Micro-Morphology and Mechanical Properties of Mg/Al Composites under Vacuum Explosion Welding

-

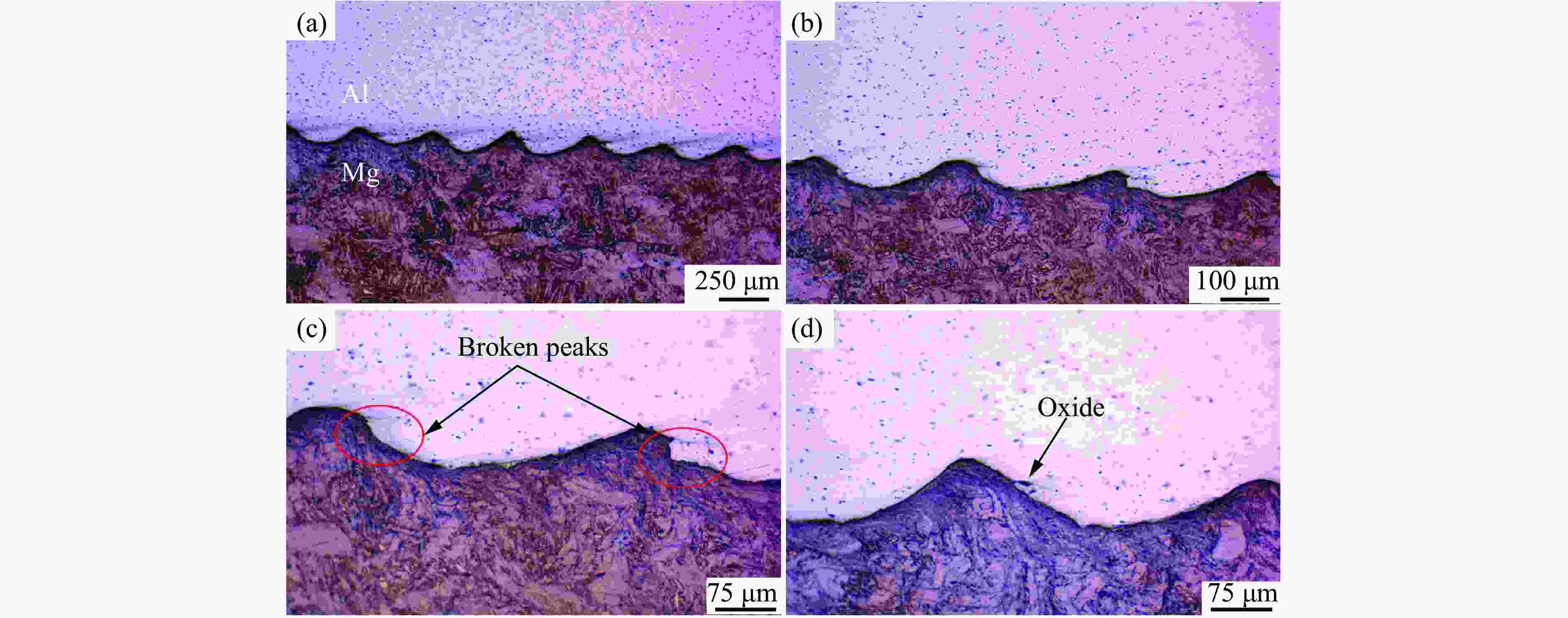

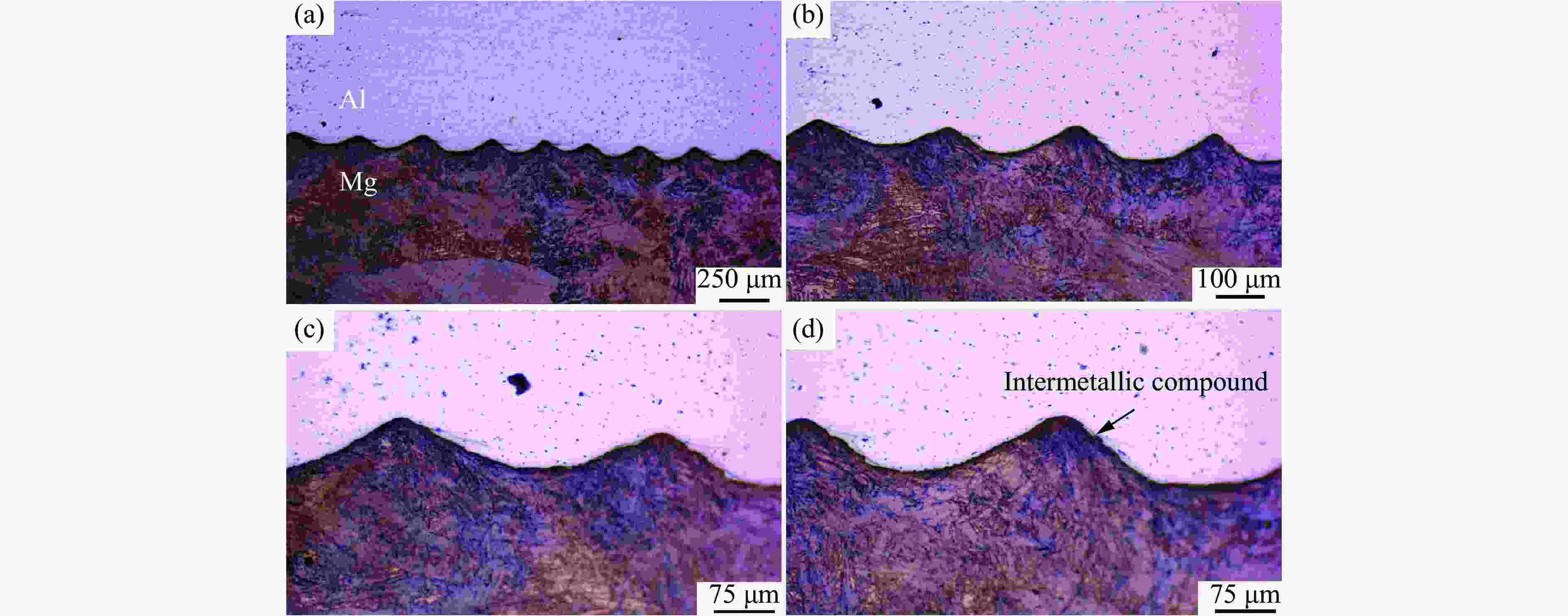

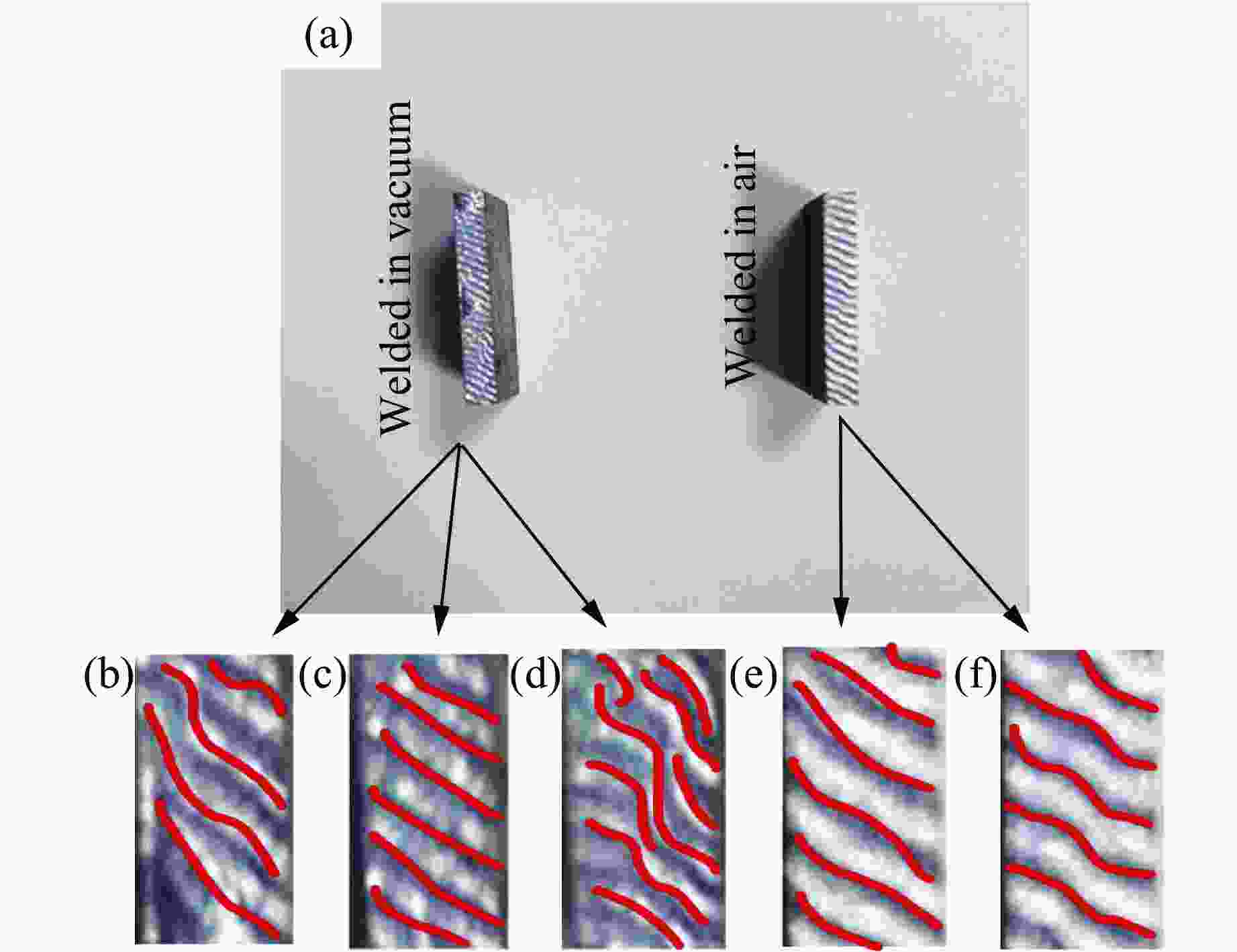

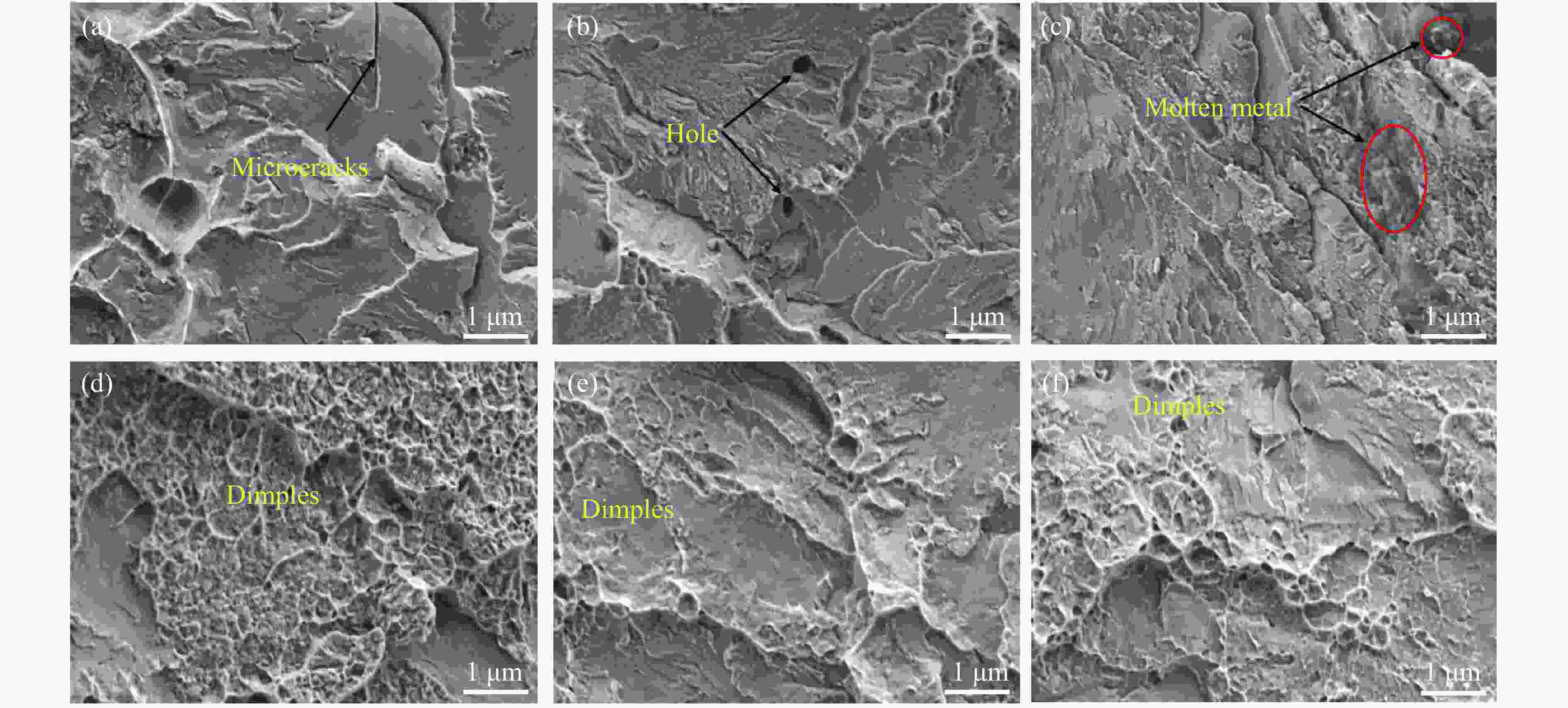

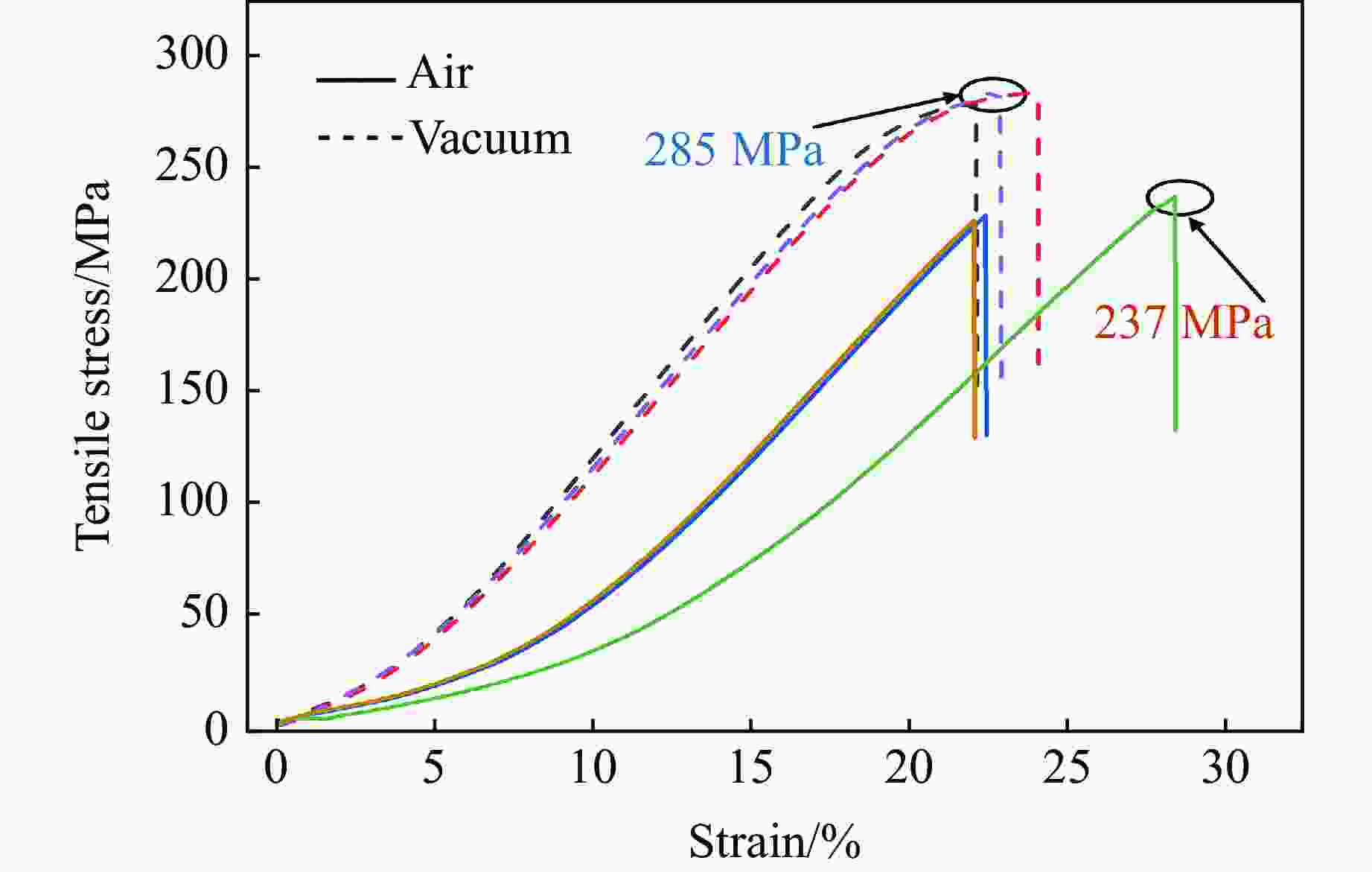

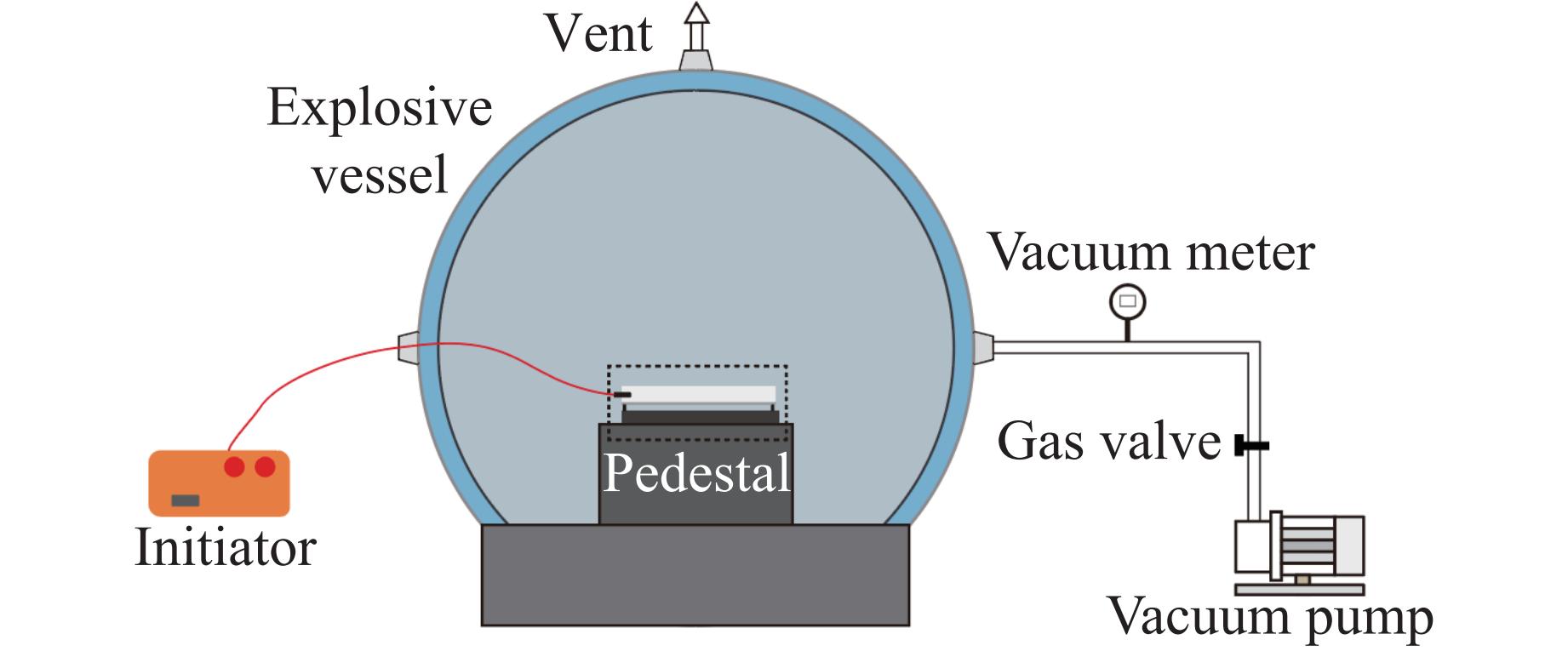

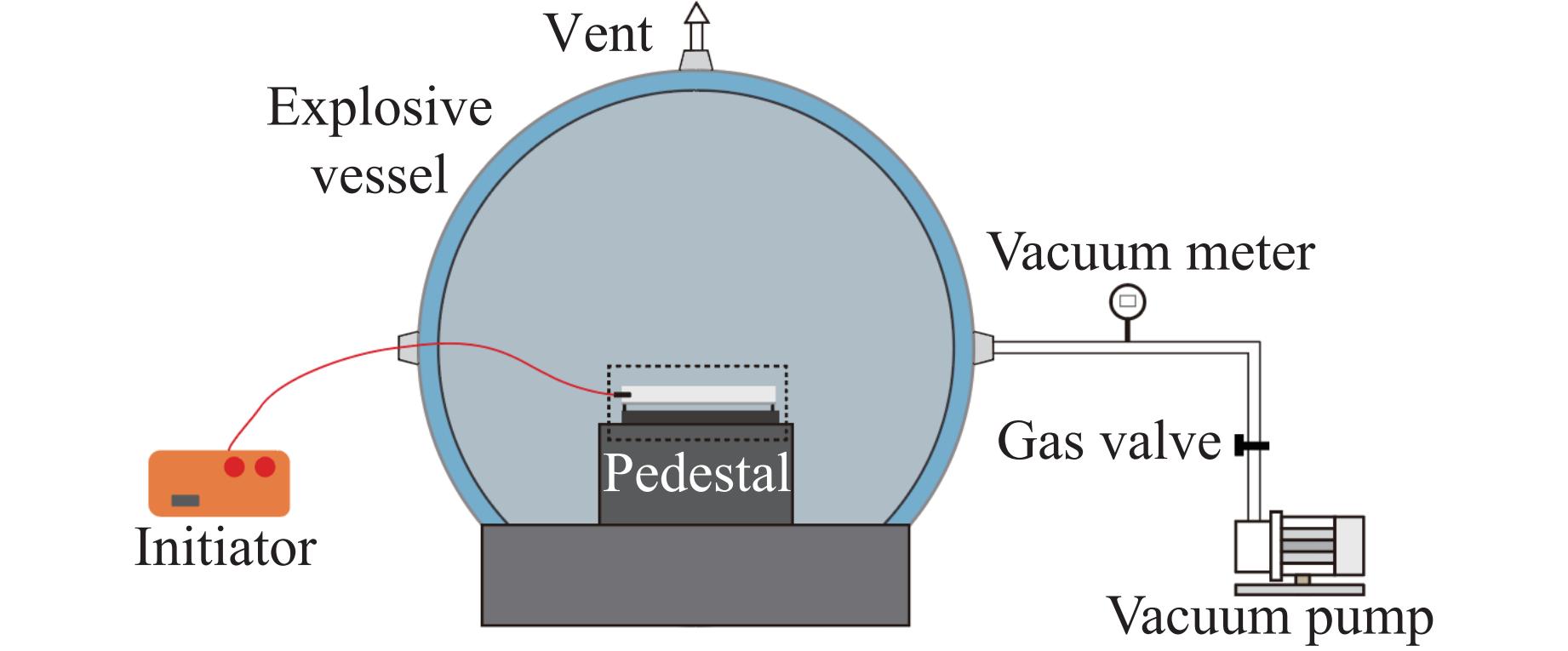

摘要: 镁合金和铝合金因具有较高的化学活性,在常规焊接方式下,其表面的氧化物会掺杂到焊接接头内,使得复合板的结合性能下降。为了提高Mg/Al复合板的结合强度,采用真空爆炸焊接法制备了Mg-AZ31B/Al-6061复合板,并与常规空气环境下制备的相同参数复合板进行了对比。通过光学显微镜、扫描电子显微镜、能谱仪以及万能试验机,对结合界面的微观形貌、元素分布和力学性能进行分析。结果表明:由于气体冲击波压力不同,真空环境下复合材料的界面形貌与空气环境下有很大区别;真空环境有效抑制了镁、铝2种金属氧化,在熔化区未检测到金属氧化物。此外,还观察到真空环境下试样的剪切强度和拉伸强度显著增大。因此,真空爆炸焊接对Mg/Al复合板性能的提升起到了重要作用,可以作为一种有效的金属焊接方法。Abstract: Oxides are prone to occur in welded joints by using of conventional welding methods due to high specific oxidation activity of magnesium and aluminum alloys, which leads to a decrease in the bonding performance of the composite plates. In order to improve the bonding strength of Mg-Al composite plates, Mg-AZ31B/Al-6061 composite plates were manufactured by vacuum explosive welding method, and compared with fabricating the same composite plates in air environment. The microstructure, elements distribution and mechanical properties of the interface were analyzed by optical microscope, scanning electron microscope, energy spectrometer and universal testing machine. The results show that the interfacial morphology of composites welded in vacuum environment is largely different from that in air environment due to the difference of gas shock pressure. The vacuum environment effectively inhibited the oxidation of magnesium and aluminum, and no metal oxides were detected in the melting zone. In addition, it was observed that the shear strength and tensile strength of the samples increased significantly under vacuum explosive welding. Therefore, vacuum explosive welding plays an important role in improving the performance of Mg/Al composite plates, and can be used as an high-performance metal welding method.

-

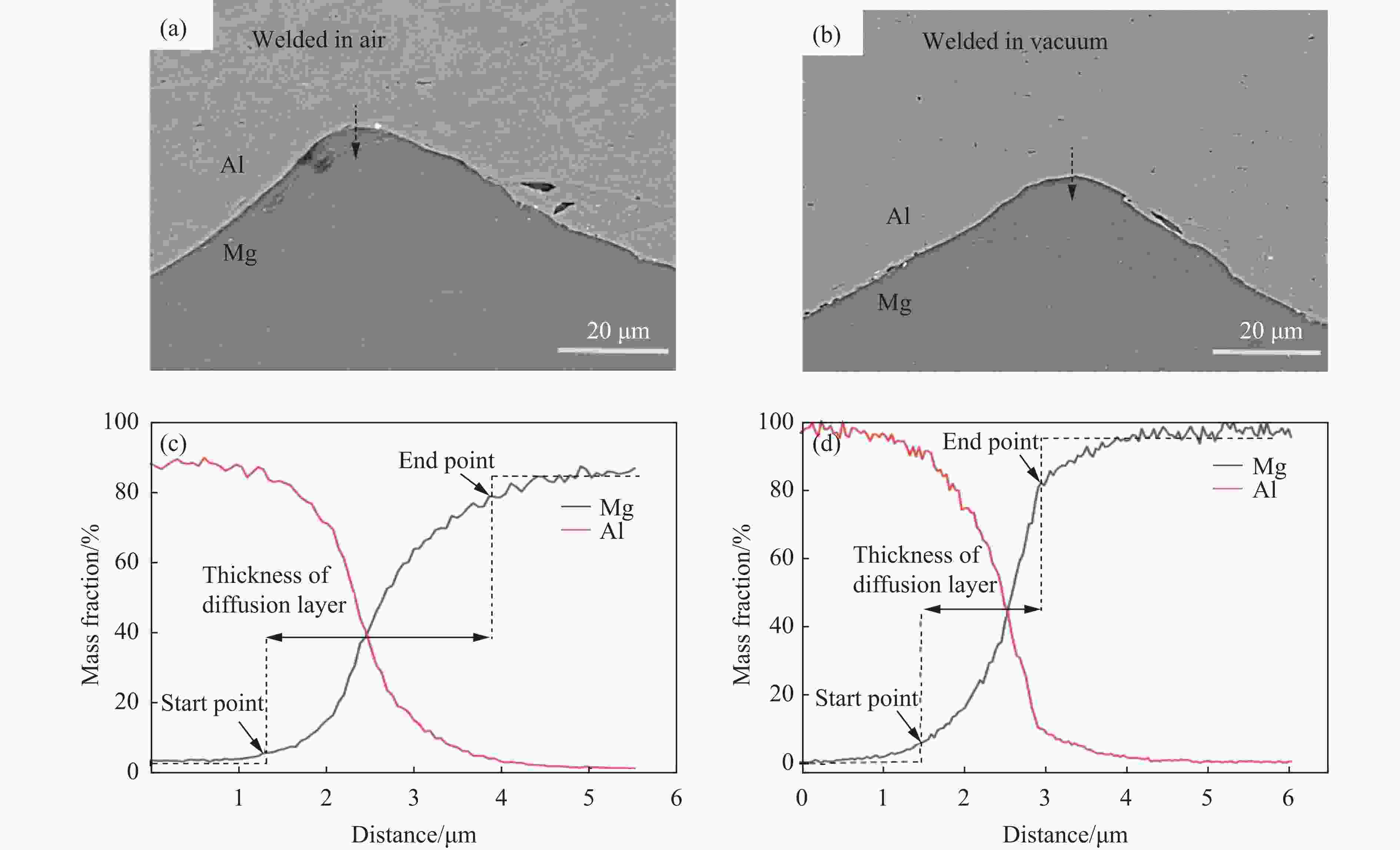

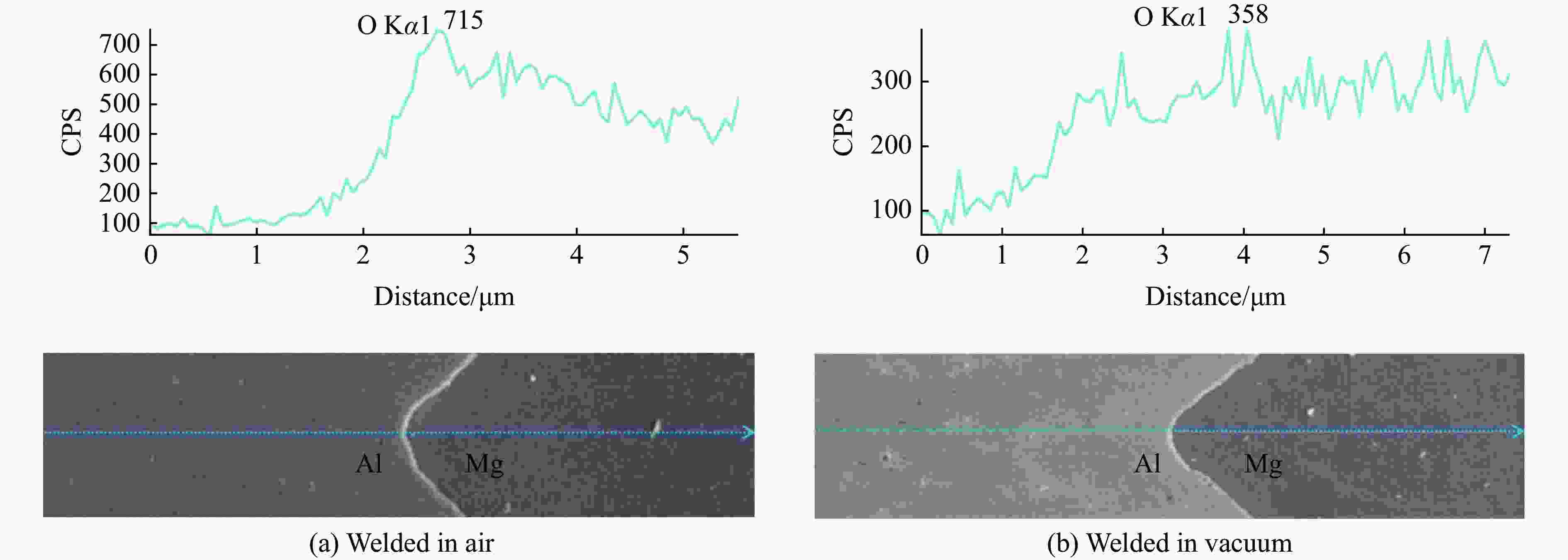

图 8 结合界面处的EDS线扫描结果:(a) 空气环境下的线扫描微观结构,(b) 真空环境下的线扫描微观结构,(c) 空气环境下的EDS线扫描界面分析,(d) 真空环境下的EDS线扫描界面分析

Figure 8. EDS line scanning results of interface: (a) scanning of microstructure in air environment; (b) scanning of microstructure in vacuum environment; (c) EDS line scan interface analysis in air environment; (d) EDS line scan interface analysis in vacuum environment

表 1 实验材料的化学成分

Table 1. Chemical composition of experimental materials

Materials Component content/% Al Si Ca Zn Mn Ti Mg Fe Mg-AZ31B 3.100 0.030 0.050 0.820 0.335 Rest 0.003 Al-6061 Rest 0.800 0.250 0.150 0.150 1.200 0.700 表 2 实验材料的力学性能

Table 2. Mechanical properties of the experimental materials

Materials Vickers hardness/HV Yied strength/MPa Tensile strength/MPa Shear strength/MPa Elongation/% Mg-AZ31B 44 140 225 130 15 Al-6061 108 220 290 124 8 表 3 乳化基质的成分

Table 3. Components of the emulsion matrix

Ingredient Mass fraction/% NH4NO3 75 NaNO3 8 H2O 11 C18H38 4 C24H4406 2 表 4 2种环境下熔化区物质的化学组成

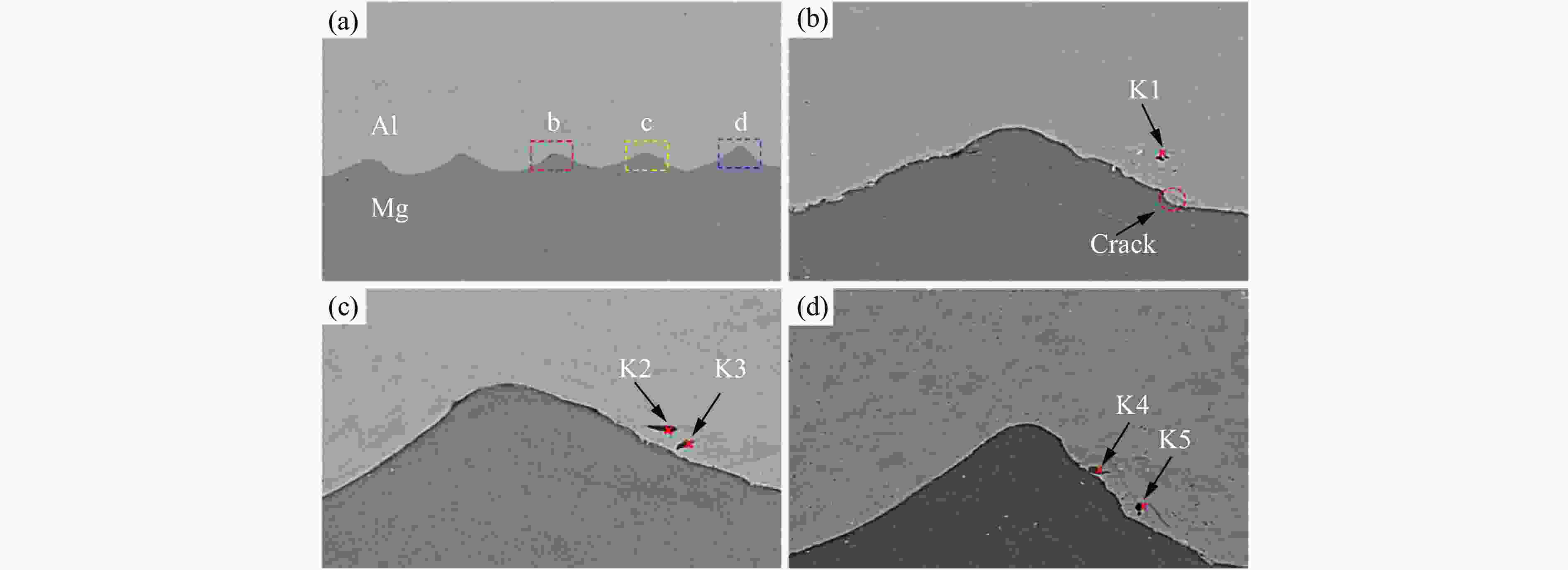

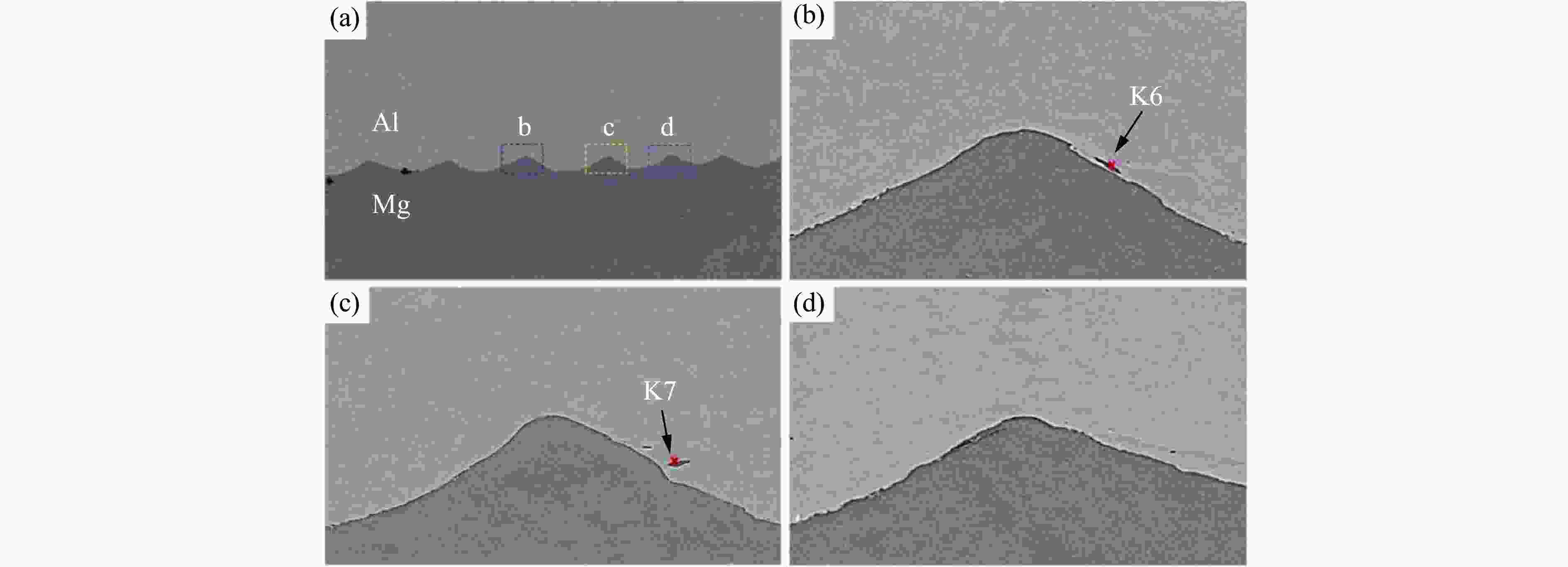

Table 4. Chemical composition of the corresponding substances in the melting zone in both environments

Melt zone

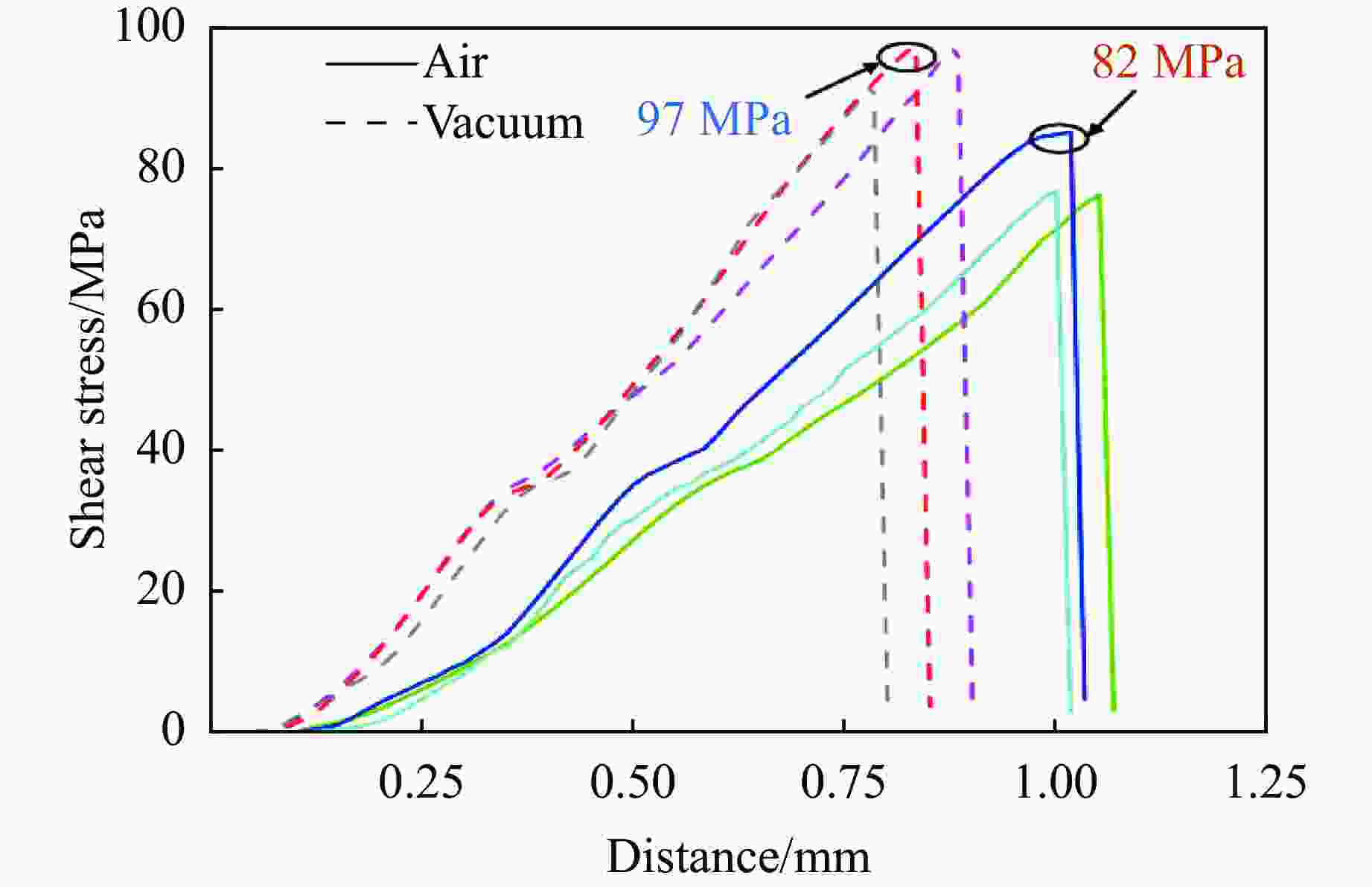

substance No.Environment Component content/% Mg Al O Mn Zn K1 Air 75.5 19.9 4.6 K2 Air 78.2 14.1 5.9 1.8 K3 Air 81.7 11.7 5.8 0.8 K4 Air 96.9 0.4 1.6 0.3 0.8 K5 Air 78.5 17.9 3.6 K6 Vacuum 79.0 18.8 0.4 1.2 0.6 K7 Vacuum 98.1 0.6 0.2 0.4 0.7 表 5 复合板不同部位的剪切强度

Table 5. Shear strength of different positions of composite plates

Experimental environment Shear strength/MPa 2 cm 6 cm 10 cm Air 60 82 71 Vacuum 68 96 83 -

[1] CHU S, MAJUMDAR A. Opportunities and challenges for a sustainable energy future [J]. Nature, 2012, 488(7411): 294–303. doi: 10.1038/nature11475 [2] BOROŃSKI D, KOTYK M, MAĆKOWIAK P, et al. Mechanical properties of explosively welded AA2519-AA1050-Ti6Al4V layered material at ambient and cryogenic conditions [J]. Materials & Design, 2017, 133: 390–403. [3] XIN T Z, ZHAO Y H, MAHJOUB R, et al. Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition [J]. Science Advances, 2021, 7(23): eabf3039. doi: 10.1126/sciadv.abf3039 [4] ZHANG N, WANG W X, CAO X Q, et al. The effect of annealing on the interface microstructure and mechanical characteristics of AZ31B/AA6061 composite plates fabricated by explosive welding [J]. Materials & Design, 2015, 65: 1100–1109. [5] YAN Y B, ZHANG Z W, SHEN W, et al. Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate [J]. Materials Science and Engineering: A, 2010, 527(9): 2241–2245. doi: 10.1016/j.msea.2009.12.007 [6] KUMAR P, GHOSH S K, SARAVANAN S, et al. Experimental and simulation studies on explosive welding of AZ31B-Al5052 alloys [J]. The International Journal of Advanced Manufacturing Technology, 2023, 127(5): 2387–2399. [7] FRONCZEK D M, CHULIST R, LITYNSKA-DOBRZYNSKA L, et al. Microstructure and kinetics of intermetallic phase growth of three-layered A1050/AZ31/A1050 clads prepared by explosive welding combined with subsequent annealing [J]. Materials & Design, 2017, 130: 120–130. [8] SATO Y S, PARK S H C, MICHIUCHI M, et al. Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys [J]. Scripta Materialia, 2004, 50(9): 1233–1236. doi: 10.1016/j.scriptamat.2004.02.002 [9] SANAMAR S, BROKMEIER H G, SCHELL N. Formation of the intermetallic phases Al12Mg17 and Al3Mg2 during heating of elemental Al-Mg composites studied by high-energy X-ray diffraction [J]. Journal of Alloys and Compounds, 2022, 911: 165114. doi: 10.1016/j.jallcom.2022.165114 [10] SHIRAN M K G, KHALAJ G, POURALIAKBAR H, et al. Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321-aluminum 1230 explosive-welding interface [J]. International Journal of Minerals, Metallurgy, and Materials, 2017, 24(11): 1267–1277. doi: 10.1007/s12613-017-1519-x [11] XU Y, KE L M, MAO Y Q, et al. Formation investigation of intermetallic compounds of thick plate Al/Mg alloys joint by friction stir welding [J]. Materials, 2019, 12(17): 2661. doi: 10.3390/ma12172661 [12] ZENG X Y, WANG W X, LI X Q, et al. Effect of inert gas-shielding on the interface and mechanical properties of Mg/Al explosive welding composite plate [J]. Journal of Manufacturing Processes, 2019, 45: 166–175. doi: 10.1016/j.jmapro.2019.07.007 [13] WANG Y X, BEOM HG, SUN M, et al. Numerical simulation of explosive welding using the material point method [J]. International Journal of Impact Engineering, 2011, 38(1): 51–60. doi: 10.1016/j.ijimpeng.2010.08.003 [14] ZHANG T T, WANG W X, ZHANG W, et al. Microstructure evolution and mechanical properties of an AA6061/AZ31B alloy plate fabricated by explosive welding [J]. Journal of Alloys and Compounds, 2018, 735: 1759–1768. doi: 10.1016/j.jallcom.2017.11.285 [15] LUO C Z, LIANG W, CHEN Z Q, et al. Effect of high temperature annealing and subsequent hot rolling on microstructural evolution at the bond-interface of Al/Mg/Al alloy laminated composites [J]. Materials Characterization, 2013, 84: 34–40. doi: 10.1016/j.matchar.2013.07.007 [16] MALLICK P K, AGARWAL L. Fatigue of spot friction welded joints of Mg-Mg, Al-Al and Al-Mg alloys [R]. SAE, 2009. [17] ZHOU Q, LU H H, LAN X K, et al. Anisotropy in microstructure and shear properties of TA2/Q235 explosive welding interfaces [J]. Journal of Materials Research and Technology, 2023, 25: 6472–6491. doi: 10.1016/j.jmrt.2023.07.080 [18] ZHOU P J, GUO C H, WANG E H, et al. Interface tensile and fracture behavior of the Ti/Al3Ti metal-intermetallic laminate (MIL) composite under quasi-static and high strain rates [J]. Materials Science and Engineering: A, 2016, 665: 66–75. doi: 10.1016/j.msea.2016.04.020 -

下载:

下载: