Acoustic Emission and Damage Evolution Characteristics of Carbon Nanotube Concrete Three-Point Bending Beam

-

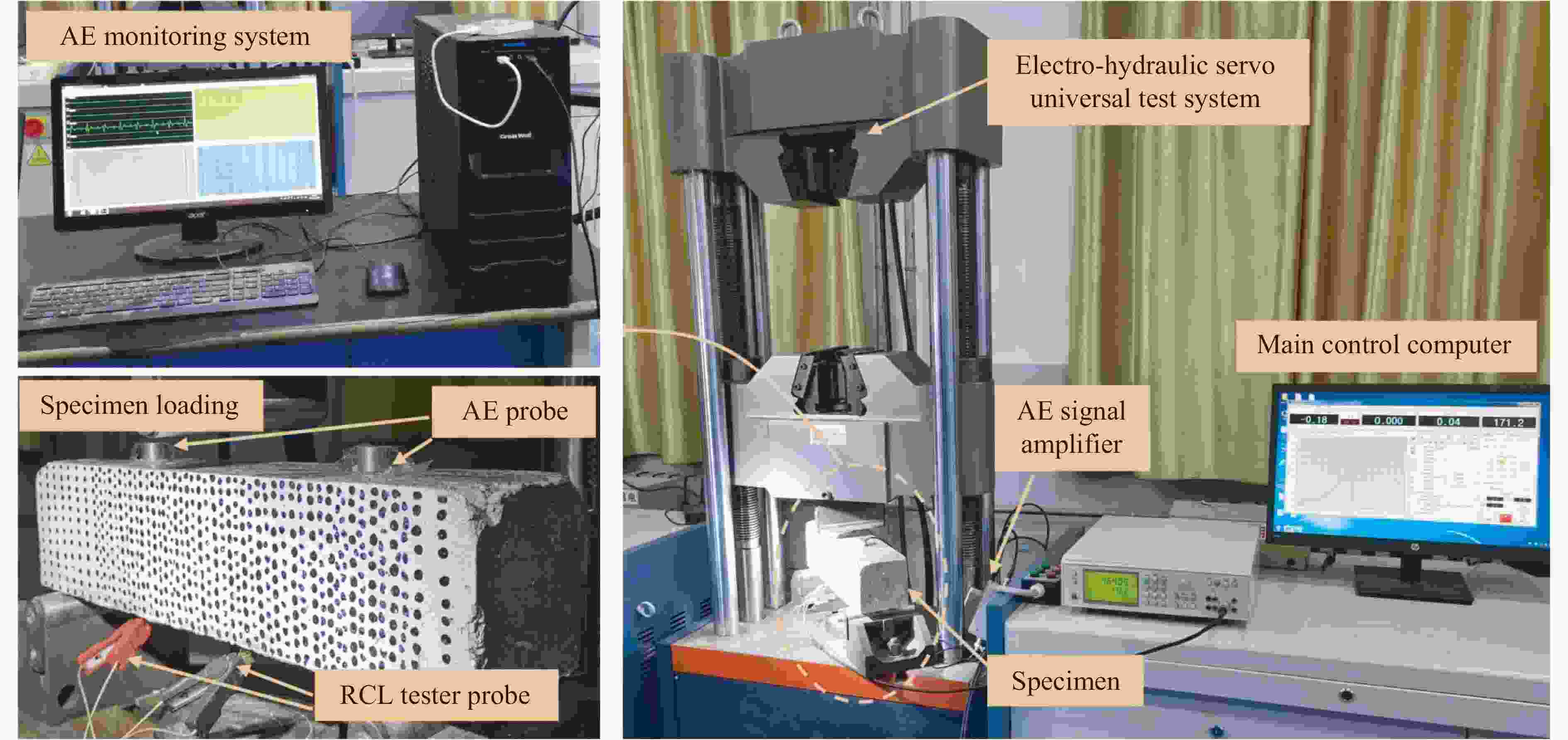

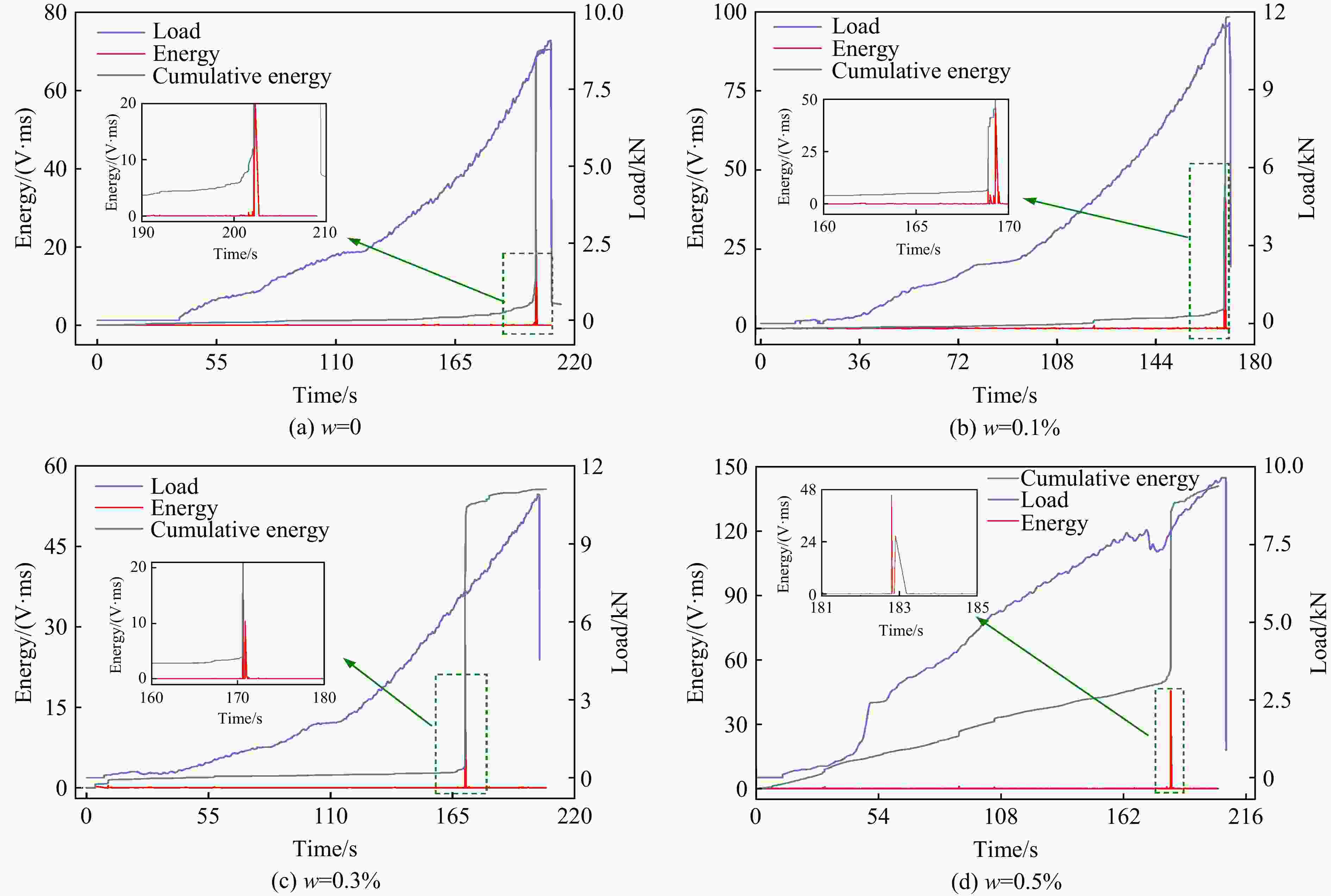

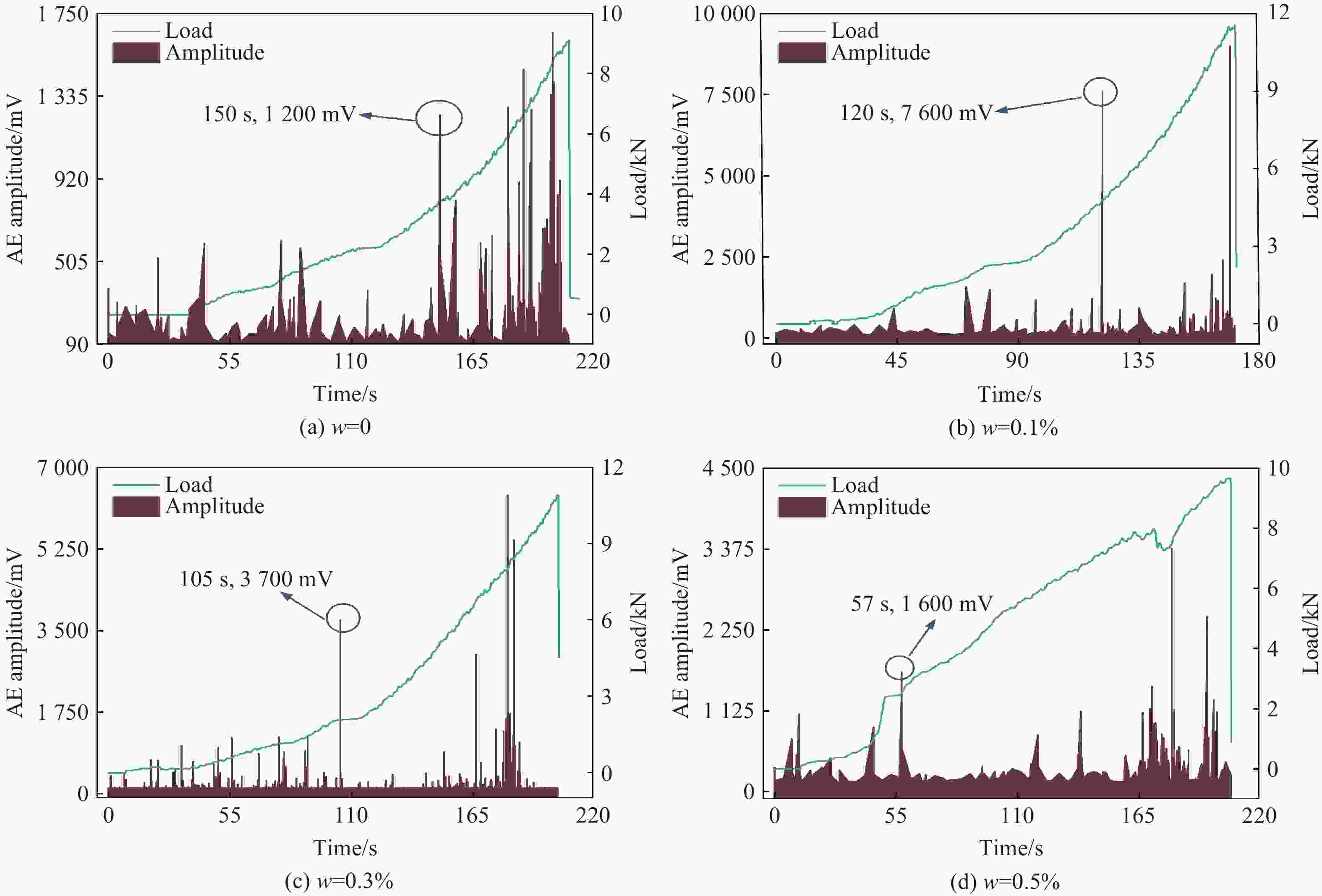

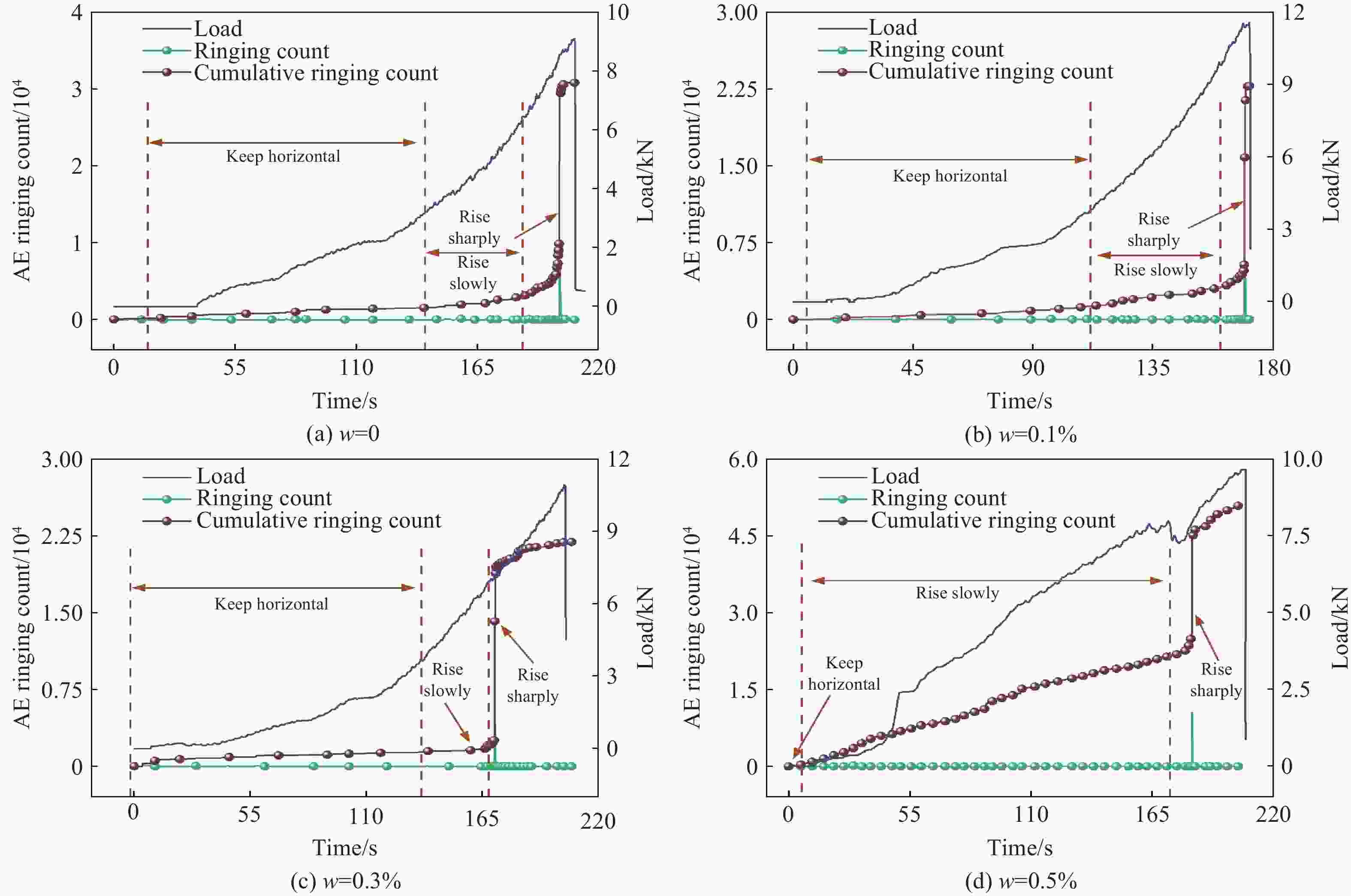

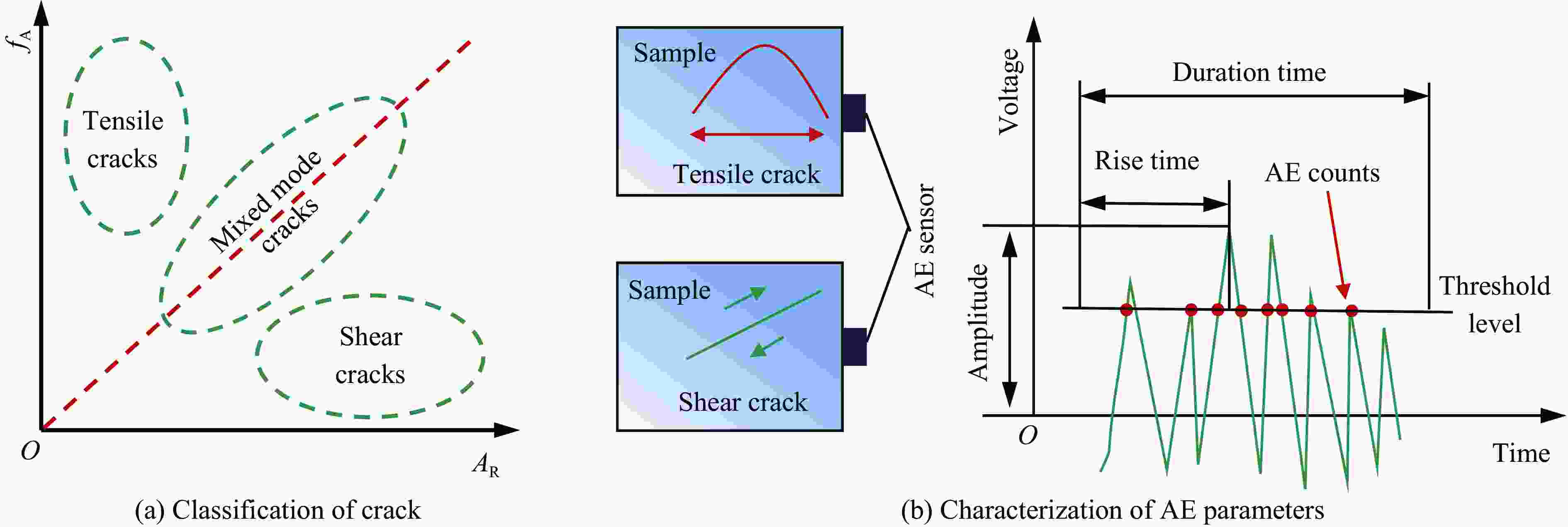

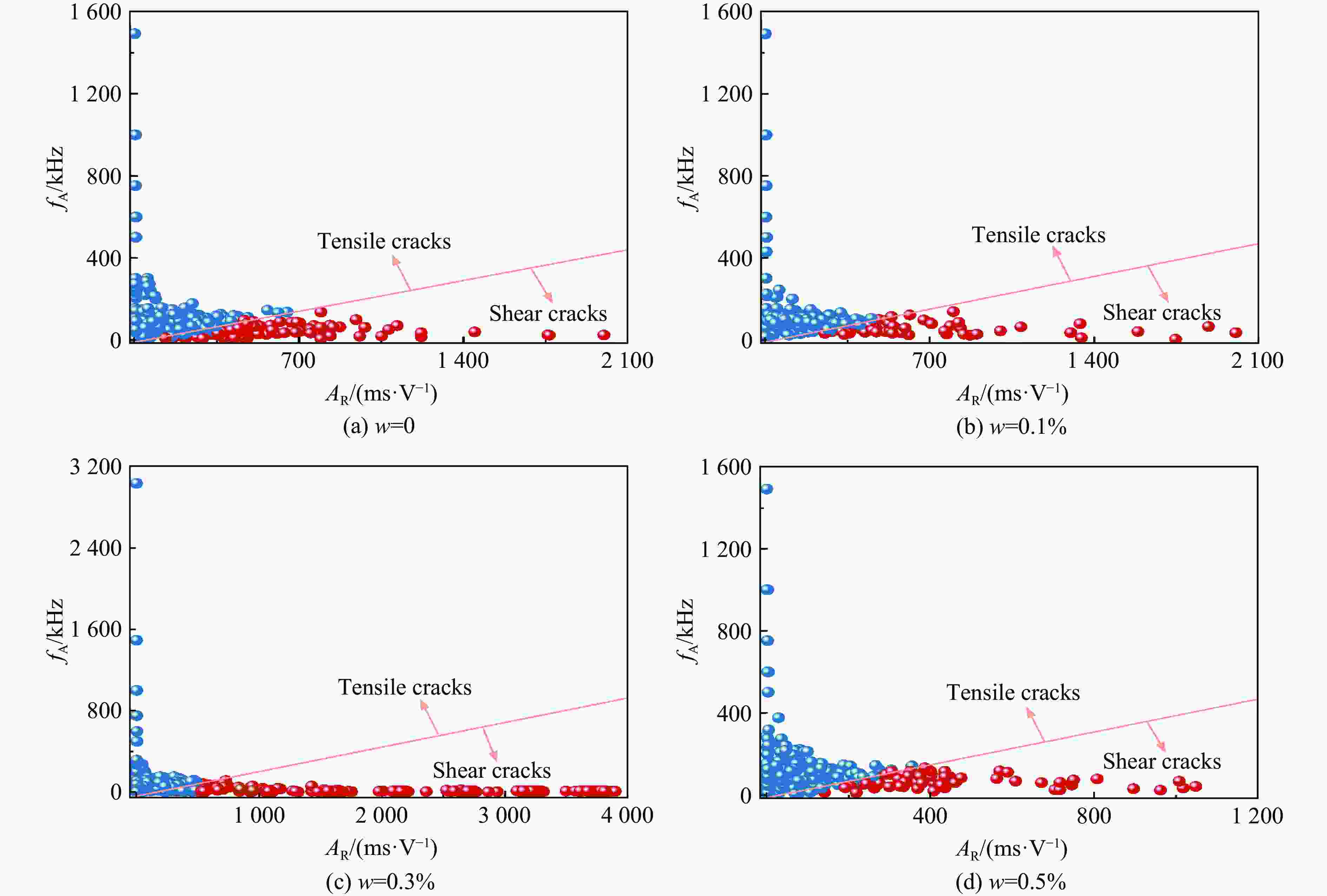

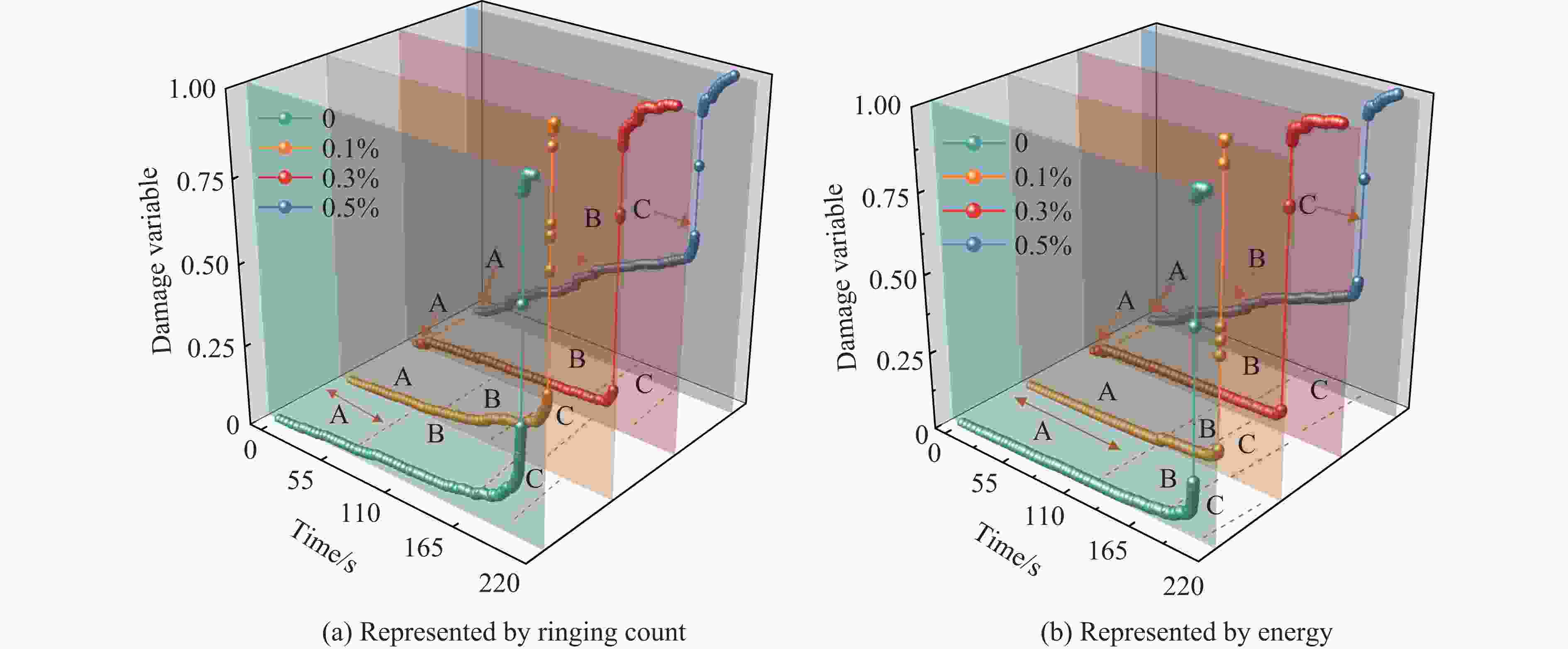

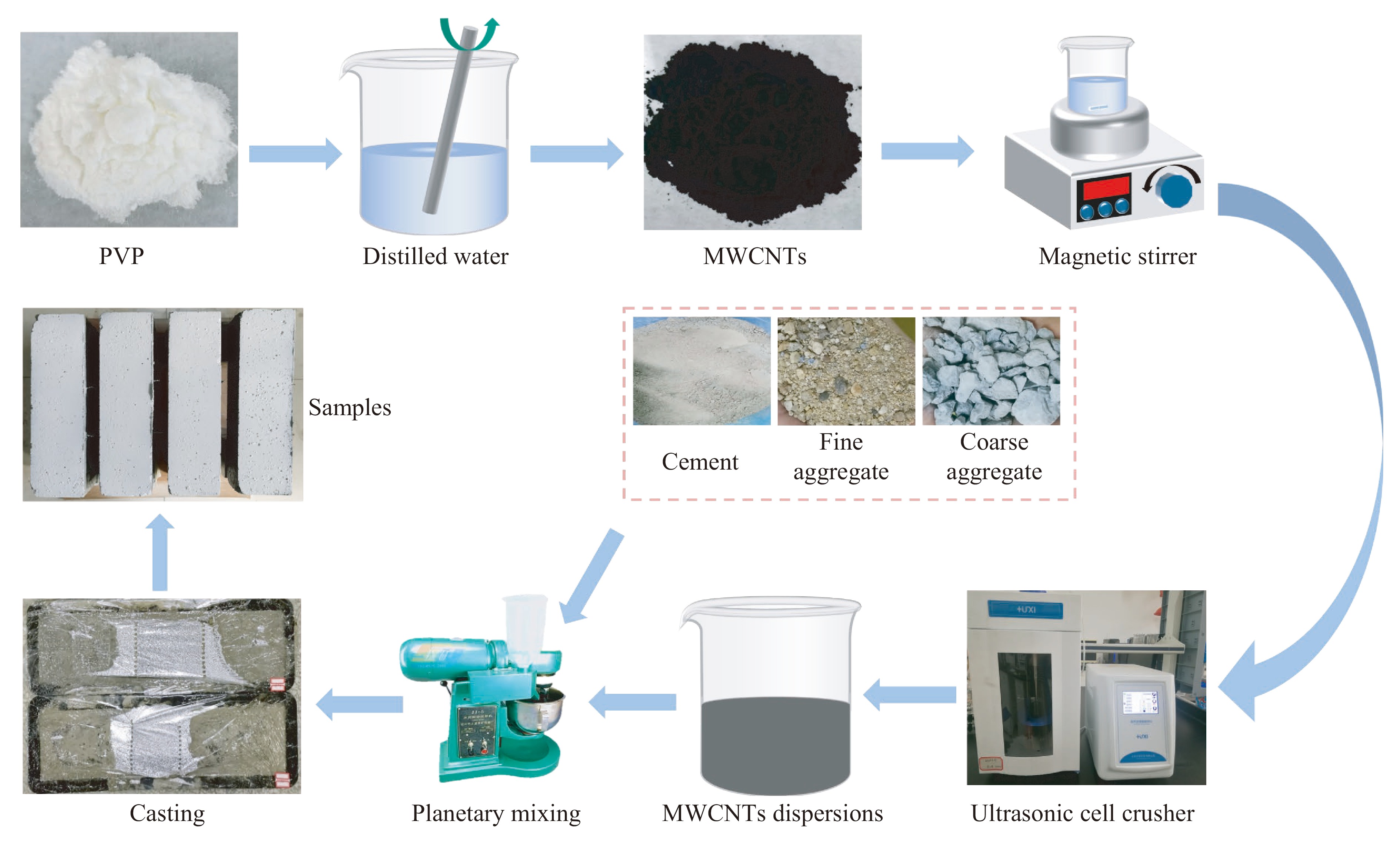

摘要: 为研究碳纳米管掺量对混凝土梁损伤演化过程及裂纹扩展规律的影响,制备了质量分数分别为0、0.1%、0.3%、0.5%的碳纳米管混凝土三点弯曲梁试件。采用搭载声发射测试系统的YNS300电液伺服万能试验机开展三点弯曲试验,得到了声发射能量、振铃计数和幅值等声学信息,并基于声发射参数对裂纹类型、损伤演化过程进行分析。结果表明:碳纳米管混凝土三点弯曲梁破坏时产生的声发射能量明显高于素混凝土梁,但随着碳纳米管掺量的增加,其破坏时产生的声发射能量逐渐减小;碳纳米管的掺入可以提高混凝土三点弯曲梁的承载能力,但超过某一界限后,其承载能力随着碳纳米管掺量的增加而降低;碳纳米管的掺入使得混凝土三点弯曲梁第一次声发射幅值突变的时间提前,试样破坏前,振铃计数及累计振铃计数增长缓慢,近似直线,试样断裂瞬间,两者均急剧上升;声发射信号源隶属于拉伸裂纹,碳纳米管混凝土三点弯曲梁断裂属于Ⅰ型断裂,拉伸裂纹和剪切裂纹占比与碳纳米管掺量之间没有明显关系,但声发射平均频率、上升角度信号源数量与碳纳米管掺量之间具有显著的相关性。不同碳纳米管掺量下,混凝土三点弯曲梁试样的损伤演化规律基本保持一致,试验前期损伤曲线基本为水平直线,破坏阶段损伤变量首先处于快速增长阶段,而后呈陡增式增长。Abstract: To study the impact of the content of carbon nanotubes (CNTs) on the damage evolution and crack propagation in concrete beams, concrete three-point bending beam specimens containing 0, 0.1%, 0.3%, and 0.5% CNTs were prepared. The three-point bending tests were conducted by using the YNS300 electro-hydraulic servo universal testing machine equipped with an acoustic emission (AE) testing system. Acoustic information such as AE energy, ringing count, and amplitude were obtained. The crack type and damage evolution process were analyzed based on AE parameters. The results show that the AE energy of carbon nanotube concrete (CNTC) three-point bending beam is significantly higher than that of plain concrete beams. However, as the content of carbon nanotubes increases, the AE energy generated during failure gradually decreases. The addition of CNTs can improve the bearing capacity of concrete beam. However, after exceeding a certain threshold, the load-bearing capacity decreases as the CNTs increases. The incorporation of carbon nanotubes advances the time of the first amplitude mutation in the concrete three-point bending beams. Prior to the failure of the specimens, the ringing count and cumulative ringing count increase slowly, approximating a straight line. However, at the instant of specimen fracture, both of them rise sharply. The AE signal sources belong to the tensile crack. The fracture of carbon nanotube-reinforced concrete three-point bending beams is classified as Mode Ⅰ fracture. There is no significant relationship between the proportions of tensile-shear cracks and the CNTs content. However, the number of AE average frequency and angle of rise of signal sources is significantly correlated with the CNTs content. The damage evolution law of concrete beam samples with different CNTs is basically consistent. In the early stage of the test, the damage curve is basically horizontal, and the damage variable in the failure stage is in a rapid growth stage at first, and then abruptly increases.

-

Key words:

- carbon nanotube /

- concrete beam /

- damage evolution /

- crack propagation /

- acoustic emission

-

表 1 碳纳米管混凝土三点弯曲梁的配合比

Table 1. Mix proportion for CNTC in three-point bending beam test

Mass/g w/% Cement Water River sand Coarse aggregate MWCNTs 1728 692 2232 4968 0 0 1728 692 2232 4968 1.728 0.1 1728 692 2232 4968 5.184 0.3 1728 692 2232 4968 8.640 0.5 -

[1] LI V C. High-performance and multifunctional cement-based composite material [J]. Engineering, 2019, 5(2): 250–260. doi: 10.1016/j.eng.2018.11.031 [2] 胡少伟, 张润, 范冰, 等. 基于DIC法的混凝土三点弯曲梁断裂性能试验研究 [J]. 人民长江, 2019, 50(10): 197–202, 228. doi: 10.16232/j.cnki.1001-4179.2019.10.035HU S W, ZHANG R, FAN B, et al. Experimental study on fracture property of three-point bending concrete beam based on DIC method [J]. Yangtze River, 2019, 50(10): 197–202, 228. doi: 10.16232/j.cnki.1001-4179.2019.10.035 [3] 陆春华, 杨钰婷, 平安, 等. 冻融作用下海工高性能混凝土梁受弯承载力试验与理论分析 [J]. 土木工程学报, 2022, 55(7): 47–56. doi: 10.15951/j.tmgcxb.21080786LU C H, YANG Y T, PING A, et al. Experimental and theoretical investigation on flexural capacity of marine high performance concrete beams under freeze-thaw action [J]. China Civil Engineering Journal, 2022, 55(7): 47–56. doi: 10.15951/j.tmgcxb.21080786 [4] 周菊萍, 李鹏, 王一超. 单向混杂碳纤维增强复合材料在三点弯曲载荷下的力学性能 [J]. 复合材料科学与工程, 2023(3): 112–119. doi: 10.19936/j.cnki.2096-8000.20230328.018ZHOU J P, LI P, WANG Y C. Mechanical properties of unidirectional hybrid carbon fiber reinforced composites under three-point bending load [J]. Composites Science and Engineering, 2023(3): 112–119. doi: 10.19936/j.cnki.2096-8000.20230328.018 [5] WEN S H, CHUNG D D L. Carbon fiber-reinforced cement as a strain-sensing coating [J]. Cement and Concrete Research, 2001, 31(4): 665–667. doi: 10.1016/S0008-8846(01)00474-4 [6] WANG J, YE H J, SUN Z W, et al. Experiment on the crack and deflection of basalt fiber reinforced concrete beams [J]. Advanced Materials Research, 2011, 243: 1058–1061. [7] 周振君, 杨正方. 带有碳涂层的尼龙纤维增强混凝土的机敏性研究 [J]. 硅酸盐学报, 2001, 29(2): 192–195. doi: 10.3321/j.issn:0454-5648.2001.02.020ZHOU Z J, YANG Z F. Study on the smart property of carbon coated nylon fiber-reinforced concrete composites [J]. Journal of the Chinese Ceramic Society, 2001, 29(2): 192–195. doi: 10.3321/j.issn:0454-5648.2001.02.020 [8] LI Y, GU Z C, ZHAO B, et al. Experimental study on mechanical properties of basalt fiber concrete after cryogenic freeze-thaw cycles [J]. Polymers, 2022, 15(1): 196. doi: 10.3390/polym15010196 [9] LIU J L, JIA Y M, WANG J. Experimental study on mechanical and durability properties of glass and polypropylene fiber reinforced concrete [J]. Fibers and Polymers, 2019, 20(9): 1900–1908. doi: 10.1007/s12221-019-1028-9 [10] MOHSEN M O, AL-NUAIMI N, AL-RUB R K A, et al. Effect of mixing duration on flexural strength of multi walled carbon nanotubes cementitious composites [J]. Construction and Building Materials, 2016, 126: 586–598. doi: 10.1016/j.conbuildmat.2016.09.073 [11] RAMEZANI M, KIM Y H, SUN Z H. Mechanical properties of carbon-nanotube-reinforced cementitious materials: database and statistical analysis [J]. Magazine of Concrete Research, 2020, 72(20): 1047–1071. doi: 10.1680/jmacr.19.00093 [12] YAZDANBAKHSH A, GRASLEY Z, TYSON B, et al. Distribution of carbon nanofibers and nanotubes in cementitious composites [J]. Transportation Research Record: Journal of the Transportation Research Board, 2010, 2142(1): 89–95. doi: 10.3141/2142-13 [13] JUNG M, LEE Y S, HONG S G, et al. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE) [J]. Cement and Concrete Research, 2020, 131: 106017. doi: 10.1016/j.cemconres.2020.106017 [14] SINDU B S, SASMAL S. Properties of carbon nanotube reinforced cement composite synthesized using different types of surfactants [J]. Construction and Building Materials, 2017, 155: 389–399. doi: 10.1016/j.conbuildmat.2017.08.059 [15] ROCHA V V, LUDVIG P, TRINDADE A C C, et al. The influence of carbon nanotubes on the fracture energy, flexural and tensile behavior of cement based composites [J]. Construction and Building Materials, 2019, 209: 1–8. doi: 10.1016/j.conbuildmat.2019.03.003 [16] CWIRZEN A, HABERMEHL-CWIRZEN K, NASIBULIN A G, et al. SEM/AFM studies of cementitious binder modified by MWCNT and nano-sized Fe needles [J]. Materials Characterization, 2009, 60(7): 735–740. doi: 10.1016/j.matchar.2008.11.001 [17] MAKAR J M, MARGESON J C, LUH J. Carbon nanotube/cement composites-early results and potential applications [J] 3rd International Conference on Construction Materials: Performance, Innovation and Structural Implications, 2005: 1–10. [18] 秦煜, 唐元鑫, 阮鹏臻, 等. 碳纳米管悬浮液分散质量影响因素试验研究 [J]. 应用化工, 2022, 51(5): 1285–1290. doi: 10.3969/j.issn.1671-3206.2022.05.013QIN Y, TANG Y X, RUAN P Z, et al. Experimental study on influencing factors of dispersion quality of carbon nanotubes in aqueous solution [J]. Applied Chemical Industry, 2022, 51(5): 1285–1290. doi: 10.3969/j.issn.1671-3206.2022.05.013 [19] XU S L, LIU J T, LI Q H. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste [J]. Construction and Building Materials, 2015, 76: 16–23. doi: 10.1016/j.conbuildmat.2014.11.049 [20] WANG B M, HAN Y, LIU S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites [J]. Construction and Building Materials, 2013, 46: 8–12. doi: 10.1016/j.conbuildmat.2013.04.014 [21] 卜路霞, 李京京, 高琳琳, 等. SDBS对多壁碳纳米管悬浮液分散性的影响 [J]. 电镀与精饰, 2019, 41(7): 10–13. doi: 10.3969/j.issn.1001-3849.2019.07.003BU L X, LI J J, GAO L L, et al. Dispersion of multi-walled carbon nanotubes in solution with surfactant SDBS [J]. Plating and Finishing, 2019, 41(7): 10–13. doi: 10.3969/j.issn.1001-3849.2019.07.003 [22] SHAO H Y, CHEN B M, LI B, et al. Influence of dispersants on the properties of CNTs reinforced cement-based materials [J]. Construction and Building Materials, 2017, 131: 186–194. doi: 10.1016/j.conbuildmat.2016.11.053 [23] LIU J X, SUH H, JEE H, et al. Synergistic effect of carbon nanotube/TiO2 nanotube multi-scale reinforcement on the mechanical properties and hydration process of Portland cement paste [J]. Construction and Building Materials, 2021, 293: 123447. doi: 10.1016/j.conbuildmat.2021.123447 [24] 李冬生, 曹海. 聚乙烯醇纤维混凝土损伤演化声发射监测及其评价 [J]. 振动与冲击, 2012, 31(9): 29–32, 43. doi: 10.3969/j.issn.1000-3835.2012.09.006LI D S, CAO H. Acoustic emission monitoring and evaluation of damage evolution for polyvinyl alcohol fiber concrete [J]. Journal of Vibration and Shock, 2012, 31(9): 29–32, 43. doi: 10.3969/j.issn.1000-3835.2012.09.006 [25] 张力伟. 混凝土损伤检测声发射技术应用研究 [D]. 大连: 大连海事大学, 2012.ZHANG L W. Research on concrete damage detection by using acoustic emission technology [D]. Dalian: Dalian Maritime University, 2012. [26] XIANG Y, CHEN K, ZHENG Z, et al. Damage mechanism of Al2O3 f/Al2O3 composites by acoustic emission technology [J]. Ceramics International, 2023, 49(2): 2730–2737. doi: 10.1016/j.ceramint.2022.09.254 [27] OHNO K, OHTSU M. Crack classification in concrete based on acoustic emission [J]. Construction and Building Materials, 2010, 24(12): 2339–2346. doi: 10.1016/j.conbuildmat.2010.05.004 [28] HILLERBORG A, MODÉER M, PETERSSON P E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements [J]. Cement and Concrete Research, 1976, 6(6): 773–781. doi: 10.1016/0008-8846(76)90007-7 [29] 杨永杰, 王德超, 郭明福, 等. 基于三轴压缩声发射试验的岩石损伤特征研究 [J]. 岩石力学与工程学报, 2014, 33(1): 98–104. doi: 10.13722/j.cnki.jrme.2014.01.008YANG Y J, WANG D C, GUO M F, et al. Study of rock damage characteristics based on acoustic emission tests under triaxial compression [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(1): 98–104. doi: 10.13722/j.cnki.jrme.2014.01.008 [30] 张强星, 刘建锋, 曾寅, 等. 膏岩三轴压缩声发射特征及损伤演化研究 [J]. 地下空间与工程学报, 2019, 15(5): 1323–1330.ZHANG Q X, LIU J F, ZENG Y, et al. Investigation on deformation characteristics and damage evolution of gypsum rock under triaxial loading test [J]. Chinese Journal of Underground Space and Engineering, 2019, 15(5): 1323–1330. [31] 周露林, 刘建锋, 鲁功达, 等. 热损伤花岗岩三轴压缩蠕变破坏声发射及损伤演化特征 [J]. 中南大学学报(自然科学版), 2023, 54(6): 2360–2369. doi: 10.11817/j.issn.1672-7207.2023.06.024ZHOU L L, LIU J F, LU G D, et al. Creep acoustic emission and damage evolution of thermally-damaged granite under triaxial stress [J]. Journal of Central South University (Science and Technology), 2023, 54(6): 2360–2369. doi: 10.11817/j.issn.1672-7207.2023.06.024 [32] CHEN Y J, JIAO Y B, YANG H, et al. Fracture characteristics and damage evolution of manufactured sand-based ultra-high performance concrete using tensile testing and acoustic emission monitoring [J]. Construction and Building Materials, 2024, 430: 136477. doi: 10.1016/j.conbuildmat.2024.136477 -

下载:

下载: