High Temperature Stable Assembly Designed for Cubic Press

-

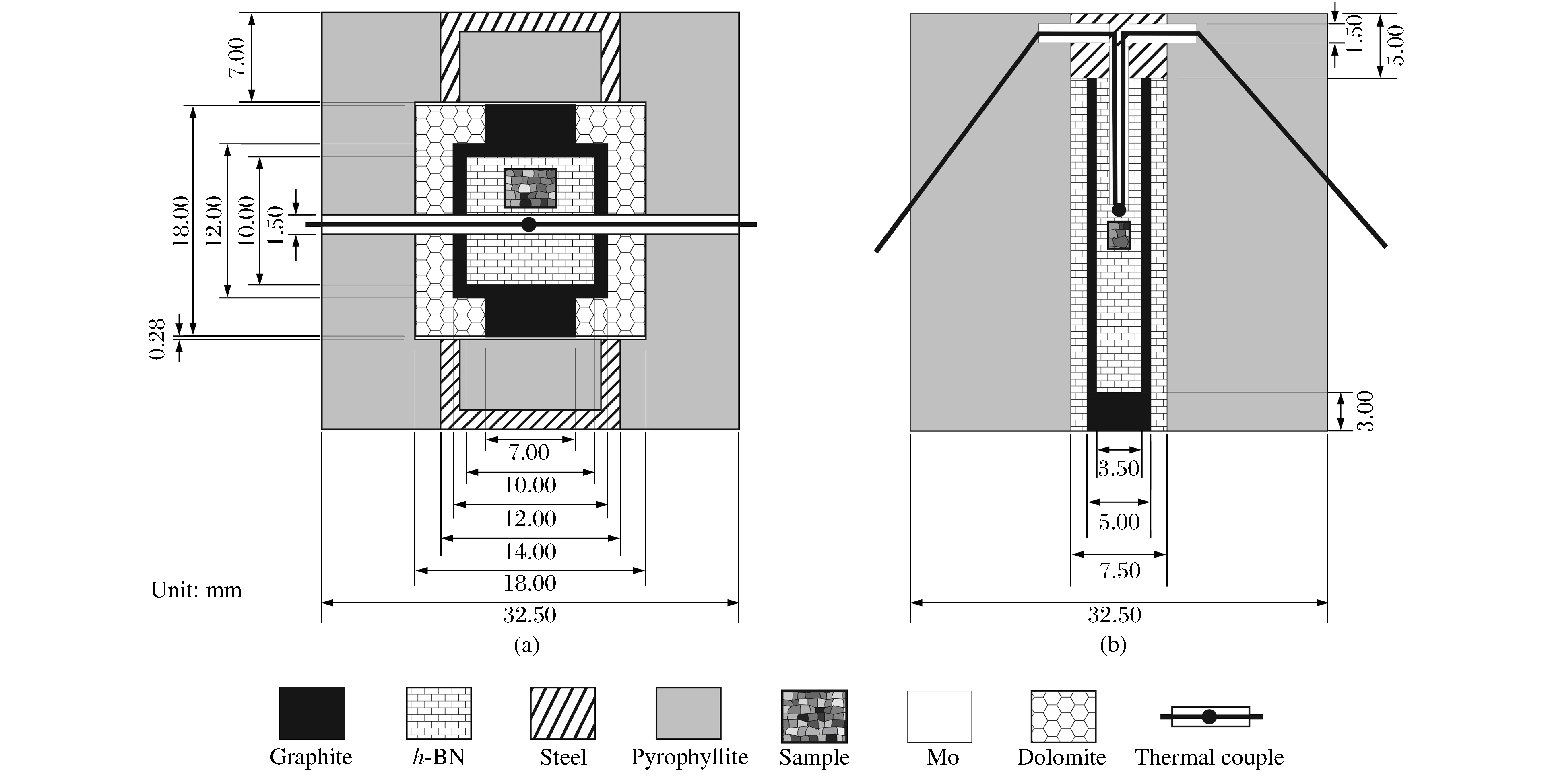

摘要: 参考活塞-圆筒高压设备常用的实验组装中热电偶的布局方式,设计了一种适用于极端高温条件的六面顶压机实验组装。在新的实验组装中,热电偶不再横穿石墨加热炉,而是在石墨炉中纵向分布,从石墨炉顶端横向引出。与传统的六面顶压机实验组装相比,这种新组装具有更强的高温稳定性。测试表明:在5 GPa压力下,1 600 ℃时实验组装的稳定性能够保持48 h以上,1 800 ℃时能够保持约30 h,2 000 ℃时能够保持约10 h。温度梯度测试表明,当组装的中心温度为1 454 ℃时,在组装中央4 mm的范围内平均温度梯度仅有27 ℃/mm,低于中心温度的2%。较长的保温时间以及低温度梯度能进一步提高六面顶压机在地球科学研究领域中的应用。Abstract: Changing the distribution of the thermal couple, a new experimental assembly, which is stable at extremely high temperatures, has been developed for the cubic press.Test experiments showed that at 5 GPa, this new experimental assembly can be stable at 1 600, 1 800 and 2 000 ℃ for more than 48 hours, about 30 h and about 10 h, respectively.Additionally, the temperature gradient in the new experimental assembly is very low:at 1 454 ℃, it is about 27 ℃/mm in the 4 mm long central part of the graphite heater.Long stable duration at extremely high temperatures and low temperature gradient make this new experimetal assembly suitable for the high-pressure experimentation in Geosciences.

-

表 1 不同温度-压力条件下新实验组装的温度梯度

Table 1. Temperature gradient at different p-T conditions for the new experimental assembly

T1/(℃) 3 GPa 4 GPa T2/(℃) Temperature gradient/(℃/mm) T2/(℃) Temperature gradient/(℃/mm) 400 412 6.0 415 7.5 600 616 8.0 618 9.0 800 823 11.5 825 12.5 1 000 1 032 16.0 1 032 16.0 1 200 1 244 22.0 1 242 21.0 1 400 1 454 27.0 1 453 26.5 Note:T2 refers to temperature at the center of the graphite heater while T1 refers to the temperature 2 mm away from the center. 表 2 不同材料、尺寸加热器的温度梯度

Table 2. Temperature gradient for heaters of different materials and sizes

Heater Length/(mm) OD/(mm) ID/(mm) Central thick portion/(mm) Temperature gradient/(℃/mm) Data source Graphite 13.7 3.0 2.6 - 100 Ref.[23] Graphite 13.7 3.0 2.6 2.3/4.2 -25 Ref.[23] LaCrO3 7.2 2.3 1.5 - 200 Ref.[23] LaCrO3 7.2 2.0 1.4 - 200 Ref.[23] Graphite 24.5 5.0 3.5 - 27 This study Note:(1) Length of the heater in Ref.[23]is calculated based on the size of the octahedron and then subtracted by 1 mm, which is estimated, from the figure given in the reference, for the thickness of the graphite lid;

(2) OD:Outer diameter;

(3) ID:Inner diameter;

(4) Central thick portion is equal to 2.3/4.2 means that ID of the thick portion of the stepped heater is 2.3 mm while the length of this portion is 4.2 mm. -

[1] Nishiyama N, Wang Y B, Sanehira T, et al. Development of the multi-anvil assembly 6-6 for DIA and D-DIA type high-pressure apparatuses[J]. High Press Res, 2008, 28(3): 307-314. doi: 10.1080/08957950802250607 [2] Wang H K, He D W, Tan N, et al. Note: An anvil-preformed gasket system to extend the pressure range for large volume cubic presses[J]. Rev Sci Instrum, 2010, 81(11): 116102. doi: 10.1063/1.3488606 [3] Liu X, Chen J L, Tang J J, et al. A large volume cubic press with a pressure-generating capability up to about 10 GPa[J]. High Press Res, 2012, 32(2): 239-254. [4] Ren G H, Xie H S, Xie X D. An experimental melting-crystallization study on basalt at high pressures[J]. Chinese Journal of Geochemistry, 1991, 10(2): 174-179. doi: 10.1007/BF02837717 [5] Chang L L, Chen Z Q, Liu X, et al. Expansivity and compressibility of wadeite-type K2Si4O9 determined by in situ high T/p experiments, and their implication[J]. Phys Chem Miner, 2013, 40(1): 29-40. [6] Liu X, Wang S C, He Q, et al. Thermal elastic behavior of CaSiO3-walstromite: A powder X-ray diffraction study up to 900 ℃[J]. Am Mineral, 2012, 97(2/3): 262-267. [7] 闻卫军, 周文戈, 范大伟, 等. 2.0 GPa, 850-1 070 ℃条件下多硅白云母榴辉岩脱水熔融研究[J].矿物岩石地球化学通报, 2012, 31(6): 622-634.Wen W J, Zhou W G, Fan D W, et al. Dehydration melting of a phengite-bearing eclogite at 2.0 GPa and 850-1 070 ℃-constraints on the petrogenesis of the early cretaceous, K-rich adakite in Dabie orogenic belt[J]. Bulletin of Mineralogy, Petrology and Geochemistry, 2012, 31(6): 622-634. (in Chinese) [8] Zhou W G, Xie H S, Liu Y G, et al. Dehydration melting of solid amphibolite at 2.0 GPa: Effects of time and temperature[J]. Sci China Earth Sci, 2005, 48(8): 1120-1133. doi: 10.1360/01yd0534 [9] Cordier P, Rubie D C. Plastic deformation of minerals under extreme pressure using a multi-anvil apparatus[J]. Mater Sci Eng A, 2001, 309/310: 38-43. doi: 10.1016/S0921-5093(00)01795-0 [10] Kawazoe T, Nishiyama N, Nishihara Y, et al. Pressure generation to 25 GPa using a cubic anvil apparatus with a multi-anvil 6-6 assembly[J]. High Press Res, 2010, 30(1): 167-174. doi: 10.1080/08957950903503912 [11] Wang Y B, Durham W B, Getting I C, et al. The deformation-DIA: A new apparatus for high temperature triaxial deformation to pressures up to 15 GPa[J]. Rev Sci Instrum, 2003, 74(6): 3002. doi: 10.1063/1.1570948 [12] Irifune T, Kurio A, Sakamoto S, et al. Ultrahard polycrystalline diamond from graphite[J]. Nature, 2003, 421: 599-560. [13] Qin J Q, He D W, Wang J H, et al. Is rhenium diboride a superhard material?[J]. Adv Mater, 2008, 20(24): 4780-4783. doi: 10.1002/adma.200801471 [14] Xu C, He D W, Wang H K, et al. Nano-polycrystalline diamond formation under ultra-high pressure[J]. Int J Refract Met H, 2013, 36: 232-237. doi: 10.1016/j.ijrmhm.2012.09.004 [15] Harlov D E, Milke R. Stability of corundum+quartz relative to kyanite and sillimanite at high temperature and pressure[J]. Am Mineral, 2002, 87(4): 424-432. doi: 10.2138/am-2002-0406 [16] Liu J, Bohlen S R, Ernst W G. Stability of hydrous phases in subducting oceanic crust[J]. Earth Planet Sc Lett, 1996, 143: 161-171. doi: 10.1016/0012-821X(96)00130-6 [17] 陈晓芳, 贺端威, 王福龙, 等.基于铰链式六面顶压机的二级6-8模超高压大腔体内置加热元件的设计与温度标定[J].高压物理学报, 2009, 23(2): 98-107.Chen X F, He D W, Wang F L, et al. Design and temperature calibration for heater cell of split-sphere high pressure apparatus based on the hinge-type cubic-anvil press[J]. Chinese Journal of High Pressure Physics, 2009, 23(2): 98-107. (in Chinese) [18] Liu X, Fleet M E. Phase relations of nahcolite and trona at high p-T conditions[J]. J Miner Petrol Sci, 2009, 104(1): 25-36. doi: 10.2465/jmps.080402 [19] Fei Y W, Bertka C M. Mantle petrology: Field observations and high-pressure experimentation[C]// Mantle Petrology: Field Observations and High Pressure Experimentation. US: Spec Publ, 1999: 189-207. [20] Dobrzhinetskaya L F. Microdiamonds-frontier of ultrahigh-pressure metamorphism: A review[J]. Gondwana Res, 2012, 21(1): 207-223. doi: 10.1016/j.gr.2011.07.014 [21] Zhu W G, Xie H S, Hu J, et al. Experimental studies on silicate structure of basaltic glasses quenched at 1 650 ℃ and 1-3.5 GPa[J]. Chinese Sci Bull, 1999, 44(5): 461-466. doi: 10.1007/BF02977889 [22] 刘芳, 刘永刚, 谢鸿森.六面顶压机高压腔体温度场的数值模拟[J].高压物理学报, 2012, 26(2): 135-140.Liu F, Liu Y G, Xie H S. Numerical simulation of temperature field in sample assembly of cubic press[J]. Chinese Journal of High Pressure Physics, 2012, 26(2): 135-140. (in Chinese) [23] Walter M J, Thibault Y, Wei K, et al. Characterizing experimental pressure and temperature conditions in multi-anvil apparatus[J]. Can J Phys, 1995, 73(5/6): 273-286. [24] Watson E B, Wark D A, Price J D, et al. Mapping the thermal structure of solid-media pressure assemblies[J]. Contrib Mineral Petr, 2002, 142(6): 640-652. doi: 10.1007/s00410-001-0327-4 [25] 冯吉福, 林峰, 李立惟, 等.六面顶压机上不同组装结构的温度研究[J].超硬材料工程, 2005, 21: 21-25.Feng J F, Lin F, Li L W, et al. Study on temperature of different assembly structure in cubic hinge apparatus[J]. Superhard Material Engineering, 2005, 21: 21-25. (in Chinese) -

下载:

下载: