Numerical Simulation of Energy Absorption Performance and Failure Mechanism of CFRP Composites under Fragment Impact after Explosion

-

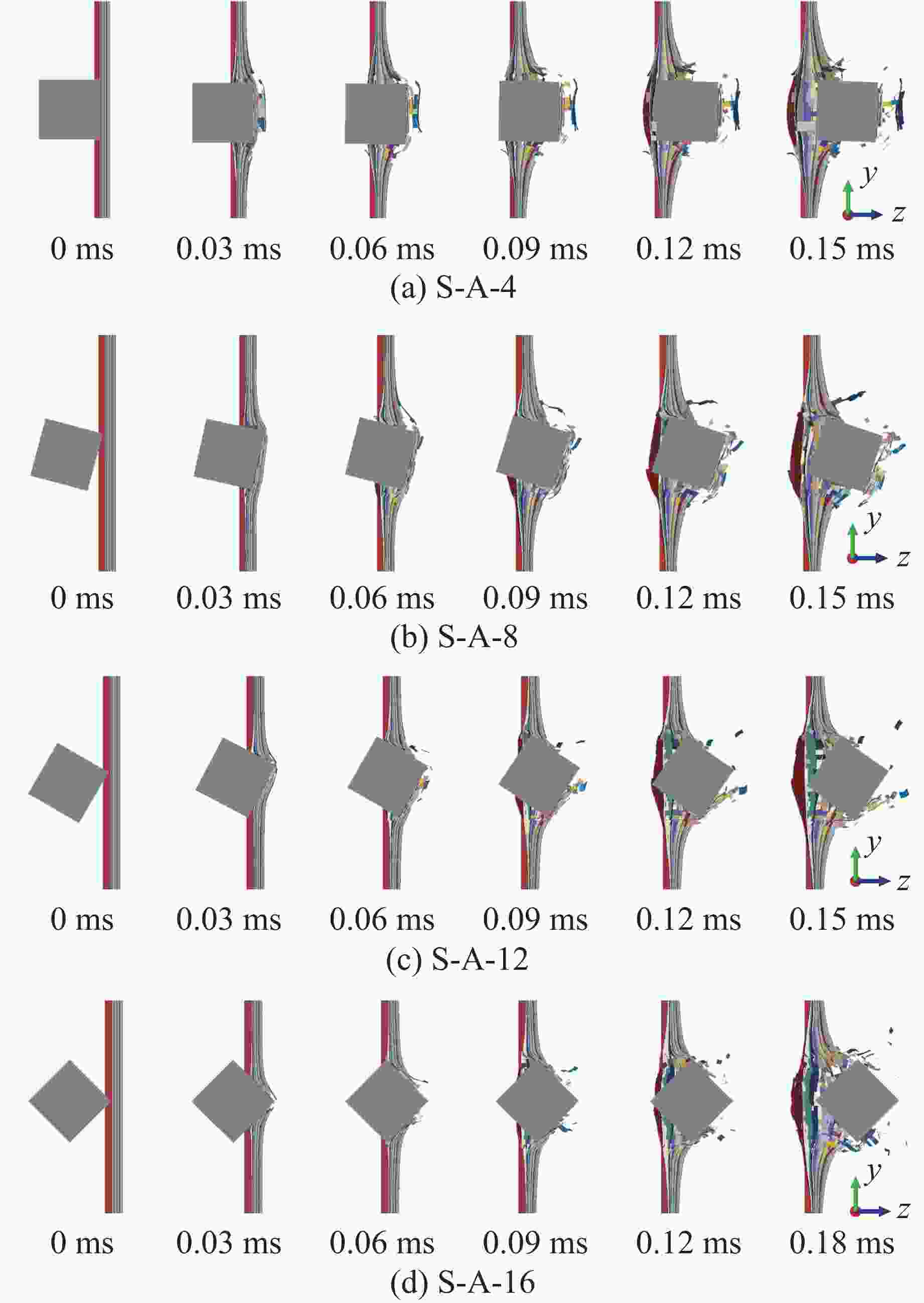

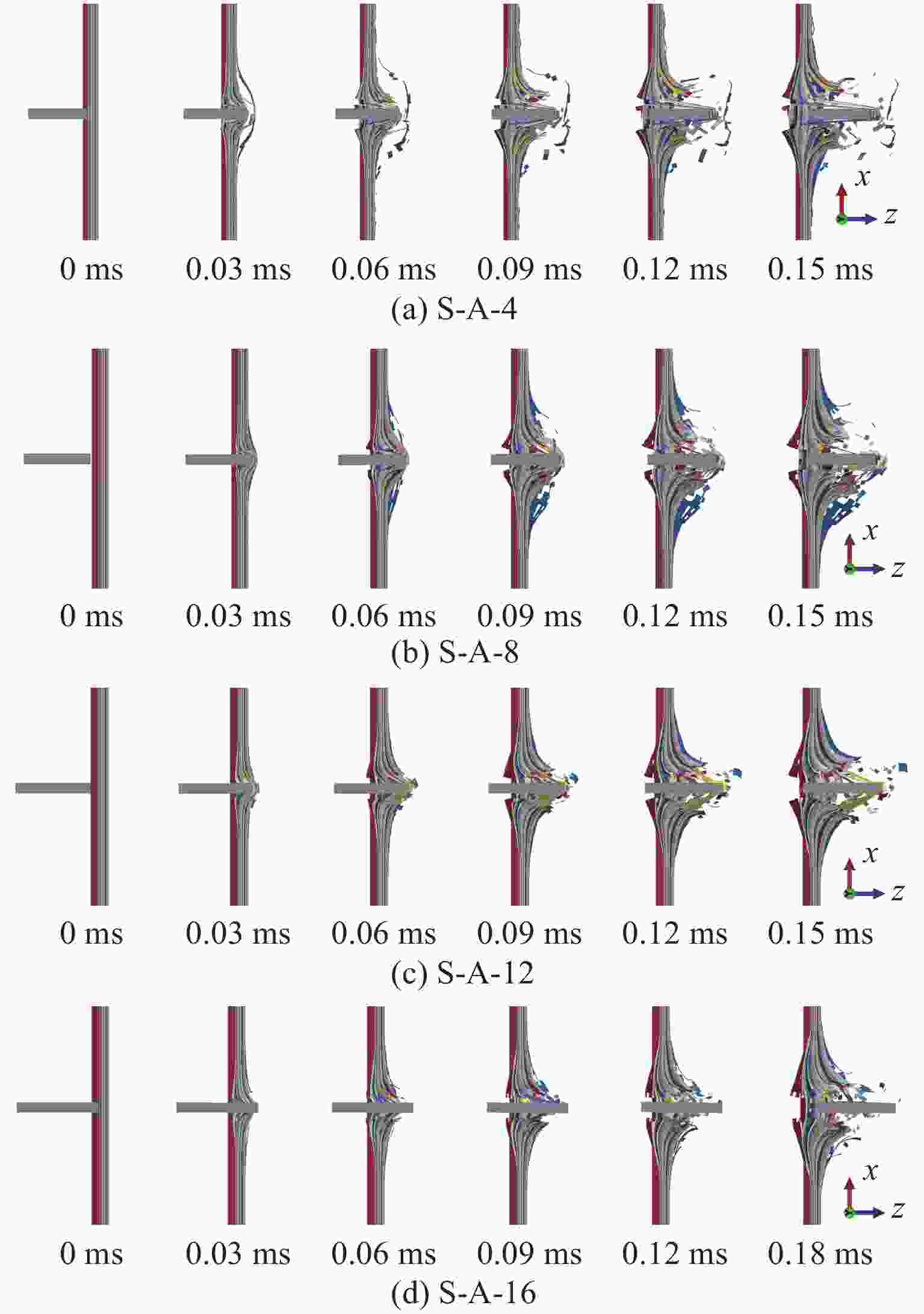

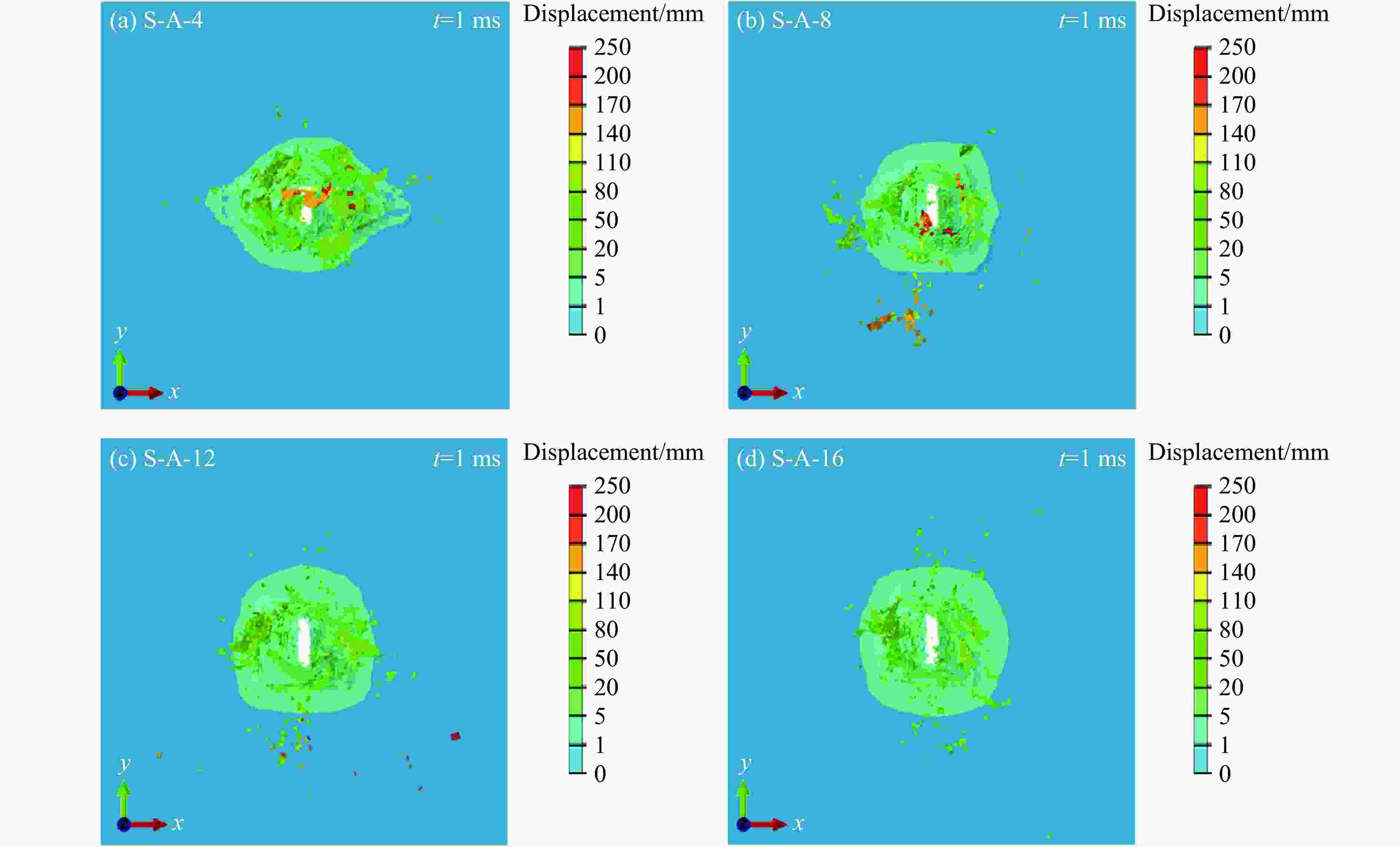

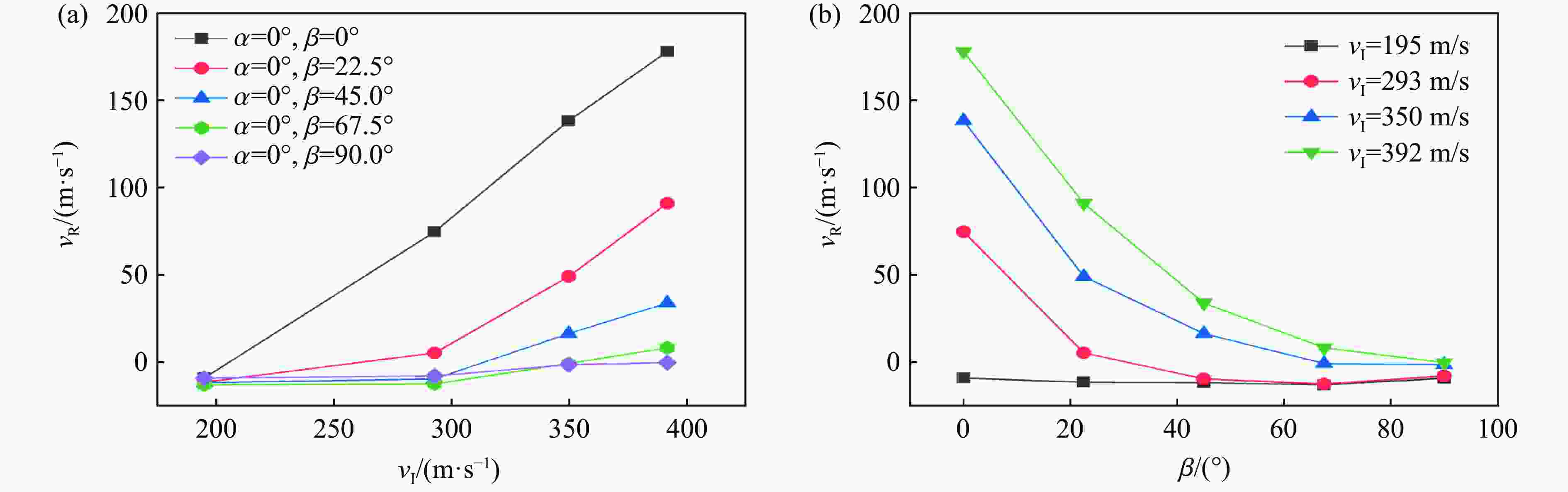

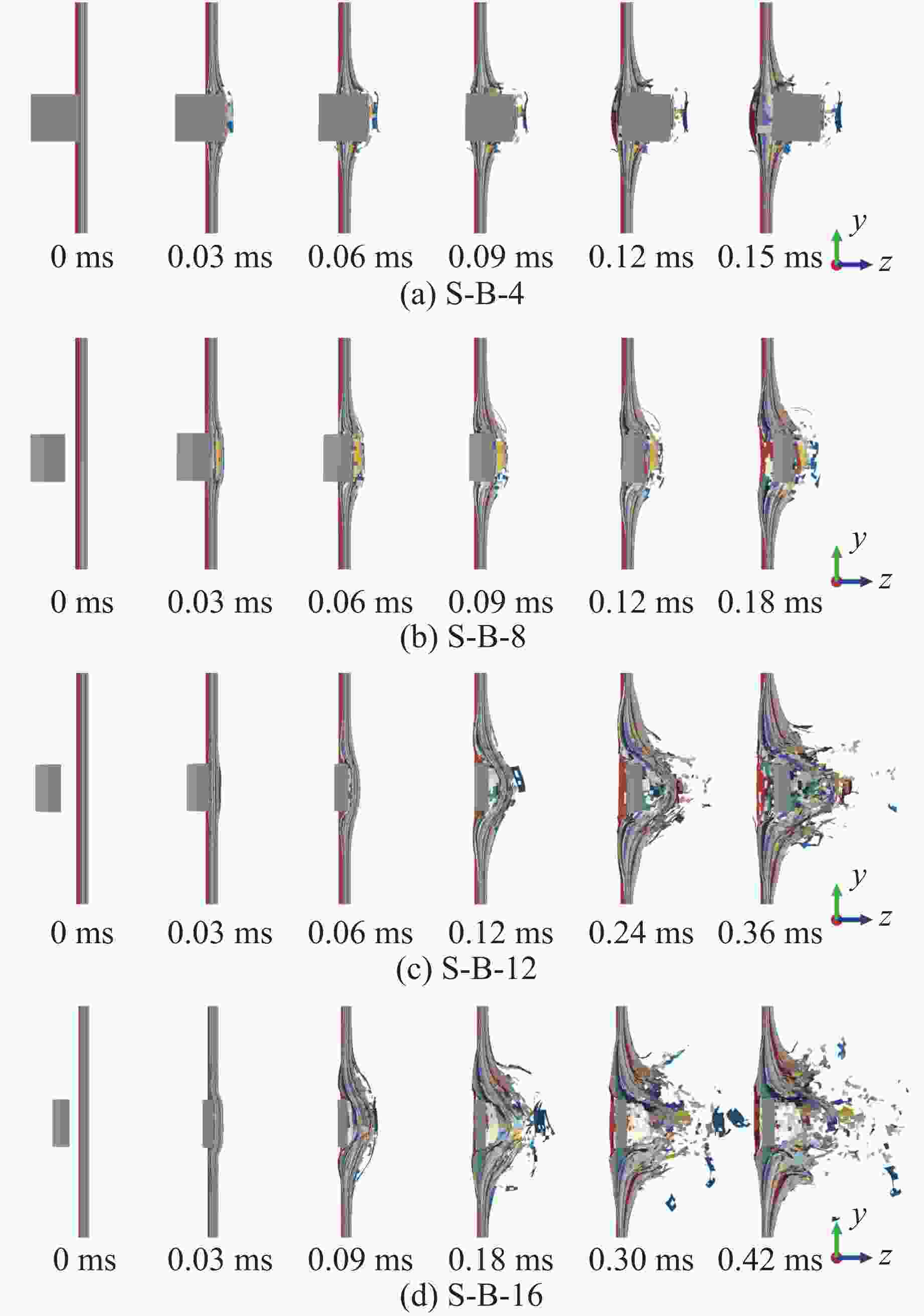

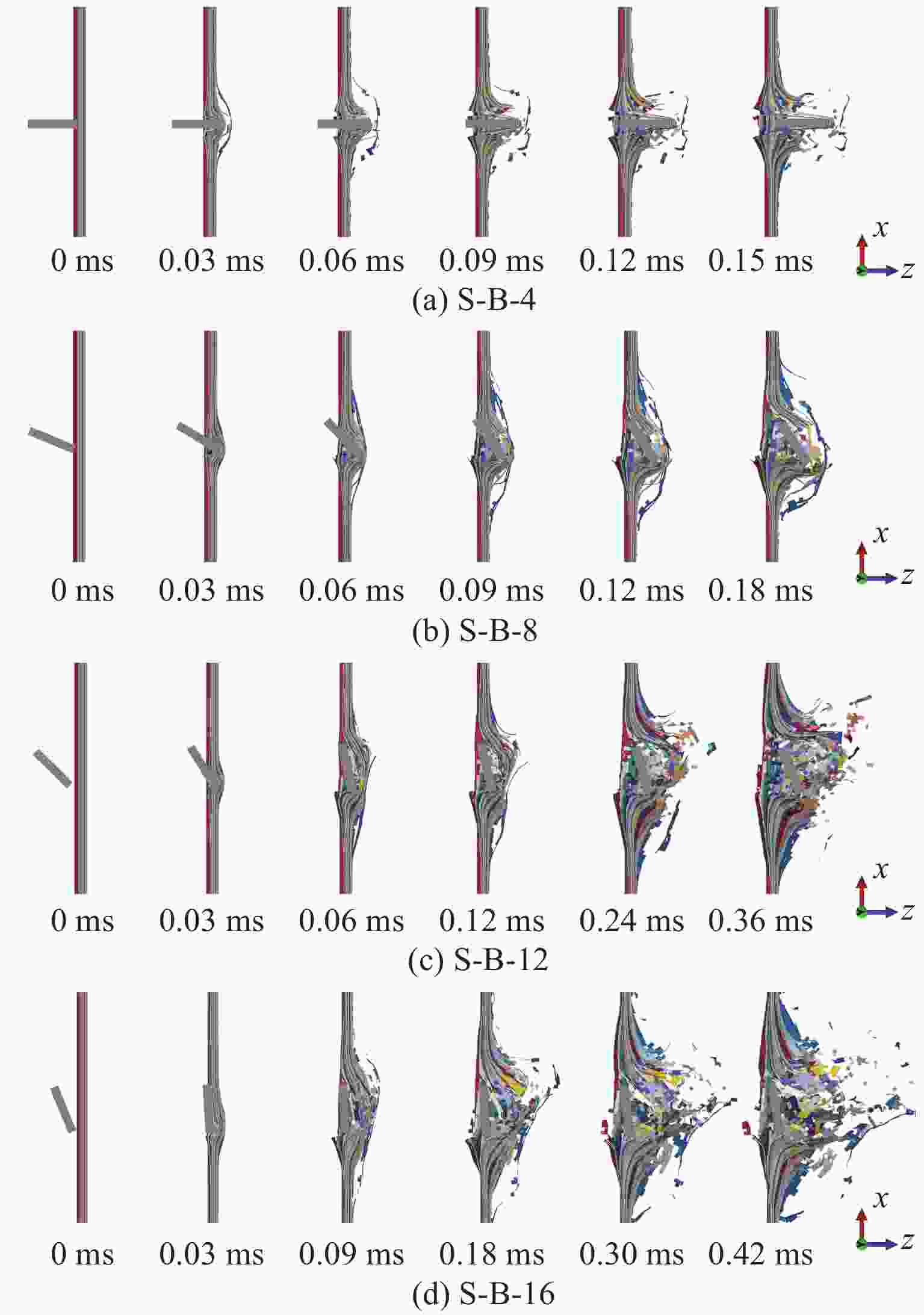

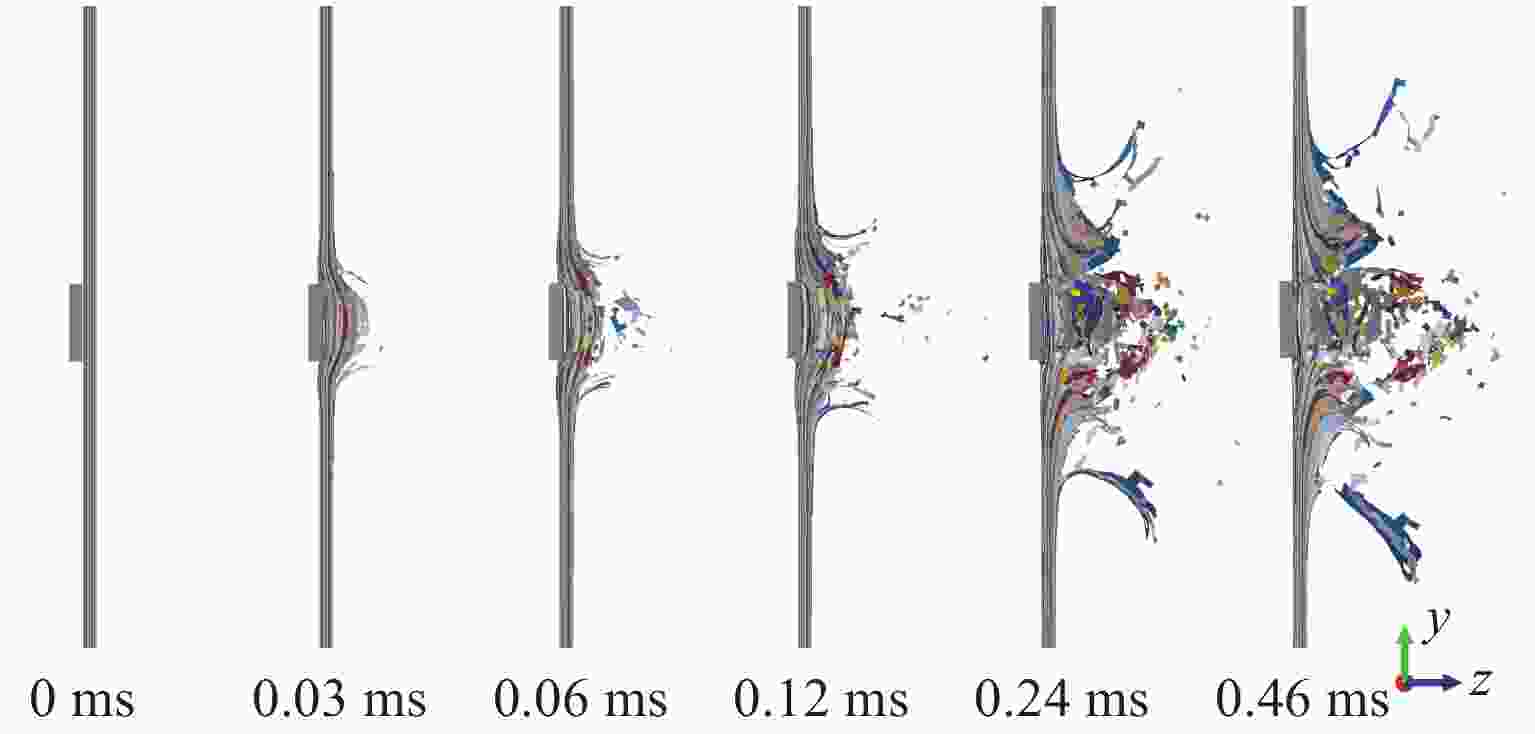

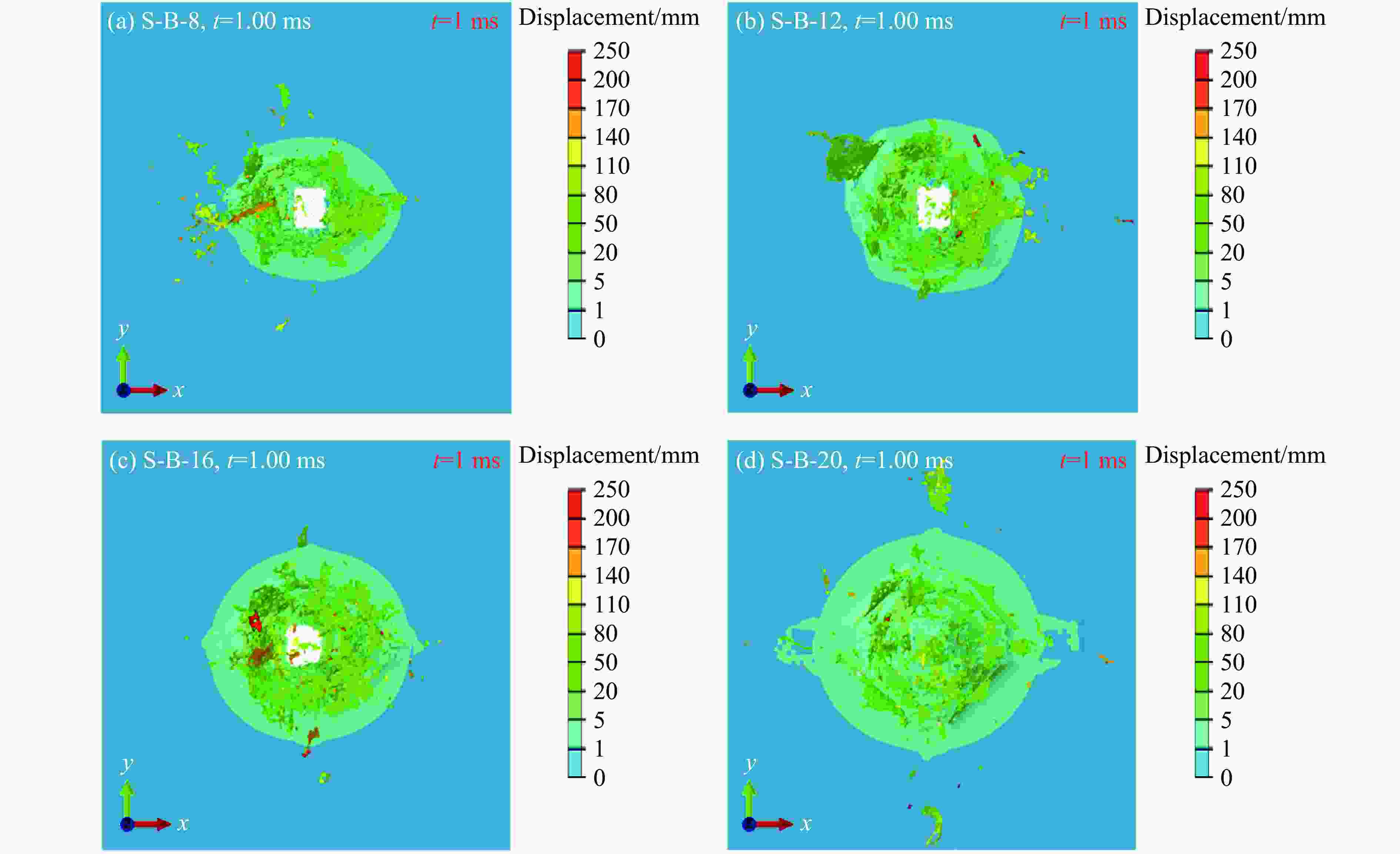

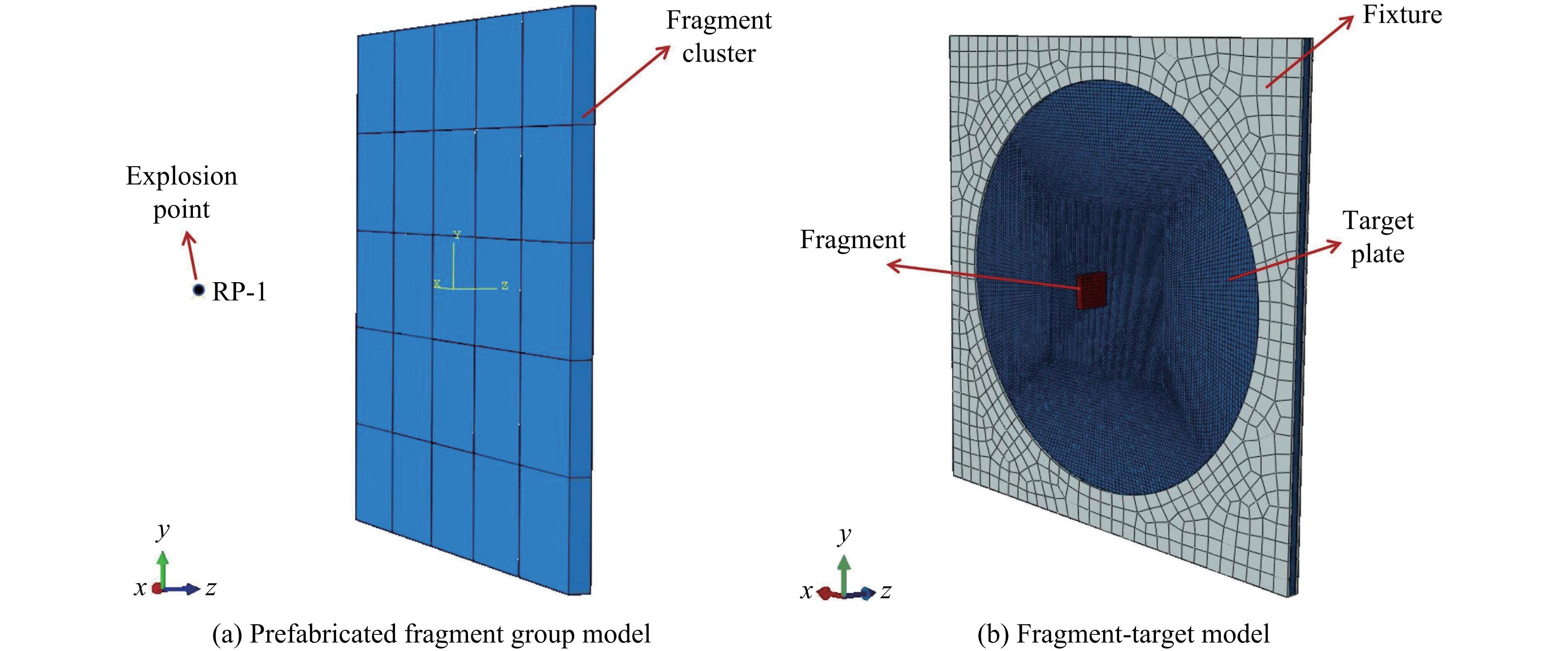

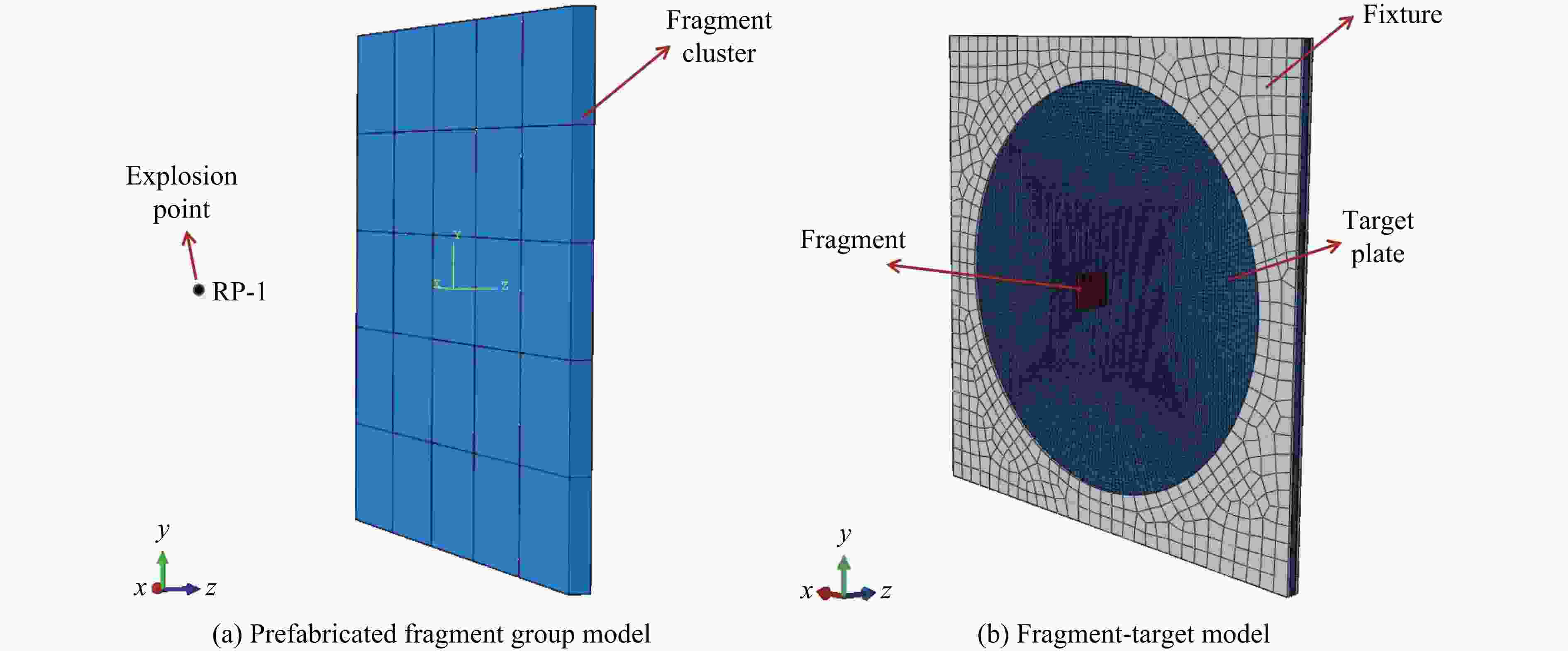

摘要: 碳纤维增强聚合物(carbon fibre-reinforced polymer, CFRP)复合材料在破片冲击作用下的复杂侵彻行为和失效机制尚不明确,这一现状制约了其在防护领域的应用。针对实验手段在获取侵彻历程信息时面临的监测难度大、成本高昂等问题,构建了CFRP复合材料破片冲击有限元分析(finite element analysis, FEA)模型,采用基于应变的三维 Hashin 失效准则,并引入强度的速率依赖性关系。通过与实验结果对比,验证了FEA模型的有效性。模拟结果表明,在不同TNT当量和破片距爆点距离的条件下,破片的初速度和撞击倾角存在显著差异。将破片相对于靶板上不同平面间的倾角分别定义为α和β。固定冲击速度仅改变倾角α时,试样的吸能效果和冲击速度敏感性未表现出明显差异,而改变倾角β时试样的吸能效果和冲击速度敏感性差异显著。当β=0°时,CFRP复合材料在195~392 m/s的速度范围内表现出明显的冲击速度敏感性。当α=0°时,CFRP复合材料在195~392 m/s的冲击速度范围内的冲击速度敏感性随着β的增大而逐渐减弱。可视化的侵彻过程和破坏区域表明,接触面积、接触时间和变形程度是导致CFRP复合材料吸能效果和冲击速度敏感性差异的重要因素。

-

关键词:

- 破片冲击 /

- 碳纤维增强聚合物复合材料 /

- 有限元模拟 /

- 失效行为

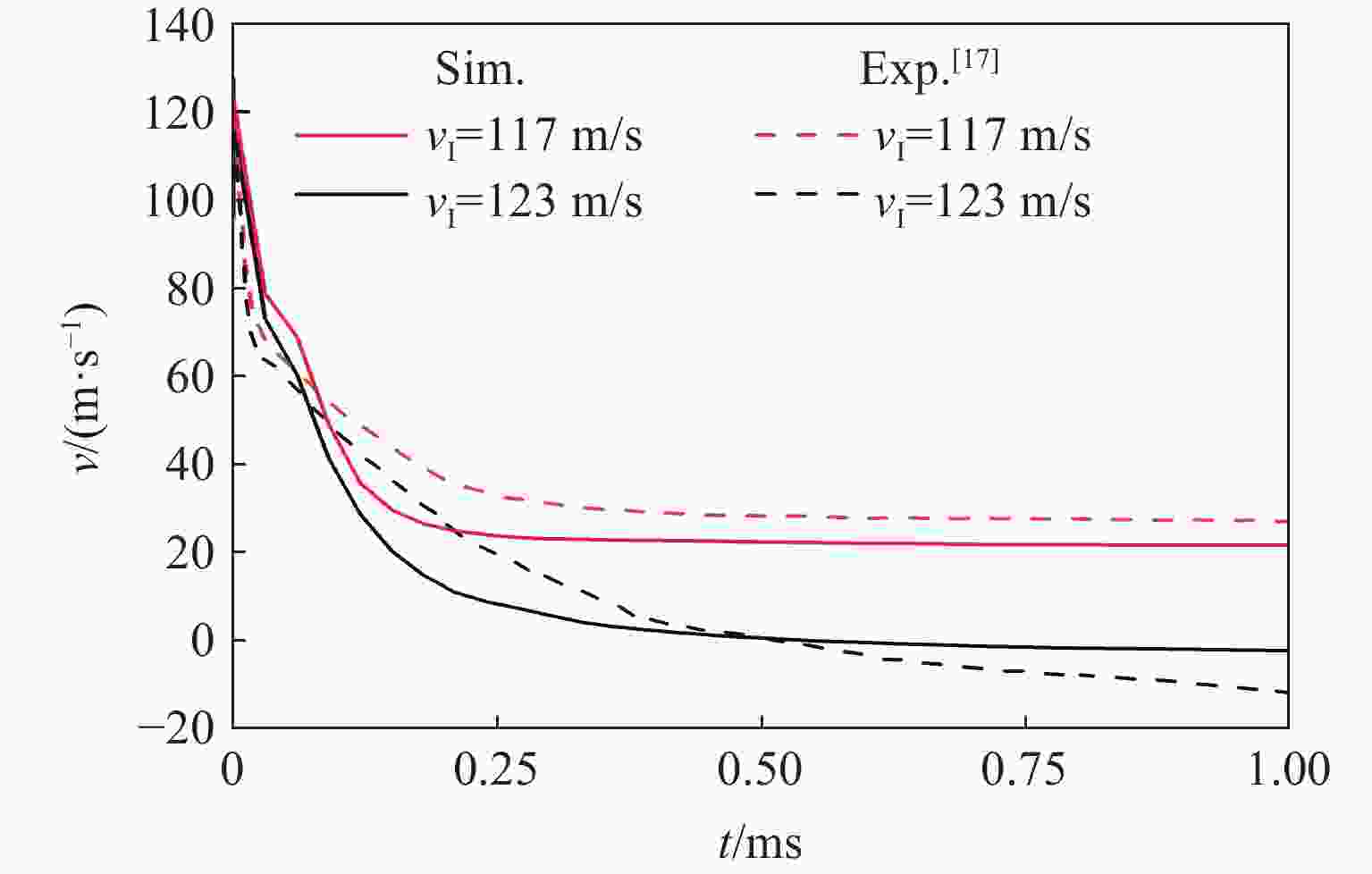

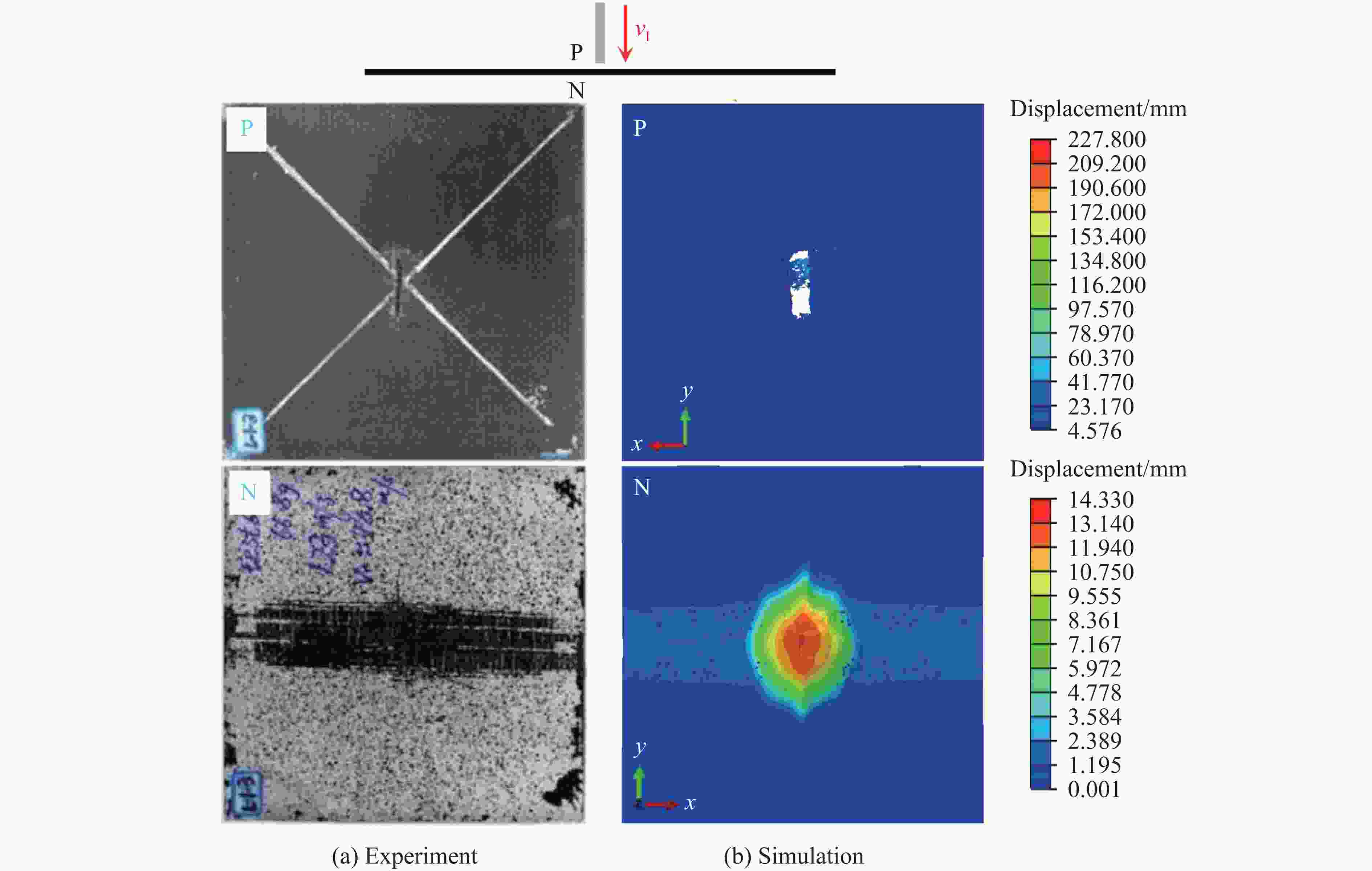

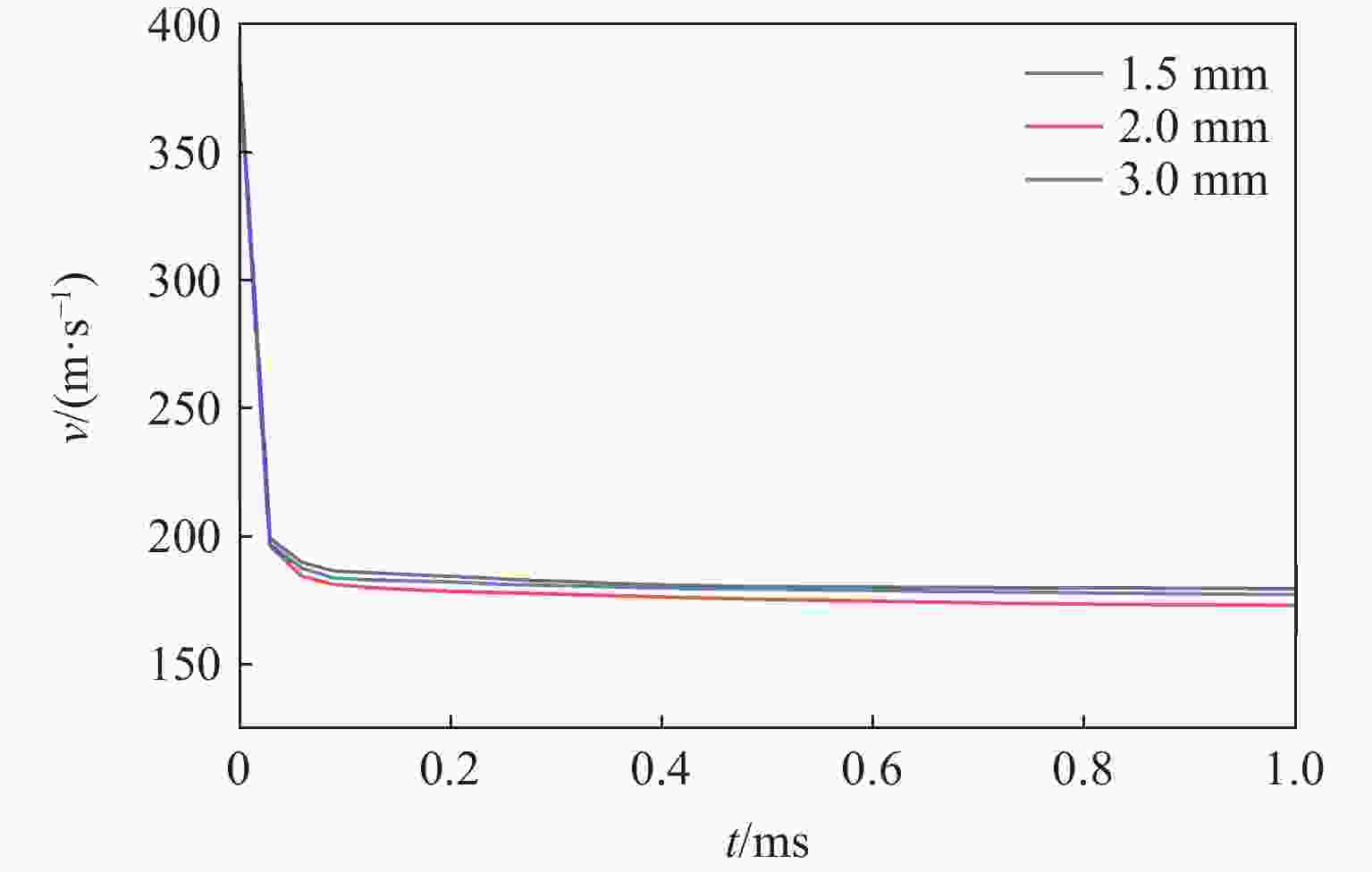

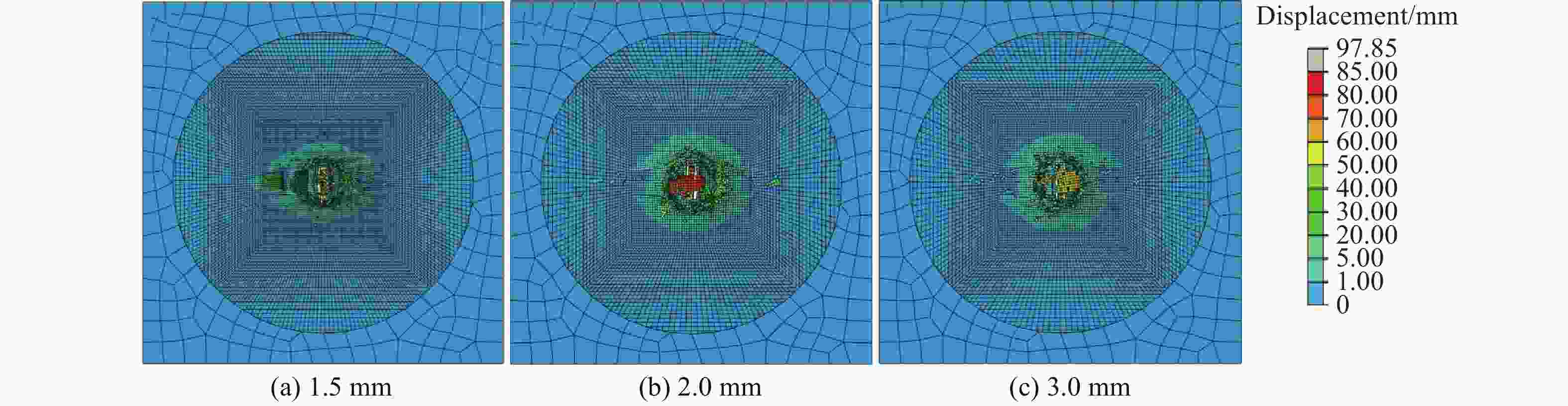

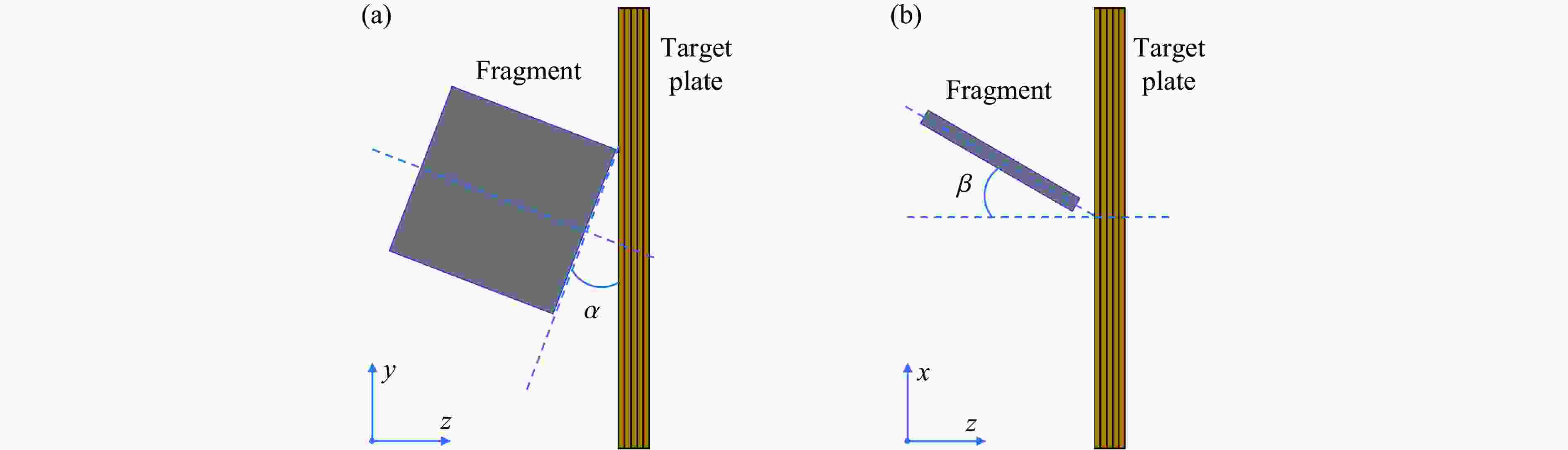

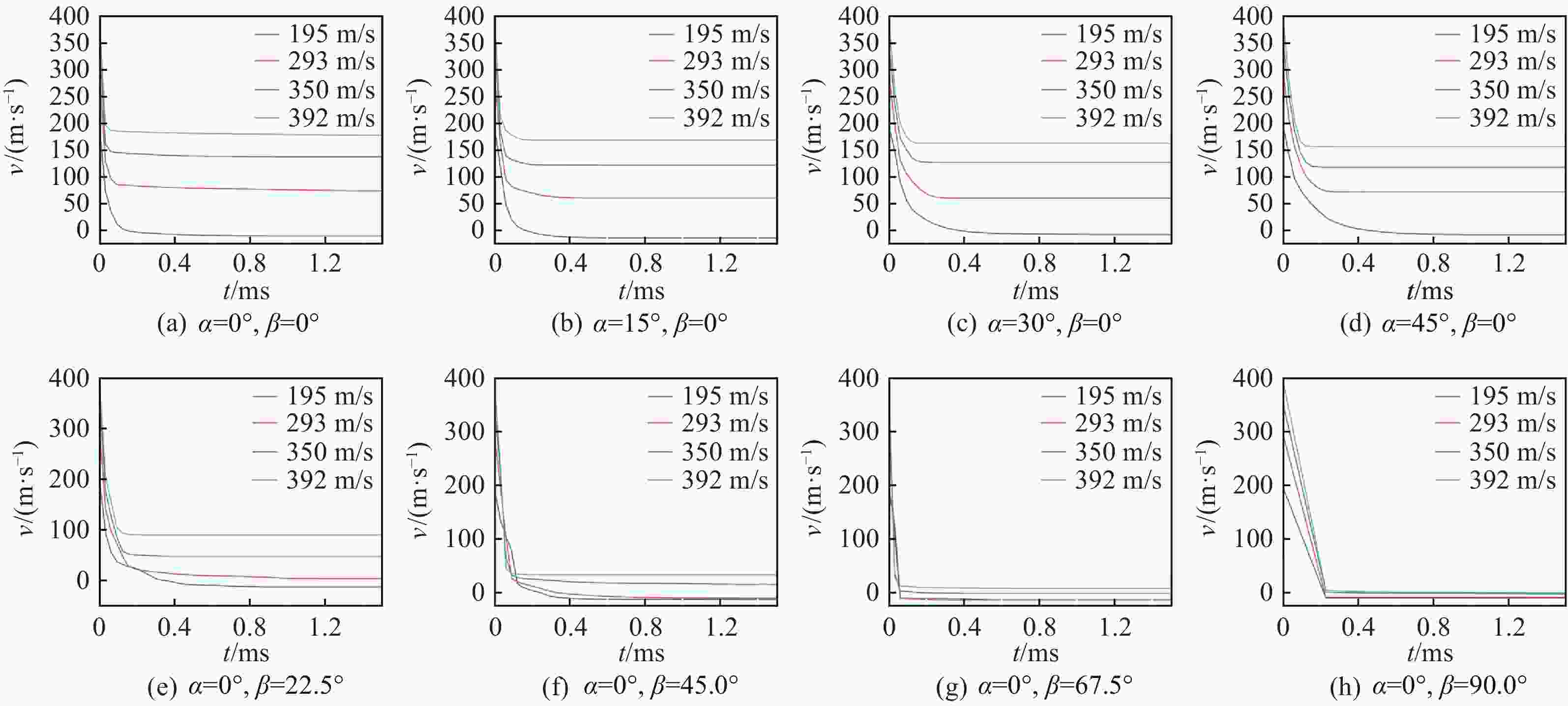

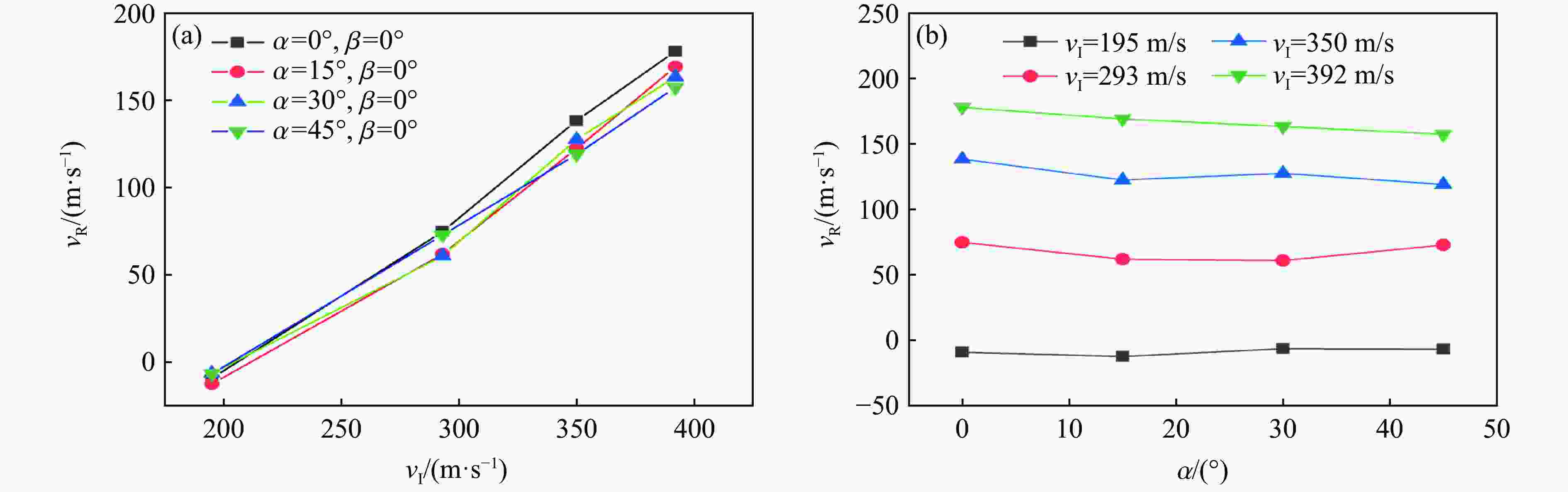

Abstract: The application of carbon fiber reinforced polymer (CFRP) composite in protective equipment is restricted by its complex penetration behavior and unclear failure mechanism under fragment impact. To overcome the difficulty and high cost of monitoring the penetration process information through experiments, a finite element analysis (FEA) model of CFRP composite under fragment impact is constructed in this study. In this model, a strain-based three-dimensional Hashin failure criterion is adopted, and the rate-dependent relationship of strength is introduced. The effectiveness of the FEA model is verified by comparison with experimental results. The simulation results show significant difference in both initial velocities and impact inclination angles under different TNT equivalents and distances from the explosion point. The inclination angles of fragments with the target plate on y-z and x-z planes are defined as α and β. When β=0°, CFRP composites exhibit pronounced impact velocity sensitivity in the velocity range of 195−392 m/s. The energy absorption capability and impact velocity sensitivity of specimens with different inclination angles β are significantly different. However, the energy absorption capability and impact velocity sensitivity of specimens with different inclination angles α do not show significant differences. When α=0°, the impact velocity sensitivity of CFRP composites in the impact velocity range of 195−392 m/s gradually declines with the increase of inclination angle β. Visualization of the penetration process and failure area indicates that the contact area and time and deformation degree are the crucial reasons for the differences in energy absorption capability and impact velocity sensitivity observed in CFRP composites. -

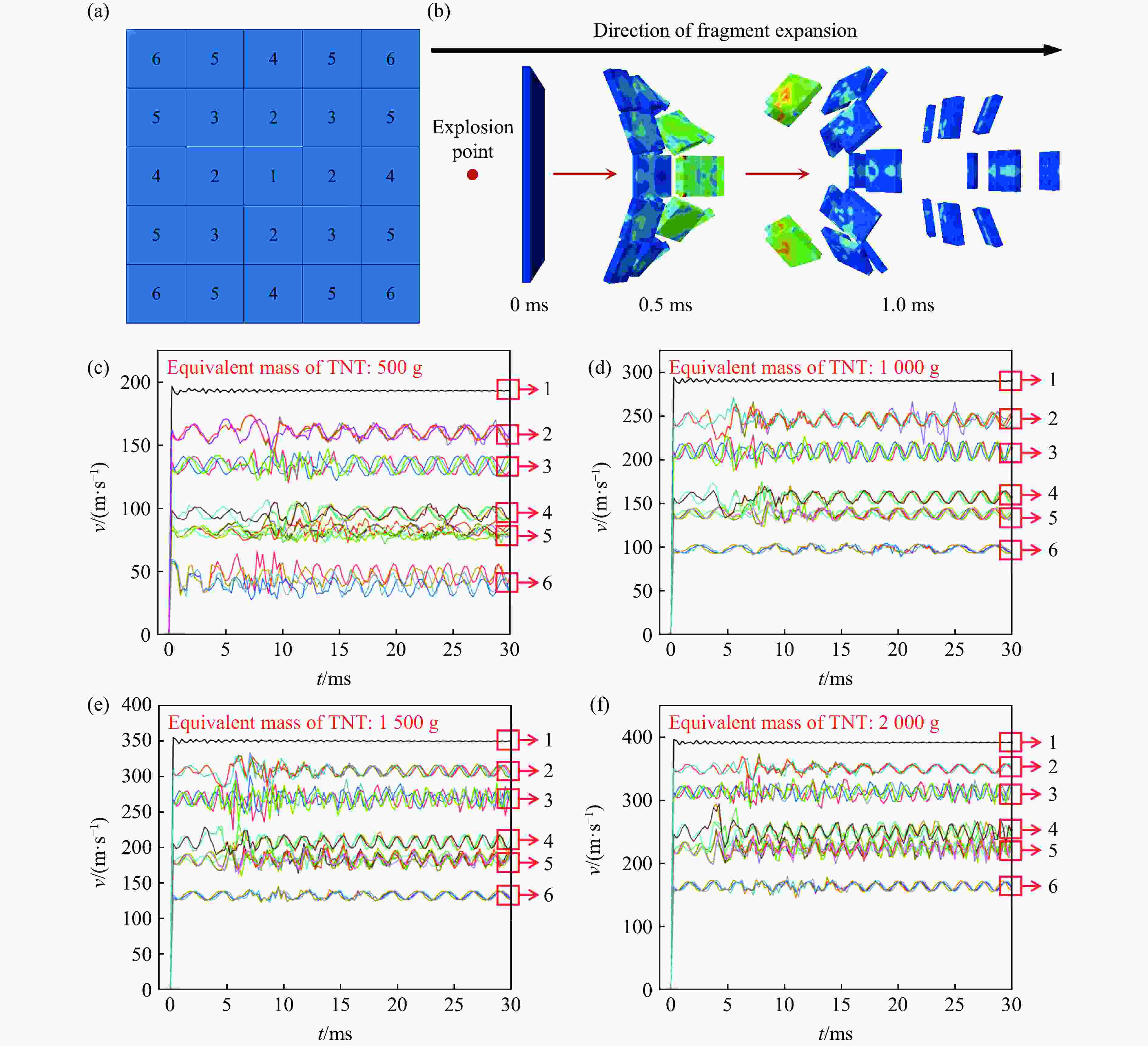

图 6 (a) 预制破片群及破片位置标注(由位置1至位置6,破片距离爆点距离增加),(b) 不同位置破片在爆炸载荷作用下的飞行姿态,(c)~(f) 500、1 000、1 500和2 000 g TNT当量下破片群中破片冲击速度随时间的变化曲线(表明位置1至位置6破片的冲击速度分布情况)

Figure 6. (a) Prefabricated fragment group and fragment location marking (from position 1 to position 6, the distance between fragment and explosion point increases); (b) the flight attitude of fragments at different locations under explosive loading; (c)−(f) is the curve of the impact velocity of each fragment in the fragment group with the TNT equivalent of 500, 1 000, 1 500 and 2 000 g, respectively, indicating the impact velocity distribution of fragments at positions 1 to 6

ρ/(g·cm −3) E11/GPa E22/GPa E33/GPa μ12 μ13 μ23 G12/GPa 1.68 139 6.655 6.655 0.0138 0.0138 0.445 3.346 G13/GPa G23/GPa F1T/MPa F2T/MPa F3T/MPa F1C/MPa F2C/MPa F3C/MPa 3.346 2.302 2961 64 64 2665 127 127 S12/MPa S13/MPa S23/MPa Gf1/(kJ·m −2) Gf2/(kJ·m −2) Gf3/(kJ·m −2) 63 63 63 62 22 22 $ t_{\mathrm{n}}^0 $/MPa $ t_{\mathrm{s}}^0 $/MPa $t_{\mathrm{t}}^0 $/MPa $ G_{\text{n}}^{\text{C}} $/(N·mm −1) $ G\mathrm{_s^C} $/(N·mm −1) $G\mathrm{_t^C} $/(N·mm −1) $ \eta $ 50 90 90 0.52 0.92 0.92 1.5 表 3 试样信息和剩余速度结果

Table 3. Specimen information and residual velocity results

Specimens α/(°) β/(°) vI/(m·s−1) vR/(m·s−1) S-A-1/S-B-1 0 0 195 −9.13 S-A-2/S-B-2 0 0 293 74.79 S-A-3/S-B-3 0 0 350 138.44 S-A-4/S-B-4 0 0 392 178.14 S-A-5 15 0 195 −12.46 S-A-6 15 0 293 61.87 S-A-7 15 0 350 122.46 S-A-8 15 0 392 169.24 S-A-9 30 0 195 −6.42 S-A-10 30 0 293 60.83 S-A-11 30 0 350 127.58 S-A-12 30 0 392 163.38 S-A-13 45 0 195 −6.75 S-A-14 45 0 293 72.79 S-A-15 45 0 350 119.09 S-A-16 45 0 392 157.46 S-B-5 0 22.5 195 −11.57 S-B-6 0 22.5 293 5.18 S-B-7 0 22.5 350 48.98 S-B-8 0 22.5 392 91.04 S-B-9 0 45.0 195 −11.90 S-B-10 0 45.0 293 −9.70 S-B-11 0 45.0 350 16.25 S-B-12 0 45.0 392 33.90 S-B-13 0 67.5 195 −13.18 S-B-14 0 67.5 293 −12.56 S-B-15 0 67.5 350 −0.87 S-B-16 0 67.5 392 8.13 S-B-17 0 90.0 195 −9.32 S-B-18 0 90.0 293 −8.03 S-B-19 0 90.0 350 −1.54 S-B-20 0 90.0 392 −0.45 -

[1] 廖斌斌, 周建武, 林渊, 等. CFRP层合板低速冲击响应及损伤特性研究 [J]. 高压物理学报, 2019, 33(4): 044202.LIAO B B, ZHOU J W, LIN Y, et al. Low-velocity impact behavior and damage characteristics of CFRP laminates [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 044202. [2] JIN L, ZHANG B L, CHEN F J, et al. Dynamic contribution of CFRP strips to CFRP-strengthened RC shear walls [J]. International Journal of Mechanical Sciences, 2023, 255: 108479. doi: 10.1016/j.ijmecsci.2023.108479 [3] XIANG X M, XIAO C K, LU G X, et al. Novel interaction effects enhance specific energy absorption in foam-filled CFRP tapered tubes [J]. Composite Structures, 2024, 343: 118288. doi: 10.1016/j.compstruct.2024.118288 [4] GUO H L, LIAO H H, SU M, et al. Shear strengthening of RC beams with prestressed NSM CFRP: influencing factors and analytical model [J]. Composite Structures, 2024, 342: 118262. doi: 10.1016/j.compstruct.2024.118262 [5] SERGI C, IERARDO N, SARASINI F, et al. Assessment of ply thickness and aluminum foils interleaving on the impact response of CFRP composites designed for cryogenic pressure vessels [J]. Composite Structures, 2025, 351: 118563. doi: 10.1016/j.compstruct.2024.118563 [6] ZHANG J Y, XIE J, ZHAO X Z, et al. Influence of void defects on impact properties of CFRP laminates based on multi-scale simulation method [J]. International Journal of Impact Engineering, 2023, 180: 104706. doi: 10.1016/j.ijimpeng.2023.104706 [7] 袁浩天, 刘钊, 孙文豪, 等. 聚能侵彻体作用下钢-CFRP层合板的防护性能 [J]. 高压物理学报, 2023, 37(2): 024202.YUAN H T, LIU Z, SUN W H, et al. Protective performance of steel-CFRP laminates under sharped charge projectile [J]. Chinese Journal of High Pressure Physics, 2023, 37(2): 024202. [8] BOCCARDI S, MEOLA C, CARLOMAGNO G M, et al. Effects of interface strength gradation on impact damage mechanisms in polypropylene/woven glass fabric composites [J]. Composites Part B: Engineering, 2016, 90: 179–187. doi: 10.1016/j.compositesb.2015.12.004 [9] ZHOU J W, LIAO B B, SHI Y Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates [J]. Composites Part B: Engineering, 2019, 161: 300–313. doi: 10.1016/j.compositesb.2018.10.090 [10] 彭捷, 张伟岐, 田锐, 等. 碳纤维层合板抗球形弹冲击动态响应特性试验研究 [J]. 复合材料科学与工程, 2020(6): 18–24,56.PENG J, ZHANG W Q, TIAN R, et al. Experimental study on the dynamic response of carbon fiber laminates impacted by spherical projectile [J]. Composites Science and Engineering, 2020(6): 18–24,56. [11] LIU J L, SINGH A K, LEE H P, et al. The response of bio-inspired helicoidal laminates to small projectile impact [J]. International Journal of Impact Engineering, 2020, 142: 103608. doi: 10.1016/j.ijimpeng.2020.103608 [12] 朱浩, 郭章新, 宋鲁彬, 等. 拉伸载荷下含孔复合材料层合板的力学性能及失效机理 [J]. 高压物理学报, 2017, 31(4): 373–381.ZHU H, GUO Z X, SONG L B, et al. Mechanical property and failure mechanism of composite laminates containing a circular hole under tension [J]. Chinese Journal of High Pressure Physics, 2017, 31(4): 373–381. [13] WANG J R, XIE W H, YI F J, et al. Numerical simulation on fracture mechanisms of CFRP with barely visible impact damage by hail impact [J]. Composite Structures, 2023, 305: 116499. doi: 10.1016/j.compstruct.2022.116499 [14] XING J, DU C L, HE X, et al. Finite element study on the impact resistance of laminated and textile composites [J]. Polymers, 2019, 11(11): 1798. doi: 10.3390/polym11111798 [15] XU Z, YANG F, GUAN Z W, et al. An experimental and numerical study on scaling effects in the low velocity impact response of CFRP laminates [J]. Composite Structures, 2016, 154: 69–78. doi: 10.1016/j.compstruct.2016.07.029 [16] PANKOW M, WAAS A M, YEN C F, et al. Modeling the response, strength and degradation of 3D woven composites subjected to high rate loading [J]. Composite Structures, 2012, 94(5): 1590–1604. doi: 10.1016/j.compstruct.2011.12.010 [17] DU C L, WANG H F, ZHAO Z Q, et al. A comparison study on the impact failure behavior of laminate and woven composites with consideration of strain rate effect and impact attitude [J]. Thin-Walled Structures, 2021, 164: 107843. doi: 10.1016/j.tws.2021.107843 [18] JIANG H Y, REN Y R, LIU Z H, et al. Low-velocity impact resistance behaviors of bio-inspired helicoidal composite laminates with non-linear rotation angle based layups [J]. Composite Structures, 2019, 214: 463–475. doi: 10.1016/j.compstruct.2019.02.034 [19] LI K M, NI X P, WU Q Q, et al. Carbon-based fibers: fabrication, characterization and application [J]. Advanced Fiber Materials, 2022, 4(4): 631–682. doi: 10.1007/s42765-022-00134-x [20] 邱晓清, 唐柏鉴, 任鹏, 等. 冲击波和破片对超高分子量聚乙烯板联合作用的仿真模拟 [J]. 江苏科技大学学报(自然科学版), 2020, 34(3): 6–13.QIU X Q, TANG B J, REN P, et al. Simulation of the damage of UHMWPE plate by the combined action of shock waves and fragments [J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition), 2020, 34(3): 6–13. [21] ZHOU Z P, SUN W F, ZHENG N, et al. Experimental and numerical investigation of the energy absorption characteristics of carbon-basalt hybrid fiber reinforced polymer composites under ballistic impact [J]. Composite Structures, 2024, 335: 118000. doi: 10.1016/j.compstruct.2024.118000 [22] LIU Q, GUO B Q, CHEN P W, et al. Investigating ballistic resistance of CFRP/polyurea composite plates subjected to ballistic impact [J]. Thin-Walled Structures, 2021, 166: 108111. doi: 10.1016/j.tws.2021.108111 [23] SHISHEVAN F A, AKBULUT H. Low-velocity impact behavior of carbon/basalt fiber-reinforced intra-ply hybrid composites [J]. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering, 2019, 43(1): 225–234. doi: 10.1007/s40995-017-0400-0 [24] CHEN D D, LUO Q T, MENG M Z, et al. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres [J]. Composites Part B: Engineering, 2019, 176: 107191. doi: 10.1016/j.compositesb.2019.107191 [25] ZHANG T G, SATAPATHY S S, VARGAS-GONZALEZ L R, et al. Ballistic impact response of ultra-high-molecular-weight polyethylene (UHMWPE) [J]. Composite Structures, 2015, 133: 191–201. doi: 10.1016/j.compstruct.2015.06.081 -

下载:

下载: