Physico-Mechanical Behavior and Size Effect of Nano-Tungsten under High Pressure

-

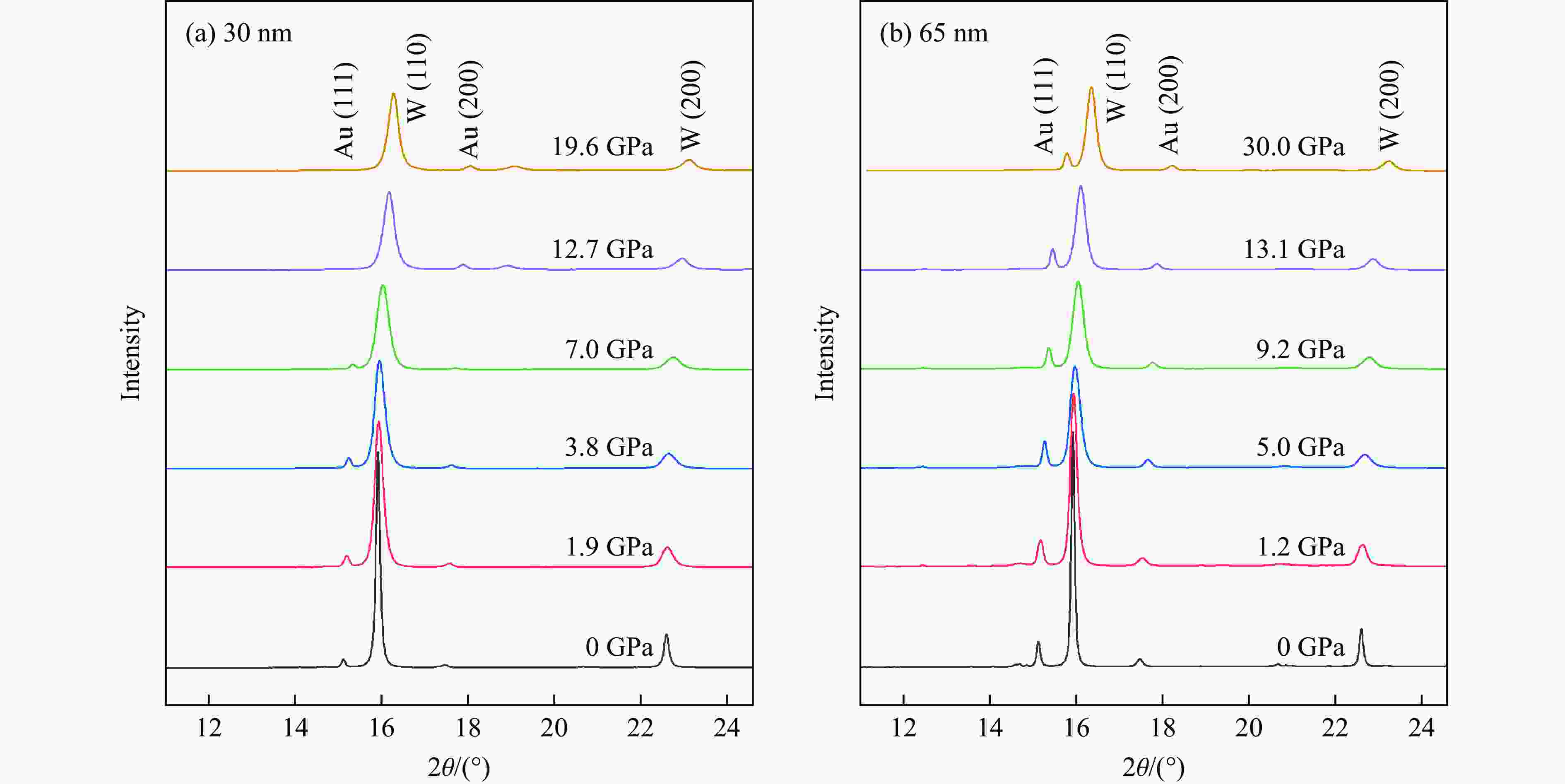

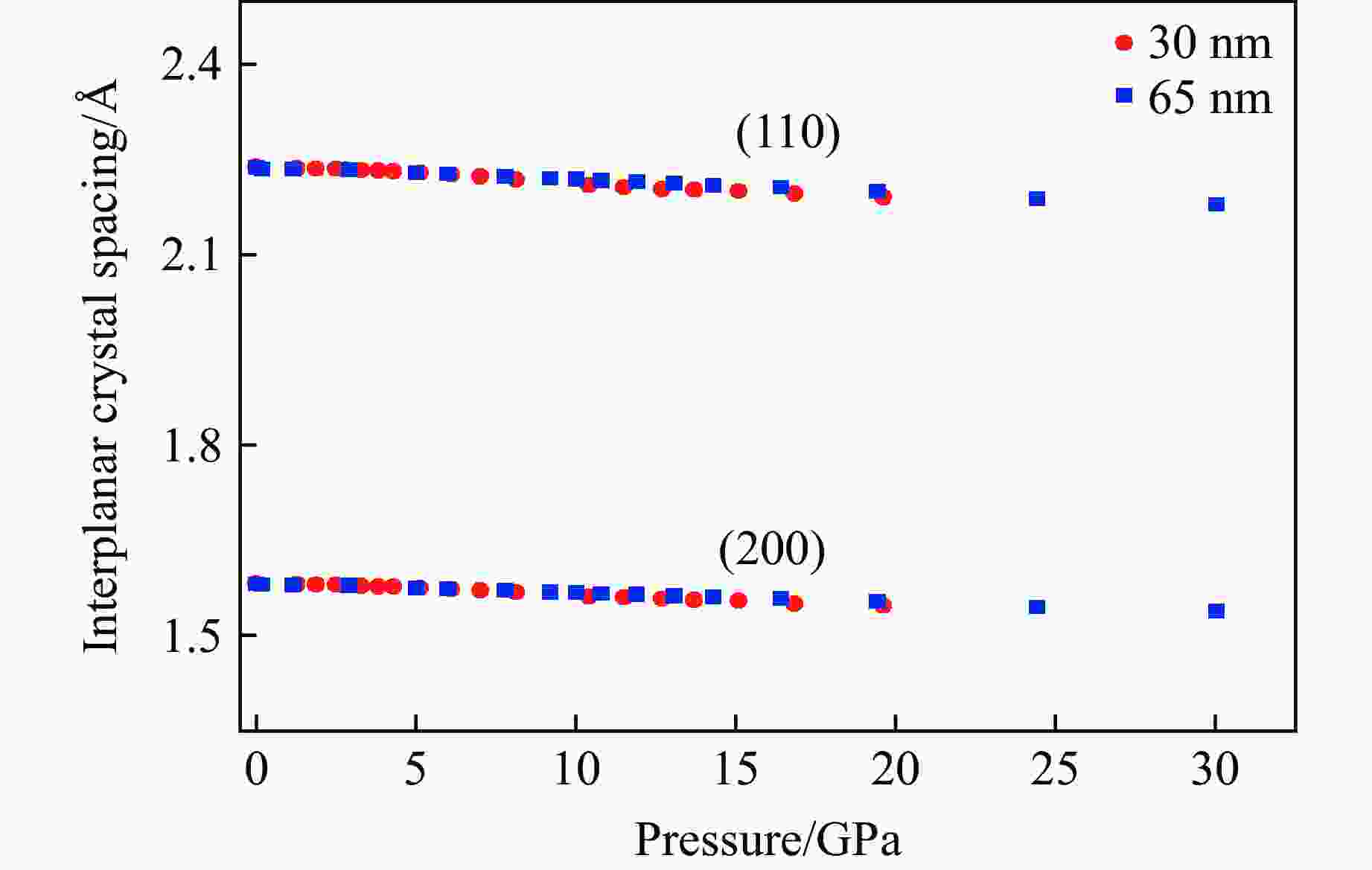

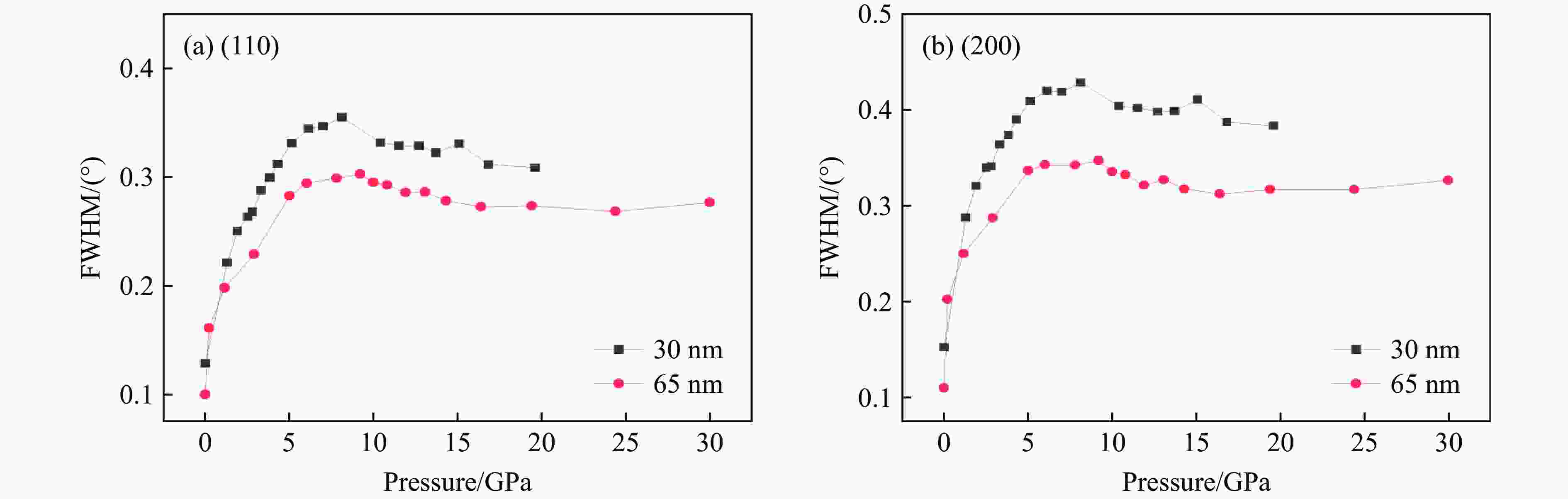

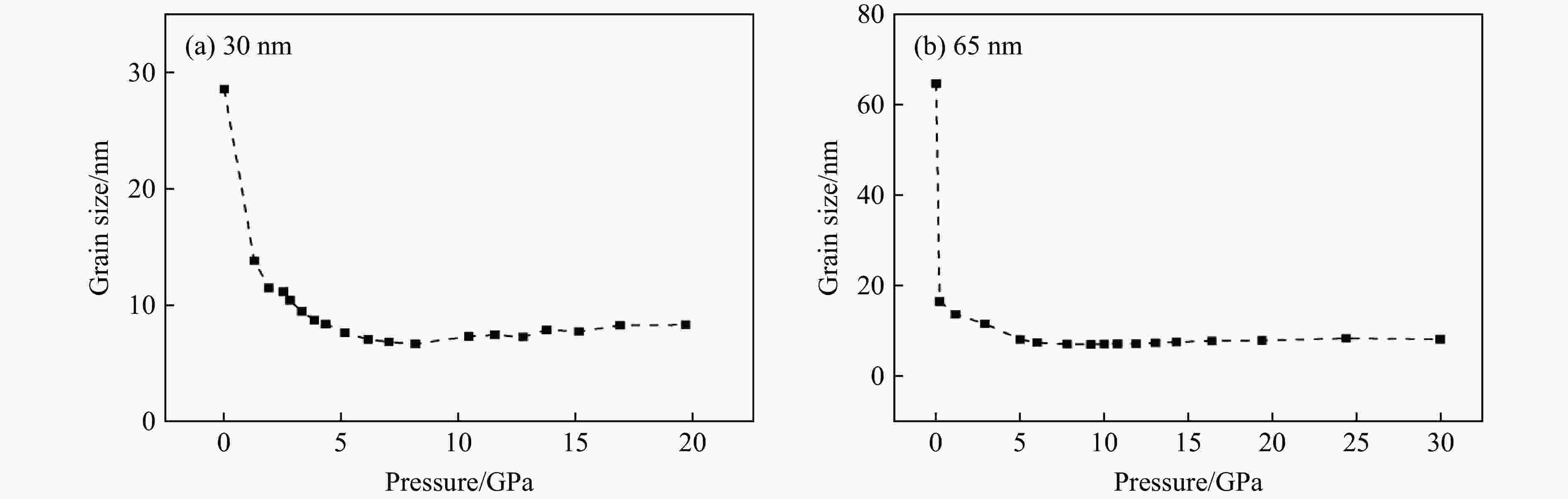

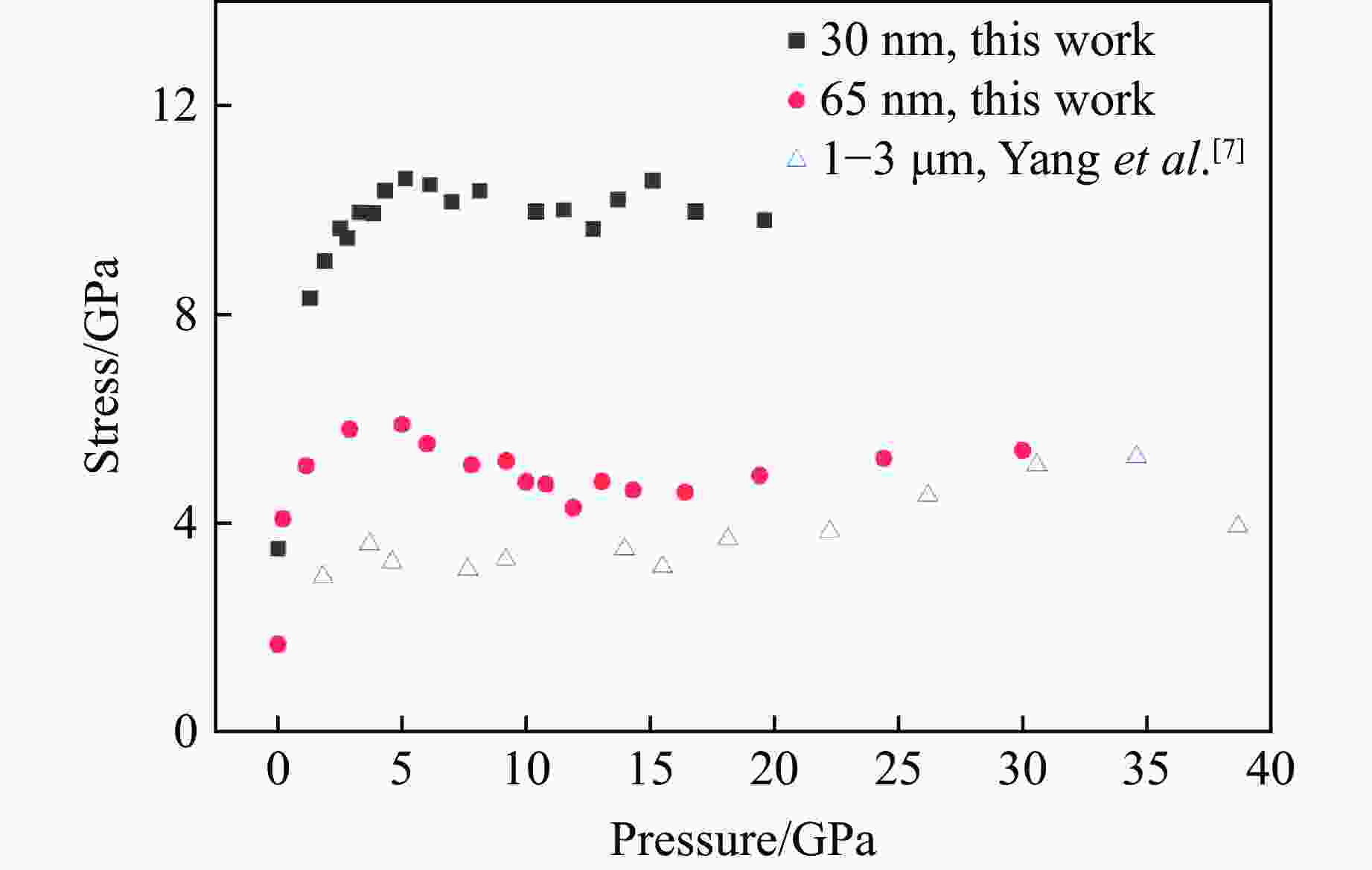

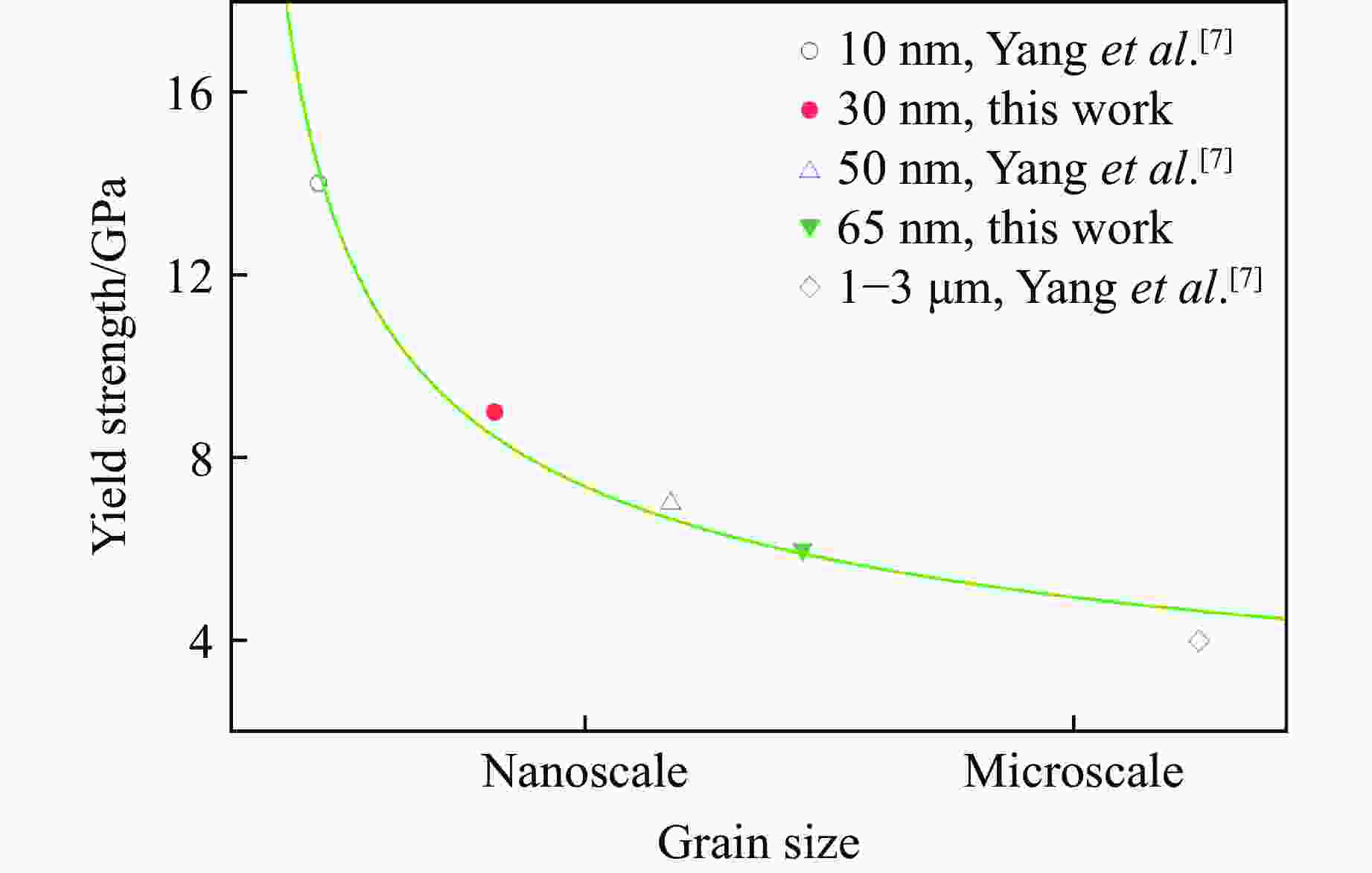

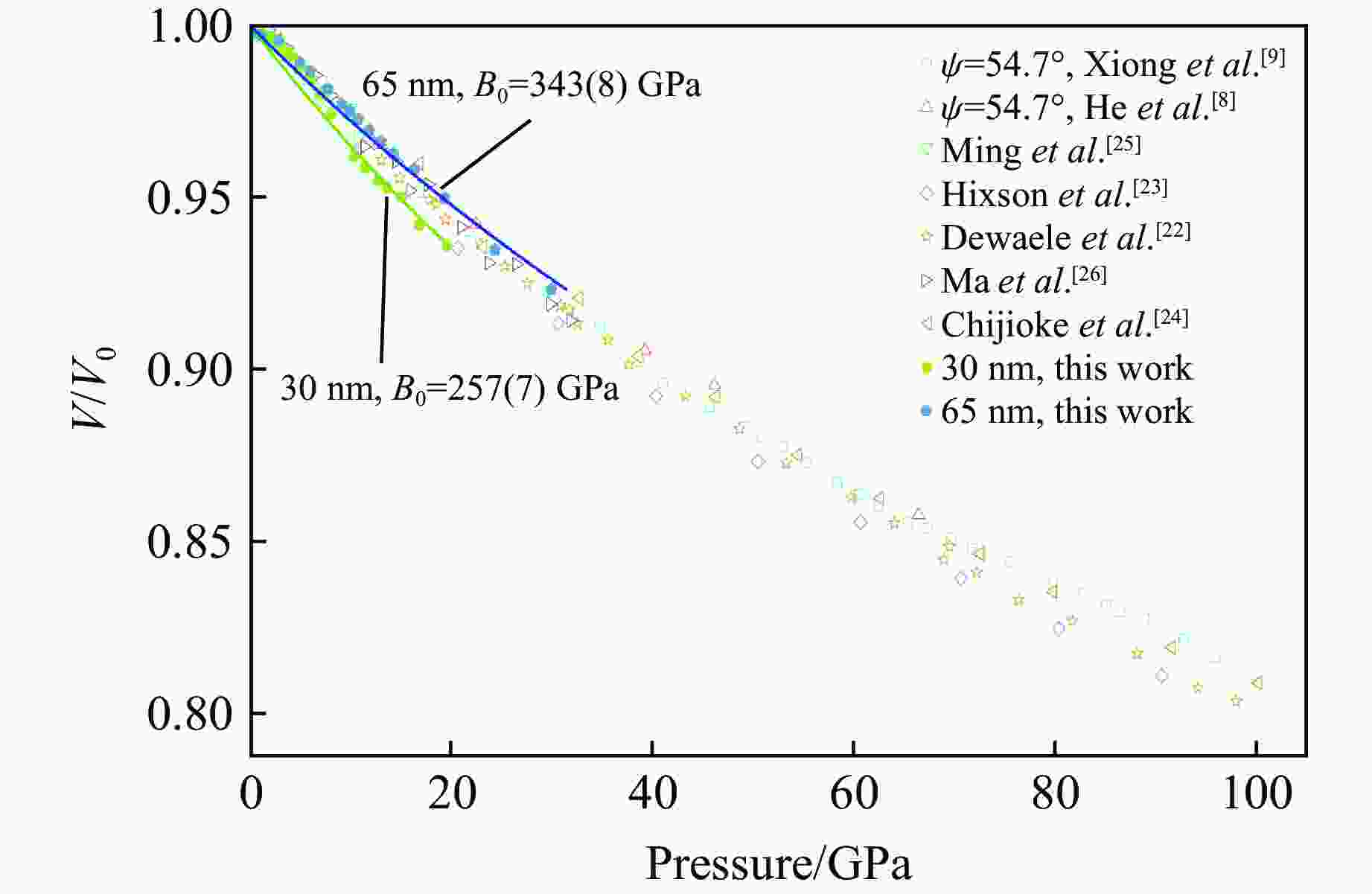

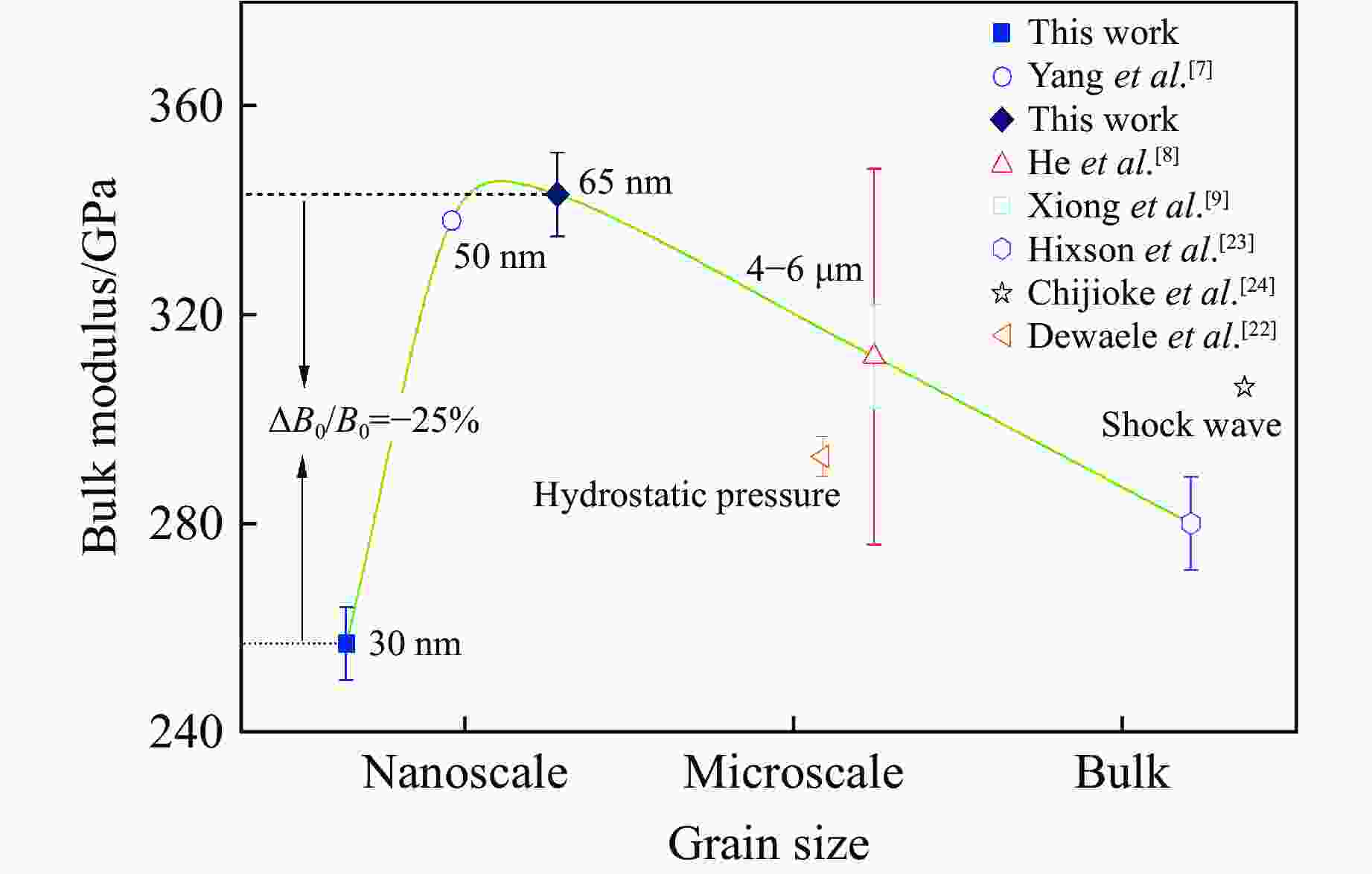

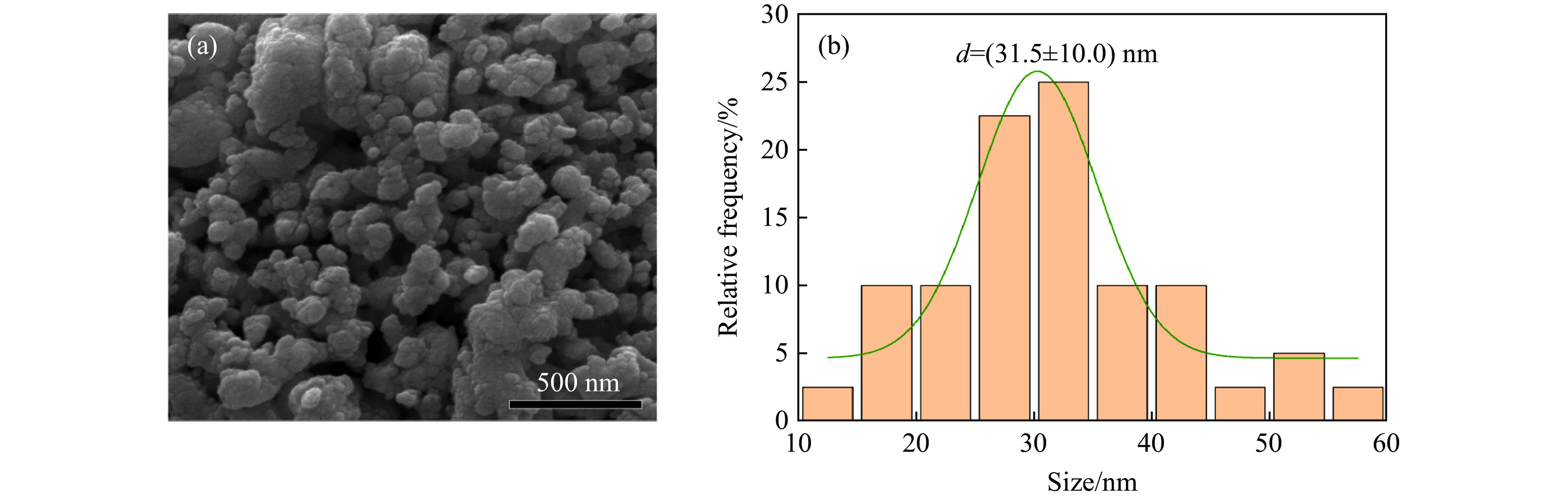

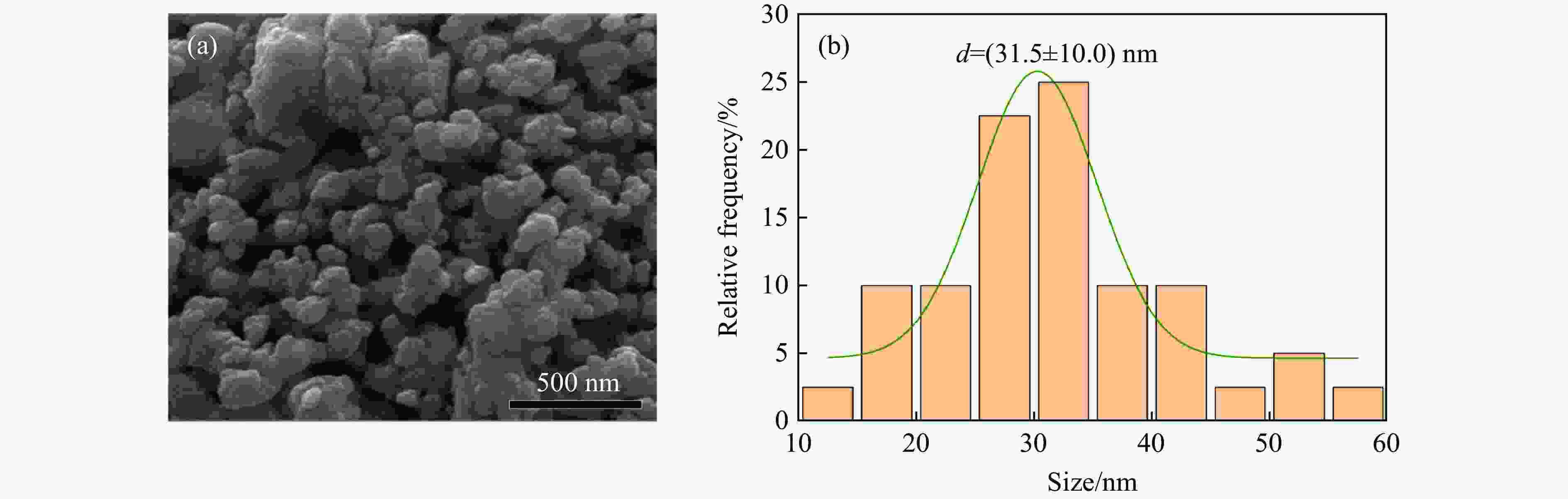

摘要: 探究尺寸效应对材料高压物性的影响规律有助于开发具有新颖或者改良特性的新材料。采用金刚石对顶砧结合同步辐射X射线衍射技术,研究了平均晶粒尺寸分别为30和65 nm的多晶钨粉在高压下的静态压缩行为。通过分析每个压力点下X射线衍射图谱的峰位和半高宽等,得到了纳米金属钨在高压下的晶胞体积、晶粒尺寸和微观应变等。通过拟合三阶Birch-Murnaghan方程,得到了30和65 nm钨的体弹模量,分别为257(7) GPa和343(8) GPa。结合前人的研究结果发现,当晶粒尺寸从微米降低至10 nm,钨的屈服强度逐渐增大,10 nm钨的屈服强度较微米晶样品的屈服强度提高了3.5倍;体弹模量呈现先增大后减小的趋势,30 nm钨的体弹模量较65 nm钨减小了25%。Abstract: Exploring the influence of size effect on the physical properties of materials under high pressure is helpful for the development of new materials with novel or improved properties. The static compression behaviors of polycrystalline tungsten powder with average grain sizes of 30 and 65 nm under high pressure were studied by using diamond anvil cell (DAC) combined with synchrotron radiation X-ray diffraction respectively. By analyzing the peak position and the half-height width of the X-ray diffraction spectrum at each pressure, the unit cell volume, grain size, and microscopic strain of nano-tungsten metal under high pressure were obtained. By fitting the third Birch-Murnaghan equation, the bulk moduli of 30 and 65 nm tungsten are obtained to be 257(7) GPa and 343(8) GPa, respectively. Combined with the results of previous studies, it is found that when the gain size decreases from micron to 10 nm, the yield strength of tungsten at 10 nm increases by 3.5 times compared with that of microcrystal samples; the bulk modulus shows a tendency of increasing firstly and then decreasing, and the bulk elastic modulus of tungsten at 30 nm decreases by 25% compared with that of tungsten at 65 nm.

-

Key words:

- equation of state /

- yield strength /

- bulk modulus /

- high pressure /

- nanocrystalline

-

图 8 钨的晶胞体积压缩率随压力的变化(实线是基于30和65 nm钨晶粒的晶胞体积压缩率-压力数据点,通过三阶Birch-Murnaghan状态方程拟合的曲线;离散的数据点为其他研究人员所得结果[8–9, 22–26])

Figure 8. Volume compression ratio of unit cell for tungsten as a function of pressure (The solid lines are fitting curves of unit cell volume compression ratio and pressure for tungsten crystals with sizes of 30 and 65 nm by the third Birch-Murnaghan equation of state; the discrete data points are obtained by other researchers[8–9, 22–26])

表 1 各种晶粒尺寸下钨的体弹模量

Table 1. Bulk modulus of tungsten with a series of particle sizes

Grain size Pressure/GPa B0/GPa $B_0' $ Pressure transmitting

mediumMethod Ref. 30 nm

65 nm

50 nm

4−6 μm

<4 μm

4−6 μm

4−6 μm

4−6 μm

Bulk

Bulk0−20

0−30

16−53

0−69

0−153

0−96

0−96

0−96

264−676

0−300257(7)

343(8)

338

312(36)

295(4)

312(10)

256(2)

342(1)

280(9)

3094.32 (fixed)

4.32 (fixed)

4.32 (fixed)

4.32 (fixed)

4.32 (0.11)

4.32 (fixed)

4.32 (fixed)

4.32 (fixed)

4.32 (fixed)

4.32 (fixed)None

None

None

None

Helium

NoneAXRD

AXRD

RXRD (ψ=54.7°)

RXRD (ψ=54.7°)

AXRD

RXRD (ψ=54.7°)

RXRD (ψ=0°)

RXRD (ψ=90°)

Shock compression

Shock compressionThis work

This work

Ref. [7]

Ref. [8]

Ref. [22]

Ref. [9]

Ref. [9]

Ref. [9]

Ref. [23]

Ref. [24] -

[1] CORDERO Z C, KNIGHT B E, SCHUH C A. Six decades of the Hall-Petch effect: a survey of grain-size strengthening studies on pure metals [J]. International Materials Reviews, 2016, 61(8): 495–512. doi: 10.1080/09506608.2016.1191808 [2] SCHIØTZ J, DI TOLLA F D, JACOBSEN K W. Softening of nanocrystalline metals at very small grain sizes [J]. Nature, 1998, 391(6667): 561–563. doi: 10.1038/35328 [3] YIP S. The strongest size [J]. Nature, 1998, 391(6667): 532–533. doi: 10.1038/35254 [4] SCHIØTZ J, JACOBSEN K W. A maximum in the strength of nanocrystalline copper [J]. Science, 2003, 301(5638): 1357–1359. doi: 10.1126/science.1086636 [5] ZHOU X L, FENG Z Q, ZHU L L, et al. High-pressure strengthening in ultrafine-grained metals [J]. Nature, 2020, 579(7797): 67–72. doi: 10.1038/s41586-020-2036-z [6] GU Q F, KRAUSS G, STEURER W, et al. Unexpected high stiffness of Ag and Au nanoparticles [J]. Physical Review Letters, 2008, 100(4): 045502. doi: 10.1103/PhysRevLett.100.045502 [7] YANG J, DENG W, LI Q, et al. Strength enhancement of nanocrystalline tungsten under high pressure [J]. Matter and Radiation at Extremes, 2020, 5(5): 058401. doi: 10.1063/5.0005395 [8] HE D W, DUFFY T S. X-ray diffraction study of the static strength of tungsten to 69 GPa [J]. Physical Review B, 2006, 73(13): 134106. doi: 10.1103/PhysRevB.73.134106 [9] XIONG L, LI B, TANG Y M, et al. Radial X-ray diffraction study of the static strength and texture of tungsten to 96 GPa [J]. Solid State Communications, 2018, 269: 83–89. doi: 10.1016/j.ssc.2017.10.016 [10] 邹勇, 陈立溁. 贵金属金的状态方程 [J]. 高压物理学报, 2006, 20(3): 308–312. doi: 10.3969/j.issn.1000-5773.2006.03.015ZOU Y, CHEN L Y. Equation of state for gold [J]. Chinese Journal of High Pressure Physics, 2006, 20(3): 308–312. doi: 10.3969/j.issn.1000-5773.2006.03.015 [11] MUSTAPHA S, NDAMITSO M M, ABDULKAREEM A S, et al. Comparative study of crystallite size using Williamson-Hall and Debye-Scherrer plots for ZnO nanoparticles [J]. Advances in Natural Sciences: Nanoscience and Nanotechnology, 2019, 10(4): 045013. doi: 10.1088/2043-6254/ab52f7 [12] WU Z Q, LIN F. Evaluation of Pt and Au pressure scales based on MgO absolute pressure scale [J]. Science China Earth Sciences, 2017, 60(1): 114–123. doi: 10.1007/s11430-015-0232-4 [13] WANG Y, AHUJA R, JOHANSSON B. Reduction of shock-wave data with mean-field potential approach [J]. Journal of Applied Physics, 2002, 92(11): 6616–6620. doi: 10.1063/1.1518781 [14] HAMMERSLEY A P, SVENSSON S O, HANFLAND M, et al. Two-dimensional detector software: from real detector to idealised image or two-theta scan [J]. High Pressure Research, 1996, 14(4): 235–248. doi: 10.1080/08957959608201408 [15] SINGH T B, REY L, GARTIA R K. Applications of PeakFit software in thermoluminescence studies [J]. Indian Journal of Pure & Applied Physics, 2011, 49(5): 297–302. [16] 李春, 刘泽民, 陈恒杰, 等. PeakFit、1stOpt在弗兰克-赫兹实验数据处理中的应用 [J]. 大学物理实验, 2018, 31(5): 117–123. doi: 10.14139/j.cnki.cn22-1228.2018.05.028LI C, LIU Z M, CHEN H J, et al. Application of PeakFit and 1stOpt in data processing of the Frank-Hertz experiment [J]. Physical Experiment of College, 2018, 31(5): 117–123. doi: 10.14139/j.cnki.cn22-1228.2018.05.028 [17] LANGFORD J. X-ray powder diffraction studies of vitromet samples [J]. Journal of Applied Crystallography, 1971, 4: 164–168. doi: 10.1107/S002188987100654X [18] 余建新, 王晓鹏, 崔喜平. 高温环境下材料泊松比测试方法研究[J]. 实验科学与技术, 2022, 20(1): 28–33.YU J X, WANG X P, CUI X P, Material poisson’s ratio measurement method at elevated temperatures [J]. Experiment Science and Technology, 2022, 20(1): 28–33. [19] EINARSDOTTER K, SADIGH B, GRIMVALL G, et al. Phonon instabilities in fcc and bcc tungsten [J]. Physical Review Letters, 1997, 79(11): 2073–2076. doi: 10.1103/PhysRevLett.79.2073 [20] KATAHARA K, MANGHNANI M, FISHER E. Pressure derivatives of the elastic-moduli of bcc Ti-V-Cr, Nb-Mo and Ta-W alloys [J]. Journal of Physics F: Metal Physics, 1979, 9(5): 773–790. doi: 10.1088/0305-4608/9/5/006 [21] ZHANG J Z, ZHAO Y S, PALOSZ B. Comparative studies of compressibility between nanocrystalline and bulk nickel [J]. Applied Physics Letters, 2007, 90(4): 043112. doi: 10.1063/1.2435325 [22] DEWAELE A, LOUBEYRE P, MEZOUAR M. Equations of state of six metals above 94 GPa [J]. Physical Review B, 2004, 70(9): 094112. doi: 10.1103/PhysRevB.70.094112 [23] HIXSON R S, FRITZ J N. Shock compression of tungsten and molybdenum [J]. Journal of Applied Physics, 1992, 71(4): 1721–1728. doi: 10.1063/1.351203 [24] CHIJIOKE A D, NELLIS W J, SILVERA I F. High-pressure equations of state of Al, Cu, Ta, and W [J]. Journal of Applied Physics, 2005, 98(7): 073526. doi: 10.1063/1.2071449 [25] MING L C, MANGHNANI M H. Isothermal compression of bcc transition metals to 100 kbar [J]. Journal of Applied Physics, 1978, 49(1): 208–212. [26] MA Y Z, CUI Q L, SHEN L H, et al. X-ray diffraction study of nanocrystalline tungsten nitride and tungsten to 31 GPa [J]. Journal of Applied Physics, 2007, 102(1): 013525. [27] CHEN B, PENWELL D, BENEDETTI L R, et al. Particle-size effect on the compressibility of nanocrystalline alumina [J]. Physical Review B, 2002, 66(14): 144101. doi: 10.1103/PhysRevB.66.144101 [28] GLEASON A E, MARQUARDT H, CHEN B, et al. Anomalous sound velocities in polycrystalline MgO under non-hydrostatic compression [J]. Geophysical Research Letters, 2011, 38: L03304. [29] LE GODEC Y, KURAKEVYCH O O, MUNSCH P, et al. Effect of nanostructuration on compressibility of cubic BN [J]. Journal of Superhard Materials, 2012, 34(5): 336–338. doi: 10.3103/S1063457612050085 [30] AL-KHATATBEH Y, LEE K K M, KIEFER B. Compressibility of nanocrystalline TiO2 anatase [J]. Journal of Physical Chemistry C, 2012, 116(40): 21635–21639. doi: 10.1021/jp3075699 [31] JIANG J Z, OLSEN J S, GERWARD L, et al. Enhanced bulk modulus and reduced transition pressure in γ-Fe2O3 nanocrystals [J]. Europhysics Letters, 1999, 45(2): 275–275. doi: 10.1209/epl/i1999-00158-3 [32] TOLBERT S H. High-pressure structural transformations in semiconductor nanocrystals [J]. Annual Review of Physical Chemistry, 1995, 46(1): 595–625. doi: 10.1146/annurev.pc.46.100195.003115 [33] HONG X G, DUFFY T S, EHM L, et al. Pressure-induced stiffness of Au nanoparticles to 71 GPa under quasi-hydrostatic loading [J]. Journal of Physics: Condensed Matter, 2015, 27(48): 485303. doi: 10.1088/0953-8984/27/48/485303 [34] MIKHEYKIN A S, DMITRIEV V P, CHAGOVETS S V, et al. The compressibility of nanocrystalline Pt [J]. Applied Physics Letters, 2012, 101(17): 173111. doi: 10.1063/1.4758000 [35] CHEN B, PENWELL D, KRUGER M B, et al. Nanocrystalline iron at high pressure [J]. Journal of Applied Physics, 2001, 89(9): 4794–4796. doi: 10.1063/1.1357780 [36] WANG Z W, PISCHEDDA V, SAXENA S K, et al. X-ray diffraction and Raman spectroscopic study of nanocrystalline CuO under pressures [J]. Solid State Communications, 2002, 121(5): 275–279. doi: 10.1016/S0038-1098(01)00509-9 [37] GU Q F, KRAUSS G, GRAMM F, et al. On the compressibility of TiC in microcrystalline and nanoparticulate form [J]. Journal of Physics: Condensed Matter, 2008, 20(44): 445226. doi: 10.1088/0953-8984/20/44/445226 [38] WANG Q M, HE D W, PENG F, et al. Compression behavior of nanocrystalline TiN [J]. Solid State Communications, 2014, 182: 26–29. doi: 10.1016/j.ssc.2013.12.015 -

下载:

下载: