Effect of Charge Defects on the Fast Cook-off Response Characteristics of Cast PBX Explosive Charge

-

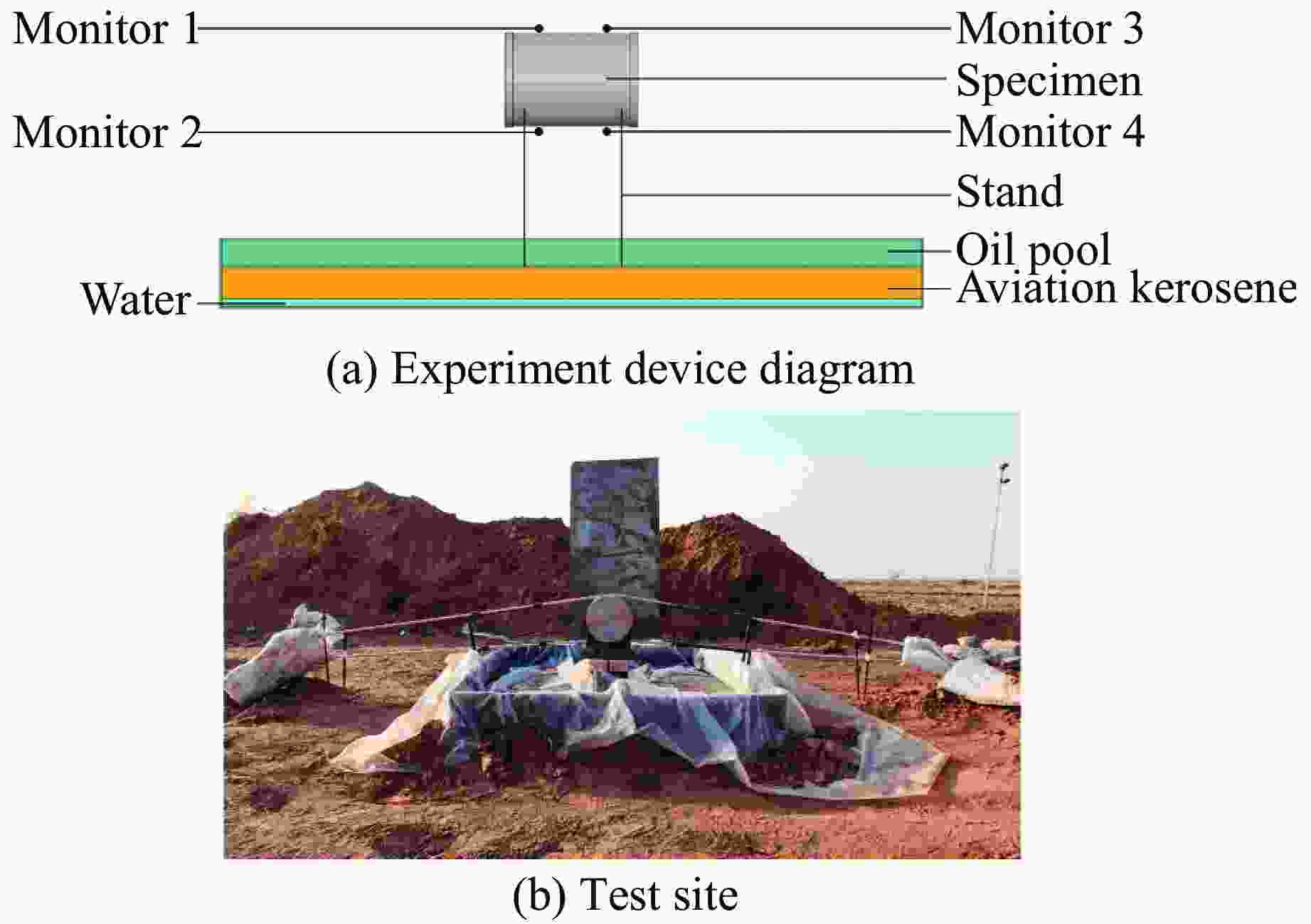

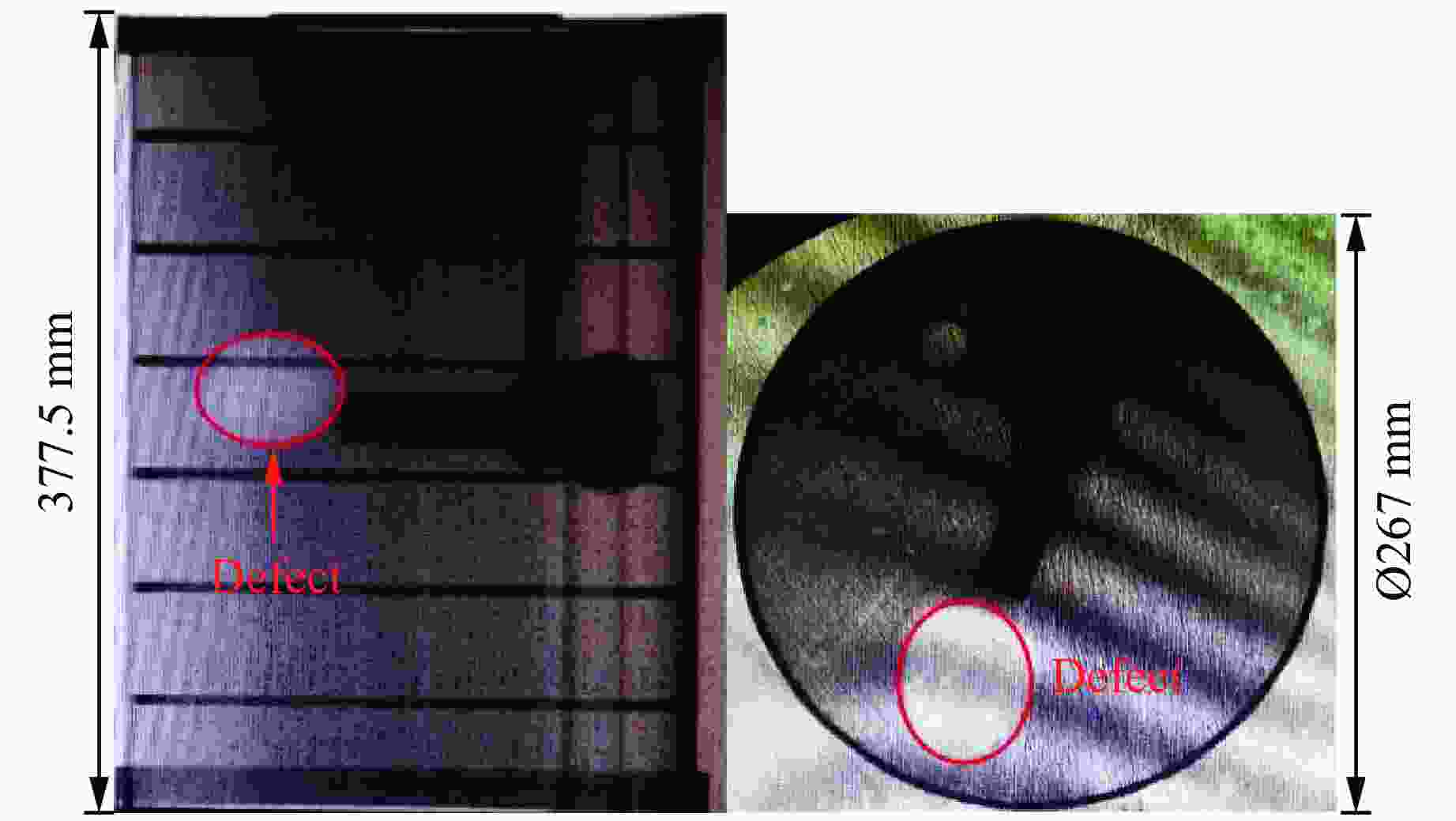

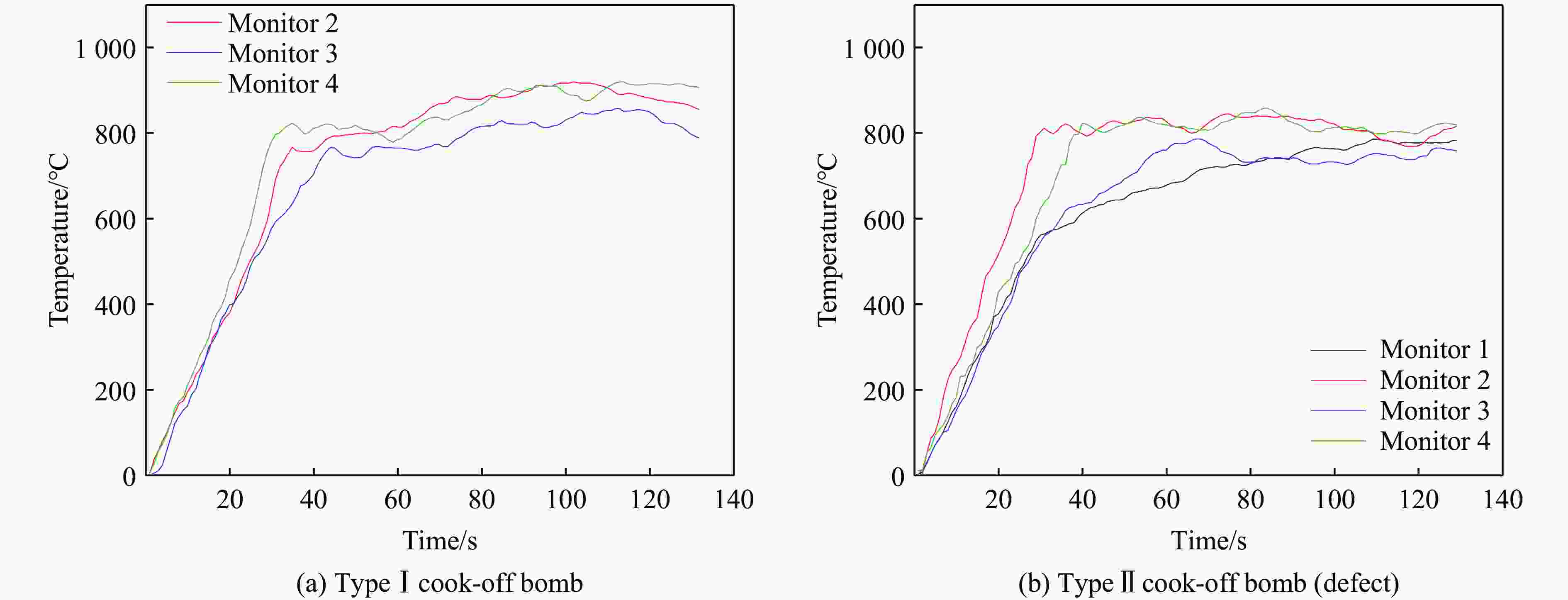

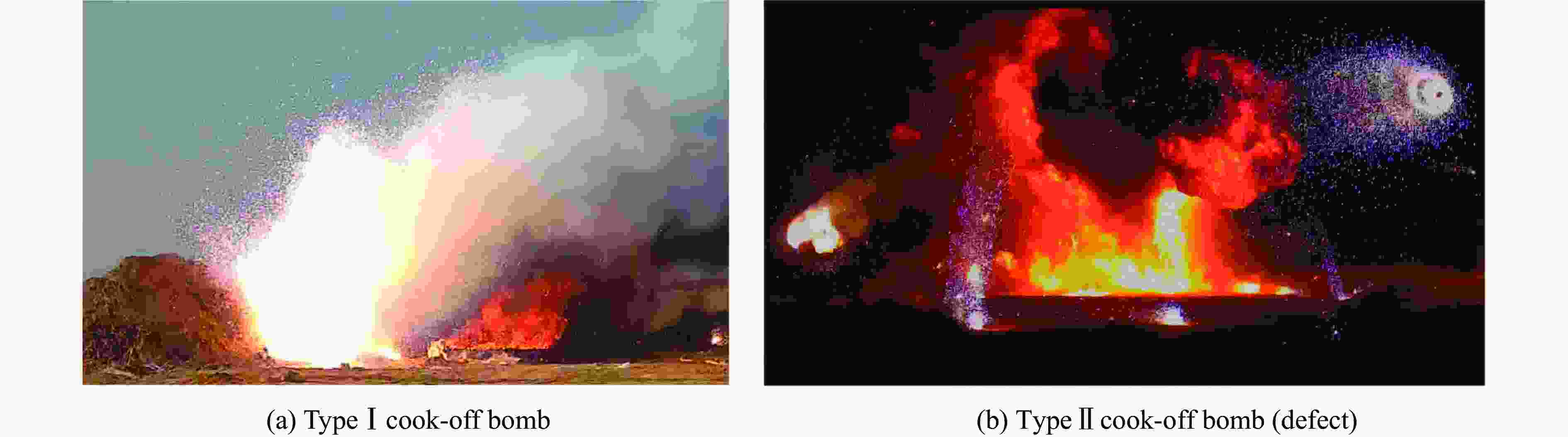

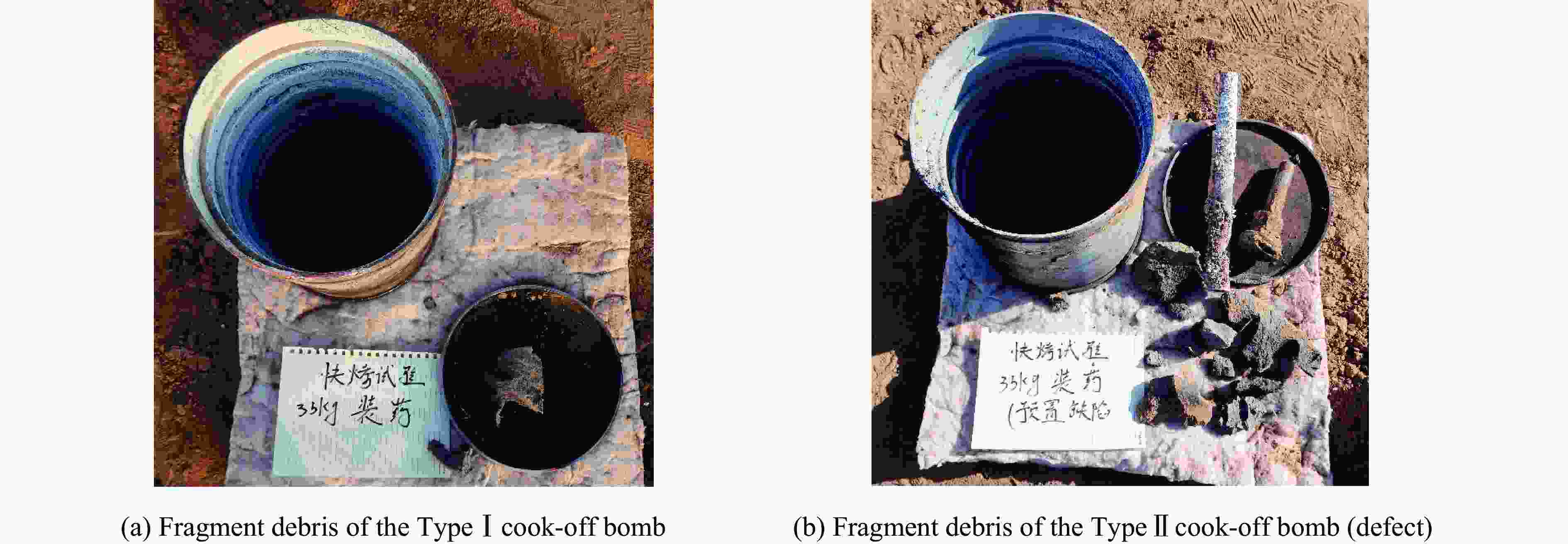

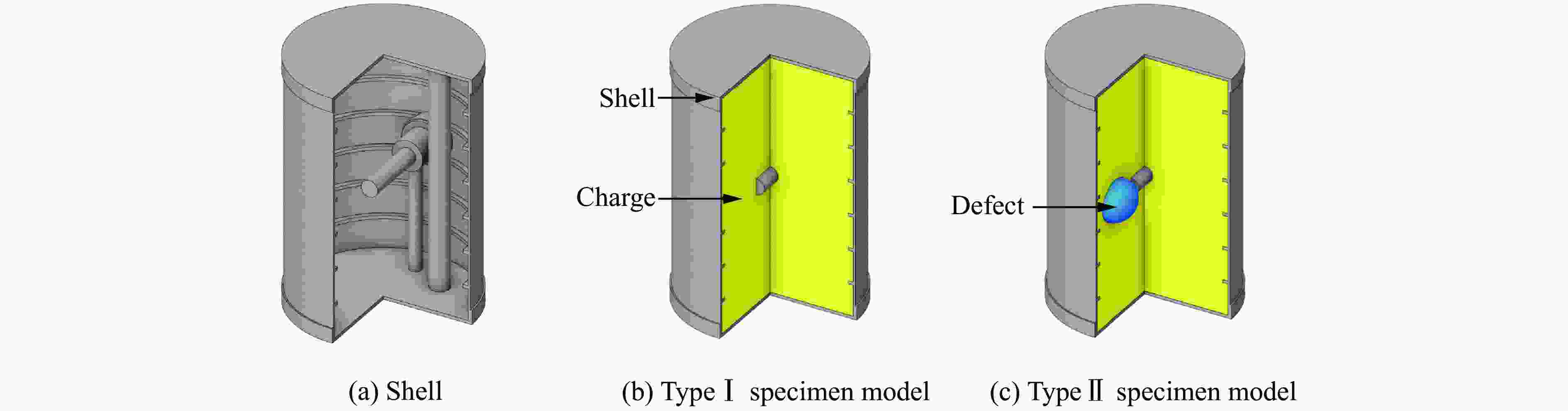

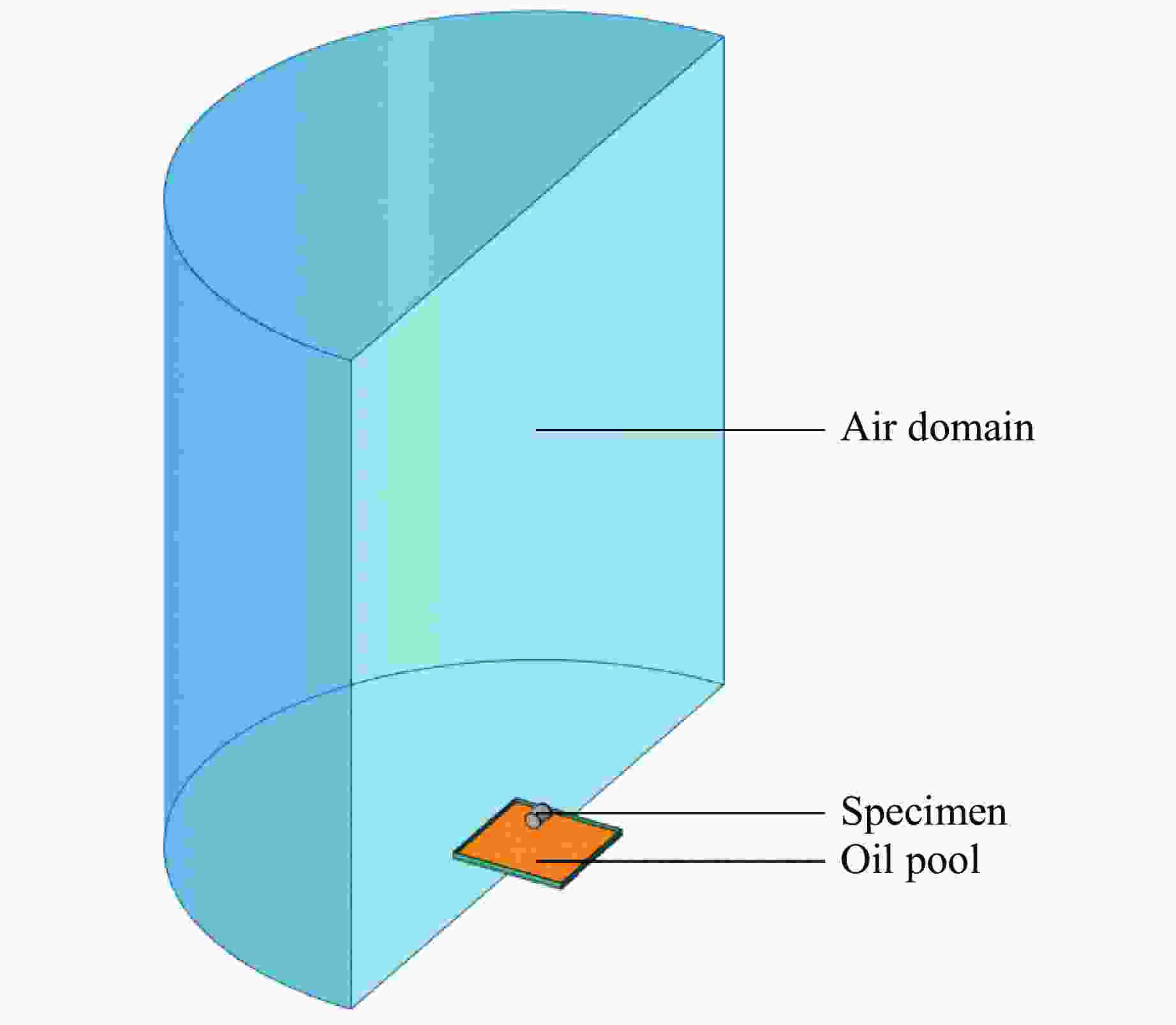

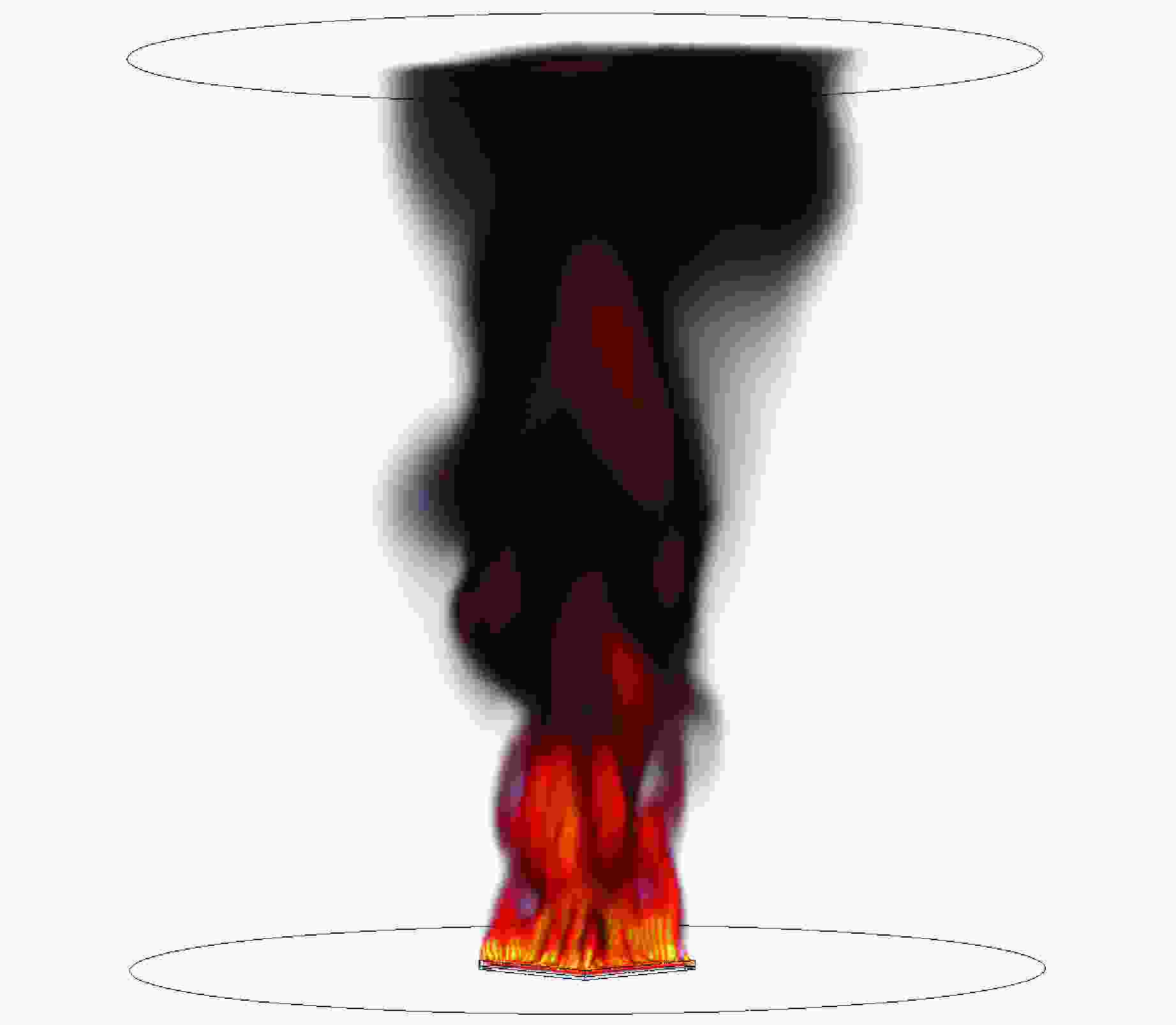

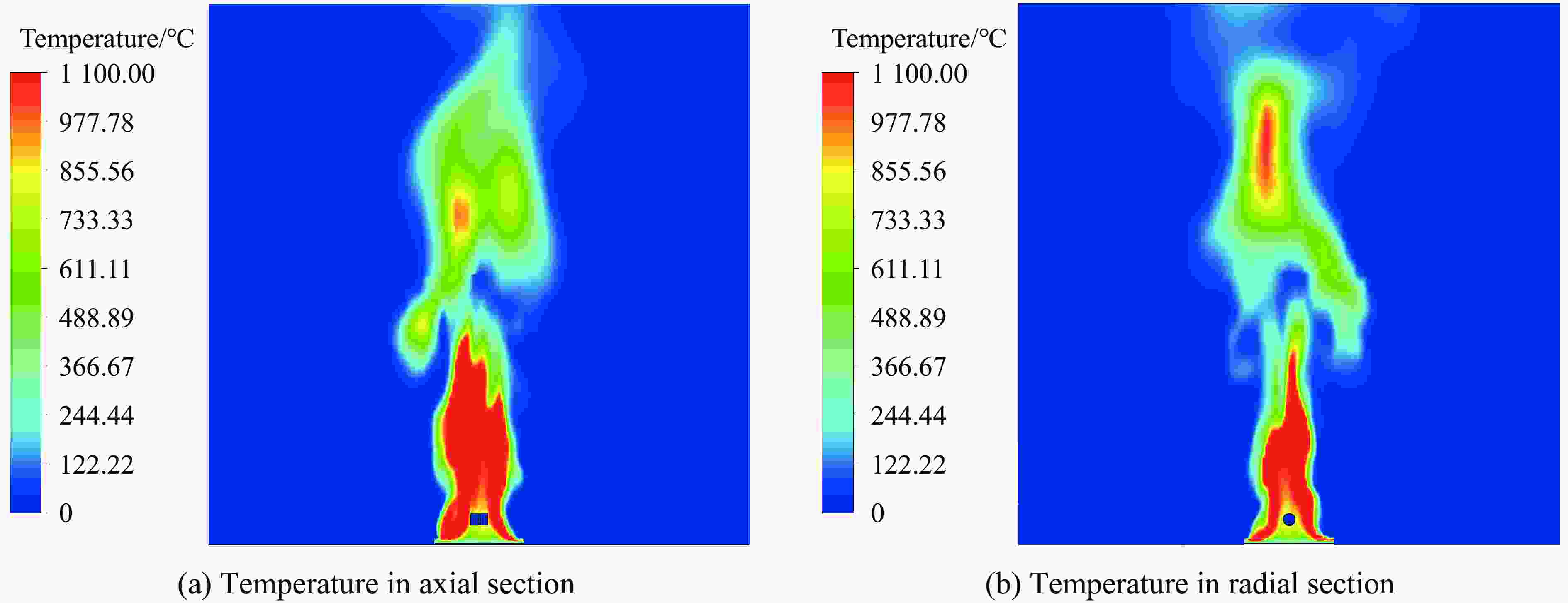

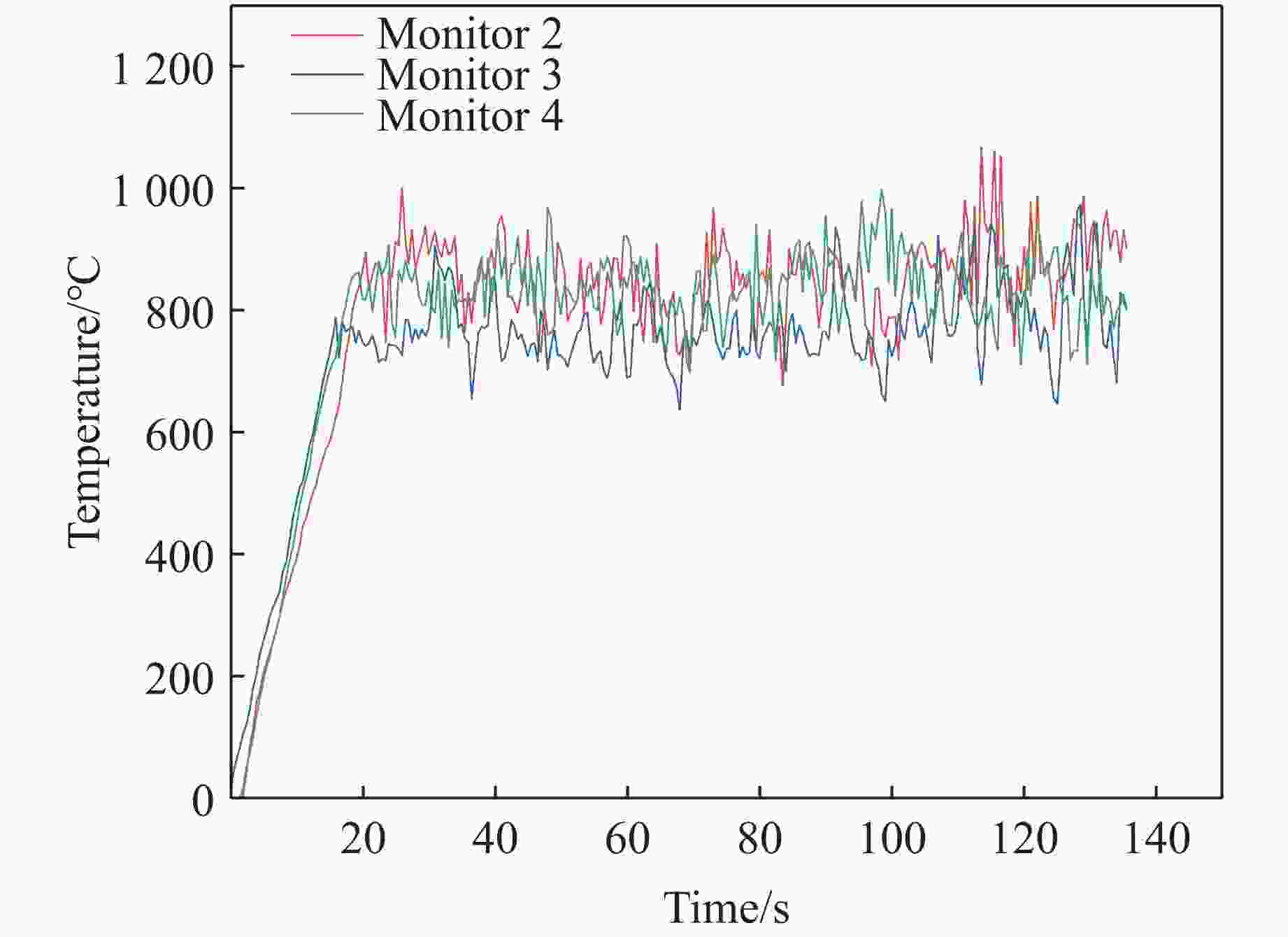

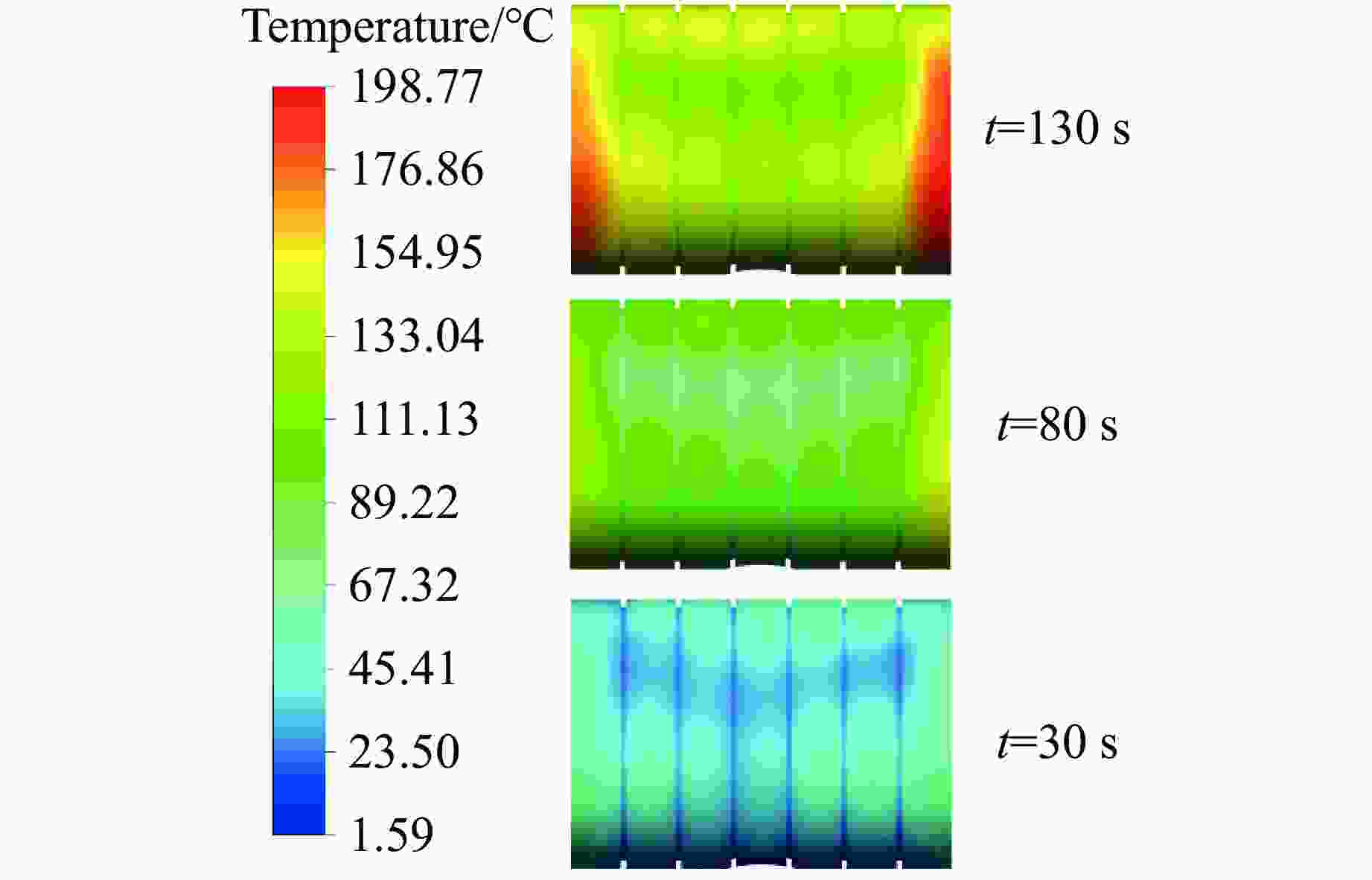

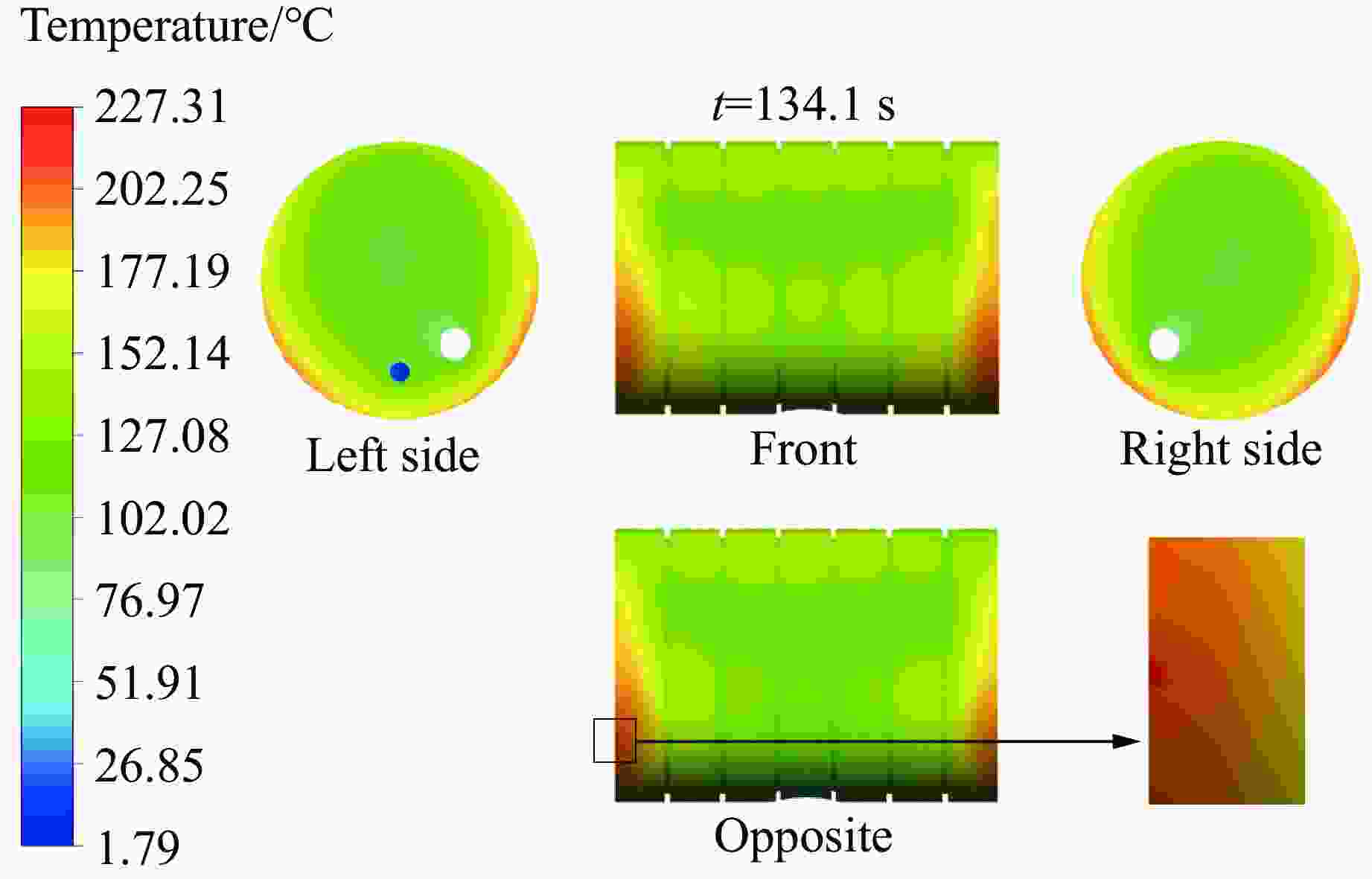

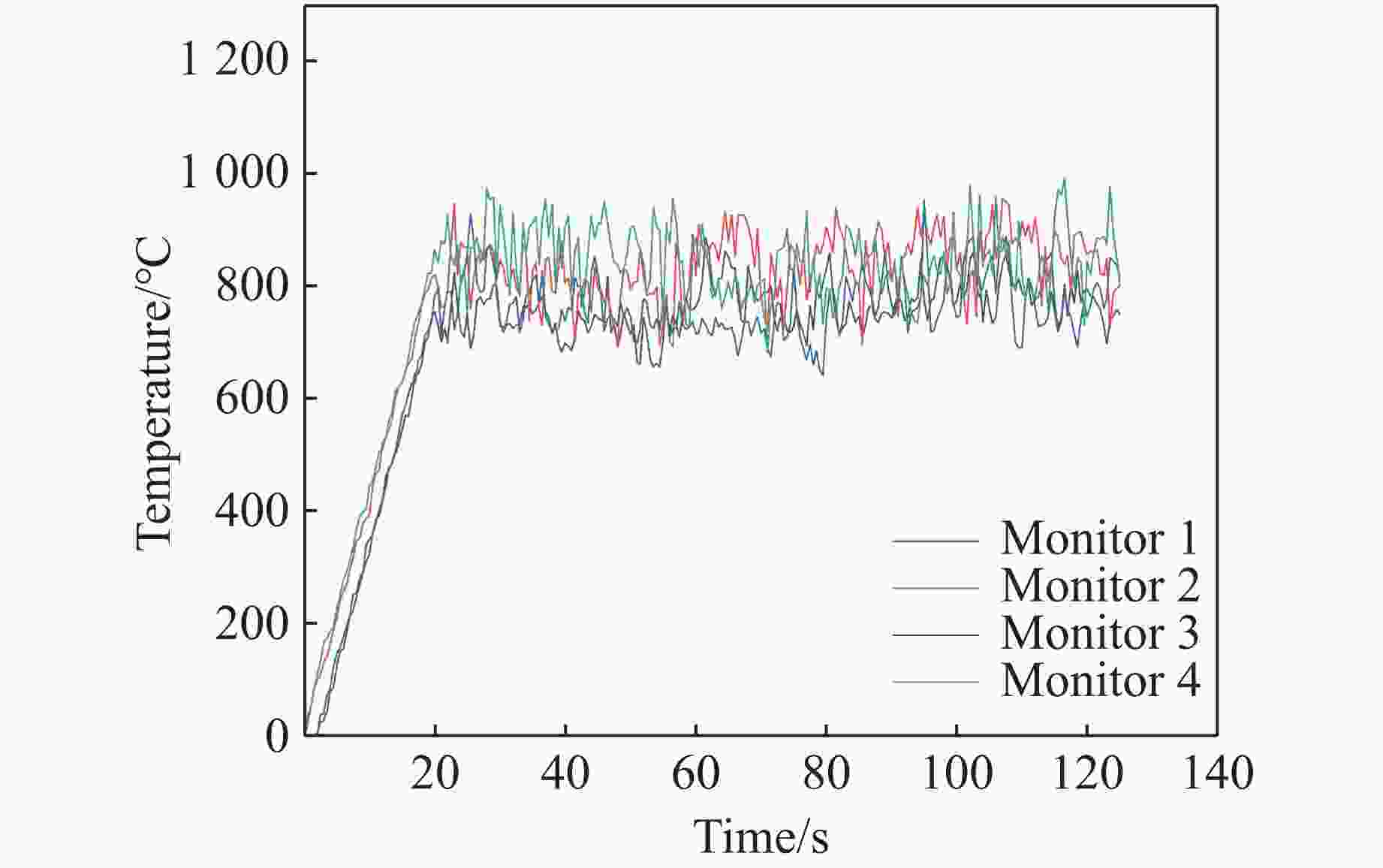

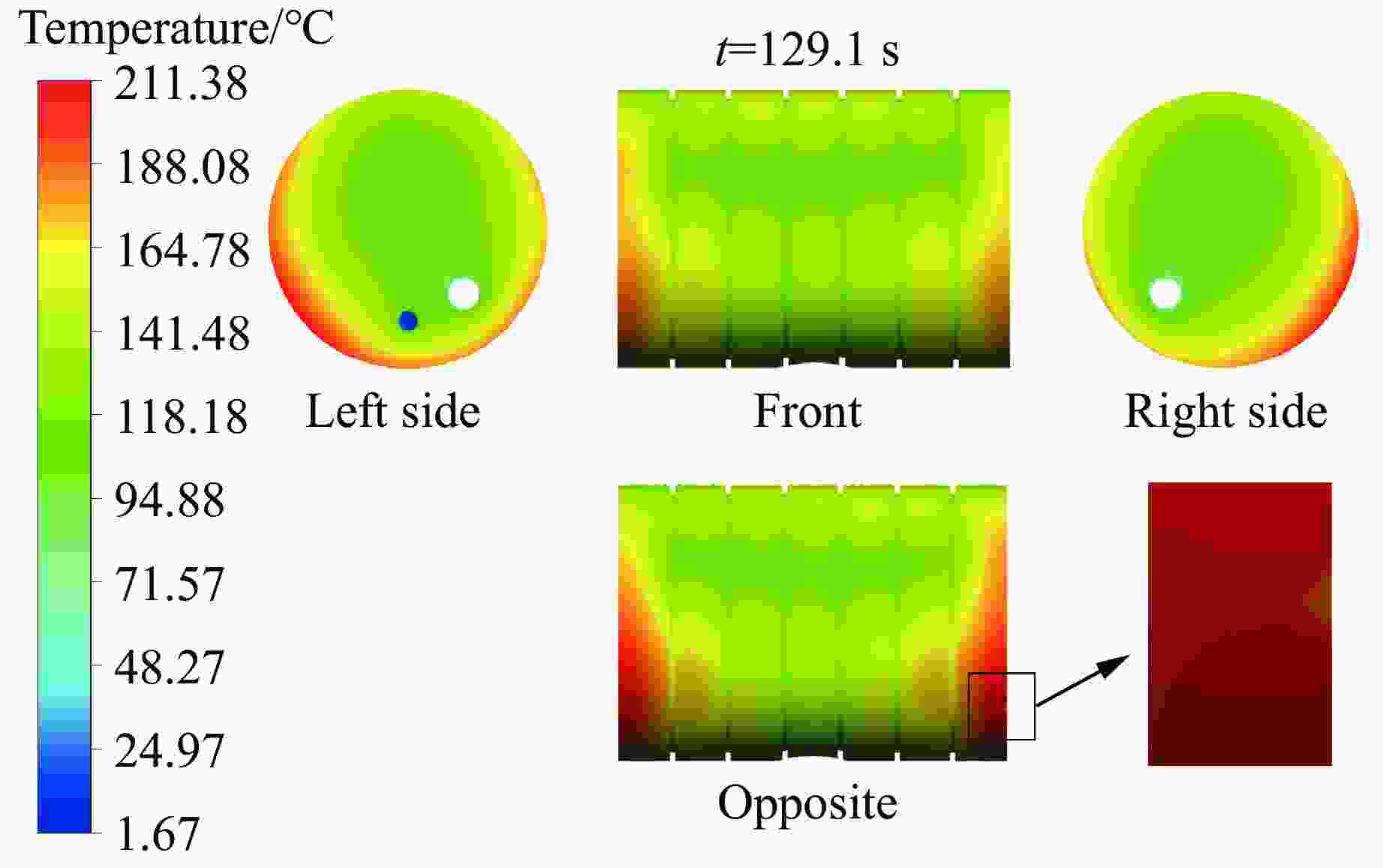

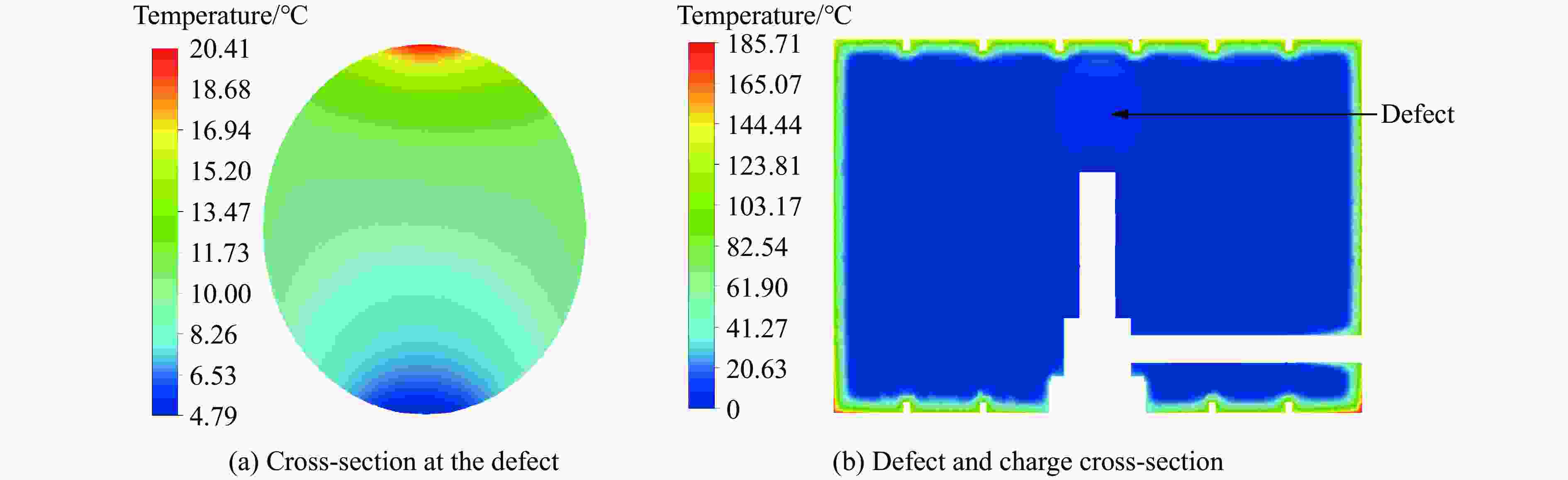

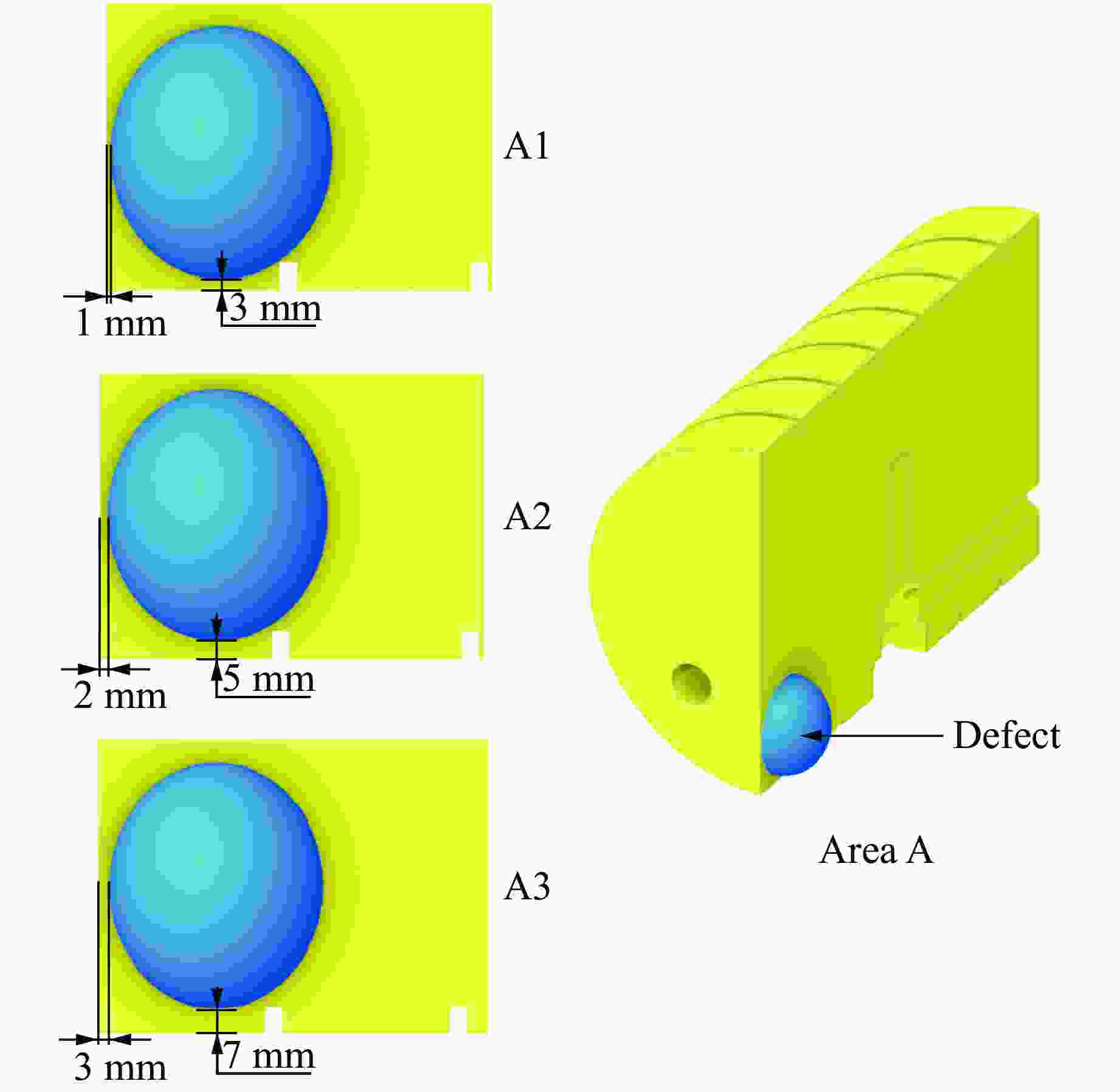

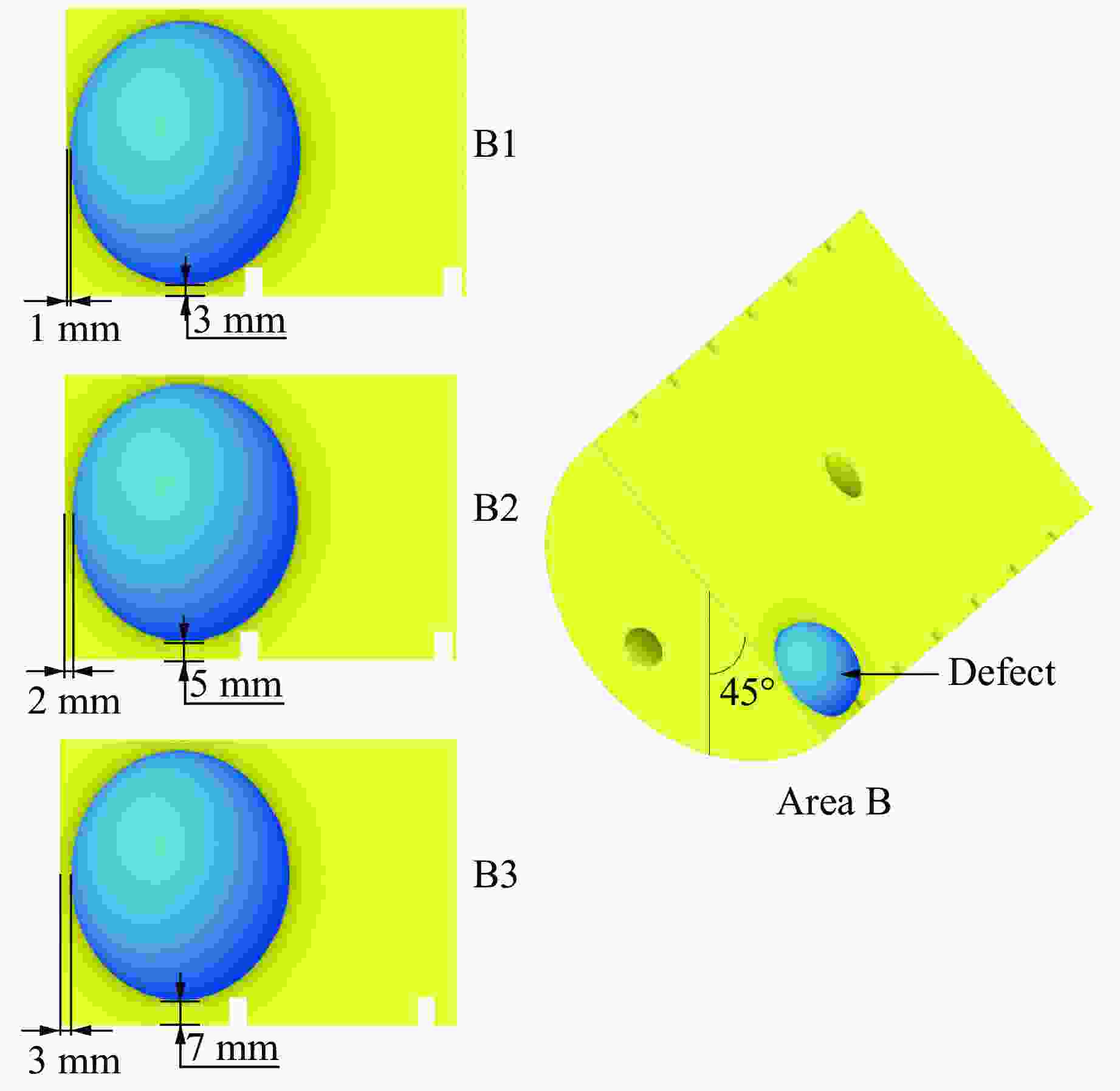

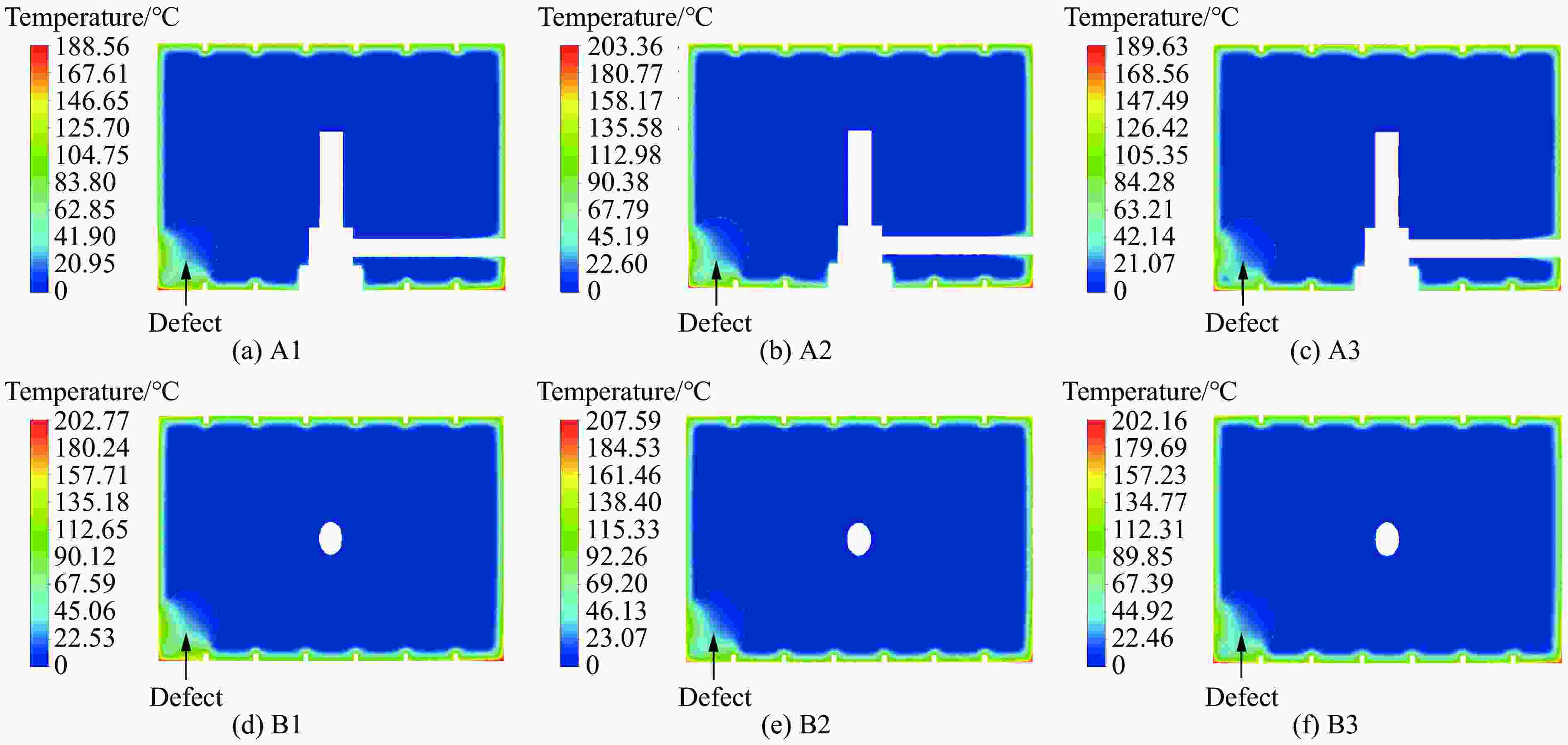

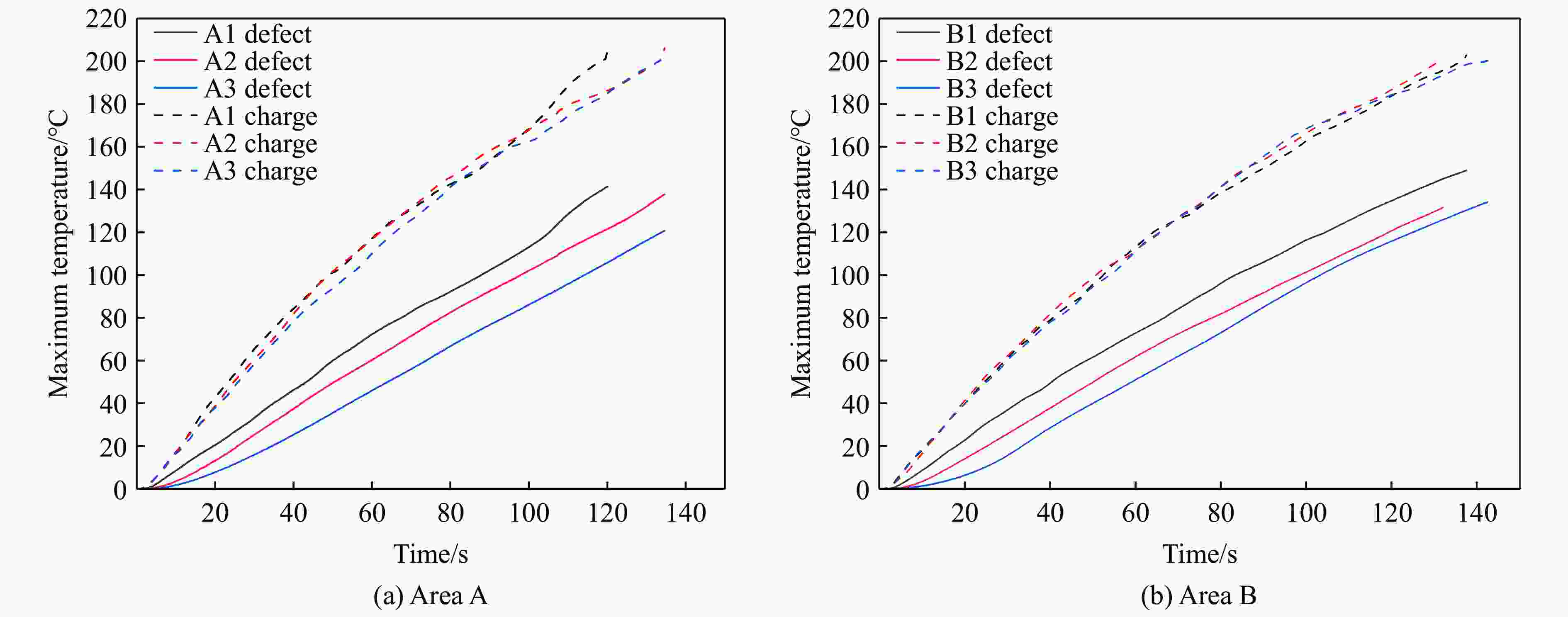

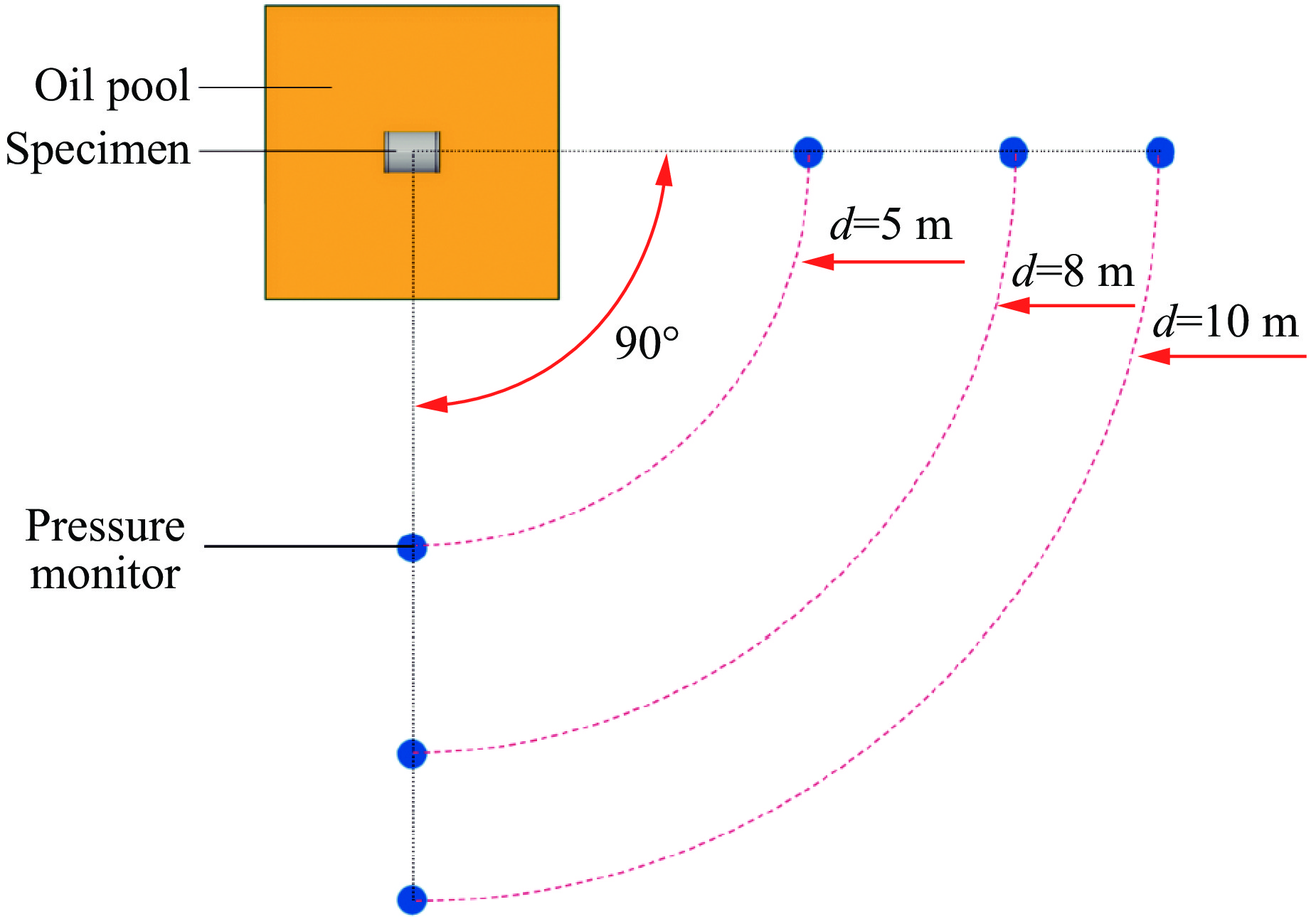

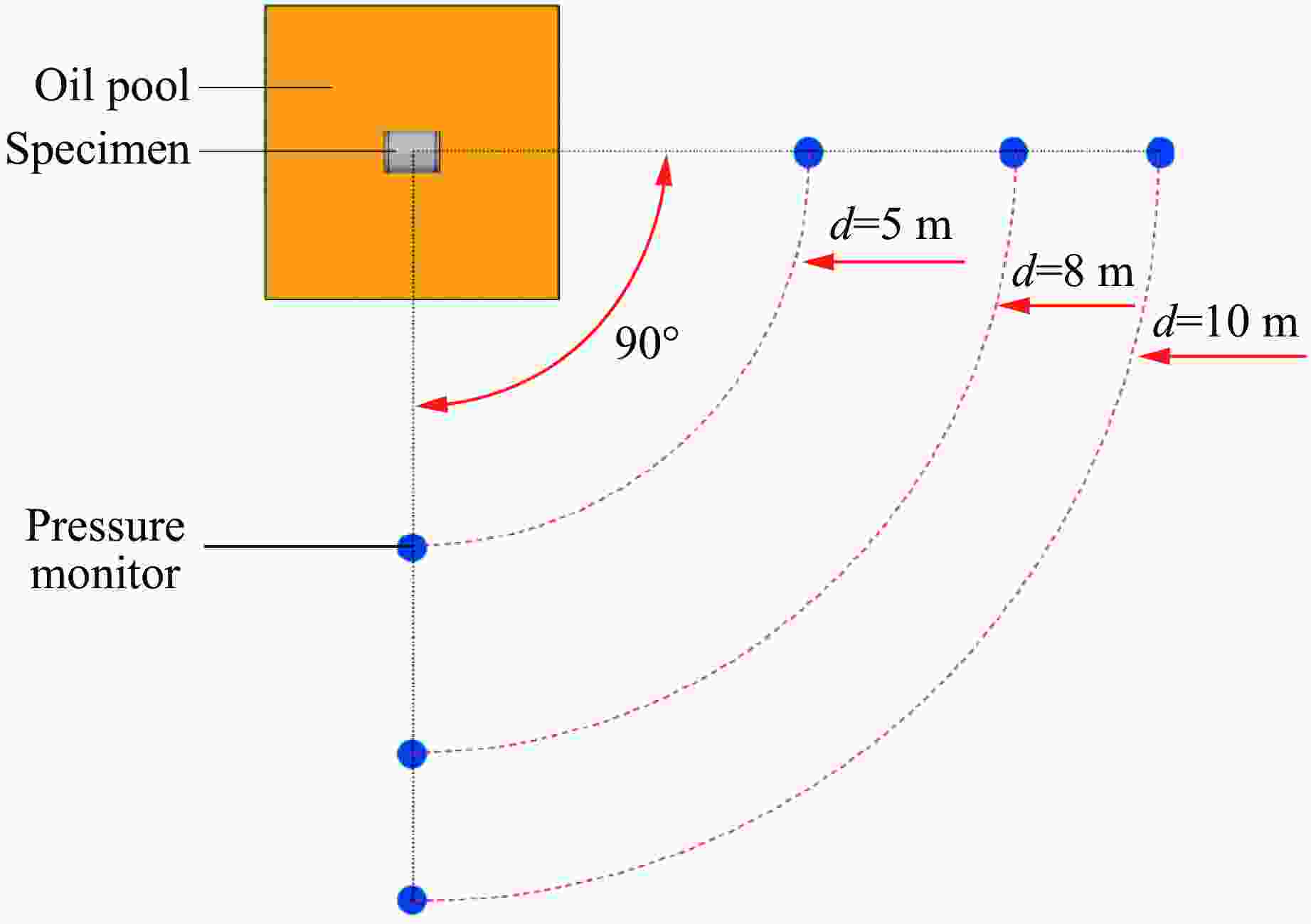

摘要: 为研究炸药装药缺陷对快速烤燃响应特性的影响,对Ⅰ型烤燃弹(无缺陷装药)和Ⅱ型烤燃弹(含缺陷装药)进行了快速烤燃试验。Ⅱ型烤燃弹的响应时间(128 s)短于Ⅰ型烤燃弹(132 s),且在5 m处的最大冲击波超压峰值(62.7 kPa)高于Ⅰ型烤燃弹(12.5 kPa)。试验结果表明,点火后Ⅱ型烤燃弹的响应较无缺陷的Ⅰ型烤燃弹更为剧烈,但二者的响应等级仍为燃烧反应。在此基础上,通过Fluent软件建立了池火与烤燃试件相互耦合的计算模型,模拟了试件在火焰中的受热情况。研究发现,缺陷越靠近装药表面,缺陷处的局部温度越高,但对装药的响应时间无明显影响。Abstract: To study the effect of explosive charge defects on fast cook-off response characteristics, fast cook-off tests were conducted on type Ⅰ cook-off bomb (with defect-free charges) and type Ⅱ cook-off bomb (with defective charges). The results showed that the response time of type Ⅱ cook-off bomb (128 s) is shorter than that of type Ⅰ cook-off bomb (132 s), and the maximum shock wave overpressure at 5 m (62.7 kPa) is higher than that of type Ⅰ cook-off bomb (12.5 kPa). This indicates that the combustion of the type Ⅱ cook-off bomb was more intense than the defect-free type Ⅰ cook-off bomb after ignition, although both of them exhibit the same response level of burning reaction. Furthermore, a coupled computational model of pool fire and cook-off specimen was established to simulate the heating of the specimen in the flame using Fluent software. It is found that the closer the defect is to the charge surface, the higher local temperature at the defect, but it does not significantly affect the response time of explosive charges.

-

Key words:

- fast cook-off /

- pool fire simulation /

- charge defects /

- defect position

-

表 1 冲击波超压峰值

Table 1. Peak overpressure of shock wave

Cook-off

bombMonitor point

locationDistance/m Overpressure

peak/kPaCook-off

bombMonitor point

locationDistance/m Overpressure

peak/kPaTypeⅠ Axial 5 5.9 TypeⅡ Axial 5 47.5 8 5.4 8 15.9 10 4.8 10 11.8 Radial 5 12.5 Radial 5 62.7 8 9.4 8 32.4 10 8.9 10 3.2 表 2 材料的物性参数

Table 2. Physical parameters of the material

Material ρ/(kg·m−3) C/(J·kg−1·K−1) λ/(W·m−1·K−1) Steel 7 850 480 43 Charge 1 809 1 012 0.49 Air 1.225 1 004 0.024 2 表 3 反应动力学参数

Table 3. Reaction kinetic parameters of explosives

E/(J·mol−1) A/s−1 Q/(J·kg−1) R/(J·mol−1·K−1) 115820 2.030×1014 2.293×106 8.314 -

[1] 江鹏. 烤燃作用下PBX炸药的热分解及细观热损伤研究 [D]. 北京: 北京理工大学, 2016.JIANG P. Thermal decomposition and microstructure study of PBX explosive subjected to cook-off [D]. Beijing: Beijing Institute of Technology, 2016. [2] 黄开书, 江涛, 吴欣欣, 等. 提高浇注PBX炸药装药品质技术途径 [J]. 兵工自动化, 2023, 42(10): 60–62. doi: 10.7690/bgzdh.2023.10.014HUANG K S, JIANG T, WU X X, et al. Technical approach to improve charging quality of cast PBX explosive [J]. Ordnance Industry Automation, 2023, 42(10): 60–62. doi: 10.7690/bgzdh.2023.10.014 [3] CUENOT B, SHUM-KIVAN F, BLANCHARD S. The thickened flame approach for non-premixed combustion: principles and implications for turbulent combustion modeling [J]. Combustion and Flame, 2022, 239: 111702. doi: 10.1016/j.combustflame.2021.111702 [4] WEI R C, WANG B W, HE Q Z, et al. An experimental study on aviation kerosene pool fire flame and thermal radiation [J]. Journal of Physics: Conference Series, 2022, 2263(1): 012018. doi: 10.1088/1742-6596/2263/1/012018 [5] 王帅, 智小琦, 贾秋琳, 等. 基于mass_flux法的炸药火烧试验与数值仿真 [J]. 兵器装备工程学报, 2020, 41(8): 1–6. doi: 10.11809/bqzbgcxb2020.08.001WANG S, ZHI X Q, JIA Q L, et al. Experiment and numerical simulation of explosive firing based on mass_flux method [J]. Journal of Ordnance Equipment Engineering, 2020, 41(8): 1–6. doi: 10.11809/bqzbgcxb2020.08.001 [6] 肖游, 智小琦, 王琦, 等. 火焰特征量对快速烤燃的影响 [J]. 高压物理学报, 2022, 36(5): 055201. doi: 10.11858/gywlxb.20220557XIAO Y, ZHI X Q, WANG Q, et al. Influence of flame characteristics on fast cook-off [J]. Chinese Journal of High Pressure Physics, 2022, 36(5): 055201. doi: 10.11858/gywlxb.20220557 [7] 王洪波, 王旗华, 卢永刚, 等. PBX炸药细观孔洞缺陷对其冲击点火特性的影响 [J]. 火炸药学报, 2015, 38(5): 31–36. doi: 10.14077/j.issn.1007-7812.2015.05.006WANG H B, WANG Q H, LU Y G, et al. Effect of Meso-defect holes on the shock-to-ignition characteristics of PBX explosives [J]. Chinese Journal of Explosives & Propellants, 2015, 38(5): 31–36. doi: 10.14077/j.issn.1007-7812.2015.05.006 [8] 周婷婷, 楼建锋. 含孔洞炸药晶体HMX冲击响应的分子动力学模拟 [J]. 含能材料, 2024, 32(1): 65–75. doi: 10.11943/CJEM2023167ZHOU T T, LOU J F. Molecular dynamic studies on the shock responses of energetic crystal HMX with cylindrical voids [J]. Chinese Journal of Energetic Materials, 2024, 32(1): 65–75. doi: 10.11943/CJEM2023167 [9] GROSS M L, HEDMAN T D, MEREDITH K V. Considerations for fast cook-off simulations [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(6): 1036–1043. doi: 10.1002/prep.201500253 [10] 王志富. 有装药缺陷的凝聚相炸药烤燃的数值模拟 [D]. 淮南: 安徽理工大学, 2020.WANG Z F. Numerical simulation of the burning of defective condensed phase explosives [D]. Huainan: Anhui University of Science and Technology, 2020. [11] PETERS N. Turbulent combustion [M]. Cambridge: Cambridge University Press, 2000. [12] Ansys Inc. Fluent A.: ANSYS fluent theory guide [Z]. USA, 2013, 15317: 724–746. [13] ATTAR A A, POURMAHDIAN M, ANVARIPOUR B. Experimental study and CFD simulation of pool fires [J]. International Journal of Computer Applications, 2013, 70(11): 9–15. doi: 10.5120/12004-5790 [14] 任玉新, 陈海昕. 计算流体力学基础 [M]. 北京: 清华大学出版社, 2006.REN Y X, CHEN H X. Fundamentals of computational fluid dynamics [M]. Beijing: Tsinghua University Press, 2006. [15] 付淑青. 国产航空煤油多组分替代燃料的燃烧反应机理研究 [D]. 沈阳: 沈阳航空航天大学, 2020.FU S Q. Study on combustion reaction mechanism of domestic aviation kerosene multi-component surrogate fuels [D]. Shenyang: Shenyang Aerospace University, 2020. [16] 黄生洪, 徐胜利, 刘小勇. 煤油超燃冲压发动机两相流场数值研究(Ⅲ)煤油在超燃流场中的多步化学反应特征 [J]. 推进技术, 2005, 26(2): 101–105. doi: 10.3321/j.issn:1001-4055.2005.02.002HUANG S H, XU S L, LIU X Y. Combustion flow of kerosene-fueled scramjet with 3D cavity (Ⅲ) multi-step chemistry characteristics of kerosene [J]. Journal of Propulsion Technology, 2005, 26(2): 101–105. doi: 10.3321/j.issn:1001-4055.2005.02.002 [17] KUNDU K, PENKO P, YANG S. Reduced reaction mechanisms for numerical calculations in combustion of hydrocarbon fuels [C]//36th AIAA Aerospace Sciences Meeting and Exhibit. Reno: AIAA, 1998. [18] 曾娇. 开放空间航空煤油池火燃烧数值模拟 [D]. 哈尔滨: 哈尔滨工程大学, 2016.ZENG J. Numerical simulation of aviation fuel pool fire in open air [D]. Harbin: Harbin Engineering University, 2016. [19] 傅献彩. 普通高等教育十五国家级规划教材: 物理化学(上) [M]. 北京: 高等教育出版社, 2005: 99–103. -

下载:

下载: