Experimental Study on High Overload Loading of Electronic Control Module inside Electronic Detonator under Delayed State

-

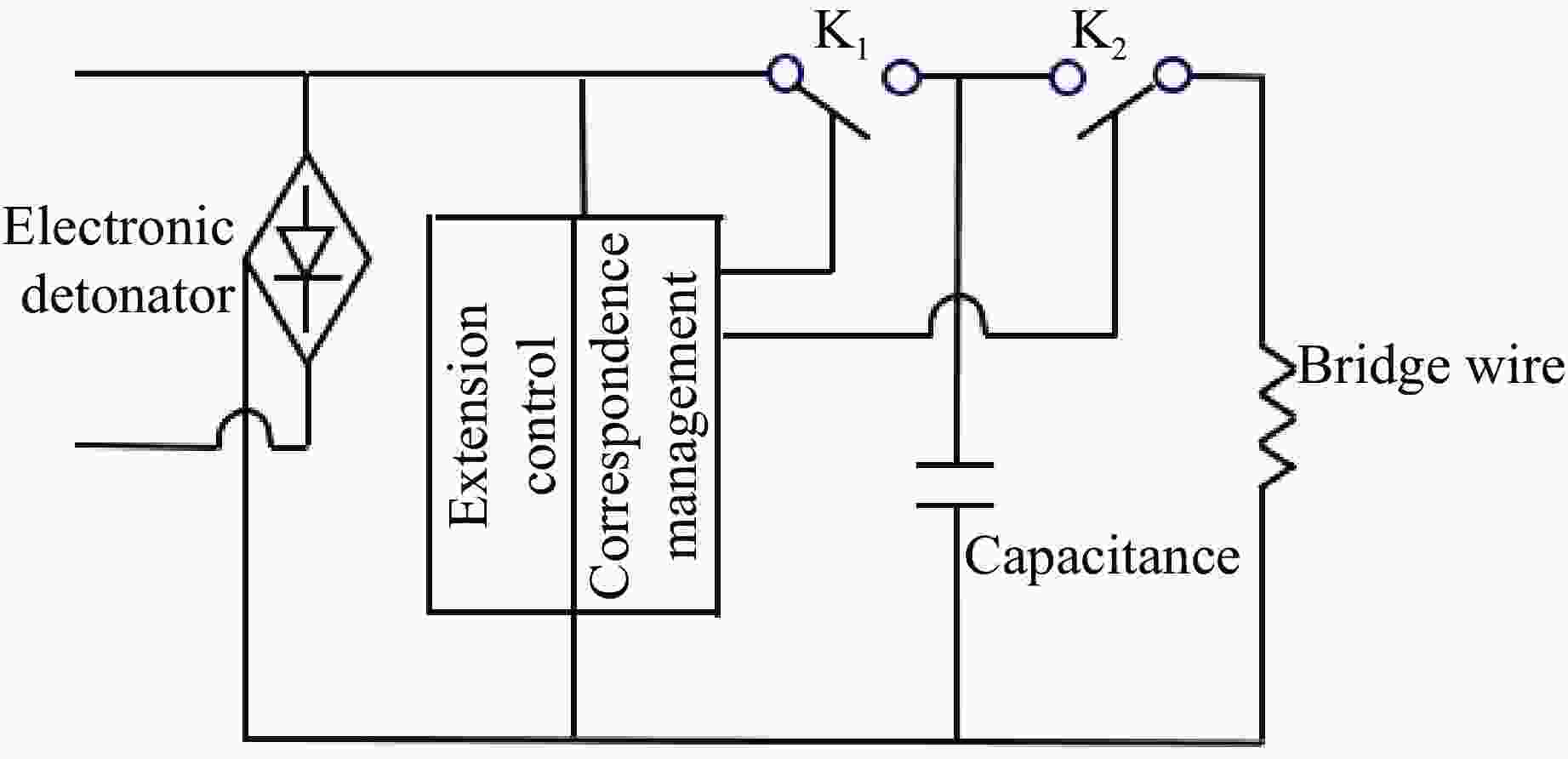

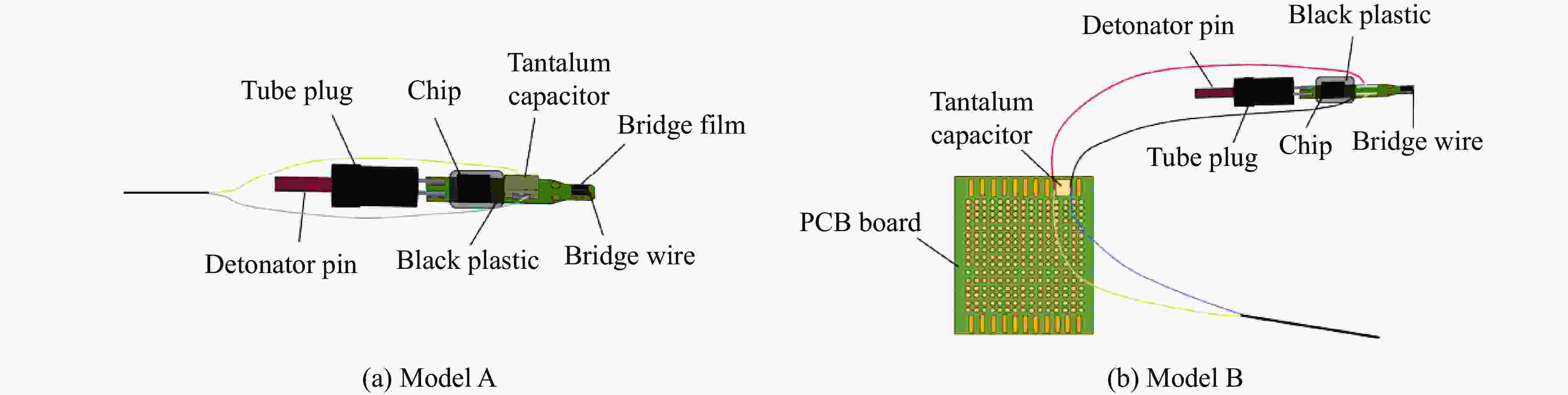

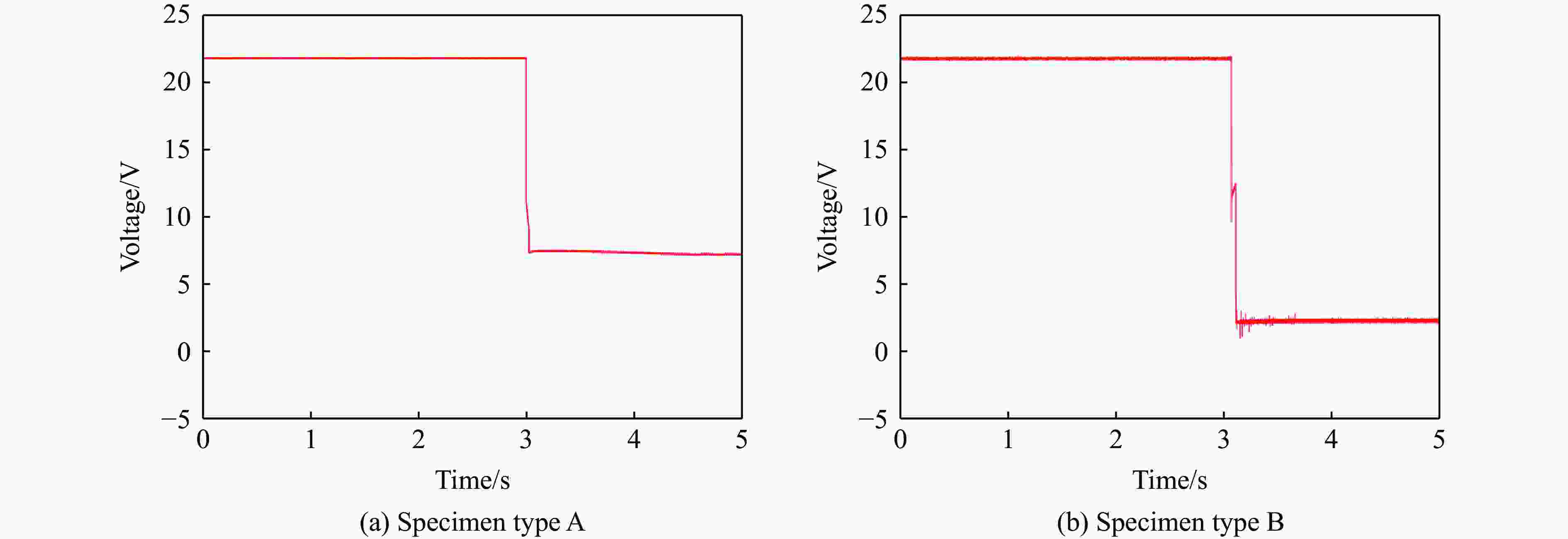

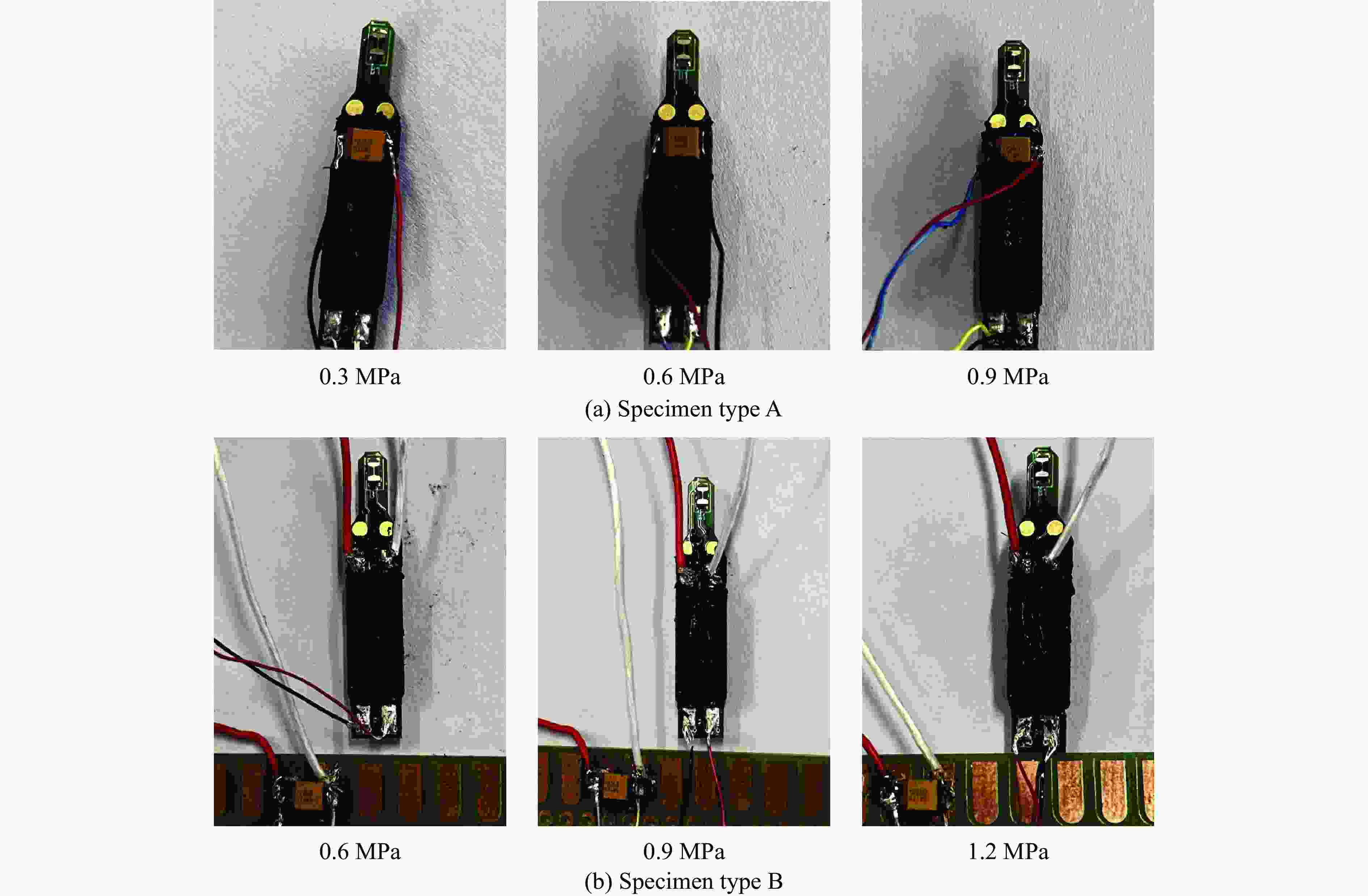

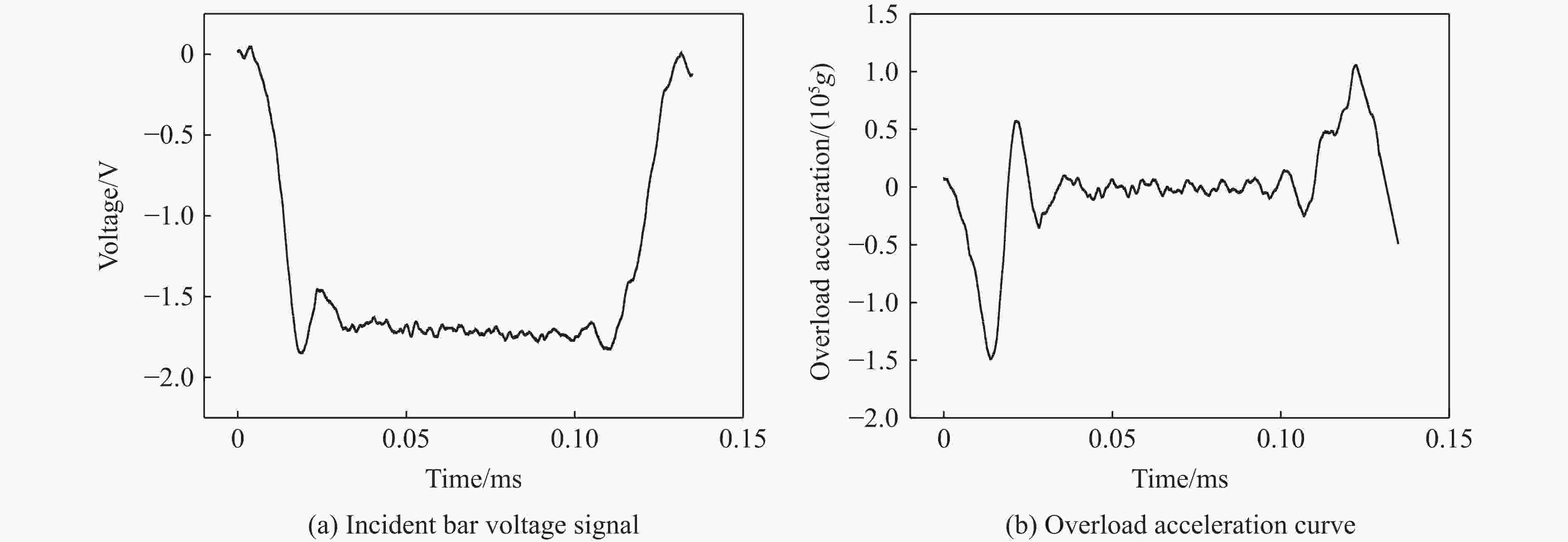

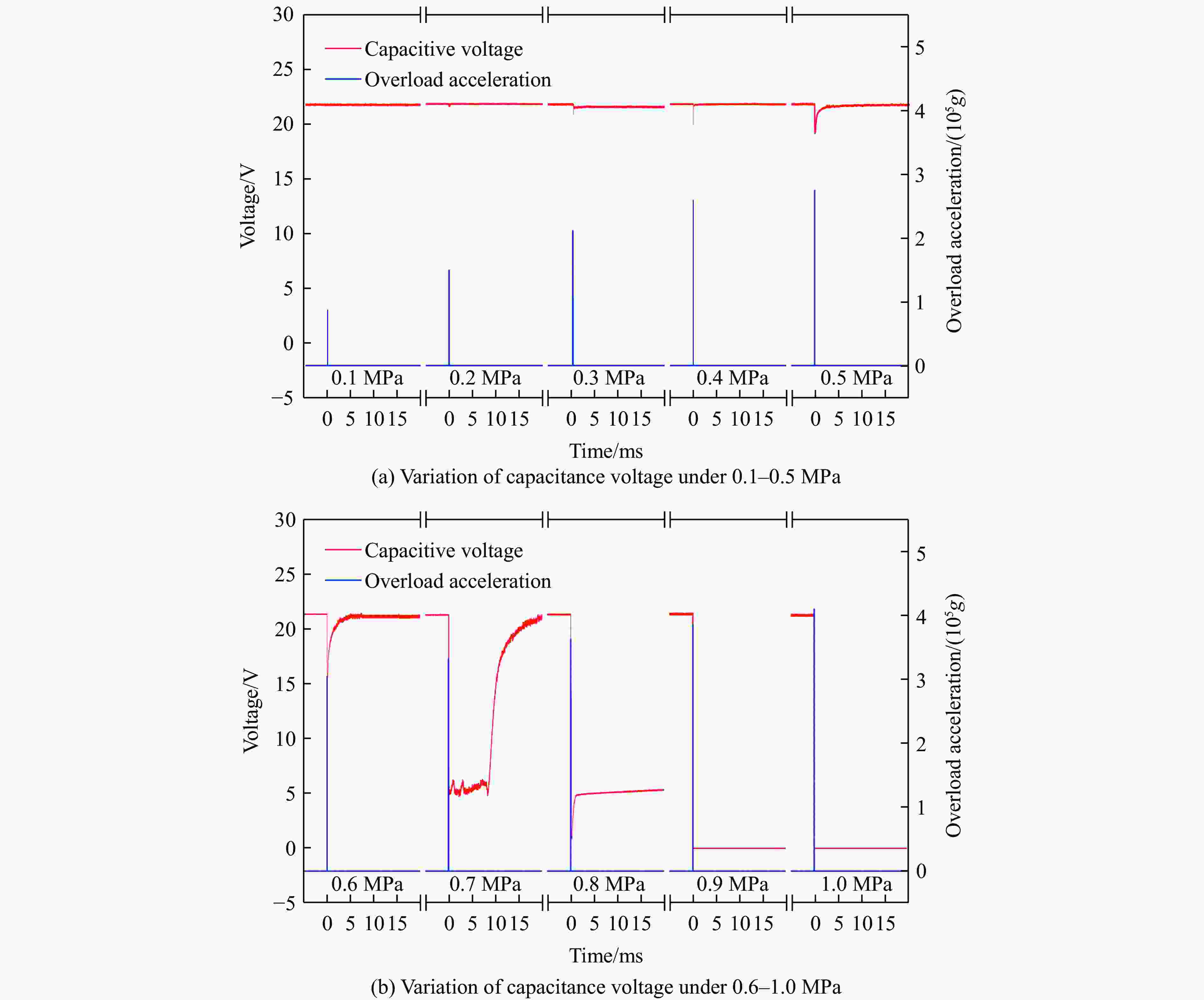

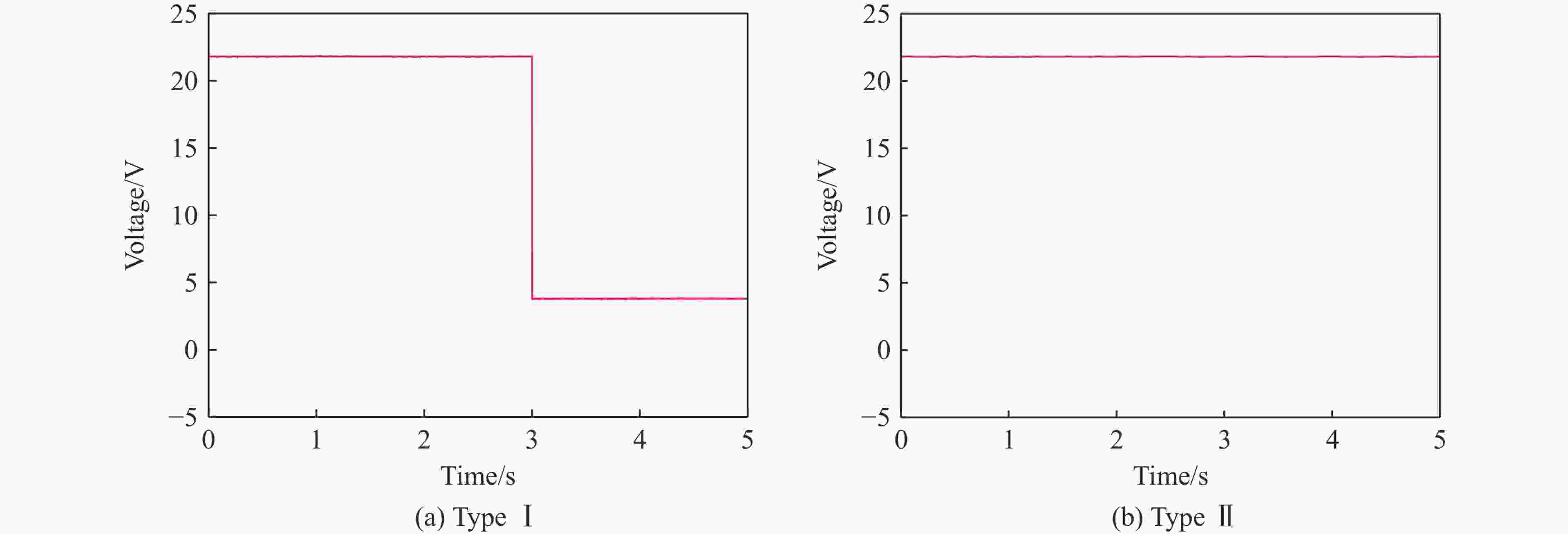

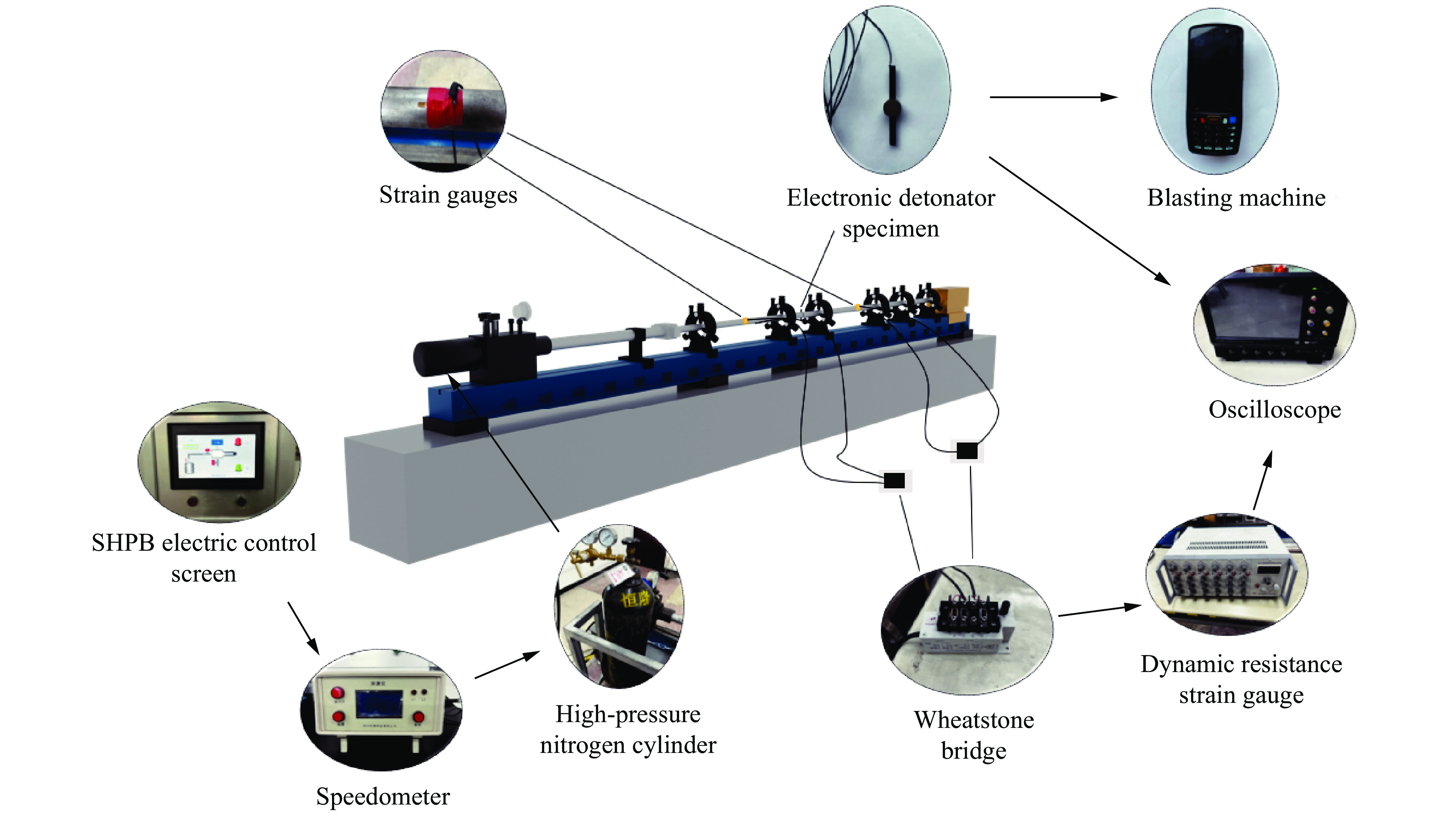

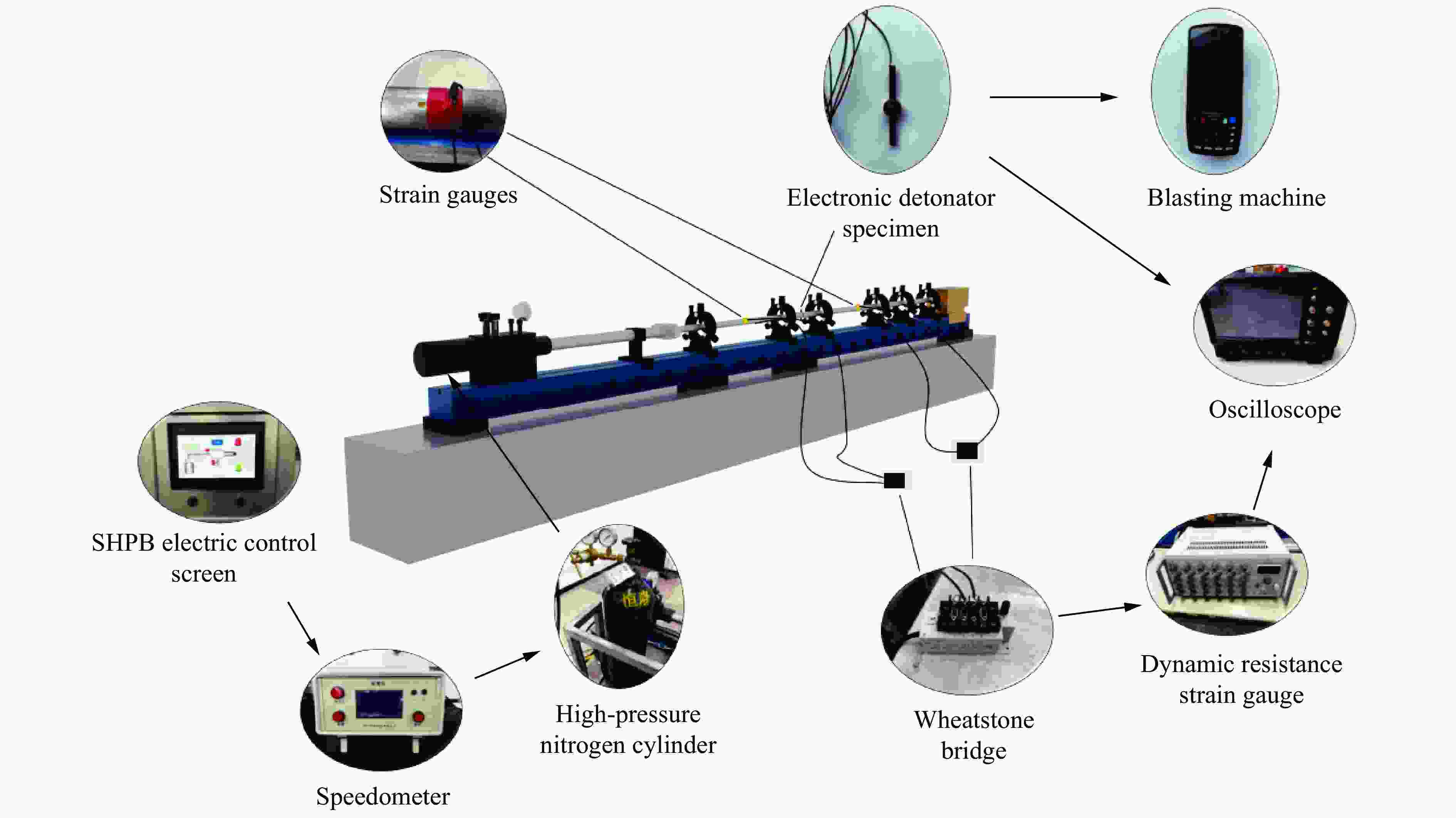

摘要: 为探究电子雷管内的电子控制模块在延期状态下受冲击载荷时的失效机制,采用分离式霍普金森压杆(split Hopkinson pressure bar,SHPB)对电子雷管试件进行了高过载加载测试,得到了整体电子控制模块和分离出钽电容的其余电子控制模块受不同加载压力时的失效情况。结果显示:钽电容在1.495×105g过载时出现电压下降现象,且过载越大,短路失效情况越明显;在一定过载范围内,钽电容因其特有的自愈性,可在短时间内回到起始量级;当过载超过临界范围,达到3.848×105g时,钽电容损坏且无法逆转。模块内其余组件的抗过载能力强于电容,芯片在4.155×105g过载后检测异常,电阻元件失效发生在4.249×105g以上过载。Abstract: In order to explore the failure mechanism of the electronic control module inside the electronic detonator under impact load during the postponement state, a split Hopkinson pressure bar (SHPB) experiment was conducted on the electronic detonator specimens under high overload loading. The failure conditions of the overall electronic control module and the remaining electronic control modules separated from the tantalum capacitors were obtained under different levels of loading experiments. The results indicate that the tantalum capacitor exhibited a voltage drop phenomenon at an overload of 1.495×105g, with a more pronounced short-circuit failure as the overload increased. Within a certain overload range, the tantalum capacitor᾽s unique self-healing properties allow it to return to its initial level rapidly. However, when the overload exceeded the critical threshold of 3.848×105g, the tantalum capacitor was irreversibly damaged. The overload resistance of other components within the module is stronger than that of the capacitor. The chip detected an anomaly after an overload of 4.155×105g, while the failure of the resistor components occurs at an overload of over 4.249×105g.

-

表 1 电子引火元件各组件类型及参数

Table 1. Types and parameters of electronic igniter components

Capacitor type Capacitance/µF Model Bridge wire material Resistance/Ω Chip Tantalum 22 22K20 Nickel chromium alloy 2 Fourth generation 表 2 B型试件在高过载加载下各组件的失效情况

Table 2. Failure conditions of components of specimen type B under high overload

Pressure/

MPaMaximum

overload/(105g)Voltage change corresponding

type chartSample module failure case Bridge wire Chip Circuit board 0.7 3.447 Type Ⅰ Melted Normal Normal 3.506 Type Ⅰ Melted Normal Normal 3.328 Type Ⅰ Melted Normal Normal 0.8 3.684 Type Ⅰ Melted Normal Normal 3.731 Type Ⅰ Melted Normal Normal 3.776 Type Ⅰ Melted Normal Normal 0.9 3.817 Type Ⅱ Unmelted, non-ablation trace Normal Resistor failure 3.984 Type Ⅰ Melted Normal Normal 3.759 Type Ⅰ Melted Normal Normal 1.0 4.155 Type Ⅰ Unmelted, ablation, deformation, discoloration Abnormal Normal 4.086 Type Ⅰ Melted Normal Normal 4.167 Type Ⅱ Unmelted, non-ablation trace Abnormal Normal 1.1 4.235 Type Ⅱ Unmelted, non-ablation trace Abnormal Normal 4.173 Type Ⅰ Unmelted, ablation, discoloration Abnormal Normal 4.249 Type Ⅱ Unmelted, non-ablation trace Normal Resistor failure 1.2 4.472 Type Ⅱ Unmelted, non-ablation trace Abnormal Normal 4.581 Type Ⅱ Unmelted, non-ablation trace Abnormal Resistor failure 4.426 Type Ⅱ Physical bending Abnormal Resistor failure -

[1] 徐振相, 周彬, 秦志春, 等. 微电子火工品的发展及应用 [J]. 爆破器材, 2004, 33(Suppl 1): 29–34. doi: 10.3969/j.issn.1001-8352.2004.z1.010XU Z X, ZHOU B, QIN Z C, et al. Development and application of the micro-electric detonator [J]. Explosive Materials, 2004, 33(Suppl 1): 29–34. doi: 10.3969/j.issn.1001-8352.2004.z1.010 [2] 颜景龙. 中国电子雷管技术与应用 [J]. 中国工程科学, 2015, 17(1): 36–41. doi: 10.3969/j.issn.1009-1742.2015.01.005YAN J L. Technology and application of Chinese electronic detonator [J]. Strategic Study of CAE, 2015, 17(1): 36–41. doi: 10.3969/j.issn.1009-1742.2015.01.005 [3] KARA S, ADAMSON W R, REISZ W J, et al. The latest generation of the electronic system enhanced safety and productivity [J]. Procedia Engineering, 2014, 83: 432–440. [4] 中华人民共和国工业和信息化部. 工业数码电子雷管: WJ 9085—2015 [S]. 2015.Ministry of Industry and Information Technology. Industrial digital electronic detonator: WJ 9085—2015 [S]. 2015. [5] CARDU M, GIRAUDI A, ORESTE P. A review of the benefits of electronic detonators [J]. Rem: Revista Escola de Minas, 2013, 66(3): 375–382. [6] 汪旭光, 沈立晋. 工业雷管技术的现状和发展 [J]. 工程爆破, 2003, 9(3): 52–57. doi: 10.3969/j.issn.1006-7051.2003.03.013WANG X G, SHEN L J. The state-of-the-arts of industrial detonators [J]. Engineering Blasting, 2003, 9(3): 52–57. doi: 10.3969/j.issn.1006-7051.2003.03.013 [7] 欧仙荣. 数码电子雷管中影响点火头性能因素分析 [J]. 四川兵工学报, 2014, 35(5): 128–131.OU X R. Influencing factors of digital detonator matchhead performance [J]. Journal of Sichuan Ordnance, 2014, 35(5): 128–131. [8] 刘忠民, 杨年华, 石磊, 等. 电子雷管小孔距爆破拒爆试验研究 [J]. 爆破器材, 2021, 50(5): 39–42, 49. doi: 10.3969/j.issn.1001-8352.2021.05.007LIU Z M, YANG N H, SHI L, et al. Experimental study on misfire in small hole-space blasting of electronic detonator [J]. Explosive Materials, 2021, 50(5): 39–42, 49. doi: 10.3969/j.issn.1001-8352.2021.05.007 [9] LENG Z D, SUN J S, LU W B, et al. Mechanism of the in-hole detonation wave interactions in dual initiation with electronic detonators in bench blasting operation [J]. Computers and Geotechnics, 2021, 129: 103873. [10] 冷振东, 范勇, 涂书芳, 等. 电子雷管起爆技术研究进展与发展建议 [J]. 中国工程科学, 2023, 25(1): 142–154.LENG Z D, FAN Y, TU S F, et al. Electronic detonator initiation technology: research progress and development strategies [J]. Strategic Study of CAE, 2023, 25(1): 142–154. [11] REN D M, HOU J H, DUAN J R, et al. Failure mode analysis of electronic detonator under high overload condition [J]. FirePhysChem, 2022, 2(2): 199–205. [12] 杨文, 岳彩新, 宋家良, 等. 工业电子雷管抗冲击性能试验研究 [J]. 火工品, 2022(2): 16–19. doi: 10.3969/j.issn.1003-1480.2022.02.004YANG W, YUE C X, SONG J L, et al. Experimental research on the impact resistance of industrial electronic detonators [J]. Initiators & Pyrotechnics, 2022(2): 16–19. doi: 10.3969/j.issn.1003-1480.2022.02.004 [13] 杨文. 工业电子雷管抗冲击性能研究 [D]. 北京: 煤炭科学研究总院, 2023.YANG W. Research on impact resistance performance of industrial electronic detonator [D]. Beijing: China Coal Research Institute, 2023. [14] 李长龙, 高世桥, 牛少华, 等. 高冲击环境对引信用储能电容性能的影响 [J]. 兵工学报, 2016, 37(Suppl 2): 16–22.LI C L, GAO S Q, NIU S H, et al. Effect of high-g shock environment on performances of energy-storage capacitors used in fuse [J]. Acta Armamentarii, 2016, 37(Suppl 2): 16–22. [15] TEVEROVSKY A. Effect of mechanical stresses on characteristics of chip tantalum capacitors [J]. IEEE Transactions on Device and Materials Reliability, 2007, 7(3): 399–406. [16] 王家乐, 李洪伟, 王小兵, 等. 冲击载荷作用下钽电容的电压瞬变特性及微观机理 [J]. 爆炸与冲击, 2024, 44(4): 043101. doi: 10.11883/bzycj-2023-0232WANG J L, LI H W, WANG X B, et al. Voltage transient characteristics and microscopic mechanism of tantalum capacitors under impact load [J]. Explosion and Shock Waves, 2024, 44(4): 043101. doi: 10.11883/bzycj-2023-0232 [17] 张学舜, 王娜, 沈瑞琪. 自由式霍普金森杆测量火工品过载加速度的数值模拟 [J]. 爆破器材, 2004, 33(Suppl 1): 39–42.ZHANG X S, WANG N, SHEN R Q. Numerical simulation on the acceleration of initiator over-loaded by freedom Hopkinson bar [J]. Explosive Materials, 2004, 33(Suppl 1): 39–42. [18] 国家市场监督管理总局, 国家标准化管理委员会. 金属材料 高应变速率高温压缩试验方法: GB/T 42900—2023 [S]. 北京: 中国标准出版社, 2023.State Administration for Market Regulation, Standardization Administration of the People’s Republic of China. Metallic materials-high strain rate compression test method at elevated temperature: GB/T 42900—2023 [S]. Beijing: Standards Press of China, 2023. [19] 赵芷伊. 电火工品在电磁发射过程中的力学过载效应研究 [D]. 南京: 南京理工大学, 2021.ZHAO Z Y. Study on the mechanical overload effect of electric explosives during electromagnetic launch [D]. Nanjing: Nanjing University of Science and Technology, 2021. [20] 邓琼, 李玉龙, 索涛, 等. 火工品高过载动态力学性能测试方法研究 [J]. 火工品, 2007(1): 28–31. doi: 10.3969/j.issn.1003-1480.2007.01.009DENG Q, LI Y L, SUO T, et al. Test method on dynamic mechanical behavior of initiating explosive device under high acceleration [J]. Initiators & Pyrotechnics, 2007(1): 28–31. doi: 10.3969/j.issn.1003-1480.2007.01.009 [21] 王凯民, 张学舜. 火工品工程设计与试验 [M]. 北京: 国防工业出版社, 2010: 252–255.WANG K M, ZHANG X S. Engineering design and teat technology of initiators & pyrotechnics [M]. Beijing: National Defense Industry Press, 2010: 252–255. [22] 刘虎, 张蕊, 付东晓, 等. 半导体桥火工品力学过载下的结构失效研究 [J]. 火工品, 2012(1): 30–33. doi: 10.3969/j.issn.1003-1480.2012.01.011LIU H, ZHANG R, FU D X, et al. Study on structure failure of SCB initiator under high overload [J]. Initiators & Pyrotechnics, 2012(1): 30–33. doi: 10.3969/j.issn.1003-1480.2012.01.011 [23] 李长龙, 高世桥, 牛少华, 等. 高冲击下引信用固态钽电容的参数变化 [J]. 爆炸与冲击, 2018, 38(2): 419–425. doi: 10.11883/bzycj-2016-0222LI C L, GAO S Q, NIU S H, et al. Parameters variation of solid tantalum capacitors used in fuze under high-g shock [J]. Explosion and Shock Waves, 2018, 38(2): 419–425. doi: 10.11883/bzycj-2016-0222 [24] 王娜. 冲击波加载过程中火工品的受力分析 [D]. 南京: 南京理工大学, 2004.WANG N. Mechanical analysis of initiator in loading of shock wave [D]. Nanjing: Nanjing University of Science and Technology, 2004. [25] 王娜, 沈瑞琪, 叶迎华. 霍普金森杆测量火工品过载情况的研究与数值模拟 [J]. 火工品, 2004(1): 42–47. doi: 10.3969/j.issn.1003-1480.2004.01.014WANG N, SHEN R Q, YE Y H. Study on the measurement of over-loaded initiator by Hopkinson bar and numerical simulation [J]. Initiators & Pyrotechnics, 2004(1): 42–47. doi: 10.3969/j.issn.1003-1480.2004.01.014 [26] TEVEROVSKY A. Breakdown and self-healing in tantalum capacitors [J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2021, 28(2): 663–671. [27] TEVEROVSKY A. Scintillation and surge current breakdown voltages in solid tantalum capacitors [J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2009, 16(4): 1134–1142. -

下载:

下载: