Numerical Study on Response of AZ31B Magnesium Alloy Subjected to High-Velocity Projectile Perforation

-

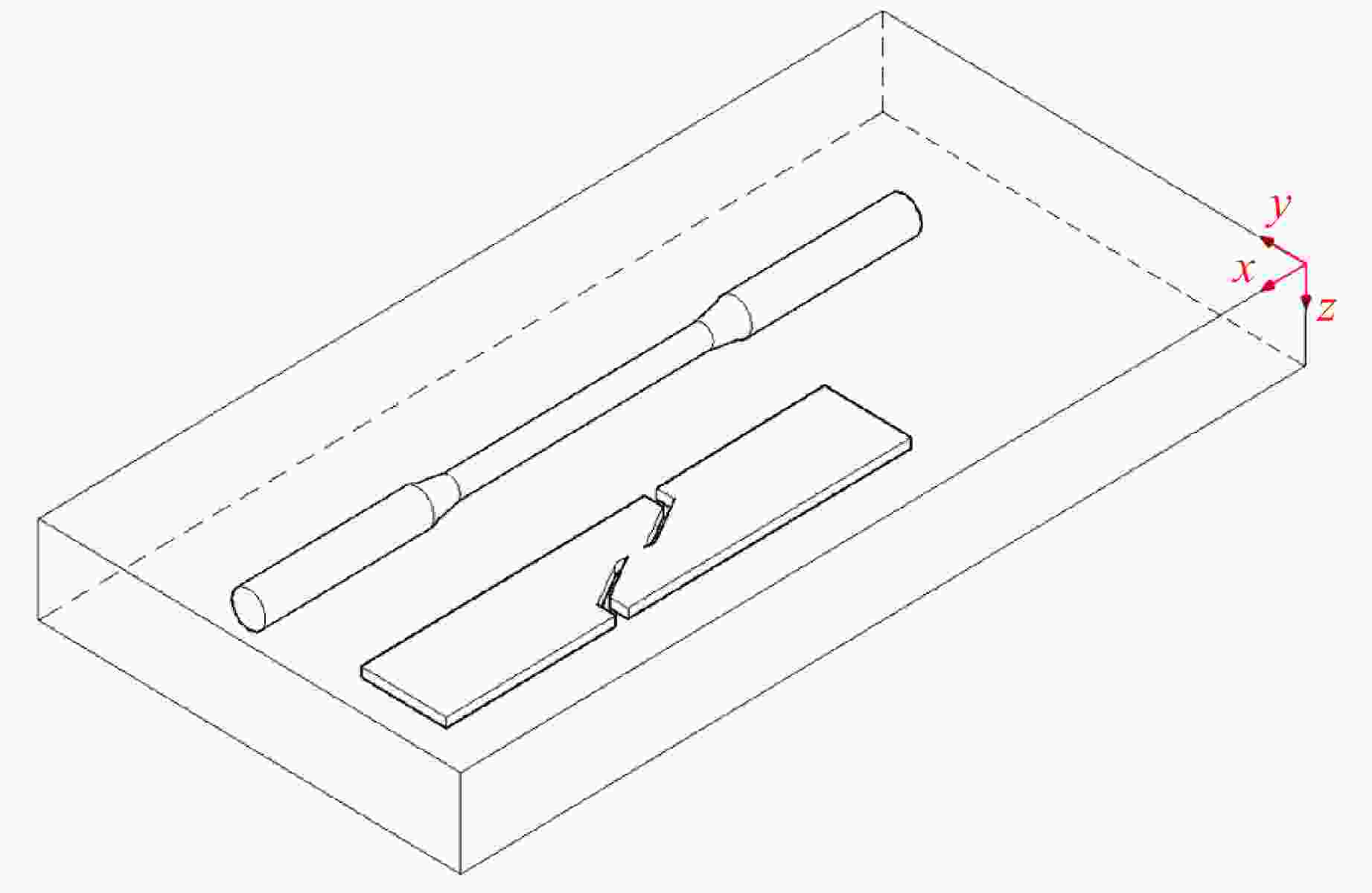

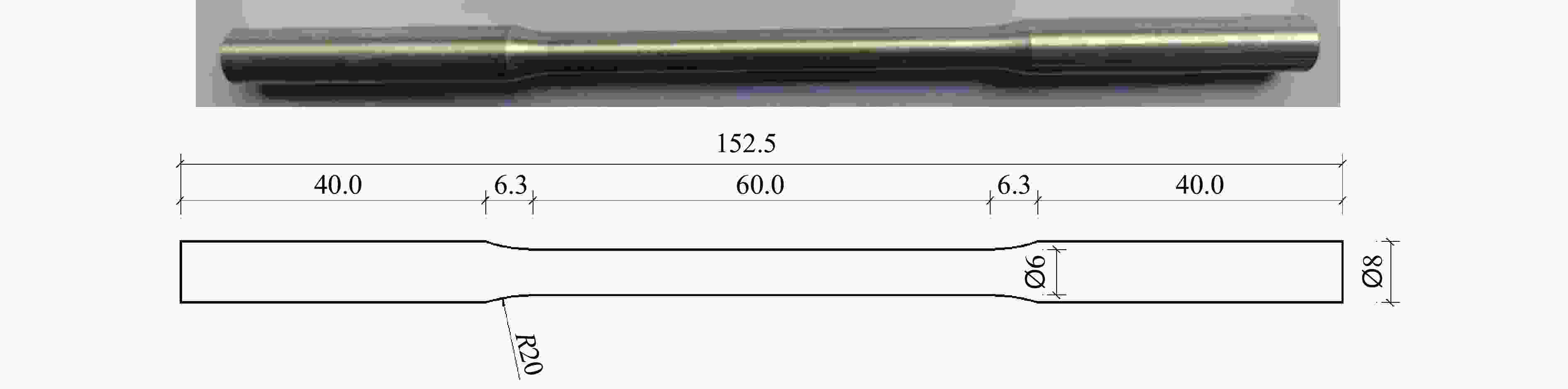

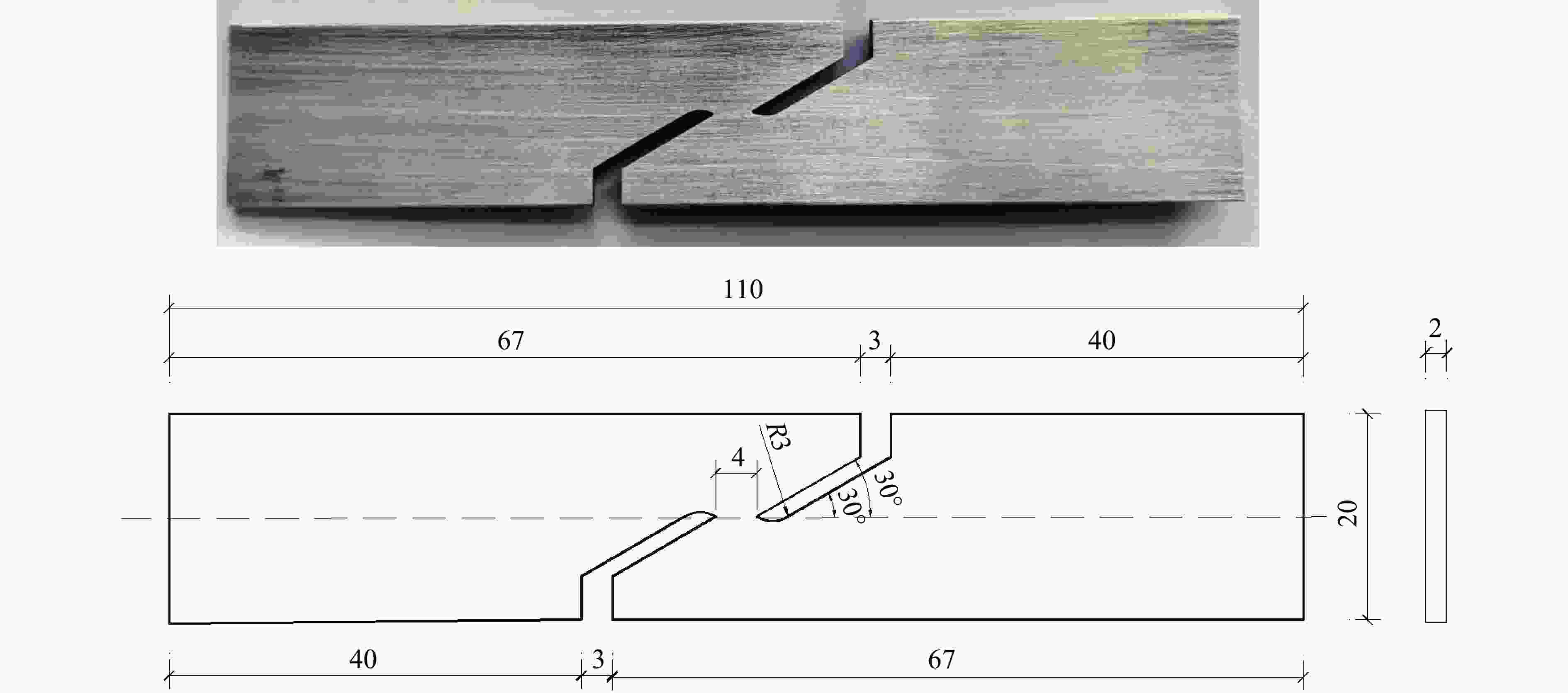

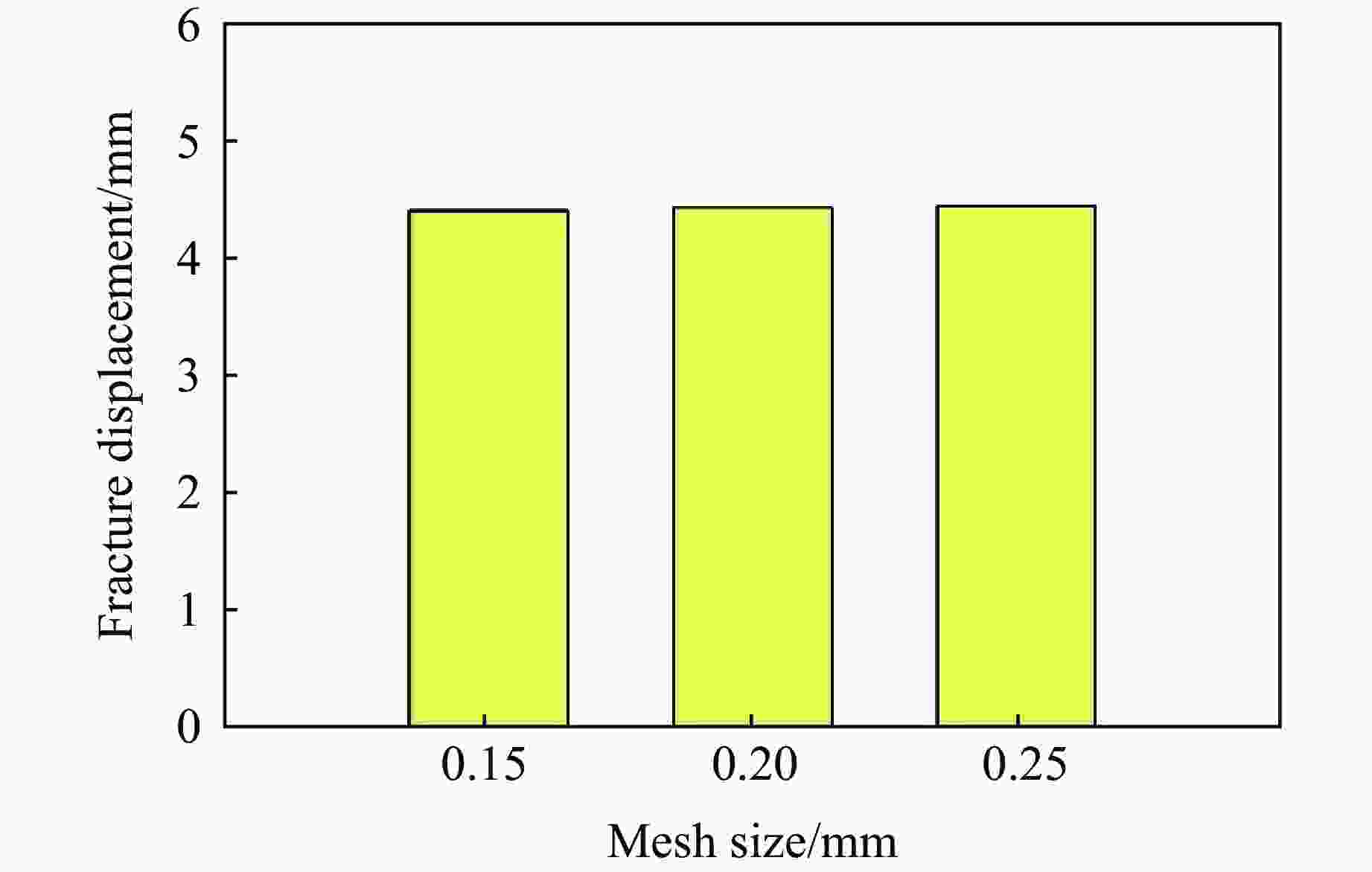

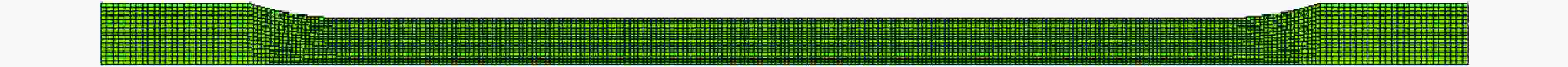

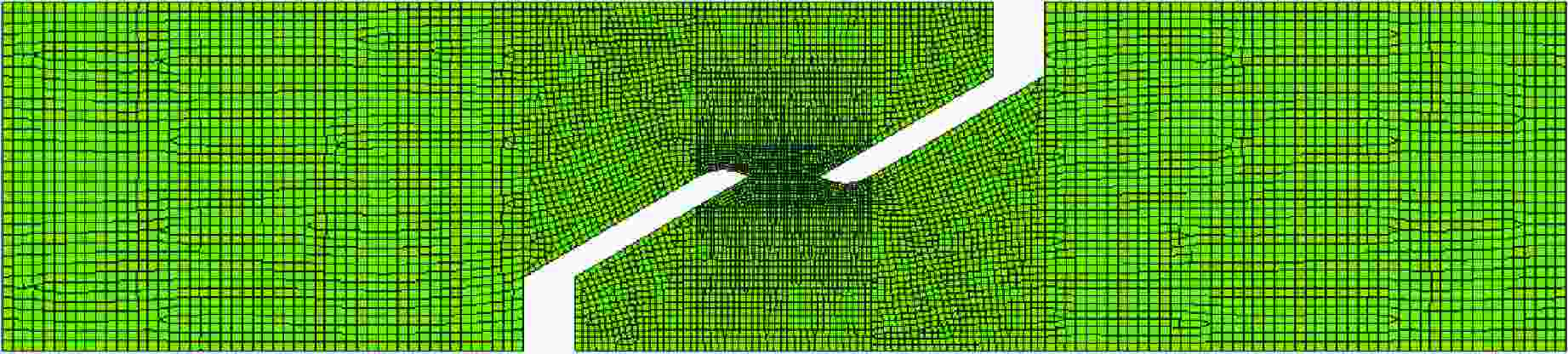

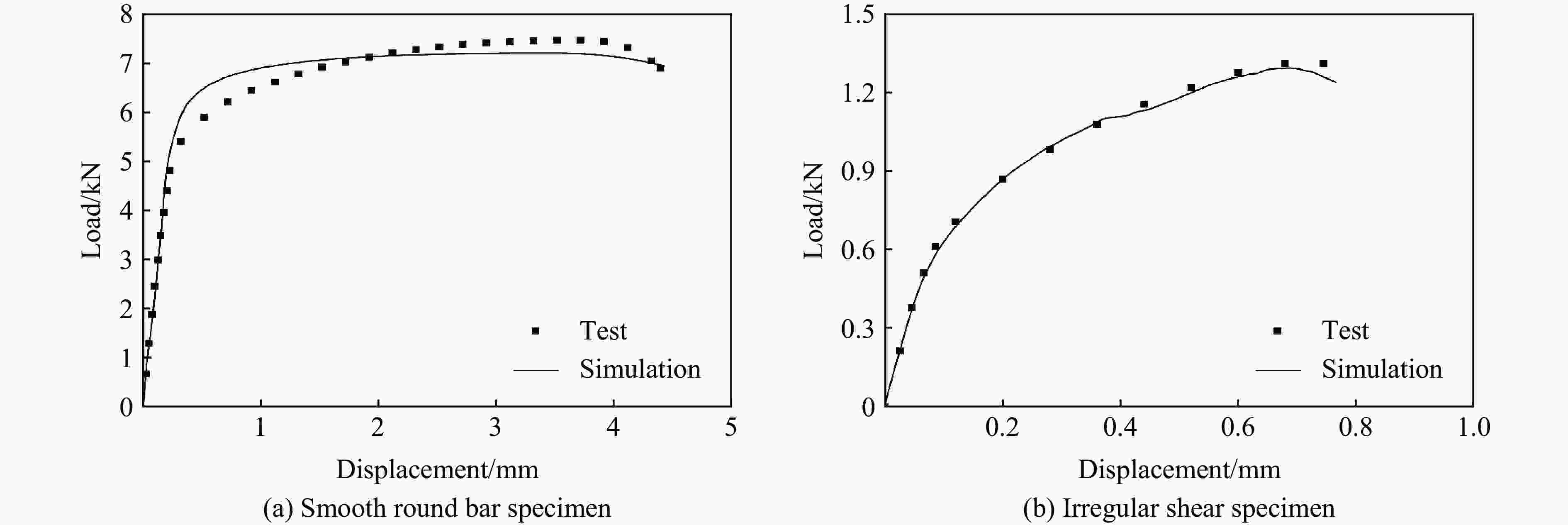

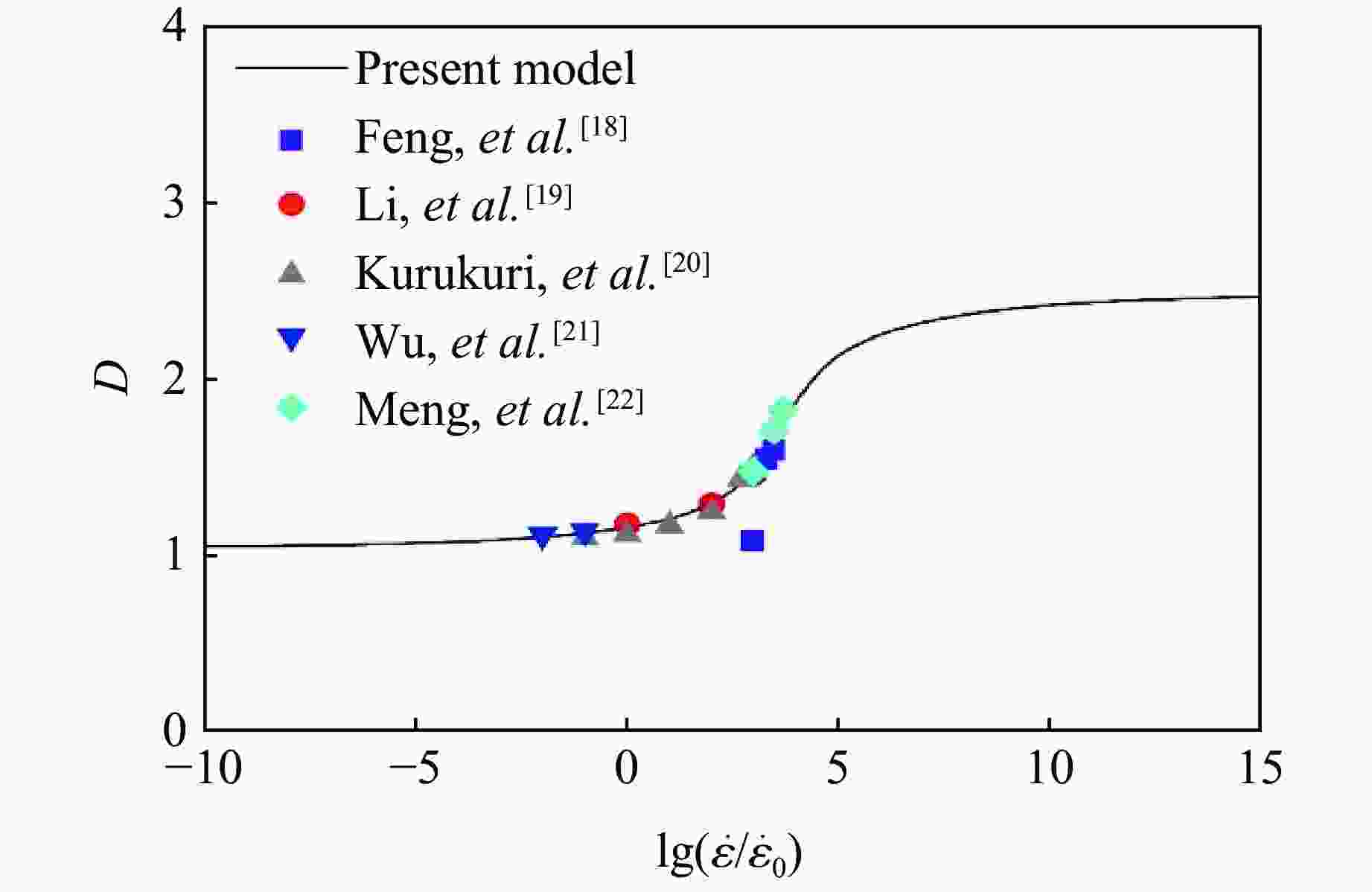

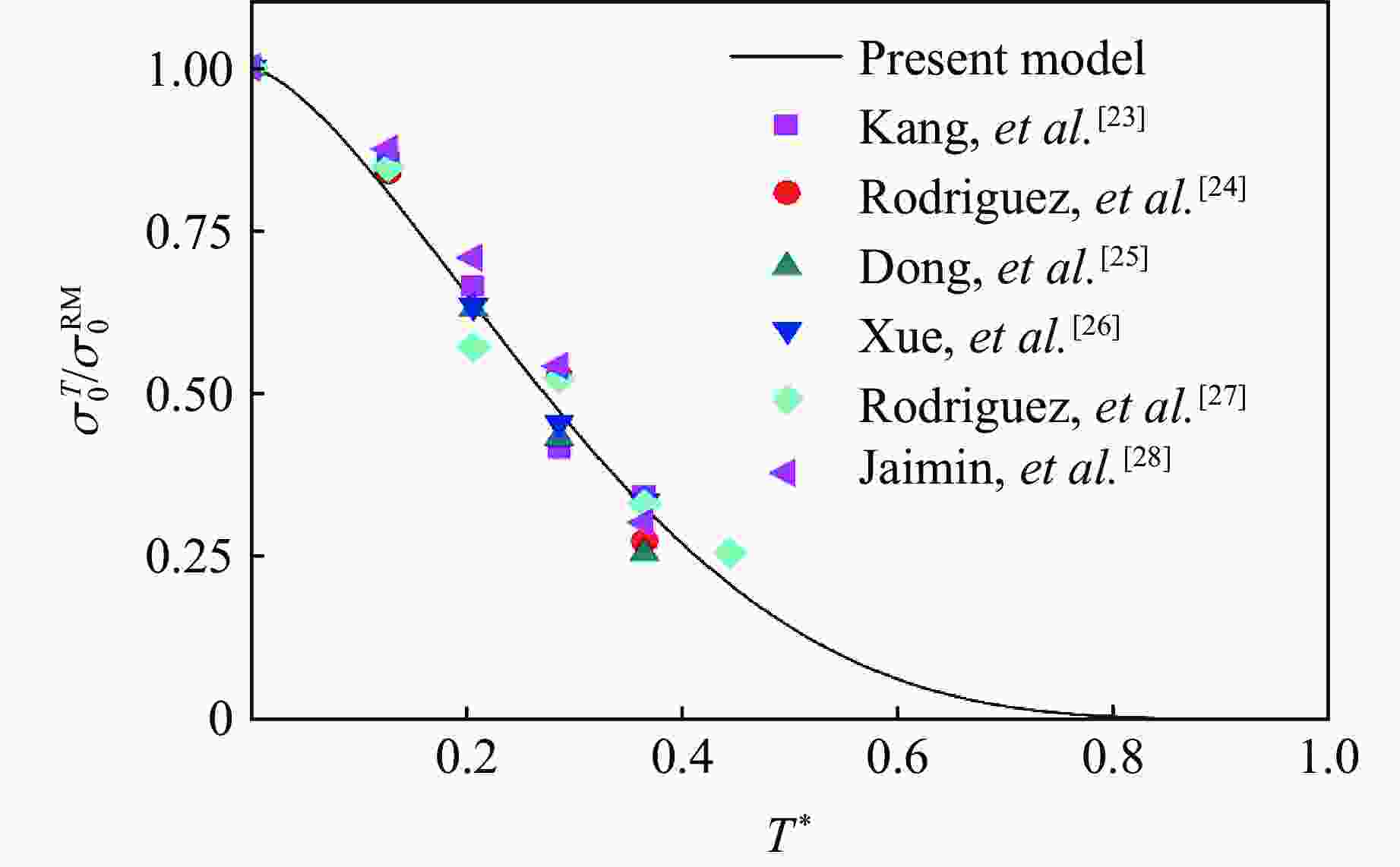

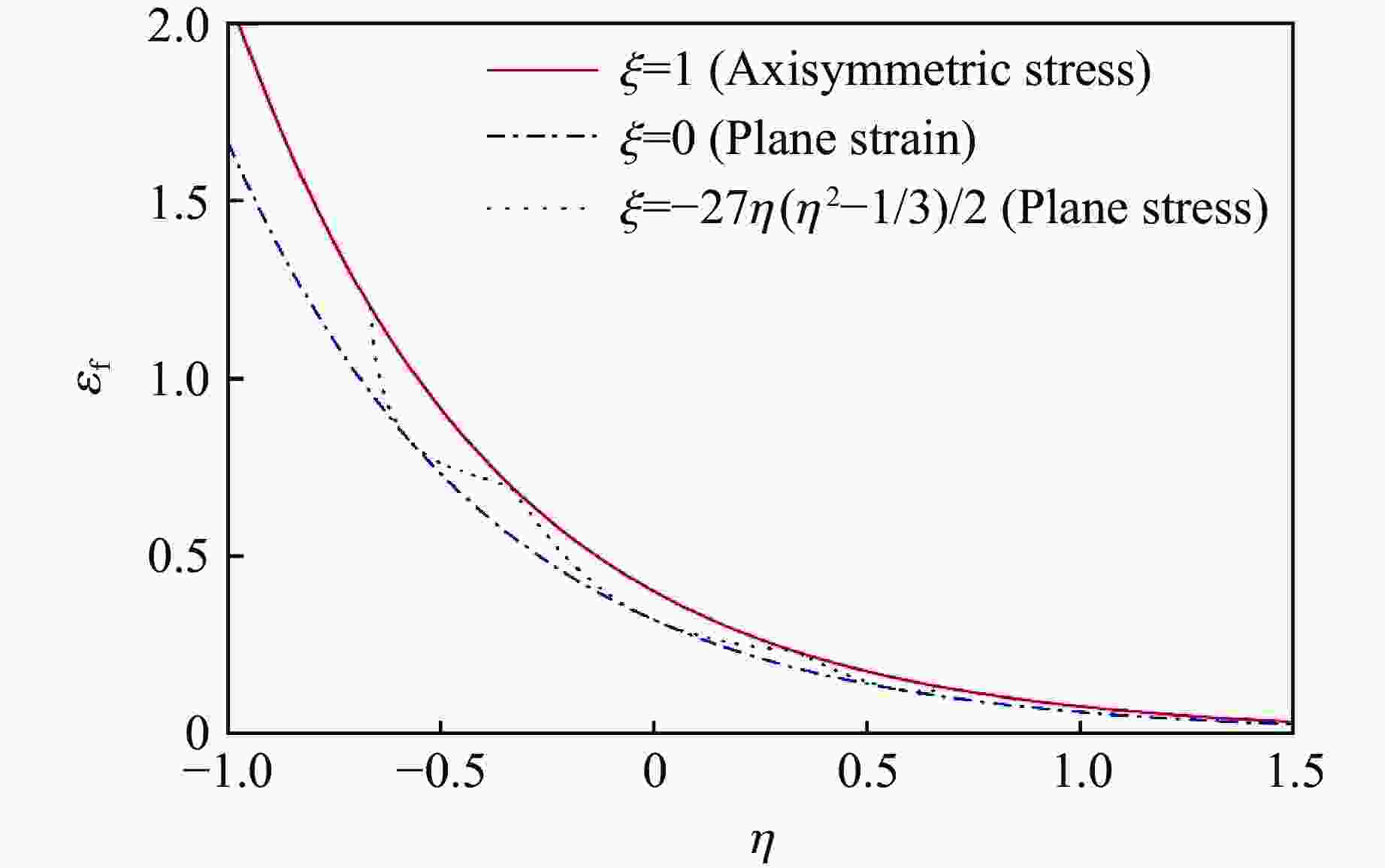

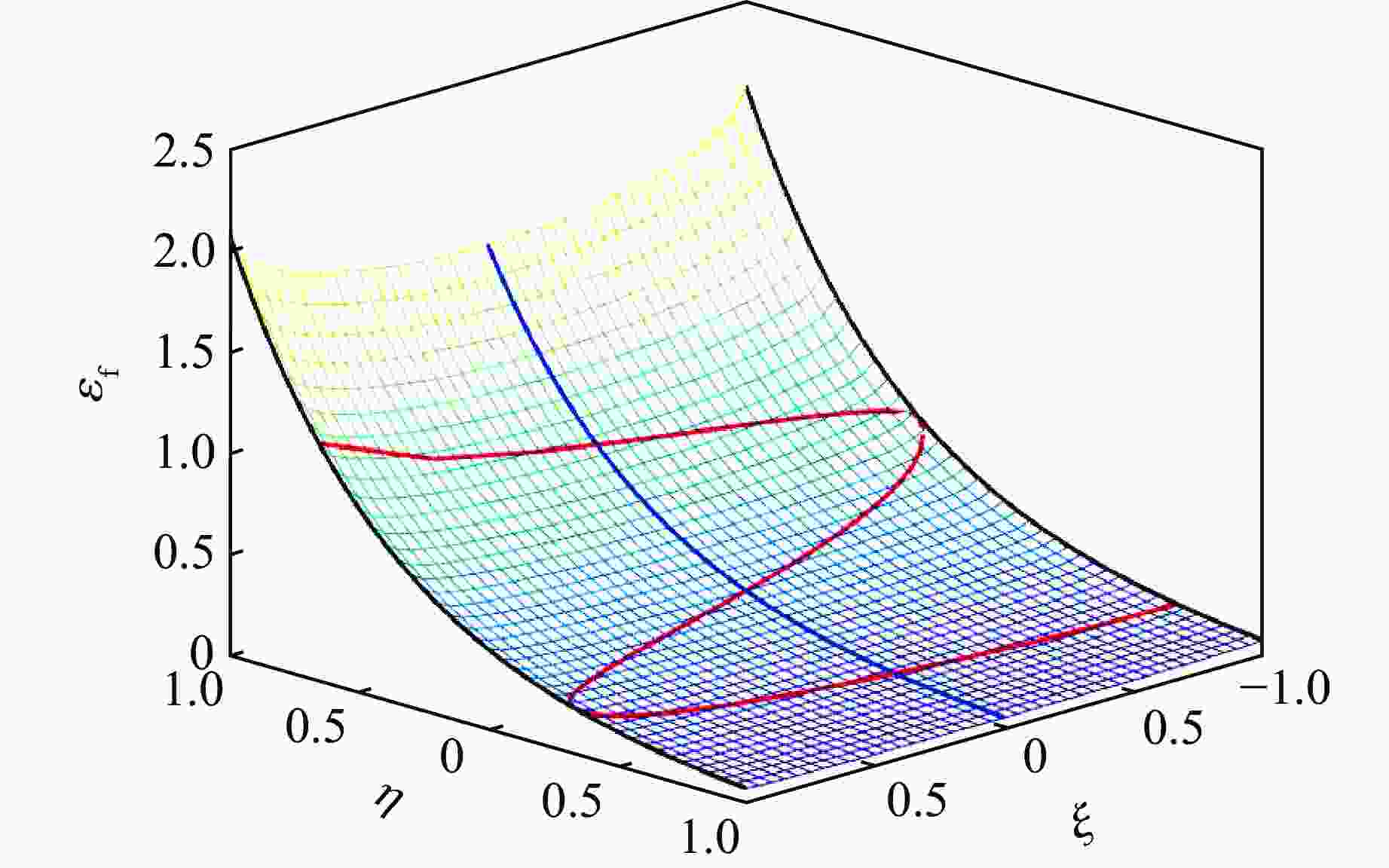

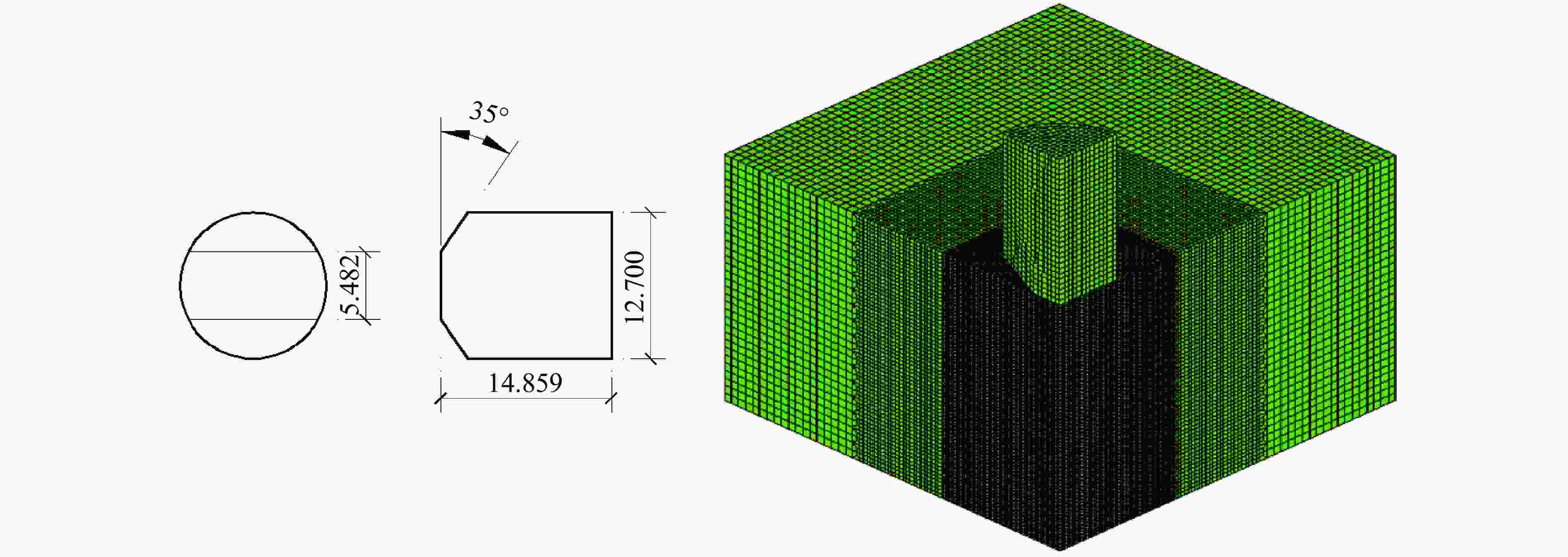

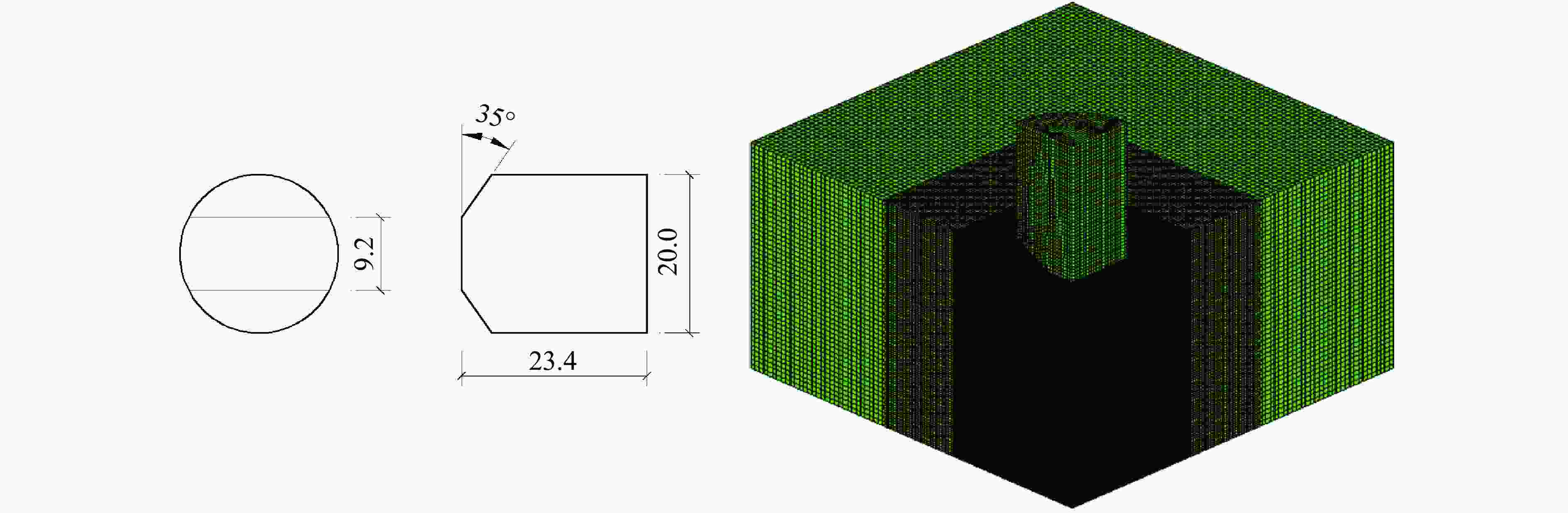

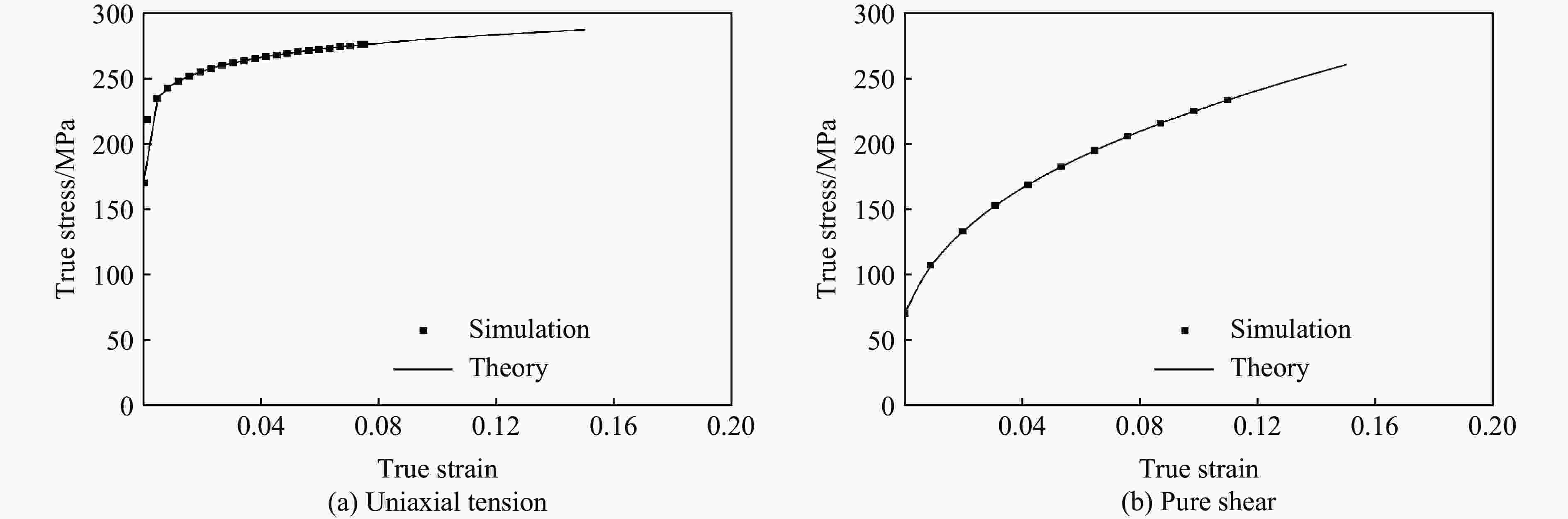

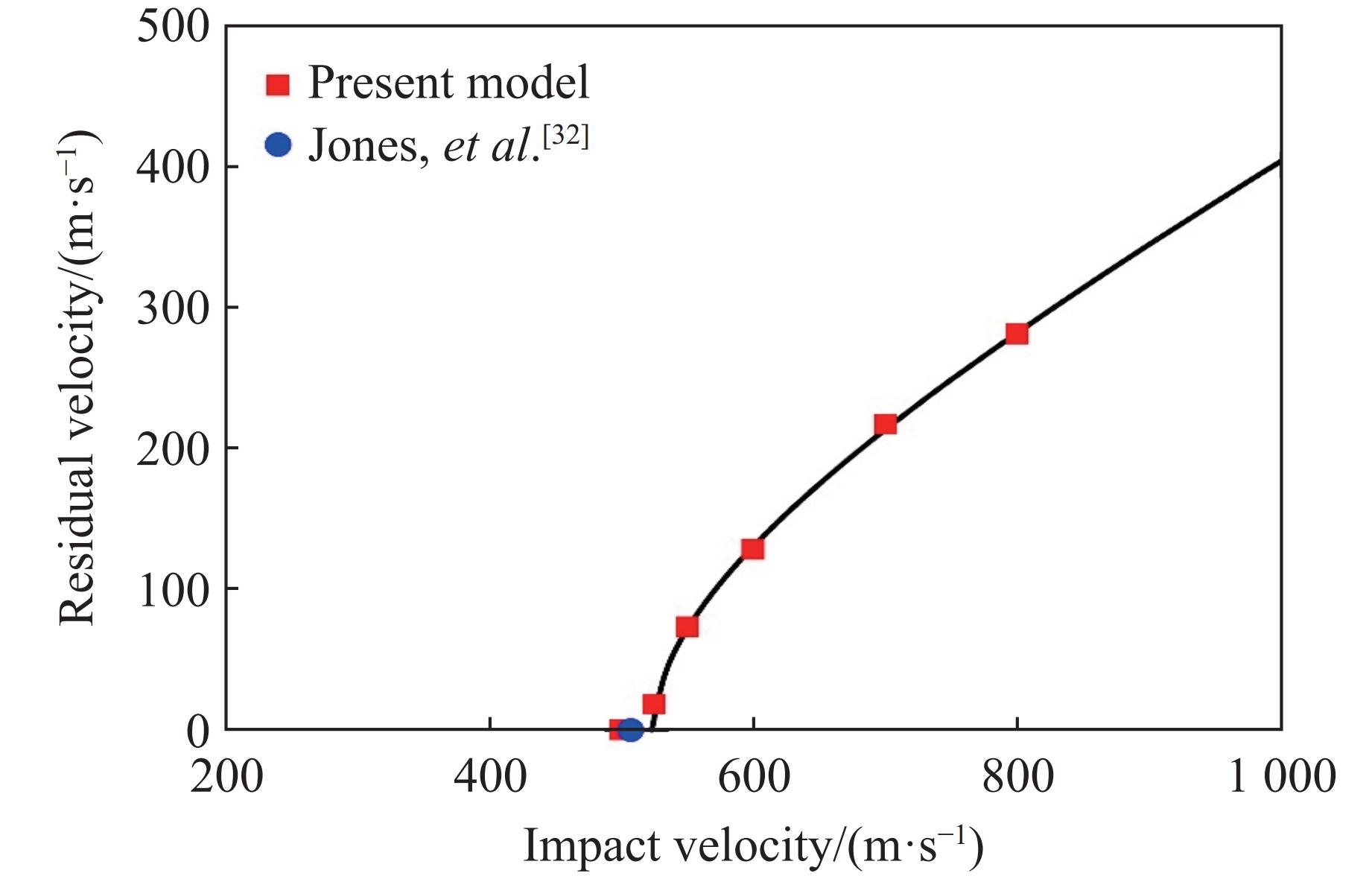

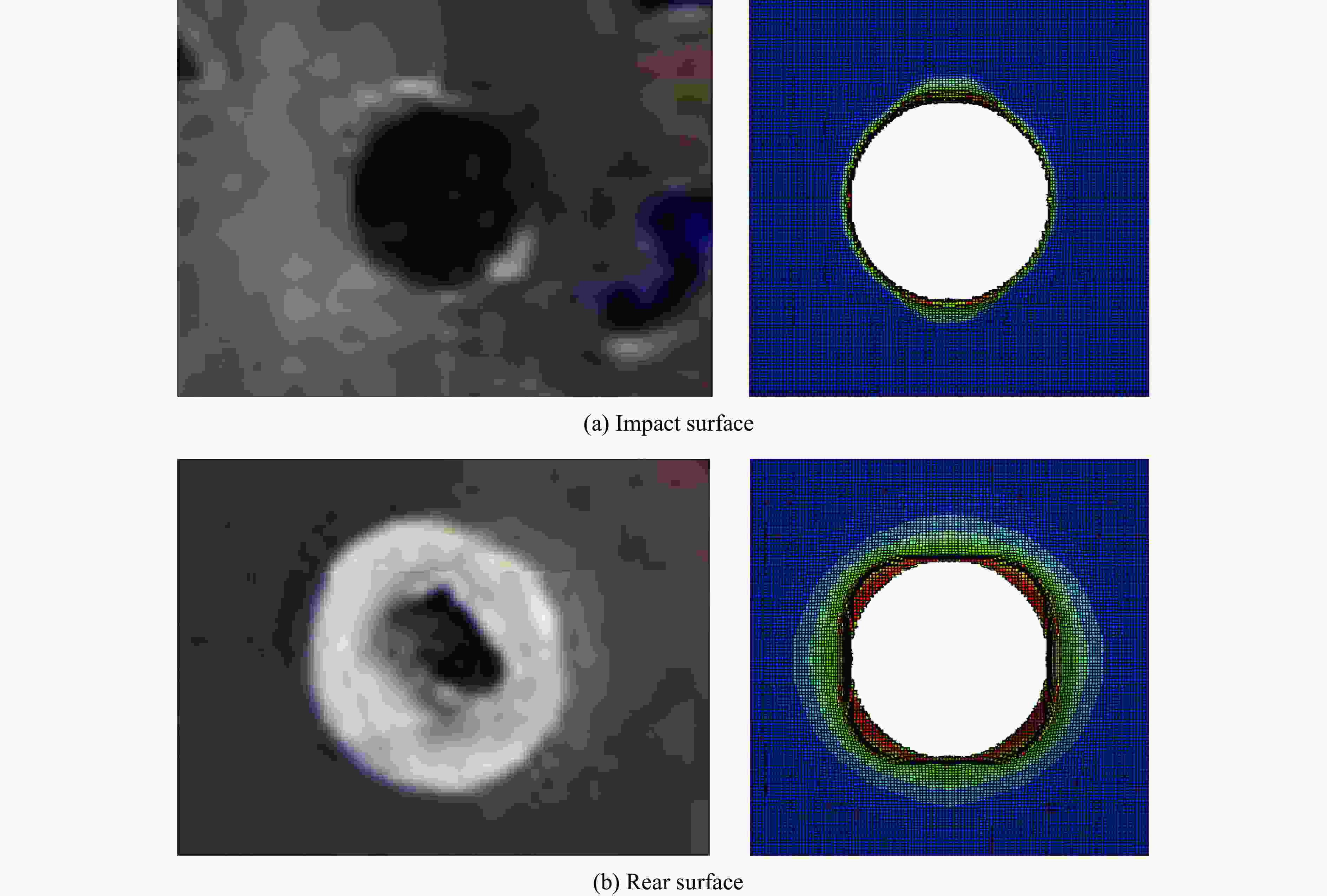

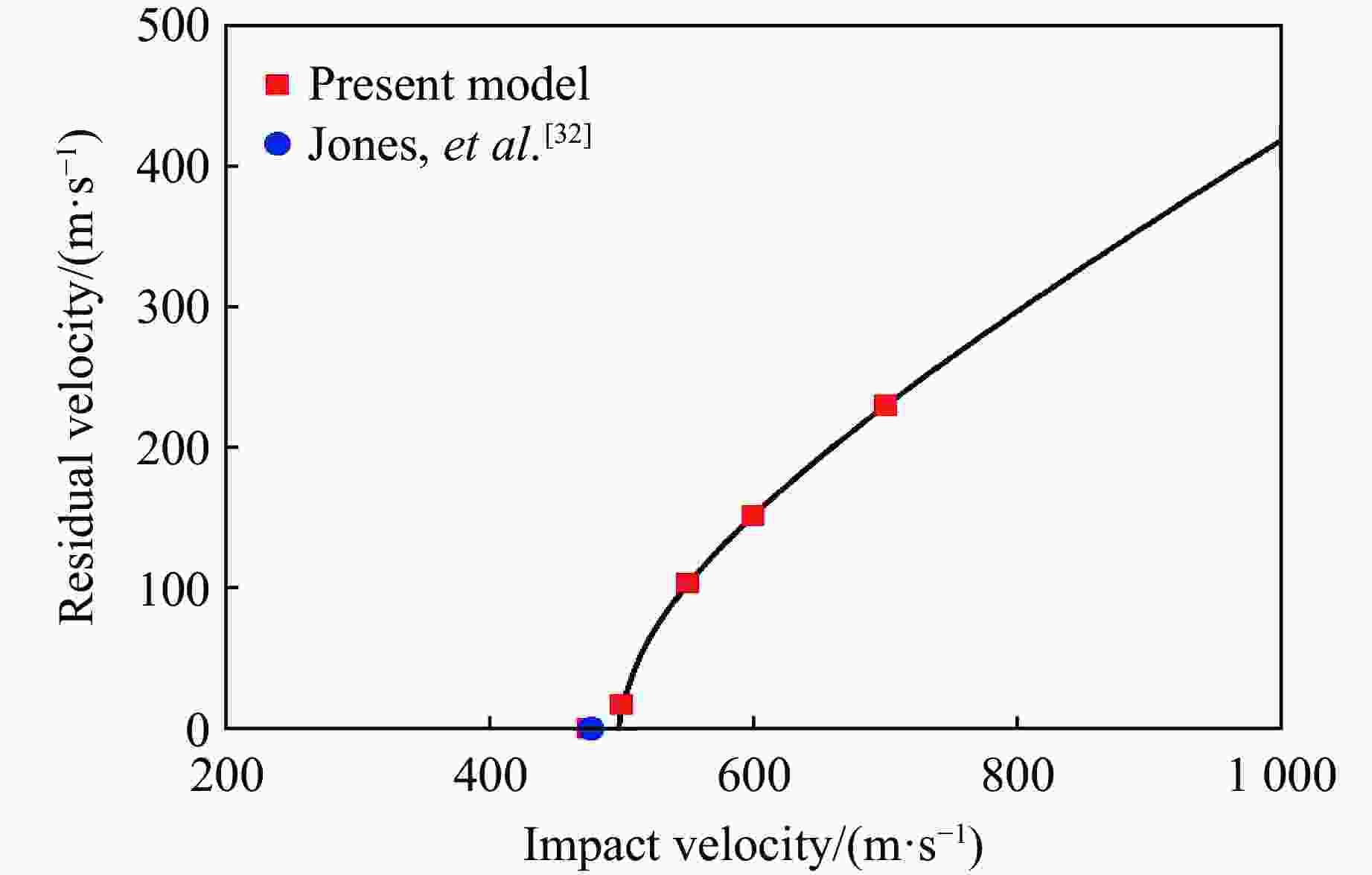

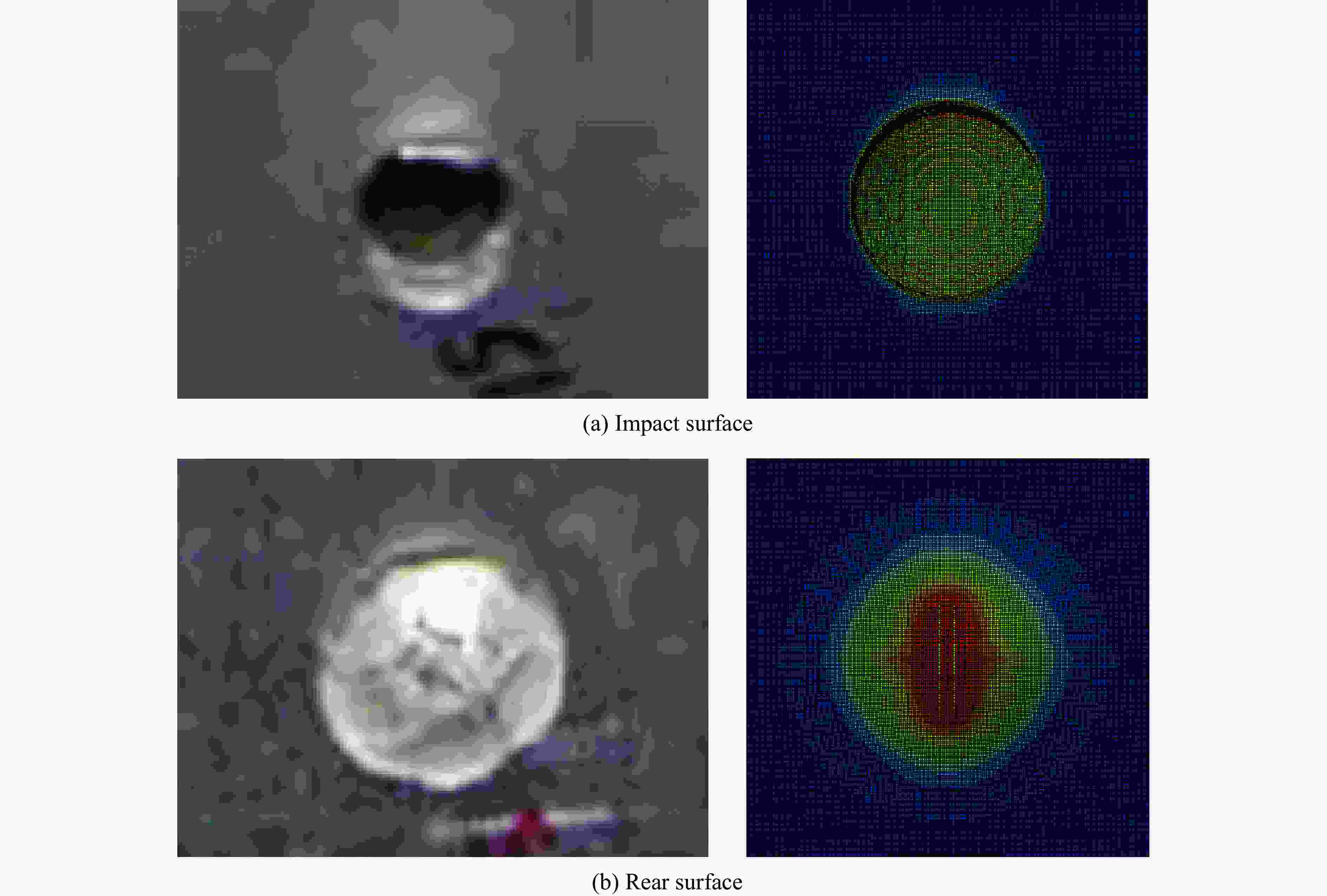

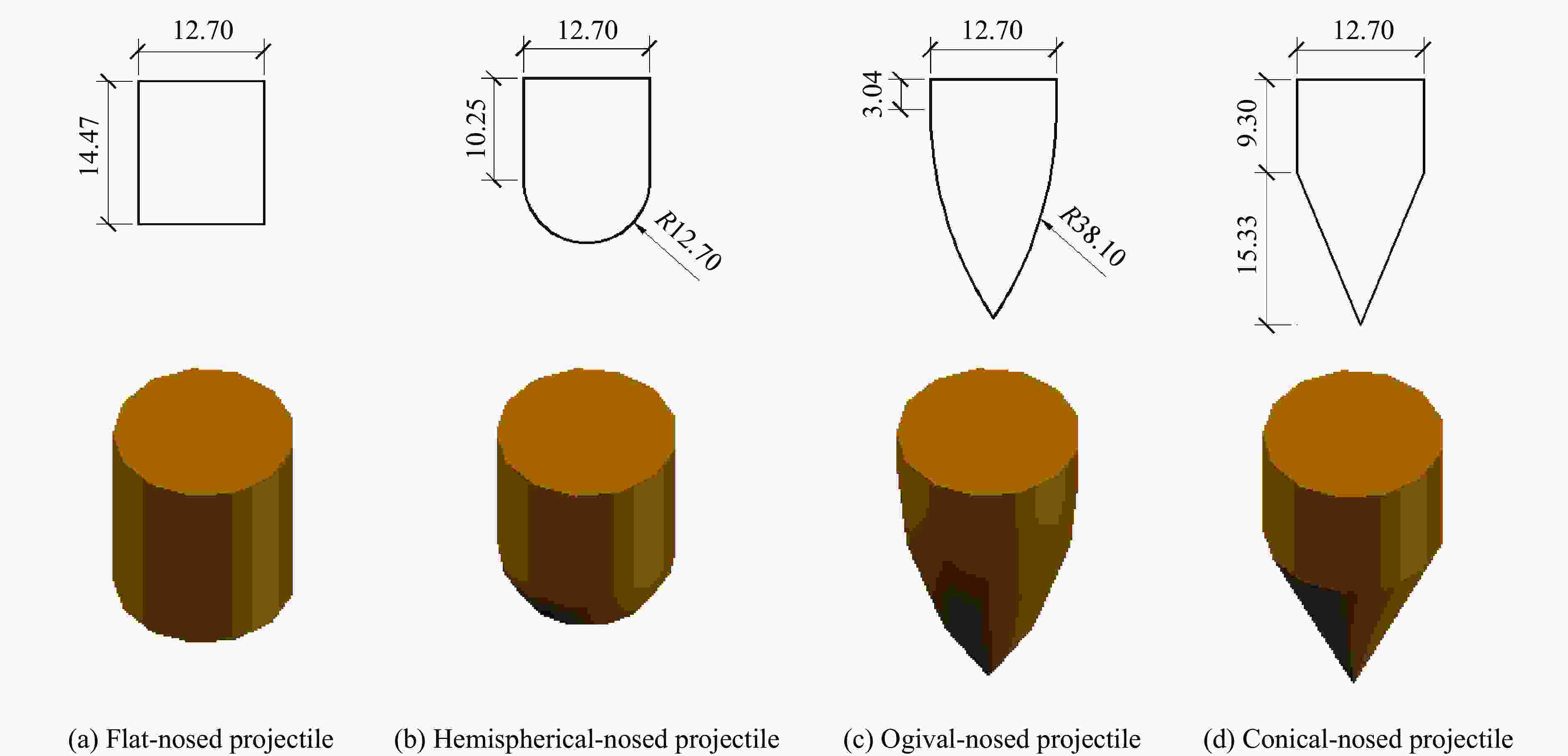

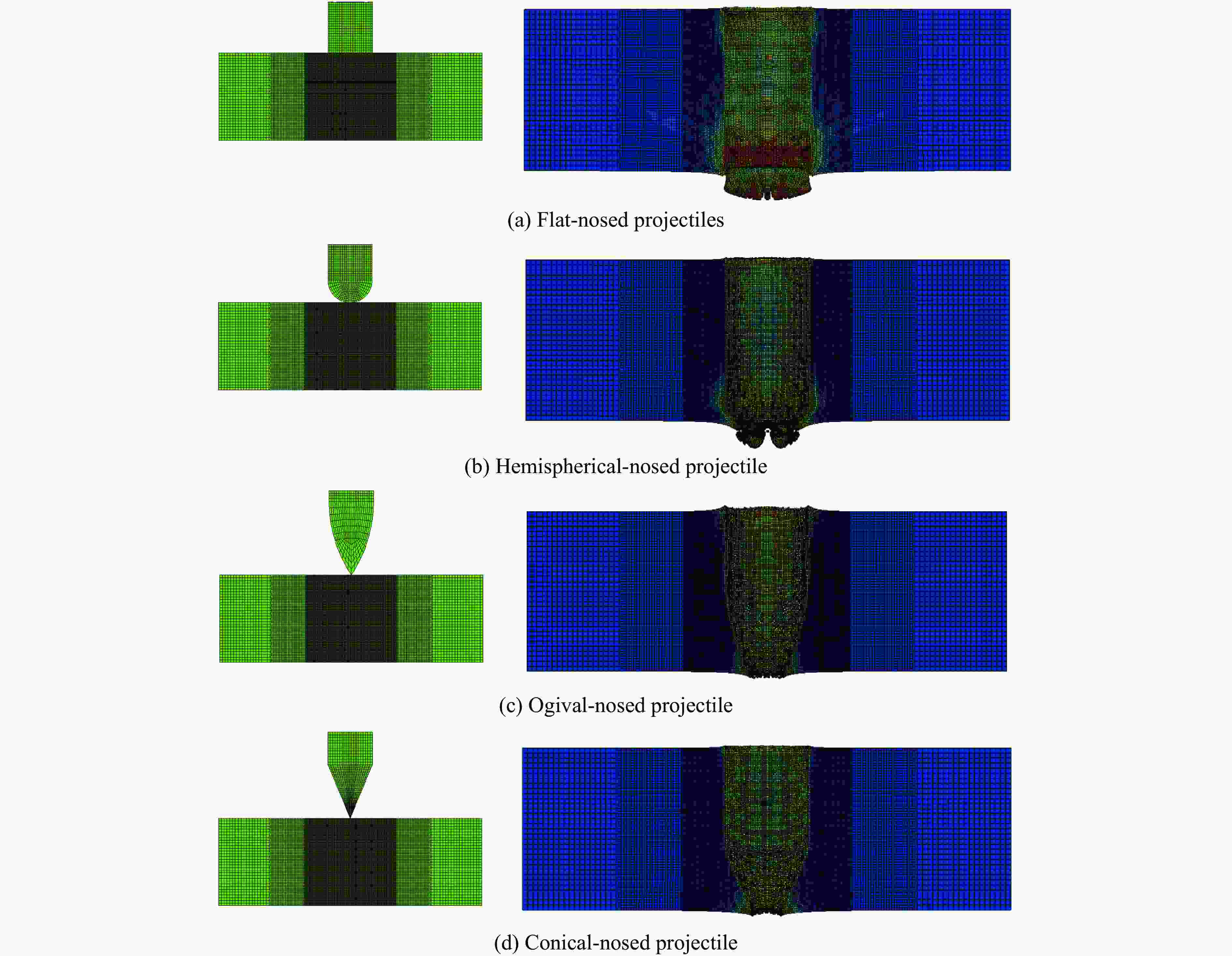

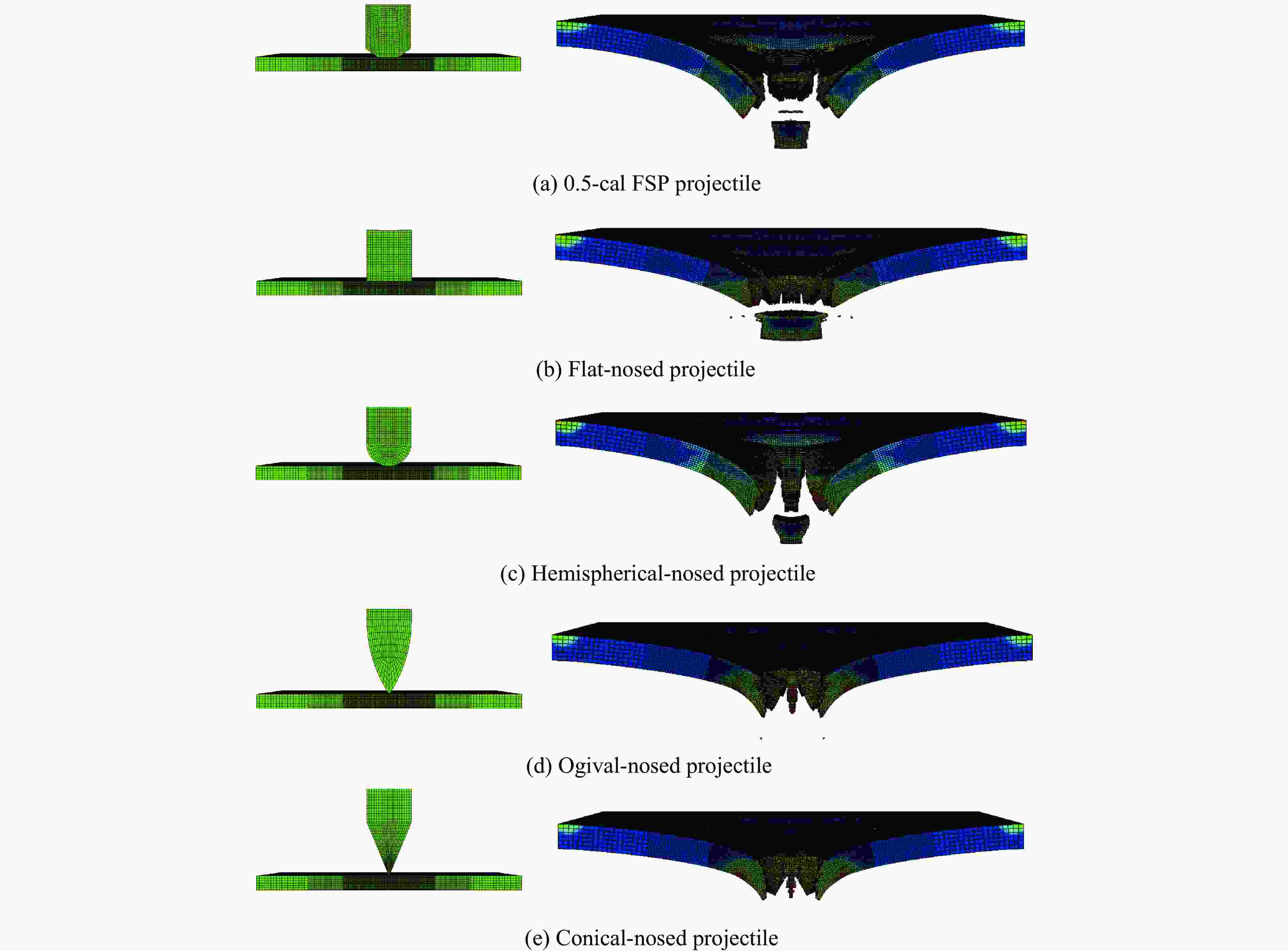

摘要: 镁合金在汽车、航空航天、电子工业等领域的应用日益广泛。为了准确描述AZ31B镁合金在高速冲击荷载作用下的响应,建立了金属动态本构模型,并编译成VUMAT用户子程序。采用万能试验机进行了光滑圆棒的准静态拉伸和异形剪切试验,基于ABAQUS/EXPLICIT建立了有限元模型,通过数值模拟校准了AZ31B镁合金的强度模型和失效准则的相关参数。通过对比数值模拟结果与0.5-cal FSP子弹及20 mm FSP子弹冲击AZ31B镁合金靶板试验结果,验证了模型的精确性和适用性,分析了弹头形状和靶板厚度对弹丸高速侵彻AZ31B镁合金的影响。研究发现:当前模型能较好地预测靶板的弹道极限和穿孔破坏形貌;不同形状弹丸冲击下AZ31B镁合金靶板的失效机制不同,平头弹对应的弹道极限最大,锥形弹对应的弹道极限最小;靶板厚度会影响失效模式,厚靶以剪切破坏为主,而薄靶以弯曲变形和花瓣形撕裂破坏为主。Abstract: Magnesium alloys have been widely utilized in the automotive, aerospace, and electronics industries. In this paper, a dynamic constitutive model for metal was developed and integrated into a VUMAT user subroutine to precisely predict the behavior of AZ31B magnesium alloy subject to high-velocity impact. Quasi-static smooth round bar tensile test and irregular shear test were conducted using a universal testing machine. Finite element models were developed in ABAQUS/EXPLICIT to numerically simulate these tests and to calibrate the relevant parameters of the strength model and failure criteria for AZ31B magnesium alloy. To validate the accuracy and applicability of the present model, the numerical results for 0.5-cal FSP bullet and 20 mm FSP bullet impacting AZ31B magnesium alloy plates were compared with test observations. It is found: the ballistic limit and perforation failure pattern of the plate can be accurately predicted by the present model; the failure mechanism of AZ31B magnesium alloy plates is influenced by projectile nose shape, with the highest ballistic limit corresponding to flat-nosed projectile and the lowest corresponding to conical-nosed projectile; the failure patterns are dependent on plate thickness, i. e., shear failure occurs in thicker plate, while bending deformation and petal-like tearing failures are dominated in thinner plate.

-

表 1 AZ31B镁合金板的化学成分及其质量分数

Table 1. Chemical compositions and mass fraction of the AZ31B magnesium alloy sheet

% Al Zn Mn Fe Cu Si Ni Ca Mg 3.01 0.97 0.3 1.8 ×10−46 ×10−43×10−3 2 ×10−51 ×10−695.7 表 2 AZ31B镁合金的材料参数

Table 2. Material parameters for AZ31B magnesium alloy

$ \rho_0 \rm{/(kg\cdot {m}^{-3}}) $ $ E\rm{/GPa} $ $ \nu $ $ {T}_{\rm{m}}\rm{/K} $ $ {T}_{\rm{a}}\rm{/K} $ $ \chi $ $ {c}_{{p}}{/({\mathrm{J}}\cdot {{\mathrm{kg}}}^{-1}\cdot {{\mathrm{K}}}^{-1})} $ 1780 [18]45[18] 0.34[18] 923 293 0.9 1020 [33]$ {C}_{0}/{({\mathrm{m}}\cdot{{\mathrm{s}}}^{-1})} $ $ {S}_{1} $ $ {\varGamma }_{0} $ $ {C}_{1} $ $ {C}_{2} $ $ {C}_{3} $ $ {C}_{4} $ 4516 [34]1.256[34] 1.43[34] 0.40 0.32 0.020 (−0.113)[31] −1.803 (2.544)[31] $ {A}_{\text{t}}\text{/MPa} $ $ {B}_{\text{t} }$ $ {n}_{\text{t}} $ $ {A}_{\text{s}}\text{/MPa} $ $ {B}_{\text{s}} $ $ {n}_{\rm s} $ $ {W}_{x} $ 170 56740 0.058 70 255 0.358 3.657 $ {B}_{y} $ $ {W}_{y} $ $ S $ $ {\dot{\varepsilon }}_{\text{quasi}}/{\rm s}^{-1} $ $ {\varepsilon }_{x} $ $ {m}_{1} $ $ {m}_{2} $ 4.617 1.064 0.2013 0.001 0.08 1.476 4.384 Note: The values in parentheses are the failure parameters when the temperature is greater than or equal to 573 K. 表 3 模型预测的弹道极限和试验数据的比较(0.5-cal FSP)

Table 3. Comparison between the ballistic limits predicted by the present model and obtained by test data (0.5-cal FSP)

$ a $ $ P $ $ {v}_{\text{bl}}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ Present model Test data 0.4924 1.839 523 507 表 4 模型预测的弹道极限与试验数据的比较(20 mm FSP)

Table 4. Comparison between the ballistic limits predicted by the present model and obtained by test data (20 mm FSP)

$ a $ $ P $ $ {v}_{\rm {bl}}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ Present model Test data 0.5018 1.819 498 477 表 5 不同子弹冲击下的弹道极限

Table 5. Ballistic limits under different bullet impacts

Bullet $ a $ $ P $ $ {v}_{\rm{bl}}/(\mathrm{m}\cdot {\mathrm{s}}^{-1}) $ Flat-nosed projectile 0.5417 1.550 560 Hemispherical-nosed projectile 0.6149 2.200 467 Ogival-nosed projectile 0.8591 2.390 422 Conical-nosed projectile 0.8919 2.105 414 -

[1] YANG Y, XIONG X M, CHEN J, et al. Research advances in magnesium and magnesium alloys worldwide in 2020 [J]. Journal of Magnesium and Alloys, 2021, 9(3): 705–747. doi: 10.1016/j.jma.2021.04.001 [2] SONG J F, CHEN J, XIONG X M, et al. Research advances of magnesium and magnesium alloys worldwide in 2021 [J]. Journal of Magnesium and Alloys, 2022, 10(4): 863–898. doi: 10.1016/j.jma.2022.04.001 [3] YANG Y, XIONG X M, CHEN J, et al. Research advances of magnesium and magnesium alloys worldwide in 2022 [J]. Journal of Magnesium and Alloys, 2023, 11(8): 2611–2654. doi: 10.1016/j.jma.2023.07.011 [4] ZHU Y P, GUO X R, LEI Y J, et al. Hydrated eutectic electrolytes for high-performance Mg-ion batteries [J]. Energy & Environmental Science, 2022, 15(3): 1282–1292. [5] DIERINGA H, STJOHN D, PÉREZ PRADO M T, et al. Editorial: latest developments in the field of magnesium alloys and their applications [J]. Frontiers in Materials, 2021, 8: 726297. doi: 10.3389/fmats.2021.726297 [6] BOBE K, WILLBOLD E, HAUPT M, et al. Biodegradable open-porous scaffolds made of sintered magnesium W4 and WZ21 short fibres show biocompatibility in vitro and in long-term in vivo evaluation [J]. Acta Biomaterialia, 2022, 148: 389–404. doi: 10.1016/j.actbio.2022.06.005 [7] MOHAMMADI ZERANKESHI M, ALIZADEH R, GERASHI E, et al. Effects of heat treatment on the corrosion behavior and mechanical properties of biodegradable Mg alloys [J]. Journal of Magnesium and Alloys, 2022, 10(7): 1737–1785. doi: 10.1016/j.jma.2022.04.010 [8] 谢奇峻. AZ31B镁合金冲击动态力学行为的实验和本构模型研究 [D]. 成都: 西南交通大学, 2018: 1–2.XIE Q J. Experimental and constitutive model study on impact dynamic mechanical behavior of AZ31B magnesium alloy [D]. Chengdu: Southwest Jiaotong University, 2018: 1–2. [9] FENG F, HUANG S Y, MENG Z H, et al. Experimental study on tensile property of AZ31B magnesium alloy at different high strain rates and temperatures [J]. Materials & Design, 2014, 57: 10–20. [10] ULACIA I, SALISBURY C P, HURTADO I, et al. Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures [J]. Journal of Materials Processing Technology, 2011, 211(5): 830–839. doi: 10.1016/j.jmatprotec.2010.09.010 [11] ZHANG W G, LI K, CHI R Q, et al. Insights into microstructural evolution and deformation behaviors of a gradient textured AZ31B Mg alloy plate under hypervelocity impact [J]. Journal of Materials Science & Technology, 2021, 91: 40–57. [12] PÄRNÄNEN T, ALDERLIESTEN R, RANS C, et al. Applicability of AZ31B-H24 magnesium in fibre metal laminates: an experimental impact research [J]. Composites Part A: Applied Science and Manufacturing, 2012, 43(9): 1578–1586. doi: 10.1016/j.compositesa.2012.04.008 [13] ZHANG F, LIU Z, WANG Y, et al. The modified temperature term on Johnson-Cook constitutive model of AZ31 magnesium alloy with {0002} texture [J]. Journal of Magnesium and Alloys, 2020, 8(1): 172–183. doi: 10.1016/j.jma.2019.05.013 [14] WANG Q L, BERTOLINI R, BRUSCHI S, et al. Anisotropic fracture behavior of AZ31 magnesium alloy sheets as a function of the stress state and temperature [J]. International Journal of Mechanical Sciences, 2019, 163: 105146. doi: 10.1016/j.ijmecsci.2019.105146 [15] EZHIL VENDHAN B, HARIKRISHNA K L, LAKSHMINARAYANAN A K. Numerical simulation on effect of impact velocity and target thickness in magnesium alloy AZ31B [J]. Applied Mechanics and Materials, 2015, 787: 291–295. doi: 10.4028/www.scientific.net/AMM.787.291 [16] 周琳. 金属材料新的动态本构模型 [D]. 合肥: 中国科学技术大学, 2019: 35–36.ZHOU L. A new dynamic constitutive model for metallic materials [D]. Hefei: University of Science and Technology of China, 2019: 35–36. [17] 潘鸿晨. AZ31B镁合金板材宏-微观力学模型和韧性断裂准则研究 [D]. 上海: 上海交通大学, 2018: 31–32.PAN H C. Study on Macro-Micro mechanical model and ductility fracture criterion of rolled AZ31B magnesium alloy [D]. Shanghai: Shanghai Jiao Tong University, 2018: 31–32. [18] FENG F, HUANG S Y, MENG Z H, et al. A constitutive and fracture model for AZ31B magnesium alloy in the tensile state [J]. Materials Science and Engineering: A, 2014, 594: 334–343. doi: 10.1016/j.msea.2013.11.008 [19] LI Z G, WANG J J, YANG H F, et al. A modified Johnson-Cook constitutive model for characterizing the hardening behavior of typical magnesium alloys under tension at different strain rates: experiment and simulation [J]. Journal of Materials Engineering and Performance, 2020, 29(12): 8319–8330. doi: 10.1007/s11665-020-05288-6 [20] KURUKURI S, WORSWICK M J, GHAFFARI TARI D, et al. Rate sensitivity and tension-compression asymmetry in AZ31B magnesium alloy sheet [J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2014, 372(2015): 20130216. doi: 10.1098/rsta.2013.0216 [21] 吴秀敏, 池成忠, 崔晓磊, 等. 应变速率与温度对AZ31B镁合金板材各向异性的影响 [J]. 轻合金加工技术, 2020, 48(5): 23–28.WU X M, CHI C Z, CUI X L, et al. Effect of strain rate and temperature on anisotropy of AZ31B magnesium alloy sheet [J]. Light Alloy Fabrication Technology, 2020, 48(5): 23–28. [22] MENG Z H, HUANG S Y, HU J H. Research on flow stress of magnesium alloy sheet under warm and high strain rate forming condition [J]. Advanced Materials Research, 2011, 189: 2522–2525. [23] KANG J E, YOON J Y, CHOI I K, et al. Development of jigs for planar measurement with DIC and determination of magnesium material properties using jigs [J]. Design & Manufacturing, 2021, 15(2): 23–29. [24] RODRIGUEZ A K, KRIDLI G, AYOUB G, et al. Effects of the strain rate and temperature on the microstructural evolution of twin-rolled cast wrought AZ31B alloys sheets [J]. Journal of Materials Engineering and Performance, 2013, 22(10): 3115–3125. doi: 10.1007/s11665-013-0598-8 [25] DONG J R, ZHANG D F, DONG Y F, et al. Critical damage value of AZ31B magnesium alloy with different temperatures and strain rates [J]. Rare Metals, 2021, 40(1): 137–142. doi: 10.1007/s12598-014-0440-y [26] XUE S, YANG T, LIU X D, et al. Strain rate and temperature effects on formability and microstructure of AZ31B magnesium alloy sheet [J]. Metals, 2022, 12(7): 1103. doi: 10.3390/met12071103 [27] RODRIGUEZ A K, AYOUB G A, MANSOOR B, et al. Effect of strain rate and temperature on fracture of magnesium alloy AZ31B [J]. Acta Materialia, 2016, 112: 194–208. doi: 10.1016/j.actamat.2016.03.061 [28] JAIMIN A, KOTKUNDE N, SADHUKHAN A, et al. Flow stress and work hardening behaviour of Mg-3Al-1Zn alloy [J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2023, 237(3): 719–730. doi: 10.1177/09544089221106970 [29] 周琳, 文鹤鸣. 金属材料失效分析的新方法 [J]. 高压物理学报, 2019, 33(1): 014103. doi: 10.11858/gywlxb.20180613ZHOU L, WEN H M. A new approach for the failure of metallic materials [J]. Chinese Journal of High Pressure Physics, 2019, 33(1): 014103. doi: 10.11858/gywlxb.20180613 [30] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures [C]//Proceedings of the 7th International Symposium on Ballistic. The Hague, Netherlands, 1983. [31] JIA W T, WANG L J, MA L F, et al. Deformation failure behavior and fracture model of twin-roll casting AZ31 alloy under multiaxial stress state [J]. Journal of Materials Research and Technology, 2022, 17: 2047–2058. [32] JONES T L, DELORME R D. Development of a ballistic specification for magnesium alloy AZ31B: ARL-TR-4664 [R]. Aberdeen Proving Ground: Army Research Laboratory, 2008. [33] GSCHNEIDNER K A JR. Physical properties and interrelationships of metallic and semimetallic elements [J]. Solid State Physics, 1964, 16: 275–426. [34] 孙洪敏. AZ31/1060磁脉冲焊接界面成形机制数值模拟与试验研究 [D]. 太原: 太原科技大学, 2021: 32.SUN H M. Numerical simulation and experimental study on interface forming mechanism of AZ31/1060 magnetic pulse welding [D]. Taiyuan: Taiyuan University of Science and Technology, 2021: 32. [35] RECHT R F, IPSON T W. Ballistic perforation dynamics [J]. Journal of Applied Mechanics, 1963, 30(3): 384–390. -

下载:

下载: