Dynamic Response of Hollow Tempered Laminated Glass under Explosive Load

-

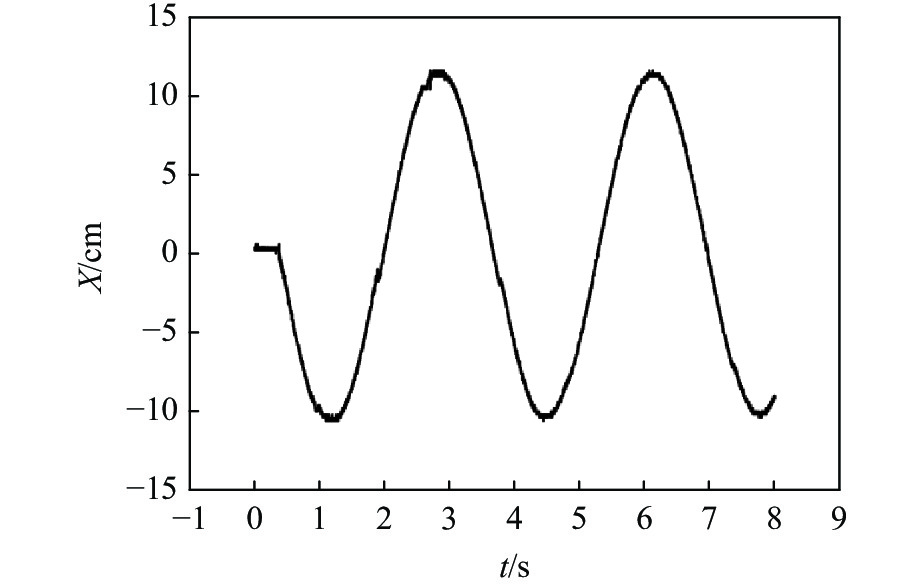

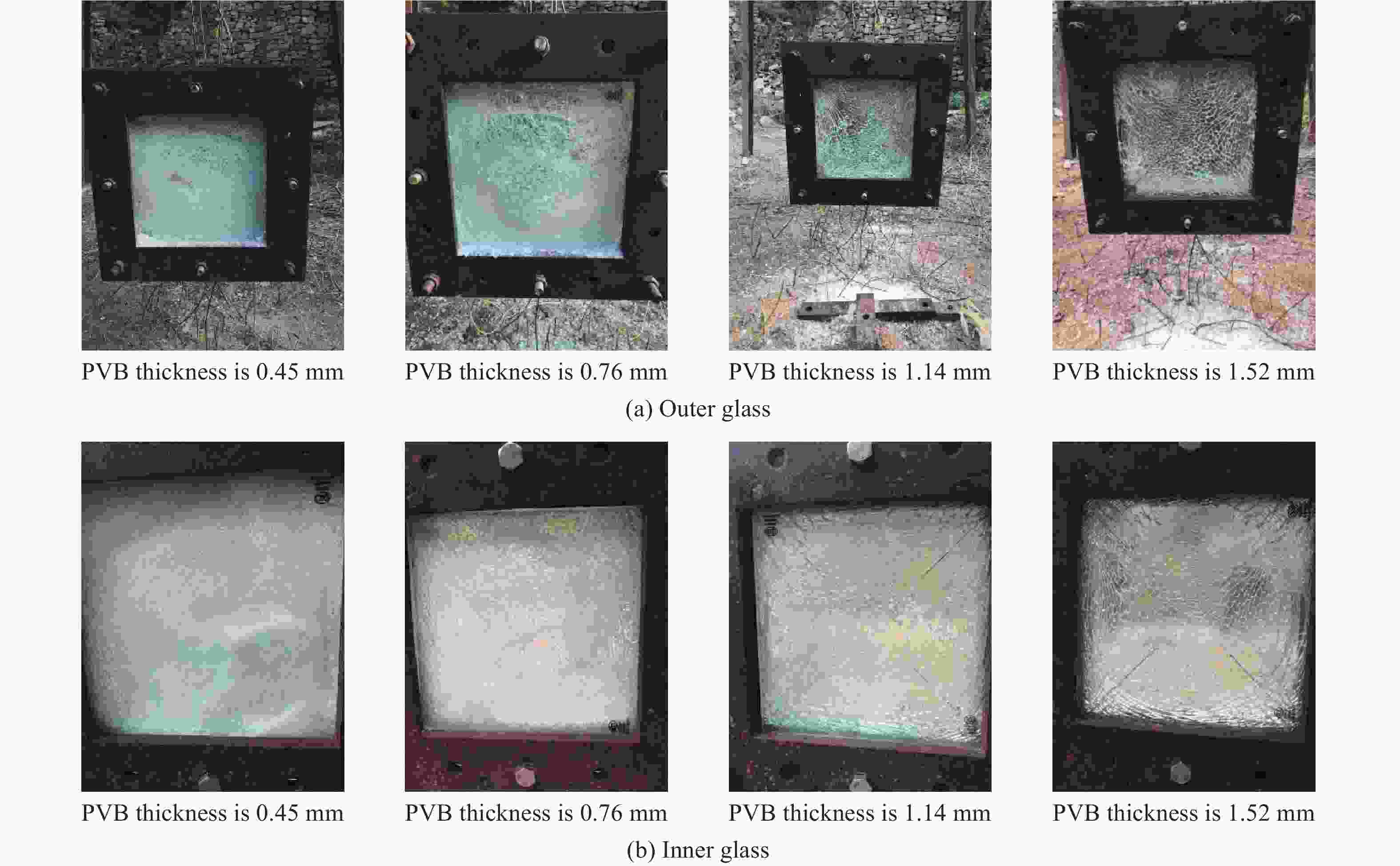

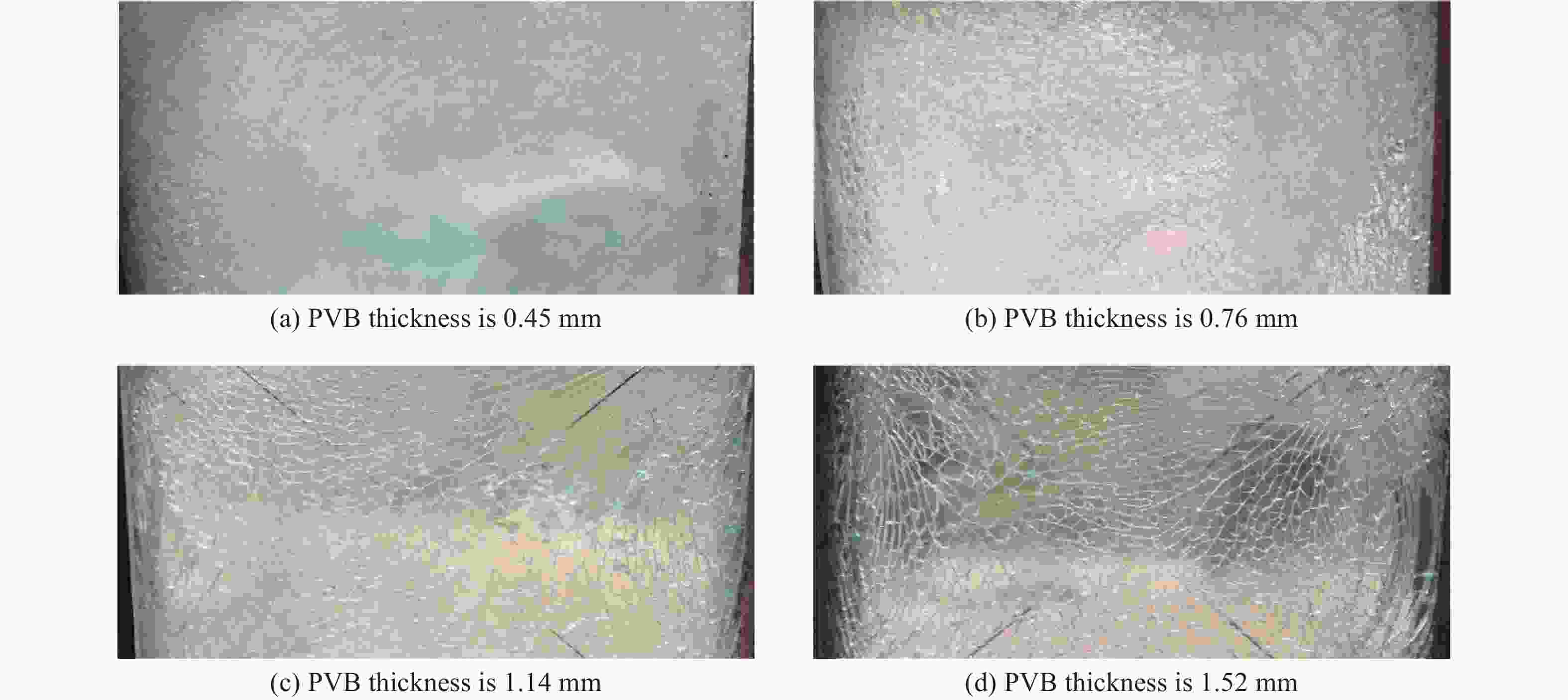

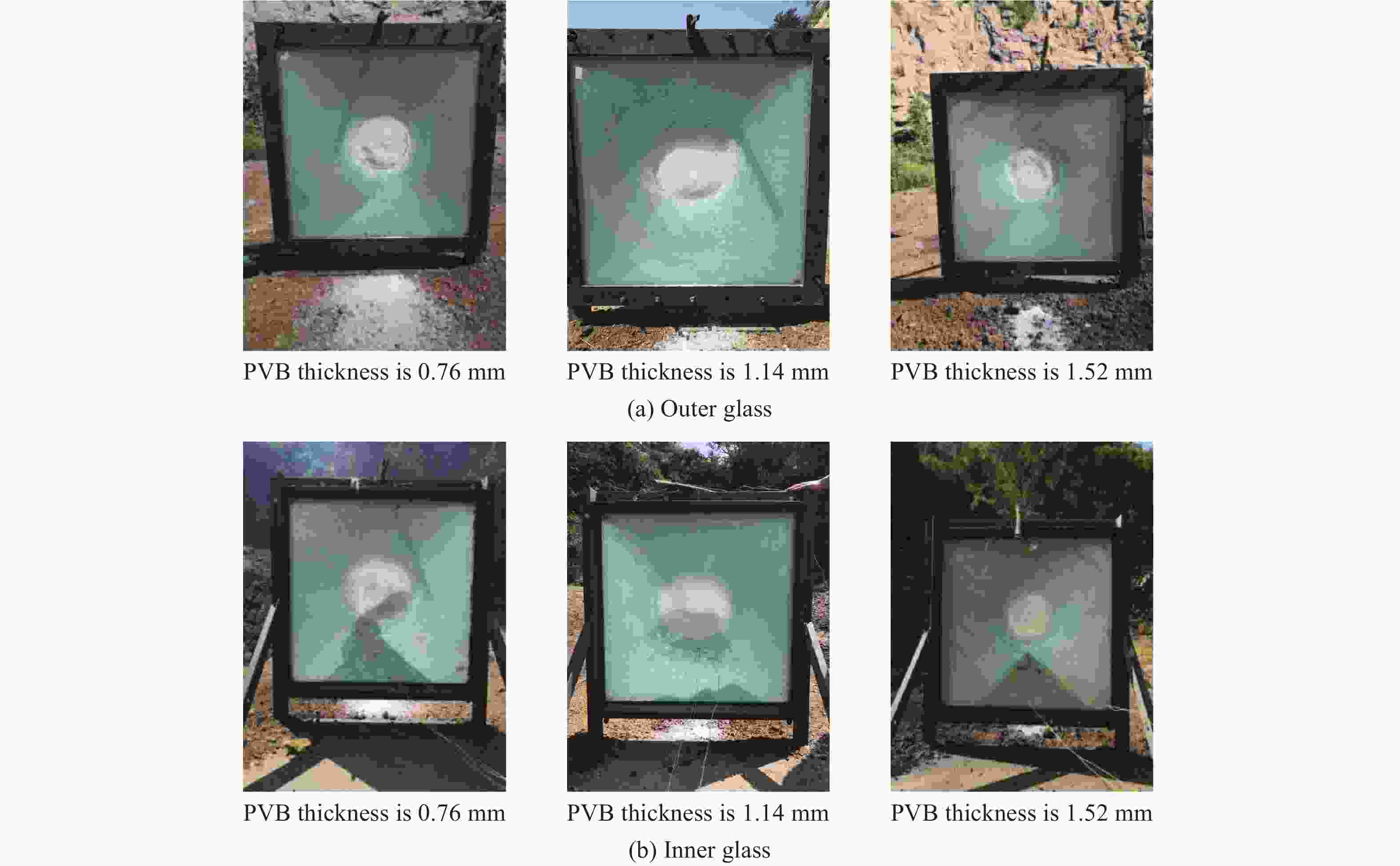

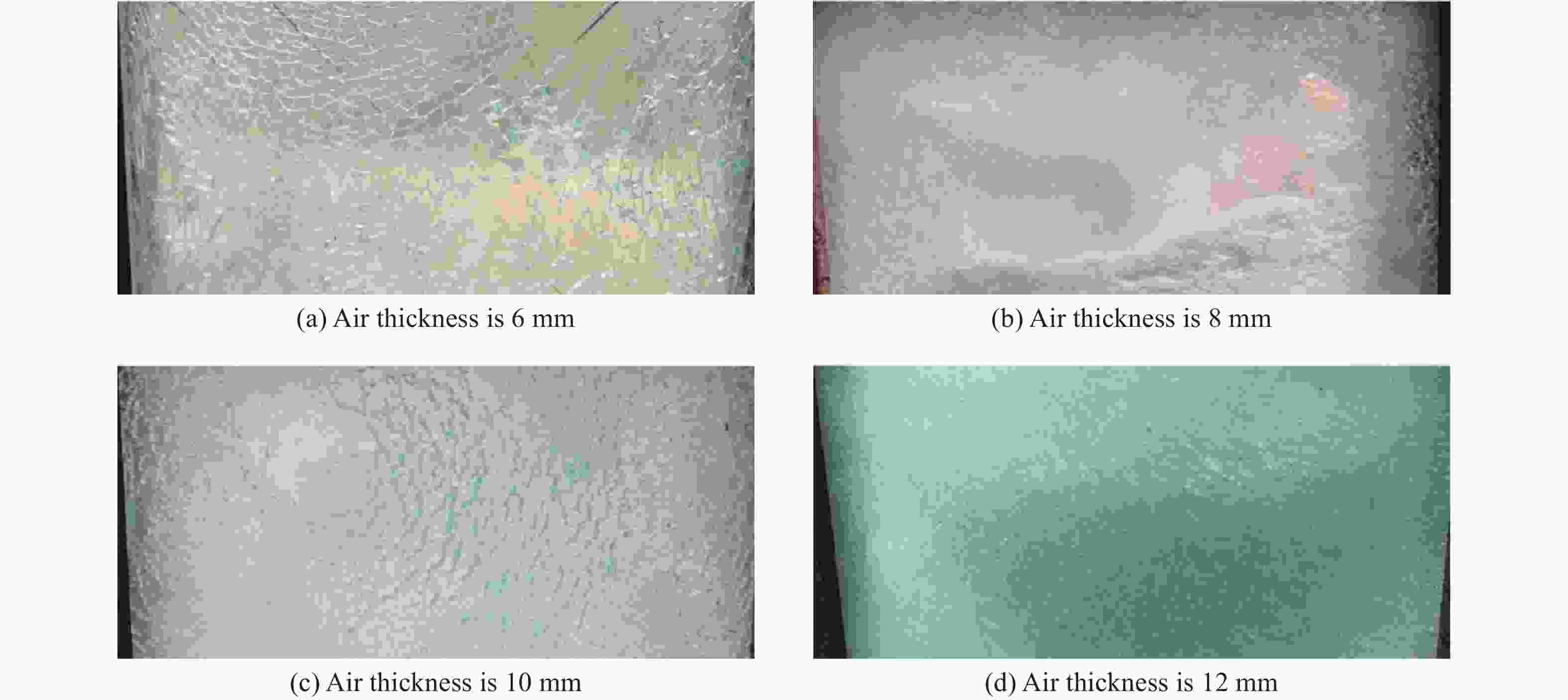

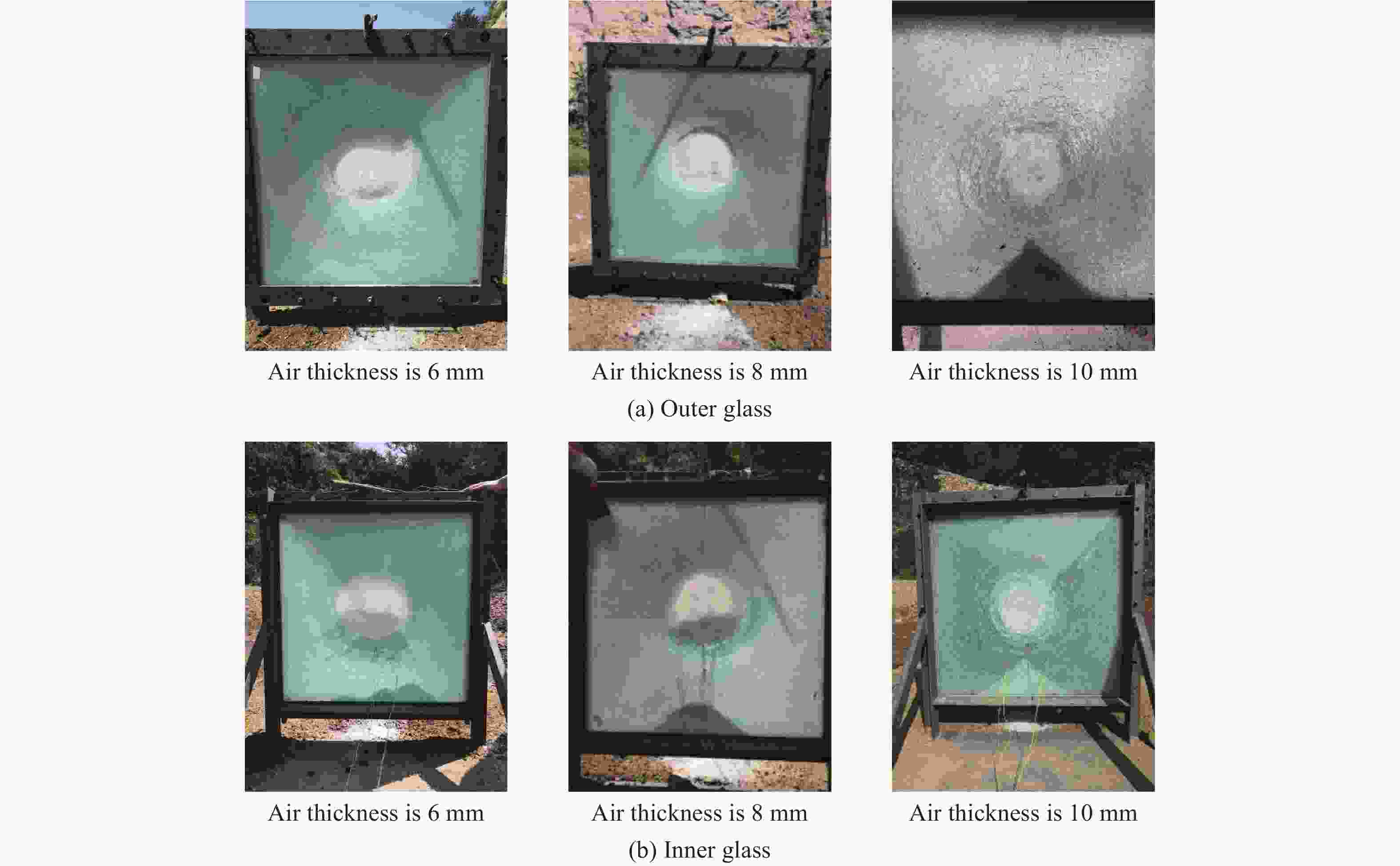

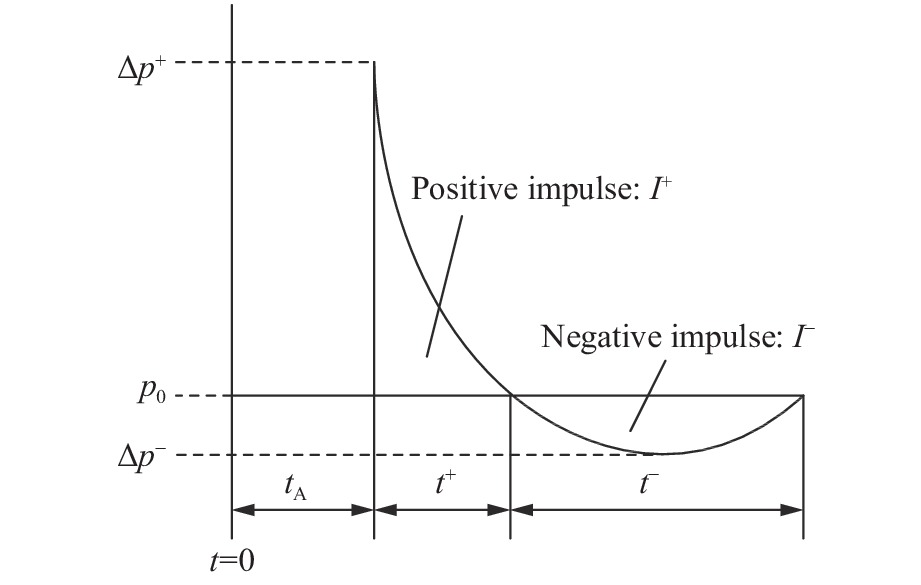

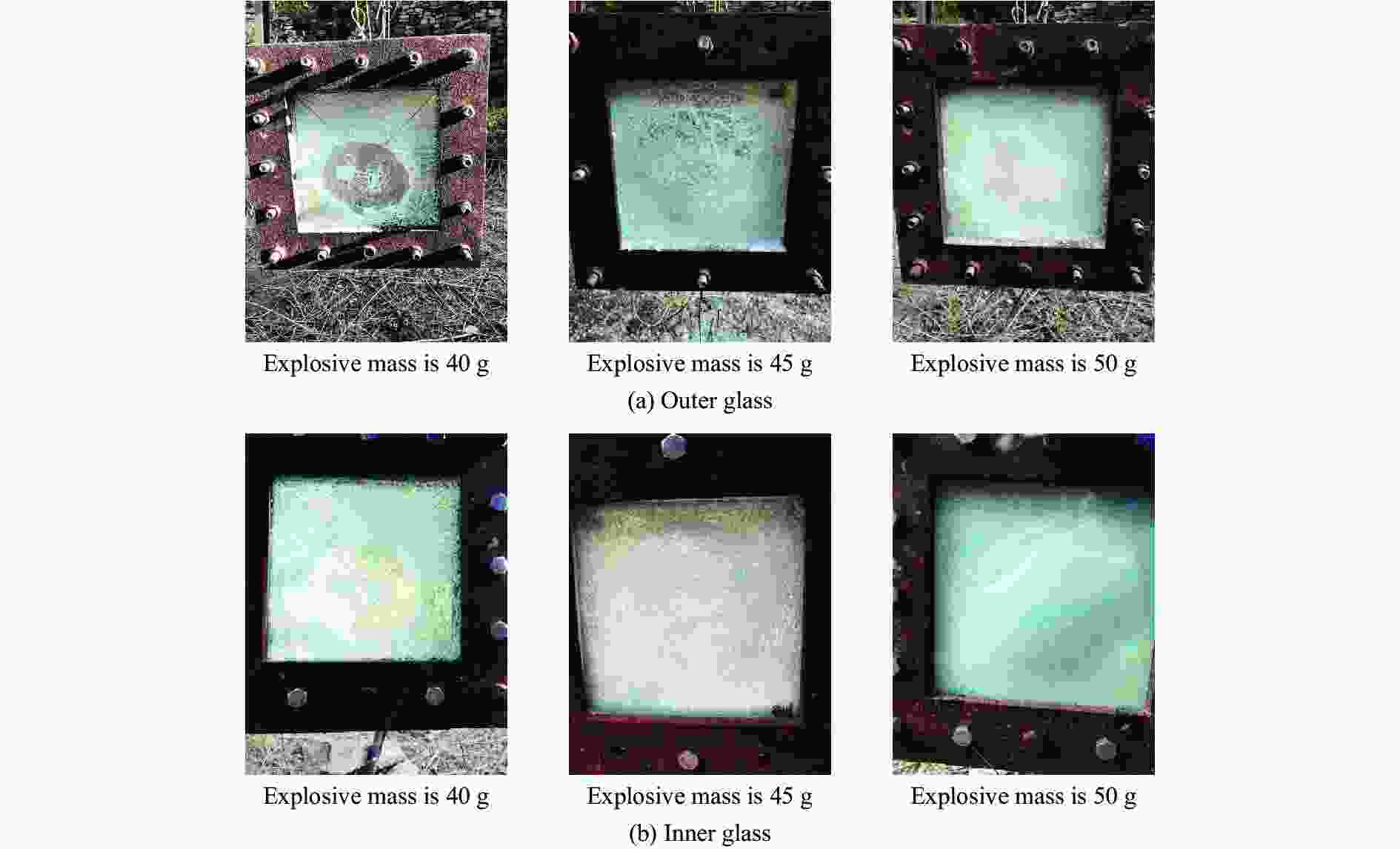

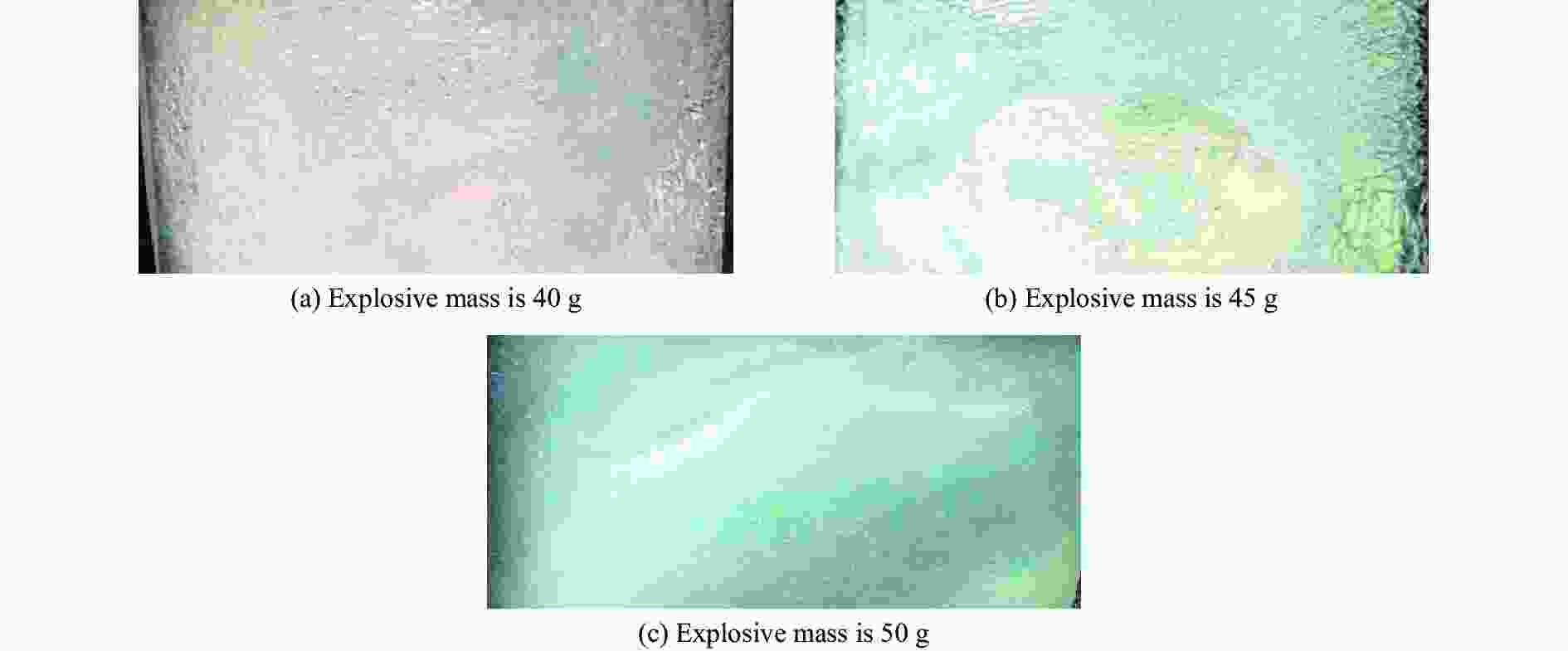

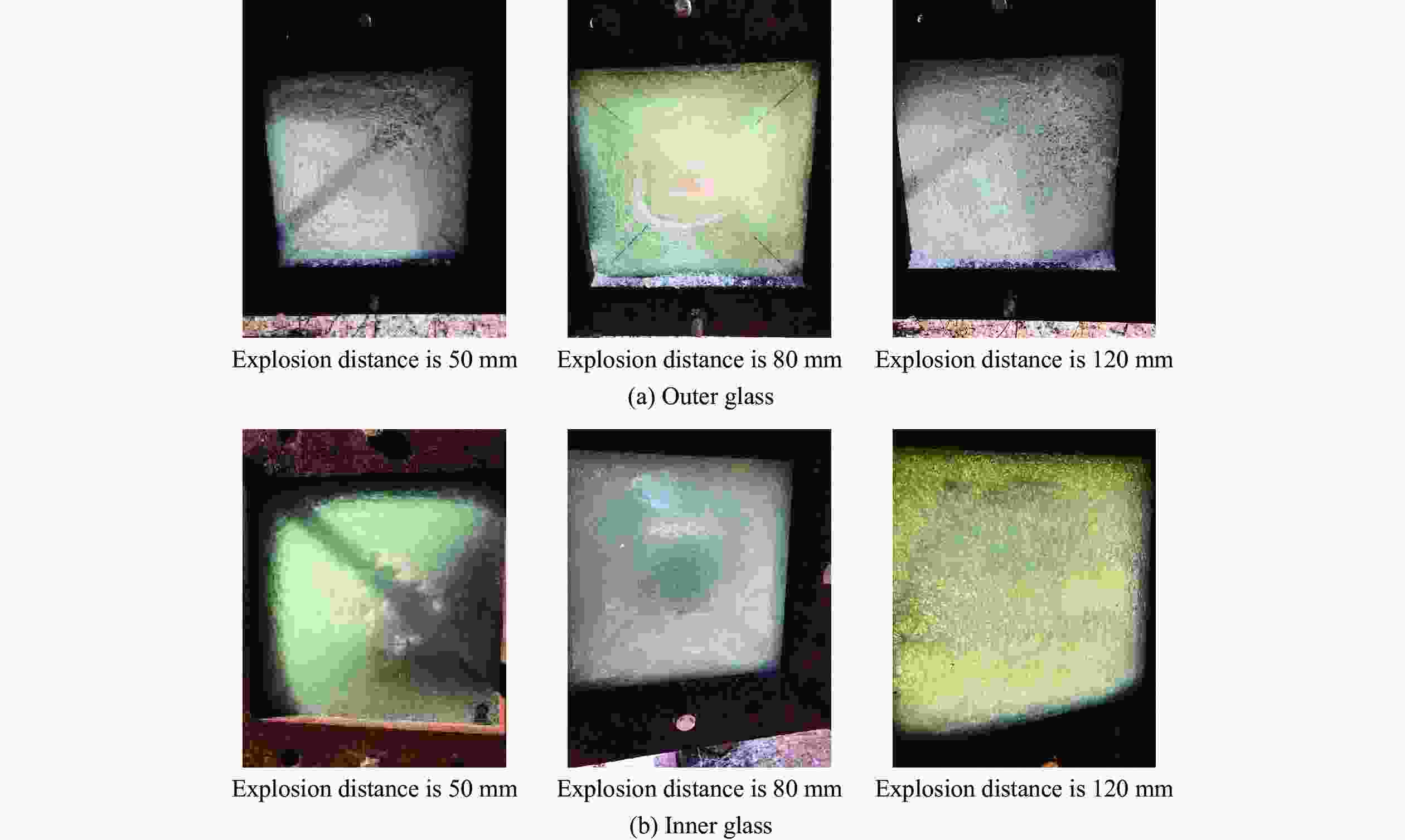

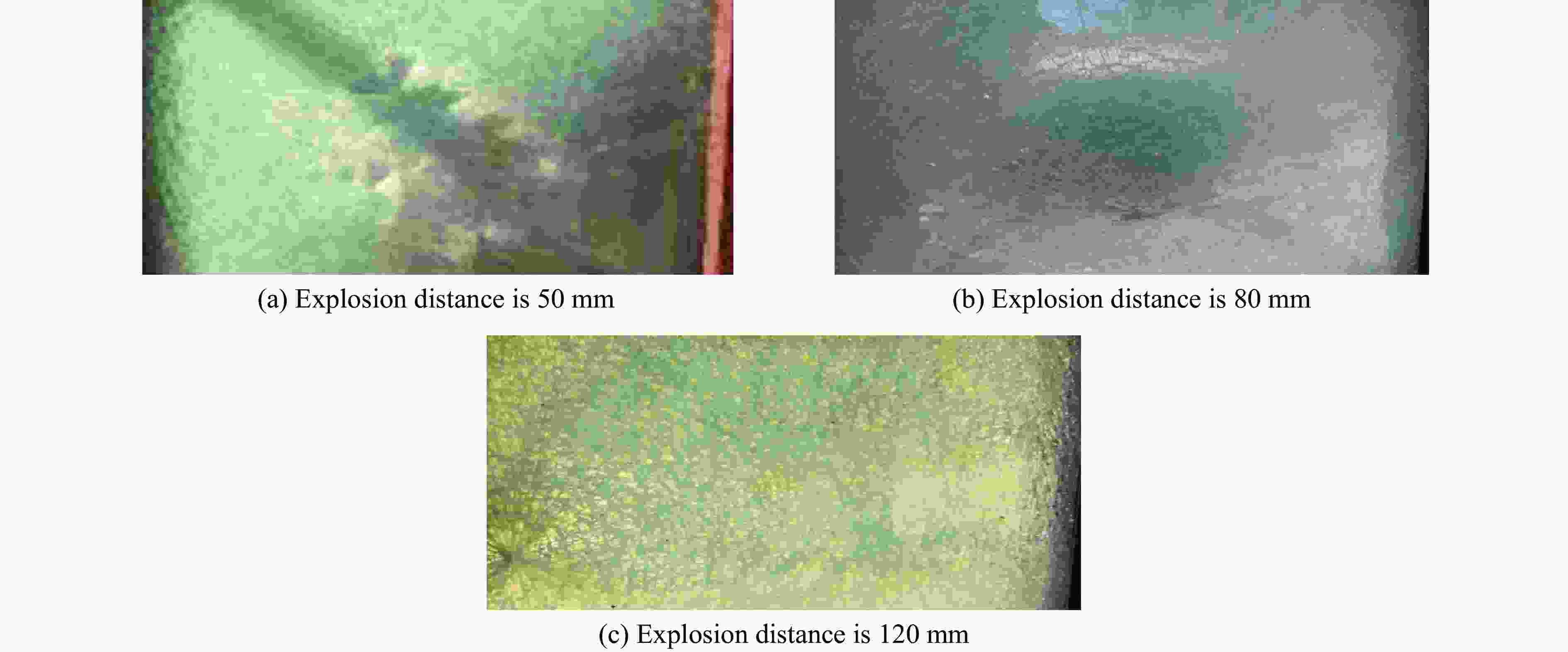

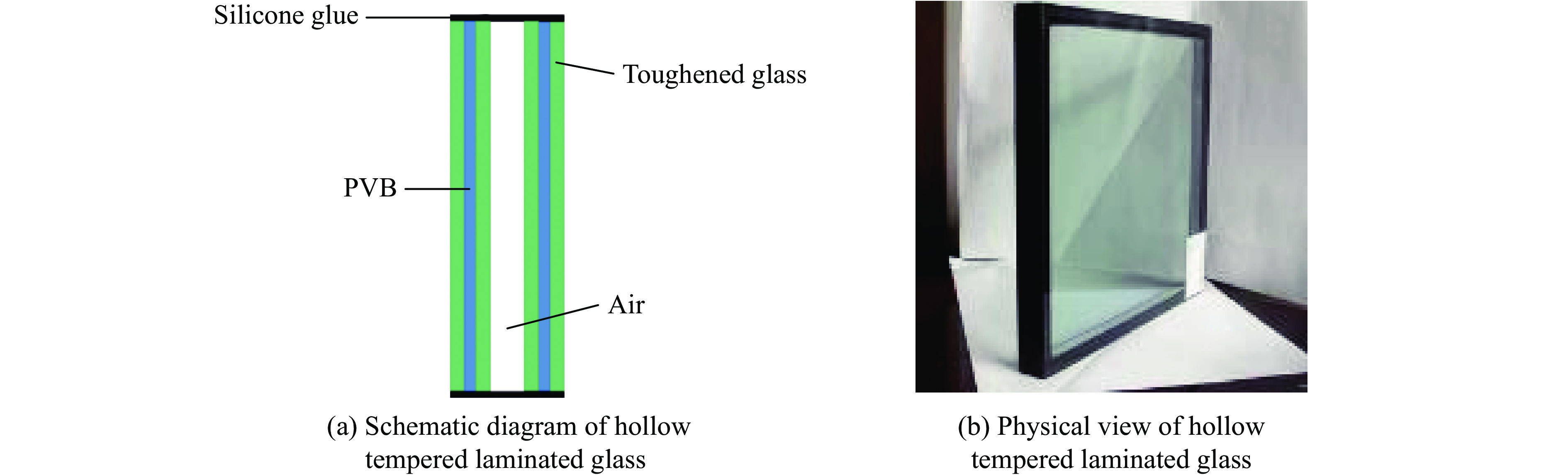

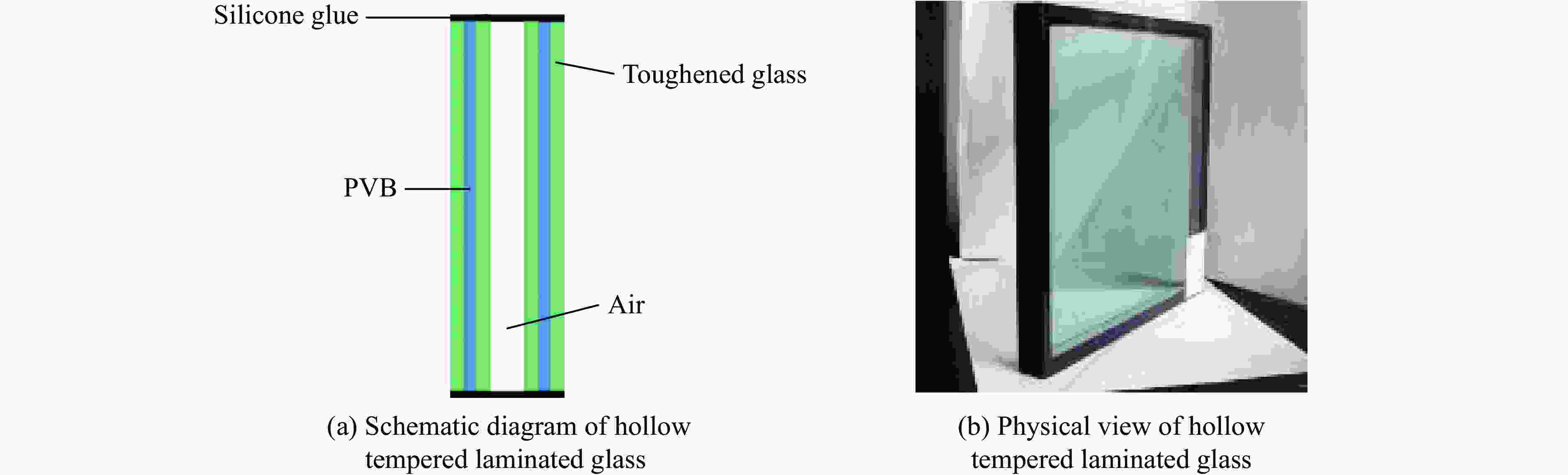

摘要: 采用自行设计的爆炸实验系统,研究了面内尺寸为300 mm × 300 mm和1 000 mm × 1 000 mm的中空钢化夹层玻璃在爆炸载荷下的动态响应规律,分析了PVB胶层厚度、空气层厚度、炸药量以及爆炸距离对中空钢化夹层玻璃抗爆性能的影响。结果表明:(1) 中空钢化夹层玻璃的抗爆性能随着面内尺寸的增加而增强;(2) 无论是大尺寸还是小尺寸的中空钢化夹层玻璃,随着PVB胶层厚度的增加,结构整体的强度增大,试样的承载能力逐渐增强,随着中间空气层厚度的增加,结构整体的稳定性降低,抗爆能力减弱;(3) 改变炸药量和爆炸距离对中空钢化夹层玻璃的动态响应有很大影响,随着炸药量增加、爆炸距离减小,中空钢化夹层玻璃的破坏程度逐渐增大。Abstract: In this paper, an independently-designed system for explosion experiment is used to investigate the dynamic response law of hollow tempered laminated glass with plane size of 300 mm × 300 mm and 1000 mm × 1000 mm under explosive load. The influence of layer thickness of PVB glue, thickness of air layer, explosive quantity and explosion distance on the anti-explosive performance of hollow tempered laminated glass is analyzed. The results show that: (1) the anti-blast performance of hollow tempered laminated glass is enhanced with the increasement of the plane size; (2) for both large-size and small-size hollow tempered laminated glass, with increasement of the thickness of the PVB glue layer, both the overall strength of the structure and the load-bearing capacity of the sample increase gradually when the thickness of the intermediate air layer increases, the overall stability of the structure decreases and the anti-explosion ability become weaker; (3) changing the amount of explosives and the explosion distance has a strong influence on the dynamic response of the hollow tempered laminated glass. With the increasement of the explosive amount and the reduction of the explosive distance, the damage degree of the hollow tempered laminated glass increases gradually.

-

表 1 试样分组

Table 1. Groups of the specimens

Group No. In-plane size/

(mm × mm)Thickness/mm W/g L/mm G1 PVB1 G2 A G3 PVB2 G4 1 300 × 300 6 0.45 6 6 6 0.45 6 45 100 6 0.76 6 6 6 0.76 6 6 1.14 6 6 6 1.14 6 6 1.52 6 6 6 1.52 6 1000 × 1000 6 0.76 6 6 6 0.76 6 120 100 6 1.14 6 6 6 1.14 6 6 1.52 6 6 6 1.52 6 2 300 × 300 6 1.14 6 6 6 1.14 6 45 100 6 1.14 6 8 6 1.14 6 6 1.14 6 10 6 1.14 6 6 1.14 6 12 6 1.14 6 1000 × 1000 6 1.14 6 6 6 1.14 6 120 100 6 1.14 6 8 6 1.14 6 6 1.14 6 10 6 1.14 6 3 300 × 300 6 0.76 6 6 6 0.76 6 40 100 45 50 4 300 × 300 6 1.14 6 6 6 1.14 6 40 50 80 120 表 2 不同PVB胶层厚度试样的凹陷深度和圆形脱离区域的范围

Table 2. Depression depth and circular detachment areas of samples with different PVB adhesive layer thicknesses

PVB thickness/mm W/g L/mm h/mm D/mm 0.76 120 100 53.4 178.2 1.14 120 100 42.7 143.7 1.52 120 100 31.5 127.6 表 3 不同空气厚度试样的凹陷深度和圆形脱落区域的范围

Table 3. Depths of depression and the ranges of circular shedding areas of samples with different air thicknesses

Air thickness/mm W/g L/mm h/mm D/mm 6 120 100 38.3 143.7 8 120 100 46.6 157.8 10 120 100 57.8 162.3 -

[1] 王承遇, 卢琪, 陶瑛. 玻璃的脆性(一) [J]. 玻璃与搪瓷, 2011, 39(6): 37–43. doi: 10.3969/j.issn.1000-2871.2011.06.009WANG C Y, LU Q, TAO Y. Brittleness of glass (1) [J]. Glass and Enamel, 2011, 39(6): 37–43. doi: 10.3969/j.issn.1000-2871.2011.06.009 [2] 朱东辉. 建筑玻璃幕墙的类型特点及设计要点分析 [J]. 建材与装饰, 2020, 615(18): 81–82. doi: 10.3969/j.issn.1673-0038.2020.18.059ZHU D H. Analysis of type characteristics and design key points of architectural glass curtain wall [J]. Construction Materials and Decoration, 2020, 615(18): 81–82. doi: 10.3969/j.issn.1673-0038.2020.18.059 [3] ZHANG X H, HAO H, WANG Z Q. Experimental investigation of monolithic tempered glass fragment characteristics subjected to blast loads [J]. Engineering Structures, 2014, 75: 259–275. doi: 10.1016/j.engstruct.2014.06.014 [4] THOMPSON D, BROWN S, MALLONEE S, et al. Fatal and non-fatal injuries among U.S. air force personnel resulting from the terrorist bombing of the Khobar Towers [J]. Journal of Trauma-Injury Infection and Critical Care, 2004, 57(2): 208–215. doi: 10.1097/01.TA.0000142672.99660.80 [5] OSNES K, HOLMEN J K, HOPPERSTAD O S, et al. Fracture and fragmentation of blast-loaded laminated glass: an experimental and numerical study [J]. International Journal of Impact Engineering, 2019, 132: 103334. doi: 10.1016/j.ijimpeng.2019.103334 [6] WANG X E, YANG J, CHONG W T A, et al. Post-fracture performance of laminated glass panels under consecutive hard body impacts [J]. Composite Structures, 2020, 254: 112777. doi: 10.1016/j.compstruct.2020.112777 [7] LI W H, LI C, QIU Y. Thermal stress analysis of photovoltaic hollow glass based on ANSYS [J]. Key Engineering Materials, 2013, 544: 339–342. doi: 10.4028/www.scientific.net/KEM.544.339 [8] 史博, 张晓颖, 李阔, 等. 爆炸载荷下中空夹层玻璃的动力响应影响因素 [J]. 爆炸与冲击, 2018, 38(1): 119–123. doi: 10.11883/bzycj-2017-0018SHI B, ZHANG X Y, LI K, et al. Influencing factors of dynamic response of hollow laminated glass subjected to blast loads [J]. Explosion and Shock Waves, 2018, 38(1): 119–123. doi: 10.11883/bzycj-2017-0018 [9] KUMAR P, SHUKLA A. Dynamic response of glass panels subjected to shock loading [J]. Journal of Non-Crystalline Solids, 2011, 357: 3917–3923. doi: 10.1016/j.jnoncrysol.2011.08.009 [10] 杨璐, 张有振, 白音, 等. 单层与中空钢化玻璃火灾下破坏机理试验研究 [J]. 工业建筑, 2017, 47(5): 111–115.YANG L, ZHANG Y Z, BAI Y, et al. Experimental research on the failure mechanism of single-layer and mid-hollow tempered glass under fire condition [J]. Industrial Construction, 2017, 47(5): 111–115. [11] 姚芬, 张英杰, 姚蓬飞, 等. 对称与非对称钢化夹层玻璃的抗冲击性能 [J]. 高压物理学报, 2020, 34(4): 044103.YAO F, ZHANG Y J, YAO P F, et al. Impact resistance of symmetric and asymmetric tempered laminated glass [J]. Chinese Journal of High Pressure Physics, 2020, 34(4): 044103. [12] 陶志雄, 张其林, 陈俊, 等. 夹层玻璃PVB胶片抗剪性能试验研究 [J]. 结构工程师, 2011, 27(1): 134–138. doi: 10.3969/j.issn.1005-0159.2011.01.022TAO Z X, ZHANG Q L, CHEN J, et al. Experimental study on shearing properties of PVB films for laminated glass [J]. Structural Engineers, 2011, 27(1): 134–138. doi: 10.3969/j.issn.1005-0159.2011.01.022 [13] 王明友. 新型车用夹层真空平板玻璃研究[D]. 扬州: 扬州大学, 2010.WANG M Y. Research on new type vacuum laminated glass for vehicle [D]. Yangzhou: Yangzhou University, 2010. [14] LARCHER M, SOLOMOS G, CASADEI F, et al. Experimental and numerical investigations of laminated glass subjected to blast loading [J]. International Journal of Impact Engineering, 2012, 39(1): 42–50. doi: 10.1016/j.ijimpeng.2011.09.006 [15] WEI J, DHARANI L R. Fracture mechanics of laminated glass subjected to blast loading [J]. Theoretical and Applied Fracture Mechanics, 2005, 44(2): 157–167. doi: 10.1016/j.tafmec.2005.06.004 [16] CASTORI G, SPERANZINI E. Structural analysis of failure behavior of laminated glass [J]. Composites Part B: Engineering, 2017, 125: 89–99. doi: 10.1016/j.compositesb.2017.05.062 [17] 敬霖. 强动载荷作用下泡沬金属夹芯壳结构的动力学行为及其失效机理硏究[D]. 太原: 太原理工大学, 2012.JING L. The dynamics mechanical behavior and failure mechanism of sandwich shells with metallic foam cores under intensive loading [D]. Taiyuan: Taiyuan University of Technology, 2012. [18] 李胜杰. 爆炸载荷下夹层玻璃的动态响应及裂纹扩展的研究[D]. 太原: 太原理工大学, 2015.LI S J. Study on dynamic response and cracks propagation of laminated glass subjected to blast load [D]. Taiyuan: Taiyuan University of Technology, 2015. [19] 王志华, 李志强, 赵隆茂, 等. 多孔金属及其夹芯结构的冲击力学行为[C]//中国力学大会. 西安: 中国力学学会, 2013.WANG Z H, LI Z Q, ZHAO L M, et al. Impact mechanical behavior of porous metal and its sandwich structures [C]//The Chinese Congress of Theoretical and Applied Mechanics. Xi’an: The Chinese Society of Theoretical and Applied Mechanics, 2013. [20] 敬霖, 王志华, 赵隆茂. 爆炸荷载作用下结构冲量的测量 [J]. 实验力学, 2009, 24 (2): 151–156.JING L, WANG Z H, ZHAO L M. Measurement of impulse acted on a structure subjected to blast load [J]. Journal of Experimental Mechanics, 2009, 24 (2): 151–156. [21] SERAFINAVIČIUS T, LEBET J-P, LOUTER C, et al. Long-term laminated glass four point bending test with PVB, EVA and SG interlayers at different temperatures [J]. Procedia Engineering, 2013, 57: 996–1004. doi: 10.1016/j.proeng.2013.04.126 [22] 邓荣兵, 金先龙, 陈峻. 中空夹胶玻璃幕墙爆炸响应的三维数值模拟 [J]. 上海交通大学学报, 2010, 44(10): 1456–1459.DENG R B, JIN X L, CHEN J. Three-dimensional numerical simulation for blast response of double laminated insulating glass curtain wall [J]. Journal of Shanghai Jiaotong University, 2010, 44(10): 1456–1459. [23] 张晓颖, 李胜杰, 李志强. 爆炸载荷作用下夹层玻璃动态响应的数值模拟 [J]. 兵工学报, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016ZHANG X Y, LI S J, LI Z Q. Numerical simulation of dynamic response of laminated glass subjected to blast load [J]. Acta Armamentarii, 2018, 39(7): 1379–1388. doi: 10.3969/j.issn.1000-1093.2018.07.016 [24] HENRYCH J. 爆炸动力学及其应用[M]. 熊建国, 译. 北京: 科学出版社, 1987.HENRYCH J. The dynamics of explosion and its use [M]. Translated by XIONG J G. Beijing: Science Press, 1987. [25] YUNOSHEV A S, SIL’VESTROV V V, PLASTININ A V, et al. Influence of artificial pores on the detonation parameters of an emulsion explosive [J]. Combustion, Explosion, and Shock Waves, 2017, 53(2): 205–210. doi: 10.1134/S0010508217020113 [26] BOBRESHOV A, USKOV G, NESKORODOV S, et al. Experimental measurement of impulse response UWB emitters [C]//2020 7th All-Russian Microwave Conference (RMC), 2020. [27] QUINN G D, SWAB J J, PATEL P. On radial, circumferential, and spiral cracks in fractured glass plates [J]. International Journal of Applied Glass Science, 2021, 12(2): 189–197. doi: 10.1111/ijag.15868 [28] HU Y H, GU W B, LIU J Q, et al. Study on dynamic response of multi-degree-of-freedom explosion vessel system under impact load [J]. Defence Technology, 2020, 16(4): 777–786. doi: 10.1016/j.dt.2019.08.012 [29] MUNIANDY K, ARIFF Z M, BAKAR A A. Digital image correlation utilization in measuring displacement and strain during plastic film blowing process: a feasibility study [J]. Measurement, 2019, 136: 487–500. doi: 10.1016/j.measurement.2018.12.093 [30] MOGILYUK Z, PROKOPIEV V. General theory of vibroacoustic simulation of blast resistance of the bearing building constructions [J]. E3S Web of Conferences, 2020, 217: 01009. doi: 10.1051/e3sconf/202021701009 [31] 周保顺, 张立恒, 王少龙, 等. TNT炸药爆炸冲击波的数值模拟与实验研究 [J]. 弹箭与制导学报, 2010, 30(3): 88–90. doi: 10.3969/j.issn.1673-9728.2010.03.025ZHOU B S, ZHANG L H, WANG S L, et al. Numerical simulation and experimental research on TNT explosion shock wave [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2010, 30(3): 88–90. doi: 10.3969/j.issn.1673-9728.2010.03.025 [32] DUA A, BRAIMAH A, KUMAR M. Experimental and numerical investigation of rectangular reinforced concrete columns under contact explosion effects [J]. Engineering Structures, 2020, 205: 109891. doi: 10.1016/j.engstruct.2019.109891 -

下载:

下载: