Dispersion Characteristics of Spherical Fragments Driven by Cylindrical Charge

-

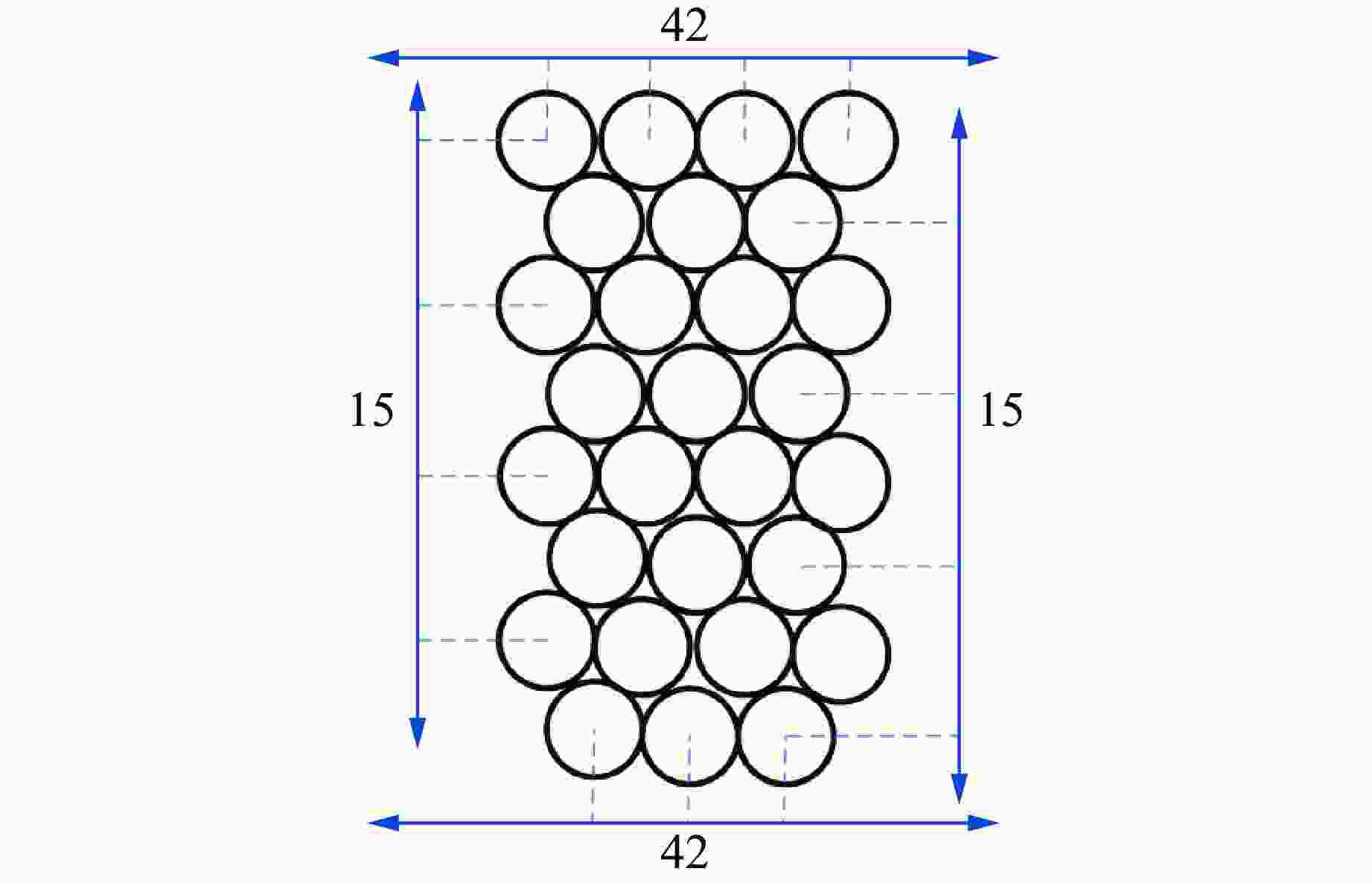

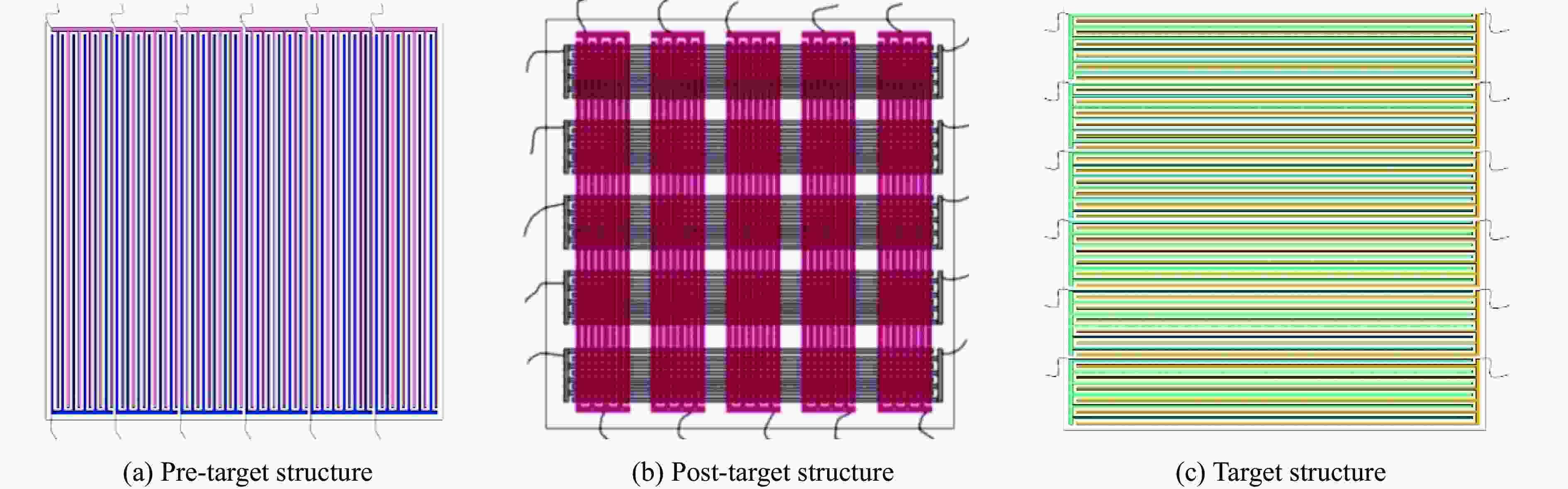

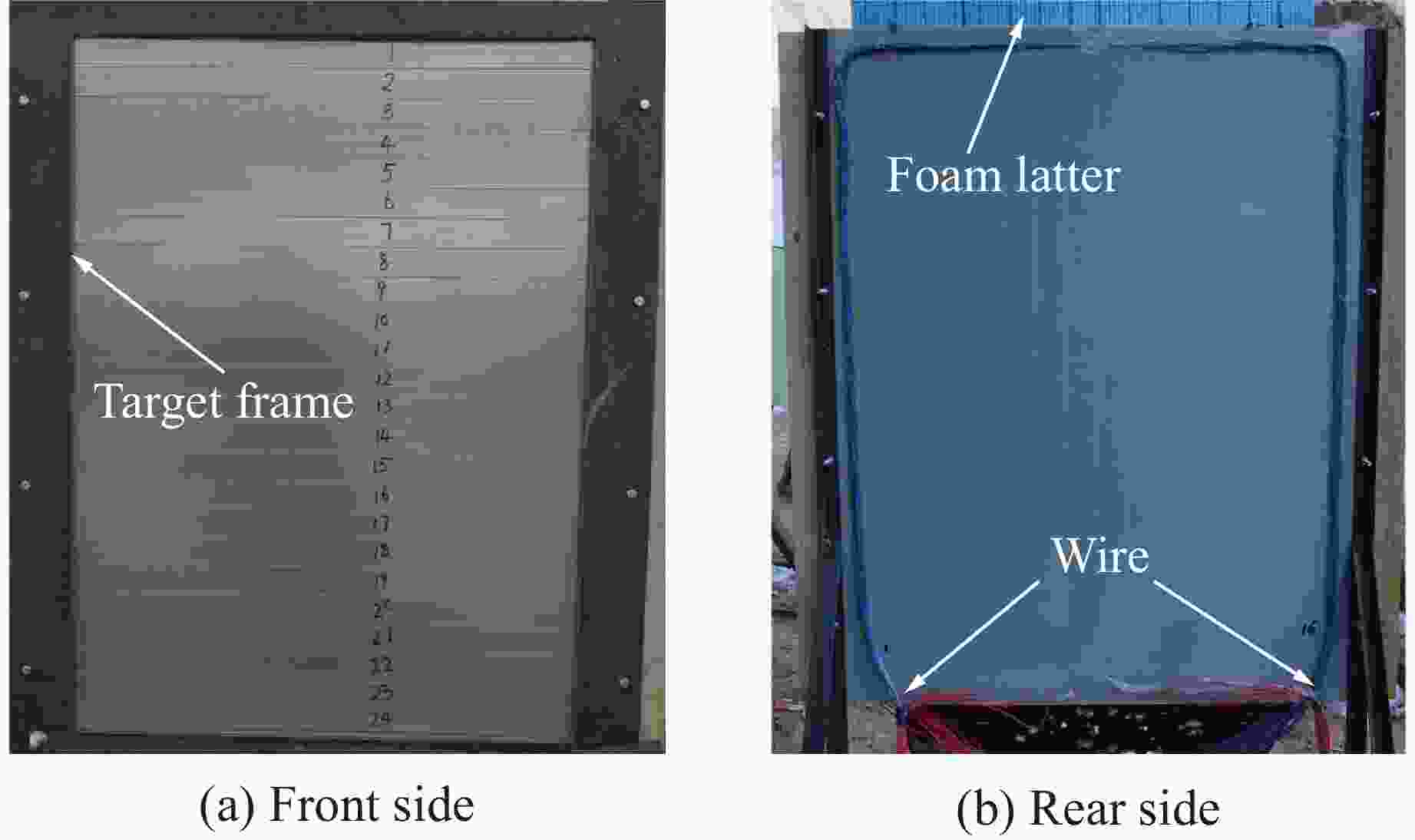

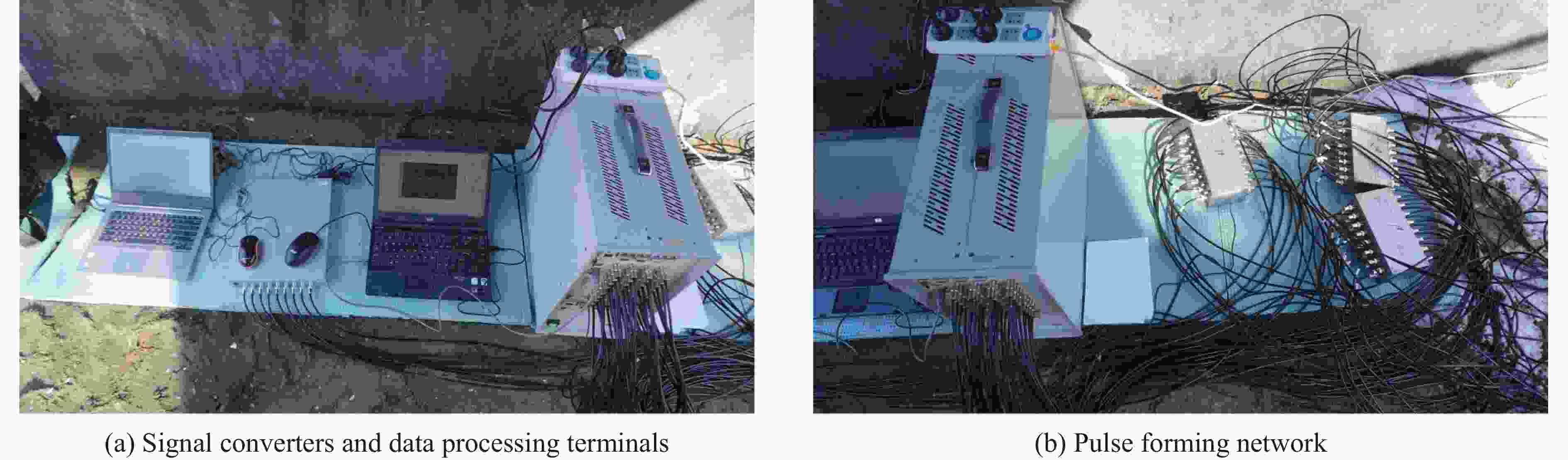

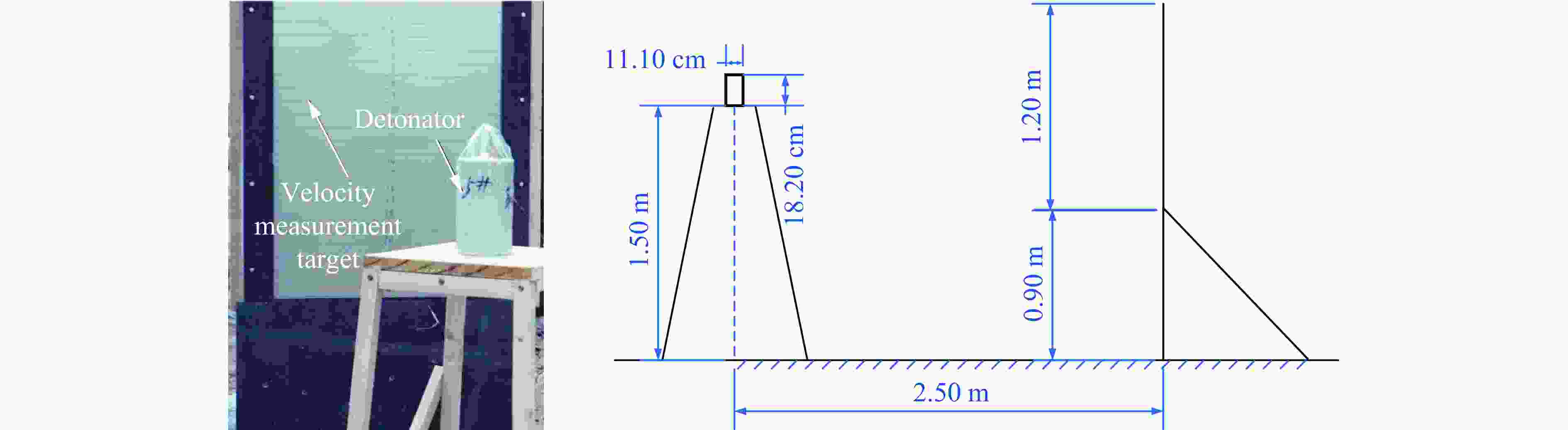

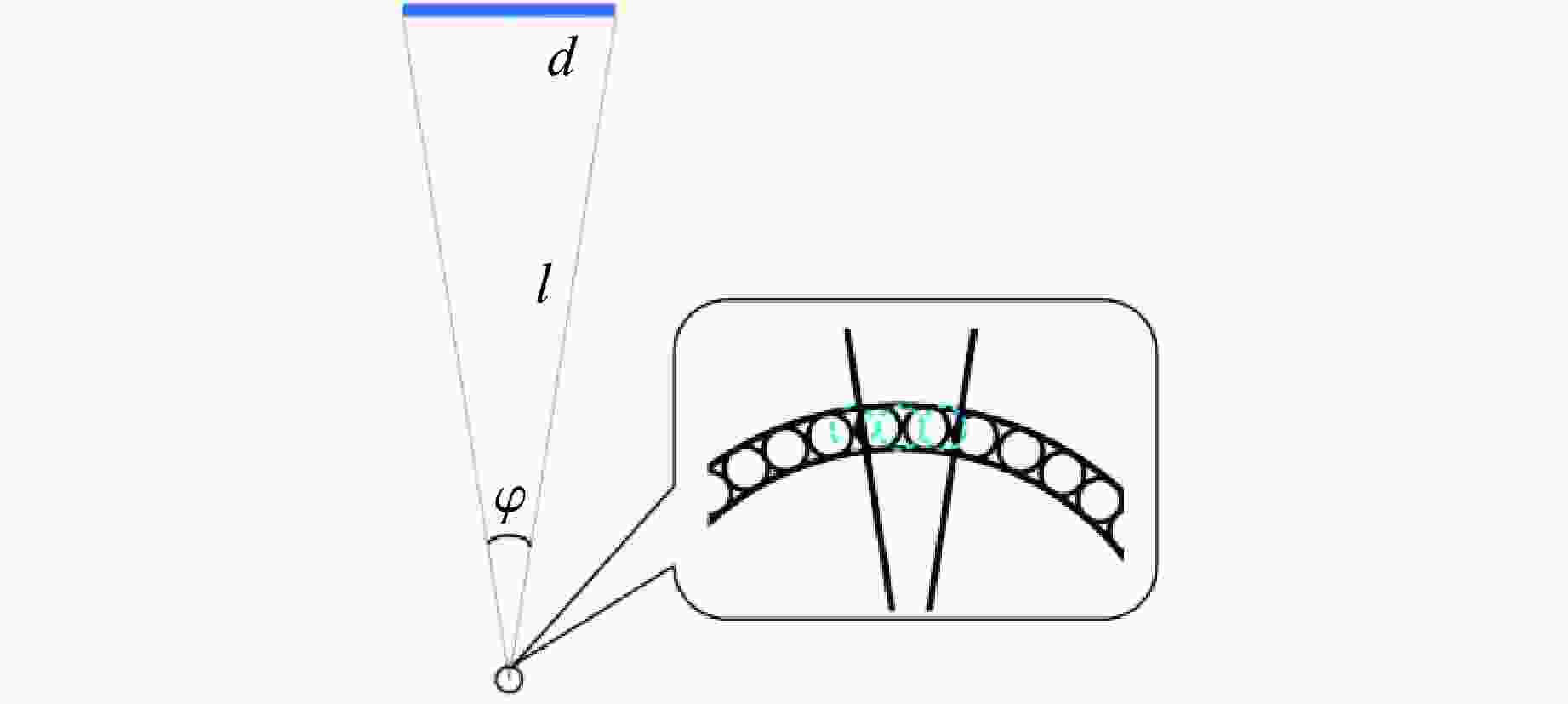

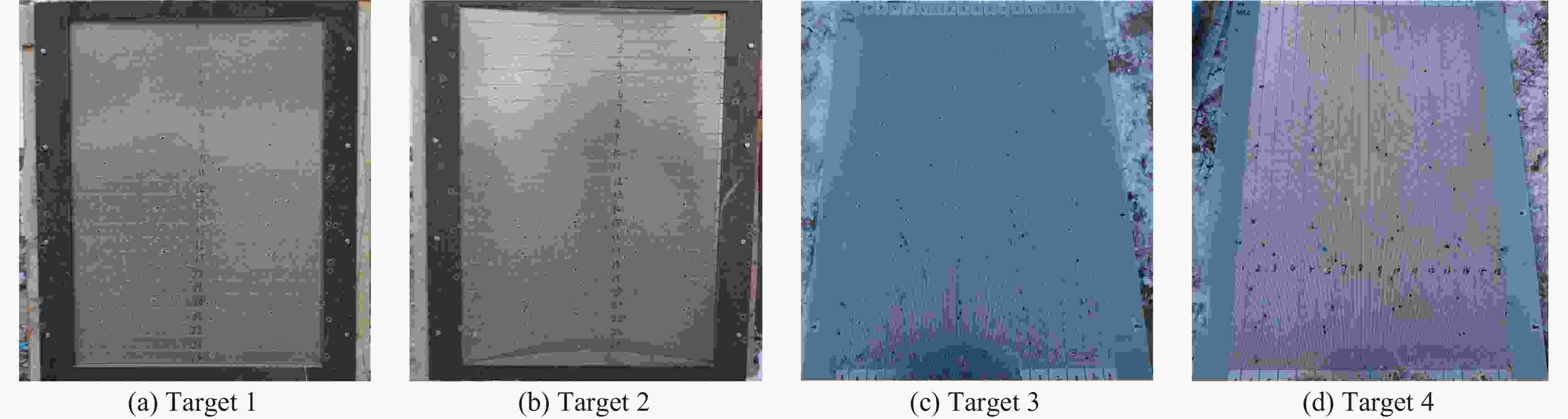

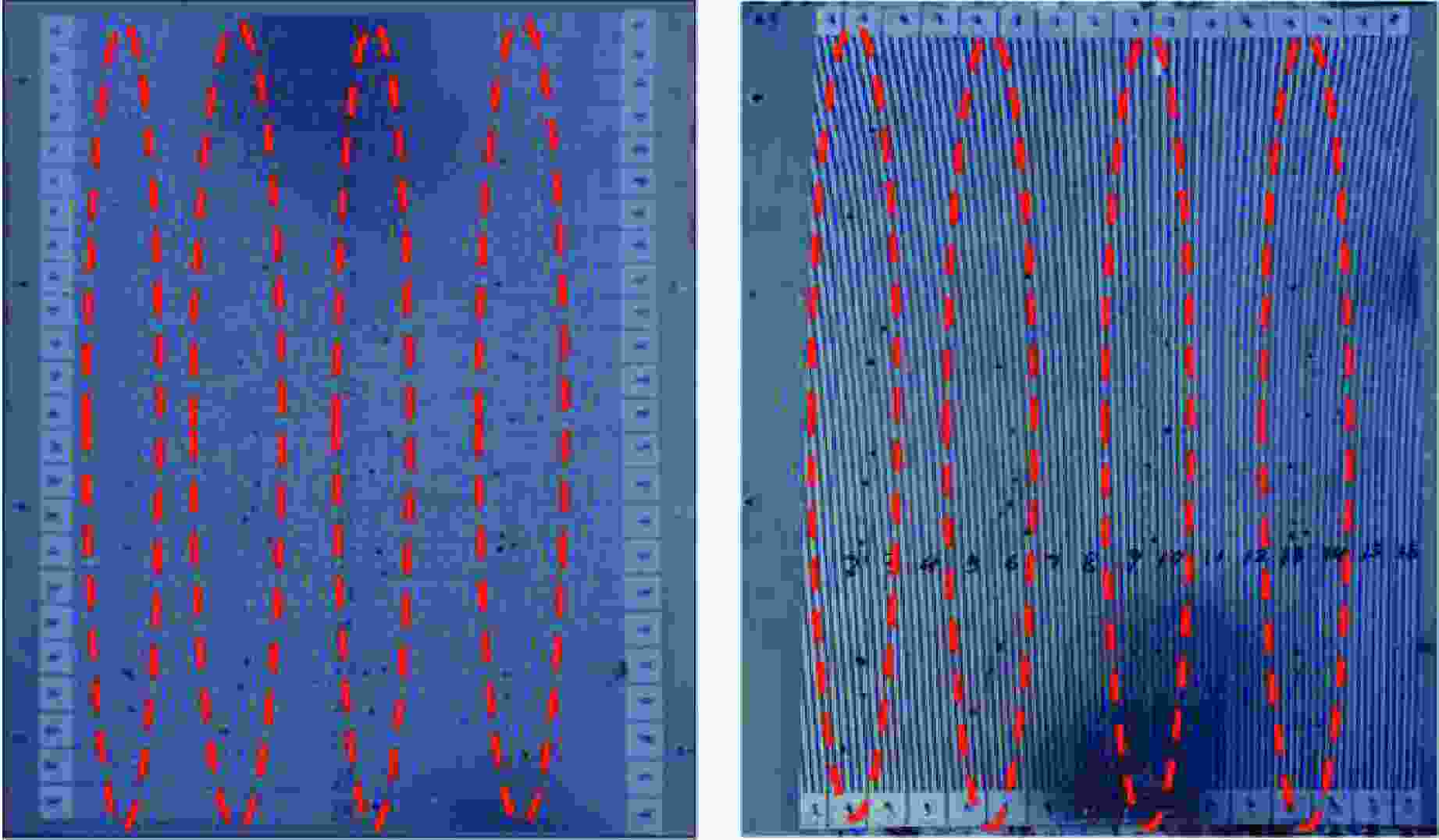

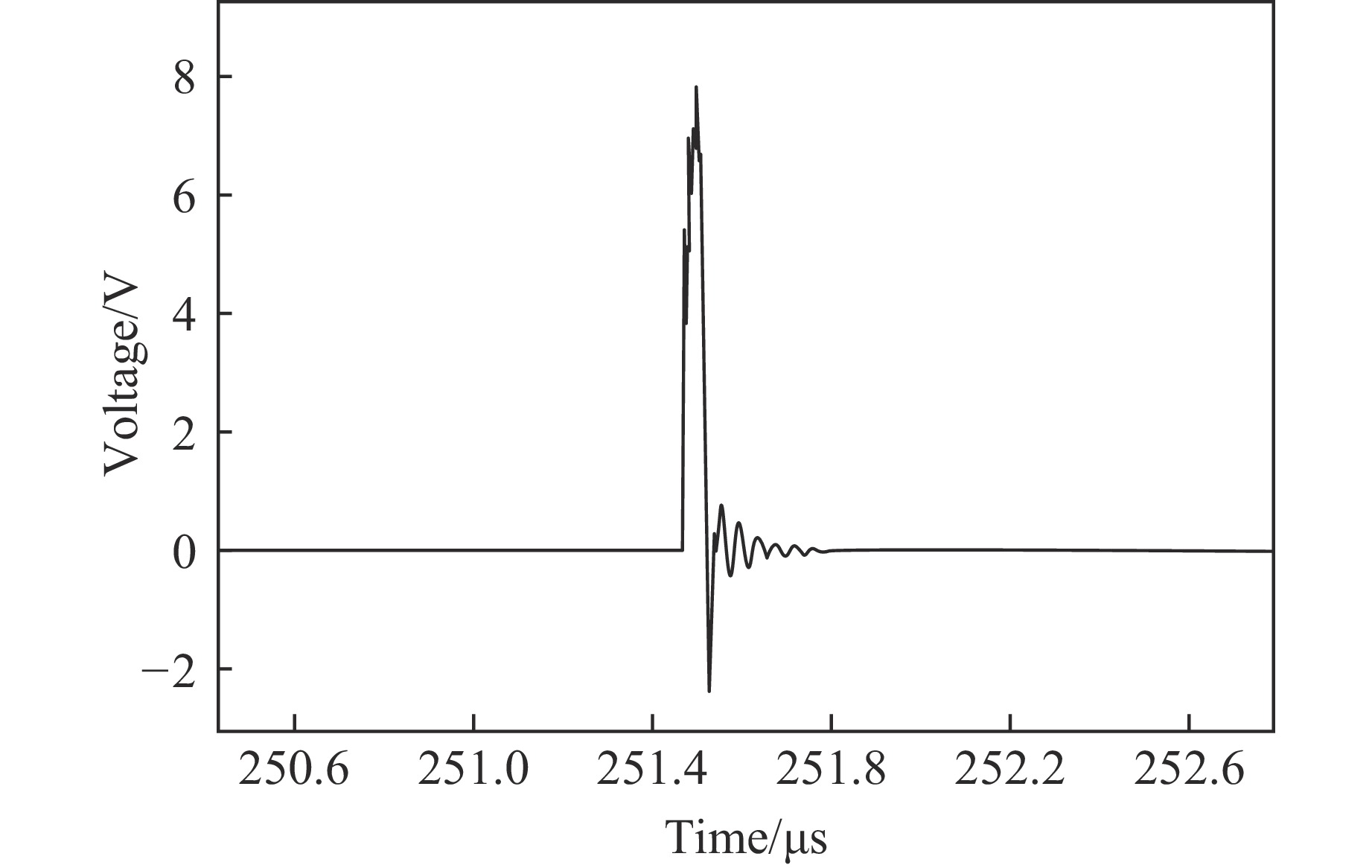

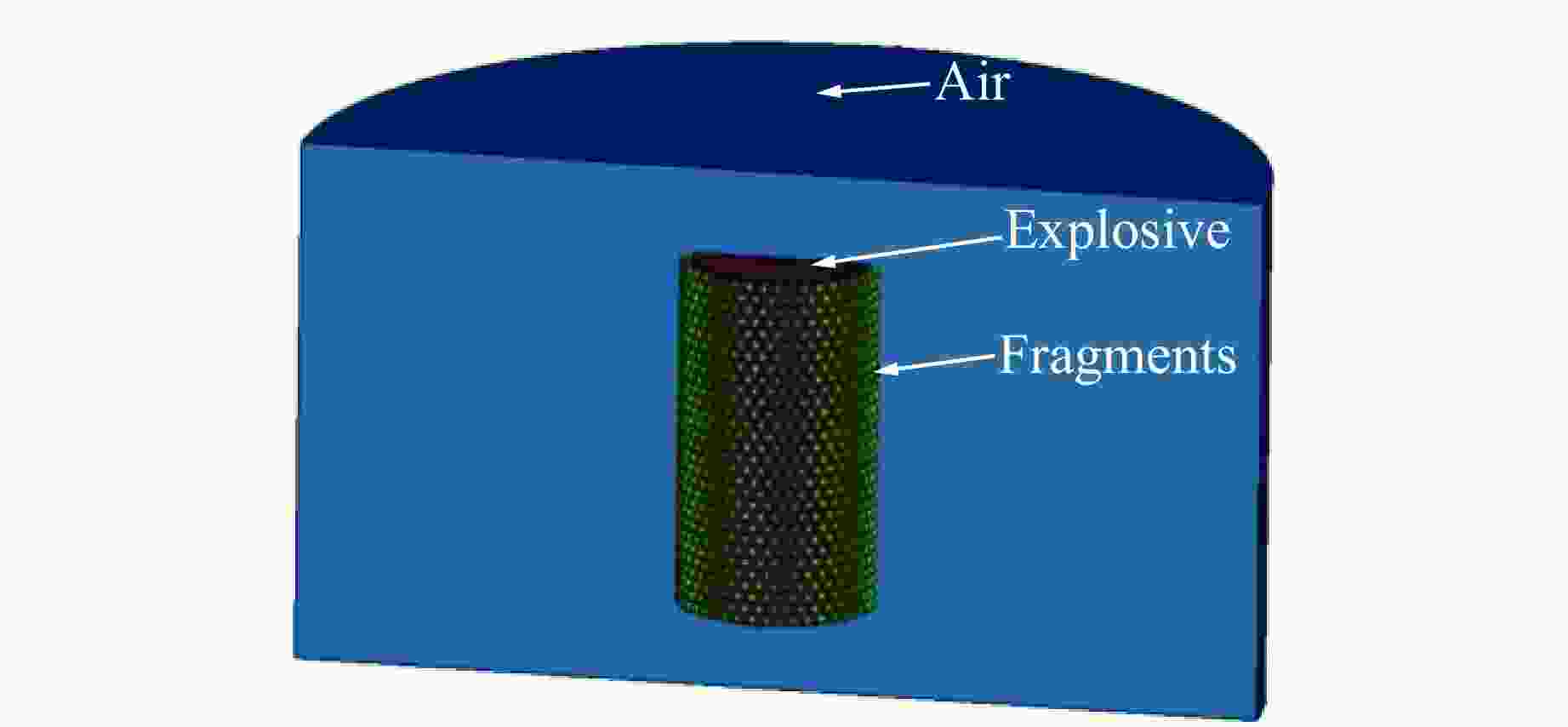

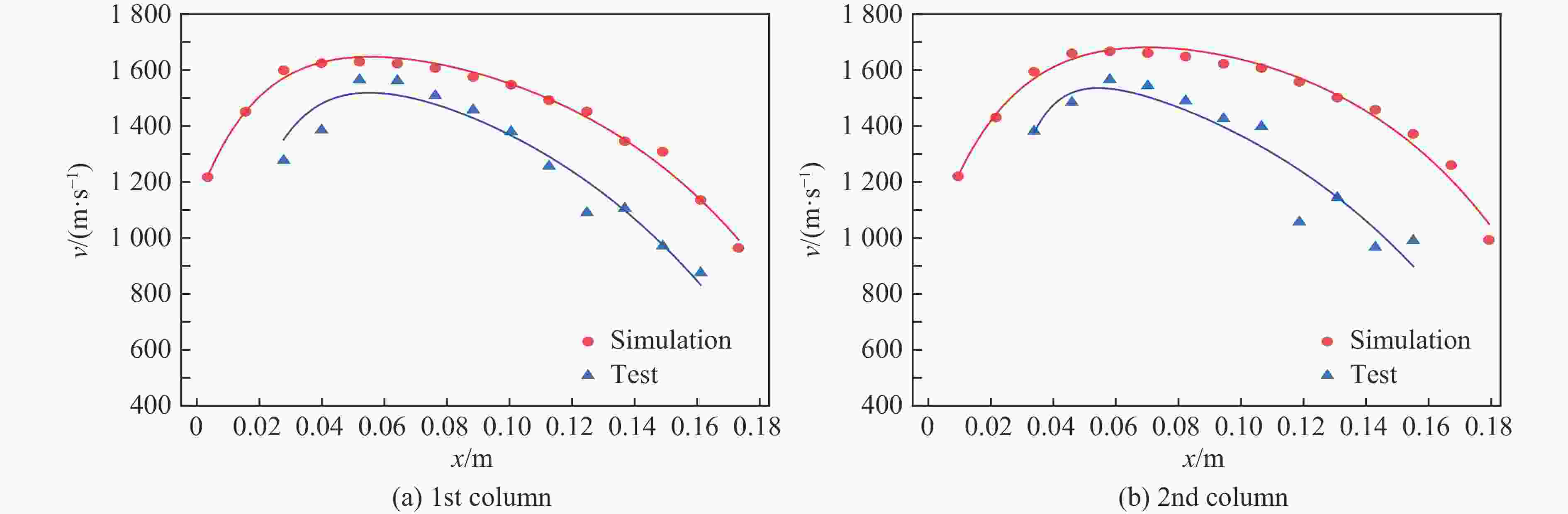

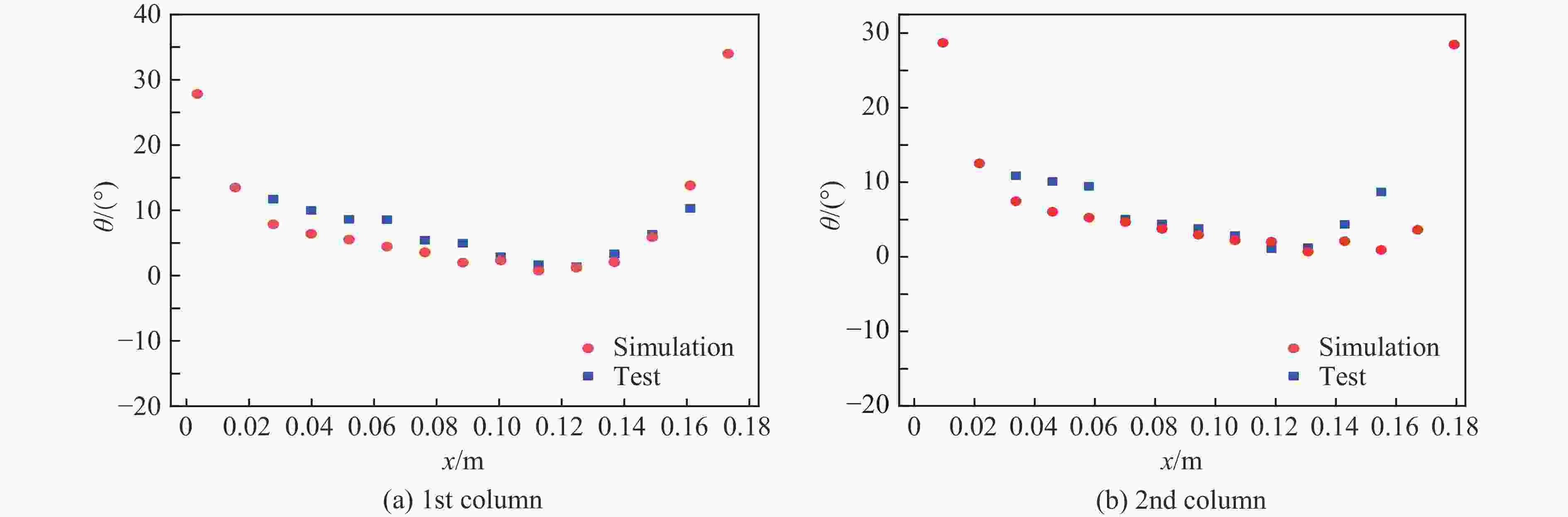

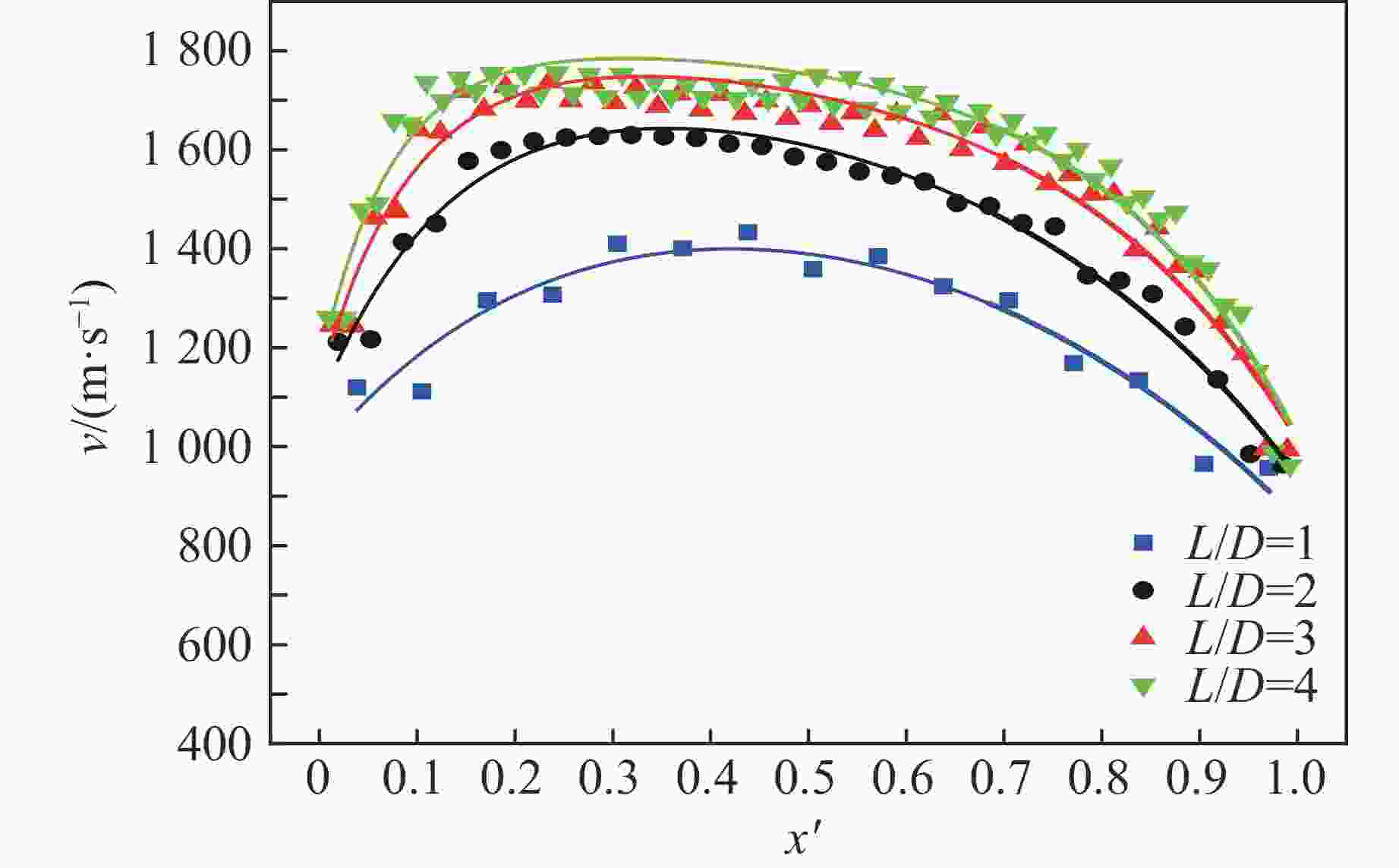

摘要: 为了研究球形预制钨破片在圆柱形装药驱动下的飞散规律,开展了预制破片战斗部飞散试验。针对传统梳状靶无法测量破片群速度分布的问题,设计并制作了一种全新的交叉梳状靶,成功测得了多个破片穿靶产生的脉冲信号和着靶位置。采用LS-DYNA模拟研究了圆柱形装药爆炸驱动球形破片的飞散特性。结果表明:数值模拟结果与试验结果吻合良好,交叉梳状测速靶能够较为准确地测量多个破片的飞散速度;增加装药长径比可以削弱装药两端稀疏波对破片速度的影响,但效果随长径比增加而逐渐减弱。Abstract: To investigate the dispersion characteristics of spherical tungsten fragments driven by a cylindrical charge, dispersion tests were conducted on a warhead with spherical prefabricated fragments. Considering the limitation of traditional comb targets, which can only measure the maximum velocity instead of the velocity distribution of the fragment group, a novel crossed-comb target was designed and fabricated. This velocity measurement device successfully recorded the pulse signals generated by multiple fragments penetrating the target and the impact positions. Numerical simulations were conducted using LS-DYNA to calculate the dispersion characteristics of spherical fragments driven by cylindrical charges. The results indicate that the numerical simulation results agree well with the test data. The designed crossed-comb shaped target can accurately measure the scattering velocities of multiple fragments. Increasing the length-to-diameter ratio can mitigate the effect of rarefaction waves at both ends of the charge on the fragment velocities; however, this mitigating effect diminishes as the length-to-diameter ratio continues to increase.

-

表 1 速度测量中靶板设置

Table 1. Target plate setting for velocity measurement

Test No. Target No. l/m 1 1 2.40 2 2 2.50 3 3 2.53 4 4 2.53 表 2 各交叉梳状靶上破片穿孔数统计

Table 2. Statistics of the number of fragment perforations on each cross-combed target

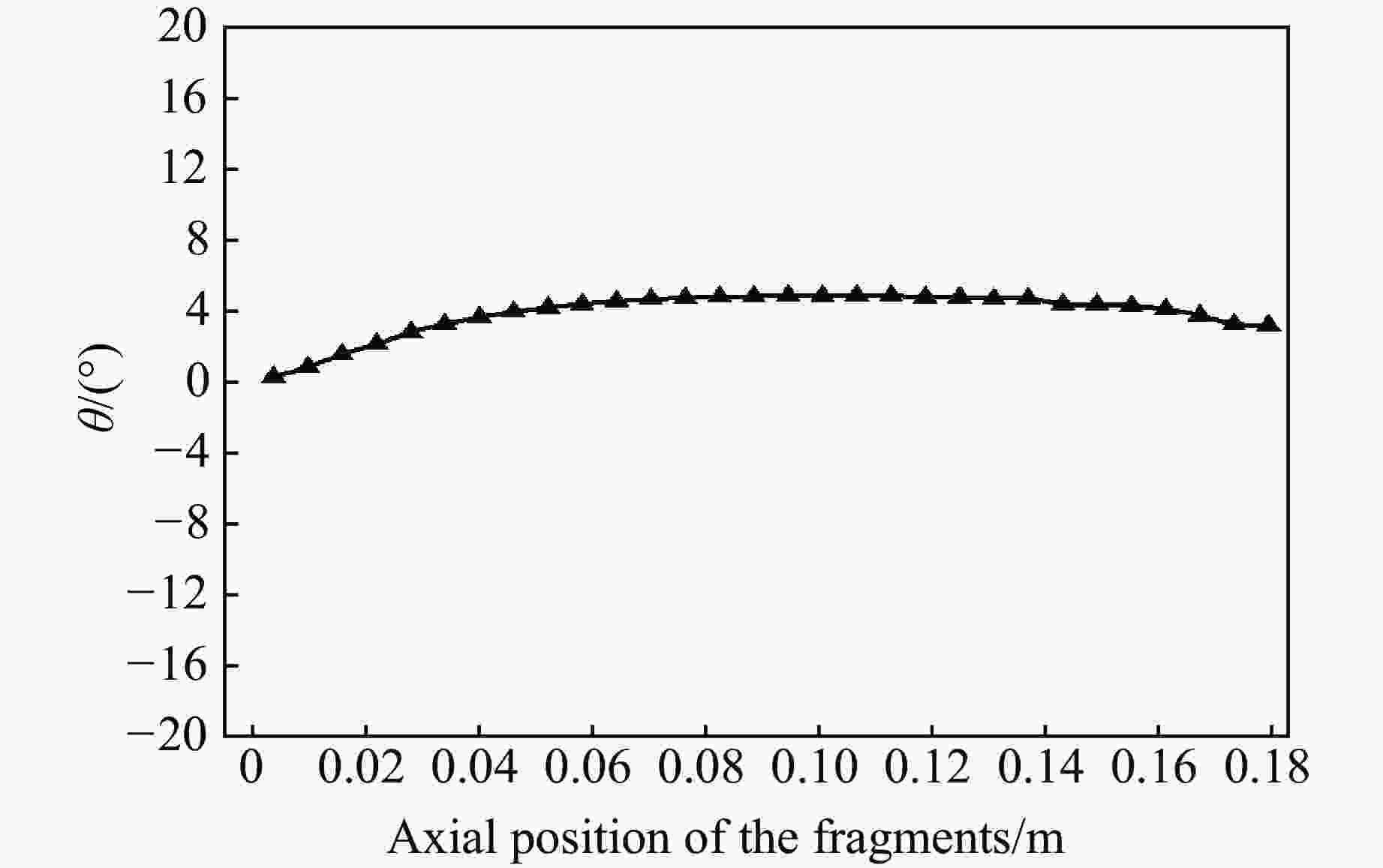

Target No. Number of perforations 1st column 2nd column 3rd column 4th column Total 1 12 11 12 12 47 2 12 11 11 13 47 3 12 11 12 12 47 4 12 14 12 12 50 表 3 测速靶3上着靶破片的飞散角

Table 3. Dispersion angles of the fragments on the velocity measurement target 3

Serial No. $ \theta $/(°) 1st column 2nd column 3rd column 4th column 1 10.30 8.70 10.72 9.07 2 6.32 4.34 5.85 3.66 3 3.34 1.22 2.85 1.18 4 1.36 1.08 1.90 0.85 5 1.69 2.85 1.04 1.10 6 2.90 3.80 2.67 2.71 7 4.97 4.40 4.99 4.44 8 5.42 5.04 5.47 4.95 9 8.59 9.45 8.72 5.06 10 8.61 10.10 8.90 8.46 11 9.99 10.87 9.95 9.48 12 11.70 10.66 11.13 表 4 试验测得的破片飞散速度

Table 4. Measured fragment dispersion velocities from the test

Serial No. v/(m·s−1) Serial No. v/(m·s−1) 1st column 2nd column 1st column 2nd column 1 874.96 988.41 7 1457.39 1489.04 2 970.88 964.78 8 1508.74 1543.37 3 1105.71 1142.22 9 1562.08 1564.86 4 1090.10 1055.14 10 1564.89 1483.69 5 1256.42 1396.95 11 1385.48 1380.44 6 1380.11 1425.48 12 1276.79 表 5 93钨球形破片的材料参数

Table 5. Material parameters of 93 tungsten spherical fragments

ρ/(g·cm−3) σs/GPa E/GPa G/GPa μ 17.6 1.506 300 137 0.22 表 6 8701炸药性能参数

Table 6. 8701 explosive performance parameters

ρ/(g·cm−3) vD/(km·s−1) pCJ/GPa A/GPa B/GPa R1 R2 1.7 8.3 30 581.4 9.8016 4.1 1.4 表 7 不同长径比下的破片速度

Table 7. Fragments velocities under varying length-to-diameter ratios

L/D vmax/(m·s−1) vmin/(m·s−1) vave/(m·s−1) 1 1432.98 956.72 1244.25 2 1629.43 963.78 1447.54 3 1737.14 993.59 1557.48 4 1755.82 961.62 1600.81 -

[1] 洪豆, 郑宇, 李文彬, 等. 破片战斗部杀伤面积影响规律研究 [J]. 兵器装备工程学报, 2021, 42(5): 37–42. doi: 10.11809/bqzbgcxb2021.05.007HONG D, ZHENG Y, LI W B, et al. Research on influence law of fragment warhead’s killing area [J]. Journal of Ordnance Equipment Engineering, 2021, 42(5): 37–42. doi: 10.11809/bqzbgcxb2021.05.007 [2] GURNEY R W. The initial velocities of fragments from bombs, shells and grenades: BRL 405 [R]. Maryland: Army Ballistic Research Laboratory, 1943. [3] ZULKOSKI T. Development of optimum theoretical warhead design criteria: B015617 [R]. China Lake, California: Naval Weapons Center, 1976: 39–44. [4] CHARRON Y J. Estimation of velocity distribution of fragmenting warheads using a modified Gurney method [D]. Wright Patterson: Air Force Institute of Technology, 1979. [5] HENNEQUIN E. Influence of the edge effects on the initial velocities of fragments from a warhead [C]//Proceedings of the 9th International Symposium on Ballistics. Shrivenham, 1986. [6] POOLE C J, OCKENDON J, CURTIS J. Gas leakage from fragmentation warheads [C]//Proceedings of the 20th International Symposium on Ballistics. Florida, 2002. [7] 蒋浩征. 杀伤战斗部破片飞散初速v0的计算 [J]. 兵工学报, 1980(1): 68–79.JIANG H Z. Calculation of initial velocity v0 of fragments of a lethal warhead [J]. Acta Armamentarii, 1980(1): 68–79. [8] BACKOFEN J E. The effects of cylinder geometry and material on Gurney velocities and gas-push Gurney velocities measured during cylinder test experiments [R]. Oak Hill: BRIGS, 2002. [9] 宋锋, 蒋建伟. 杀爆战斗部设计专家系统研究 [J]. 弹箭与制导学报, 2007, 27(4): 119–122. doi: 10.3969/j.issn.1673-9728.2007.04.035SONG F, JIANG J W. Research on the expert design system of blast and fragmentation warhead [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2007, 27(4): 119–122. doi: 10.3969/j.issn.1673-9728.2007.04.035 [10] TAYLOR G I. The fragmentation of tubular bombs [J]. Scientific Papers of GI Taylor, 1963, 3(44): 387–390. [11] LI Y, CHEN D, JIANG M, et al. Research on the characteristic of projectile fragments dispersion based on fragment warhead design [J]. IOP Conference Series: Materials Science and Engineering, 2019, 573: 012104. doi: 10.1088/1757-899X/573/1/012104 [12] 冯顺山, 崔秉贵. 战斗部破片初速轴向分布规律的实验研究 [J]. 兵工学报, 1987(4): 60–63.FENG S S, CUI B G. An experimental investigation for the axial distribution of initial velocity of shells [J]. Acta Armamentarii, 1987(4): 60–63. [13] HUANG G Y, LI W, FENG S S. Axial distribution of fragment velocities from cylindrical casing under explosive loading [J]. International Journal of Impact Engineering, 2015, 76: 20–27. doi: 10.1016/j.ijimpeng.2014.08.007 [14] 王高, 尹国鑫, 李仰军, 等. 电阻网靶破片群速度测量方法 [J]. 探测与控制学报, 2011, 33(3): 47–50, 55. doi: 10.3969/j.issn.1008-1194.2011.03.011WANG G, YIN G X, LI Y J, et al. Fragments velocity measuring based on resistor net target [J]. Journal of Detection & Control, 2011, 33(3): 47–50, 55. doi: 10.3969/j.issn.1008-1194.2011.03.011 [15] 田会, 金朋刚, 田亚男, 等. 一种用于破片测速的环形光幕装置 [J]. 测试技术学报, 2018, 32(4): 353–357. doi: 10.3969/j.issn.1671-7449.2018.04.014TIAN H, JIN P G, TIAN Y N, et al. Study on the circular ring light screen device for measuring velocity of flying fragments [J]. Journal of Test and Measurement Technology, 2018, 32(4): 353–357. doi: 10.3969/j.issn.1671-7449.2018.04.014 [16] 马竹新, 王代华, 张瑞刚, 等. 基于可变阻抗靶网的多通道破片测速系统 [J]. 现代电子技术, 2022, 45(11): 83–87. doi: 10.16652/j.issn.1004⁃373x.2022.11.016MA Z X, WANG D H, ZHANG R G, et al. Burst fragment’s multi-channel speed measuring system based on variable impedance target [J]. Modern Electronics Technique, 2022, 45(11): 83–87. doi: 10.16652/j.issn.1004⁃373x.2022.11.016 [17] 戴志远, 闫克丁. 基于高速相机的破片速度计算方法 [J]. 计算机与数字工程, 2021, 49(8): 1647–1650. doi: 10.3969/j.issn.1672-9722.2021.08.028DAI Z Y, YAN K D. Fragment velocity calculation method based on high speed camera [J]. Computer & Digital Engineering, 2021, 49(8): 1647–1650. doi: 10.3969/j.issn.1672-9722.2021.08.028 [18] 史志鑫, 尹建平. 起爆方式对预制破片飞散性能影响的数值模拟研究 [J]. 兵器装备工程学报, 2018, 39(12): 84–88. doi: 10.11809/bqzbgcxb2018.12.017SHI Z X, YIN J P. Numerical simulation study on effect of detonation method on the dispersion performance of prefabricated fragments [J]. Journal of Ordnance Equipment Engineering, 2018, 39(12): 84–88. doi: 10.11809/bqzbgcxb2018.12.017 [19] 邓吉平, 胡毅亭, 贾宪振, 等. 爆炸驱动球形破片飞散的数值模拟 [J]. 弹道学报, 2008, 20(4): 96–99.DENG J P, HU Y T, JIA X Z, et al. Numerical simulation of scattering characteristics of spherical fragment under blasting [J]. Journal of Ballistics, 2008, 20(4): 96–99. [20] 刘荣琦. 预制破片爆轰过程模拟与仿真 [D]. 沈阳: 沈阳理工大学, 2023.LIU R Q. Simulation and simulation of detonation process of prefabricated fragments [D]. Shenyang: Shenyang Ligong University, 2023. [21] 李明星, 王志军, 黄阳洋, 等. 不同形状轴向预制破片的飞散特性研究 [J]. 兵器装备工程学报, 2017, 38(12): 65–69. doi: 10.11809/scbgxb2017.12.016LI M X, WANG Z J, HUANG Y Y, et al. Study on the scattering characteristics of different shape axial prefabricated fragment [J]. Journal of Ordnance Equipment Engineering, 2017, 38(12): 65–69. doi: 10.11809/scbgxb2017.12.016 [22] 李明静. 破片和冲击波对典型飞机机翼联合毁伤效应的研究 [D]. 北京: 北京理工大学, 2020.LI M J. Research on combined effects of fragment and blast loading on the wing of typical aircraft [D]. Beijing: Beijing Institute of Technology, 2020. [23] 马宏伟, 王珂, 李艳, 等. 基于数字图像处理的破片速度参数测量 [J]. 测试技术学报, 2004, 18(4): 355–358. doi: 10.3969/j.issn.1671-7449.2004.04.017MA H W, WANG K, LI Y, et al. Fragment velocity measurement based on digital image processing [J]. Journal of Test and Measurement Technology, 2004, 18(4): 355–358. doi: 10.3969/j.issn.1671-7449.2004.04.017 [24] 李丽萍, 孔德仁, 易春林, 等. 战斗部破片速度测量方法综述 [J]. 测控技术, 2014, 33(11): 5–7, 13. doi: 10.3969/j.issn.1000-8829.2014.11.002LI L P, KONG D R, YI C L, et al. Review of method to measure the velocity of warhead fragments [J]. Measurement & Control Technology, 2014, 33(11): 5–7, 13. doi: 10.3969/j.issn.1000-8829.2014.11.002 [25] 谭多望, 王广军, 龚晏青, 等. 球形钨合金破片空气阻力系数实验研究 [J]. 高压物理学报, 2007, 21(3): 231–236. doi: 10.11858/gywlxb.2007.03.002TAN D W, WANG G J, GONG Y Q, et al. Experimental studies on air drag coefficient of spherical tungsten fragments [J]. Chinese Journal of High Pressure Physics, 2007, 21(3): 231–236. doi: 10.11858/gywlxb.2007.03.002 -

下载:

下载: