A Brief Discussion on the Perforation of Steel Plates Impacted by Flat-Nosed Projectiles

doi: 10.11858/gywlxb.20240912

-

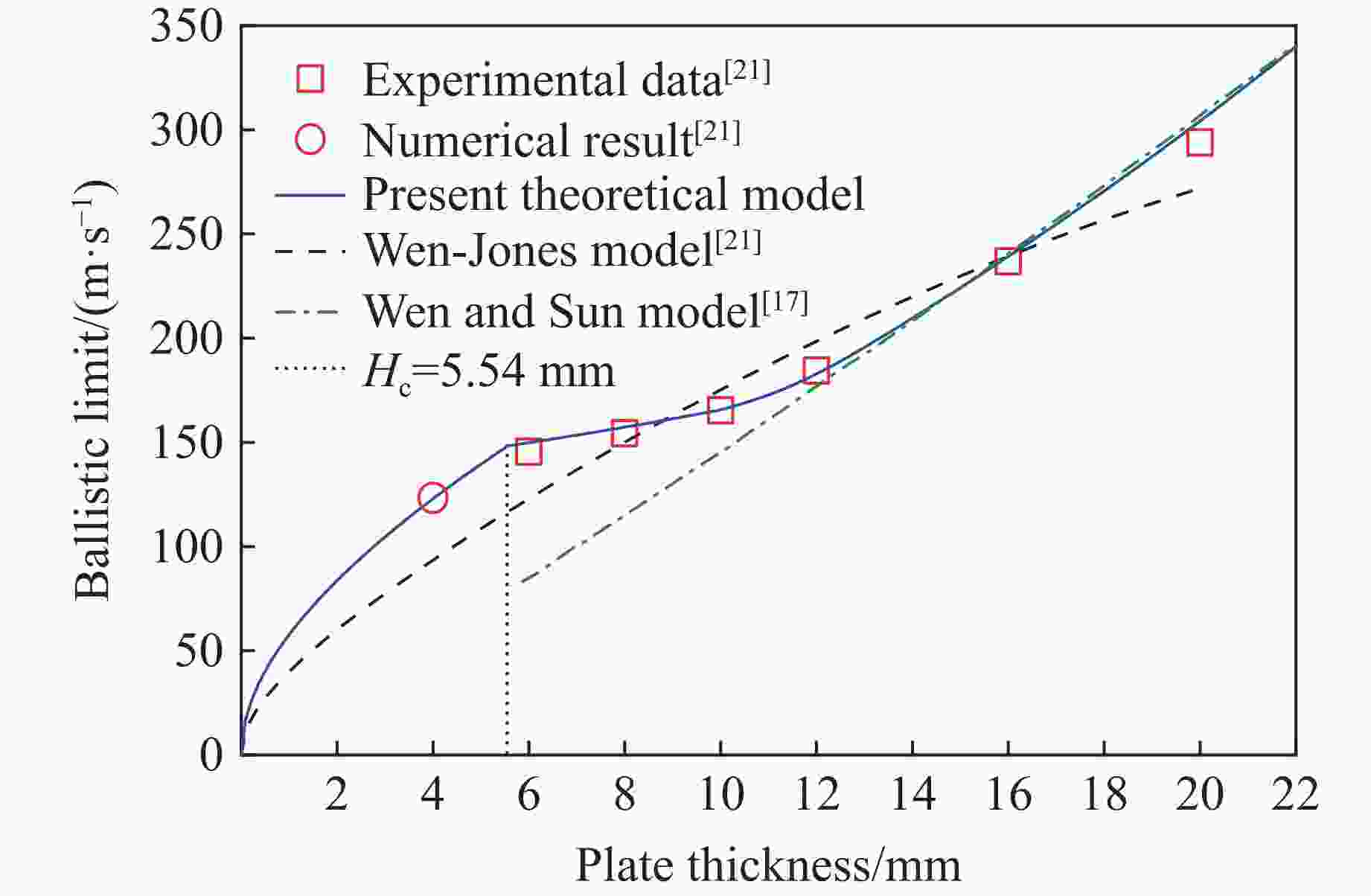

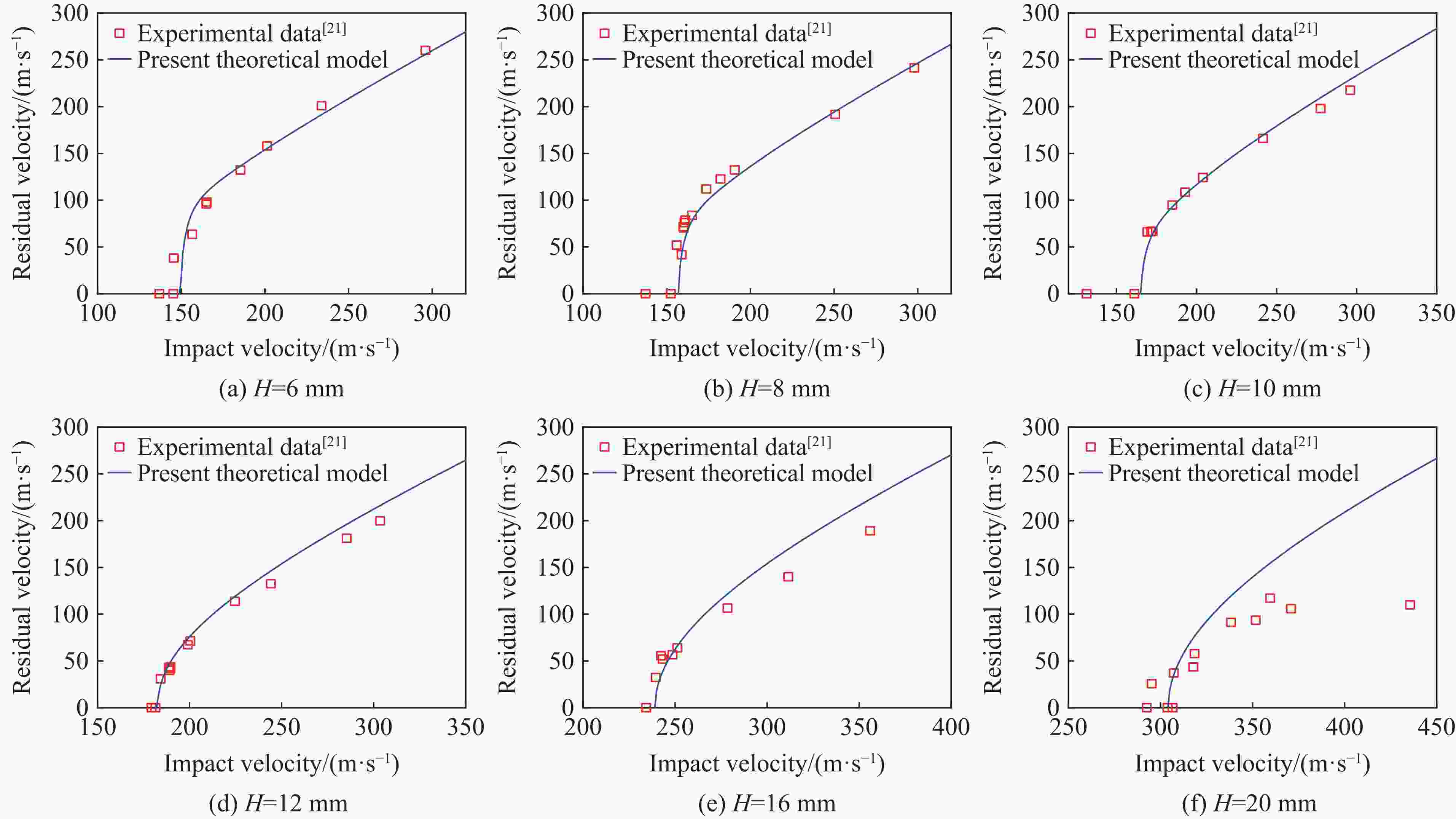

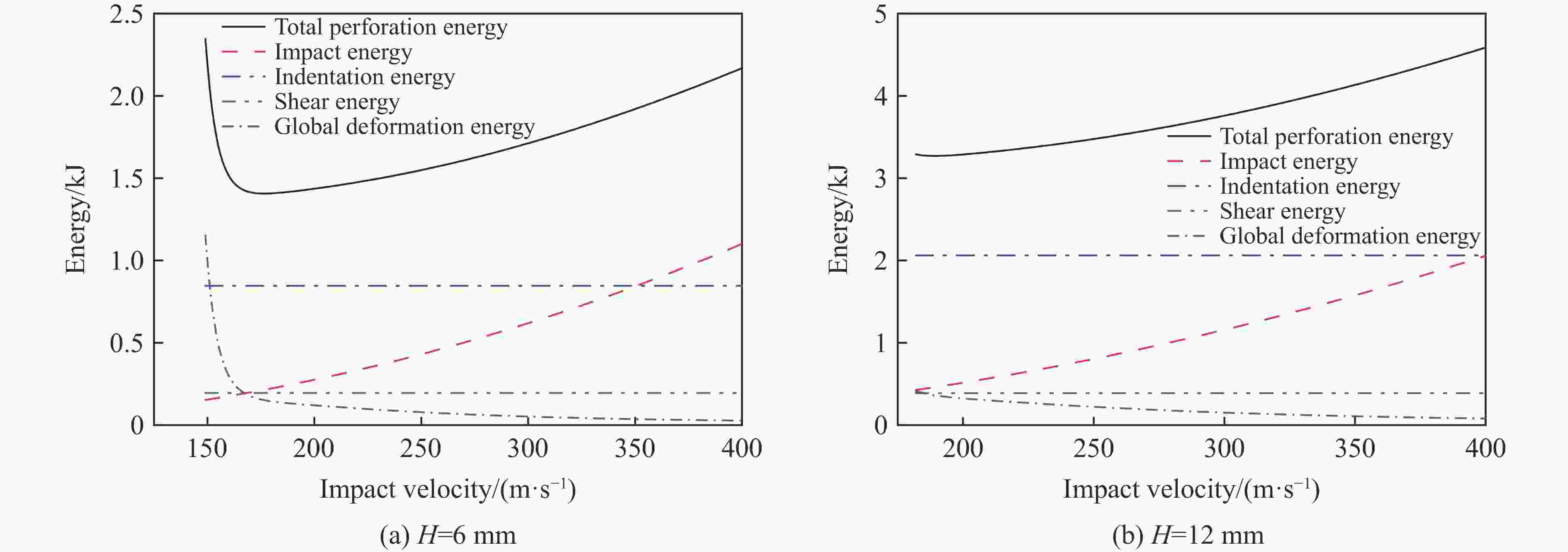

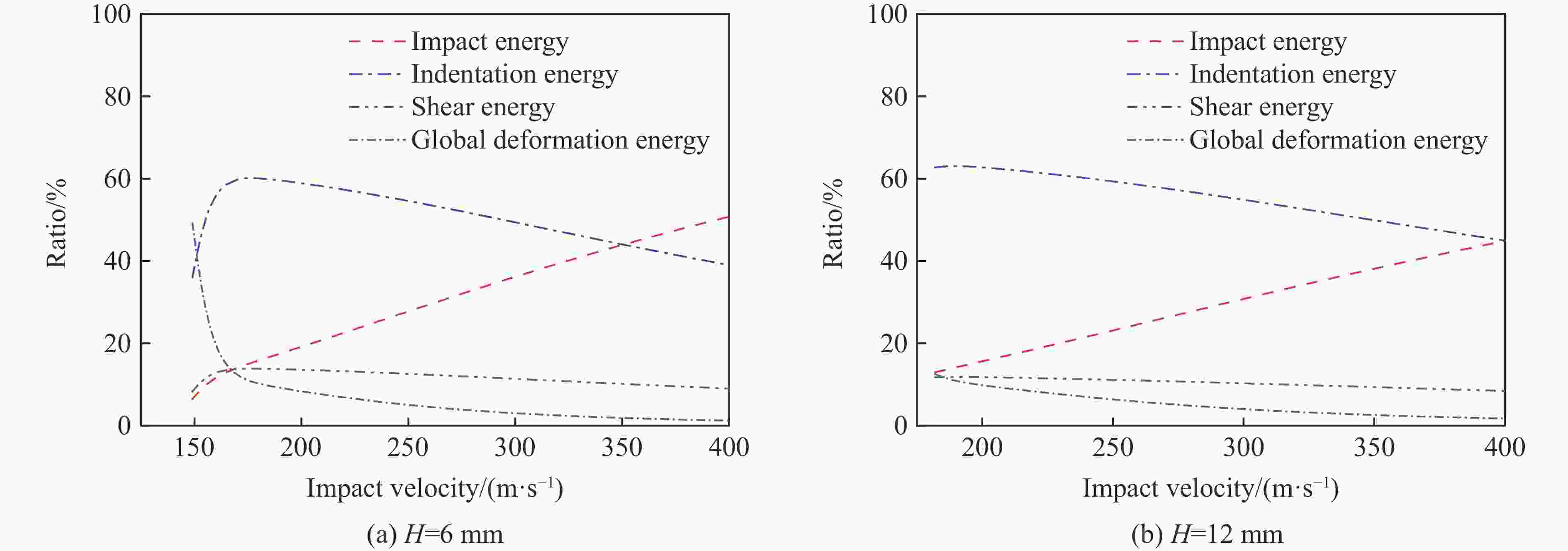

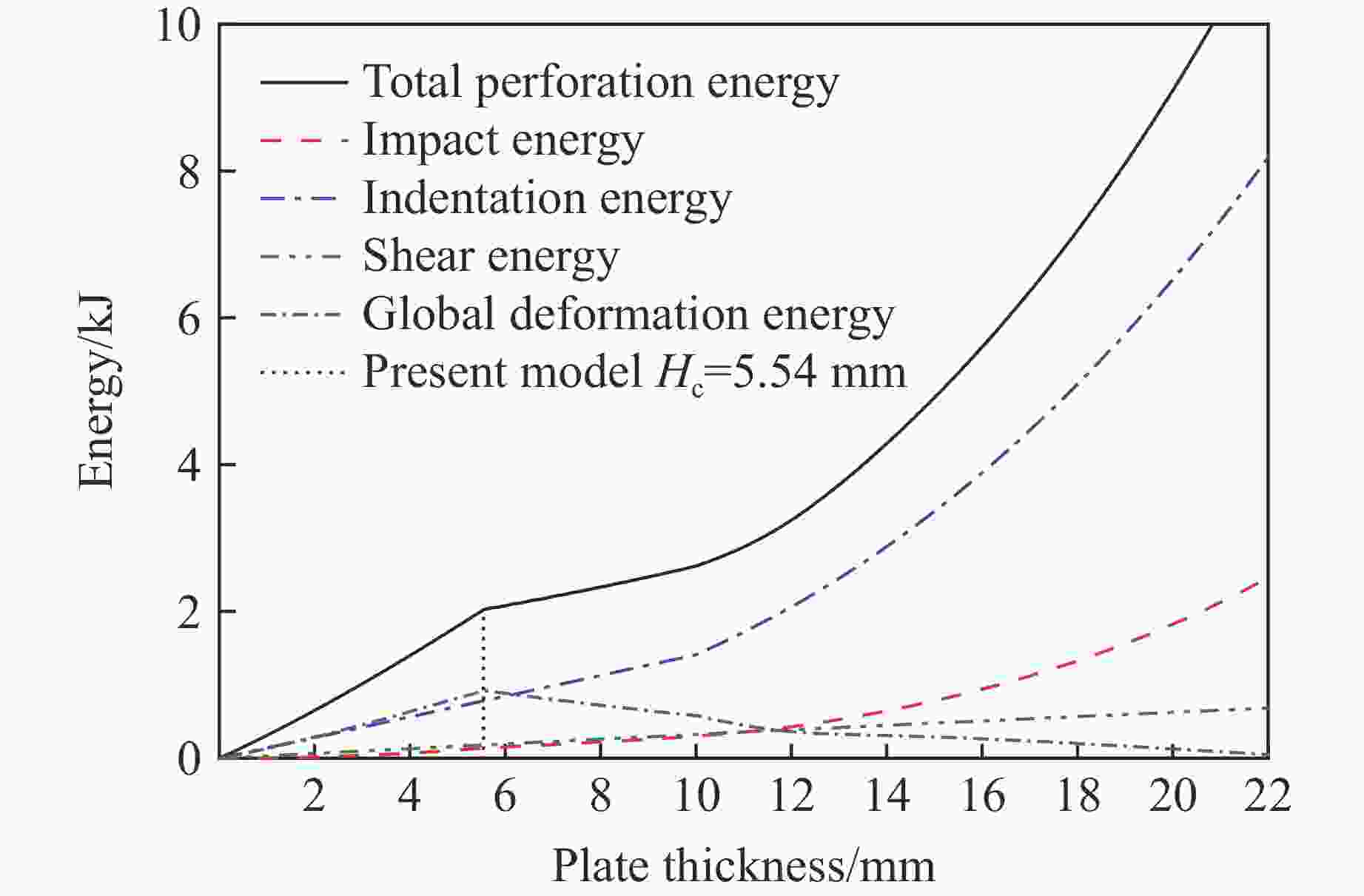

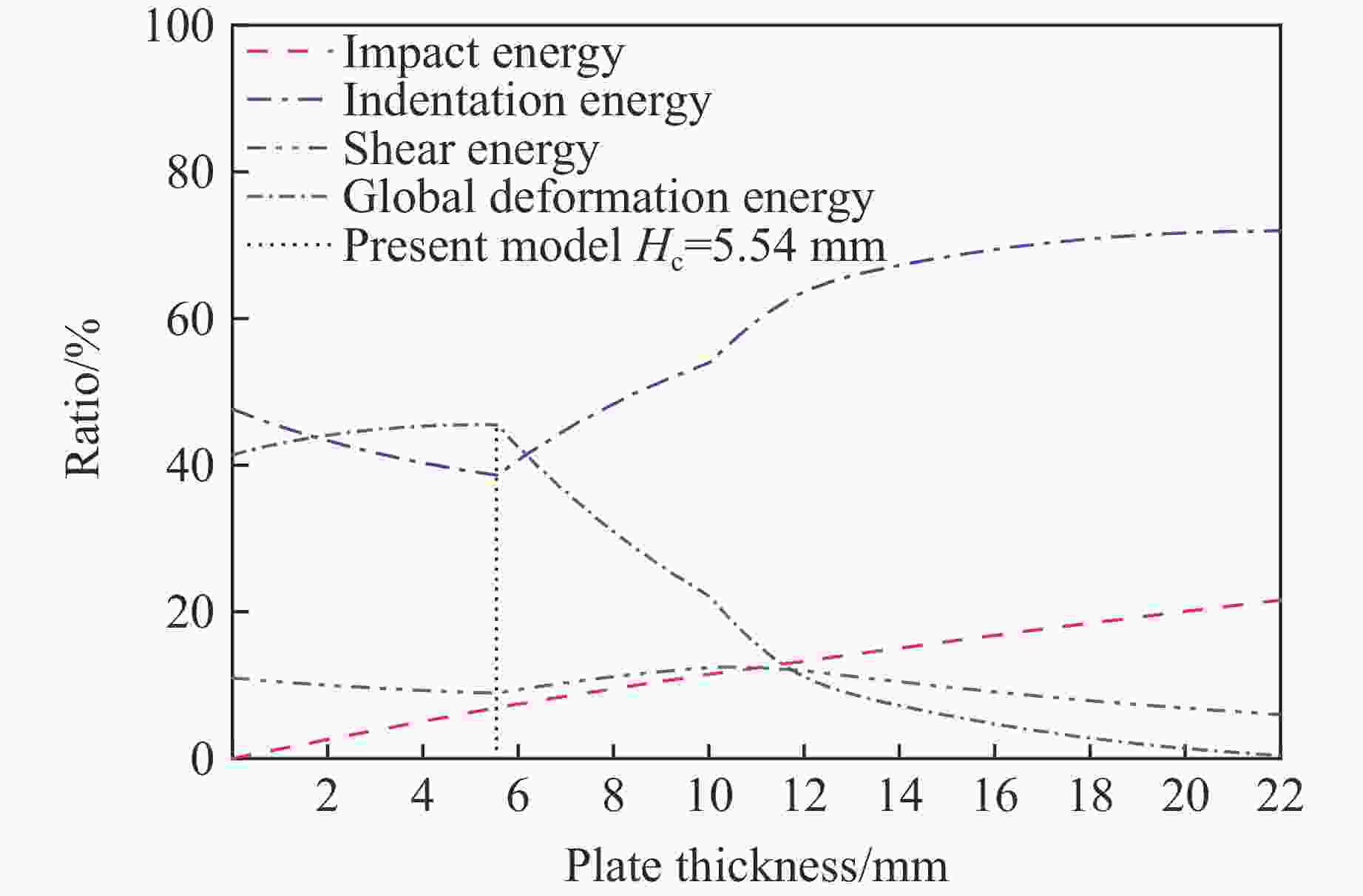

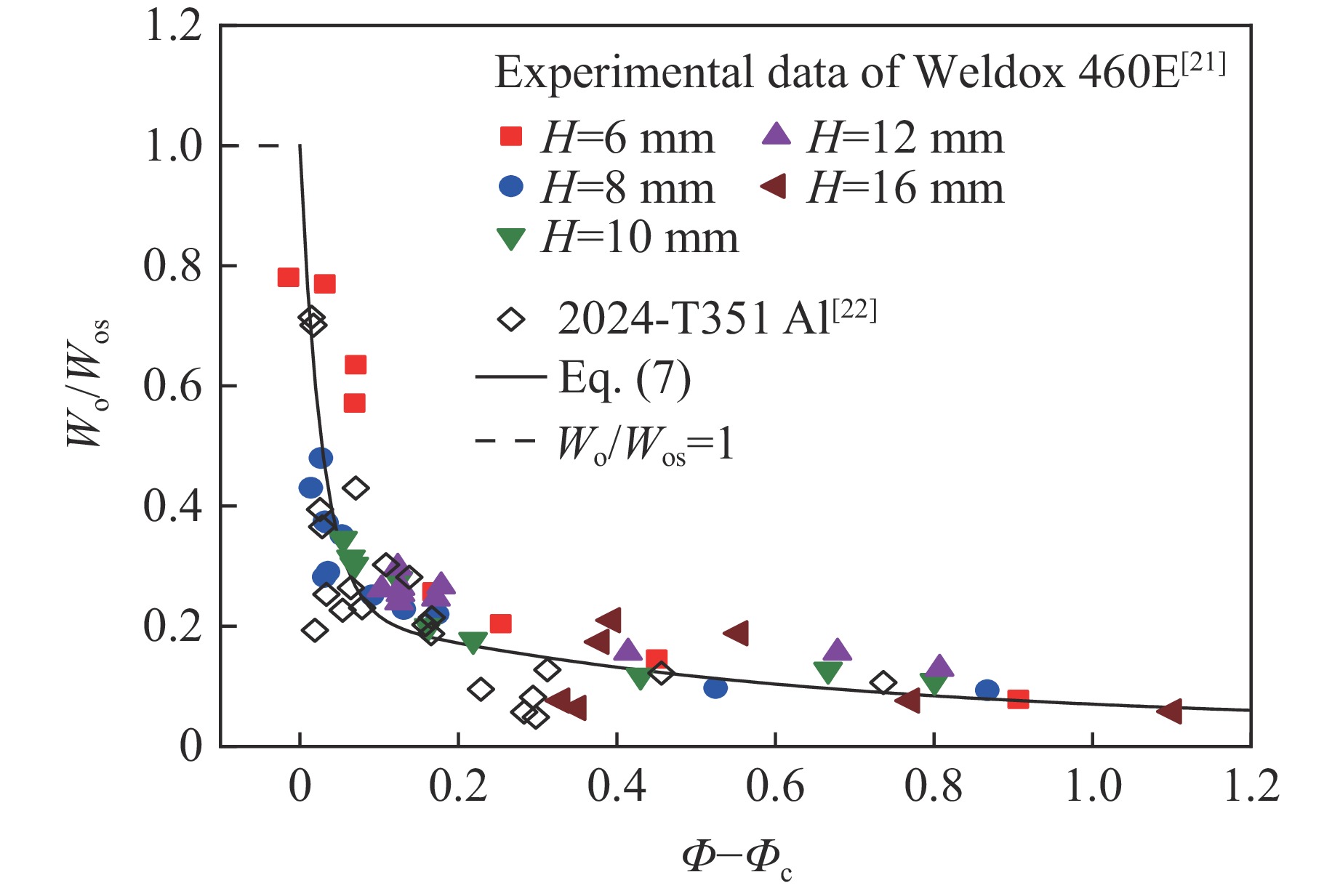

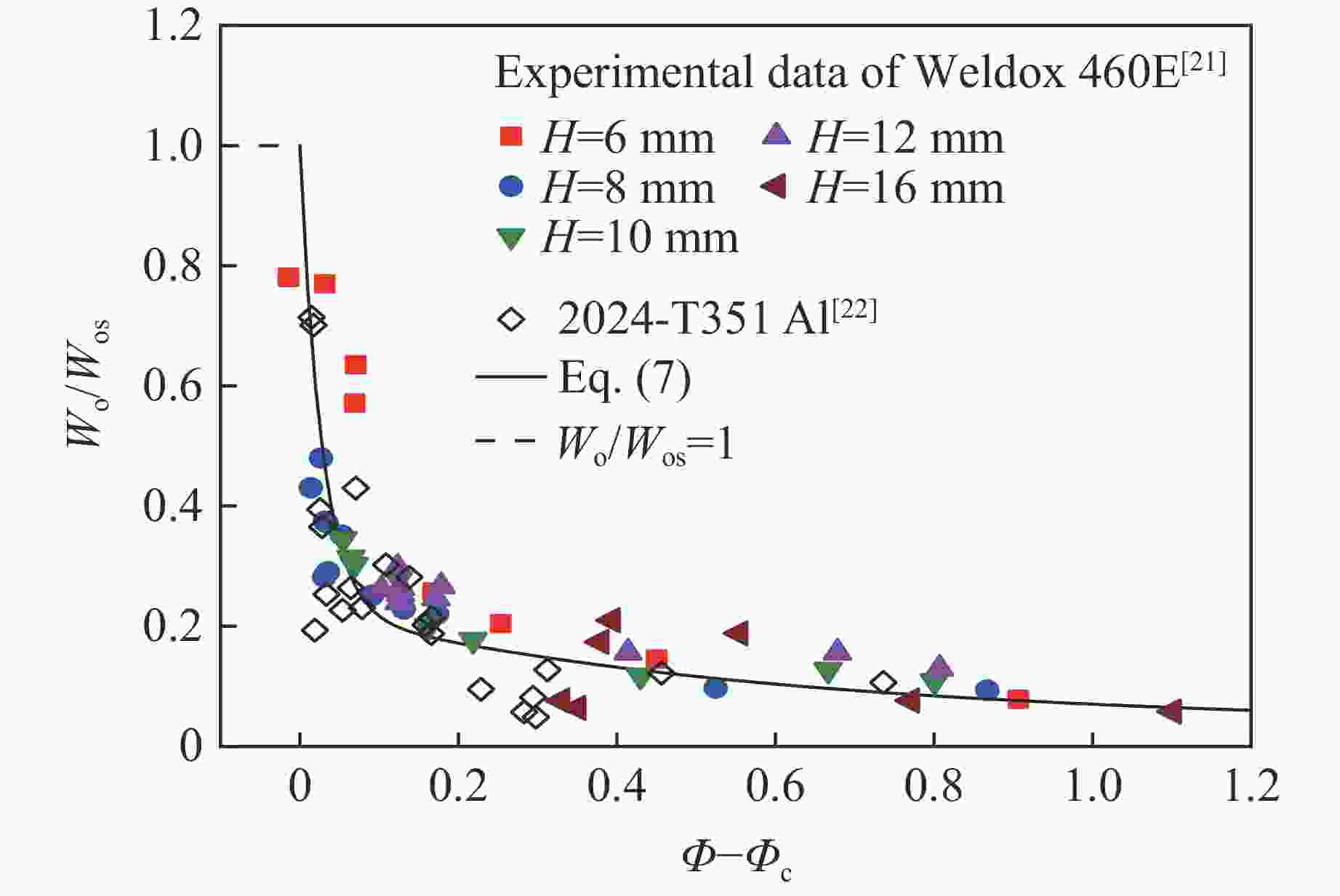

摘要: 利用先前提出的统一框架内平头弹穿透有限金属靶板的理论模型,对平头弹撞击下Weldox 460E钢板的穿透问题进行了研究。该模型包含一个无量纲半经验方程,考虑了整体变形吸能随撞击速度的变化,由此讨论了Weldox 460E钢板的能量吸收机理,解释了“平台”现象(随着板厚的增大,弹道极限的提高有限),并将Weldox 460E钢板结果与先前研究的2024-T351铝板结果进行了对比。结果表明:模型预测的Weldox 460E钢板在平头弹撞击下的整体变形与撞击速度之间的关系、弹道极限、残余速度以及破坏模式临界转化条件等均与实验结果吻合得很好;模型也能很好地预测中厚板范围内的“平台”现象。与2024-T351铝板相比,被平头弹贯穿的Weldox 460E钢板的压入吸能在总吸能中的占比明显更大,这是两种靶板材料的不同特性所导致的。Abstract: A theoretical analysis on the perforation of Weldox 460E steel plates struck by flat-nosed projectiles is presented using a previously developed model within a unified framework. This model contains a dimensionless empirical equation to describe the variation of energy absorbed through global deformation as a function of impact velocity. The study further investigates the energy absorption mechanisms of Weldox 460E steel plates, with particular focus on the “plateau” phenomenon, i. e., limited increase in ballistic limit with increasing plate thickness. This phenomenon is explained and compared with results from previously studied 2024-T351 aluminium plates. The model predictions agree well with experimental data for Weldox 460E steel plates impacted by flat-nosed projectiles, including: relationship between global deformation and impact velocity, ballistic limit, residual velocity, and critical conditions for the transition of failure modes. Moreover, the model effectively predicts the “plateau” phenomenon observed in intermediate plate thickness range. It is also found that the indentation absorption energy contributes a significantly larger fraction of the total absorption energy in Weldox 460E steel plates perforated by flat-nosed projectiles than in 2024-T351 aluminium plates, due to the differences in material properties.

-

Key words:

- theoretical model /

- flat-nosed projectile /

- steel plate /

- perforation /

- ballistic limit /

- residual velocity

-

Figure 1. Comparison of Eq. (7) with the experimental data of Wo/Wos versus Φ−Φc[21] for the Weldox 460E steel plates perforated by a flat-nosed projectile

Figure 3. Comparisons between the theoretically predicted residual velocities and the experimental data[21] for the Weldox 460E plates impacted by a 20 mm diameter flat-nosed projectile

-

[1] CORBETT G G, REID S R, JOHNSON W. Impact loading of plates and shells by free-flying projectiles: a review [J]. International Journal of Impact Engineering, 1996, 18(2): 141–230. doi: 10.1016/0734-743X(95)00023-4 [2] BEN-DOR G, DUBINSKY A, ELPERIN T. Ballistic impact: recent advances in analytical modeling of plate penetration dynamics: a review [J]. Applied Mechanics Reviews, 2005, 58(6): 355–371. doi: 10.1115/1.2048626 [3] ROSENBERG Z, DEKEL E. Terminal ballistics [M]. 3rd ed. Cham: Springer, 2020. [4] SHADBOLT P J, CORRAN R S J, RUIZ C. A comparison of plate perforation models in the sub-ordnance impact velocity range [J]. International Journal of Impact Engineering, 1983, 1(1): 23–49. doi: 10.1016/0734-743X(83)90011-8 [5] WOODWARD R L. A structural model for thin plate perforation by normal impact of blunt projectiles [J]. International Journal of Impact Engineering, 1987, 6(2): 129–140. doi: 10.1016/0734-743X(87)90015-7 [6] LIU D Q, STRONGE W J. Perforation of rigid-plastic plate by blunt missile [J]. International Journal of Impact Engineering, 1995, 16(5/6): 739–758. [7] WEN H M, JONES N. Low-velocity perforation of punch-impact-loaded metal plates [J]. Journal of Pressure Vessel Technology, 1996, 118(2): 181–187. doi: 10.1115/1.2842178 [8] XU W, HOU H L, ZHU X, et al. Investigation on the damage mechanism of blunt projectile against thin plate [J]. Acta Armamentarii, 2018, 39(5): 883–892. doi: 10.3969/j.issn.1000-1093.2018.05.007 [9] RECHT R F, IPSON T W. Ballistic perforation dynamics [J]. Journal of Applied Mechanics, 1963, 30(3): 384–390. doi: 10.1115/1.3636566 [10] WOODWARD R L, DE MORTON M E. Penetration of targets by flat-ended projectiles [J]. International Journal of Mechanical Sciences, 1976, 18(3): 119–127. doi: 10.1016/0020-7403(76)90061-8 [11] RAVID M, BODNER S R. Dynamic perforation of viscoplastic plates by rigid projectiles [J]. International Journal of Engineering Science, 1983, 21(6): 577–591. doi: 10.1016/0020-7225(83)90105-2 [12] CHEN X W, LI Q M. Shear plugging and perforation of ductile circular plates struck by a blunt projectile [J]. International Journal of Impact Engineering, 2003, 28(5): 513–536. doi: 10.1016/S0734-743X(02)00077-5 [13] LU Z C, HE Y, WEN H M, et al. A plastic wave model for the perforation of a finite metal plate struck by a flat-ended projectile [J]. International Journal of Impact Engineering, 2023, 173: 104466. doi: 10.1016/j.ijimpeng.2022.104466 [14] CAO S, FAN J T. Numerical model for penetration process of a deformable projectile into ductile metallic target plate considering the interaction of projectile and target [J]. International Journal of Impact Engineering, 2025, 195: 105107. doi: 10.1016/j.ijimpeng.2024.105107 [15] BAI Y L, JOHNSON W. Plugging: physical understanding and energy absorption [J]. Metals Technology, 1982, 9(1): 182–190. doi: 10.1179/030716982803285945 [16] CHEN X W, LI Q M, FAN S C. Initiation of adiabatic shear failure in a clamped circular plate struck by a blunt projectile [J]. International Journal of Impact Engineering, 2005, 31(7): 877–893. doi: 10.1016/j.ijimpeng.2004.04.011 [17] WEN H M, SUN W H. Transition of plugging failure modes for ductile metal plates under impact by flat-nosed projectiles [J]. Mechanics Based Design of Structures and Machines, 2010, 38(1): 86–104. doi: 10.1080/15397730903415892 [18] BØRVIK T, LANGSETH M, HOPPERSTAD O S, et al. Ballistic penetration of steel plates [J]. International Journal of Impact Engineering, 1999, 22(9/10): 855–886. [19] BØRVIK T, LEINUM J R, SOLBERG J K, et al. Observations on shear plug formation in Weldox 460E steel plates impacted by blunt-nosed projectiles [J]. International Journal of Impact Engineering, 2001, 25(6): 553–572. doi: 10.1016/S0734-743X(00)00069-5 [20] BØRVIK T, HOPPERSTAD O S, BERSTAD T, et al. A computational model of viscoplasticity and ductile damage for impact and penetration [J]. European Journal of Mechanics A: Solids, 2001, 20(5): 685–712. doi: 10.1016/S0997-7538(01)01157-3 [21] BØRVIK T, HOPPERSTAD O S, LANGSETH M, et al. Effect of target thickness in blunt projectile penetration of Weldox 460E steel plates [J]. International Journal of Impact Engineering, 2003, 28(4): 413–464. doi: 10.1016/S0734-743X(02)00072-6 [22] YANG L F, WEN H M. A numerical and theoretical study on the perforation of aluminum plates struck by flat-nosed projectiles [J/OL]. Acta Mechanica Solida Sinica [2024-10-17]. https://link.springer.com/article/ 10.1007/s10338-024-00557-6. DOI: 10.1007/s10338-024-00557-6. [23] WANG Z H, ZHENG H, WEN H M. Determination of the mechanical properties of metals at very high strain rates [J]. Chinese Journal of High Pressure Physics, 2020, 34(2): 024102. doi: 10.11858/gywlxb.20190794 -

下载:

下载: