Flow Field Analysis and Structure Optimization of the Nozzle Tail Flow

-

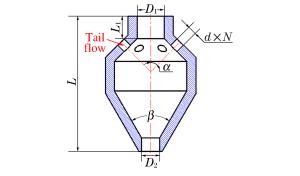

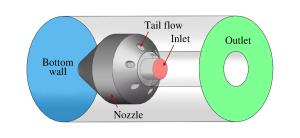

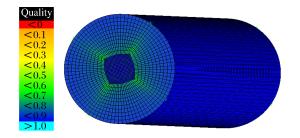

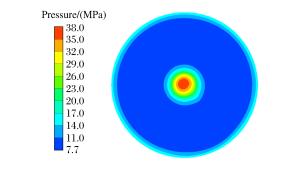

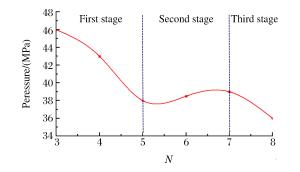

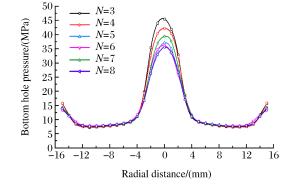

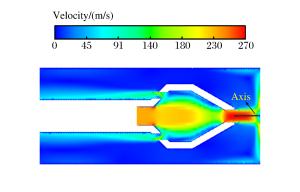

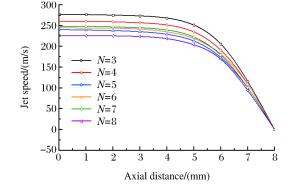

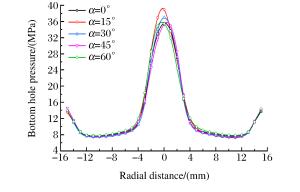

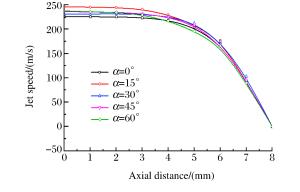

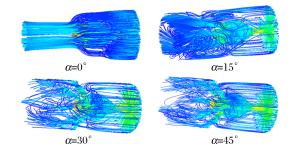

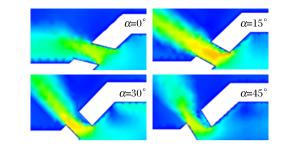

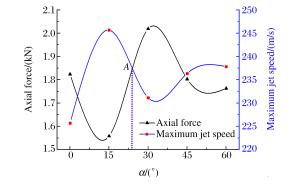

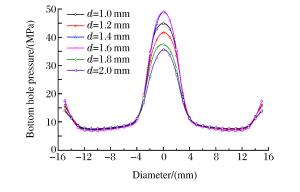

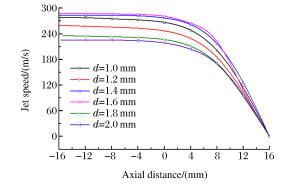

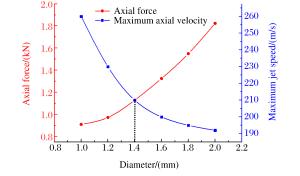

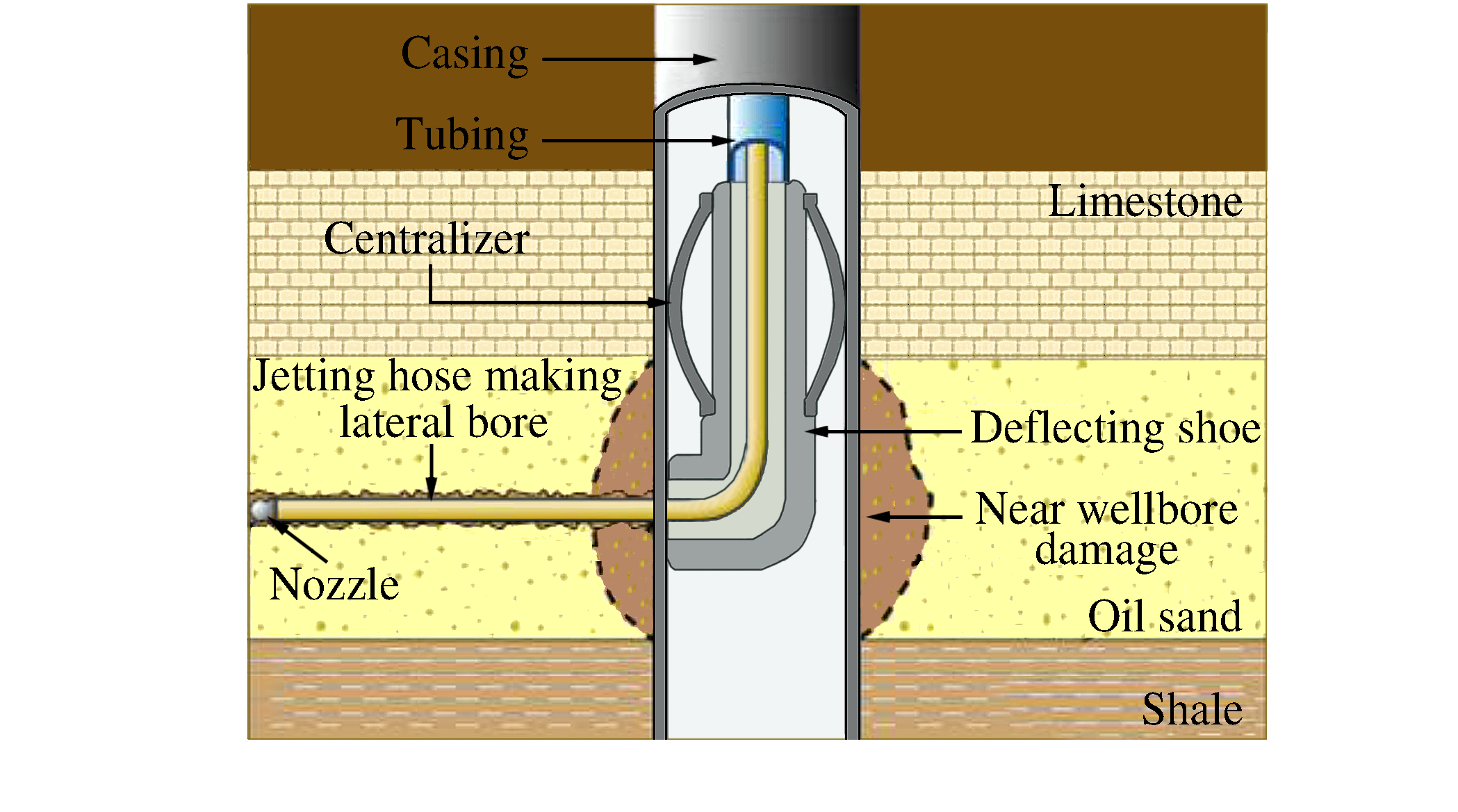

摘要: 喷嘴是水力水平钻孔设备的核心元件,改善其结构有利于提高低渗透油气资源开采的施工效率。因此基于计算流体动力学(CFD)技术,分析尾部流道结构参数对射流流场的影响,得出以下结论:尾部流道数N=6、倾角α满足15°<α<30°,喷嘴出口直径d=1.4mm时,喷嘴的破岩和排屑性能较好;合理设计N和d,有利于实现喷嘴自推进和射流破岩两项功能;合理设计α,能有效改善尾部流道的磨损情况,延长喷嘴使用寿命。Abstract: The nozzle is the core component of a hydraulic horizontal drilling equipment, and optimizing its structure is crucial for helping to improve the construction efficiency of exploiting low permeability oil and gas resources.Based on the computational fluid dynamics (CFD) approach, we studied the effects of the structural parameters of the tail flow (evenly distributed on the end of the nozzle) on the jet flow field.The results show that:when the number of the tail flow (N) is 6, with an angle (α) between 15° and 30° and a diameter (D) of 1.4mm, the nozzle exhibits good performance on the rock fragmentation and discharge; the reasonable design of N and D contributes to implementing the nozzle propulsion and the rock destruction by jet; the reasonable design of the jet nozzle angle α contributes to effectively reducing the abrasion of the jet nozzle and extending its service life.

-

Key words:

- computational fluid dynamics /

- hydraulic jet drilling /

- tail flow /

- nozzle /

- numerical simulation

-

表 1 喷嘴几何参数

Table 1. Geometric parameters of the nozzle

D1/(mm) L1/(mm) D2/(mm) L/(mm) d/(mm) N S α/(°) β/(°) 6 5 4 30 2 6 0.75 15 60 表 2 分析方案

Table 2. Analysis scheme

Scheme N d/(mm) α/(°) 1 3 2.0 0 2 4 2.0 0 3 5 2.0 0 4 6 2.0 0 5 7 2.0 0 6 8 2.0 0 7 6 2.0 15 8 6 2.0 30 9 6 2.0 45 10 6 2.0 60 11 6 1.0 15 12 6 1.2 15 13 6 1.4 15 14 6 1.6 15 15 6 1.8 15 表 3 喷嘴轴向推进力

Table 3. The axial thrust of the nozzle

N Wall stress/(N) Recoilforce/(N) Propulsion/(N) Bottomstress/(N) 3 1190 -574 616 1923 4 1342 -467 875 1713 5 1369 -158 1211 1453 6 1525 -130 1395 1436 7 1760 -97 1663 1425 8 1737 87 1824 1280 -

[1] MASTERS J A.Deep basin gas trap, western Canada[J].AAPG Bulletin, 1979, 63(2):152-181. http://cn.bing.com/academic/profile?id=37657635966e8fb1f97ebc12ae18775c&encoded=0&v=paper_preview&mkt=zh-cn [2] 李道品, 张连春.我国低渗透油田开发当前之新进展[J].低渗透油气田, 2004, 9(1):1-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK200402515114LI D P, ZHANG L C.Advances on development of the low permeability oil fields in China[J].Low Permeability Oil&Gas Fields, 2004, 9(1):1-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK200402515114 [3] LOVE T G, MCCARTY R A.Selectively placing many fractures in openhole horizontal wells improves production: SPE-74331-PA[R].Society of Petroleum Engineers, 2001: 219-224. [4] 孙晓超.水力深穿透水平钻孔技术的研究[D].大连: 大连理工大学, 2005: 1-2. http://cdmd.cnki.com.cn/Article/CDMD-10141-2006021939.htmSUN X C.Study on the water jet perforating technique[D].Dalian: Dalian University of Technology, 2005: 1-2. http://cdmd.cnki.com.cn/Article/CDMD-10141-2006021939.htm [5] 张毅, 李根生, 熊伟, 等.高压水射流深穿透射孔增产机理研究[J].石油大学学报(自然科学版), 2004, 28(2):38-41. http://d.old.wanfangdata.com.cn/Periodical/sydxxb200402010ZHANG Y, LI G S, XIONG W, et al.Stimulation mechanism of oil well using high-pressure water jet deep-penetrating perforation technique[J].Journal of the University of Petroleum (Edition of Natural Science), 2004, 28(2):38-41. http://d.old.wanfangdata.com.cn/Periodical/sydxxb200402010 [6] 丁徐亮.酸再生系统喷嘴数值模拟及结构参数优化[D].上海: 华东理工大学, 2014: 9-10. http://cdmd.cnki.com.cn/Article/CDMD-10251-1014170745.htmDING X L.Numerical simulation and structure parameters optimization of the nozzle used in acid regeneration system[D].Shanghai: East China University of Science and Technology, 2014: 9-10. http://cdmd.cnki.com.cn/Article/CDMD-10251-1014170745.htm [7] 黄中华, 谢雅.圆锥形喷嘴结构参数设计研究[J].机械设计, 2011, 28(12):62-64. http://d.old.wanfangdata.com.cn/Periodical/jxsj201112015HUANG Z H, XIE Y.Research on structure parameters of conical nozzle[J].Journal of Machine Design, 2011, 28(12):62-64. http://d.old.wanfangdata.com.cn/Periodical/jxsj201112015 [8] 径向水力喷射简介[EB/OL].[2015-11-27].http://www.docin.com/p-1373181499.html. [9] 倪红坚, 王瑞和.高压水射流破岩的数值模拟分析[J].岩石力学与工程学报, 2004, 23(4):550-554. doi: 10.3321/j.issn:1000-6915.2004.04.004NI H J, WANG R H.Numerical simulation on rock breaking under high pressure water jet[J].Chinese Journal of Rock Mechanics and Engineering, 2004, 23(4):550-554. doi: 10.3321/j.issn:1000-6915.2004.04.004 [10] 张作龙, 梁忠民.高压淹没水射流破岩实验研究[J].石油矿场机械, 2000, 29(5):27-29 http://d.old.wanfangdata.com.cn/Periodical/sykcjx200005008ZHANG Z L, LIANG Z M.Experimental study of breaking rock with pressure water jet[J].Oil Field Equipment, 2000, 29(5):27-29. http://d.old.wanfangdata.com.cn/Periodical/sykcjx200005008 [11] 熊继有, 廖荣庆.射流辅助钻井破岩理论与技术[M].四川:四川科学技术出版社, 2007:24-25.XIONG J Y, LIAO R Q.Rock damage theory and technology by jet assisted drilling[M].Sichuan:Sichuan Science and Technology Publishing House, 2007:24-25. [12] 王瑞和.高压水射流破岩机理研究[J].石油大学学报(自然科学版), 2002, 26(4):118-122. doi: 10.3321/j.issn:1000-5870.2002.04.036WANG R H.Research of rock fragmentation mechanism with high-pressure water jet[J].Journal of the University of Petroleum (Edition of Natural Science), 2002, 26(4):118-122. doi: 10.3321/j.issn:1000-5870.2002.04.036 [13] 陆朝晖.高压脉冲水射流流场结构的数值模拟及破硬岩机理研究[D].重庆: 重庆大学, 2012: 32-33. http://cdmd.cnki.com.cn/Article/CDMD-10611-1012047346.htmLUC H.CFD modeling on flow-field structure of high pressure pulse water jet and its hard rock fragmentation mechanism[D].Chongqing: Chongqing University, 2012: 32-33. http://cdmd.cnki.com.cn/Article/CDMD-10611-1012047346.htm -

下载:

下载: