Preliminary Experiment Exploring for Improving Pressure Limit of Two-Stage Hydrostatic High-Pressure Apparatus Using Confining Pressure

-

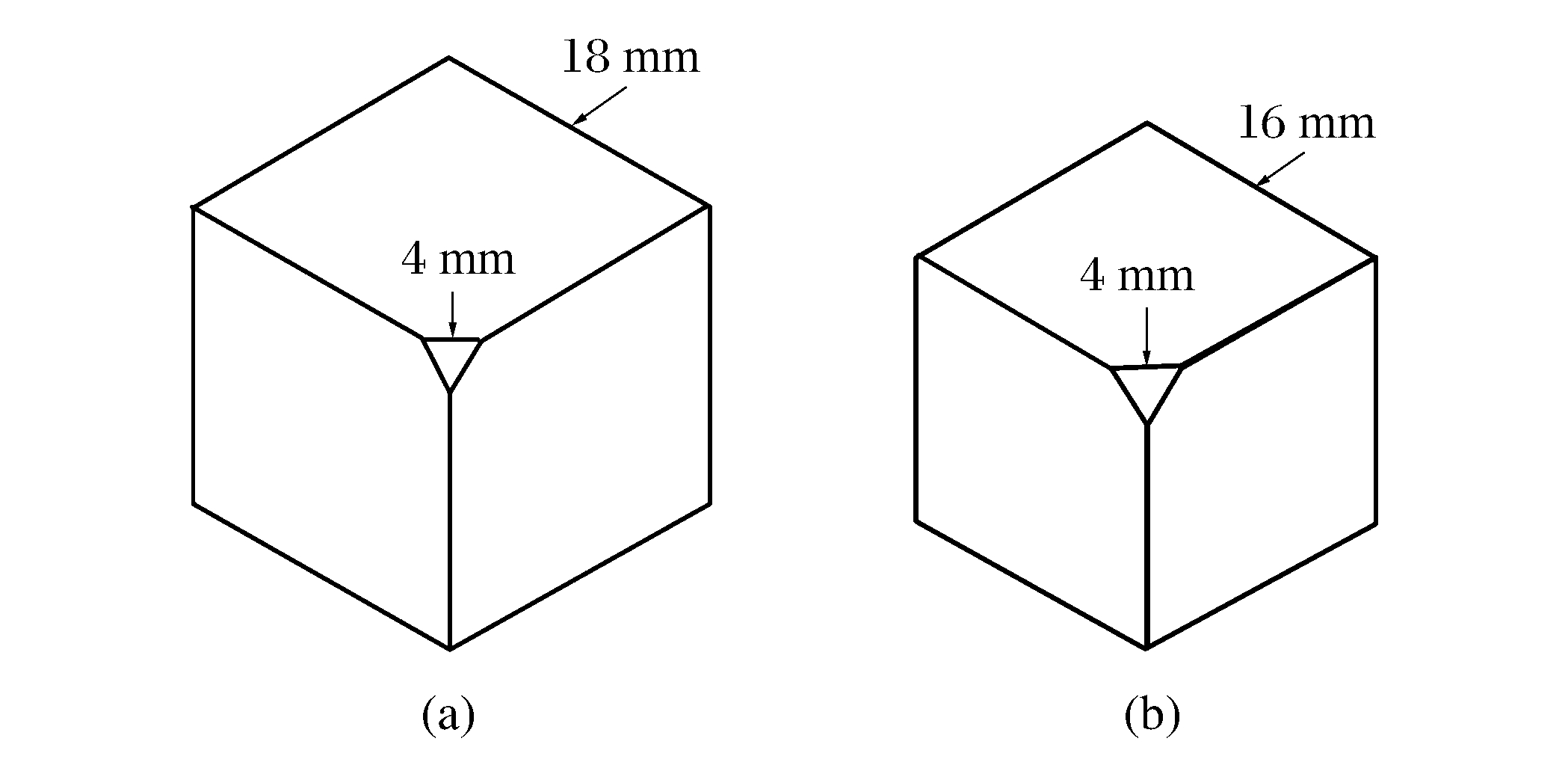

摘要: 采用基于国产铰链式六面顶压机二级6-8型大腔体静高压装置中的10/4(即八面体传压介质边长为10 mm, 二级WC-Co硬质合金立方块截角边长为4 mm)组装,选择不同的围压材料和传压硬质合金台棱、圆片,在室温下用ZnTe的高压相变对压腔进行了压力标定。实验结果表明,叶蜡石是较合适的围压材料; 但由于传压台棱、圆片自身强度的限制,及一级压腔形成的围压值较低等原因, 致使实验没有达到预期的末级压砧围压增强效果。通过结合两种压腔的力学简化模型分析得知,围压材料与二级增压装置的预密封边共同形成了二级压腔的密封边,该大面积密封边消耗了系统的大部分加载力,因此在围压实验中没有观测到二级6-8型大腔体静高压装置压力极限的提高。Abstract: In this study, we choose different confining pressure materials, pressure transmitting WC-Co platforms and WC-Co wafers, to calibrate pressure of 10/4 (The edge length of octahedral transmitting pressure medium is 10 mm/the truncated angle edge length of WC-Co cemented carbide anvil is 4 mm) assembly of two-stage 6-8 type hydrostatic high-pressure apparatus based on the hinge-type cubic-anvil 6×8 MN press at room temperature, using phase transition of ZnTe under high pressure.The experimental results show that the pyrophyllite is a relatively ideal confining pressure material, but it can not pressurize obviously because of the strength limitations of platforms and wafers.By combining simplified mechanics model of 2 kinds of presses, we also find out that the large-area gasket, formed by pre-gasket and initial confining pressure material together, consumes most of the loading, and the gap is oversized between the first anvils.Therefore, we did not observe any improvement of the 10/4 assembly pressure limit in our experiments.

-

表 1 基于6×14 MN六面顶压机, 相同油压下对应的实际压力、理想压力及压力损失率

Table 1. Actual pressure, ideal pressure and pressure loss ratio at the same oil pressure based on cubic-anvil 6×14 MN press

Oil

pressure/

(MPa)Actual

pressure/

(GPa)Ideal

pressure/

(GPa)Pressure

loss ratio/

(%)40 5.0 10.00 50.0 25 3.7 6.25 41.0 15 2.5 3.75 33.3 表 2 基于6×8 MN压机二级6-8型大腔体高压装置的标准10/4组装, 相同油压下的实际压力、理想压力及压力损失率

Table 2. Actual pressure, ideal pressure and pressure loss ratio at the same oil pressure employing standard 10/4 assemble of two-stage 6-8 type pressure apparatus based on the domestic cubic-anvil 6×8 MN press

Oil pressure/(MPa) Actual pressure/(GPa) Ideal pressure/(GPa) Percentage of pressure loss/(%) 33 18.8 165 89 22 15.6 110 86 16 11.5-13.0 80 84 12 8.5-9.2 60 84 6 5.0 30 83 -

[1] Fukura S, Nakagawa T, Kaga H. High spatial resolution photoluminescence and Raman spectroscopic measurements of a natural polycrystalline diamond and carbonado[J]. Diamond Relat Mater, 2005, 14(11): 1950-1954. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=84bf34b894c66492a350f411a1dea260 [2] Hemley R J, Soos Z G, Hanfland M, et al. Charge-transfer states in dense hydrogen charge-transfer states in dense hydrogen[J]. Nature, 1994, 369: 384-391. doi: 10.1038/369384a0 [3] Ma Y, Eremets M, Oganov A R, et al. Transparent dense sodium[J]. Nature, 2009, 458: 182-185. doi: 10.1038/nature07786 [4] Oganov A R, Ono S. Theoretical and experimental evidence for a post-perovskite phase of MgSiO3 in earth's D″ layer[J]. Nature, 2004, 430: 445-448. doi: 10.1038/nature02701 [5] Qin J Q, He D W, Wang J H, et al. Is rhenium diboride a superhard material?[J]. Adv Mater, 2008, 20(24): 4780-4783. doi: 10.1002/adma.200801471 [6] Tian Y J, Xu B, Yu D L, et al. Ultrahard nanotwinned cubic boron nitride[J]. Nature, 2013, 493: 385-493. doi: 10.1038/nature11728 [7] Xu C, He D W, Wang H K, et al. Nano-polycrysalline diamond formation under ultrahigh pressure[J]. Int J Refract metals Hard Mater, 2013, 36: 232-237. doi: 10.1016/j.ijrmhm.2012.09.004 [8] Han Q G, Ma H G, Zhou L, et al. Finite element design of double bevel anvils of large volume cubic high pressure apparatus[J]. Rev Sci Instrum, 2007, 78(11): 354-359. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5341ad93d8919691406f19542822cb39 [9] Weidner D J, Wang Y, Vaughat M T. Strength of diamond[J]. Science, 1994, 266(5184): 419-422. doi: 10.1126/science.266.5184.419 [10] Dubrovinsky L, Dubrovinskaia N. Implementation of micro-ball nanodiamond anvils for high-pressure studies above 6 Mbar[J]. Nat Commun, 2012, 3: 1163-1166. doi: 10.1038/ncomms2160 [11] 王文丹, 贺端威, 王海阔, 等.二级6-8型大腔体装置的高压发生效率机理研究[J].物理学报, 2010, 59(5): 3107-3115. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb201005030Wang W D, He D W, Wang H K, et al. Reaserch on pressure generation efficiency of 6-8 type multianvil high pressure apparatus[J]. Acta Phys Sin, 2010, 59(5): 3107-3015. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb201005030 [12] Gao C X, Han Y H, MA Y Z, et al. Accurate measurements of high pressure resistivity in a diamond anvil cell[J]. Rev Sci Instrum, 2005, 76(8): 1035-1039. [13] Liu L G. Disproportionation of kyanite to corundum plus stishovite at high pressure and temperature[J]. Earth Planet Sci Lett, 1974, 24(2): 224-228. [14] Liu X, Shieh S R, Fleet M E, et al. High-pressure study on lead fluorapatite[J]. Am Miner, 2008, 93(10): 1581-1584. doi: 10.2138/am.2008.2816 [15] Khvostantsev L G. A verkh-niz(up-down)toroid device for generation of high pressure[J]. High Temp High press, 1984, 16(2): 165-169. [16] Sverjensky D A. Europium redox equilibria in aqueous solution[J]. Earth Planet Sci Lett, 1984, 67(1): 70-78. [17] Syono Y, Manghani M H. High-Pressure Research: Application to Earth and Planetary Sciences[M]. Washington: AGU, 1992: 19. [18] Dobson D P, Ju L M, Alfe D, et al. A new belt-type apparatus for neutron-based rheological measurements at gigapascal pressures[J]. High Press Res, 2005, 25(2): 107-118. doi: 10.1080/08957950500143500 [19] Tange Y, Irifune T, Funakoshi I. Pressure generation to 80 GPa using multianvil apparatus with sintered diamond anvils[J]. High Press Res, 2008, 28(3): 245-54. doi: 10.1080/08957950802208936 [20] Kunimoto T, Irifune T. Pressure generation to 125 GPa using a 6-8-2 type multianvil apparatus with nano-polycrystalline diamond anvils[J]. J Phys: Condens Mater, 2010, 25(1): 2150-2160. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Open J-Gate000001850854 [21] 贺端威, 王福龙, 寇自力, 等.用于产生超高压的新型装置: 中国, 200710048839.2[P]. 2007-10-16.He D W, Wang F L, Kou Z L, et al. New device used to produce ultra high pressur: China, 2007, 200710048839.2[P]. 2007-10-16. (in Chinese) [22] 王福龙, 贺端威, 房雷鸣, 等.基于铰链式六面顶压机的二级6-8型大腔体静高压装[J].物理学报, 2008, 57: 5429-5434. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb200809014Wang F L, He D W, Fang L M, et al. Design and assembley of split-sphere high pressure apparatus based on the hinge-type cubic-anvil press[J]. Acta Phys Sin, 2008, 57: 5429-5334. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb200809014 [23] Wang H K, He D W, Tan N, et al. Note: An anvil-preformed gasket system to extend the pressure range for large volume cubic presses[J]. Rev Sci Instrum, 2010, 81(11): 1134-1139. [24] Wang H K, He D W, Yan X Z, et al. Quantitative measurements of pressure gradients for the pyrophyllite and magnesium oxide pressure-transmitting mediums to 8 GPa in a large-volume cubic cell[J]. High Press Res, 2011, 31(4): 581-591. doi: 10.1080/08957959.2011.614238 [25] 管俊伟, 贺端威, 王海阔, 等.力学结构及末级压砧硬度对八面体压腔高压发生效率的影响[J].物理学报, 2012, 61(10): 100701. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb201210014Guan J W, He D W, Wang H K, et al. Influence of mechanical configuration and hardness of last stage anvil on high pressure producing efficiency for octahedral cell[J]. Acta Phys sin, 2012, 61: 100701. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wlxb201210014 [26] 王海阔, 贺端威.一种新型大腔体高压装置: 中国, 201110091480.3[P]. 2011-09-21.Wang H K, He D W. A new large-volume high pressure apparatus: China, 201110091480.3[P]. 2011-09-21. (in Chinese) [27] 贺端威, 王海阔, 谭宁, 等.一种顶锤-预密封边高压装置: 中国, 2010101428204.7[P]. 2010-08-18.He D W, Wang H K, Tan N, et al. An anvil-performed gasket appratus: China, 2010101428204.7[P]. 2010-08-18. (in Chinese) [28] 曾绍连, 李卫.碳化钨增强钢铁基耐磨复合材料的研究和应用[J].特种铸造及有色合金, 2007, 27(6): 441-444. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=tzzzjyshj200706011Ceng L S, Li W. Research and application of tungsten carbide reinforced steel matrix wear resistant composite material[J]. Special casting and nonferrous alloys, 2007, 27(6): 441-444. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=tzzzjyshj200706011 [29] 高富强, 杨军, 甯尤军.围压对脆性材料力学性能影响的研究现状[J].有色金属, 2009, 61(2): 46-49. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ysjs-ks200902015Gao F Q, Yang J, Ning Y J. Research status in the effect of confining pressure on brittle material mechanics[J]. Non-ferrous metal, 2009, 61(2): 46-49. (in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ysjs-ks200902015 [30] McWilliams R S, Eggert J H, Hicks D G, et al. Strength effects in diamond under shock compression from 0.1 to 1 TPa[J]. Phys Rev B, 2010, 81(1): 014111. doi: 10.1103/PhysRevB.81.014111 [31] Dubrovinsky L, Dubrovinskaia N, Prakapenka V B, et al. Implementation of micro-ball nanodiamond anvils for high-pressure studies above 640 Mbar[J]. Nat commun, 2012, 3: 1163. doi: 10.1038/ncomms2160 -

下载:

下载: