Influence of Dispersion Pressure and Ignition Delay Time on the Dust Explosion Parameters

-

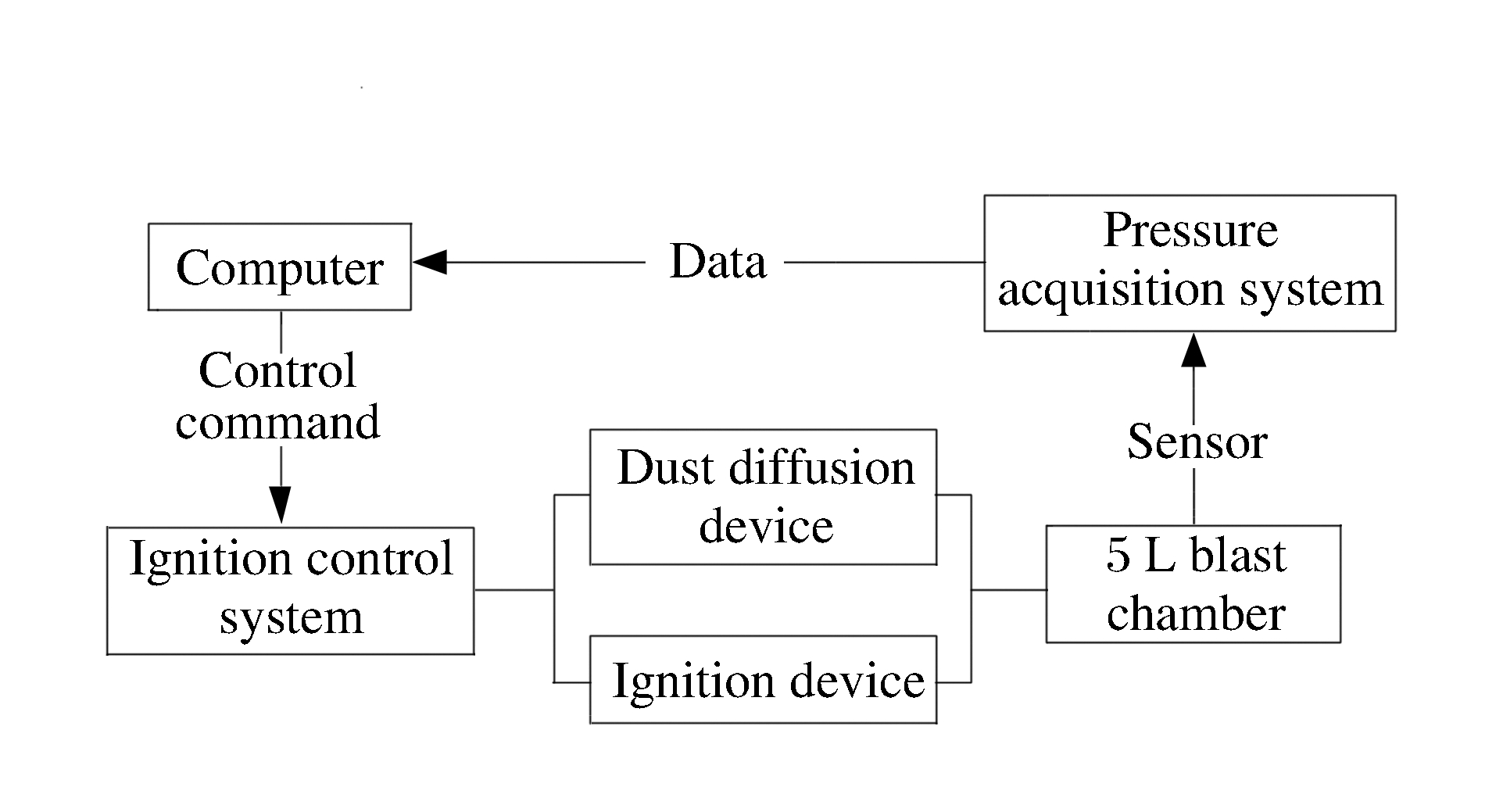

摘要: 为进一步研究影响粉尘爆炸特性参数的因素,在5 L柱形密闭爆炸容器中,以食用玉米淀粉为试样,利用高压放电火花点火,并通过压力采集系统记录容器内压力的变化,研究了不同吹粉压力下,点火延迟时间对粉尘爆炸压力参数的影响,并对实验现象进行了理论分析。实验结果表明:点火延迟时间对粉尘爆炸压力和压力上升速率影响显著;吹粉压力存在一个临界值,当吹粉压力大于临界值时,存在一个最佳点火延迟时间,使得爆炸压力峰值和压力上升速率峰值最大,且随着吹粉压力的增大,粉尘爆炸的最佳点火延迟时间缩短;当吹粉压力小于临界值时,点火延迟时间越长,粉尘爆炸压力越小。Abstract: Dust explosion experiments were carried out in a 5 L closed cylindrical vessel using cornstarch dispersed with compressed air and ignited by high-voltage spark, for further study of the factors which affect the dust explosion parameters.With different dispersion pressure, the influence of ignition delay time on the pressure parameters of dust explosion was studied, and the experimental results were analyzed theoretically.The results show that the influence of ignition delay time on explosion pressure and rise rate of pressure is significant, a critical value of dispersion pressure is found.When dispersion pressure is higher than the critical pressure, there is an optimum ignition delay time, making the explosion pressure and pressure rise rate maximal.With the increasing of dispersion pressure, the optimum ignition delay time decreases.When dispersion pressure is lower than the critical pressure, the pressure of dust explosion rises as the ignition delay time increases.

-

Key words:

- dust explosion /

- dispersion pressure /

- ignition delay time /

- explosion pressure /

- rise rate of pressure /

- cornstarch

-

表 1 吹粉压力ps=0.60 MPa时玉米淀粉爆炸的实验结果

Table 1. Experimental results of cornstarch explosion when ps=0.60 MPa

td/

(ms)pm/

(MPa)(dp/dt)m/

(MPa·s-1)60 0.361 01 3.033 62 60 0.665 67 9.056 72 60 0.465 52 7.563 77 60 0.444 53 6.109 54 70 0.500 15 3.991 76 70 0.544 28 7.852 13 70 0.569 44 9.729 07 80 0.634 00 10.290 85 80 0.517 41 5.129 42 80 0.579 26 7.071 67 90 0.519 76 6.352 63 90 0.477 99 5.160 00 90 0.619 91 7.399 39 90 0.450 68 4.203 25 100 0.491 06 5.676 09 100 0.468 73 5.516 08 100 0.507 04 5.072 21 100 0.462 93 3.264 08 200 0.239 90 1.547 67 200 0.166 92 0.763 07 200 0.098 89 0.641 56 表 2 吹粉压力ps=0.50 MPa时玉米淀粉爆炸的实验结果

Table 2. Experimental results of cornstarch explosion when ps=0.50 MPa

td/

(ms)pm/

(MPa)(dp/dt)m/

(MPa·s-1)100 0.295 03 2.308 47 100 0.300 19 2.192 18 100 0.393 72 2.919 47 100 0.331 01 2.636 61 140 0.335 51 0.263 26 140 0.417 63 3.202 63 140 0.349 47 2.784 11 140 0.467 10 4.731 72 140 0.265 01 2.183 12 150 0.361 09 3.494 08 150 0.412 51 2.983 27 150 0.441 82 5.056 85 150 0.297 59 2.392 74 160 0.405 75 4.068 13 160 0.229 82 1.293 99 160 0.373 91 2.834 65 160 0.422 29 4.078 94 表 3 吹粉压力ps=0.40 MPa时玉米淀粉爆炸的实验结果

Table 3. Experimental results of cornstarch explosion when ps=0.40 MPa

td/

(ms)pm/

(MPa)(dp/dt)m/

(MPa·s-1)150 0.225 56 1.645 16 150 0.250 91 2.002 67 150 0.288 42 1.750 54 180 0.306 51 2.655 32 180 0.390 02 3.944 88 180 0.203 12 1.292 90 190 0.343 05 2.866 37 190 0.309 87 2.458 32 190 0.345 24 2.670 65 200 0.393 38 3.620 61 200 0.254 82 1.996 56 200 0.403 90 3.591 35 210 0.313 44 2.746 62 210 0.325 07 2.600 36 210 0.265 78 1.874 49 250 0.255 14 1.271 95 250 0.227 22 1.194 41 250 0.227 22 1.194 41 表 4 吹粉压力ps=0.35 MPa时玉米淀粉爆炸的实验结果

Table 4. Experimental results of cornstarch explosion when ps=0.35 MPa

td/

(ms)pm/

(MPa)(dp/dt)m/

(MPa·s-1)30 0.352 07 5.368 77 30 0.484 84 10.142 86 30 0.471 23 8.504 05 50 0.475 84 8.486 99 50 0.381 88 4.383 70 50 0.406 40 4.490 46 100 0.353 59 3.264 20 100 0.572 16 3.264 20 100 0.328 90 4.000 88 200 0.256 87 1.738 46 200 0.118 17 0.969 86 200 0.198 13 1.302 51 200 0.096 87 0.707 28 表 5 吹粉压力ps=0.30 MPa时玉米淀粉爆炸的实验结果

Table 5. Experimental results of cornstarch explosion when ps=0.30 MPa

td/

(ms)pm/

(MPa)(dp/dt)m/

(MPa·s-1)30 0.504 01 10.075 03 30 0.401 68 6.089 00 30 0.507 93 9.291 64 50 0.375 40 4.994 49 50 0.363 59 3.882 16 50 0.391 82 4.382 96 80 0.304 17 2.565 62 80 0.375 98 4.790 62 80 0.394 49 3.687 00 100 0.358 69 3.602 43 100 0.261 19 2.450 56 100 0.357 29 3.700 16 150 0.270 90 1.767 62 150 0.316 10 3.698 96 150 0.291 30 2.699 97 200 0.185 97 1.080 47 200 0.186 12 1.052 11 200 0.197 82 1.979 10 200 0.236 38 2.114 03 250 0.191 49 1.353 56 250 0.157 11 1.113 00 250 0.112 26 1.011 96 250 0.146 25 0.869 75 300 0.110 93 0.415 76 300 0.152 07 0.910 87 300 0.191 98 0.975 18 350 0.068 79 0.462 72 350 0.166 58 1.054 05 350 0.069 84 0.353 86 -

[1] Cashdollar K L. Overview of dust explosibility characteristics[J]. J Loss Prev Process Ind, 2000, 13(3): 183-199. [2] Abbasi T, Abbasi S A. Dust explosions-Cases, causes, consequences, and control[J]. J Hazard Mater, 2007, 140(1): 7-44. [3] 谭汝媚, 李仕雄, 刘东.高湿度下点火延迟时间对粉尘爆炸参数的影响[J].中北大学学报(自然科学版), 2013, 34(6): 652-657.Tan R M, Li S X, Liu D. Effect of the ignition delay time on the explosion characteristic parameters of dusts in high humidity environment[J]. Journal of North University of China(Natural Science Edition), 2013, 34(6): 652-657. (in Chinese) [4] 牛芳, 刘庆明, 白春华, 等.甲烷-煤尘爆炸物火焰传播特性[J].高压物理学报, 2012, 26(4): 455-461.Niu F, Liu Q M, Bai C H, et al. Flame propagation and combustion in methane-coal-air mixture[J]. Chinese Journal of High Pressure Physics, 2012, 26(4): 455-461. (in Chinese) [5] Scheid M, Geißler A, Krause U. Experiments on the influence of pre-ignition turbulence on vented gas and dust explosions[J]. J Loss Prev Process Ind, 2006, 19(2): 194-199. [6] 袁旌杰, 伍毅, 陈瑜, 等.点火延迟时间对粉尘最大爆炸压力测定影响的研究[J].中国安全科学学报, 2010, 20(3): 65-69.Yuan J J, Wu Y, Chen Y, et al. Effect of ignition delay time on measurement of maximum explosion pressure of dusts[J]. China Safety Science Journal, 2010, 20(3): 65-69. (in Chinese) [7] Liu Q M, Bai C H, Li X D, et al. Coal dust/air explosions in a large-scale tube[J]. Fuel, 2010, 89(2): 329-335. doi: 10.1016/j.fuel.2009.07.010 [8] Mercer D B, Amyotte P R, Dupuis D J, et al. The influence of injector design on the decay of pre-ignition turbulence in a spherical explosion chamber[J]. J Loss Prev Process Ind, 2001, 14(4): 269-282. doi: 10.1016/S0950-4230(00)00051-6 -

下载:

下载: