High-Pressure Preparation of High-Strength Wood Materials

-

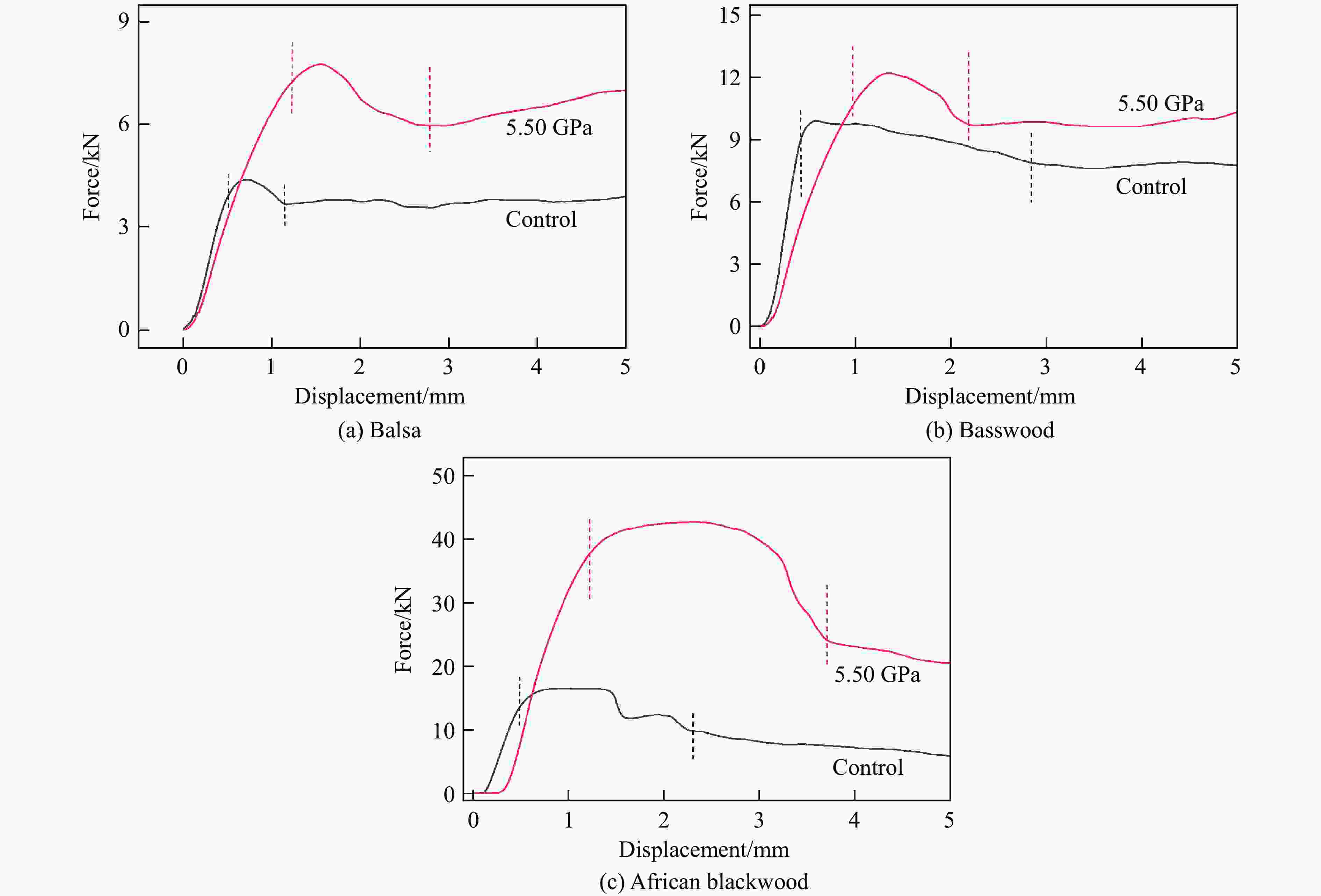

摘要: 地球上的矿产资源是有限的,而木材则可以再生。用改性木材代替储量有限的工业材料是人类长期追求的目标。采用大腔体六面顶压机对轻木、椴木和东非黑紫檀3种木材试样进行室温高压处理,分析了高压处理对其气干密度、抗压强度、弹性模量等性能的影响,并通过CT和扫描电子显微镜观察其内部微观结构变化。结果表明,3种木材的物理力学性能均有所提升。轻木、椴木和东非黑紫檀经5.50 GPa高压处理后,其密度分别提升239%、112%和11%,表面硬度分别提升79%、46%和15%,抗压强度分别提升33%、9%和28%。东非黑紫檀压密材的比强度(101.55 kJ/kg)接近铝合金(109.23 kJ/kg);东非黑紫檀具有比陶瓷材料轻质、比铝合金绝缘和隔热的特点;高比强度东非黑紫檀有潜力取代铝合金,有望在很多特殊环境中获得应用,为未来工业的可持续发展提供支持。研究结果为木材高值化应用提供了新思路。Abstract: Mineral resources on Earth are finite, but wood is renewable. Therefore, replacing limited industrial materials with modified wood remains a long-term pursuit. This study processed samples of three wood types, including balsa (Ochroma lagopus), basswood (Tilia tuan), and African blackwood (Dalbergia melanoxylon), with a large volume cubic press to compress these samples at room temperature under high pressure. The effects of high-pressure treatment on the air dry density, compressive strength, and elastic modulus of the three wood species were analyzed, and changes in their internal microstructures were observed using CT and scanning electron microscope. The results showed that the physical and mechanical properties of all three wood species improved. After high-pressure processing at 5.50 GPa, the density of balsa, basswood, and African blackwood increased by 239%, 112%, and 11%, respectively. Additionally, the surface hardness increased by 79%, 46%, and 15%, respectively, and the compressive strength increased by 33%, 9%, and 28%, respectively. Notably, the specific strength of compressed African blackwood (101.55 kJ/kg) approaches that of aluminum alloys (109.23 kJ/kg). The results demonstrate that African blackwood is lighter than ceramic materials. Furthermore, this wood offers superior electrical insulation and thermal insulation compared to aluminum alloy. Crucially, African blackwood possesses high specific strength, and this property gives it significant potential to replace aluminum alloy in numerous special environments. Such application supports sustainable development for future industries. In conclusion, this research opens new possibilities for high-value wood applications.

-

Key words:

- large volume cubic press /

- wood compression /

- wood density /

- mechanical properties

-

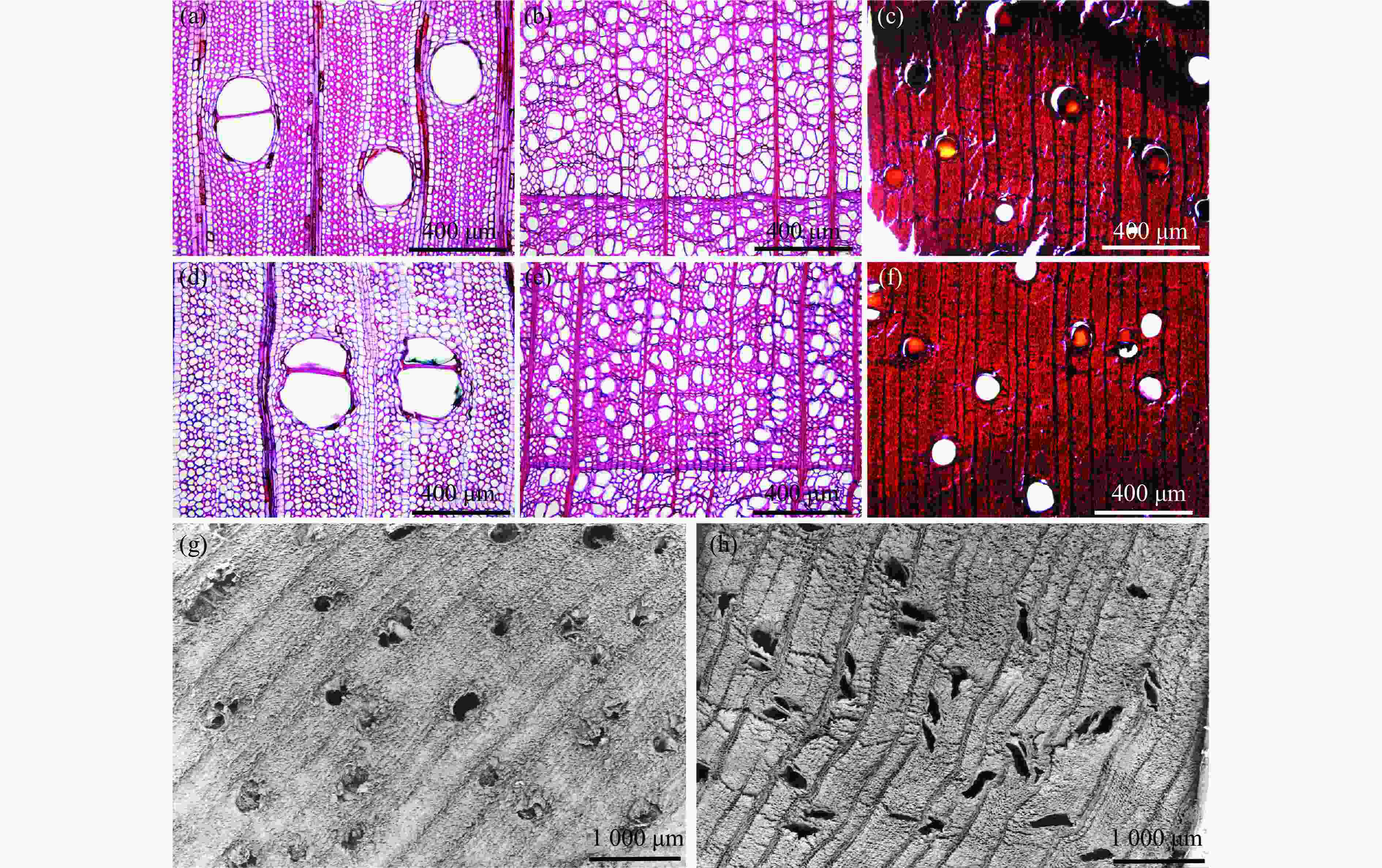

图 3 轻木(a)、椴木(b)和东非黑紫檀(c)对照样的横切面显微构造图像;轻木(d)、椴木(e)及东非黑紫檀(f)经5.50 GPa高压处理试样的横切面显微构造图像;轻木对照样(g)与5.50 GPa压力处理试样(h)的横切面SEM图像

Figure 3. Cross-sectional micrographs of the control samples for balsa (a), basswood (b), and African blackwood (c), respectively; cross-sectional micrographs of balsa (d), basswood (e), and African blackwood (f) samples treated at 5.50 GPa, respectively; cross-sectional SEM images of balsa control (g) and 5.50 GPa-treated (h) samples, respectively

表 1 木材高压处理前、后的气干密度

Table 1. Airdry densities of wood samples before and after high-pressure treatment

Wood species Airdry density at different pressure treatments/(g·cm−3) Increase rate/% Control 2.55 GPa 4.00 GPa 5.50 GPa Treated 1 year Balsa 0.30 1.03 0.97 1.05 239 197 Basswood 0.49 1.03 1.04 1.05 112 100 African blackwood 1.27 1.35 1.38 1.48 11 4 表 2 对照组木材的组分含量

Table 2. Component content of control wood

Wood species Cellulose/% Hemicellulose/% Lignin/% Balsa 40.64 15.53 19.55 Basswood 43.21 22.34 14.45 African blackwood 48.85 21.52 11.83 表 3 不同材料的比强度

Table 3. Specific strength of different materials

Material Strength/MPa Density/(g·cm−3) Specific strength/(kJ·kg−1) 5.50 GPa-treated balsa 36.24 1.05 34.24 5.50 GPa-treated basswood 48.35 1.05 46.05 5.50 GPa-treated African blackwood 150.30 1.48 101.55 Concrete RC40[29] 47.5 1.95 24.36 Concrete P·I 42.5[30] 45.2 2.3 19.65 Polyethylene plastic 39 0.91 42.86 Steel[31] 1340 7.83 171.14 Aluminum alloy[31] 296 2.71 109.23 Titanium alloy[31] 1060 4.43 239.28 -

[1] 吴义强. 木材科学与技术研究新进展 [J]. 中南林业科技大学学报, 2021, 41(1): 1–28. doi: 10.14067/j.cnki.1673-923x.2021.01.001WU Y Q. Newly advances in wood science and technology [J]. Journal of Central South University of Forestry & Technology, 2021, 41(1): 1–28. doi: 10.14067/j.cnki.1673-923x.2021.01.001 [2] ZHU Y M, ZHANG J, ZHANG Y, et al. Editorial: design and mechanical failure of deep-sea pressure structures [J]. Frontiers in Materials, 2023, 10: 1292283. doi: 10.3389/fmats.2023.1292283 [3] MACDONALD A. High-pressure equipment for use in the laboratory, at sea and at depth [M]//MACDONALD A. Life at High Pressure: In the Deep Sea and Other Environments. Cham: Springer, 2021: 353–417. [4] AMAN Z, WEIXING Z, SHIPING W, et al. Dynamic response of the non-contact underwater explosions on naval equipment [J]. Marine Structures, 2011, 24(4): 396–411. doi: 10.1016/j.marstruc.2011.05.005 [5] GUO X S, FAN N, LIU Y H, et al. Deep seabed mining: frontiers in engineering geology and environment [J]. International Journal of Coal Science & Technology, 2023, 10(1): 23. doi: 10.1007/s40789-023-00580-x [6] 涂登云, 陈川富, 周桥芳, 等. 木材压缩改性技术研究进展 [J]. 林业工程学报, 2021, 6(1): 13–20. doi: 10.13360/j.issn.2096-1359.202001036TU D Y, CHEN C F, ZHOU Q F, et al. Research progress of thermo-mechanical compression techniques for wood products [J]. Journal of Forestry Engineering, 2021, 6(1): 13–20. doi: 10.13360/j.issn.2096-1359.202001036 [7] NAVI P, PIZZI A. Property changes in thermo-hydro-mechanical processing: COST action FP0904 2010–2014: thermo-hydro-mechanical wood behavior and processing [J]. Holzforschung, 2015, 69(7): 863–873. doi: 10.1515/hf-2014-0198 [8] SONG J W, CHEN C J, ZHU S Z, et al. Processing bulk natural wood into a high-performance structural material [J]. Nature, 2018, 554(7691): 224–228. doi: 10.1038/nature25476 [9] HUANG W Z, JIN Y X, GUO Y, et al. Fabrication of high-performance densified wood via high-pressure steam treatment and hot-pressing [J]. Polymers, 2024, 16(7): 939. doi: 10.3390/polym16070939 [10] LI H H, ZHANG F M, RAMASWAMY H S, et al. High-pressure treatment of Chinese fir wood: effect on density, mechanical properties, humidity-related moisture migration, and dimensional stability [J]. BioResources, 2016, 11(4): 10497–10510. doi: 10.15376/biores.11.4.10497-10510 [11] YU Y, ZHANG F M, ZHU S M, et al. Effects of high-pressure treatment on poplar wood: density profile, mechanical properties, strength potential index, and microstructure [J]. BioResources, 2017, 12(3): 6283–6297. doi: 10.15376/biores.12.3.6283-6297 [12] 侯俊峰, 周永东. 木材热压干燥研究现状与应用前景 [J]. 世界林业研究, 2017, 30(6): 41–45. doi: 10.13348/j.cnki.sjlyyj.2017.0077.yHOU J F, ZHOU Y D. Research status and application prospect of wood hot-press drying [J]. World Forestry Research, 2017, 30(6): 41–45. doi: 10.13348/j.cnki.sjlyyj.2017.0077.y [13] 赵钟声, 刘一星, 孟令联. 高温高压水蒸汽处理制造压缩木、人造板材的研究 [J]. 林业机械与木工设备, 2001, 29(11): 16–17. doi: 10.3969/j.issn.2095-2953.2001.11.005 [14] ORMONDROYD G, SPEAR M, CURLING S. Modified wood: review of efficacy and service life testing [J]. Construction Materials, 2015, 168(4): 187–203. doi: 10.1680/coma.14.00072 [15] 王海阔, 贺端威, 许超, 等. 基于国产铰链式六面顶压机的大腔体静高压技术研究进展 [J]. 高压物理学报, 2013, 27(5): 633–661. doi: 10.11858/gywlxb.2013.05.001WANG H K, HE D W, XU C, et al. Development of large volume-high static pressure techniques based on the hinge-type cubic presses [J]. Chinese Journal of High Pressure Physics, 2013, 27(5): 633–661. doi: 10.11858/gywlxb.2013.05.001 [16] BÁDER M, NÉMETH R. The effect of the relaxation time on the mechanical properties of longitudinally compressed wood [J]. Wood Research, 2018, 63(3): 383–398. [17] FELHOFER M, BOCK P, SINGH A, et al. Wood deformation leads to rearrangement of molecules at the nanoscale [J]. Nano Letters, 2020, 20(4): 2647–2653. doi: 10.1021/acs.nanolett.0c00205 [18] LIANG X, GUO Y F, YAN J, et al. Pressure-mediated reconstruction of hydrogen bonding networks under ambient temperature towards high-strength cellulosic bulk materials [J]. Cellulose, 2024, 31(9): 5461–5477. doi: 10.1007/s10570-024-05936-3 [19] 周欢, 徐朝阳, 李健昱. 樟子松密实化前后吸能特性的对比 [J]. 林业工程学报, 2016, 1(3): 38–41. doi: 10.13360/j.issn.2096-1359.2016.03.007ZHOU H, XU Z Y, LI J Y. A comparison of energy absorption characteristics of Mongolian pine wood before and after densification [J]. Journal of Forestry Engineering, 2016, 1(3): 38–41. doi: 10.13360/j.issn.2096-1359.2016.03.007 [20] LAINE K, SEGERHOLM K, WÅLINDER M, et al. Wood densification and thermal modification: hardness, set-recovery and micromorphology [J]. Wood Science and Technology, 2016, 50(5): 883–894. doi: 10.1007/s00226-016-0835-z [21] KELLOGG R M, WANGAARD F F. Variation in the cell-wall density of wood [J]. Wood and Fiber Science, 1969, 1(3): 180–204. [22] BORREGA M, GIBSON L J. Mechanics of balsa (Ochroma pyramidale) wood [J]. Mechanics of Materials, 2015, 84: 75–90. doi: 10.1016/j.mechmat.2015.01.014 [23] 张双燕. 化学成分对木材细胞壁力学性能影响的研究 [D]. 北京: 中国林业科学研究院, 2011.ZHANG S Y. Chemical components effect on mechanical properties of wood cell wall [D]. Beijing: Chinese Academy of Forestry, 2011. [24] 刘一星, 赵广杰. 木材学 [M]. 2版. 北京: 中国林业出版社, 2012: 207–219.LIU Y X, ZHAO G J. Wood science [M]. 2nd ed. Beijing: China Forestry Publishing House, 2012: 207–219. [25] PAPANDREA S F, CATALDO M F, BERNARDI B, et al. The predictive accuracy of modulus of elasticity (MOE) in the wood of standing trees and logs [J]. Forests, 2022, 13(8): 1273. doi: 10.3390/f13081273 [26] 尹维, 田煜, 陶大帅, 等. 天然树木和竹子纤维材料的力学性能及仿生研究进展 [J]. 科学通报, 2015, 60(31): 2949–2962. doi: 10.1360/N972014-01318YIN W, TIAN Y, TAO D S, et al. Research progress of mechanical properties of natural wood and bamboo fiber composites and their biomimetics [J]. Chinese Science Bulletin, 2015, 60(31): 2949–2962. doi: 10.1360/N972014-01318 [27] 田蜜, 董晓娜, 曾祥全, 等. 黑黄檀木材物理和力学性质研究 [J]. 四川林业科技, 2024, 45(1): 115–119. doi: 10.12172/202304170003TIAN M, DONG X N, ZENG X Q, et al. Physical and mechanical properties of Dalbergia fusca wood [J]. Journal of Sichuan Forestry Science and Technology, 2024, 45(1): 115–119. doi: 10.12172/202304170003 [28] WANG W H. Bulk metallic glasses with functional physical properties [J]. Advanced Materials, 2009, 21(45): 4524–4544. doi: 10.1002/adma.200901053 [29] 张爱丽, 田光辉, 郭颜凤. 不同强度等级下再生混凝土的力学及路用性能研究 [J]. 混凝土, 2023(12): 192–195. doi: 10.3969/j.issn.1002-3550.2023.12.039ZHANG A L, TIAN G H, GUO Y F. Research on mechanical and road performance of recycled concrete under different strength grades [J]. Concrete, 2023(12): 192–195. doi: 10.3969/j.issn.1002-3550.2023.12.039 [30] 黄友芬, 高奇, 李伟, 等. 高强自密实混凝土抗压强度影响因素分析 [J]. 中国建材科技, 2022, 31(6): 30–33. doi: 10.12164/j.issn.1003-8965.2022.06.008HUANG Y F, GAO Q, LI W, et al. Analysis of influencing factors on compressive strength of high strength self-compacting concrete [J]. China Building Materials Science & Technology, 2022, 31(6): 30–33. doi: 10.12164/j.issn.1003-8965.2022.06.008 [31] GIBSON A J. Wood in the plastics industry [J]. Empire Forestry Journal, 1942, 21(2): 116–119. [32] 龚勋, 魏文华, 赵小舟, 等. 碳化硼陶瓷的军工应用及前沿制备技术 [J]. 中国军转民, 2021(5): 56–59. doi: 10.3969/j.issn.1008-5874.2021.05.033 [33] 刘一星, 李坚, 刘君良, 等. 水蒸气处理法制作压缩整形木的研究(Ⅰ): 构造变化和尺寸稳定性 [J]. 东北林业大学学报, 2000, 28(4): 9–12. doi: 10.3969/j.issn.1000-5382.2000.04.003LIU Y X, LI J, LIU J L, et al. Study on compressive orthopaedy wood by stream treating at high temperature (Ⅰ): structure change and dimension stability [J]. Journal of Northeast Forestry University, 2000, 28(4): 9–12. doi: 10.3969/j.issn.1000-5382.2000.04.003 -

下载:

下载: