Effect of High Hydrostatic Pressure as a Physical Modification Method on Waxy Maize Starch Gelatinization and Retrogradation

-

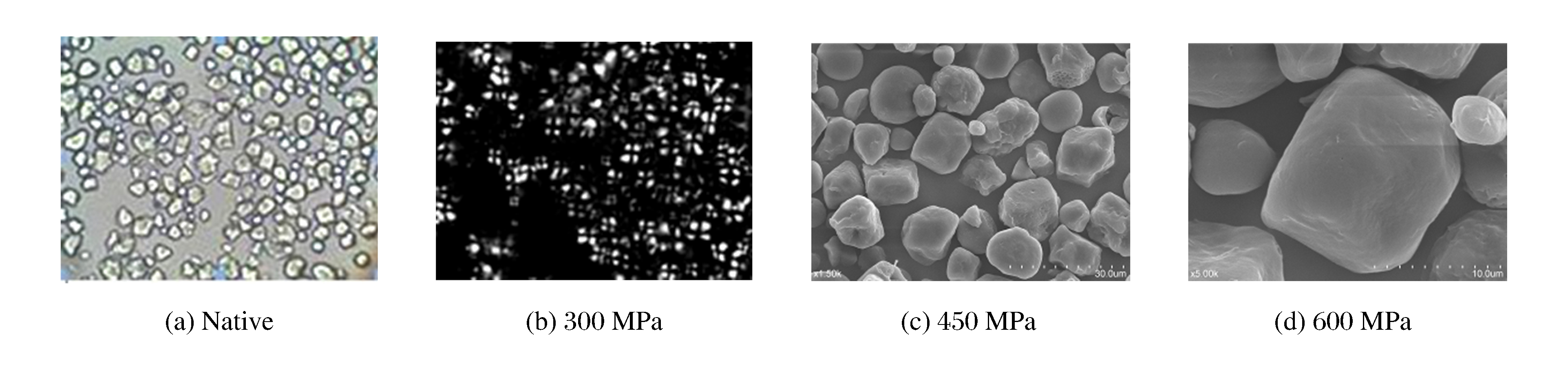

摘要: 采用高静压技术(HHP)作为物理变性方法处理糯玉米淀粉,考察高静压力对糯玉米淀粉糊化及重结晶的影响。采用偏光显微镜及扫描电子显微镜观测处理后的淀粉颗粒的形态变化,激光粒度分析仪用于记录淀粉颗粒的粒度分布及变化规律;利用红外光谱技术分析可能发生的微观二级结构变化,结合X射线衍射曲线及DSC差热分析曲线,验证淀粉颗粒内部结构的变化。结果表明:300 MPa的高静压对淀粉具有压缩作用,使其粒度减小,结晶度提高,起始糊化温度、糊化焓值增加;450 MPa高静压处理后,淀粉的结晶结构几乎完全被破坏,糊化度达到95%,膨胀度为57.07%,并以此验证了HHP处理会导致淀粉颗粒发生有限膨胀;600 MPa高静压处理后,淀粉颗粒发生重结晶现象,表现为典型的多峰、宽峰DSC曲线,结晶度增加。综合本研究及其他研究成果,提出“3个发展阶段”的HHP对糯玉米淀粉颗粒微观结构变化的新机制,包括:颗粒被压缩、内部结晶结构解体及颗粒解体并重新排序阶段。Abstract: High hydrostatic pressure(HHP) of 300, 450, 600 MPa was applied on waxy corn starch as a physical modification.The effects of high hydrostatic pressure on gelatinization and retrogradation properties of waxy corn starch were investigated.The appearance and particle size of the granules were studied by micro-polariscopy, scanning electron microscopy and laser diffraction instrument.Combining X-diffraction and DSC spectrum, the change from crystal to non-crystal was confirmed.A compressing effect on HHP treated starch at 300 MPa was proved by the decreased granule diameter, the strengthened H-OH stretching in the infrared spectra and a slightly increased in onset temperature, peak temperature, and enthalpy of gelatinization; For HHP treated starch at 450 MPa, the starch gelatinization was observed by light microscopy, FTIR spectra and confirmed by DSC analysis.The birefringence of granules disappeared, the bands weakened in the infrared spectra, and onset temperature, peak temperature, and enthalpy of gelatinization decreased sharply.In contrast, the retrogradation of HHP treated starch at 600 MPa was observed, which was illustrated by the reappearance of birefringence in granules and the biphasic gelatinization endotherms.The results prove that the granules under high hydrostatic pressure processing experience "3 development stages" including compressing, disappearance of crystalline structure and recrystallization after granule disintegration.

-

Key words:

- high hydrostatic pressure /

- physical modification /

- starch /

- gelatinization /

- recrystallization

-

表 1 不同高静压对糯玉米淀粉颗粒分布的影响

Table 1. Parameters of particle size distribution for native and HHP modified starch

Sample Mean/(μm) Particle distribution/(%) dspan CV/(%) DS/(%) < 10 μm 10~20 μm 20~40 μm 40~70 μm >70 μm Native 28.08±2.09ab 10.20±1.68a 32.54±4.33b 34.70±2.26b 18.50±3.25b 3.79±0.43a 1.99±0.11a 66.85±2.90a 0.00±0.00a 300 MPa 18.70±5.32a 22.65±2.05d 53.55±4.60c 17.20±0.99a 3.15±1.76a 3.43±0.84a 2.22±1.03b 82.35±9.27a 23.19±2.19b 450 MPa 29.14±2.72b 17.55±1.06c 40.35± 2.33b 20.75±0.78a 10.40±0.85a 10.79±3.27a 3.70±0.61b 105.00±5.66a 57.07±8.46c 600 MPa 34.13±2.28b 13.10±0.14b 21.55±1.34a 34.80±1.84b 21.55±0.92b 8.98±2.15a 2.20±0.14b 80.55±3.46a 20.49±3.01b Note:(1) All values were mean values of triplicate determinations±standard deviations;

(2) Values sharing the same uppercase letter within a line were not significantly different(P<0.05);

(3) Mean:De Brouckere diameter;dspan:Measurement of the width of size distribution, the narrower the distribution, the smaller the dspan became; CV:Volumetric concentration; DS:Swelling degree,DS=(CV-CV Native)/CV Native.表 2 糯玉米淀粉在不同压力处理后的热力学参数

Table 2. Thermal properties of waxy corn starch under various HHP conditions

Sample To/(℃) Tp/(℃) Tp/(℃) ΔHgel/(J/g) p R/(℃) Native 99.4±0.4b 107.5±0.5c 119.5±0.9b 216.5±1.8b 26.7±0.1b 16.2±0.2b 300 MPa 99.9±0.0b 106.4±0.4b 112.6±1.1a 225.6±1.0c 34.7±3.4c 12.9±1.7a 450 MPa 84.4±0.4a 103.6±0.3a 122.7±0.1c 34.6±0.8a 1.8±0.0a 38.5±0.1d 600 MPa 105.7±0.4c 116.3±0.4d 126.8±1.9d 793.4±5.1d 74.5±0.7d 21.3±0.7c Note:(1) All values were mean values of triplicate determinations±standard deviations;

(2) Values sharing the same uppercase letter within a line were not significantly different(P<0.05);

(3) To:Onset temperature; Tp:Peak temperature;Tc:Conclusion temperature;ΔHgel:Enthalpy of gela-tinization; R:Temperature range for gelatinization. -

[1] Farr D. High pressure technology in the food industry[J]. Trends Food Sci Tech, 1990, 1: 14-17. doi: 10.1016/0924-2244(90)90004-I [2] Mertens B, Knorr D. Development of nonthermal processes for food preservation[J]. Food Technol, 1992, 46(5): 124-133. http://ci.nii.ac.jp/naid/80006500922 [3] Farkas D F, Hoover D G. High pressure processing: kinetics of microbial inactivation for alternative food processing technologies[J]. J Food Sci, 2000(Suppl): 47-64. http://www.mendeley.com/catalog/kinetics-microbial-inactivation-alternative-food-processing-technologies-high/ [4] Meyer R S, Cooper K L, Knorr D, et al. High-pressure sterilization of foods[J]. Food Technol, 2000, 54(11): 67-72. [5] Butz P, Tauscher B. Emerging technologies: Chemical aspects[J]. Food Res Int, 2002, 35(2): 279-284. http://www.sciencedirect.com/science/article/pii/S0963996901001971 [6] 刘培玲, 张甫生, 白云飞, 等.高静压对淀粉结构及糊化性质的影响[J].高压物理学报. 2010, 24(6): 472-480.Liu P L, Zhang F S, Bai Y F, et al. Effect of high hydrostatic pressure on starch structure and gelatinization[J]. Chinese Journal of High Pressure Physics, 2010, 24(6): 472-480. [7] Stute R, Klingler R W, Boguslawski S, et al. Effects of high pressures treatment on starches[J]. Starch-Stärke, 1996, 48(11/12): 399-408. http://ci.nii.ac.jp/naid/80009417610 [8] Stolt M, Oinonen S, Autio K. Effect of high pressure on the physical properties of barley starch[J]. Innovat Food Sci Emerg Tech, 2001, 1(3): 167-175. http://europepmc.org/abstract/AGR/IND23291646 [9] Liu Y, Selomulyo V O, Zhou W. Effect of high pressure on some physicochemical properties of several native starches[J]. J Food Eng, 2008, 88(1): 126-136. doi: 10.1016/j.jfoodeng.2008.02.001 [10] Rubens P, Heremans K. Pressure-temperature gelatinisation phase diagram of starch: An in situ fourier transform infrared study[J]. Biopolymers, 2000, 54(7): 524-530. doi: 10.1002/1097-0282(200012)54:7<524::AID-BIP50>3.0.CO;2-Y [11] Douzals J, Marechal P, Coquille J, et al. Microscopic study of starch gelatinization under high hydrostatic pressure[J]. J Agric Food Chem, 1996, 44(6): 1403-1408. doi: 10.1021/jf950239c [12] Kudla E, Tomasik P. The modification of starch by high pressure. Part Ⅱ: Compression of starch with additives[J]. Starch-Stärke, 1992, 44(7): 253-259. doi: 10.1002/star.19920440704 [13] Onwulata C, Elchediak E. Starches and fibers treated by dynamic pulsed pressure[J]. Food Res Int, 2000, 33(5): 367-374. doi: 10.1016/S0963-9969(00)00057-0 [14] 陆大雷, 王德成, 景立权, 等.基肥配比和拔节期追施氮肥对糯玉米淀粉胶凝和回生特性的影响[J].作物学报, 2009, 35(5): 867-874. http://www.cnki.com.cn/Article/CJFDTotal-XBZW200905019.htmLu D L, Wang D C, Jing L Q, et al. Starch gelatinization and retrogradation properties under different basic fertilizer regimes and nitrogen topdressing at jointing stage of waxy maize[J]. Acta Agronomica Sinica, 2009, 35(5): 867-874. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-XBZW200905019.htm [15] Sandhu K S, Singh N. Some properties of corn starches Ⅱ: Physicochemical, gelatinization, retrogradation, pasting and gel textural properties[J]. Food Chem, 2007, 101(4): 1499-1507. doi: 10.1016/j.foodchem.2006.01.060 [16] Imberty A, Buléon A, Tran V, et al. Recent advances in knowledge of starch structure[J]. Starch-Stärke, 1991, 43(10): 375-384. doi: 10.1002/star.19910431002 [17] Singh N, Chawla D, Singh J. Influence of acetic anhydride on physicochemical, morphological and thermal properties of corn and potato starch[J]. Food Chem, 2004, 86(4): 601-608. doi: 10.1016/j.foodchem.2003.10.008 [18] Stolt M, Stoforos N G, Taoukis P S, et al. Evaluation and modeling of rheological properties of high pressure waxy maize starch dispersion[J]. J Food Eng, 1999, 40(4): 293-298. doi: 10.1016/S0260-8774(99)00069-2 [19] Baszczak W, Valverde S, Fornal J. Effect of high pressure on the structure of potato starch[J]. Carbohyd Polym, 2005, 59(3): 377-383. doi: 10.1016/j.carbpol.2004.10.008 [20] Capron I, Robert P, Colonna P, et al. Starch in rubbery and glassy states by FTIR spectroscopy[J]. Carbohydrate Polymers, 2007, 68(2): 249-259. doi: 10.1016/j.carbpol.2006.12.015 [21] van Soest J J G, de Wit D, Tournois H, et al, Retrogradation of potato starch as studied by Fourier transform infrared spectroscopy[J]. Starch-Stärke, 1994, 46(12): 453-457. doi: 10.1002/star.19940461202 [22] Cael J J, Koenig J L, Blackwell J. Infrared and Raman Spectroscopy of carbohydrates. Part Ⅵ: Normal coordinate analysis of V-amylose[J]. Biopolymers, 1975, 14(9): 1885-1903. doi: 10.1002/bip.1975.360140909 [23] Sevenou O, Hill S E, Farhat I A, et al. Organisation of the external region of the starch granule as determined by infrared spectroscopy[J]. Int J Bio Macromol, 2002, 31(1): 79-85. http://old.med.wanfangdata.com.cn/viewHTMLEn/PeriodicalPaper_JJ029246142.aspx [24] Capron I, Robert P, Colonna P, et al. Starch in rubbery and glassy states by FTIR spectroscopy[J]. Carbohyd Polym, 2007, 68(2): 249-259. doi: 10.1016/j.carbpol.2006.12.015 [25] Tester R F, Debon S J J. Annealing of starch-A review[J]. Int J Bio Macromol, 2000, 27(1): 1-12. doi: 10.1016/S0141-8130(99)00121-X [26] Jayakody L, Hoover R. The effect of lintnerization on cereal starch granules[J]. Food Res Int, 2002, 35(7): 665-680. doi: 10.1016/S0963-9969(01)00204-6 [27] Kawai K, Fukami K, Yamamoto K, et al. Effects of treatment pressure, holding time, and starch content on gelatinisation and retrogradation properties of potato starch-water mixtures treated with high hydrostatic pressure[J]. Carbohyd Polym, 2007, 69(3): 590-596. doi: 10.1016/j.carbpol.2007.01.015 [28] Seow C C, Thevamalar K. Internal plasticization of granular rice starch by hydroxypropylation: Effects on phase transitions associated with gelatinization[J]. Starch-Stärke, 1993, 45(3): 85-88. doi: 10.1002/star.19930450303 [29] Miles M J, Morris V J, Orford P D, et al. The roles of amylase and amylopectin in the gelation and retrogradation of starch. Carbohyd Polym, 1985, 135(2): 271-281. [30] Orford P D, Ring S G, Carroll V, et al. The effect of concentration and botanical source on the gelation and retrogradation of starch[J]. J Sci Food Agr, 1987, 39(2): 169-177. doi: 10.1002/jsfa.2740390210 -

下载:

下载: