Explosion Suppression Characteristics of Explosion-SuppressiveHigh Flash-Point Jet Fuel

-

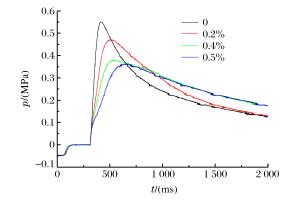

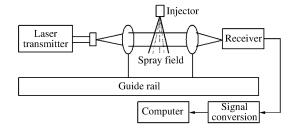

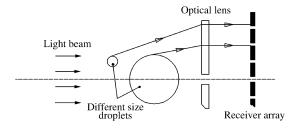

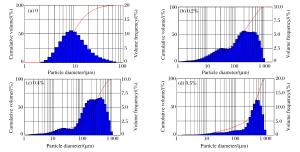

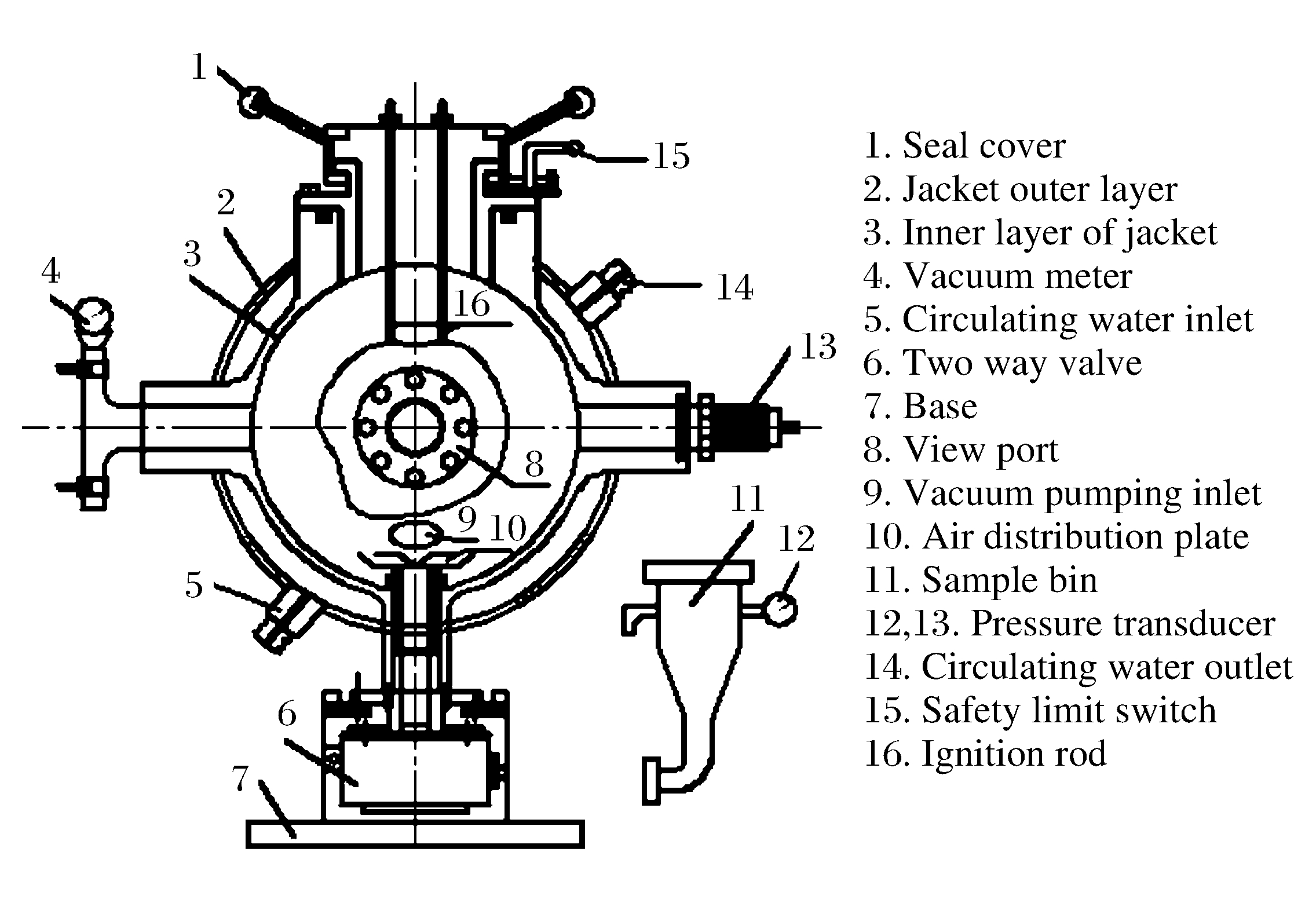

摘要: 配制了含有不同比例抑爆剂的抑爆高闪点喷气燃料, 利用液体燃料燃爆性能评价装置测得油样在0.343、0.687、1.030、1.373和1.717 MPa喷雾压力条件下的爆炸参数。结果表明:喷雾压力越高, 油样燃烧爆炸越充分; 油样中的抑爆剂含量越高, 抑爆性能越好。进一步利用马尔文实时喷雾粒度分析仪研究了在喷雾压力为1.717 MPa时油样雾滴的粒径分布情况。根据实验结果, 给出了油样雾化性能和抑爆效果的内在联系, 并对抑爆高闪点喷气燃料的抑爆机理做出了解释。Abstract: In this work high flash-point jet fuel containing different proportions of explosion-suppressive material, called as explosion-suppressive high flash-point jet fuel, was prepared.The liquid fuel combustion and explosion performance evaluation devices were used to measure the explosion parameters of the fuel under different conditions of the spray pressures in the range of 0.343, 0.687, 1.030, 1.373 and 1.717 MPa.The results from the experiment show that the explosion will be more sufficient with the increase of the spray pressure, and the explosion-suppressive capability of the high flash-point jet fuel becomes stronger as the content of the explosion-suppressive material proportion increases.Further, to study the internal relationship between the atomization property and the explosion-suppressive characteristics, the droplet size distribution under the spray pressure of 1.717 MPa was measured using the Malvern particle size analyzer.Based on the above research results, the explosion-suppressive mechanism of the explosion-suppressive high flash-point jet fuel was discussed in detail.

-

Key words:

- high flash-point jet fuel /

- explosion suppression /

- atomization /

- mechanism

-

表 1 不同油样的基本理化特性

Table 1. Main physical and chemical properties of the fuel

Mass fraction/(%) ν/(mm2/s) Tf/(℃) σ/(mN/m) 0 2.140 73 25.373 0.2 7.078 70 25.387 0.4 16.295 68 25.521 0.5 27.800 67 25.566 表 2 约束条件下不同油样的爆炸参数

Table 2. Explosion parameters of oil samples under constraint conditions

Mass fraction/(%) pspray/(MPa) pm/(MPa) τ/(MPa/s) Tm/(K) pm/(MPa) 0 0.343 0.491 3.401 461.7 0.520 4 0.687 0.500 4.488 464.1 1.030 0.524 4.495 470.3 1.373 0.535 5.358 473.1 1.717 0.552 5.412 477.4 0.2 0.343 0.185 0.503 349.3 0.366 6 0.687 0.308 1.885 404.1 1.030 0.420 2.244 441.5 1.373 0.447 2.281 449.4 1.717 0.473 2.442 456.8 0.4 0.343 0.169 0.456 340.4 0.316 2 0.687 0.322 0.881 409.2 1.030 0.351 0.996 419.4 1.373 0.360 1.163 422.5 1.717 0.379 1.721 428.7 0.5 0.343 0.131 0.453 316.5 0.261 0 0.687 0.202 0.437 358.2 1.030 0.263 0.754 386.2 1.373 0.345 1.072 417.4 1.717 0.364 1.115 423.8 表 3 喷雾压力为1.717 MPa时液滴的粒径分布

Table 3. Droplet size distribution when the spray pressure is 1.717 MPa

Mass fraction/(%) DV10/(μm) DV50/(μm) DV90/(μm) D[3,2]/(μm) D[4,3]/(μm) 0 5.8 19.7 581.6 13.1 125.3 0.2 78.2 401.3 737.8 101.9 408.1 0.4 112.6 459.0 770.7 141.0 458.7 0.5 376.6 591.9 779.2 195.7 569.8 -

[1] 黄勇, 鲁长波, 安高军, 等.柴油爆炸性能外场实验研究[J].爆炸与冲击, 2015, 35(4):482-488. http://d.old.wanfangdata.com.cn/Periodical/bzycj201504006HUANG Y, LU C B, AN G J, et al.Experimental research on explosion performance of diesel fuel on the external field[J]. Explosion and Shock Waves, 2015, 35(4):482-488. http://d.old.wanfangdata.com.cn/Periodical/bzycj201504006 [2] OCHOTERENA R, LIF A, NYDEN M, et al.Optical studies of spray development and combustion of water-in-diesel emulsion and microemulsion fuels[J]. Fuel, 2010, 89(1):122-132. doi: 10.1016/j.fuel.2009.06.039 [3] 魏成龙.阻燃抑爆柴油性能评定研究[D].南京: 南京理工大学, 2014: 57-76.WEI C L.Performance assessment research of fire resistant and explosion suppression diesel[D]. Nanjing: Nanjing University of Science and Technology, 2014: 57-76. [4] 吴珣.抑爆柴油的配制及影响因素研究[D].北京: 北京化工大学, 2011: 22-29. https://max.book118.com/html/2016/0118/33543419.shtmWU X.Preparation and influence factor of explosion proof diesel oil[D]. Beijing: Beijing University of Chemical Technology, 2011: 22-29. https://max.book118.com/html/2016/0118/33543419.shtm [5] GJB 560A—97.高闪点喷气燃料规范[S].北京: 中国标准出版社, 1997.GJB 560A—97.Specification for high flash jet fuel[S]. Beijing: China Standard Press, 1997. [6] 田震.提高可燃液体闪点的试验研究[J].消防科学与技术, 2007, 26(3):270-272. doi: 10.3969/j.issn.1009-0029.2007.03.011TIAN Z.Experimental study on the increasing the flash point of flammable liquid[J]. Fire Science and Technology, 2007, 26(3):270-272. doi: 10.3969/j.issn.1009-0029.2007.03.011 [7] 董亚琴, 安高军, 熊春华, 等.含氧柴油的性能研究[J].石油化工安全环保技术, 2013, 29(5):43-48. doi: 10.3969/j.issn.1673-8659.2013.05.014DONG Y Q, AN G J, XIONG C H, et al.Research on the performance of oxygenated diesel[J]. Petrochemical Safety and Environmental Protection Technology, 2013, 29(5):43-48. doi: 10.3969/j.issn.1673-8659.2013.05.014 [8] 曾丹苓, 敖越, 张新铭, 等.工程热力学[M].第3版.北京:高等教育出版社, 2002:206-208.ZENG D L, AO Y, ZHANG X M, et al.Engineering thermodynamics[M]. 3rd ed.Beijing:Higher Education Press, 2002:206-208. [9] 朱英中.柴油与安全柴油燃爆性能研究[D].南京: 南京理工大学, 2011: 53-54. http://cdmd.cnki.com.cn/Article/CDMD-10288-1012320161.htmZHU Y Z.Research on the explosion characteristic of diesel fuel and safety diesel[D]. Nanjing: Nanjing University of Science and Technology, 2011: 53-54. http://cdmd.cnki.com.cn/Article/CDMD-10288-1012320161.htm [10] 雷正, 鲁长波, 安高军, 等.基于激光粒度仪测量油品喷雾粒径的方法研究[J].中国粉体技术, 2015, 21(1):11-15. http://d.old.wanfangdata.com.cn/Periodical/zgftjs201501003LEI Z, LU C B, AN G J, et al.Methods research on oil particle size based on laser particle size analyzer[J]. China Powder Science and Technology, 2015, 21(1):11-15. http://d.old.wanfangdata.com.cn/Periodical/zgftjs201501003 [11] SIMMONS M J, HANRATTY T J.Droplet size measurements in horizontal annular gas-liquid flow[J]. Int J Multiphase Flow, 2001, 27(5):861-883. doi: 10.1016/S0301-9322(00)00053-7 [12] 杨刚, 唐亚鸣, 赵磊.干雾抑尘喷嘴雾化粒径与气压关系实验[J].液压与气动, 2012(9):126-128. doi: 10.3969/j.issn.1000-4858.2012.09.042YANG G, TANG Y M, ZHAO L.Relationship between droplet size and spay pressure of dry fog nozzle for dust suppression[J]. Chinese Hydraulics and Pneumatics, 2012(9):126-128. doi: 10.3969/j.issn.1000-4858.2012.09.042 [13] 张茂根, 翁志学, 黄志明.颗粒统计平均粒径及其分布的表征[J].高分子材料科学与工程, 2000, 16(5):1-4. doi: 10.3321/j.issn:1000-7555.2000.05.001ZHANG M G, WENG Z X, HU Z M.Charaterization of statistical average particle size and particle distribution[J]. Polymer Material Science and Engineering, 2000, 16(5):1-4. doi: 10.3321/j.issn:1000-7555.2000.05.001 [14] MITU M, BRANDES E.Explosion parameters of methanol-air mixtures[J]. Fuel, 2015, 158:217-223. doi: 10.1016/j.fuel.2015.05.024 -

下载:

下载: