Mechanical Property and Failure Mechanism of Composite Laminates Containing a Circular Hole under Tension

-

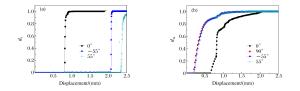

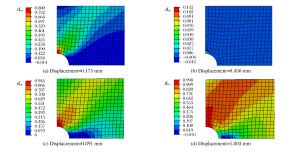

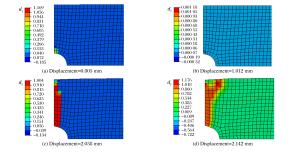

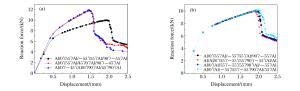

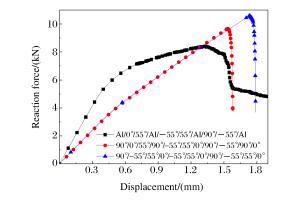

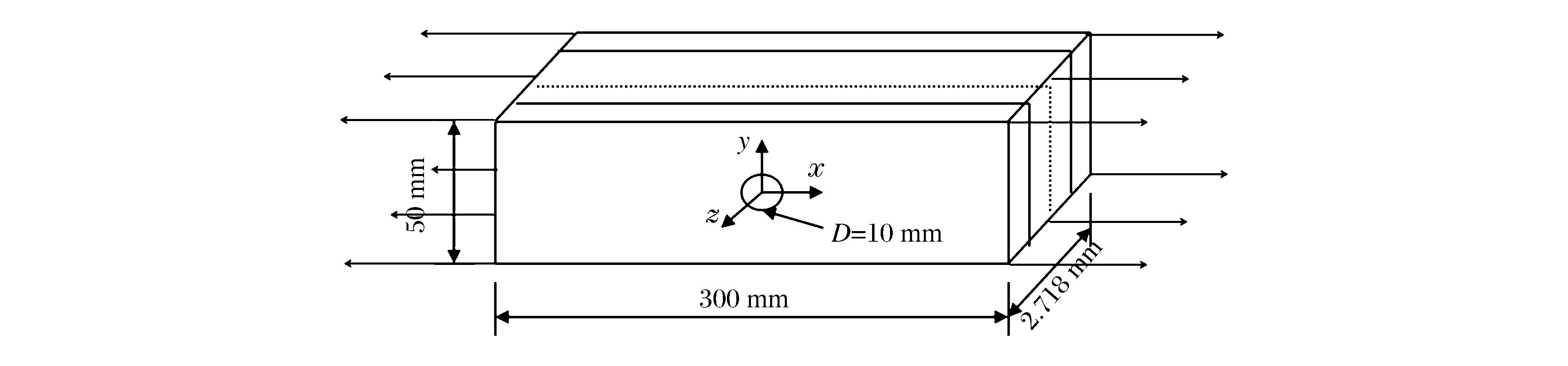

摘要: 采用有限元软件ABAQUS,基于前人提出的失效准则,通过引入纤维损伤因子和基体损伤因子并编制用户材料子程序UMAT,建立了含孔复合材料层合板的三维渐进损伤破坏模型。利用该损伤破坏模型,研究了在轴向拉伸载荷作用下不同圆孔直径和铺层角度的复合材料层合板的纤维和基体的渐进损伤失效过程及规律。结果表明:不同铺层角度条件下,纤维和基体的损伤失效差别较大;圆孔直径和铺设角度对含孔复合材料层合板的失效破坏载荷的影响十分显著,而铺设顺序和开孔位置对失效破坏载荷的影响较小。建立的失效破坏模型能有效地分析层合板的渐进失效破坏过程,为层合板的工程应用和设计提供有益的参考。Abstract: In order to set up a three dimensional damage model for composite laminates with a circular hole, based on the failure criteria proposed by Linde et al., we at first implemented the user-defined material subroutine UMAT in the finite element code ABAQUS using the factors of fiber and matrix to characterize the gradual degradation of material.Then we used the damage model to study the mechanical property and failure mechanism of composite laminates with different ply angels, stacking sequences, hole diameters or positions subjected to uniaxial tension.The results show that the damage factors of the fiber and matrix varied differently for plies with different ply angels.In addition, the hole diameter and ply angle have significant effects on the reaction force of the composite laminates, while the influence of the hole position and stacking sequence of plies are much smaller.Our model can be used to predict qualitatively and quantitatively the progressive failure behavior of composite laminates under tension, thus it can serve as a reference for engineering application and design of composite laminates.

-

Key words:

- composite laminates /

- damage mechanics /

- progressive failure analysis /

- numerical simulation /

- UMAT

-

表 1 铝的材料参数

Table 1. Isotropic hardening data for aluminum

σY/(MPa) εp/(%) 300 0 320 0.016 340 0.047 355 0.119 375 0.449 390 1.036 410 2.130 430 3.439 450 5.133 470 8.000 484 14.710 表 2 层合板的弹性性能及损伤性能参数

Table 2. Orthotropic elastic and damage properties of fiber-enforced epoxy

EL/(GPa) ET/(GPa) GLT/(GPa) GTT/(GPa) νTT νLT σLf, t/(GPa) σLf, c/(GPa) σTf, t/(MPa) σTf, c/(MPa) τLTf/(MPa) 55 9.5 5.5 3 0.45 0.33 2.5 2 50 150 50 -

[1] 杜善义, 关志东.我国大型客机先进复合材料应对策略思考[J].复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU S Y, GUAN Z D.Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001 [2] MOURE M M, GARCIA-CASTILLO S K, SANCHEZ-SAEZ S, et al.Influence of ply cluster thickness and location on matrix cracking evolution in open-hole composite laminates[J]. Compos Part B-Eng, 2016, 95:40-47. doi: 10.1016/j.compositesb.2016.03.091 [3] 杜善义.先进复合材料与航空航天[J].复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y.Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001 [4] 卓越, 关志东, 周睿, 等.复合材料开孔层板压缩渐进损伤试验[J].复合材料学报, 2015, 32(6):1762-1768. http://d.old.wanfangdata.com.cn/Periodical/fhclxb201506028ZHUO Y, GUAN Z D, ZHOU R, et al.Test on progressive damage of open-hole composite laminates under compression load[J]. Acta Materiae Compositae Sinica, 2015, 32(6):1762-1768. http://d.old.wanfangdata.com.cn/Periodical/fhclxb201506028 [5] 韩小平, 郭章新, 朱西平, 等.含孔复合材料层合板孔边的应力集中[J].复合材料学报, 2009, 26(1):168-173. doi: 10.3321/j.issn:1000-3851.2009.01.029HAN X P, GUO Z X, ZHU X P, et al.Stress distribution near the opening and stress concentration for composite laminates with a circular opening[J]. Acta Materiae Compositae Sinica, 2009, 26(1):168-173. doi: 10.3321/j.issn:1000-3851.2009.01.029 [6] 孙旋, 童明波, 陈智, 等.碳纤维复合材料接头力学性能试验与仿真分析[J].复合材料学报, 2016, 33(11):2517-2527. http://d.old.wanfangdata.com.cn/Periodical/fhclxb201611015SUN X, TONG M B, CHEN Z, et al.Test and simulation analysis of mechanical properties for joint of carbon fiber composites[J]. Acta Materiae Compositae Sinica, 2016, 33(11):2517-2527. http://d.old.wanfangdata.com.cn/Periodical/fhclxb201611015 [7] 韩小平, 郭章新, 王彬, 等.含孔层合板孔口缝合补强的数值模拟[J].复合材料学报, 2011, 28(3):148-153. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yylxxb200904037HAN X P, GUO Z X, WANG B, et al.Numerical simulations of the effect of stitching reinforcement on composite laminates with a circular hole[J]. Acta Materiae Compositae Sinica, 2011, 28(3):148-153. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yylxxb200904037 [8] GUO Z X, HAN X P, ZHU X P.Finite element analysis of interlaminar stresses for composite laminates stitched around a circular hole[J]. Appl Compos Mater, 2012, 19:561-571. doi: 10.1007/s10443-011-9234-7 [9] CARLSSON L.Interlaminar stresses at a hole in a composite member subjected to in-plane loading[J]. J Compos Mater, 1991, 17(3):238-249. doi: 10.1177-002199838301700305/ [10] MAA R H, CHENG J H.A CDM-based failure model for predicting strength of notched composite laminates[J].Compos Part B-Eng, 2002, 33(6):479-489. doi: 10.1016/S1359-8368(02)00030-6 [11] DAI S, CUNNINGHAM P R, MARSHALL S, et al.Open hole quasi-static and fatigue characterisation of 3D woven composites[J]. Compos Struct, 2015, 131:765-774. doi: 10.1016/j.compstruct.2015.06.032 [12] GAO X, YU G, XUE J, et al.Failure analysis of C/SiC composites plate with a hole by the PFA and DIC method[J]. Ceram Int, 2017. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=c371452838531c8f6dee86b7421b10b3 [13] TANG Y L, ZHOU Z G, PAN S D, et al.Mechanical property and failure mechanism of 3D carbon-carbon braided composites bolted joints under unidirectional tensile loading[J]. Mater Design, 2015, 65:243-253. doi: 10.1016/j.matdes.2014.08.073 [14] 昌磊, 李书欣, 丁安心, 等.基于Zinoviev理论的含孔复合材料层合板三维有限元渐进失效分析[J].玻璃钢/复合材料, 2016(8):44-49. doi: 10.3969/j.issn.1003-0999.2016.08.007CHANG L, LI S X, DING A X, et al.3D finite element method progressive damage analysis for the open-hole laminates based on zinoviev theory[J]. Fiber Reinforced Plastics/Composites, 2016(8):44-49. doi: 10.3969/j.issn.1003-0999.2016.08.007 [15] 肖梦丽, 张勇波, 王治华, 等.分层损伤对含孔复合材料层合板剩余强度影响[J].航空动力学报, 2016, 31(5):1081-1086. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201605008XIAO M L, ZHANG Y B, WANG Z H, et al.Effect analysis of delamination damage on the residual strength of notched composite laminates[J]. Journal of Aerospace Power, 2016, 31(5):1081-1086. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201605008 [16] TAN S C.A progressive failure model for composite laminates containing opening[J]. J Compos Mater, 1991, 25(5):556-577. doi: 10.1177/002199839102500505 [17] RAMAKRISHNAN V, JAYARAMAN N.Mechanistically based fatigue-damage evolution model for brittle matrix fibre-reinforced composites[J]. J Mater Sci, 1993, 28(20):5592-5602. doi: 10.1007/BF00367835 [18] SHIRAZI A, VARVANI-FARAHANI A.A stiffness degradation based fatigue damage model for FRP composites of (0/θ) laminate systems[J]. Appl Compos Mater, 2010, 17(2):137-150. doi: 10.1007/s10443-009-9099-1 [19] 黎增山, 关志东, 何为, 等.复合材料层板开孔拉伸损伤分析[J].复合材料学报, 2012, 29(1):169-175. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201200146821LI Z S, GUAN Z D, HE W, et al.Damage analysis of open-hole tension laminates[J]. Acta Materiae Compositae Sinica, 2012, 29(1):169-175. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201200146821 [20] GUAN Z, YANG C.Low-velocity impact and damage process of composite laminates[J]. J Compos Mater, 2002, 36(7):851-871. doi: 10.1177/0021998302036007512 [21] 崔海涛, 郝勇, 温卫东.含孔复合材料层合板逐渐损伤破坏分析[J].理化检验:物理分册, 2002, 38(4):150-153. http://d.old.wanfangdata.com.cn/Periodical/lhjy-wl200204005CUI H T, HAO Y, WEN W D.Accumulative damage and failure analysis of laminated composites with hole[J]. Physical Testing and Chemical Analysis Part A:Physical Testing, 2002, 38(4):150-153. http://d.old.wanfangdata.com.cn/Periodical/lhjy-wl200204005 [22] 郑君, 温卫东, 崔海涛.2.5维机织复合材料强度准则[J].材料科学与工程学报, 2012, 30(5):672-676. http://d.old.wanfangdata.com.cn/Periodical/clkxygc201205005ZHENG J, WEN W D, CUI H T.Failure criteria of 2.5D woven composites[J]. Journal of Materials Science and Engineering, 2012, 30(5):672-676. http://d.old.wanfangdata.com.cn/Periodical/clkxygc201205005 [23] 王丹勇, 温卫东, 崔海涛.含孔复合材料层合板静拉伸三维逐渐损伤分析[J].力学学报, 2005, 37(6):788-794. http://d.old.wanfangdata.com.cn/Periodical/lxxb200506017WANG D Y, WEN W D, CUI H T.Three-dimensional progressive damage analysis of composite laminates containing a hole subjected to tensile loading[J]. Acta Mechanica Sinica, 2005, 37(6):788-795. http://d.old.wanfangdata.com.cn/Periodical/lxxb200506017 [24] LINDE P, PLEITER J, BOER H D.Modeling and simulation of fiber metal laminates[C]//ABAQUS User's Conference.Boston: Massachusetts, 2004: 421-439. https://www.researchgate.net/publication/266268763_Modelling_and_Simulation_of_Fibre_Metal_Laminates -

下载:

下载: