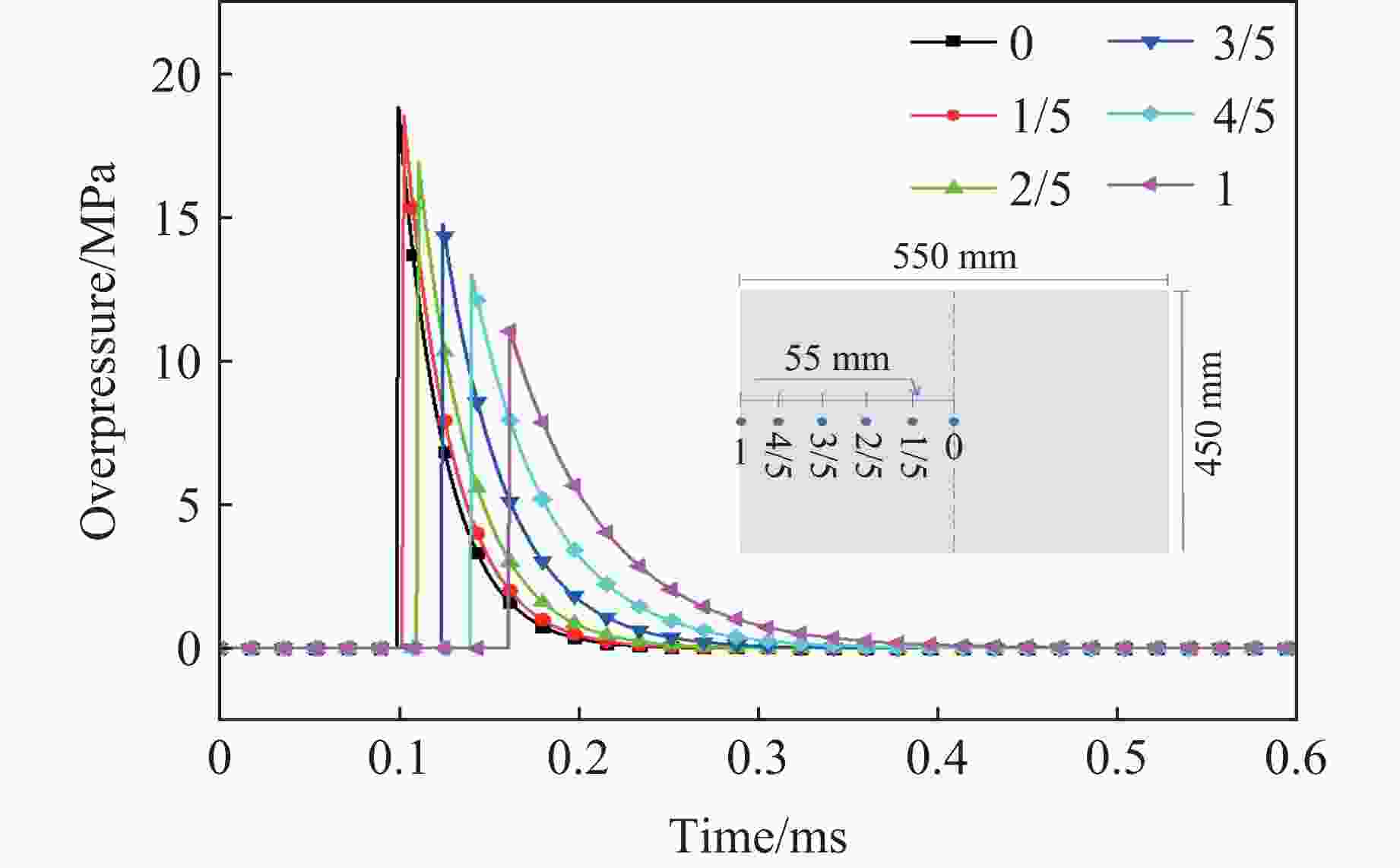

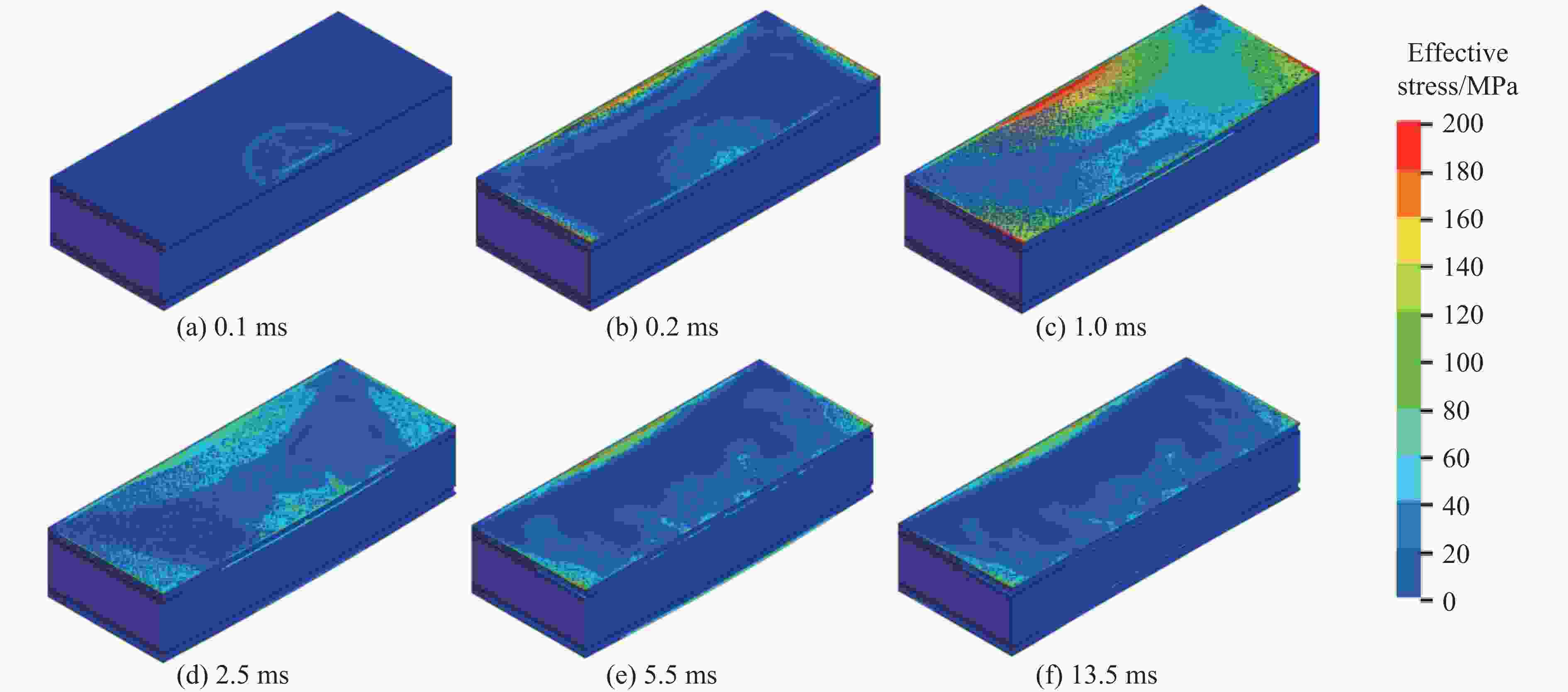

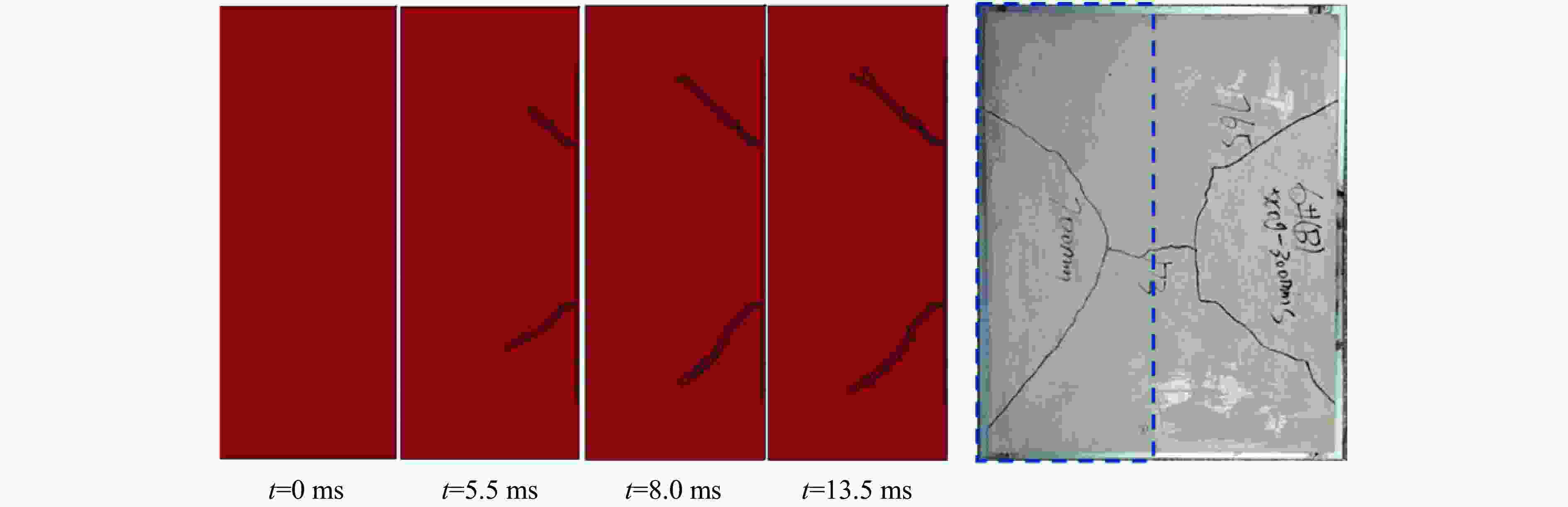

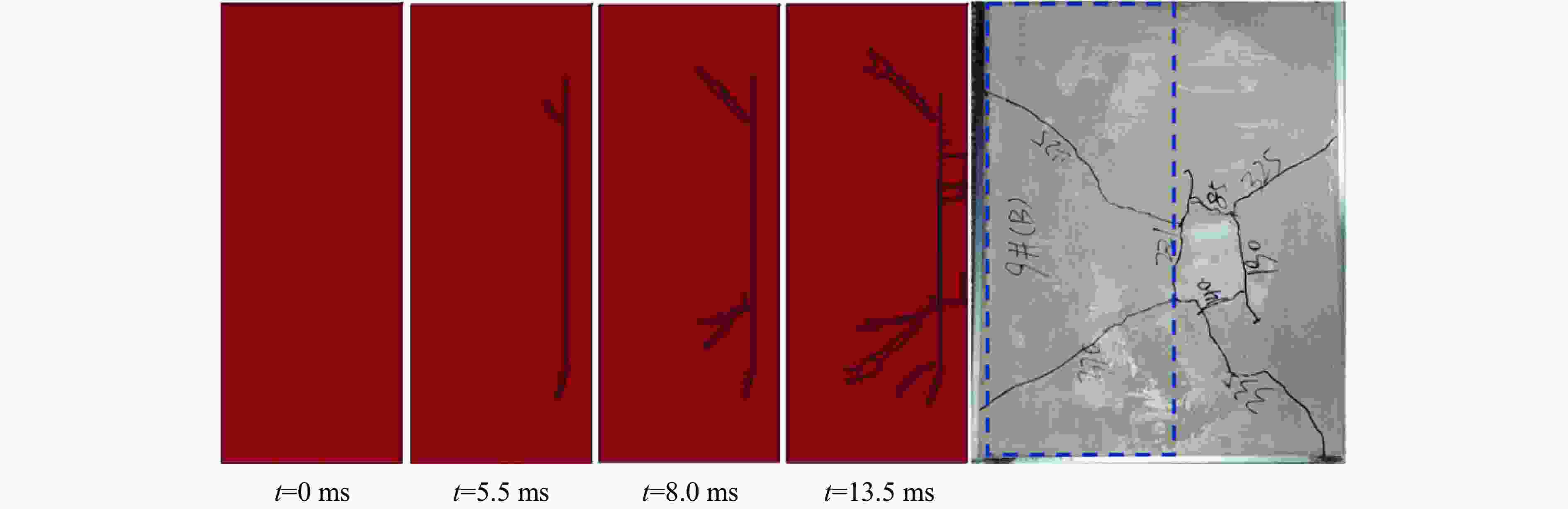

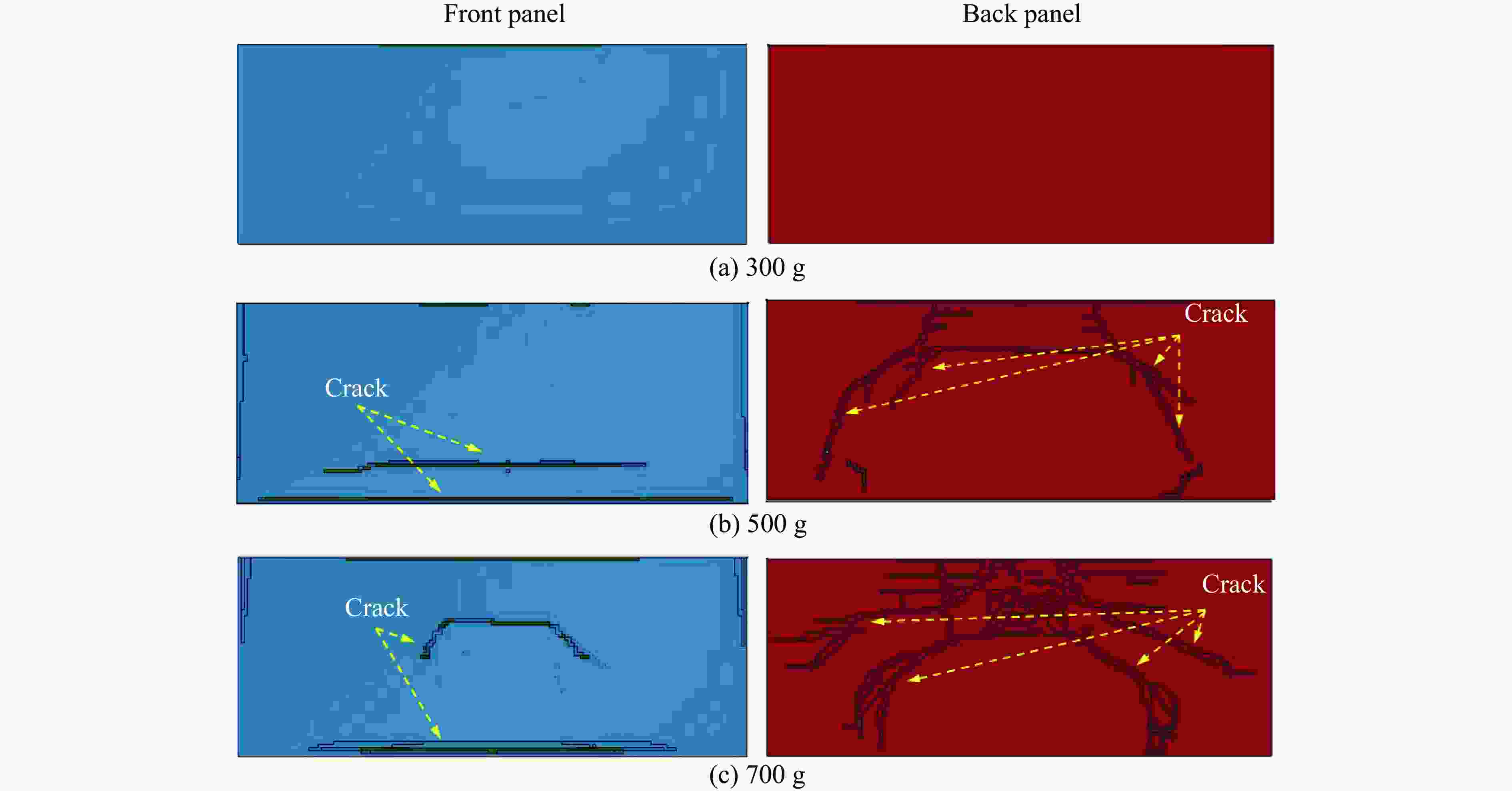

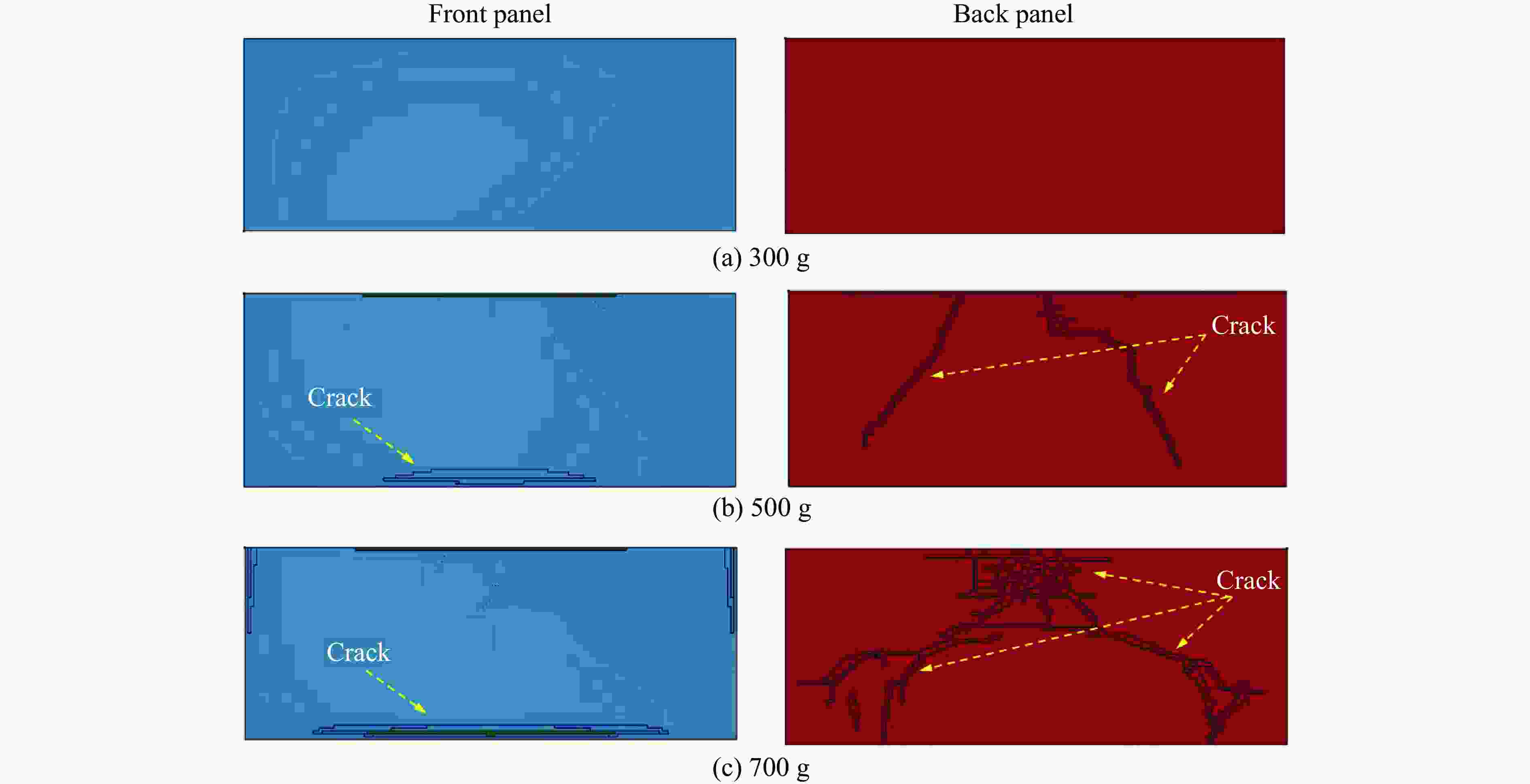

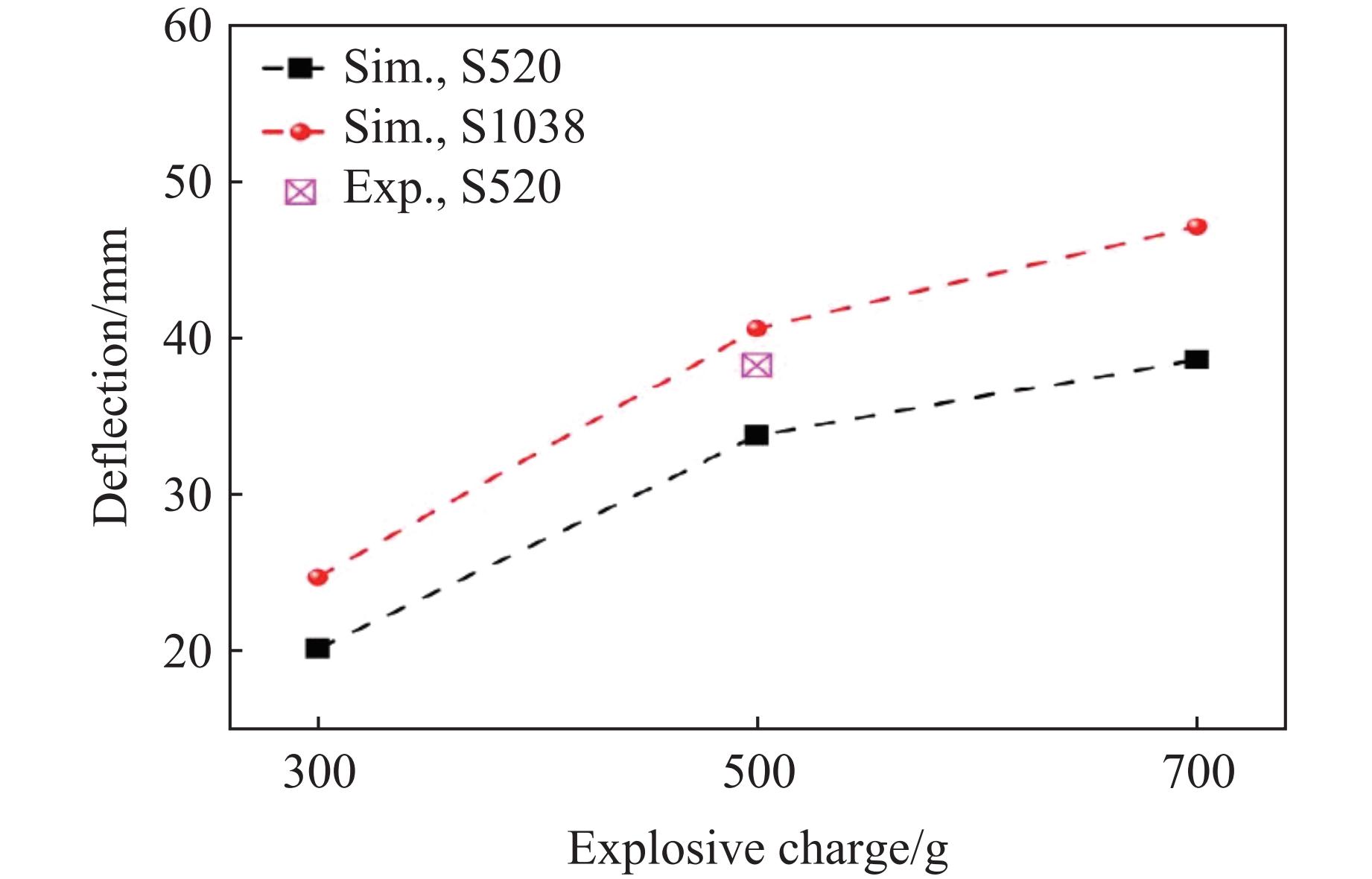

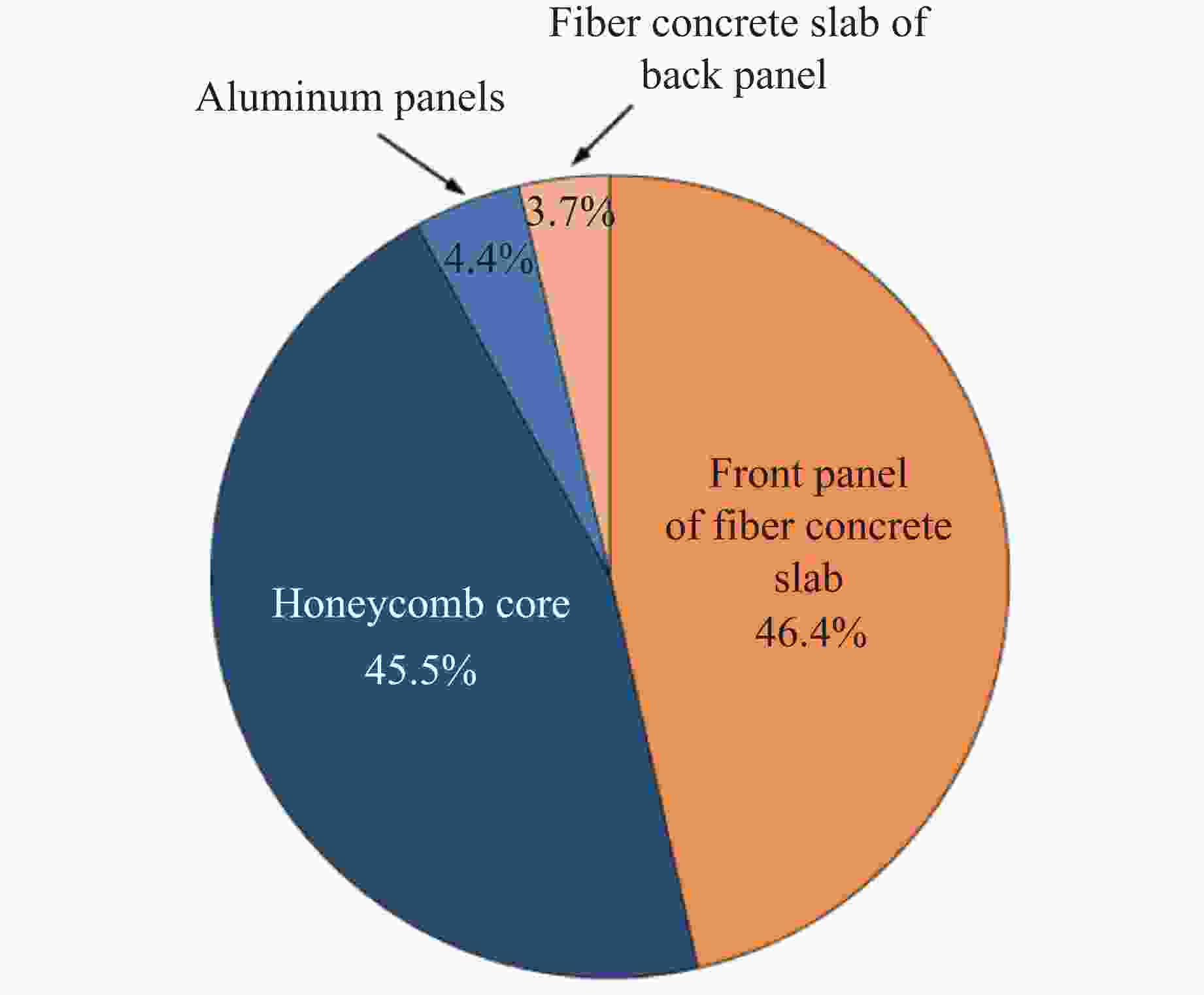

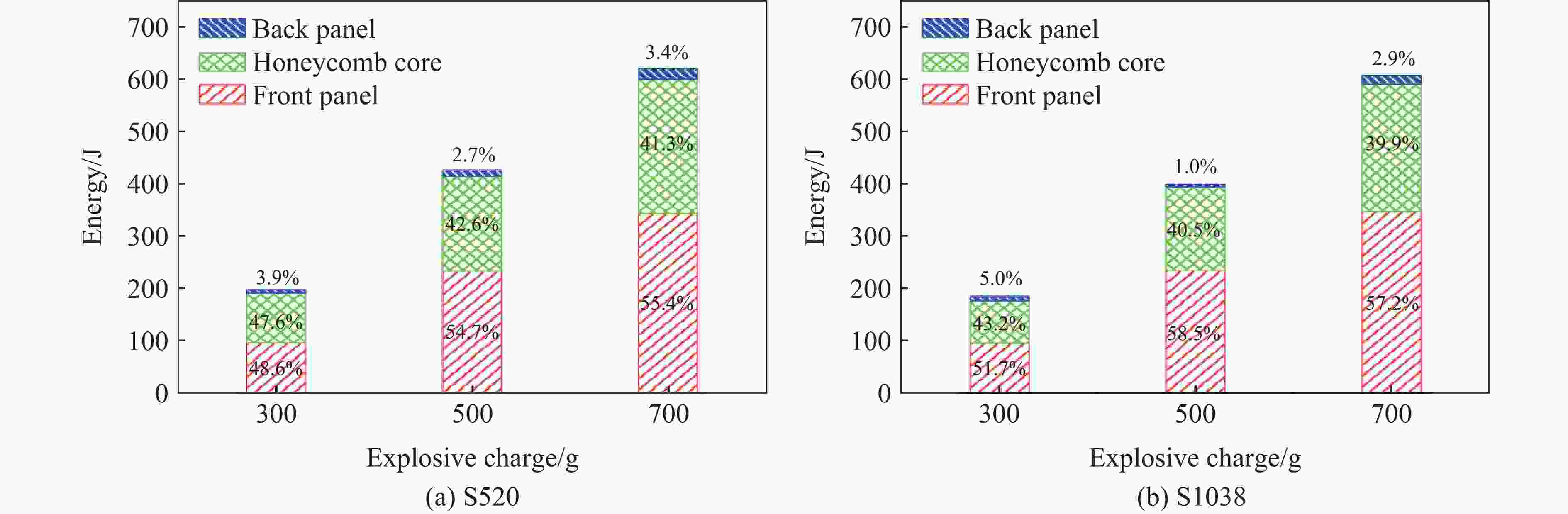

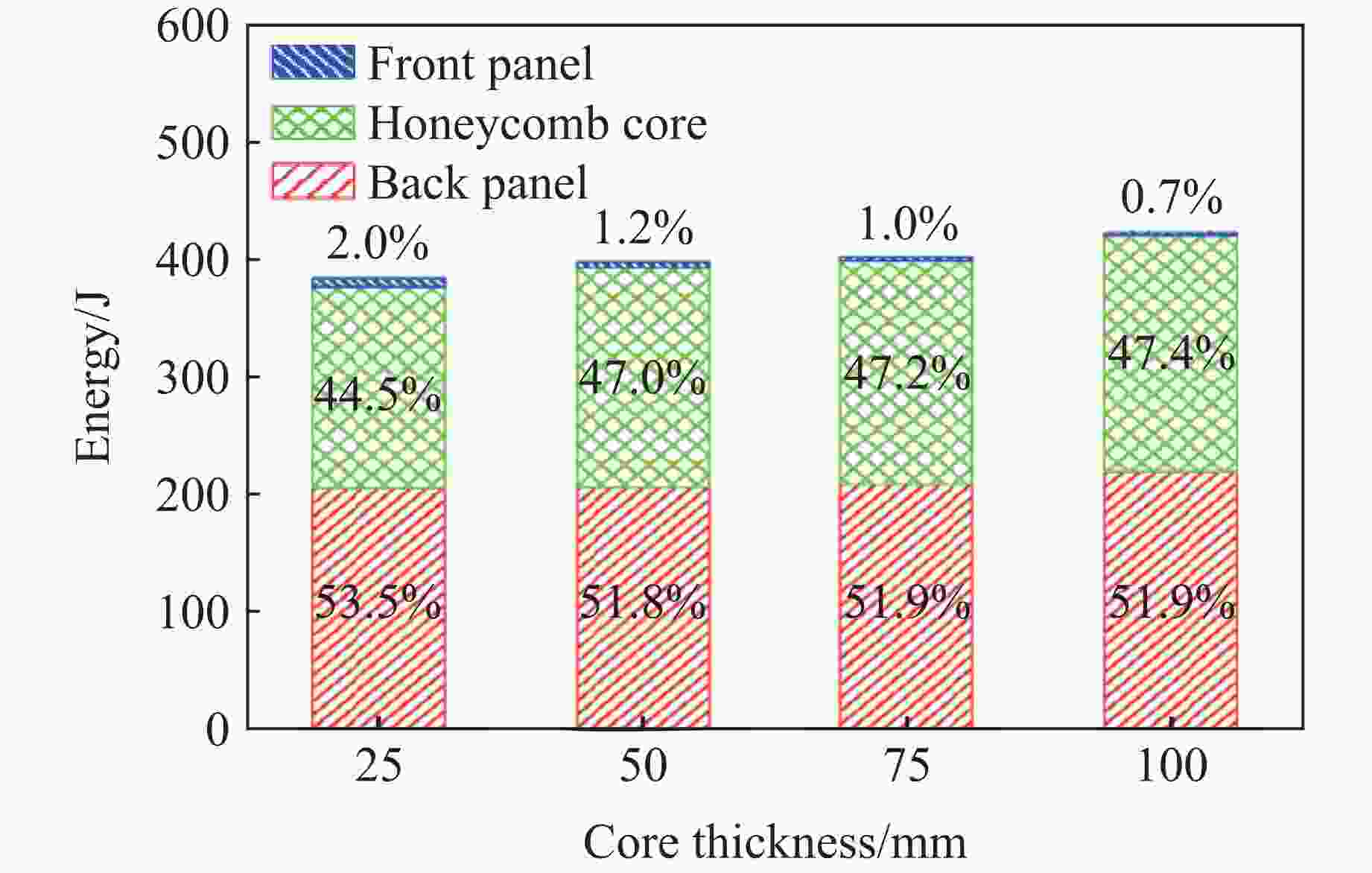

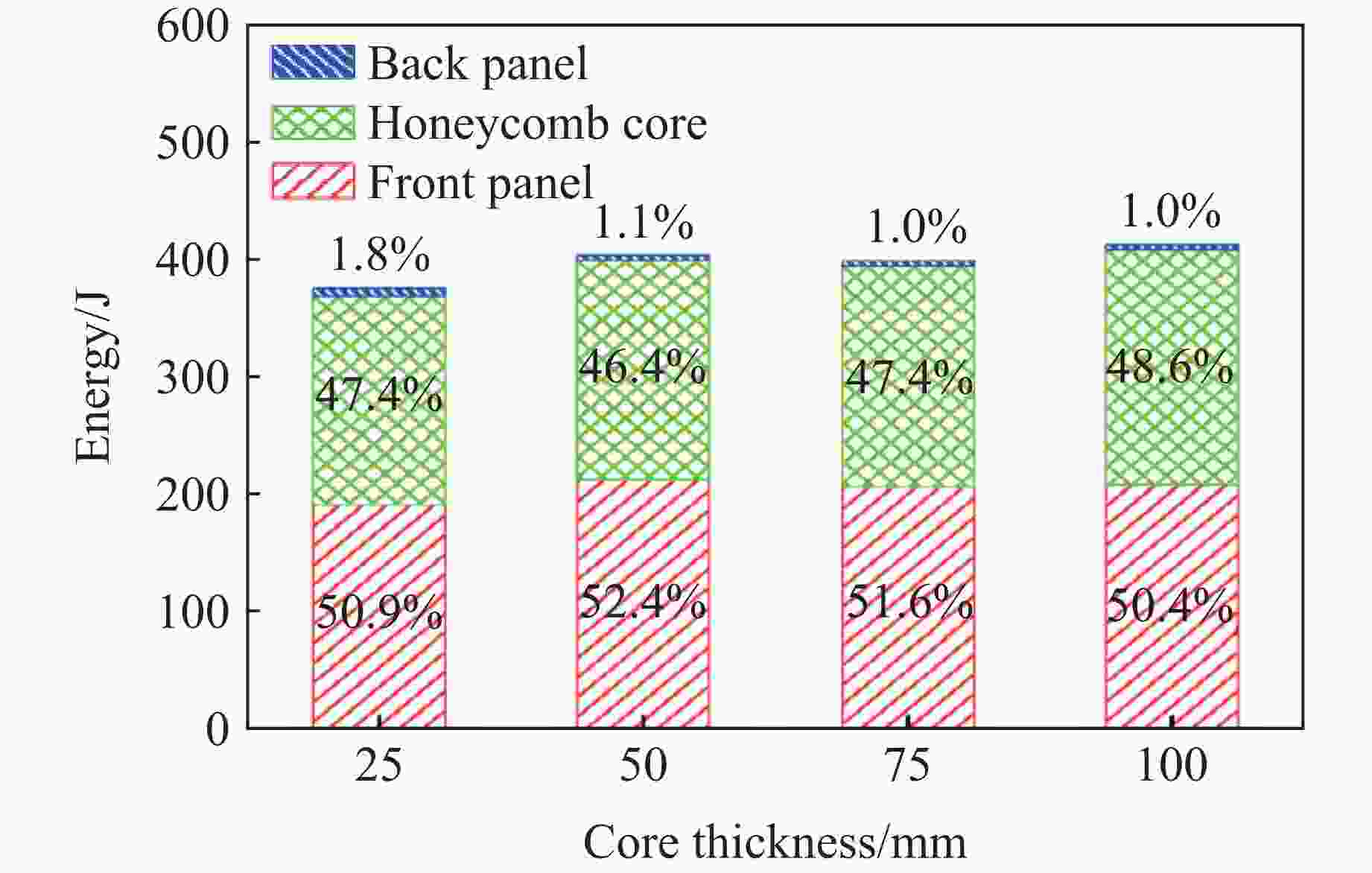

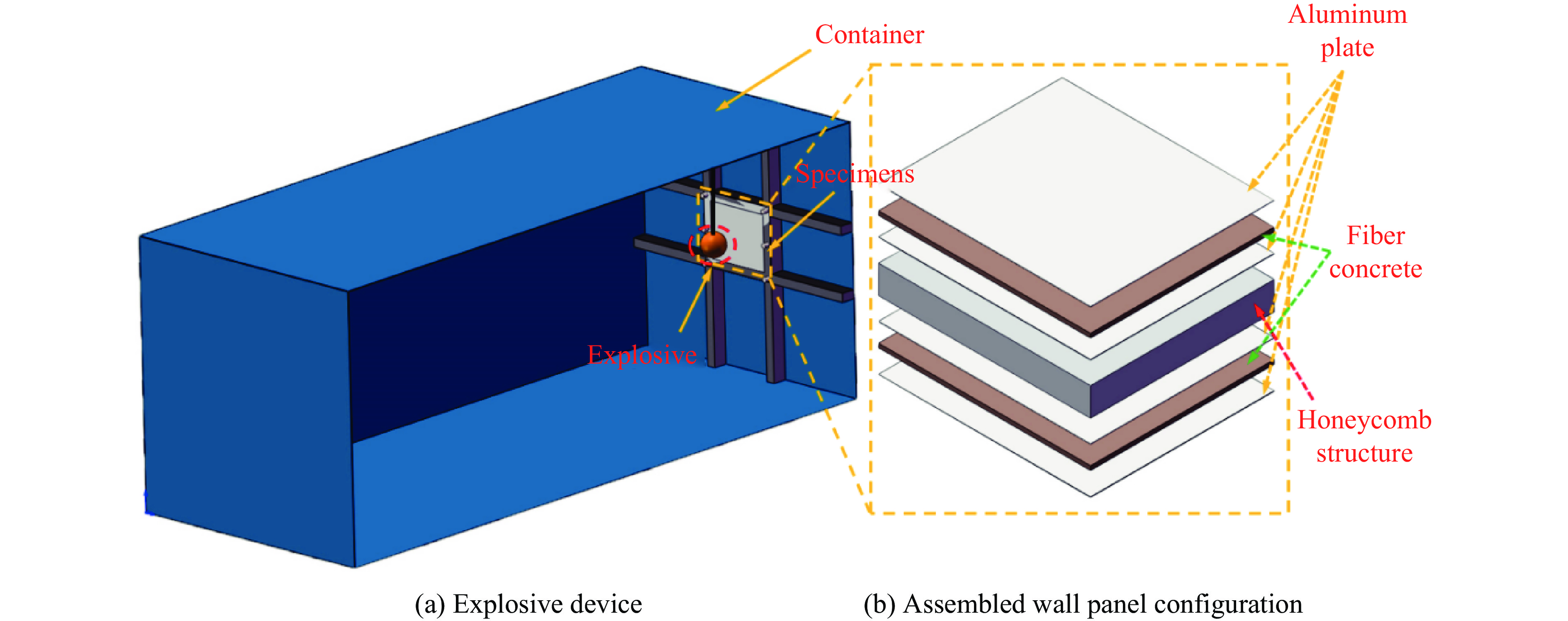

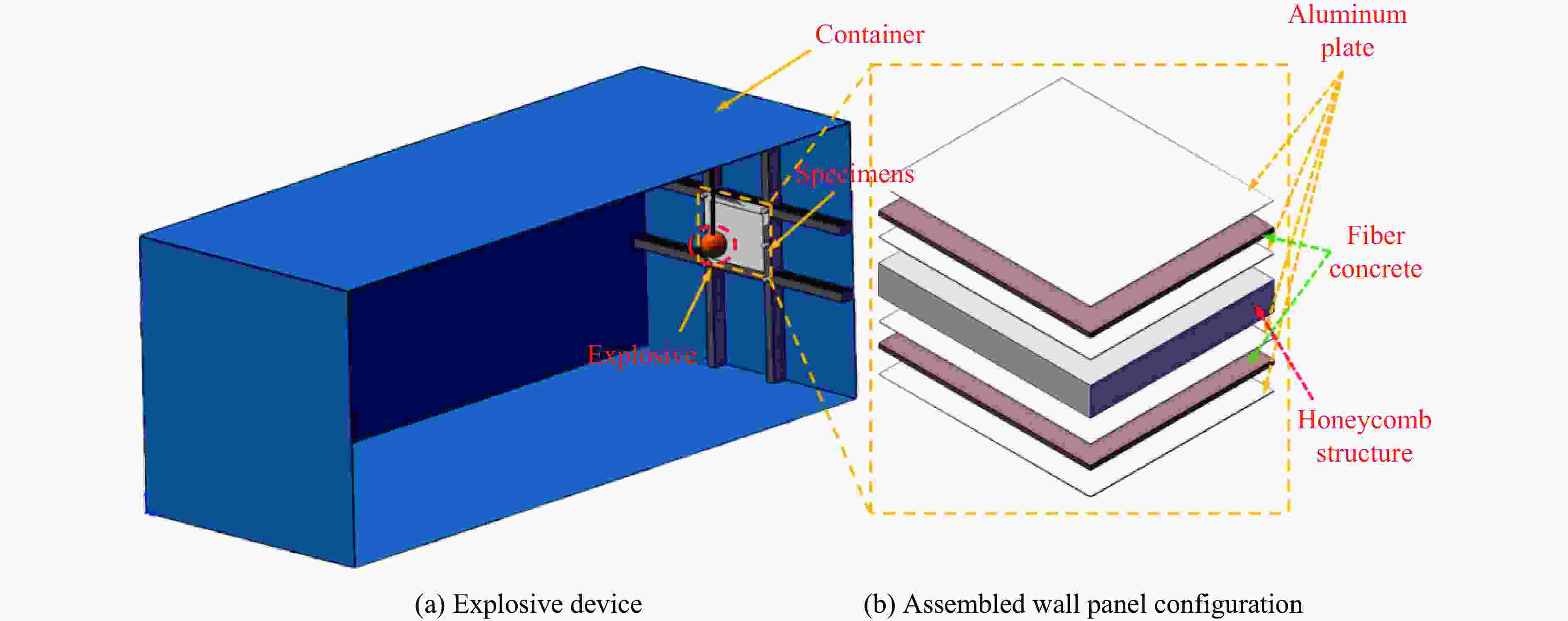

摘要: 蜂窝芯层具有轻质、比刚度高、比强度高和比吸能高等优点。将纤维混凝土板、蜂窝芯层、铝合金板组合设计一种新型变电站装配式墙板结构,对其进行爆炸冲击实验,研究不同炸药药量、蜂窝孔径下结构的动力学响应。基于实验建立相应的有限元模型,数值模拟结果与实验吻合较好。通过改变炸药量和蜂窝芯层配置,详细分析了结构变形失效演化过程、后面板中点挠度、能量分配特性。结果表明:结构主要呈现前面板凹陷、后面板凸起的变形模式;纤维水泥前面板边界处发生了剪切破坏,同时蜂窝芯层被压缩,导致整体变形,随后前面板与蜂窝芯层分离,后面板中心处以及对角线处出现裂纹,并且随着结构继续响应,裂纹不断扩展,芯层压缩量也同时增加。减小蜂窝芯层孔径能够有效降低后面板的挠度。装药距离为300 mm,药量为300、500和700 g时,小孔径蜂窝结构后面板中点的挠度相较于大孔径蜂窝结构分别降低了18.5%、17.1%和18.1%,小孔径蜂窝结构的吸能比大孔径蜂窝结构分别增大了7.8%、6.7%和2.2%,小孔径蜂窝结构具有较好的抗冲击性能。爆炸载荷下,纤维混凝土前面板的吸收能量最大,占50%以上;蜂窝芯层的能量吸收次之,占比为45%左右;纤维混凝土后面板的吸能较少,在5%以内。Abstract: The honeycomb core layer is light and has the advantage of high specific stiffness, specific strength and specific energy absorption. A novel prefabricated wall panel structure for substations was designed by combining fiber-reinforced concrete panels, honeycomb core layers, and aluminum alloy panels. The dynamic response of the structure under the blast load was investigated, as well as the effect of the explosive mass and the size of the honeycomb core. In this paper, a finite element model was established and compared with the experimental results, which was found to be in good agreement with each other, thus validating the model. On this basis, the effects of explosive mass and honeycomb core layer on the structural deformation failure mode, midpoint deflection of back panel and energy absorption were investigated. It is shown that the deformation pattern of the structure is mainly concave at the front and convex at the back, and the honeycomb core layer is compressed, resulting in the whole deformation. Then the fiber cement of the front panel is separated with the honeycomb core layer, and the fiber-reinforced concrete panels of the back panel have failure at the center and diagonal, and the crack expandes, and the compression of the core layer increases. It was found that for the same amount of explosion, the center deflection of the back panel of the honeycomb structure with small size was reduced by 18.5%, 17.1%, and 18.1% compared to the honeycomb structure with large size. Meanwhile, the energy absorption of the honeycomb structure with small size was increased by 7.8%, 6.7%, and 2.2% respectively compared with that of the honeycomb structure with large size. Thus, the honeycomb structure with small size has better impact resistance. Under blast load, the fiber-reinforced concrete panels on the front panel absorbs the most energy, accounting for more than 50%, followed by the honeycomb core layer, accounting for about 45%, and the back panel fiber-reinforced concrete panels absorbs less energy, and the energy absorption is within 5%.

-

表 1 铝合金的材料参数

Table 1. Material parameters of aluminum alloy

$ \mathrm{\rho } $/(kg·m−3) E/GPa $ \mu $ $ {\mathrm{\sigma }}_{\mathrm{y}} $/MPa 2900 65.67 0.30 255 表 2 纤维混凝土的材料参数

Table 2. Material parameters of fiber concrete

$ \rho $/(kg·m−3) G/MPa $ \mathrm{\mathit{F}}_{\mathrm{c}} $/MPa A B C $ {\varepsilon }_{\mathrm{f}\mathrm{m}\mathrm{i}\mathrm{n}} $ 2.500 0.1343 3.000×10−4 0.20 1.85 0.006 0.004 N $ {S}_{\mathrm{m}\mathrm{a}\mathrm{x}} $ T/MPa $ {p}_{\mathrm{c}} $/MPa $ {\mu }_{\mathrm{c}} $ $ {p}_{\mathrm{L}} $/MPa $ {\dot \varepsilon _0}/{{\text{s}}^{ - 1}} $ 0.610 15.00 2.500×10−5 7.000×10−5 0.005 0.0121 1 $ {\mu }_{\mathrm{L}} $ $ {K}_{1} $/GPa $ {K}_{2} $/GPa $ {K}_{3} $/GPa $ {D}_{1} $ $ {D}_{2} $ $ {f}_{\mathrm{s}} $ 0.1200 8.500×10−7 −1.71×10−6 2.08×10−6 0.040 0.500 0.80 表 3 蜂窝芯层的材料参数

Table 3. Material parameters of honeycomb core

$ \rho $/(kg·m−3) E/MPa $ \mu $ 450 89.5 0 -

[1] 中华人民共和国住房和城乡建设部. 火力发电厂与变电站设计防火标准:GB 50229—2019 [S]. 北京: 中国计划出版社, 2019.Ministry of Housing and Urban Rural Development of the People’s Republic of China. Standard for design of fire protection for fossil fuel power plants and substations: GB 50229—2019 [S]. Beijing: China Planning Press, 2019. [2] 黄荣健, 房涛, 张兴卫. 考虑基础-结构动力相互作用的500 kV变电站地震预警系统的设计与应用研究 [J]. 中国战略新兴产业, 2024(9): 166–168. doi: 10.12230/j.issn.2095-6657.2024.09.051HUANG R J, FANG T, ZHANG X W. Design and application study of seismic early warning system for 500 kV substation considering foundation-structure dynamic interaction [J]. China Strategic Emerging Industry, 2024(9): 166–168. doi: 10.12230/j.issn.2095-6657.2024.09.051 [3] 刘慕娴, 陆力瑜, 莫蓓蓓, 等. 智能变电站安全运维策略研究 [J]. 新型工业化, 2021, 11(10): 88–90. doi: 10.19335/j.cnki.2095-6649.2021.10.018LIU M X, LU L Y, MO B B, et al. Research on security operation and maintenance strategy of smart substation [J]. The Journal of New Industrialization, 2021, 11(10): 88–90. doi: 10.19335/j.cnki.2095-6649.2021.10.018 [4] JU W H. Study on fire risk and disaster reducing factors of cotton logistics warehouse based on event and fault tree analysis [J]. Procedia Engineering, 2016, 135: 418–426. doi: 10.1016/j.proeng.2016.01.150 [5] 国网基建部. 变电站模块化建设2.0版技术导则 [R]. 2021. [6] ZHU F, WANG Z H, LU G X, et al. The impulsive response of aluminium foam core sandwich structures [J]. International Journal of Materials Engineering Innovation, 2009, 1(2): 133–153. doi: 10.1504/IJMATEI.2009.029361 [7] 崔天宁, 秦庆华. 轻质多孔夹芯结构的弹道侵彻行为研究进展 [J]. 力学进展, 2023, 53(2): 395–432. doi: 10.6052/1000-0992-23-002CUI T N, QIN Q H. Ballistic performance of lightweight cellular sandwich structures: a review [J]. Advances in Mechanics, 2023, 53(2): 395–432. doi: 10.6052/1000-0992-23-002 [8] 吴志恩. 波音787的复合材料构件生产 [J]. 航空制造技术, 2008(15): 92–94. doi: 10.3969/j.issn.1671-833X.2008.15.021WU Z E. Production for composite component of Boeing 787 [J]. Aerospace Manufacturing Technology, 2008(15): 92–94. doi: 10.3969/j.issn.1671-833X.2008.15.021 [9] 杨德庆, 马涛, 张梗林. 舰艇新型宏观负泊松比效应蜂窝舷侧防护结构 [J]. 爆炸与冲击, 2015, 35(2): 243–248. doi: 10.11883/1001-1455(2015)02-0243-06YANG D Q, MA T, ZHANG G L. A novel auxetic broadside defensive structure for naval ships [J]. Explosion and Shock Waves, 2015, 35(2): 243–248. doi: 10.11883/1001-1455(2015)02-0243-06 [10] 胡宗波, 魏敬徽. 爆炸荷载作用下钢板混凝土夹芯砌体防爆墙的防护性能分析 [J]. 钢结构(中英文), 2023, 38(5): 33–42. doi: 10.13206/j.gjgS22102401HU Z B, WEI J H. Analysis on protective performance of explosion-proof wall with masonry sandwich steel plate under blast load [J]. Steel Construction (Chinese & English), 2023, 38(5): 33–42. doi: 10.13206/j.gjgS22102401 [11] CAO K L, FU Q F, MA W C, et al. Study on the underwater anti-explosion mechanism and damage grade prediction of wall panels reinforced by corrugated steel-concrete slab composite structures with different wave heights [J]. Structures, 2024, 60: 105922. doi: 10.1016/j.istruc.2024.105922 [12] WANG H R, QIU A, LONG S C, et al. Effect of fluid-structure interaction on the underwater blast response and failure of composite panels [J]. Thin-Walled Structures, 2023, 191: 111065. doi: 10.1016/j.tws.2023.111065 [13] LANGDON G S, KARAGIOZOVA D, THEOBALD M D, et al. Fracture of aluminium foam core sacrificial cladding subjected to air-blast loading [J]. International Journal of Impact Engineering, 2010, 37(6): 638–651. doi: 10.1016/j.ijimpeng.2009.07.006 [14] LI S Q, LI X, WANG Z H, et al. Finite element analysis of sandwich panels with stepwise graded aluminum honeycomb cores under blast loading [J]. Composites Part A: Applied Science and Manufacturing, 2016, 80: 1–12. doi: 10.1016/j.compositesa.2015.09.025 [15] WADLEY H N G, BØRVIK T, OLOVSSON L, et al. Deformation and fracture of impulsively loaded sandwich panels [J]. Journal of the Mechanics and Physics of Solids, 2013, 61(2): 674–699. doi: 10.1016/j.jmps.2012.07.007 [16] NI C Y, JIN F, LU T J. Penetration of sandwich plates with hybrid-cores under oblique ballistic impact [J]. Theoretical and Applied Mechanics Letters, 2014, 4(2): 021001. doi: 10.1063/2.1402101 [17] 李林, 刘勇, 魏珍中, 等. 爆炸作用下全户内变电站装配式墙板的动力响应实验研究 [J]. 高压物理学报, 2025, 39(4): 044101. doi: 10.11858/gywlxb.20240873LI L, LIU Y, WEI Z Z, et al. Dynamic response experiment of prefabricated wall panels for a whole-indoor substation under blast loading [J]. Chinese Journal of High Pressure Physics, 2025, 39(4): 044101. doi: 10.11858/gywlxb.20240873 [18] 王嵩, 刘润清, 赵硕, 等. 玄武岩纤维混凝土动态力学性能及数值模拟 [J]. 混凝土与水泥制品, 2022(7): 64–68. doi: 10.19761/j.1000-4637.2022.07.064.05WANG S, LIU R Q, ZHAO S, et al. Dynamic mechanical properties and numerical simulation of basalt fiber reinforced concrete [J]. China Concrete and Cement Products, 2022(7): 64–68. doi: 10.19761/j.1000-4637.2022.07.064.05 [19] 杨飞, 王志华, 赵隆茂. 泡沫铝夹芯板抗侵彻性能的数值研究 [J]. 科学技术与工程, 2011, 11(15): 3377–3383. doi: 10.3969/j.issn.1671-1815.2011.15.005YANG F, WANG Z H, ZHAO L M. Numerical simulation on anti-penetration performance of aluminum foam-based sandwich panels [J]. Science Technology and Engineering, 2011, 11(15): 3377–3383. doi: 10.3969/j.issn.1671-1815.2011.15.005 [20] HALLQUIST J O. LS-DYNA keyword user’s manual version 971 [R]. Livermore: Livermore Software Technology Corporation, 2007. [21] SUN G Y, ZHANG J T, LI S Q, et al. Dynamic response of sandwich panel with hierarchical honeycomb cores subject to blast loading [J]. Thin-Walled Structures, 2019, 142: 499–515. doi: 10.1016/j.tws.2019.04.029 [22] WU G, WANG X, WANG Y T, et al. Blast response of bioinspired nacre-like staggered composite plates combined with steel and polyurea [J]. International Journal of Impact Engineering, 2023, 180: 104719. doi: 10.1016/j.ijimpeng.2023.104719 -

下载:

下载: