Constraint Mechanism and Mechanical Characteristics of CFRP Partially Wrapped Coal Columns

-

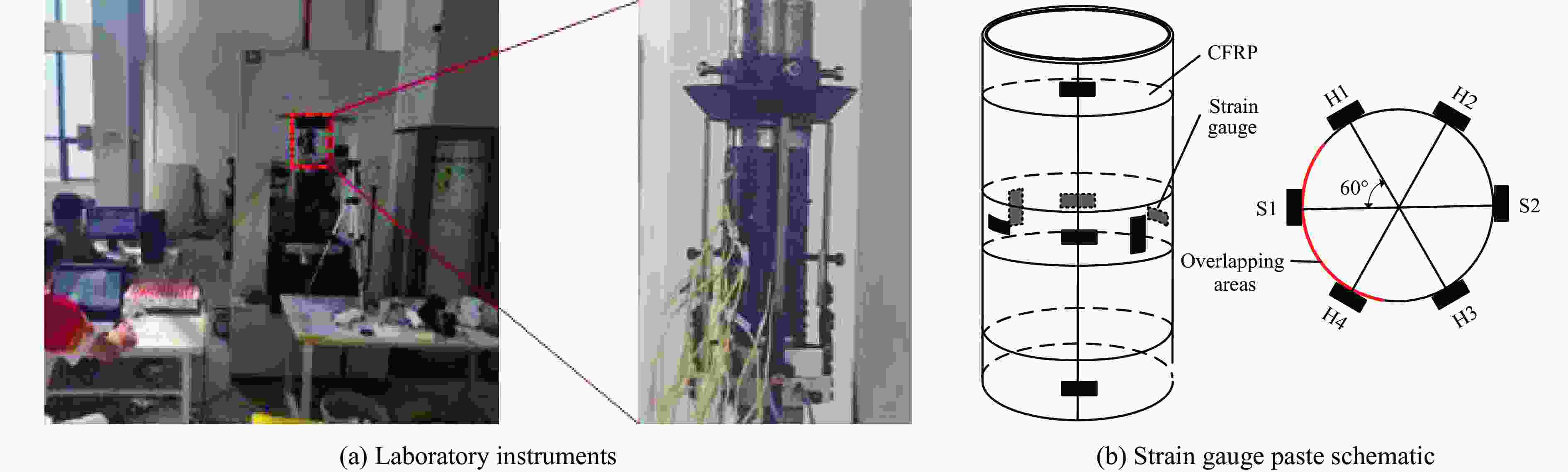

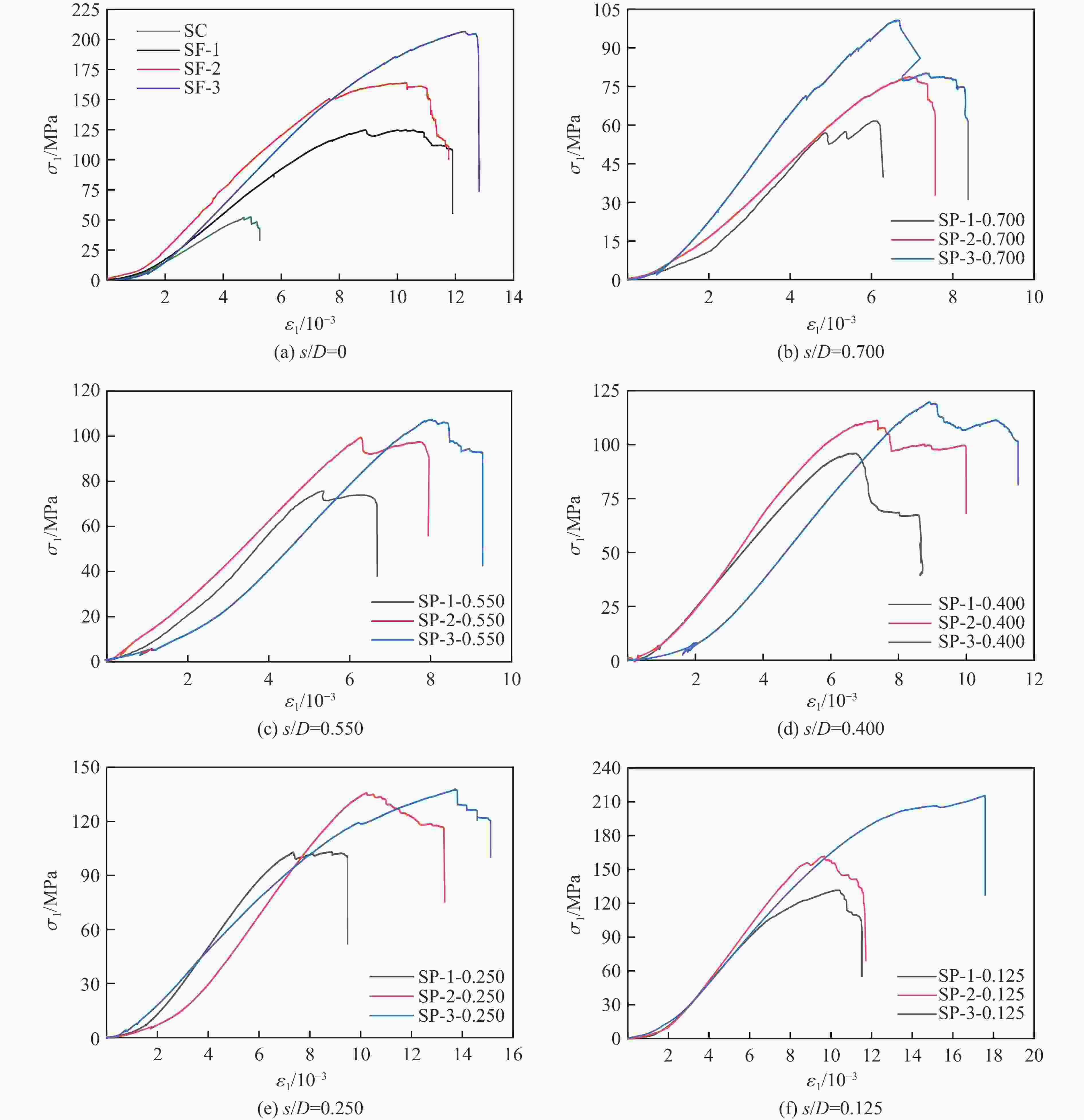

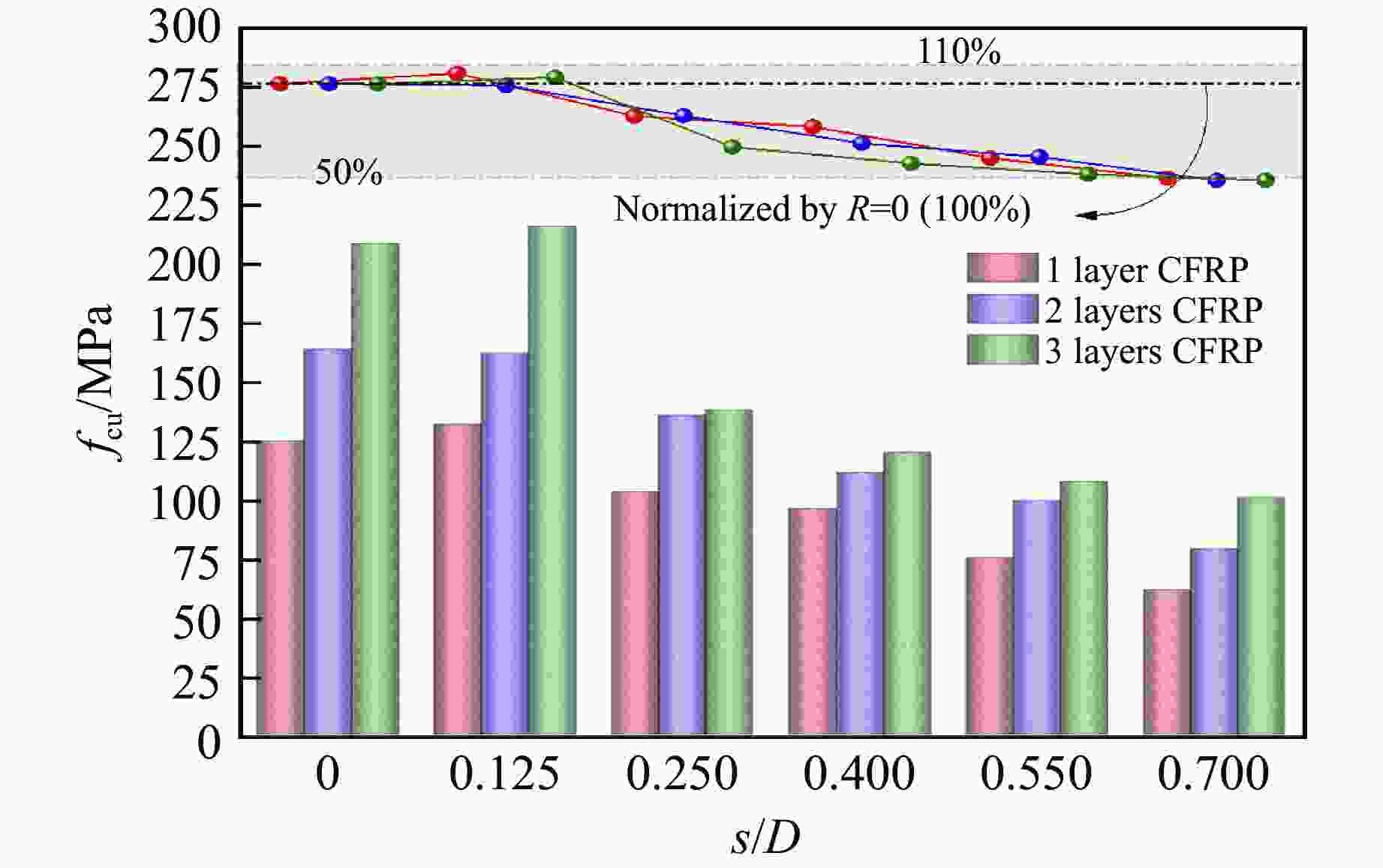

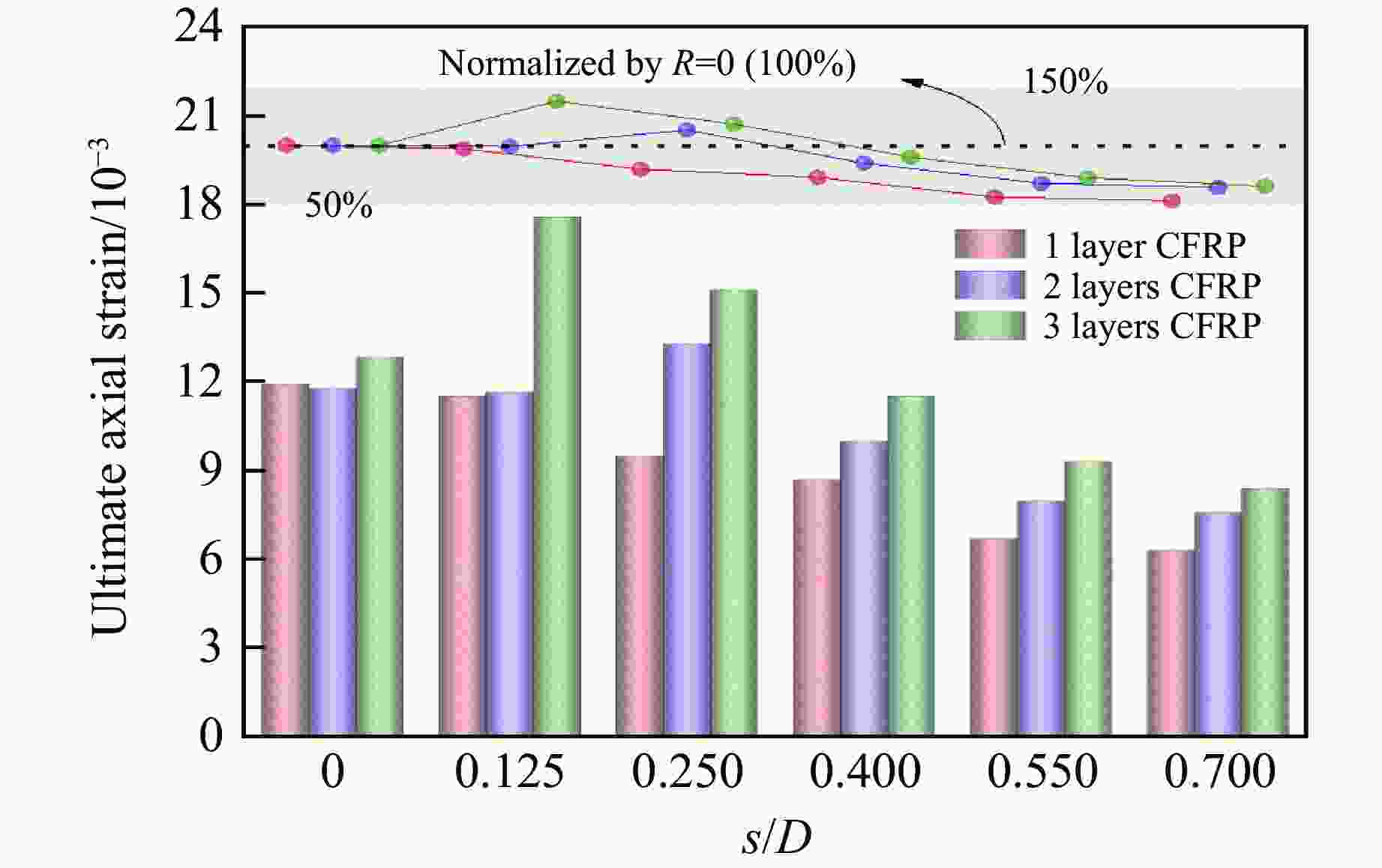

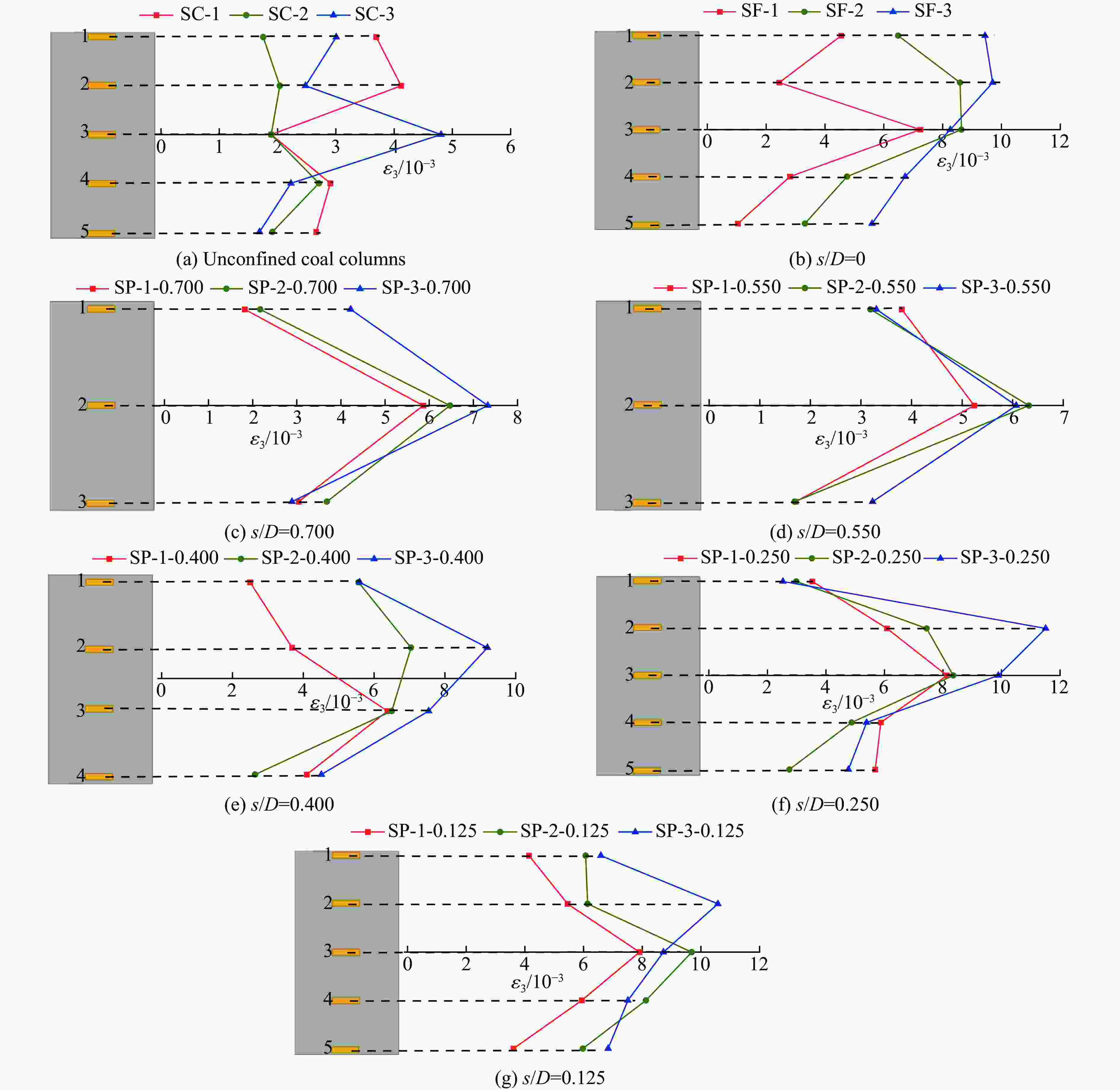

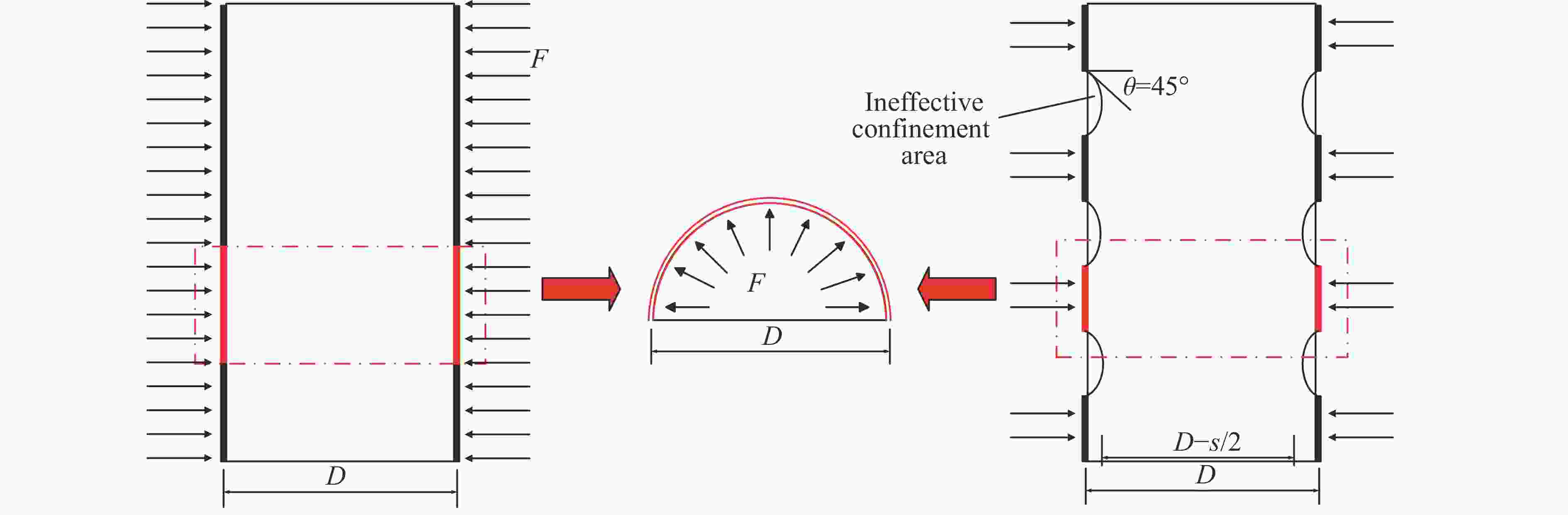

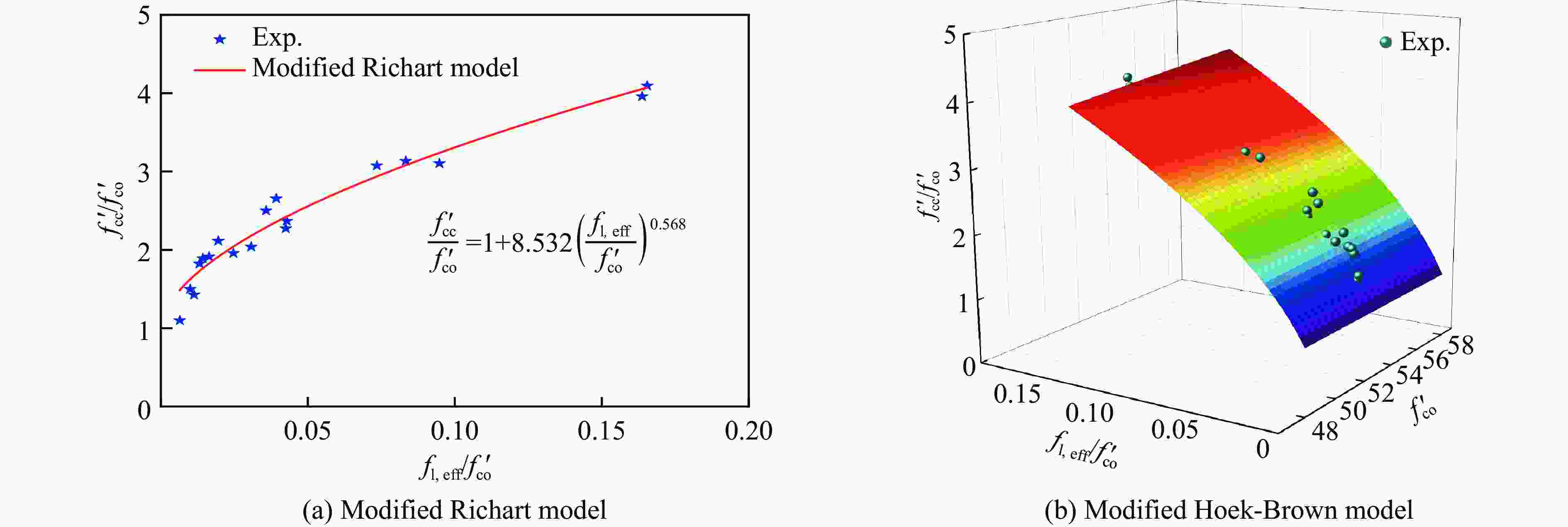

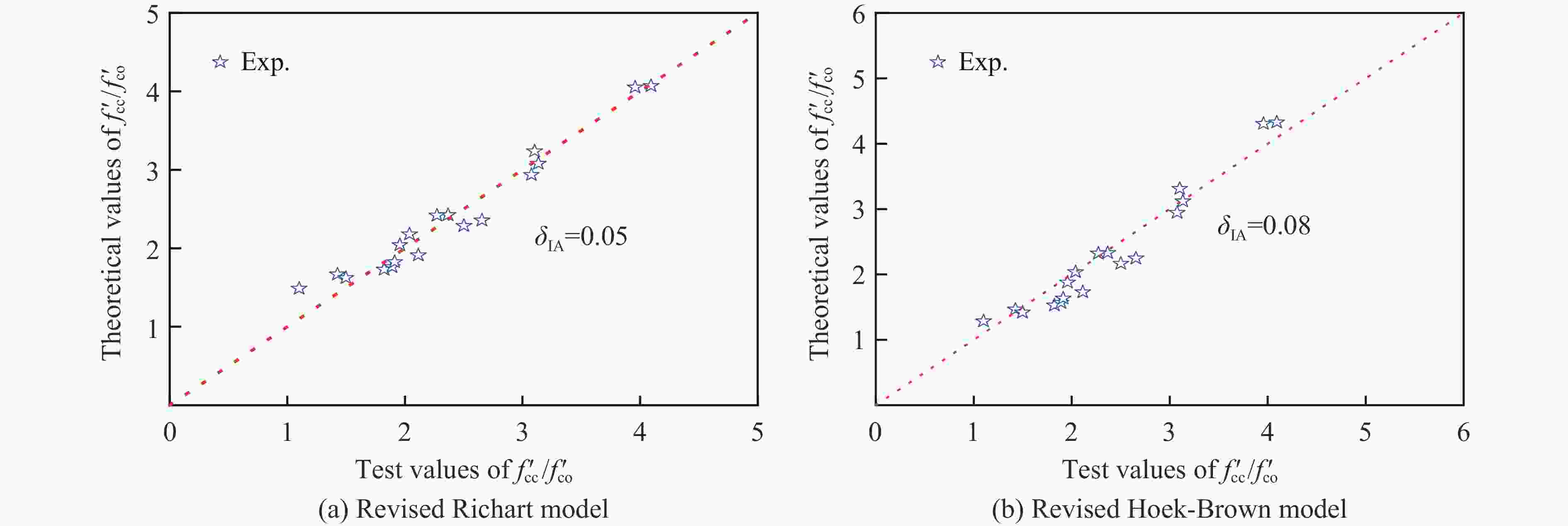

摘要: 碳纤维增强复合材料(carbon fiber reinforced plastic, CFRP)包裹是一种极具吸引力的煤柱加固技术。三向受压煤柱因侧向膨胀受限,其抗压强度明显高于单轴受压煤柱,在巷道中CFRP加固预留煤柱比未加固煤柱更具优势。为此,设计了不同CFRP层数和净间距比的煤圆柱试样,通过单轴压缩试验,测定了各试样的应力-应变曲线、峰值强度、极限应变等力学参数,深入探讨了CFRP约束对煤圆柱力学行为的影响,以及不同参数下煤圆柱的破坏模式。结果表明,CFRP条带约束煤圆柱和CFRP全约束煤圆柱表现出相似的力学特性。CFRP条带约束煤圆柱在单轴压缩下表现出显著的强化效果,随着净间距比的减小和CFRP层数的增加,煤圆柱的峰值强度和抗变形能力均显著增强。同时,CFRP的约束作用能够有效抑制煤圆柱的横向膨胀,改变其破坏模式,延缓破坏的发生。此外,基于Richart模型和Hoek-Brown模型,利用试验数据进行修正和对比分析,得到了CFRP条带约束煤圆柱的Richart修正强度模型。Abstract: Carbon fiber-reinforced plastic (CFRP) wrapping is a promising technique for enhancing the structural integrity of coal columns. When applied to coal columns in roadway environments, CFRP reinforcement offers significant advantages over unreinforced columns. Specifically, the compressive strength of coal columns subjected to triaxial compression is markedly higher than that of columns subjected to uniaxial compression, primarily due to the restricted lateral expansion in the former case. This study investigates coal column specimens with varying CFRP layer configurations and net spacing ratios, evaluating mechanical properties such as stress-strain behavior, peak strength, and ultimate strain through uniaxial compression testing. The research explores the impact of CFRP confinement on the mechanical performance and damage modes of coal columns under different conditions. The results indicate that coal columns confined by CFRP strips or fully wrapped with CFRP exhibit similar mechanical behaviors. CFRP strip confinement provides a notable strengthening effect under uniaxial compression, with peak strength and deformation resistant capacity significantly improved as the net spacing ratio decreases and the number of CFRP layers increases. Additionally, the CFRP reinforcement effectively mitigates lateral expansion, alters the failure mode, and delays the onset of damage. Furthermore, using the Richart and Hoek-Brown models, the study incorporates the test data for model refinement and comparative analysis, leading to the development of a modified Richart strength model for CFRP-constrained coal columns.

-

Key words:

- carbon fiber-reinforced plastic /

- coal column /

- net spacing ratio /

- hoop strain /

- strength model

-

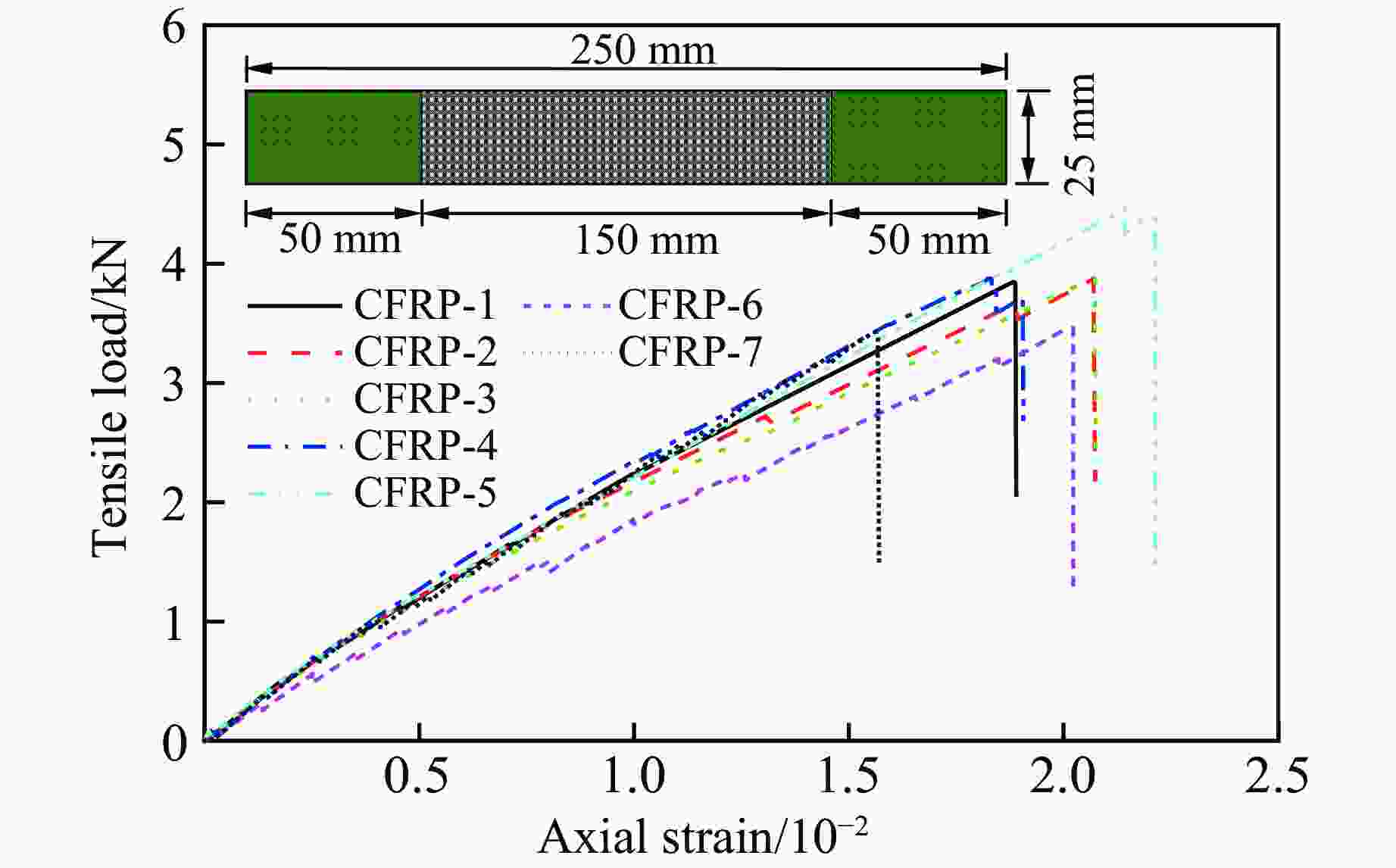

Elastic modulus/GPa Thickness/mm Tensile strength/MPa Ultimate tensile strain/% 47.54 0.167 918.07 1.94 表 2 A、B胶参数

Table 2. Parameters of A and B glue

Type Tensile strength/MPa Elastic modulus/MPa Elongation ratio/% Compressive strength/MPa A ≥40 ≥2 500 ≥1.5 ≥70 B ≥30 ≥1 500 ≥1.5 ≥70 表 3 试验方案

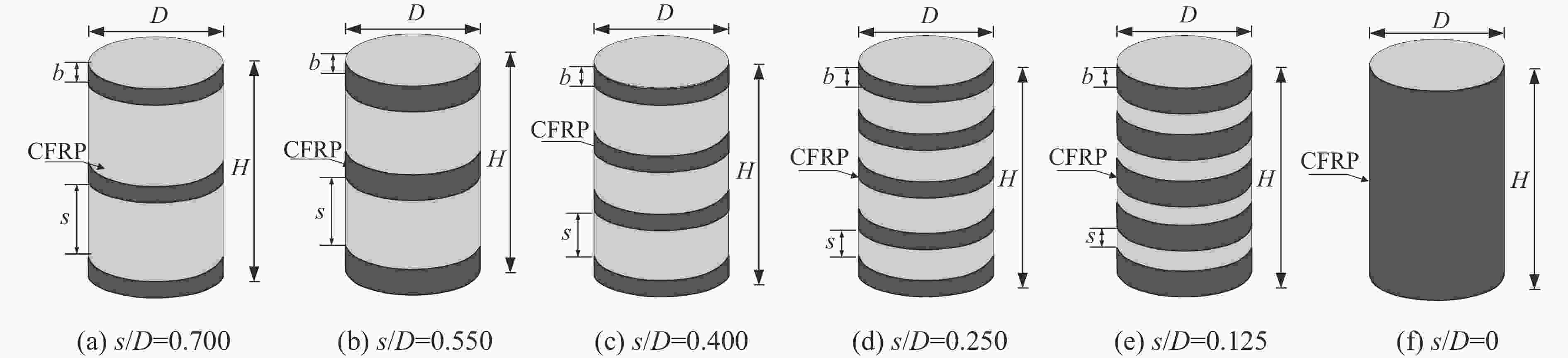

Table 3. Test scheme

Group No. Specimen s/D L s/mm n b/mm 1 SC 0 3 2 SF-1 0 1 0 2 100 SF-2 0 2 0 2 100 SF-3 0 3 0 2 100 3 SP-1-0.700 0.700 1 35.00 2 10 SP-1-0.550 0.550 1 27.50 2 15 SP-1-0.400 0.400 1 20.00 2 10 SP-1-0.250 0.250 1 12.50 2 10 SP-1-0.125 0.125 1 6.25 2 15 4 SP-2-0.700 0.700 2 35.00 2 10 SP-2-0.550 0.550 2 27.50 2 15 SP-2-0.400 0.400 2 20.00 2 10 SP-2-0.250 0.250 2 12.50 2 10 SP-2-0.125 0.125 2 6.25 2 15 5 SP-3-0.700 0.700 3 35.00 2 10 SP-3-0.550 0.550 3 27.50 2 15 SP-3-0.400 0.400 3 20.00 2 10 SP-3-0.250 0.250 3 12.50 2 10 SP-3-0.125 0.125 3 6.25 2 15 表 4 不同CFRP约束形式下煤圆柱的破坏模式

Table 4. Failure modes of coal columns under different CFRP confinement

L s/D Unconfined coal

column0 0.125 0.250 0.400 0.550 0.700 1

2

3

Note: The areas circled by the white dashed lines in the table indicate localized crushing of the coal column, while the areas circled by the blue dashed lines indicate the fracture of the CFRP strips. -

[1] ZHOU Z L, ZANG H Z, CAO W Z, et al. Risk assessment for the cascading failure of underground pillar sections considering interaction between pillars [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 124: 104142. doi: 10.1016/j.ijrmms.2019.104142 [2] POULSEN B A, SHEN B. Subsidence risk assessment of decommissioned bord-and-pillar collieries [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 60: 312–320. doi: 10.1016/j.ijrmms.2013.01.014 [3] LI Z, YU S C, ZHU W B, et al. Dynamic loading induced by the instability of voussoir beam structure during mining below the slope [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 132: 104343. doi: 10.1016/j.ijrmms.2020.104343 [4] FAN D Y, LIU X S, TAN Y L, et al. Energy mechanism of bolt supporting effect to fissured rock under static and dynamic loads in deep coal mines [J]. International Journal of Mining Science and Technology, 2024, 34(3): 371–384. doi: 10.1016/j.ijmst.2024.03.001 [5] XIA Z, YAO Q L, XU Q, et al. Numerical-modeling-based assessment of the impact of two-end-type cable support on failure characteristics of yield pillars [J]. Engineering Failure Analysis, 2021, 128: 105619. doi: 10.1016/j.engfailanal.2021.105619 [6] 张修峰, 陈洋. 煤柱型冲击地压类型、发生机理与防治对策研究 [J]. 煤炭科学技术, 2023, 51(10): 1–11. doi: 10.12438/cst.2022-1608ZHANG X F, CHEN Y. Research on the type and occurrence mechanism and prevention of coal pillar rockbursts [J]. Coal Science and Technology, 2023, 51(10): 1–11. doi: 10.12438/cst.2022-1608 [7] HUANG S J, ZHAO G M, MENG X R, et al. Development of cement-based grouting material for reinforcing narrow coal pillars and engineering applications [J]. Processes, 2022, 10(11): 2292. doi: 10.3390/pr10112292 [8] 谷长宛, 王波, 王军, 等. 基于胀锁式对穿锚索的沿空掘巷窄煤柱双向加固机理研究 [J]. 煤炭科学技术, 2022, 50(4): 106–116.GU C W, WANG B, WANG J, et al. Research on bidirectional-reinforcement mechanism of narrow coal pillar of gob-side entry driving based on inflatable lock-type anchor [J]. Coal Science and Technology, 2022, 50(4): 106–116. [9] 崔博强, 白锦文, 冯国瑞, 等. 柱旁单侧充填煤充结构体的破坏响应特征与失稳机制 [J]. 中南大学学报(自然科学版), 2023, 54(6): 2431–2446.CUI B Q, BAI J W, FENG G R, et al. Failure response characteristics and mechanism of coal-backfilling structures in single pillar-side backfilling [J]. Journal of Central South University (Science and Technology), 2023, 54(6): 2431–2446. [10] CHAN C W, YU T, ZHANG S S, et al. Compressive behaviour of FRP-confined rubber concrete [J]. Construction and Building Materials, 2019, 211: 416–426. doi: 10.1016/j.conbuildmat.2019.03.211 [11] LI G Q, PANG S S, IBEKWE S I. FRP tube encased rubberized concrete cylinders [J]. Materials and Structures, 2011, 44(1): 233–243. doi: 10.1617/s11527-010-9622-8 [12] YOUSSF O, HASSANLI R, MILLS J E. Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content [J]. Journal of Building Engineering, 2017, 11: 115–126. doi: 10.1016/j.jobe.2017.04.011 [13] RAFFOUL S, GARCIA R, ESCOLANO-MARGARIT D, et al. Behaviour of unconfined and FRP-confined rubberised concrete in axial compression [J]. Construction and Building Materials, 2017, 147: 388–397. doi: 10.1016/j.conbuildmat.2017.04.175 [14] WANG J Z, XIAO H Q, LU L T, et al. Axial stress-strain model for concrete in partially FRP wrapped reinforced concrete columns [J]. Construction and Building Materials, 2024, 416: 135028. doi: 10.1016/j.conbuildmat.2024.135028 [15] ISMAIL R, RASHID R S M, CHAN W C, et al. Compressive behavior of concrete cylinder fully and partially confined by carbon fibre-reinforced polymer (CFRP) [J]. Construction and Building Materials, 2019, 201: 196–206. doi: 10.1016/j.conbuildmat.2018.12.095 [16] SHEN Q H, WANG J F, WANG J X, et al. Axial compressive performance of circular CFST columns partially wrapped by carbon FRP [J]. Journal of Constructional Steel Research, 2019, 155: 90–106. doi: 10.1016/j.jcsr.2018.12.017 [17] DAS A J, MANDAL P K, GHOSH C N, et al. Extraction of locked-up coal by strengthening of rib pillars with FRP: a comparative study through numerical modelling [J]. International Journal of Mining Science and Technology, 2017, 27(2): 261–267. doi: 10.1016/j.ijmst.2017.01.024 [18] LI G D, LIU H L, DENG W T, et al. Behavior of CFRP-confined sand-based material columns under axial compression [J]. Polymers, 2021, 13(22): 3994. doi: 10.3390/polym13223994 [19] 白锦文, 杨欣宇, 史旭东, 等. FRP包裹对煤充结构体劈裂破坏特征的影响 [J]. 岩石力学与工程学报, 2023, 42(Suppl 1): 3541–3557.BAI J W, YANG X Y, SHI X D, et al. Influence of FRP restricting on the splitting failure characteristics of coal-backfilling composite structures [J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(Suppl 1): 3541–3557. [20] SHI X D, BAI J W, FENG G R, et al. Crack propagation law at the interface of FRP wrapped coal-backfilling composite structure [J]. Construction and Building Materials, 2022, 344: 128229. doi: 10.1016/j.conbuildmat.2022.128229 [21] 李庆文, 曾杏钢, 张向东, 等. 碳纤维布层数对煤圆柱力学特性影响的细观研究 [J]. 煤炭科学技术, 2023, 51(8): 73–85.LI Q W, ZENG X G, ZHANG X D, et al. Mesoscopic study on the effect of CFRP layers on the mechanical properties of coal circular-columns [J]. Coal Science and Technology, 2023, 51(8): 73–85. [22] 李庆文, 胡露露, 曹行, 等. CFRP布均匀约束煤圆柱轴压性能 [J]. 复合材料学报, 2022, 39(11): 5611–5624.LI Q W, HU L L, CAO H, et al. Axial compressive behavior of CFRP uniformly wrapped coal in circular columns [J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5611–5624. [23] 李庆文, 高安梁, 禹萌萌, 等. 碳纤维布均匀约束下煤圆柱的损伤演化 [J]. 金属矿山, 2024(2): 104–113.LI Q W, GAO A L, YU M M, et al. Damage evolution of coal cylinder under uniform confinement of carbon fiber sheets [J]. Metal Mine, 2024(2): 104–113. [24] 李庆文, 禹萌萌, 高森林, 等. 加载速率对碳纤维布被动约束煤能量演化的影响 [J]. 煤炭学报, 2024, 49(Suppl 1): 236–247.LI Q W, YU M M, GAO S L, et al. Effect of loading rate on energy evolution of coal confined passively by CFRP sheets [J]. Journal of China Coal Society, 2024, 49(Suppl 1): 236–247. [25] LI Q W, NIE F F, PAN C C, et al. Energy dissipation damage constitutive relation of CFRP passively confined coal sample [J]. Heliyon, 2024, 10(18): e37586. doi: 10.1016/j.heliyon.2024.e37586 [26] XIA Z, YAO Q L, LI X H, et al. Acoustic emission characteristics and energy mechanism of CFRP-jacketed coal specimens under uniaxial compression [J]. Construction and Building Materials, 2022, 342: 127936. doi: 10.1016/j.conbuildmat.2022.127936 [27] XIA Z, YAO Q L, LI X H, et al. Acoustic emission responses and damage estimation of coal with carbon fiber-reinforced polymer confinement under uniaxial compression [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2024, 16(12): 5077–5094. doi: 10.1016/j.jrmge.2024.04.022 [28] 唐劲舟, 唐文豪, 杨科, 等. 循环荷载作用下含倾斜单裂隙砂岩力学响应特征及渗流演化规律 [J]. 岩土力学, 2025, 46(1): 199–212.TANG J Z, TANG W H, YANG K, et al. Mechanical response characteristics and seepage evolution law of sandstone with an inclined single fracture under cyclic loading [J]. Rock and Soil Mechanics, 2025, 46(1): 199–212. [29] YU L L, XIA J W, XIA Z, et al. Axial compressive behavior of basalt and carbon FRP-confined coal gangue concrete [J]. Construction and Building Materials, 2023, 371: 130803. doi: 10.1016/j.conbuildmat.2023.130803 [30] LIANG J F, ZOU W J, LI W, et al. Behaviour of CFRP strips confined partially encased concrete columns under axial compressive load [J]. Composite Structures, 2021, 275: 114468. doi: 10.1016/j.compstruct.2021.114468 [31] YANG J L, WANG J Z, WANG Z R. Behavior and modeling of CFRP nonuniformly wrapped circular seawater sea-sand concrete (SSC) columns under axial compression [J]. Construction and Building Materials, 2021, 299: 123887. doi: 10.1016/j.conbuildmat.2021.123887 [32] YANG J L, WANG J Z, WANG Z R. Axial compressive behavior of partially CFRP confined seawater sea-sand concrete in circular columns–part Ⅰ: experimental study [J]. Composite Structures, 2020, 246: 112373. doi: 10.1016/j.compstruct.2020.112373 [33] LI S, MA W T, LU Y Y, et al. Axial behavior of concrete cylinders retrofitted with a hybrid system of CFRP textile grid and engineered geopolymer composite [J]. Journal of Building Engineering, 2024, 91: 109536. doi: 10.1016/j.jobe.2024.109536 [34] 赵兵朝, 王京滨, 张晴, 等. 侧限条件下充填体-煤柱耦合承载协同作用机理 [J]. 煤炭学报, 2023, 48(12): 4380–4392.ZHAO B C, WANG J B, ZHANG Q, et al. Synergistic mechanism of coupling bearing of backfill-coal pillar under lateral confinement condition [J]. Journal of China Coal Society, 2023, 48(12): 4380–4392. [35] RICHARD R M, ABBOTT B J. Versatile elastic-plastic stress-strain formula [J]. Journal of the Engineering Mechanics Division, 1975, 101(4): 511–515. doi: 10.1061/JMCEA3.0002047 [36] WU Y F, ZHOU Y W. Unified strength model based on Hoek-Brown failure criterion for circular and square concrete columns confined by FRP [J]. Journal of Composites for Construction, 2010, 14(2): 175–184. doi: 10.1061/(ASCE)CC.1943-5614.0000062 [37] ZHANG Y, LU Z F, CAO Y G. Unified strength model based on the Hoek-Brown failure criterion for fibre-reinforced polymer-confined pre-damaged concrete columns with circular and square cross sections [J]. Journal of Central South University, 2020, 27(12): 3807–3820. doi: 10.1007/s11771-020-4563-z [38] YANG J L, LU S W, WANG J Z, et al. Behavior of CFRP partially wrapped square seawater sea-sand concrete columns under axial compression [J]. Engineering Structures, 2020, 222: 111119. doi: 10.1016/j.engstruct.2020.111119 -

下载:

下载: