High Temperature and High Pressure Experiment and Modification of Phosphogypsum

-

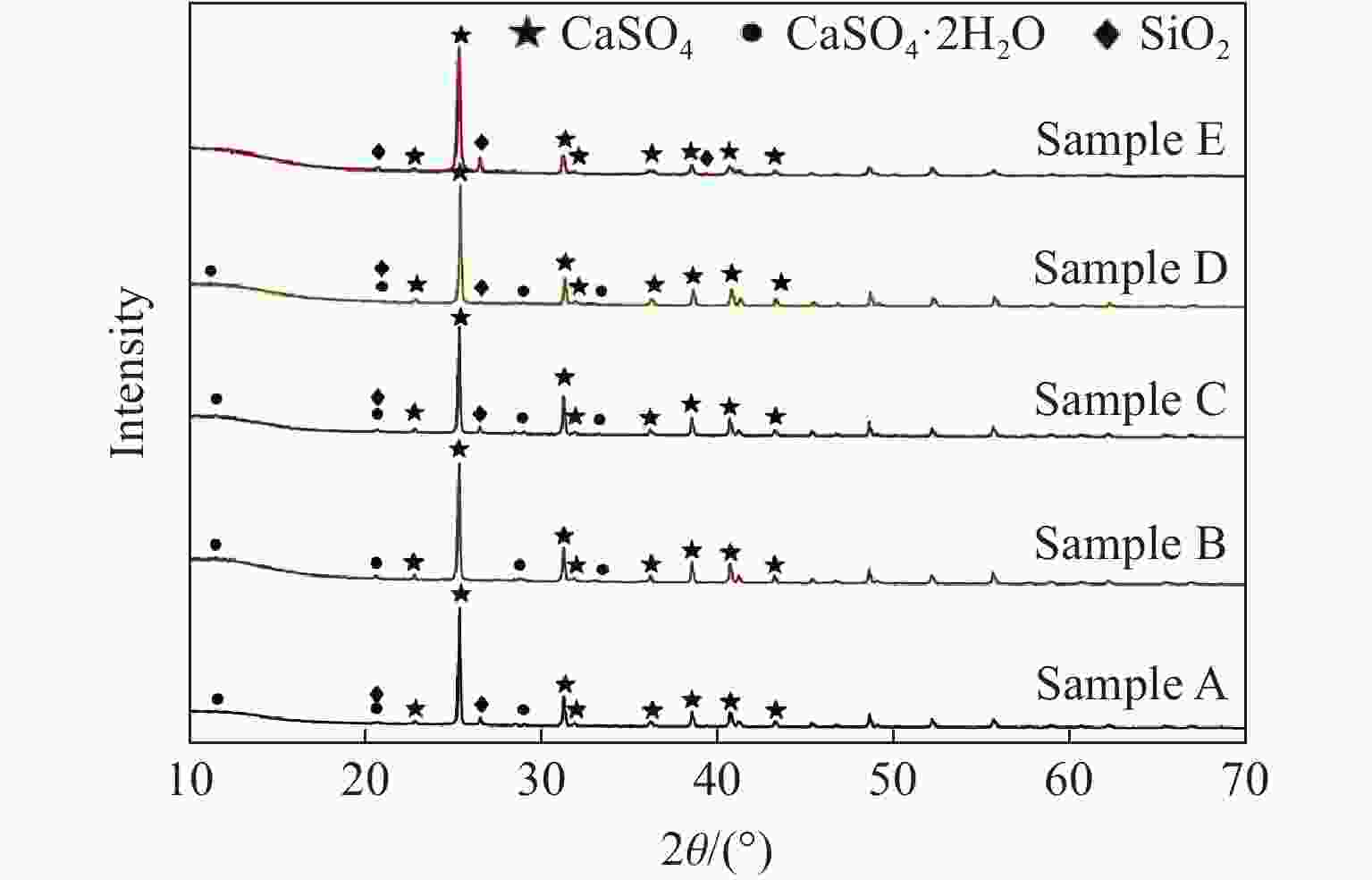

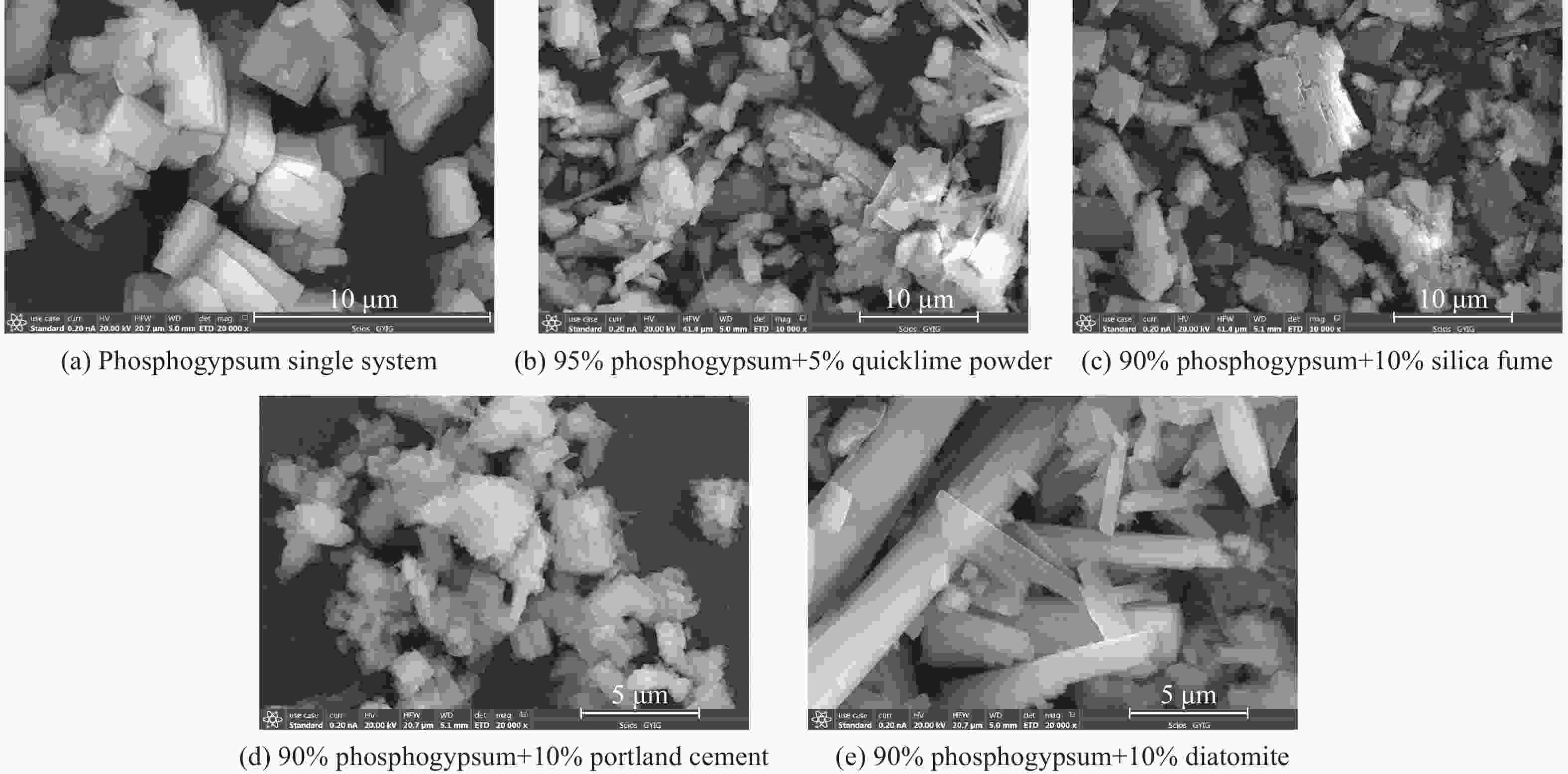

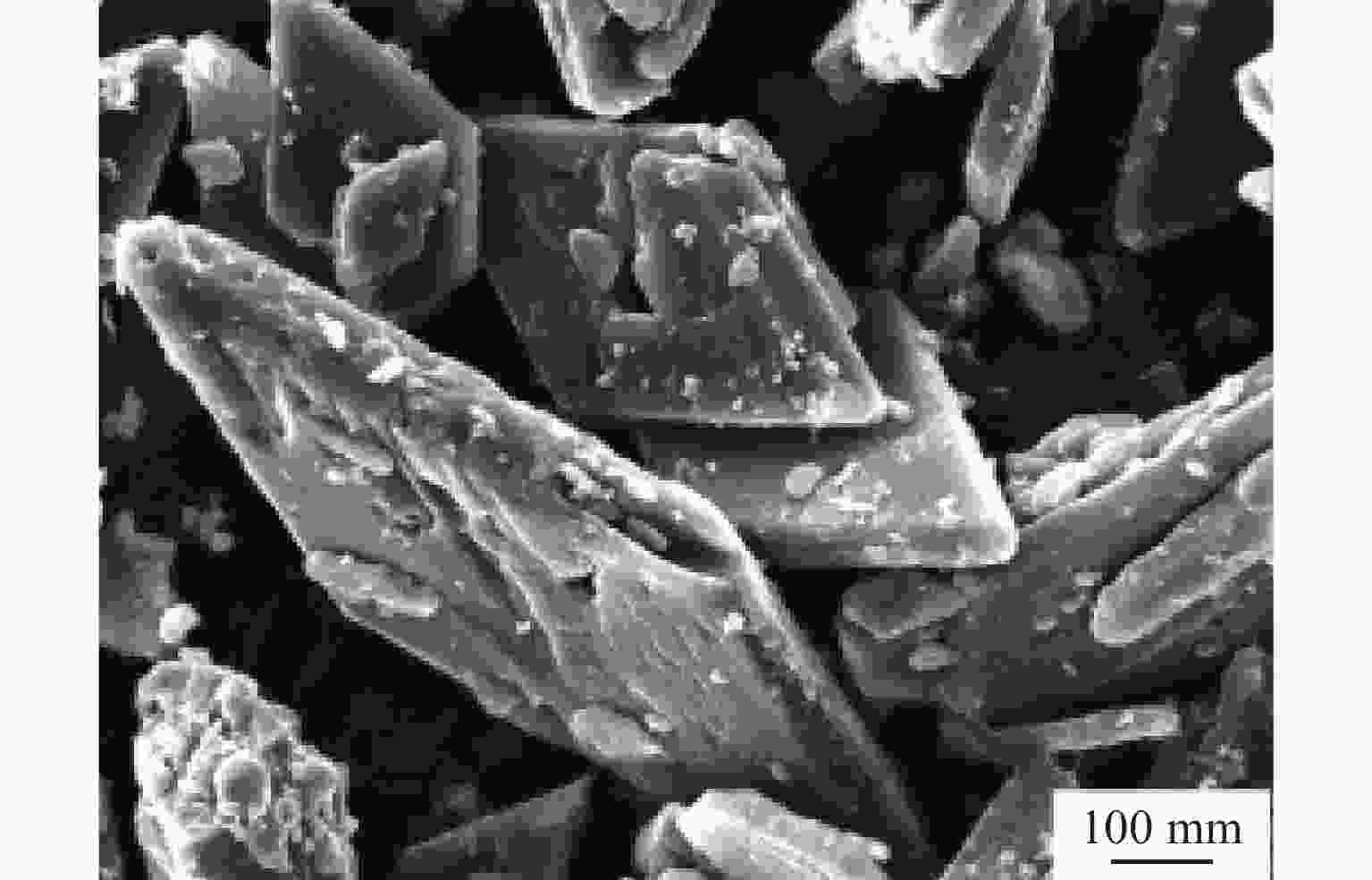

摘要: 以磷石膏高温高压实验及其改性处理为重点研究内容,探讨了高温高压条件对磷石膏单一体系和磷石膏复合体系的影响。通过控制高温高压实验条件,探究不同磷石膏体系在300 ℃、300 MPa的温压条件下的晶体形貌及矿物组成。采用X射线衍射(XRD)、扫描电子显微镜(SEM)对合成样品的物相和形貌进行分析。XRD表征结果表明,在高温高压条件下,不同磷石膏体系的矿物种类及含量发生了明显变化,具体表现为:磷石膏-生石灰复合体系经高温高压实验后,其SiO2含量低于检测限;磷石膏-硅藻土复合体系经高温高压实验后,其矿物由二水石膏全部转化为无水石膏。SEM表征结果显示:在磷石膏单一体系、磷石膏-生石灰复合体系、磷石膏-硅灰复合体系、磷石膏-水泥复合体系中,磷石膏晶体在高温高压下可在反应釜内自发生长结晶,形貌规整且分散均匀,晶形大多呈四棱柱状,晶体表面光滑,且出现团聚现象。磷石膏-硅藻土复合体系在高温高压条件下生成大量的硫酸钙晶须,其形貌规整、分散均匀,平均直径为 2.61 μm,平均长径比约为8。Abstract: In this paper, the effects of high temperature and high pressure on single system and composite system of phosphogypsum were studied. By controlling the experimental conditions of high temperature and high pressure, the crystal morphology and mineral composition of different phosphogypsum systems at 300 ℃ and 300 MPa were studied. The phase and morphology of the synthesized samples were analyzed by X-ray diffraction (XRD) and scanning electron microscopy (SEM). XRD characterization results show that the mineral types and contents of different phosphogypsum systems were changed significantly under high temperature and high pressure. The specific performance is as follows: after high temperature and high pressure test, the SiO2 content of phosphogypsum-quicklime composite system is lower than the detection limit; after high temperature and high pressure test, the mineral of phosphogypsum-diatomite composite system is completely transformed from dihydrate gypsum to anhydrous gypsum. SEM characterization results show that: in single phosphogypsum system, phosphogypsum-quicklime composite system, phosphogypsum-silica fume composite system and phosphogypsum-cement composite system, phosphogypsum crystals can spontaneously grow and crystallize in the reactor under high temperature and high pressure, with regular morphology and uniform dispersion. Most of the crystals are tetragonal, with smooth surface and agglomeration. The results show that the morphology of calcium sulfate whiskers is regular and uniform, the average diameter is 2.61 μm, and the average aspect ratio is about 8.

-

Key words:

- phosphogypsum /

- high temperature and high pressure /

- admixture /

- calcium sulfate whisker /

- aspect ratio

-

表 1 磷石膏的化学成分及含量(质量分数)[24]

Table 1. Chemical composition and content of phosphogypsum (Mass fraction)[24]

% CaO Fe2O3 Al2O3 SiO2 SO3 MgO P2O5 TiO2 CaF2 H2O Other 31.060 0.190 0.520 4.910 42.050 0.131 1.350 0.017 0.780 4.992 14.000 表 2 磷石膏基复合体系配料

Table 2. Ingredients of phosphogypsum based composite system

Sample Mixed ingredients A Phosphogypsum B 95% phosphogypsum + 5% quicklime powder C 90% phosphogypsum + 10% silica fume D 90% phosphogypsum + 10% portland cement E 90% phosphogypsum + 10% diatomite 表 3 磷石膏复合体系的矿物成分

Table 3. Mineral composition of phosphogypsum composite system

Sample Mass fraction/% CaSO4·2H2O SiO2 CaSO4 A 2.2 6.8 91.0 B 4.6 0 95.4 C 5.4 6.4 88.3 D 1.5 0.8 97.8 E 0 10.3 89.7 -

[1] ATTAR L A, AL-OUDAT M, KANAKRI S, et al. Radiological impacts of phosphogypsum [J]. Journal of Environmental Management, 2011, 92(9): 2151–2158. doi: 10.1016/j.jenvman.2011.03.041 [2] 夏海建. 磷石膏渣场池水循环利用过程中防堵塞技术研究[D]. 武汉: 武汉工程大学, 2015.XIA H J. The study on the technology of preventing blockage in recirculating water systems of phosphogypsum stacking [D]. Wuhan: Wuhan Institute of Technology, 2015. [3] 王河, 吴维兴, 赵谊, 等. 磷石膏防渗渣场污水控制关键技术研究 [J]. 磷肥与复肥, 2019, 34(12): 36–39. doi: 10.3969/j.issn.1007-6220.2019.12.014WANG H, WU W X, ZHAO Y, et al. Research on key technology of sewage control in anti-seepage field for phosphogypsum [J]. Phosphate and Compound Fertilizer, 2019, 34(12): 36–39. doi: 10.3969/j.issn.1007-6220.2019.12.014 [4] TIAN T, YAN Y, HU Z H, et al. Utilization of original phosphogypsum for the preparation of foam concrete [J]. Construction and Building Materials, 2016, 115: 143–152. doi: 10.1016/j.conbuildmat.2016.04.028 [5] MACÍAS F, CÁNOVAS C R, CRUZ-HERNÁNDEZ P, et al. An anomalous metal-rich phosphogypsum: characterization and classification according to international regulations [J]. Journal of Hazardous Materials, 2017, 331: 99–108. doi: 10.1016/j.jhazmat.2017.02.015 [6] 刘骥, 唐小春, 韦显文, 等. 浅谈磷石膏对水泥性能的影响 [J]. 企业科技与发展, 2020(9): 82–83. doi: 10.3969/j.issn.1674-0688.2020.09.035LIU J, TANG X C, WEI X W, et al. Influence of phosphogypsum on cement properties [J]. Sci-Tech and Development of Enterprise, 2020(9): 82–83. doi: 10.3969/j.issn.1674-0688.2020.09.035 [7] 付强强, 沈彦辉, 陈宏坤, 等. 磷石膏综合利用现状及建议 [J]. 磷肥与复肥, 2020, 35(8): 44–46. doi: 10.3969/j.issn.1007-6220.2020.08.014FU Q Q, SHEN Y H, CHEN H K, et al. Present situation and suggestions of comprehensive utilization of phosphogypsum [J]. Phosphate and Compound Fertilizer, 2020, 35(8): 44–46. doi: 10.3969/j.issn.1007-6220.2020.08.014 [8] PAPASTEFANOU C, STOULOS S, IOANNIDOU A, et al. The application of phosphogypsum in agriculture and the radiological impact [J]. Journal of Environmental Radioactivity, 2006, 89(2): 188–198. doi: 10.1016/j.jenvrad.2006.05.005 [9] 张富存, 吴洪生, 周晓冬, 等. 磷石膏资源化利用对玉米生长影响 [J]. 西南农业学报, 2012, 25(2): 566–570. doi: 10.3969/j.issn.1001-4829.2012.02.043ZHANG F C, WU H S, ZHOU X D, et al. Effect of recycling and reuse of phosphogypsum on corn growth [J]. Southwest China Journal of Agricultural Sciences, 2012, 25(2): 566–570. doi: 10.3969/j.issn.1001-4829.2012.02.043 [10] 李季, 吴洪生, 高志球, 等. 磷石膏对麦田CO2排放和小麦产量的影响及其经济环境效益分析 [J]. 环境科学, 2015, 36(8): 3099–3105. doi: 10.13227/j.hjkx.2015.08.051LI J, WU H S, GAO Z Q, et al. Impact of phosphogypsum wastes on the wheat growth and CO2 emissions and evanuation of economic-environmental benefit [J]. Environmental Science, 2015, 36(8): 3099–3105. doi: 10.13227/j.hjkx.2015.08.051 [11] SHEN W G, GAN G J, DONG R, et al. Utilization of solidified phosphogypsum as Portland cement retarder [J]. Journal of Material Cycles and Waste Management, 2012, 14(3): 228–233. doi: 10.1007/s10163-012-0065-x [12] 贾兴文, 吴洲, 马英. 磷石膏建材资源化利用现状 [J]. 材料导报, 2013, 27(23): 139–141, 146.JIA X W, WU Z, MA Y. Present status of phosphogypsum utilization in building materials [J]. Materials Review, 2013, 27(23): 139–141, 146. [13] 谭明洋, 张西兴, 相利学, 等. 磷石膏作水泥缓凝剂的研究进展 [J]. 无机盐工业, 2016, 48(7): 4–6.TAN M Y, ZHANG X X, XIANG L X, et al. Research progress of phosphorus gypsum as cement retarder [J]. Inorganic Chemicals Industry, 2016, 48(7): 4–6. [14] 谢占金, 石文建, 金翠霞, 等. 晶种及晶型助长剂对磷石膏制备硫酸钙晶须的影响 [J]. 环境工程学报, 2012, 6(4): 1348–1352.XIE Z J, SHI W J, JIN C X, et al. Effect of crystal seed and crystal promoter on the preparation of calcium sulphate whiskers using phosphogypsum [J]. Chinese Journal of Environmental Engineering, 2012, 6(4): 1348–1352. [15] 杨荣华, 宋锡高. 磷石膏的净化处理及制备硫酸钙晶须的研究 [J]. 无机盐工业, 2012, 44(4): 31–34. doi: 10.3969/j.issn.1006-4990.2012.04.011YANG R H, SONG X G. Research on purification of phosphogypsum and preparation of calcium sulfate whisker [J]. Inorganic Chemicals Industry, 2012, 44(4): 31–34. doi: 10.3969/j.issn.1006-4990.2012.04.011 [16] SHENG Z M, ZHOU J, SHU Z, et al. Calcium sulfate whisker reinforced non-fired ceramic tiles prepared from phosphogypsum [J]. Boletín de la Sociedad Española de Cerámicay Vidrio, 2018, 57(2): 73–78. doi: 10.1016/j.bsecv.2017.09.005 [17] TAYIBI H, CHOURA M, LÓPEZ F A, et al. Environmental impact and management of phosphogypsum [J]. Journal of Environmental Management, 2009, 90(8): 2377–2386. doi: 10.1016/j.jenvman.2009.03.007 [18] 王慧媛, 郑海飞. 高温高压实验及原位测量技术 [J]. 地学前缘, 2009, 16(1): 17–26. doi: 10.3321/j.issn:1005-2321.2009.01.004WANG H Y, ZHENG H F. High pressure-temperature experiment and in-situ measurement technology [J]. Earth Science Frontiers, 2009, 16(1): 17–26. doi: 10.3321/j.issn:1005-2321.2009.01.004 [19] MCMILLAN P F. New materials from high-pressure experiments [J]. Nature Materials, 2002, 1(1): 19–25. doi: 10.1038/nmat716 [20] 余光, 柯龙华, 叶友章. 高温高压制备微晶纤维素新工艺的研究 [J]. 福建林业科技, 2010, 37(4): 58–61. doi: 10.3969/j.issn.1002-7351.2010.04.012YU G, KE L H, YE Y Z. Study on the new process of microcrystalline cellulose in high temperature and pressure [J]. Journal of Fujian Forestry Science and Technology, 2010, 37(4): 58–61. doi: 10.3969/j.issn.1002-7351.2010.04.012 [21] 陶强, 王欣, 崔田, 等. 钼-硼化合物的高温高压制备及硬度特性探索[C]//第十四届全国物理力学学术会议缩编文集. 绵阳: 中国力学学会, 2016.TAO Q, WANG X, CUI T, et al. Preparation of molybdenum boron compounds at high temperature and high pressure and exploration of their hardness characteristics [C]//Abstracts of the 14th National Conference on Physical Mechanics. Mianyang: Chinese Society of Mechanics, 2016. [22] 侯领, 沈维霞, 房超, 等. 高导热金刚石/铝复合材料的高温高压制备 [J]. 高压物理学报, 2020, 34(5): 053101. doi: 10.11858/gywlxb.20200514HOU L, SHEN W X, FANG C, et al. High thermal conductivity of diamond/Al composites via high pressure and high temperature sintering [J]. Chinese Journal of High Pressure Physics, 2020, 34(5): 053101. doi: 10.11858/gywlxb.20200514 [23] 贾晓鹏. 类天然金刚石的高温高压合成研究 [J]. 原子与分子物理学报, 2020, 37(6): 909–915. doi: 10.19855/j.1000-0364.2020.064001JIA X P. Study on the synthesis of “natural” diamond at high temperature and high pressure [J]. Journal of Atomic and Molecular Physics, 2020, 37(6): 909–915. doi: 10.19855/j.1000-0364.2020.064001 [24] 刘江, 杨红艳, 石文建, 等. 磷石膏水热法合成硫酸钙晶须 [J]. 化工环保, 2014, 34(2): 141–144. doi: 10.3969/j.issn.1006-1878.2014.02.011LIU J, YANG H Y, SHI W J, et al. Synthesis of calcium sulphate whisker from phosphogypsum by hydrothermal method [J]. Environmental Protection of Chemical Industry, 2014, 34(2): 141–144. doi: 10.3969/j.issn.1006-1878.2014.02.011 [25] 李箫, 王莹, 万惠文, 等. 磷石膏制建筑石膏的试验研究 [J]. 武汉理工大学学报, 2015, 37(12): 40–46.LI X, WANG Y, WAN H W, et al. Experimental study on the gypsum preparation by the phosphogypsum [J]. Journal of Wuhan University of Technology, 2015, 37(12): 40–46. [26] 熊春杨, 吕淑珍, 牛云辉, 等. 四川某地磷石膏制备建筑石膏及其性能研究 [J]. 非金属矿, 2020, 43(3): 33–36. doi: 10.3969/j.issn.1000-8098.2020.03.009XIONG C Y, LÜ S Z, NIU Y H, et al. Preparation of building gypsum from phosphogypsum in Sichuan and its properties [J]. Non-Metallic Mines, 2020, 43(3): 33–36. doi: 10.3969/j.issn.1000-8098.2020.03.009 [27] 耿乾, 孙红娟, 彭同江, 等. 焙烧与生石灰改性对磷石膏中可溶磷含量的影响 [J]. 矿产保护与利用, 2019, 39(4): 9–13, 82. doi: 10.13779/j.cnki.issn1001-0076.2019.04.002GENG Q, SUN H J, PENG T J, et al. Effect of roasting and quicklime modification on soluble phosphorus content in phosphogypsum [J]. Conservation and Utilization of Mineral Resources, 2019, 39(4): 9–13, 82. doi: 10.13779/j.cnki.issn1001-0076.2019.04.002 [28] 万惠文, 王银, 戴鹏, 等. 磷石膏/矿粉复合过硫胶凝材料的制备研究 [J]. 武汉理工大学学报, 2014, 36(3): 23–27.WAN H W, WANG Y, DAI P, et al. Study of phosphogysum/slag compound persulfate cementitious material [J]. Journal of Wuhan University of Technology, 2014, 36(3): 23–27. -

下载:

下载: