Dynamic Response Experiment of Prefabricated Wall Panels for a Whole-Indoor Substation under Blast Loading

-

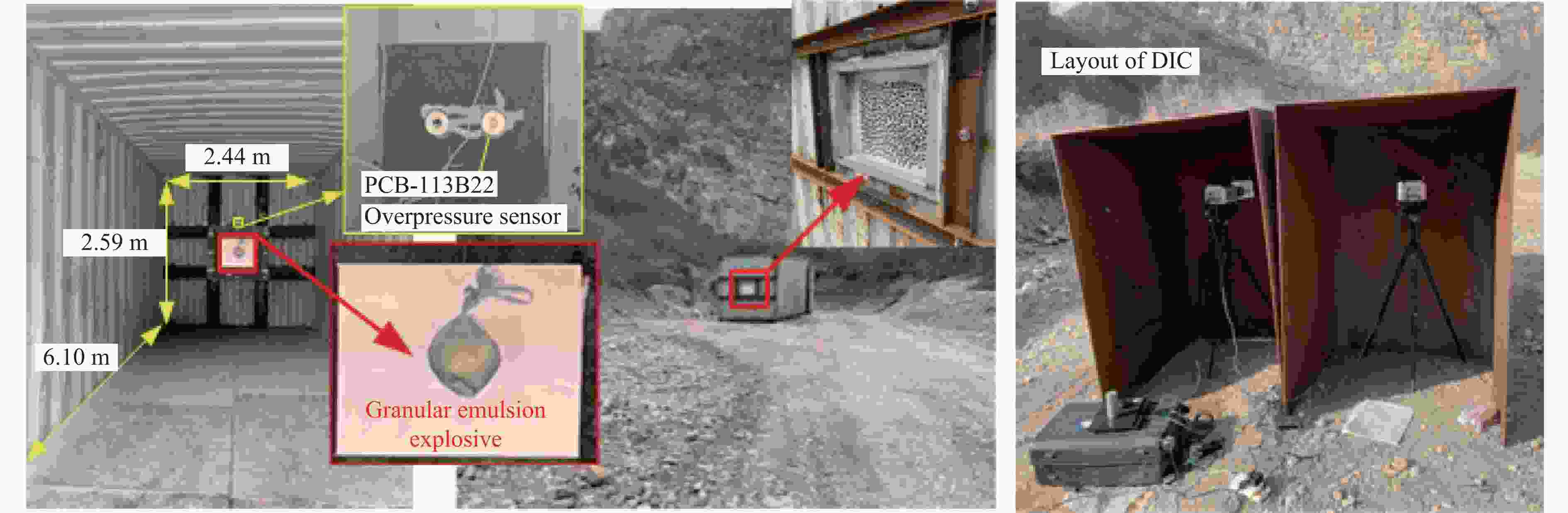

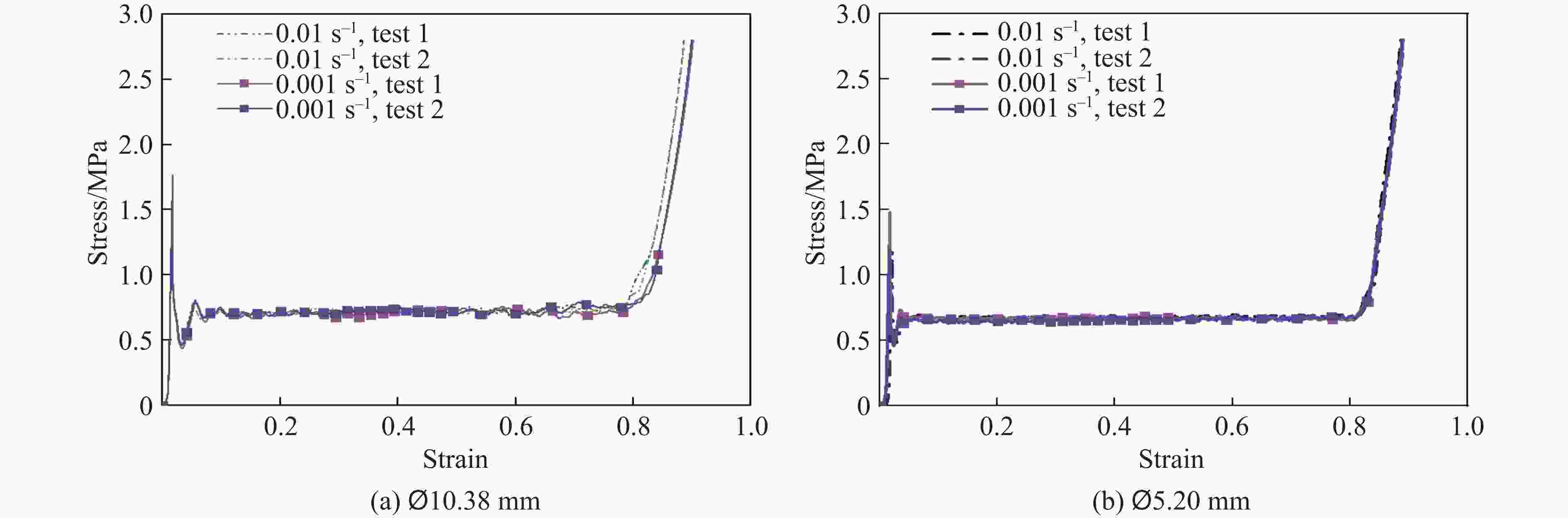

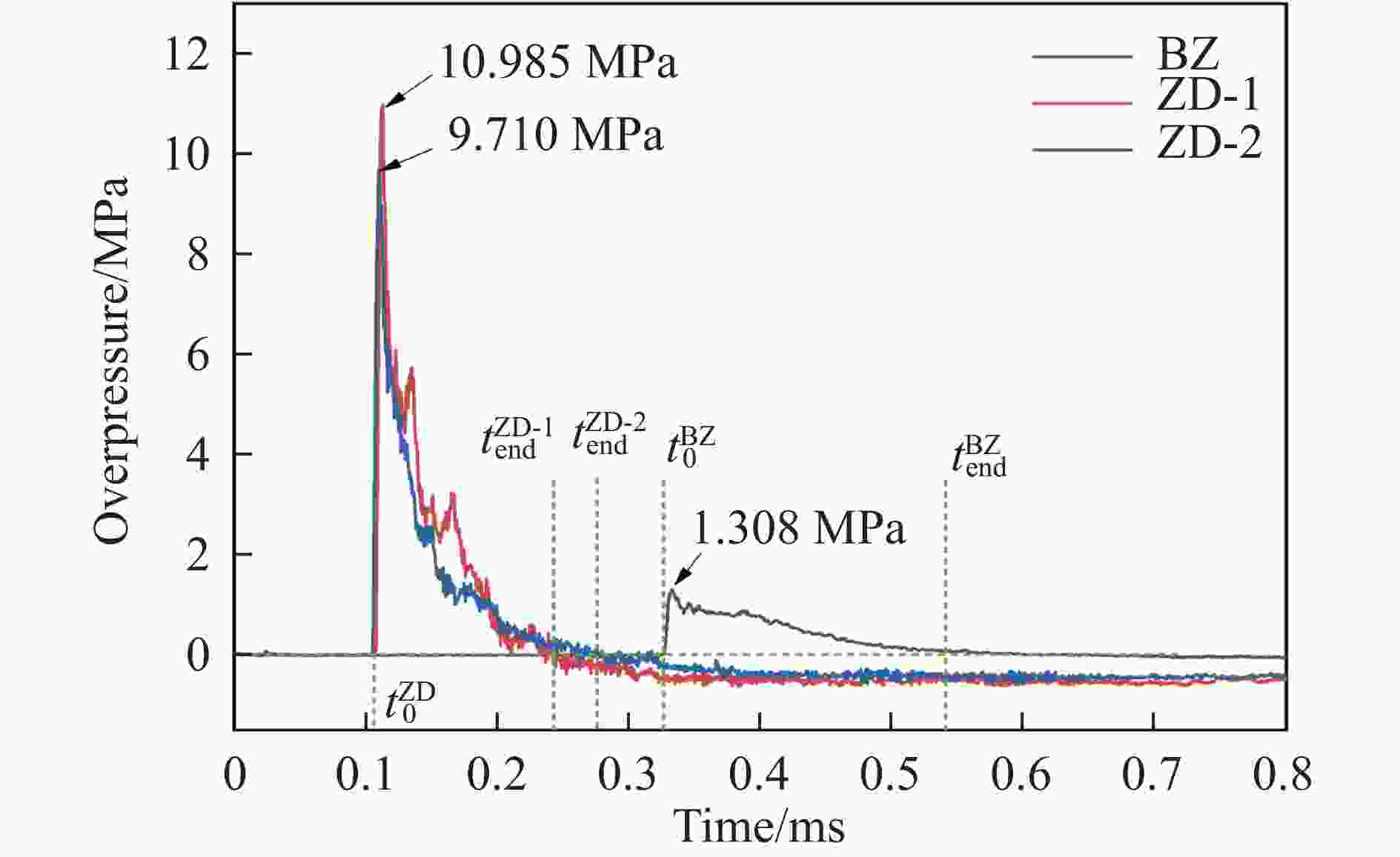

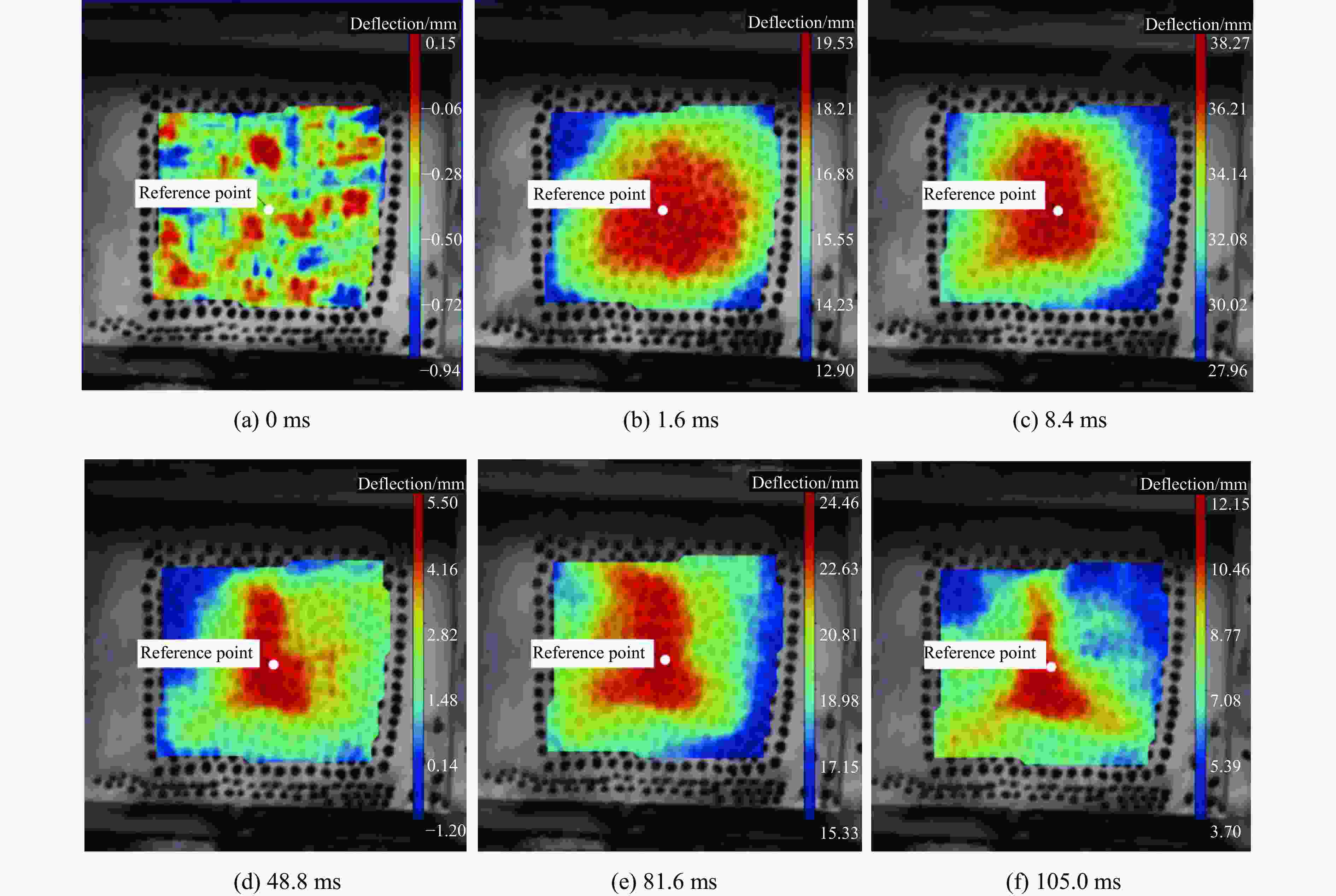

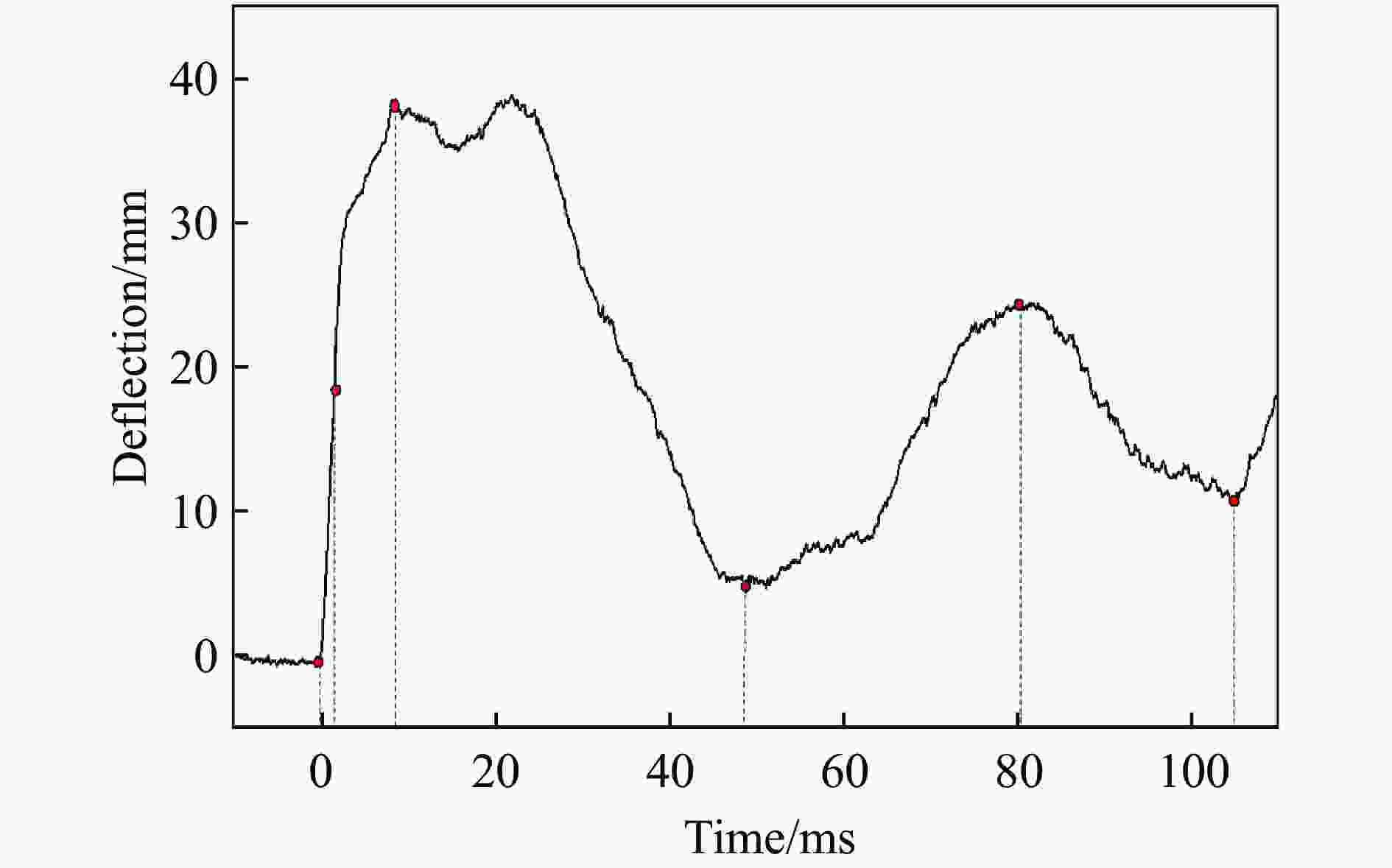

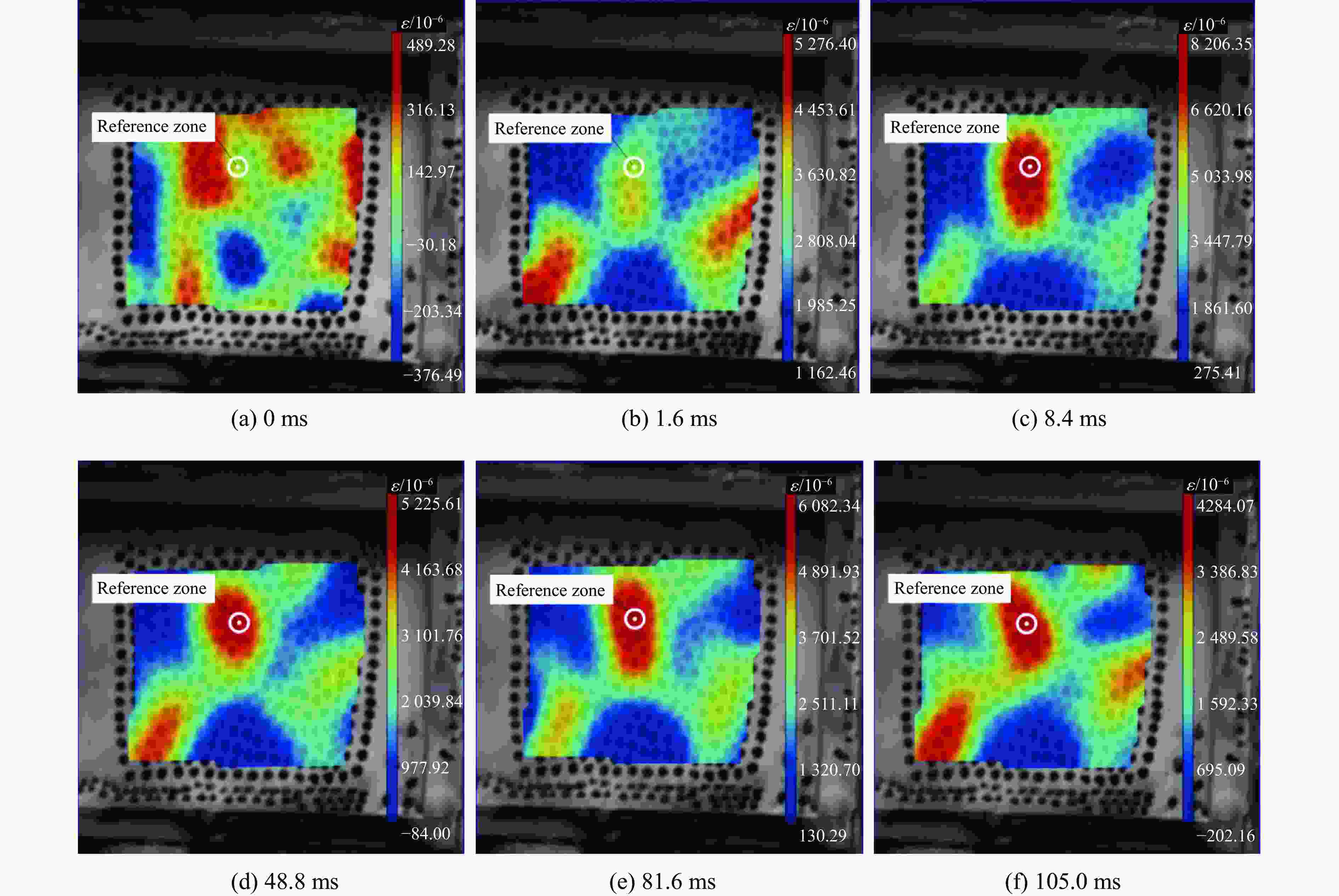

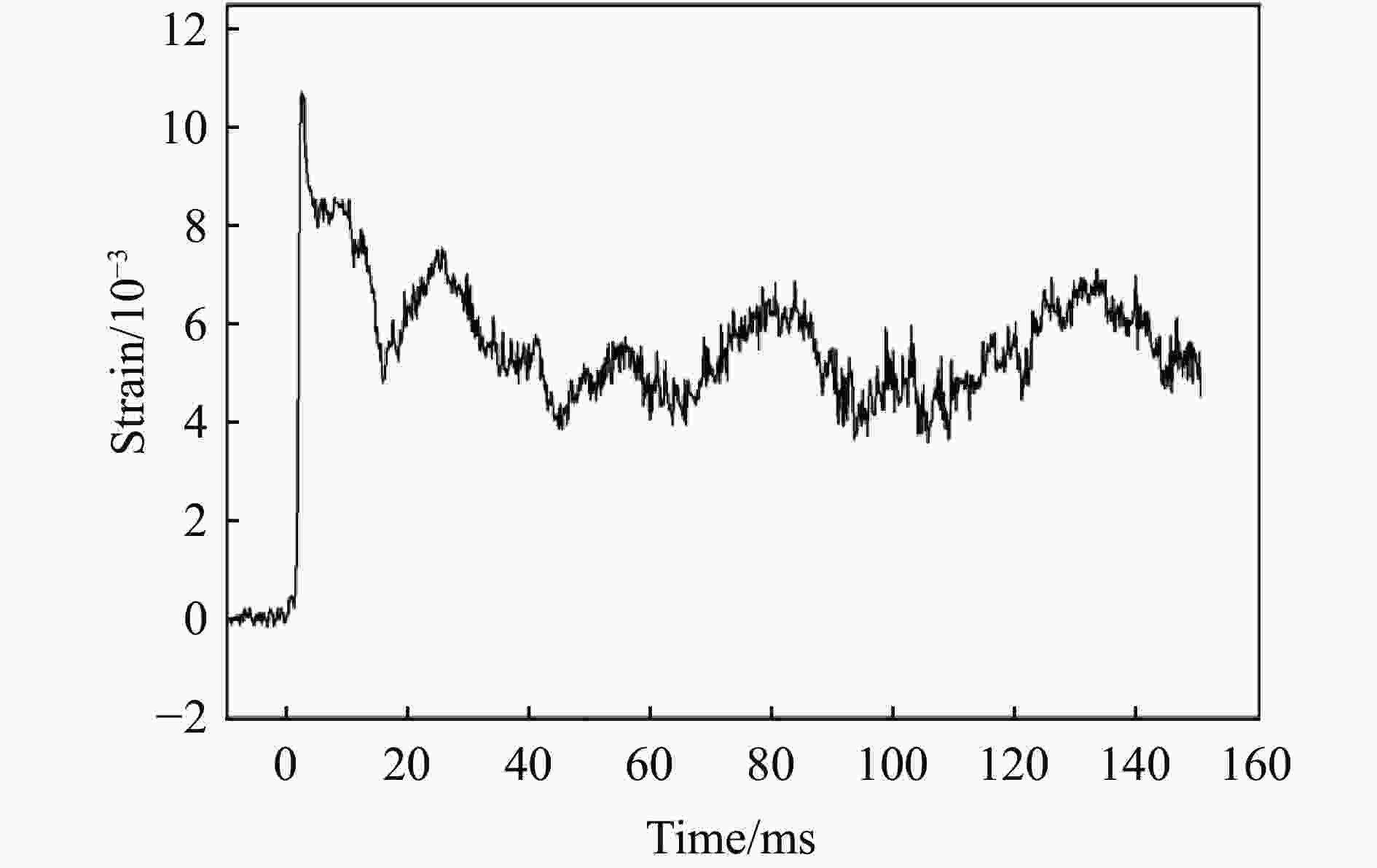

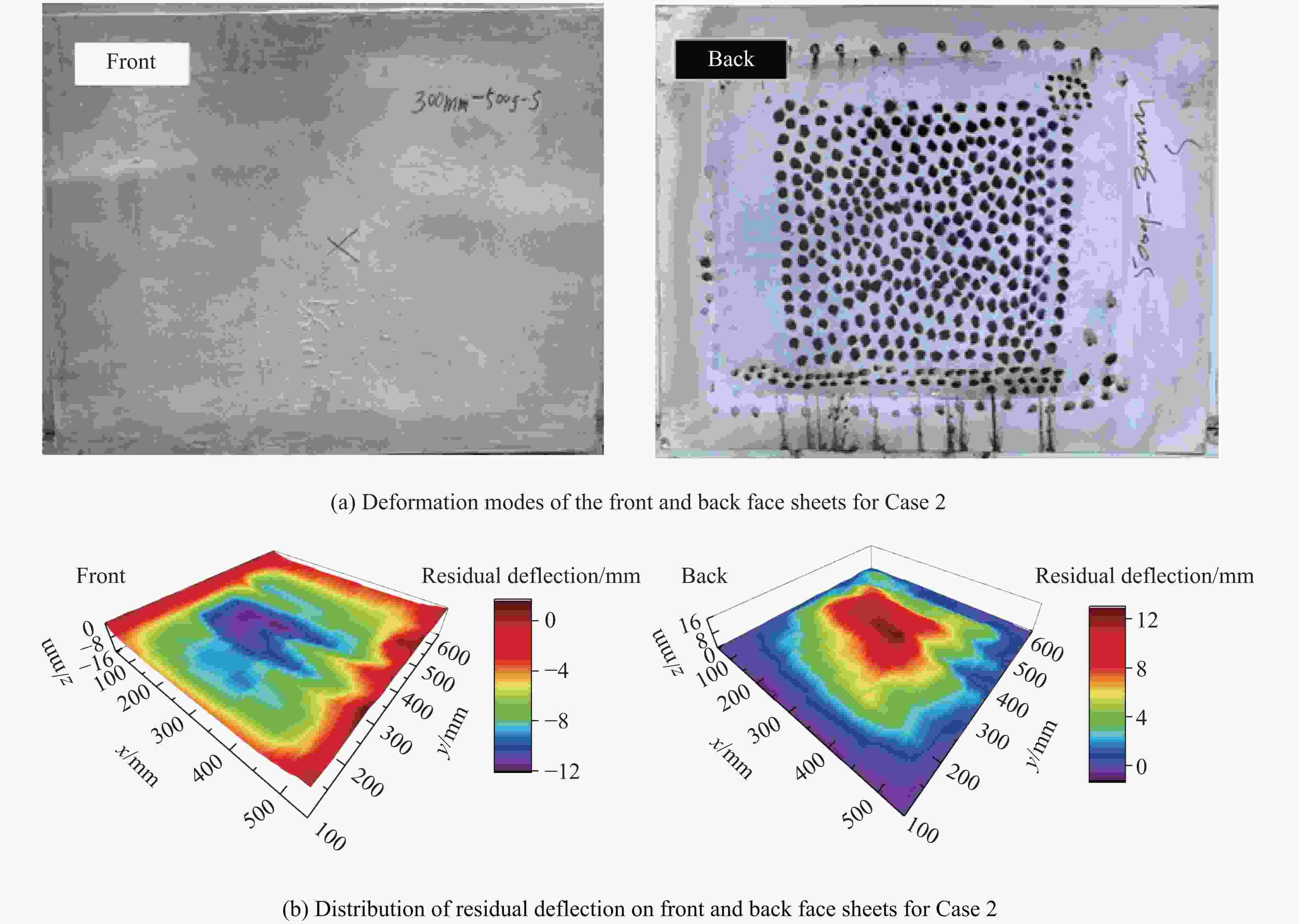

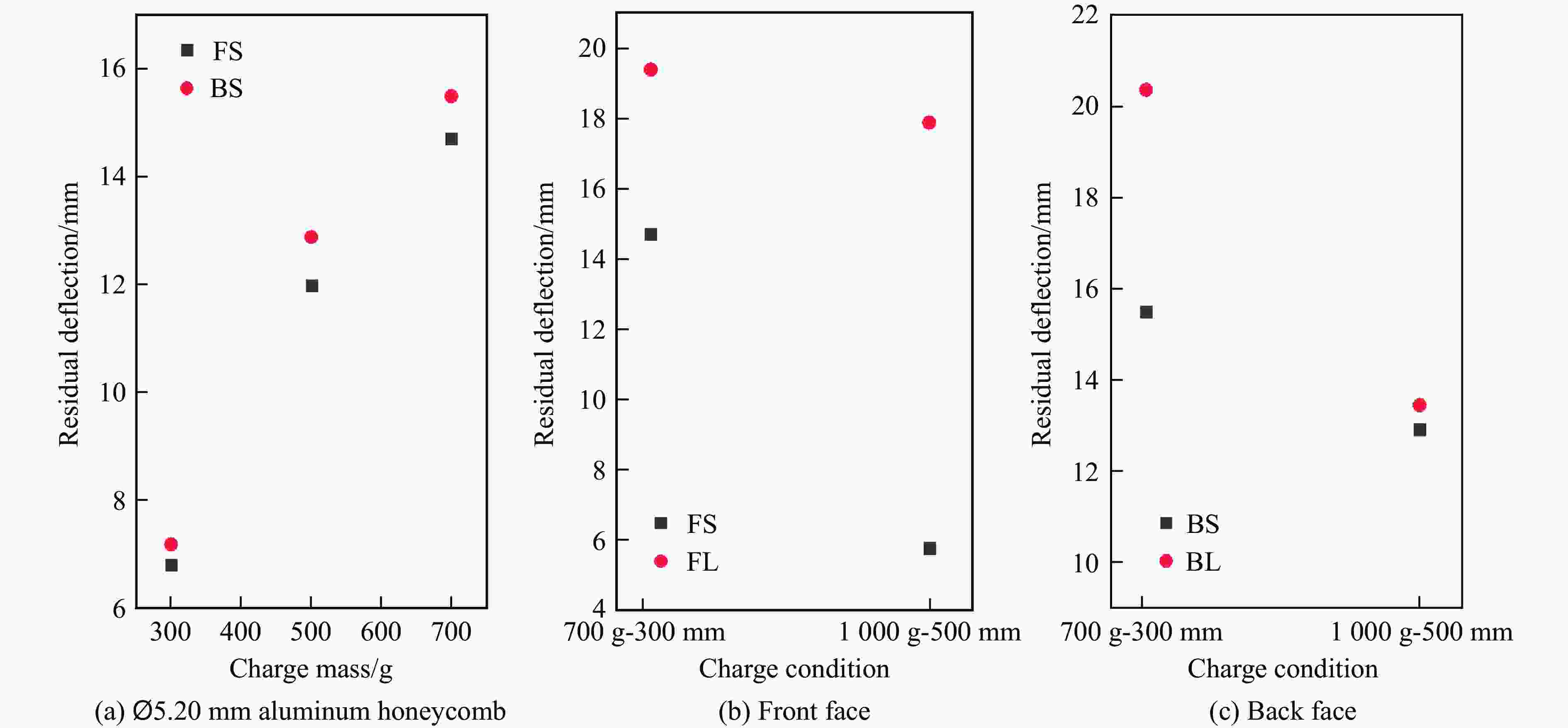

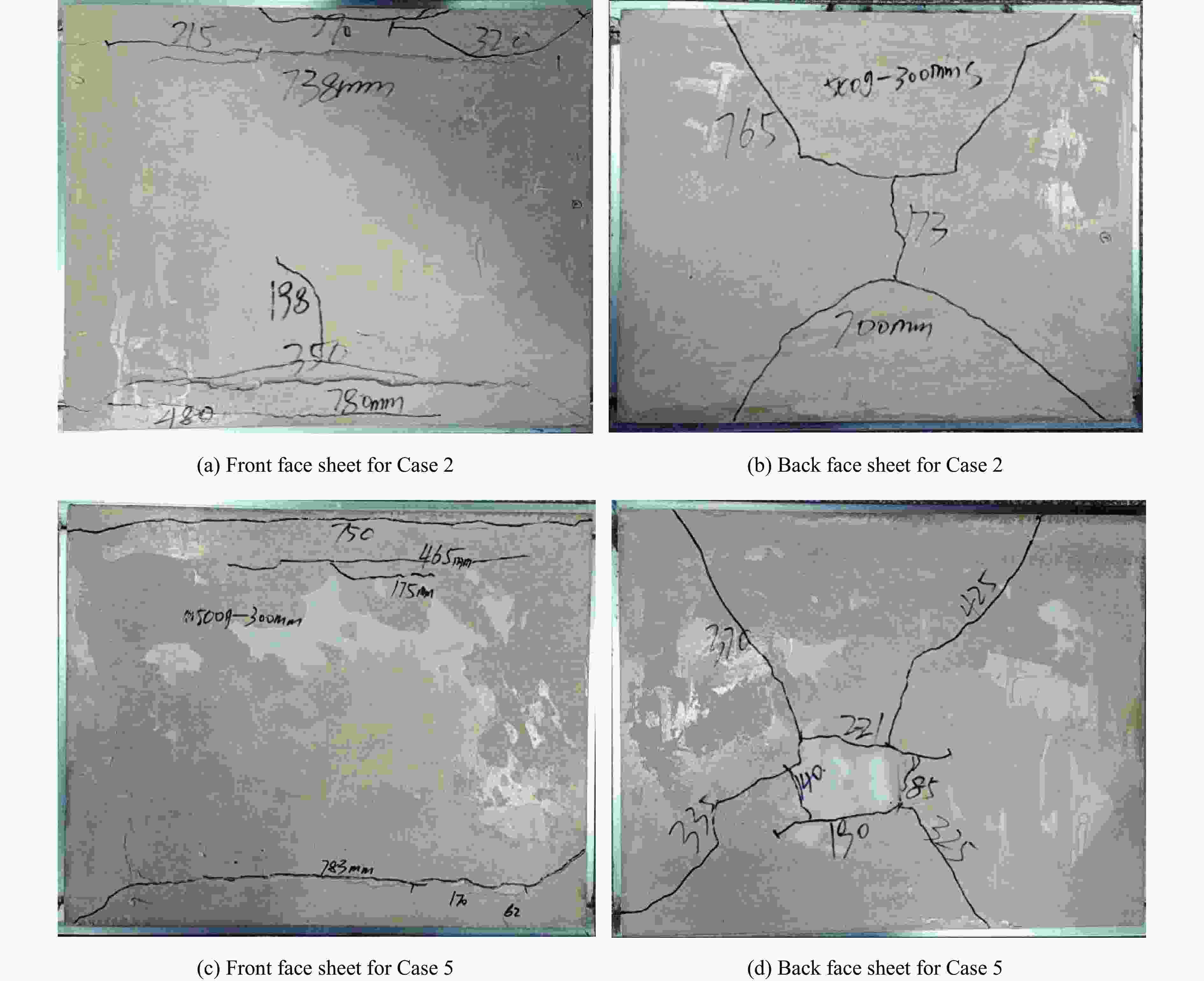

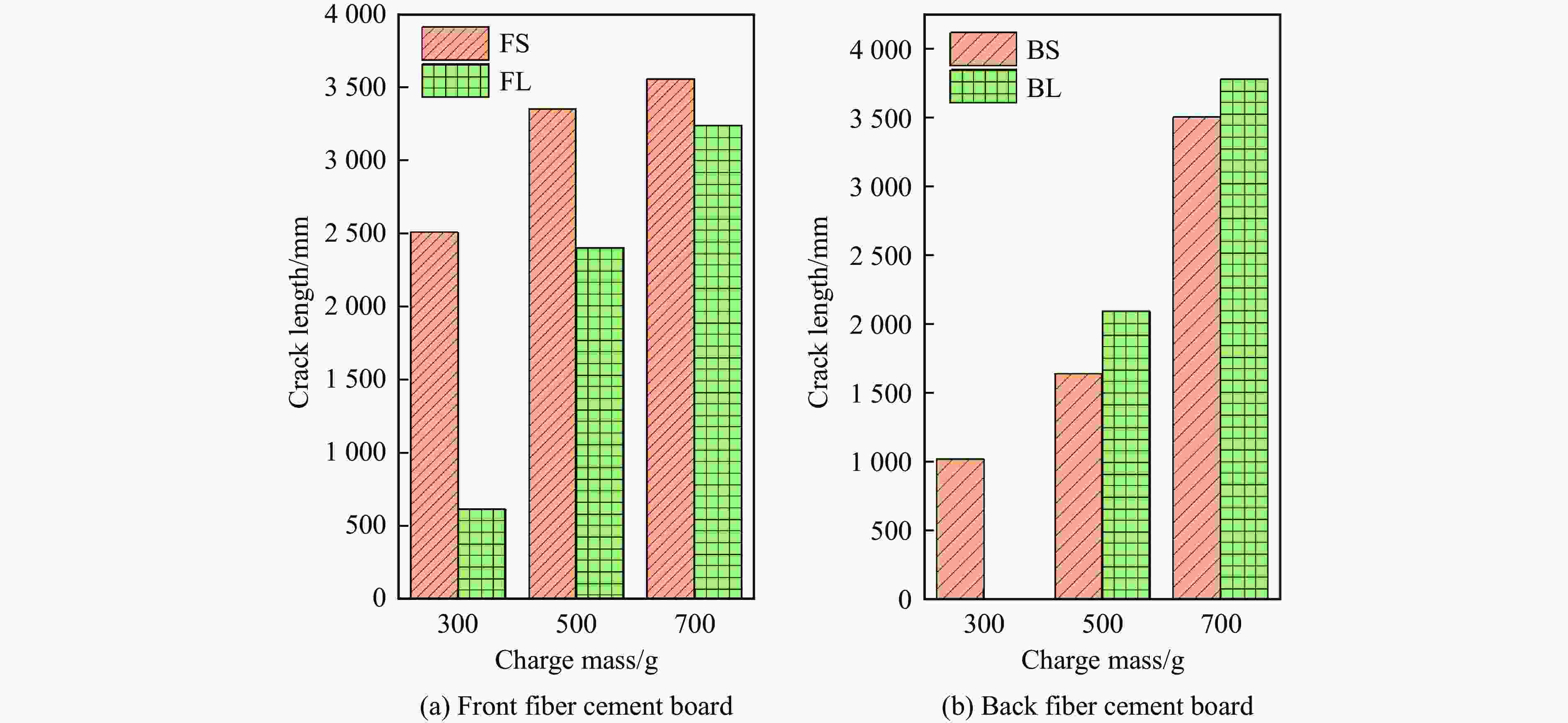

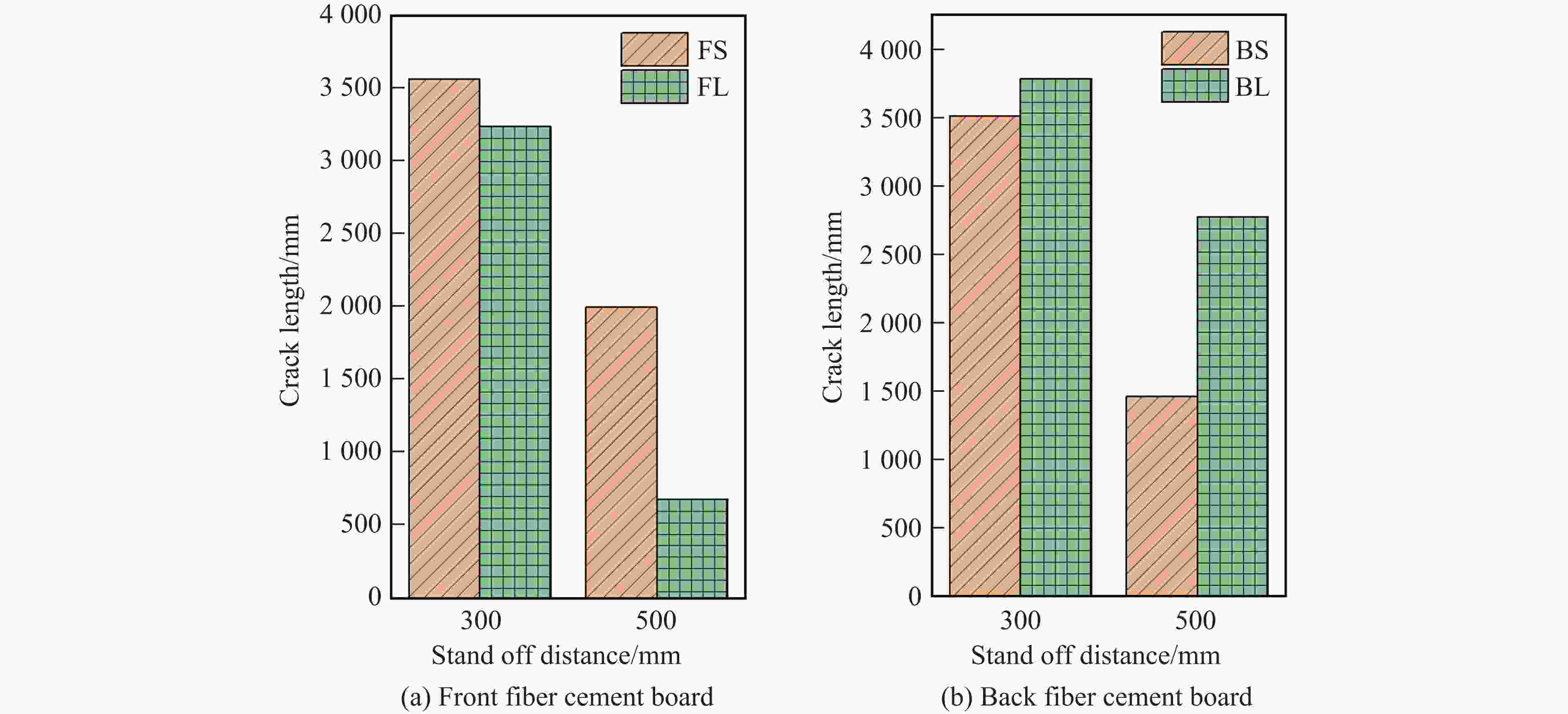

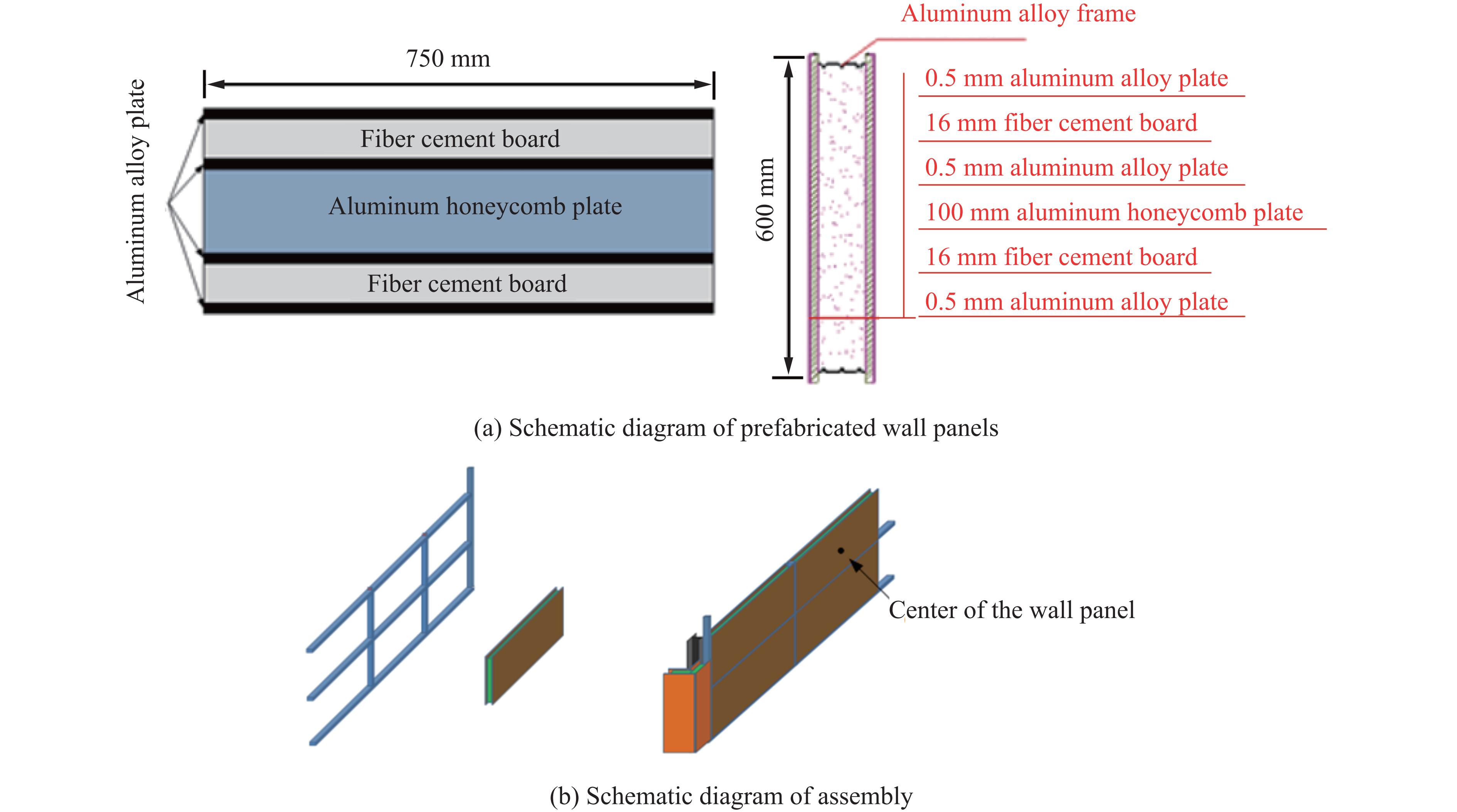

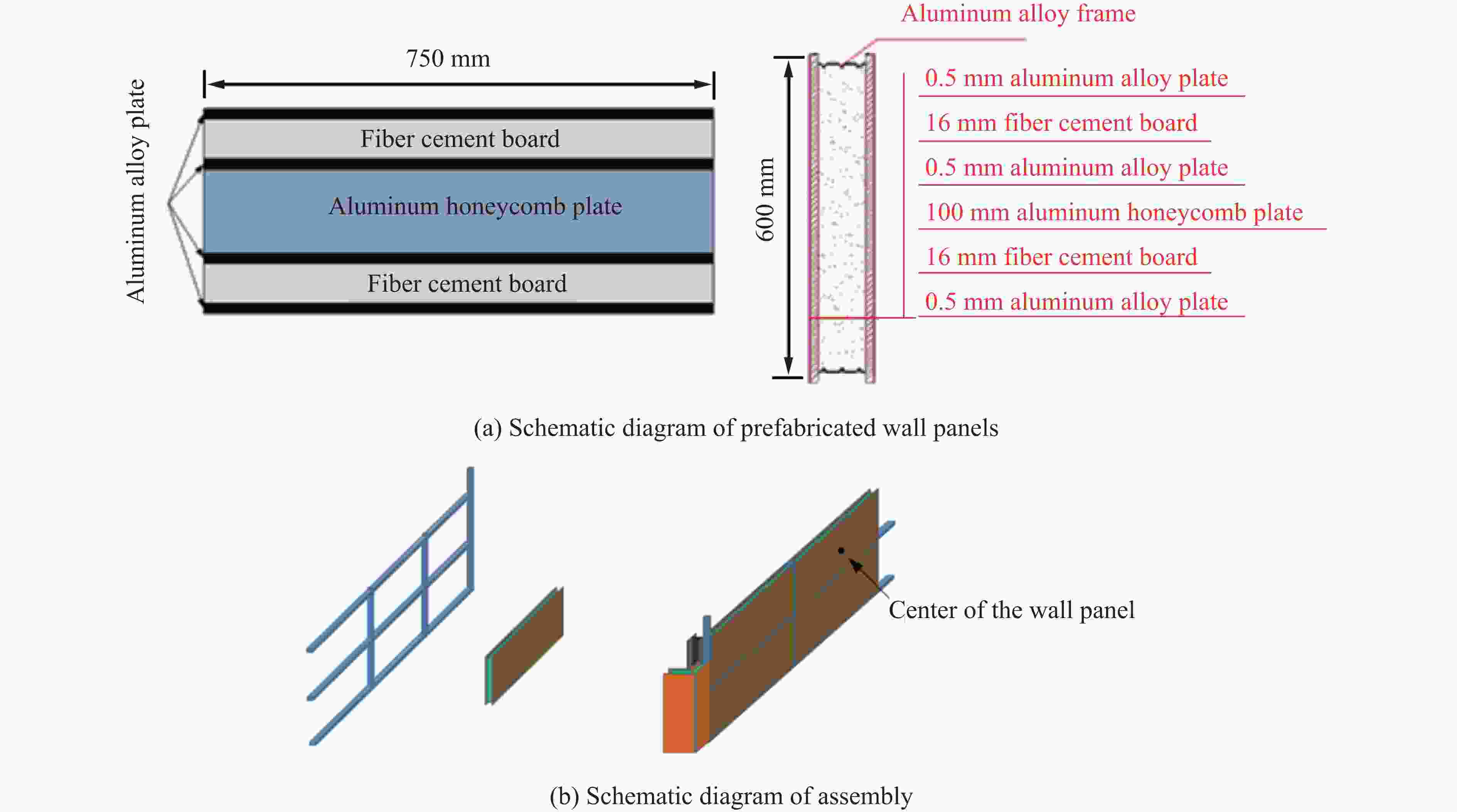

摘要: 利用纤维水泥板、蜂窝铝板和铝合金板组合设计了一种新型的变电站装配式墙板结构,通过实验研究了该结构在爆炸载荷下的动力响应特性。考察了不同炸药量、不同装药距离时的超压载荷特征,分析了蜂窝孔径等参数对结构变形失效模式、背爆面挠度及应变、芯层压缩量、纤维水泥板裂纹分布的影响。结果表明:在有限空间内,爆炸超压的时间特征与在无限空间中类似,中心独立测量的超压峰值和正压持续时间分别为边缘直接测量的2.4~10.0倍和0.44~0.71倍;结构主要呈现前面板凹陷、后面板凸起的变形模式;迎爆面纤维水泥板水平裂纹多分布于长边边界处,背爆面裂纹多分布于中心和对角线附近;与较小孔径的蜂窝结构相比,具有较大孔径的蜂窝结构的背爆面残余挠度较大,纤维水泥板裂纹总长度较长。因此,小孔径蜂窝板具有较好的抗冲击性能。Abstract: A novel prefabricated wall panel structure for substations was developed by integrating fiber cement board, aluminum honeycomb plate, and aluminum alloy plate. The dynamic response characteristics of the structure under explosive loads were investigated through experimental studies. The effects of overpressure loads at different explosive mass and loading distances were examined, and the impact of varying honeycomb cell sizes on structural deformation failure mode, back face deflection and strain, core compression, and fiber cement board crack distribution was analyzed. The results indicate that within a confined space, the time characteristics of explosion overpressure are similar to those in an unconfined space. The peak overpressure measured independently at the center is between 2.4 and 10.0 times that measured directly at the edge. The positive pressure duration measured independently at the center is between 0.44 and 0.71 times that measured directly at the edge. The predominant deformation mode of the structure involves front panel depression and rear panel bulging. Horizontal cracks in the front face of the fiber cement board are predominantly located near its long side boundary, while cracks in the back face are mainly distributed near its center and diagonal areas. Compared with structures featuring smaller honeycomb cell sizes, those with larger honeycomb cell sizes exhibit greater residual deflection on their back faces and longer total crack lengths in their fiber cement boards.

-

表 1 实验工况

Table 1. Experimental conditions

Case D/mm m/g d/mm Case D/mm m/g d/mm 1 5.20 300 300 7 5.20 700 500 2 5.20 500 300 8 5.20 500 500 3 5.20 700 300 9 5.20 1000 500 4 10.38 300 300 10 10.38 700 500 5 10.38 500 300 11 10.38 1000 500 6 10.38 700 300 表 2 超压特征参数

Table 2. Parameters of overpressure

m/g mTNT/g $ {p}_{\mathrm{m}\mathrm{a}\mathrm{x}}^{\mathrm{T}} $/MPa d/mm $ {{{\overline{p}_{\mathrm{max}}^{\rm{ZD}}}}} $/MPa $ {{{\overline{p}_{\mathrm{max}}^{\rm{BZ}}}}} $/MPa $\Delta \overline{t}^{\mathrm{Z}\mathrm{D}} $/μs $\Delta \overline{t}^{\mathrm{B}\mathrm{Z}} $/μs $ {\rho }_{p} $ $ {\rho }_{t} $ 300 60–90 10.603–15.121 300 10.348 1.033 153 350 10.0 0.44 500 100–150 16.534–23.034 300 18.655 2.424 216 320 7.7 0.68 700 140–210 21.800–29.878 300 22.549 3.963 223 313 5.7 0.71 500 100–150 4.059–5.998 500 4.769 2.045 192 388 2.3 0.49 700 140–210 5.617–8.221 500 8.490 3.593 184 350 2.4 0.53 1 000 200–300 7.858–11.357 500 11.413 200 -

[1] 刘聪, 张世联. 垂直围壁对爆炸载荷作用下固支方板动力响应特性影响分析 [J]. 船舶力学, 2021, 25(1): 13–14.LIU C, ZHANG S L. Influence of vertical surroundings on the dynamic response of fixed square plate subjected to blast loading [J]. Journal of Ship Mechanics, 2021, 25(1): 13–14. [2] 中华人民共和国住房和城乡建设部. 火力发电厂与变电站设计防火规范: GB 50229—2019 [S]. 北京: 中国计划出版社, 2019. [3] 国网基建部. 变电站模块化建设2.0版技术导则 [EB/OL]. (2021-12-01) [2023-07-22]. http://xy-cost.com/archives/213442. [4] LIU H, LIU H, YANG J L. Clamped sandwich beams with thick weak cores from central impact: a theoretical study [J]. Composite Structures, 2017, 169: 21–28. doi: 10.1016/j.compstruct.2017.02.028 [5] HOU W H, ZHU F, LU G X, et al. Ballistic impact experiments of metallic sandwich panels with aluminium foam core [J]. International Journal of Impact Engineering, 2010, 37(10): 1045–1055. doi: 10.1016/j.ijimpeng.2010.03.006 [6] 朱浩霖, 张天辉, 刘志芳. 重复冲击载荷下泡沫铝夹芯壳的动态响应 [J]. 高压物理学报, 2024, 38(5): 054205. doi: 10.11858/gywlxb.20240721ZHU H L, ZHANG T H, LIU Z F. Dynamic responses of aluminum foam sandwich shells under repeated impact loadings [J]. Chinese Journal of High Pressure Physics, 2024, 38(5): 054205. doi: 10.11858/gywlxb.20240721 [7] ZHU F, ZHAO L M, LU G X, et al. A numerical simulation of the blast impact of square metallic sandwich panels [J]. International Journal of Impact Engineering, 2009, 36(5): 687–699. doi: 10.1016/j.ijimpeng.2008.12.004 [8] ZHU F, WANG Z H, LU G X, et al. Some theoretical considerations on the dynamic response of sandwich structures under impulsive loading [J]. International Journal of Impact Engineering, 2010, 37(6): 625–637. doi: 10.1016/j.ijimpeng.2009.11.003 [9] CHANG W S, VENTSEL E, KRAUTHAMMER T, et al. Bending behavior of corrugated-core sandwich plates [J]. Composite Structures, 2005, 70(1): 81–89. doi: 10.1016/j.compstruct.2004.08.014 [10] SHU C F, ZHAO S Y, HOU S J. Crashworthiness analysis of two-layered corrugated sandwich panels under crushing loading [J]. Thin-Walled Structures, 2018, 133: 42–51. doi: 10.1016/j.tws.2018.09.008 [11] LIU H, LIU H, YANG J L, et al. Cantilever sandwich beams with pyramidal truss cores subjected to tip impact [J]. Science China: Technological Sciences, 2013, 56(1): 181–187. doi: 10.1007/s11431-012-5058-4 [12] WICKS N, HUTCHINSON J W, Performance of sandwich plates with truss cores [J]. Mechanics of Materials, 2004, 36(8): 739–751. -

下载:

下载: