Blast Resistance of POZD-Coated Reinforced Concrete Beams under Contact Explosion

-

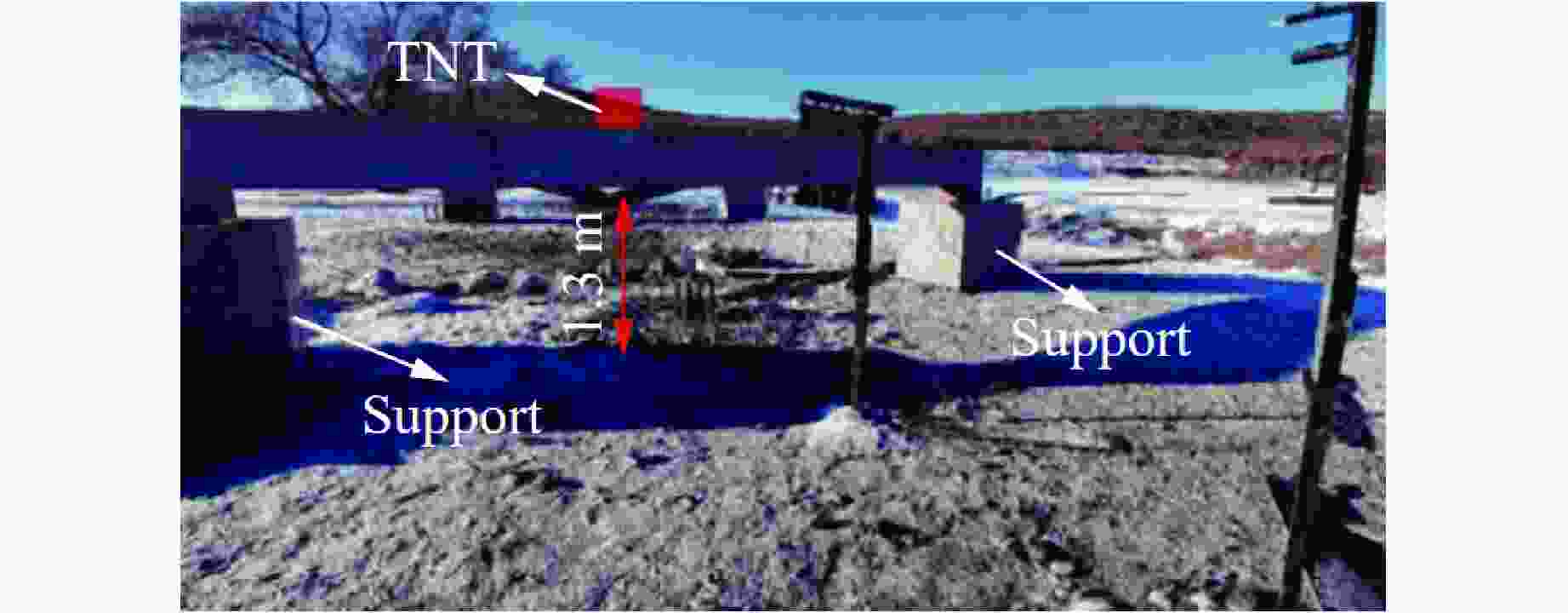

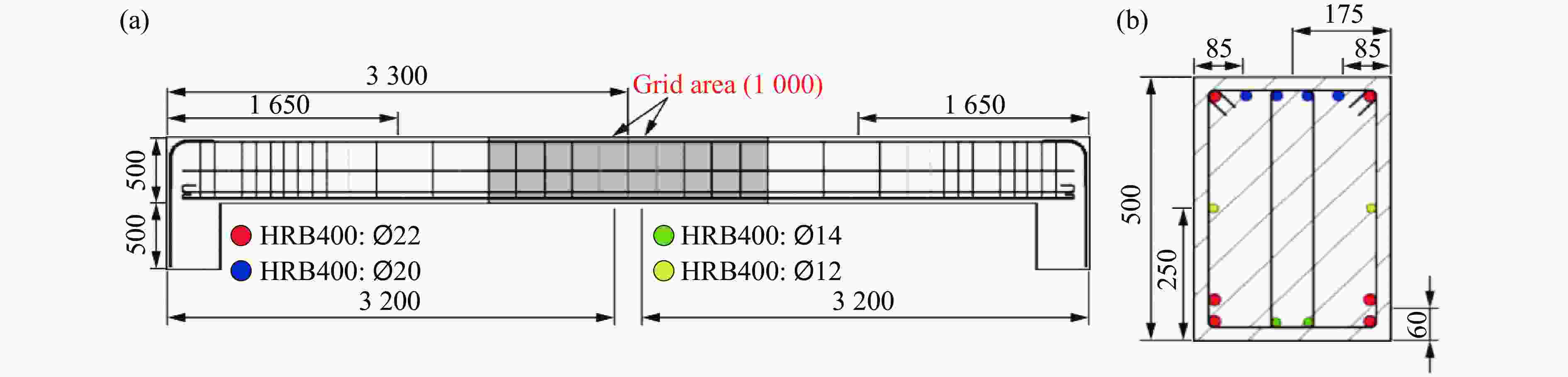

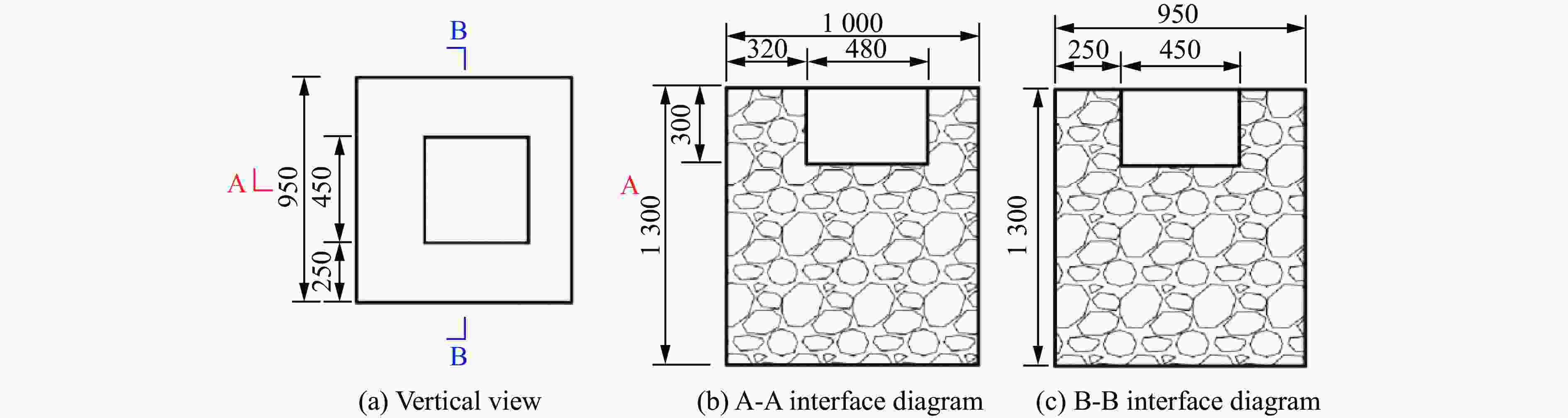

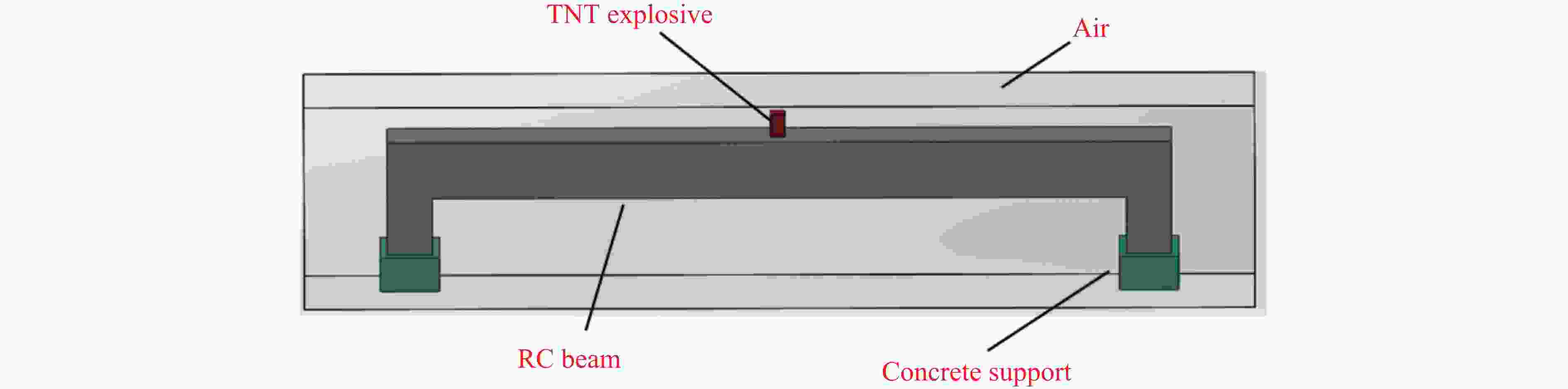

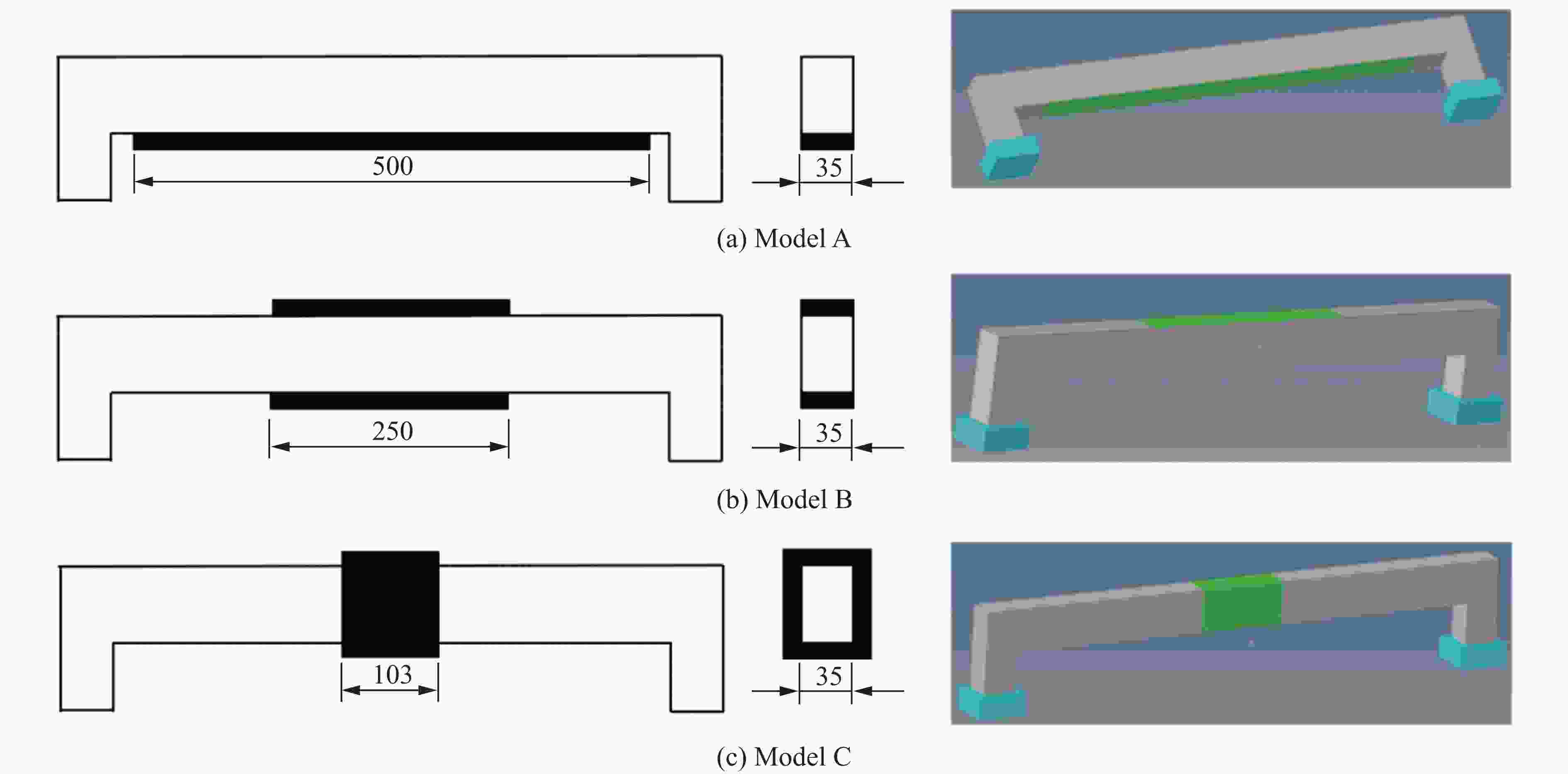

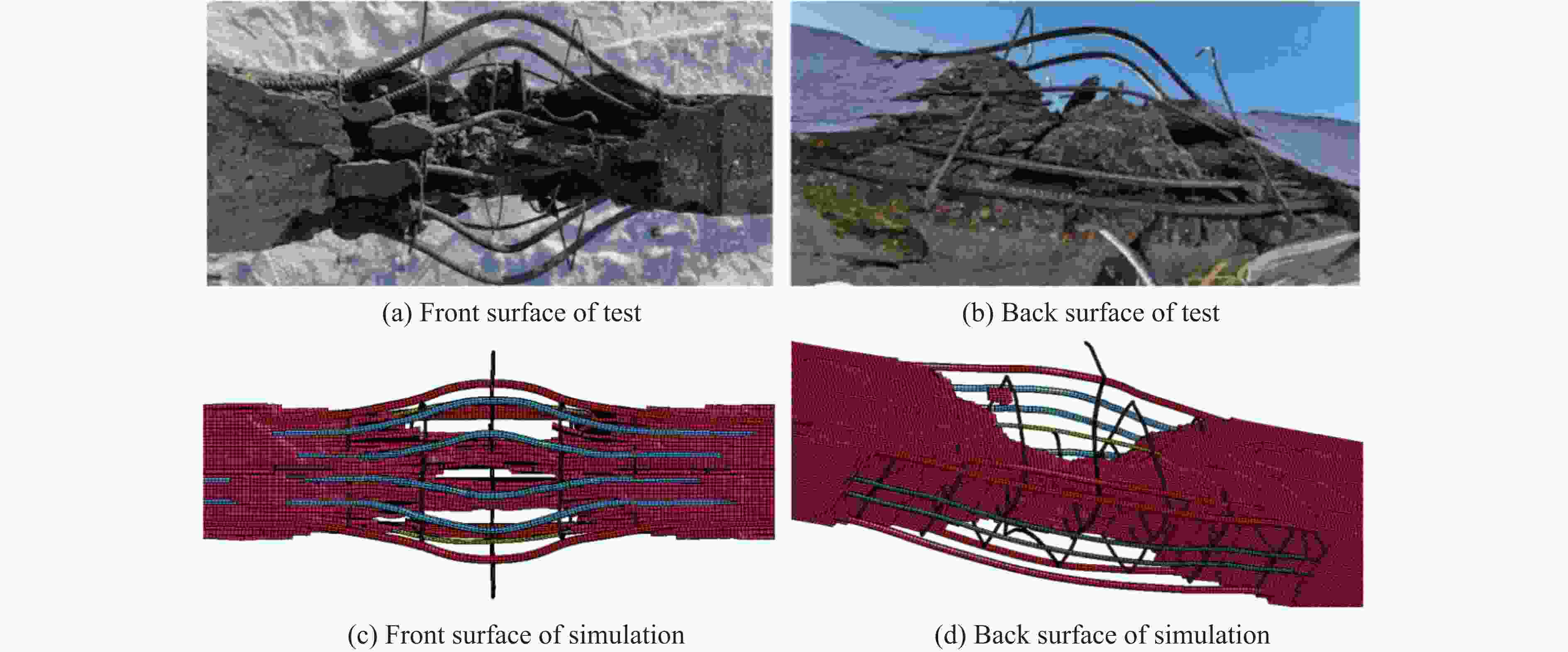

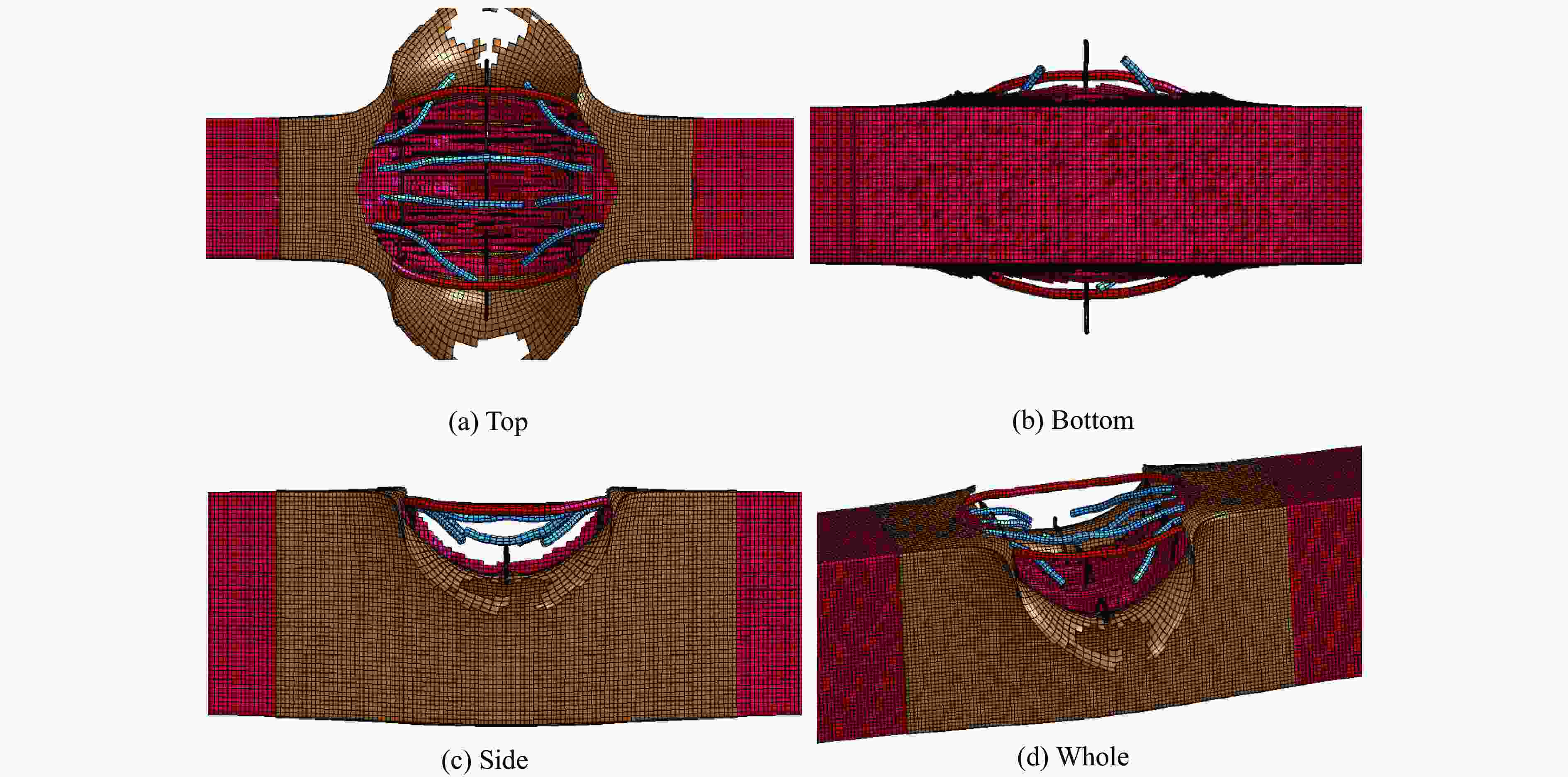

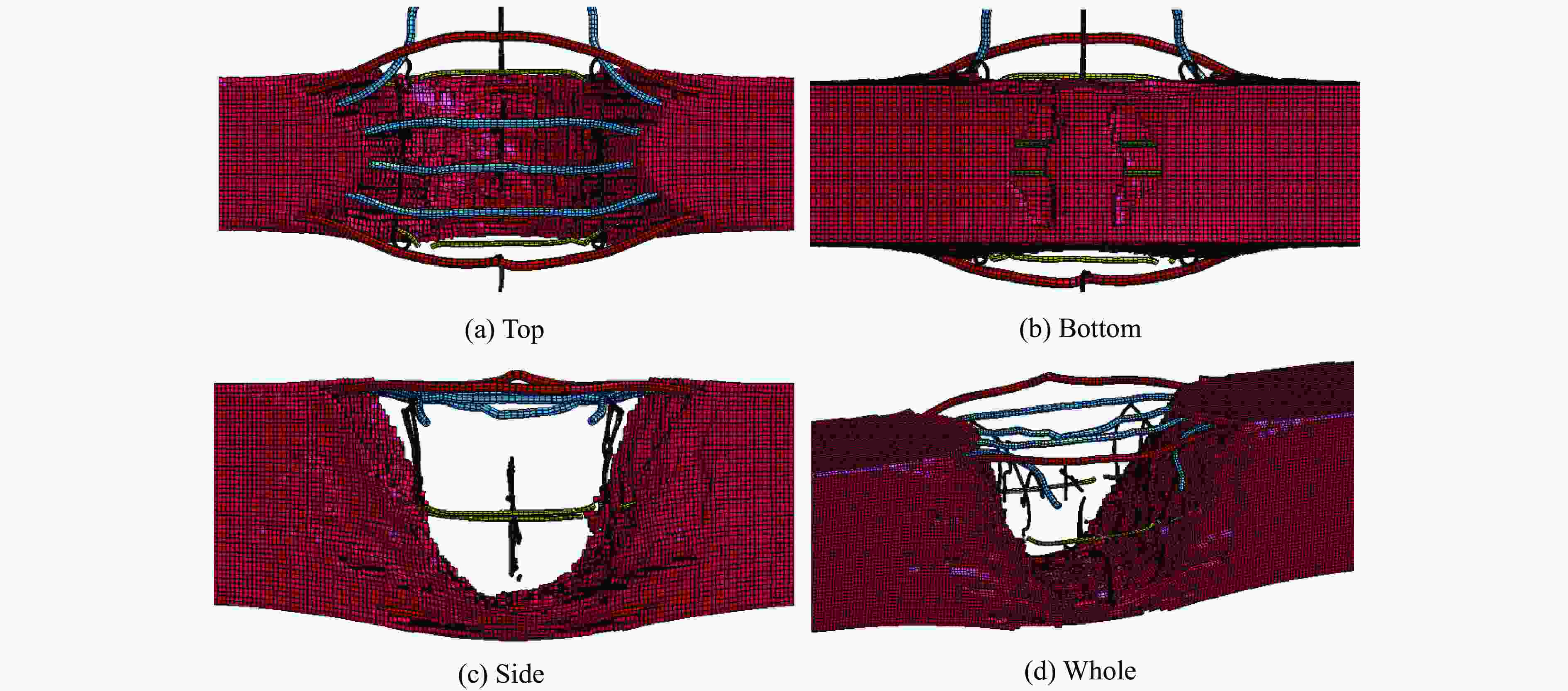

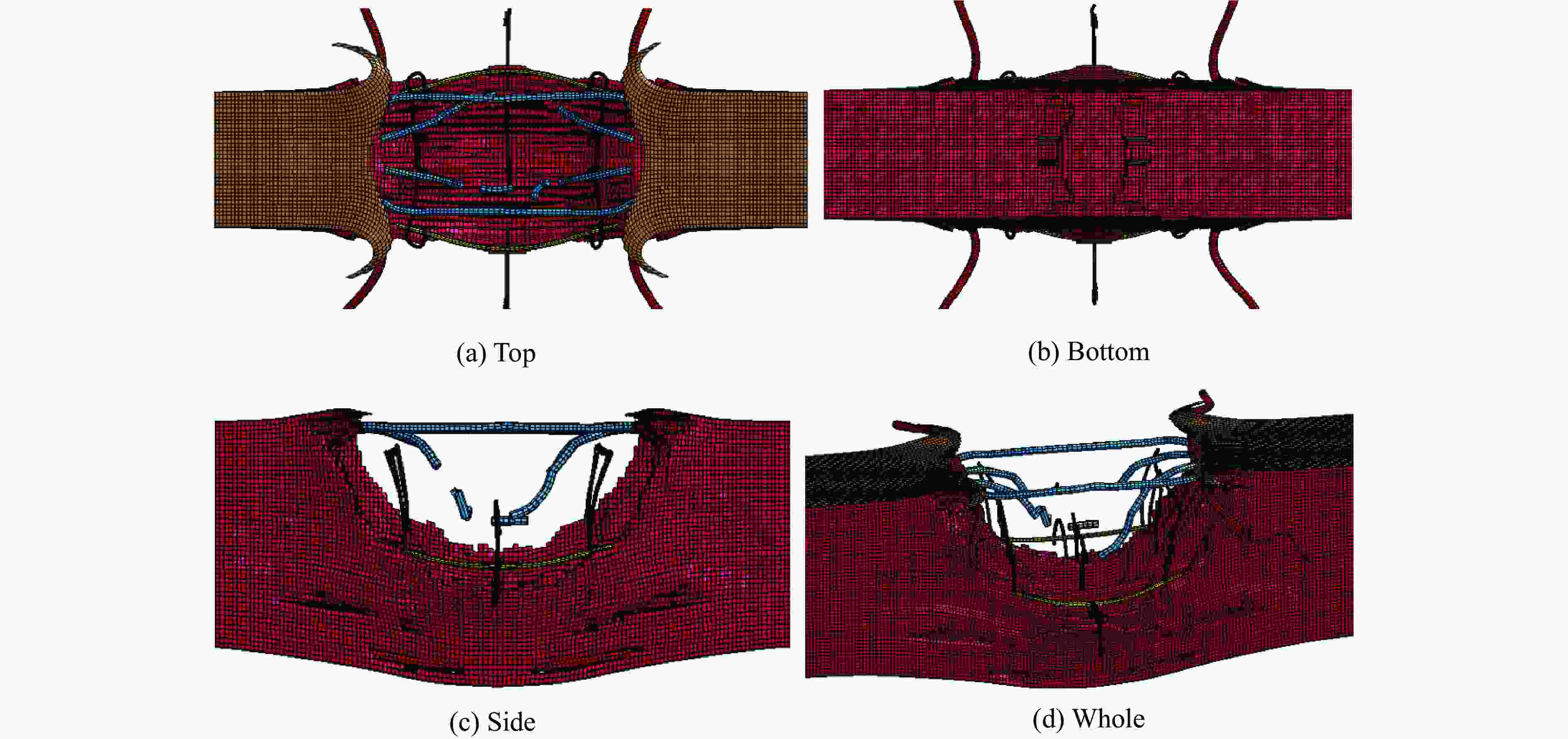

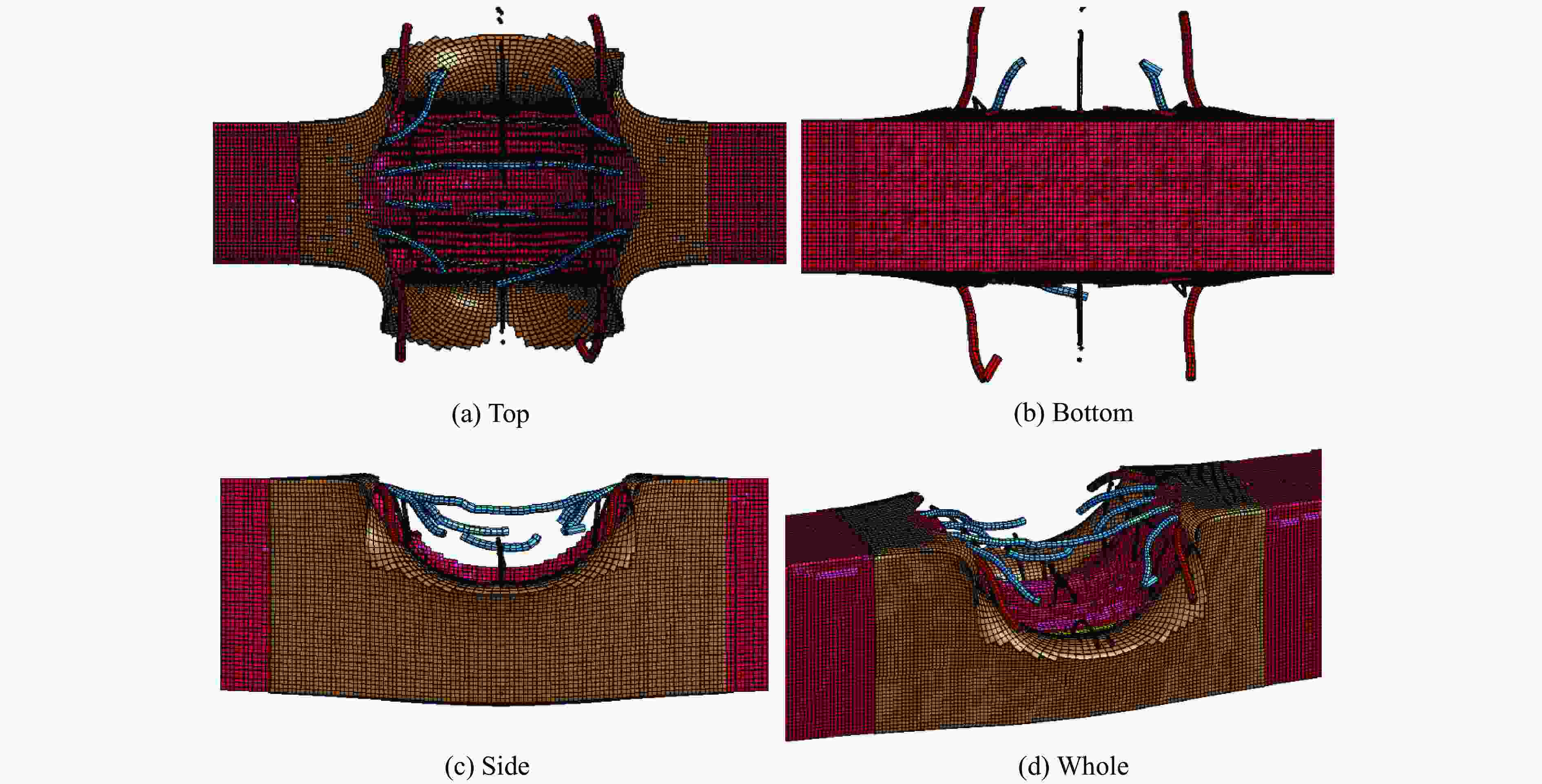

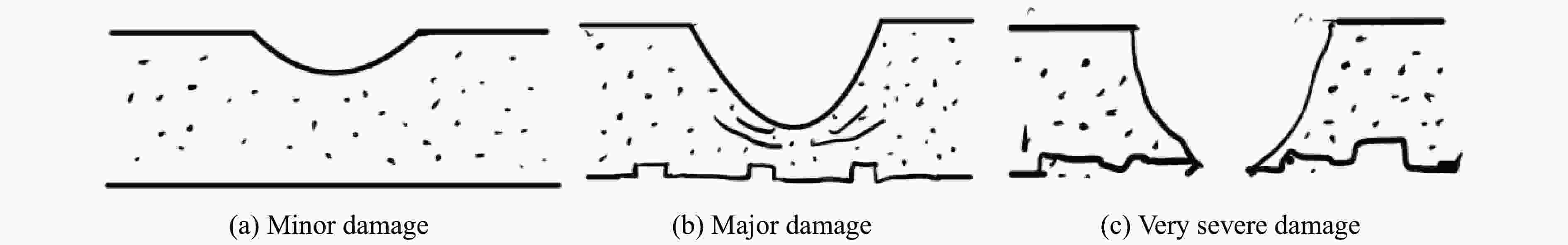

摘要: 为得到接触爆炸下聚脲(polyisocyanate-oxazodone,POZD)涂覆钢筋混凝土梁的抗爆性能,对同一尺寸的钢筋混凝土梁开展了数值模拟研究。采用HyperMesh和LS-DYNA软件建立POZD涂覆钢筋混凝土梁模型,开展了接触爆炸下POZD涂覆钢筋混凝土梁的破坏模式和毁伤效应分析。对普通钢筋混凝土梁在接触爆炸下的破坏模式进行了模拟验证试验,研究了钢筋混凝土梁结构在不同POZD涂层位置和不同装药量条件下的破坏模式和毁伤情况,并对不同POZD涂覆位置的防护效果进行了评估,最后,将接触爆炸下POZD涂覆钢筋混凝土梁划分为3个局部毁伤等级。Abstract: In order to obtain the anti-blast performance of polyisocyanate-oxazodone (POZD) coated reinforced concrete beams under contact explosion, numerical simulation studies were carried out on reinforced concrete beams of the same size. Hypemesh and LS-DYNA were used to establish the model of POZD-coated reinforced concrete beams, and the failure modes and damage effects of POZD-coated reinforced concrete beams under contact explosion were analyzed. The failure mode of ordinary reinforced concrete beams under contact explosion was simulated and verified, the failure modes and damage conditions of reinforced concrete beams under different POZD coating positions and different charge amounts were studied, and the protective effects of different POZD coating positions were evaluated.

-

$ \rho /({\mathrm{g\cdot c{m}}}^{-3}) $ $ D_{{\mathrm{CJ}}}/(\text{km}\cdot {\text{s}}^{-\text{1}}) $ $ {p_{{\mathrm{CJ}}}}/{\text{GPa}} $ $ A/{\text{GPa}} $ $ B/{\text{MPa}} $ $ {R_1} $ $ {R_2} $ $ \omega $ 1.63 0.693 21 371.2001 32.31 4.15 0.95 0.3 $ \rho/(\mathrm{kg\cdot m}^{-3}) $ $ {C_0} $ $ {C_1} $ $ {C_2} $ $ {C_3} $ $ {C_4} $ $ {C_5} $ $ {C_6} $ 1.29 0 0 0 0 0.4 0.4 0 $ \rho /({\mathrm{g\cdot c{m}}}^{-3}) $ $ E/{\text{GPa}} $ $ \nu $ 7.83 210 0.30 $ \rho /({\mathrm{g\cdot c{m}}}^{-3}) $ $ E/{\text{GPa}} $ $ \nu $ $ \sigma _{\mathrm{s}}/{\text{GPa}} $ $ F_{\mathrm{S}} $ 7.89 206 0.30 1.724 0.500 $ \rho /({\mathrm{g\cdot c{m}}}^{-3}) $ $ {A_{\text{0}}} $/MPa Rsize/(m/inches) wUCF/(Pa/PSI) LCRATE 2.30 −45.4 3.94×10−2 145 723 $ \rho /({\mathrm{g\cdot c{m}}}^{-3}) $ $ E/{\text{MPa}} $ $ \nu $ $ {\sigma _{\mathrm{Y}}}/{\text{MPa}} $ $ G/{\text{MPa}} $ 1.02 230 0.4 1.38 3.5 表 7 3种工况下RC梁的数值模拟与试验结果对比

Table 7. Comparison of RC beam numerical simulation and test results

Mass of

TNT/kgMidspan

displacementFailure length of

front surfaceFailure length of

back surfaceDepth of crater Test/

mmSim./

mmError/

%Test/

mmSim./

mmError/

%Test/

mmSim./

mmError/

%Test/

mmSim./

mmError/

%6 330 269 18.4 1400 1337 4.5 1480 1450 2.0 210 221 5.2 8 900 805 10.6 1470 1412 3.9 1500 1628 8.5 255 269 5.5 16 Fracture Fracture 1900 1790 5.8 1690 1805 6.8 Perforation Perforation 表 8 6 kg TNT工况下迎爆面和背爆面的数值模拟结果

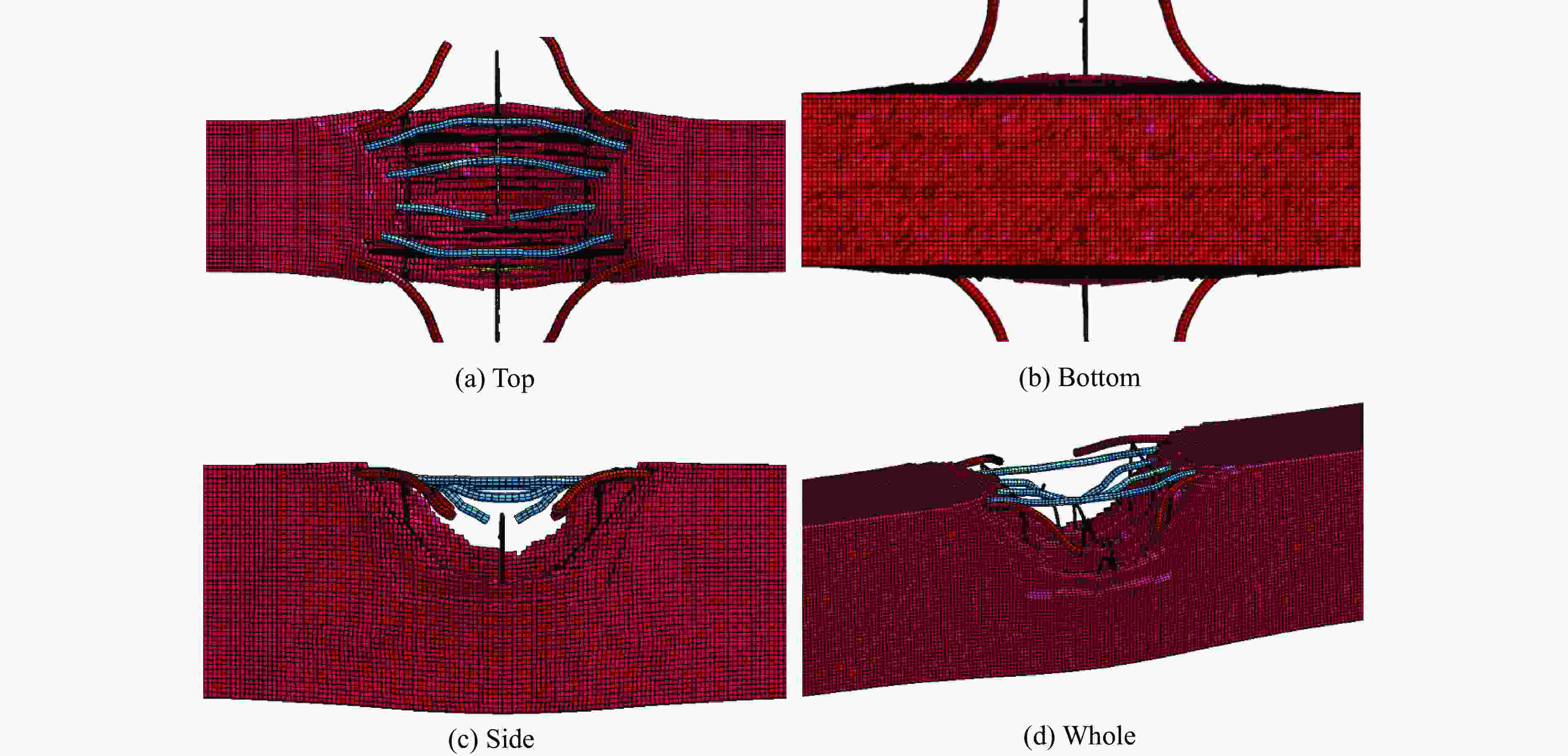

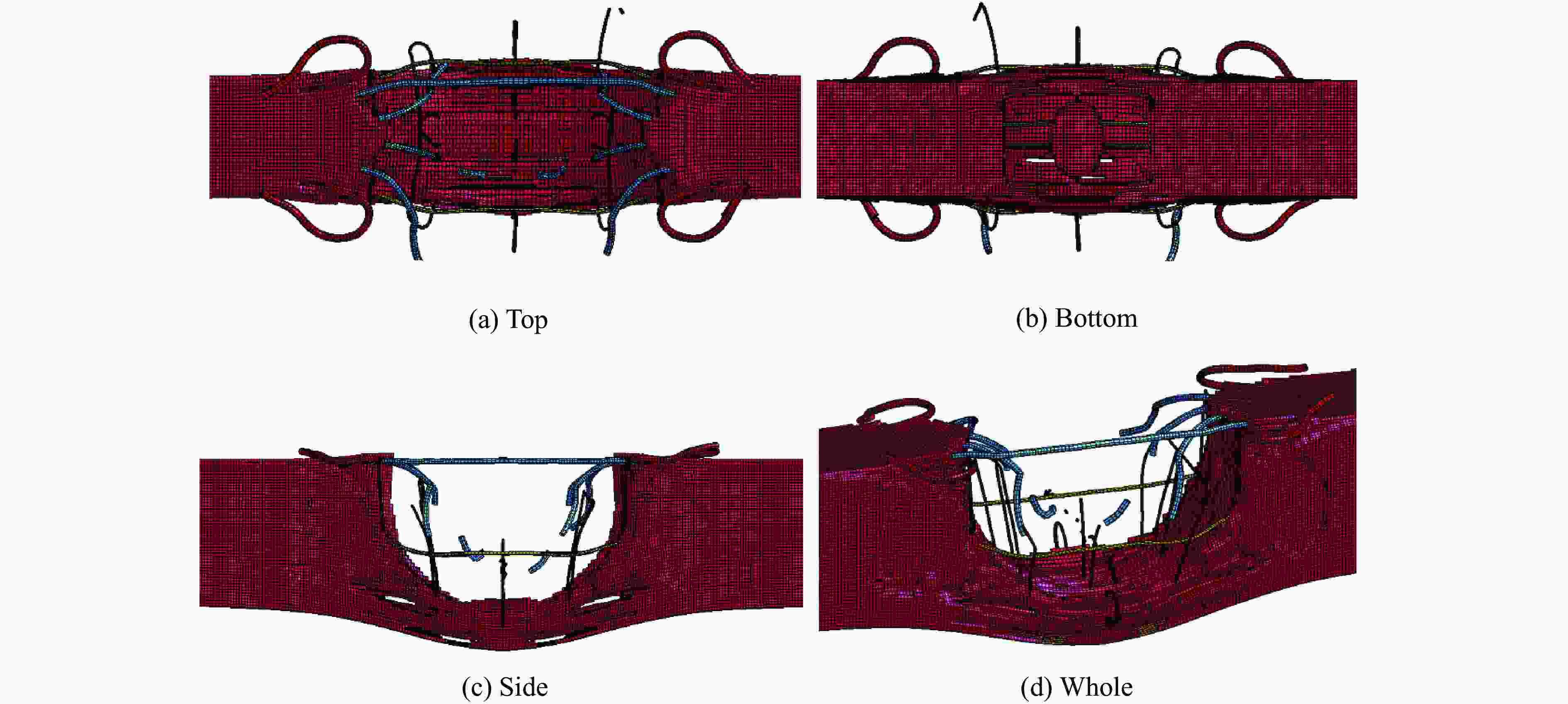

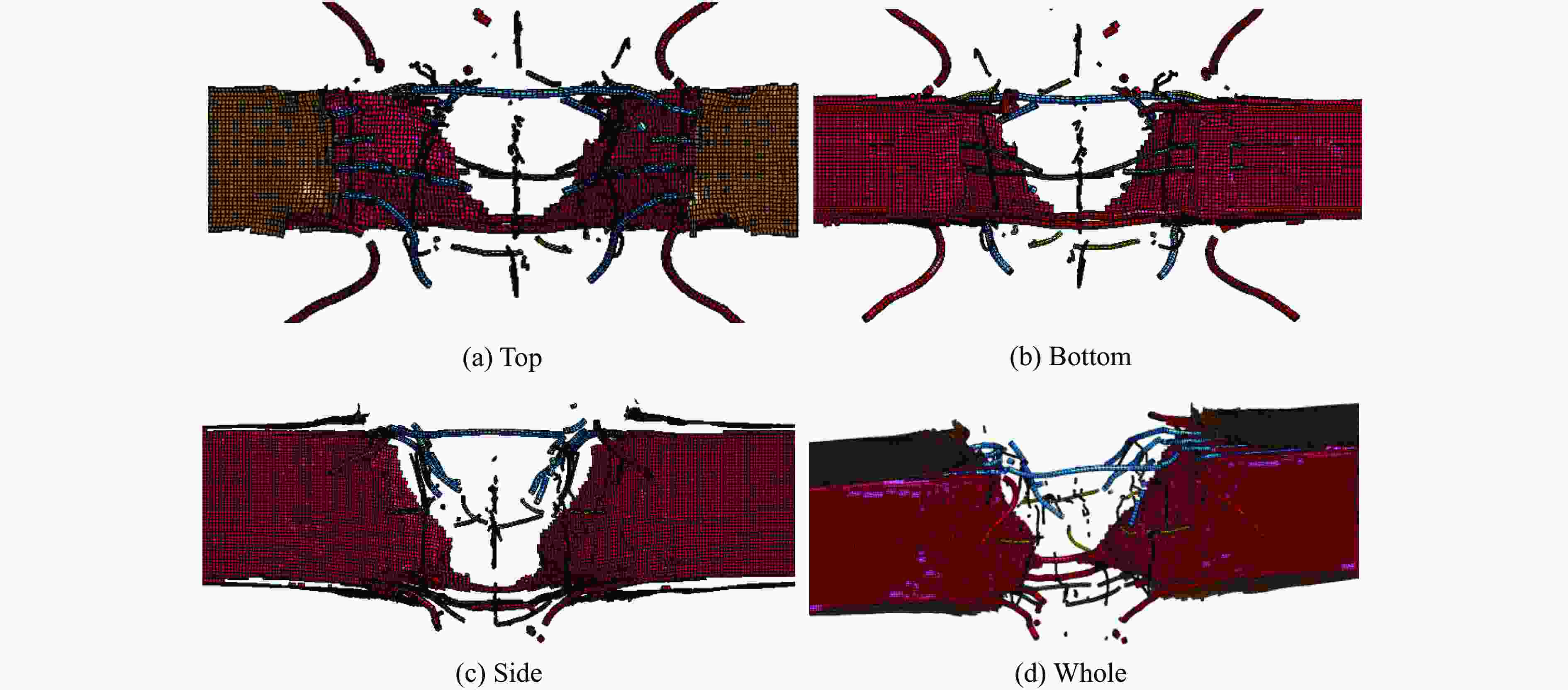

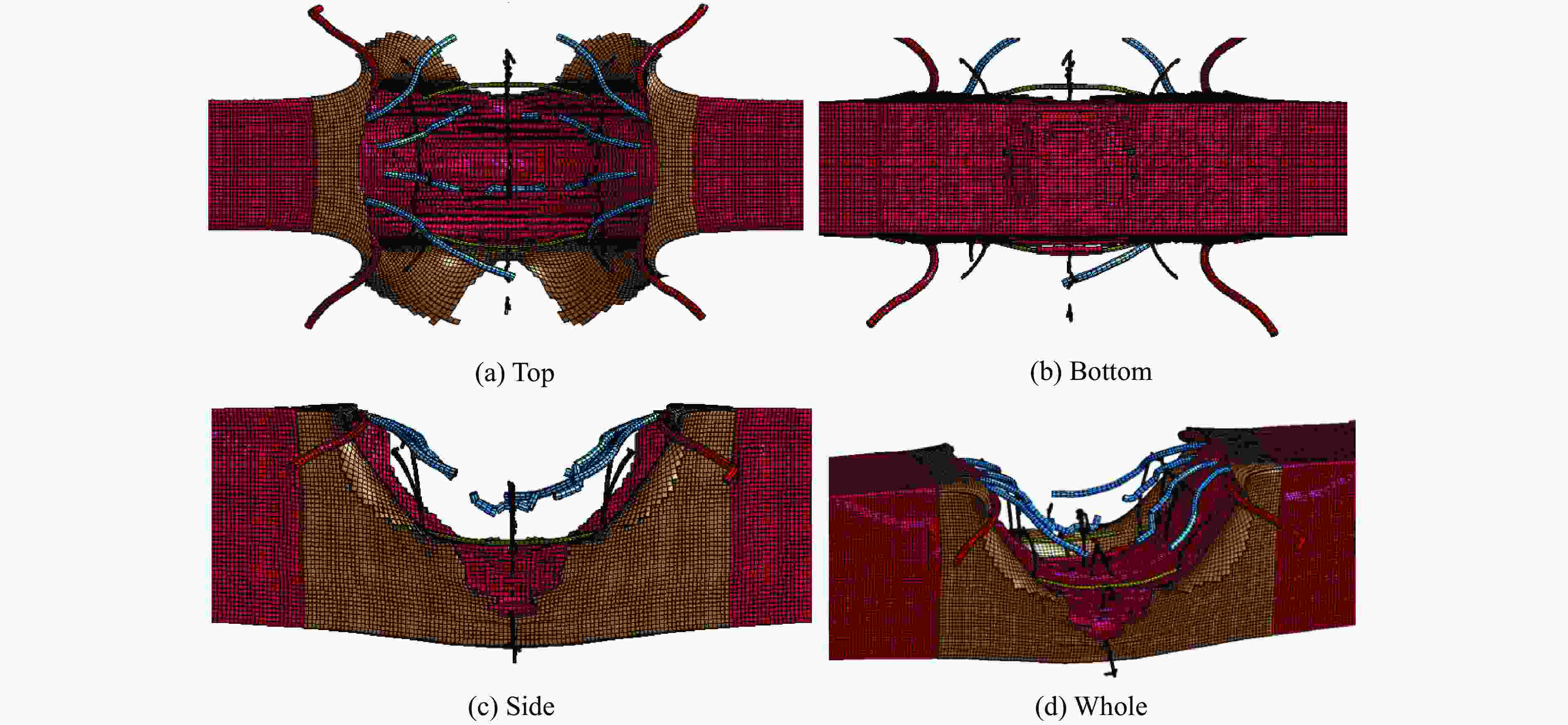

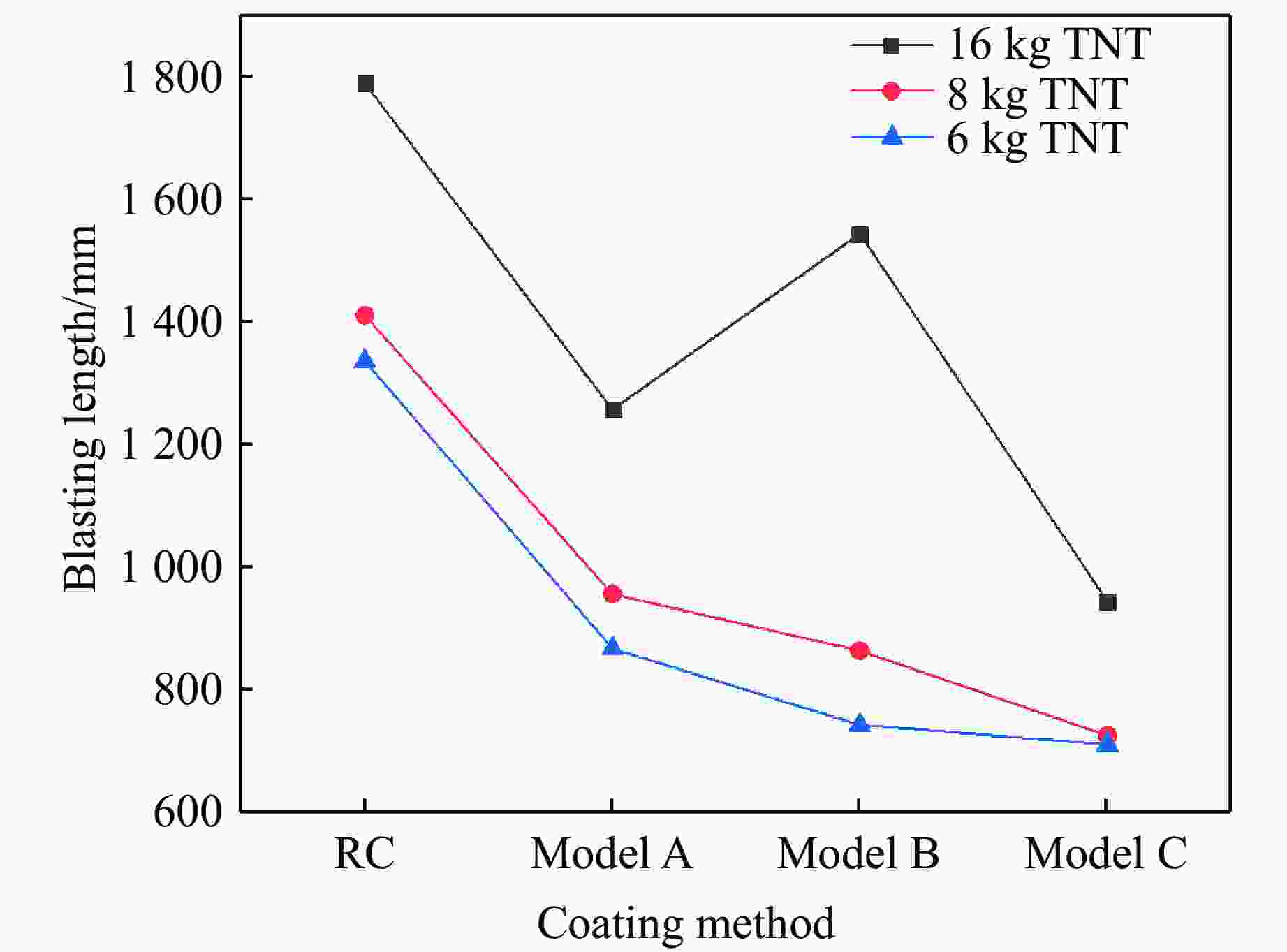

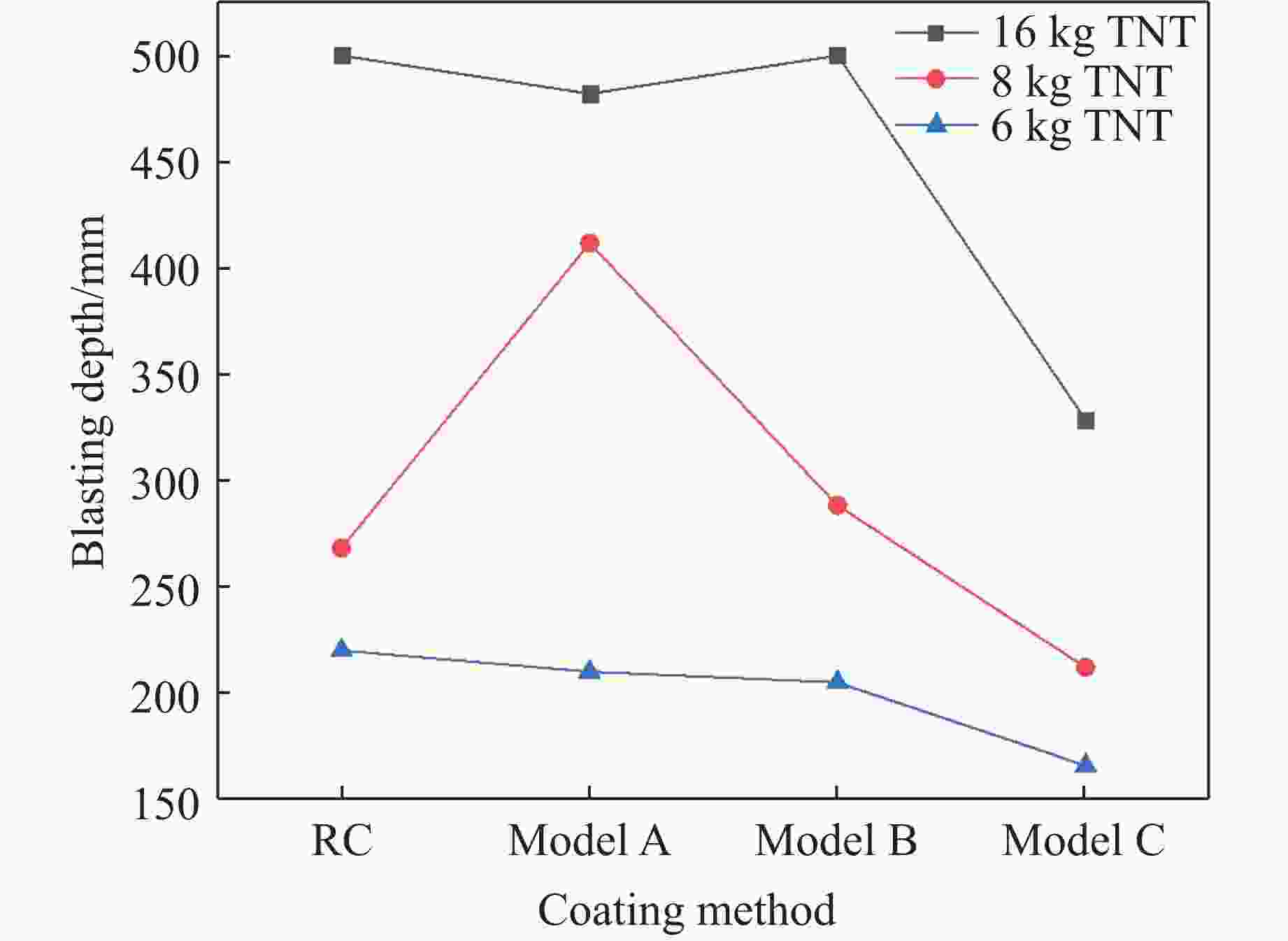

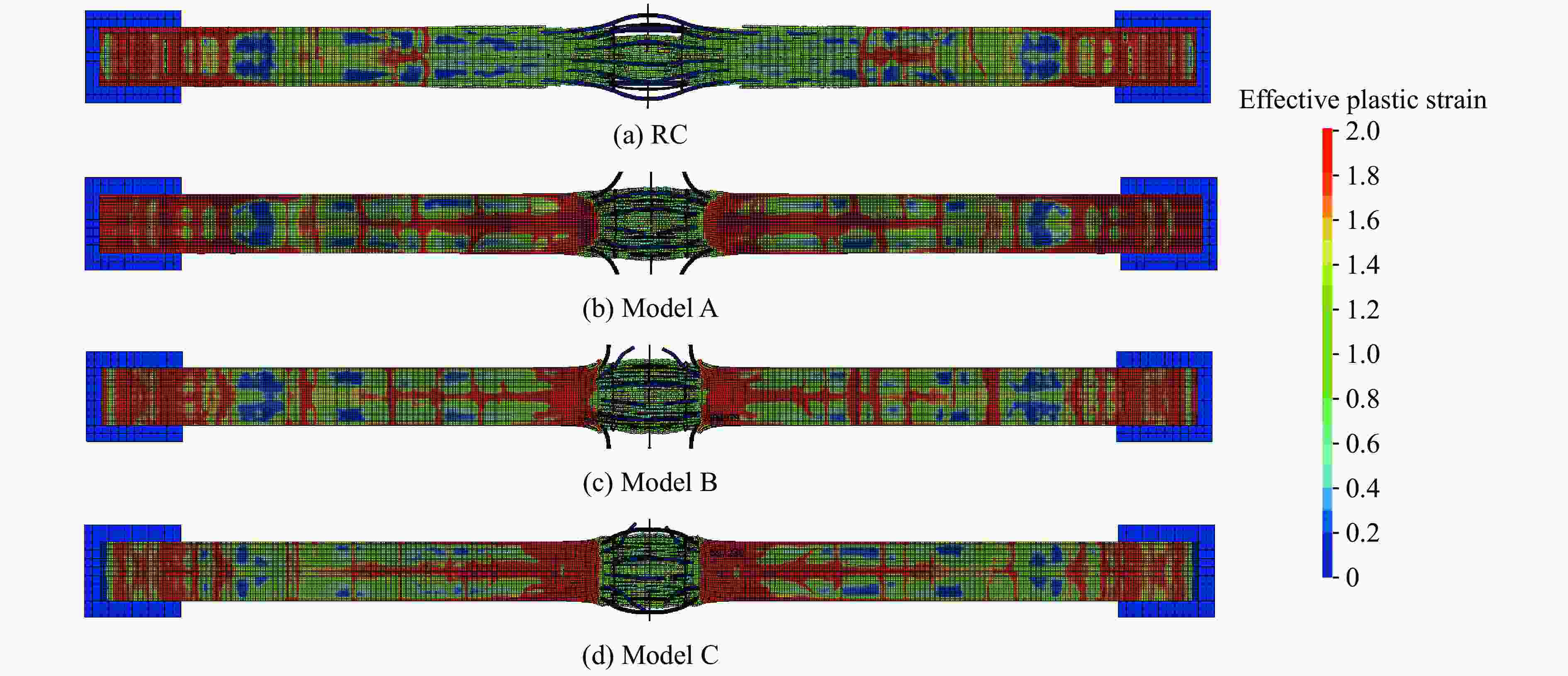

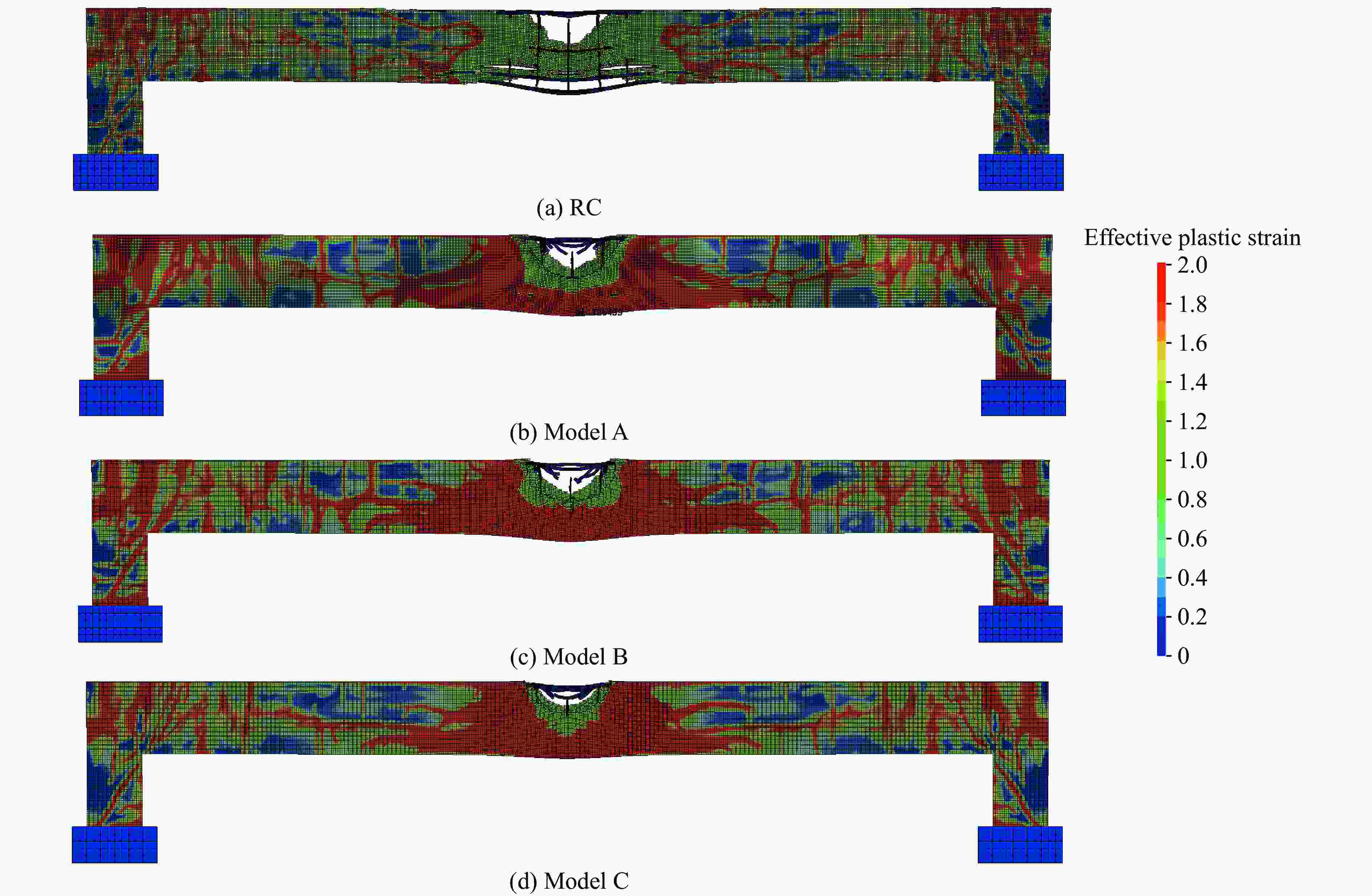

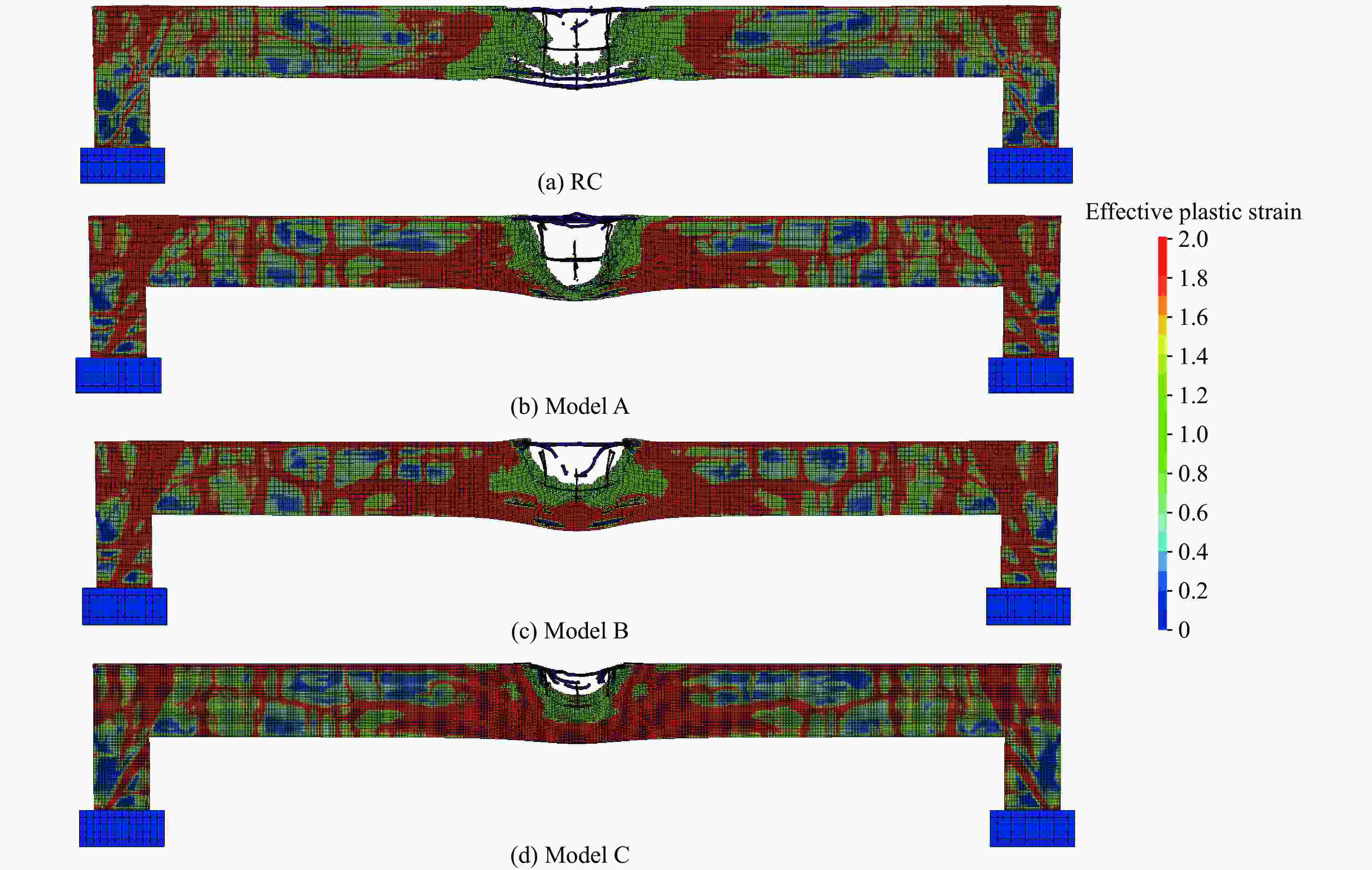

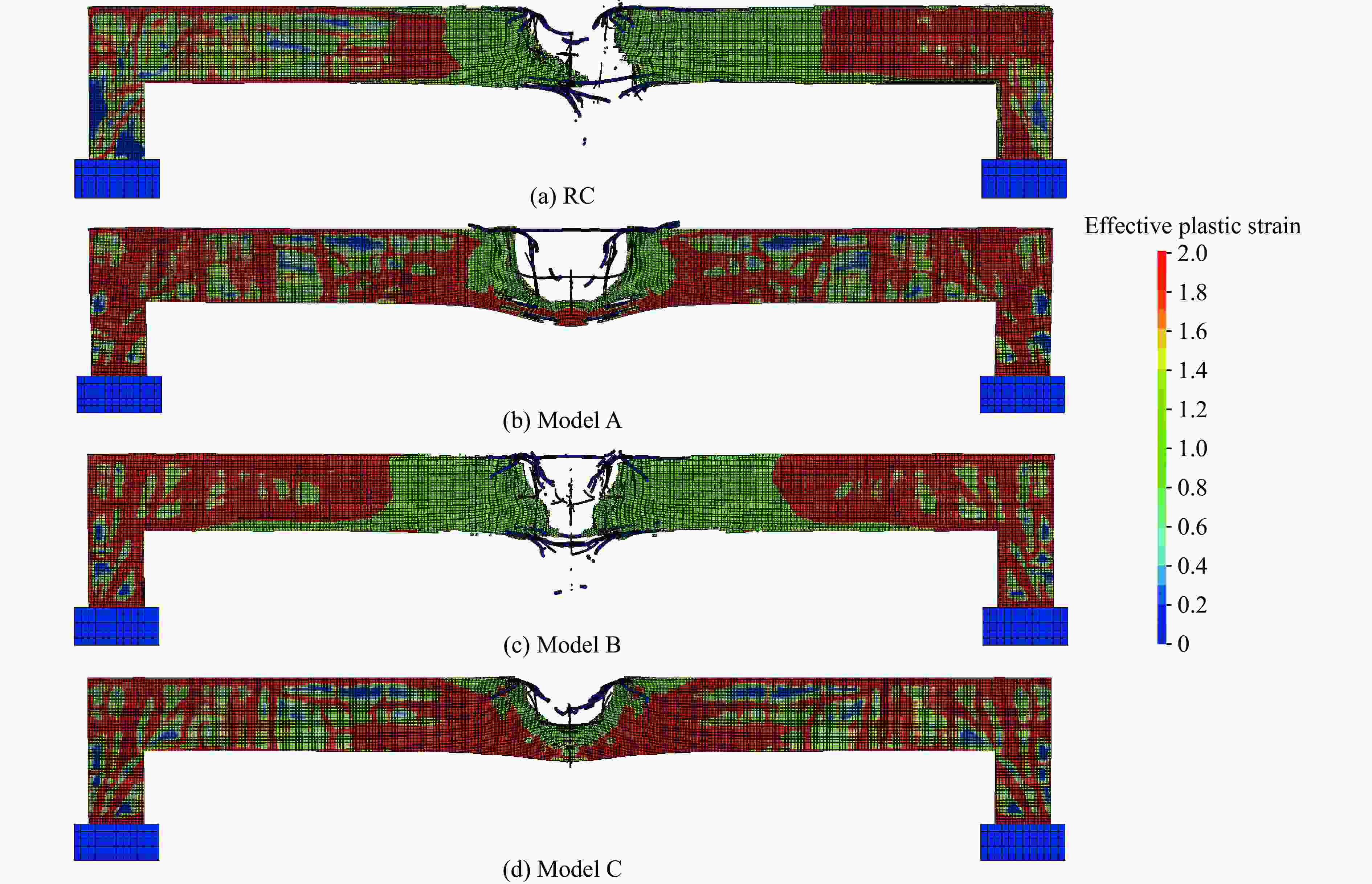

Table 8. Simulation results of the front and back surface of RC beam under 6 kg TNT

Model Failure length of front surface/mm Failure length of back surface/mm Depth of crater/mm RC 1337 1450 221 A 868 Good 211 B 744 Less peeling 206 C 712 Good 167 表 9 8 kg TNT工况下迎爆面和背爆面的数值模拟结果

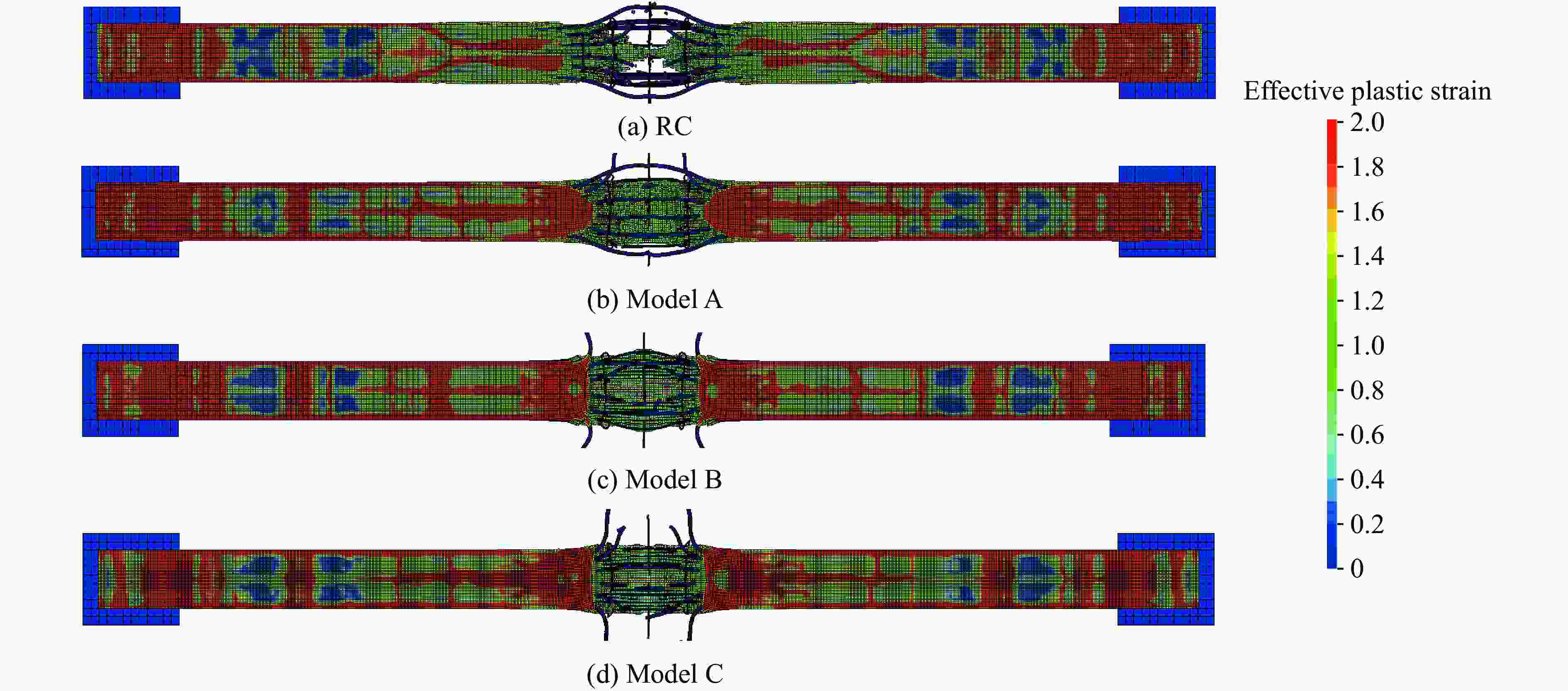

Table 9. Simulation results of the front and back surface of RC beam under 8 kg TNT

Model Failure length of front surface/mm Failure length of back surface/mm Depth of crater/mm RC 1412 1628 269 A 957 Less peeling 412 B 865 Less peeling 289 C 726 Good 213 表 10 16 kg TNT工况下迎爆面和背爆面的数值模拟结果

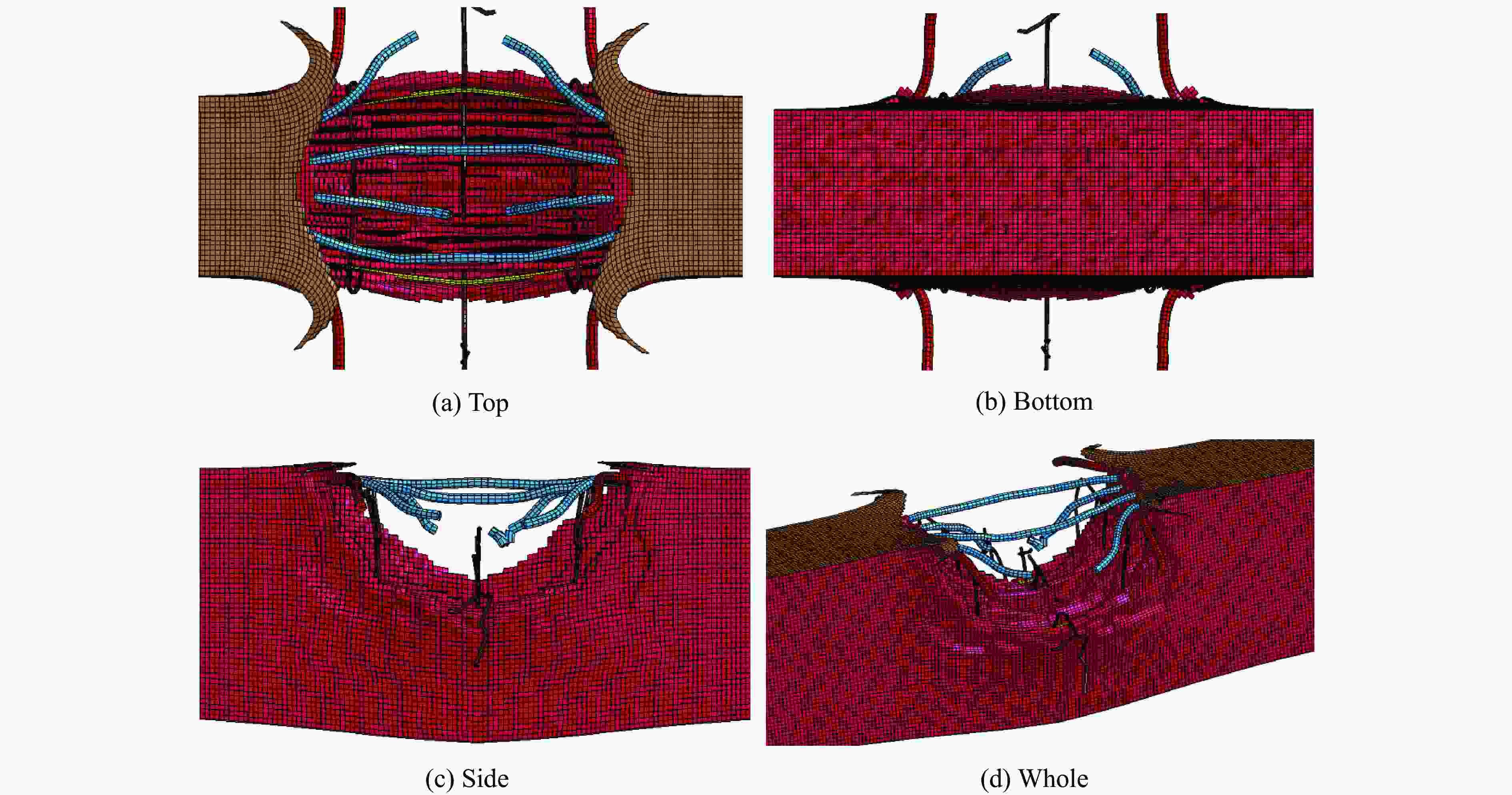

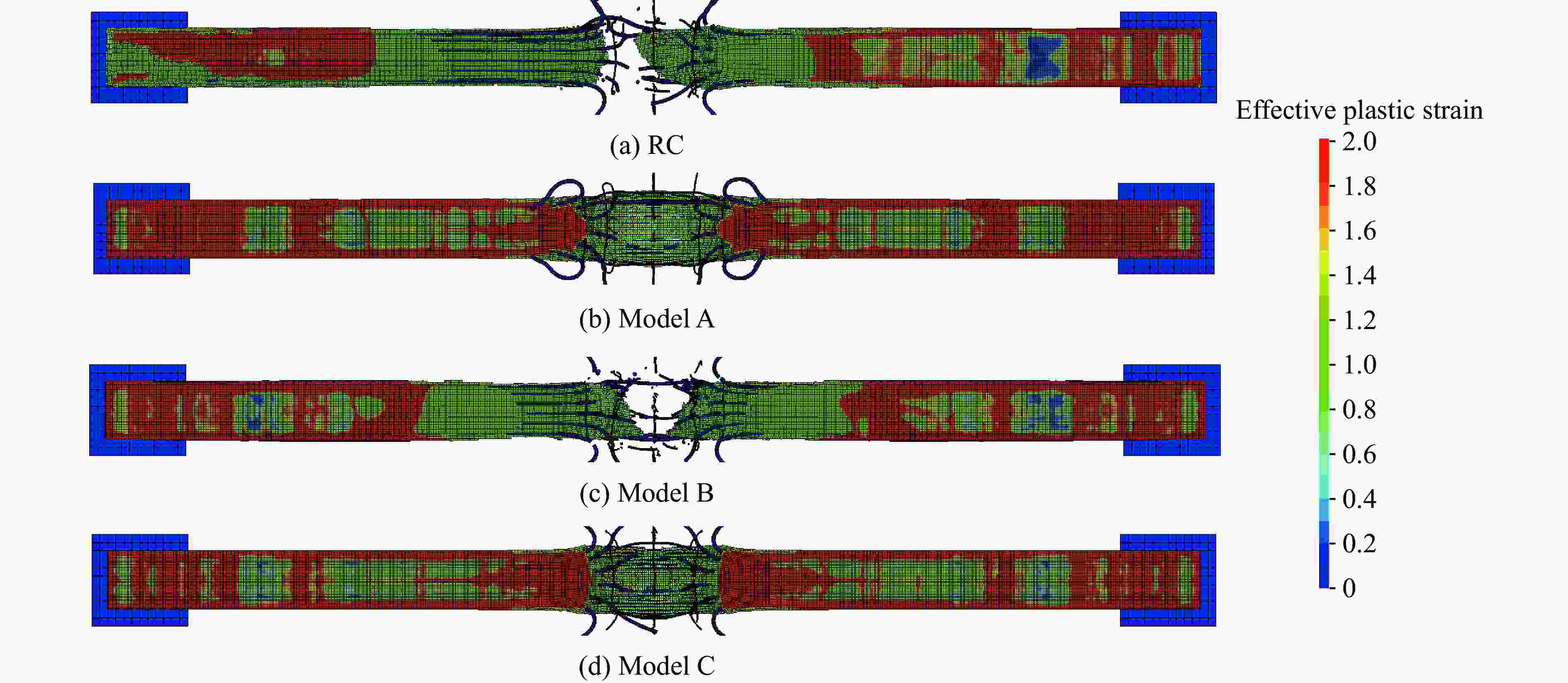

Table 10. Simulation results of the front and back surface of RC beam under 16 kg TNT

Model Failure length of front surface/mm Failure length of back surface/mm Depth of crater/mm RC 1790 1805 Perforation A 1258 More peeling 482 B 1545 1626 Perforation C 945 Less peeling 329 -

[1] 赵春风, 王强, 王静峰, 等. 近场爆炸作用下核电厂安全壳穹顶钢筋混凝土板的抗爆性能 [J]. 高压物理学报, 2019, 33(2): 025101. doi: 10.11858/gywlxb.20180598ZHAO C F, WANG Q, WANG J F, et al. Blast resistance of containment dome reinforced concrete slab in NPP under close-in explosion [J]. Chinese Journal of High Pressure Physics, 2019, 33(2): 025101. doi: 10.11858/gywlxb.20180598 [2] WANG W, WEI G S, YANG J C, et al. Study on antexplosion performance of reinforced concrete slabs strengthened with POZD coated steel plate under contact explosion [J]. Engineering Failure Analysis, 2022, 140: 106589. doi: 10.1016/j.engfailanal.2022.106589 [3] WANG W, YANG G R, YANG J C, et al. Experimental and numerical research on reinforced concrete slabs strengthened with POZD coated corrugated steel under contact explosive load [J]. International Journal of Impact Engineering, 2022, 166: 104256. doi: 10.1016/j.ijimpeng.2022.104256 [4] 吴东, 刘志鹏, 张瑞云, 等. 聚脲喷涂加固钢筋混凝土柱抗爆性能分析 [J]. 四川建筑, 2022, 42(2): 305–309. doi: 10.3969/j.issn.1007-8983.2022.02.098WU D, LIU Z P, ZHANG R Y, et al. Analysis of anti-explosive performance of reinforced concrete column [J]. Sichuan Architecture, 2022, 42(2): 305–309. doi: 10.3969/j.issn.1007-8983.2022.02.098 [5] 赵苏政, 葛文璇. 聚脲涂层防护下钢筋混凝土柱的抗爆性能研究 [J]. 工程爆破, 2022, 28(6): 85–91. doi: 10.19931/j.EB.20210253ZHAO S Z, GE W X. Study on anti-detonation performance of reinforced concrete columns protected by polyurea coating [J]. Engineering Blasting, 2022, 28(6): 85–91. doi: 10.19931/j.EB.20210253 [6] 徐赵威, 汪维, 李奕硕, 等. 接触爆炸下聚脲/钢筋混凝土厚板复合结构的抗爆性能 [J]. 爆炸与冲击, 2025, 45(3): 033104. doi: 10.11883/bzycj-2024-0083XU Z W, WANG W, LI Y S, et al. Blast resistance of polyurea/reinforced concrete thick slab composite structures under contact explosion [J]. Explosion and Shock Waves, 2025, 45(3): 033104. doi: 10.11883/bzycj-2024-0083 [7] RAHEEM A H A, MAHDY M, MASHALY A A. Mechanical and fracture mechanics properties of ultra-high-performance concrete [J]. Construction and Building Materials, 2019, 213: 561–566. doi: 10.1016/j.conbuildmat.2019.03.298 [8] ZHANG C W, GHOLIPOUR G, MOUSAVI A A. State-of-the-art review on responses of RC structures subjected to lateral impact loads [J]. Archives of Computational Methods in Engineering, 2021, 28(4): 2477–2507. doi: 10.1007/s11831-020-09467-5 [9] HALLQUIST J O. LS-DYNA theory manual [M]. Livermore: Livermore Software Technology Corporation, 2006. [10] 周清, 齐麟. LS-DYNA软件中5种常用抗爆混凝土材料模型的分析与比较 [J]. 混凝土, 2019(11): 43–49. doi: 10.3969/j.issn.1002-3550.2019.11.010ZHOU Q, QI L. Analysis and comparison of 5 different common anti-explosion concrete material models of LS-DYNA software [J]. Concrete, 2019(11): 43–49. doi: 10.3969/j.issn.1002-3550.2019.11.010 [11] ZHAO C F, CHEN J Y. Damage mechanism and mode of square reinforced concrete slab subjected to blast loading [J]. Theoretical and Applied Fracture Mechanics, 2013, 63/64: 54–62. doi: 10.1016/j.tafmec.2013.03.006 [12] 王喜梦, 刘均, 陈长海, 等. 近距空爆载荷下钢板/聚脲复合结构动响应特性仿真 [J]. 中国舰船研究, 2021, 16(2): 116–124. doi: 10.19693/j.issn.1673-3185.01833WANG X M, LIU J, CHEN C H, et al. Simulation on dynamic response characteristics of steel/polyurea composite structures under close-range air blast loading [J]. Chinese Journal of Ship Research, 2021, 16(2): 116–124. doi: 10.19693/j.issn.1673-3185.01833 [13] 王辉明, 刘飞, 晏麓晖, 等. 接触爆炸荷载对钢筋混凝土梁的局部毁伤效应 [J]. 爆炸与冲击, 2020, 40(12): 121404. doi: 10.11883/bzycj-2020-0171WANG H M, LIU F, YAN L H, et al. Local damage effects of reinforced concrete beams under contact explosions [J]. Explosion and Shock Waves, 2020, 40(12): 121404. doi: 10.11883/bzycj-2020-0171 [14] 陈锐林, 李康, 董琪, 等. CFRP加固钢筋混凝土板爆炸冲击作用下动力响应分析的数值模拟 [J]. 铁道科学与工程学报, 2020, 17(6): 1517–1527. doi: 10.19713/j.cnki.43-1423/u.T20180143CHEN R L, LI K, DONG Q, et al. Numerical simulation of dynamic response analysis of reinforced concrete slabs strengthened with CFRP under blast load [J]. Journal of Railway Science and Engineering, 2020, 17(6): 1517–1527. doi: 10.19713/j.cnki.43-1423/u.T20180143 [15] DAVIDSON J S, SUDAME S, DINAN R J. Development of computational models and input sensitivity study of polymer reinforced concrete masonry walls subjected to blast: AFRL-ML-TY-TR-2006-4522 [R]. Barnes Drive: Air Force Research Laboratory, 2004: 26–29. [16] WANG W, HUO Q, YANG J C, et al. Damage analysis of POZD coated square reinforced concrete slab under contact blast [J]. Defence Technology, 2021, 18(9): 1715–1726. doi: 10.1016/j.dt.2021.07.005 [17] 王逸平, 汪维, 杨建超, 等. 钢板/POZD 复合结构在近距空爆载荷下的抗爆性能 [J]. 高压物理学报, 2023, 37(1): 014104. doi: 10.11858/gywlxb.20220650WANG Y P, WANG W, YANG J C, et al. Blast resistant performance of steel/POZD composite structures under close-range air blast loading [J]. Chinese Journal of High Pressure Physics, 2023, 37(1): 014104. doi: 10.11858/gywlxb.20220650 [18] 杨光瑞, 汪维, 杨建超, 等. POZD涂覆波纹钢加固钢筋混凝土板抗爆性能 [J]. 兵工学报, 2023, 44(5): 1374–1383. doi: 10.12382/bgxb.2022.0024YANG G R, WANG W, YANG J C, et al. Blast resistance of reinforced concrete slabs strengthened with POZD coated corrugated steel [J]. Acta Armamentarii, 2023, 44(5): 1374–1383. doi: 10.12382/bgxb.2022.0024 [19] WANG W, WEI G, WANG X, et al. Structural damage assessment of RC slab strengthened with POZD coated steel plate under contact explosion [J]. Structures, 2023, 48: 31–39. doi: 10.1016/j.istruc.2022.12.090 [20] WANG W, ZHANG C, YANG G. Anti-explosion performance of a new type of polyurea-coated corrugated steel plate reinforced concrete slab [J]. International Journal of Concrete Structures and Materials, 2024, 18(1): 42. doi: 10.1186/s40069-024-00682-z -

下载:

下载: