Loading Rate Effect on Crack Resistance Curves and Their Correlations

-

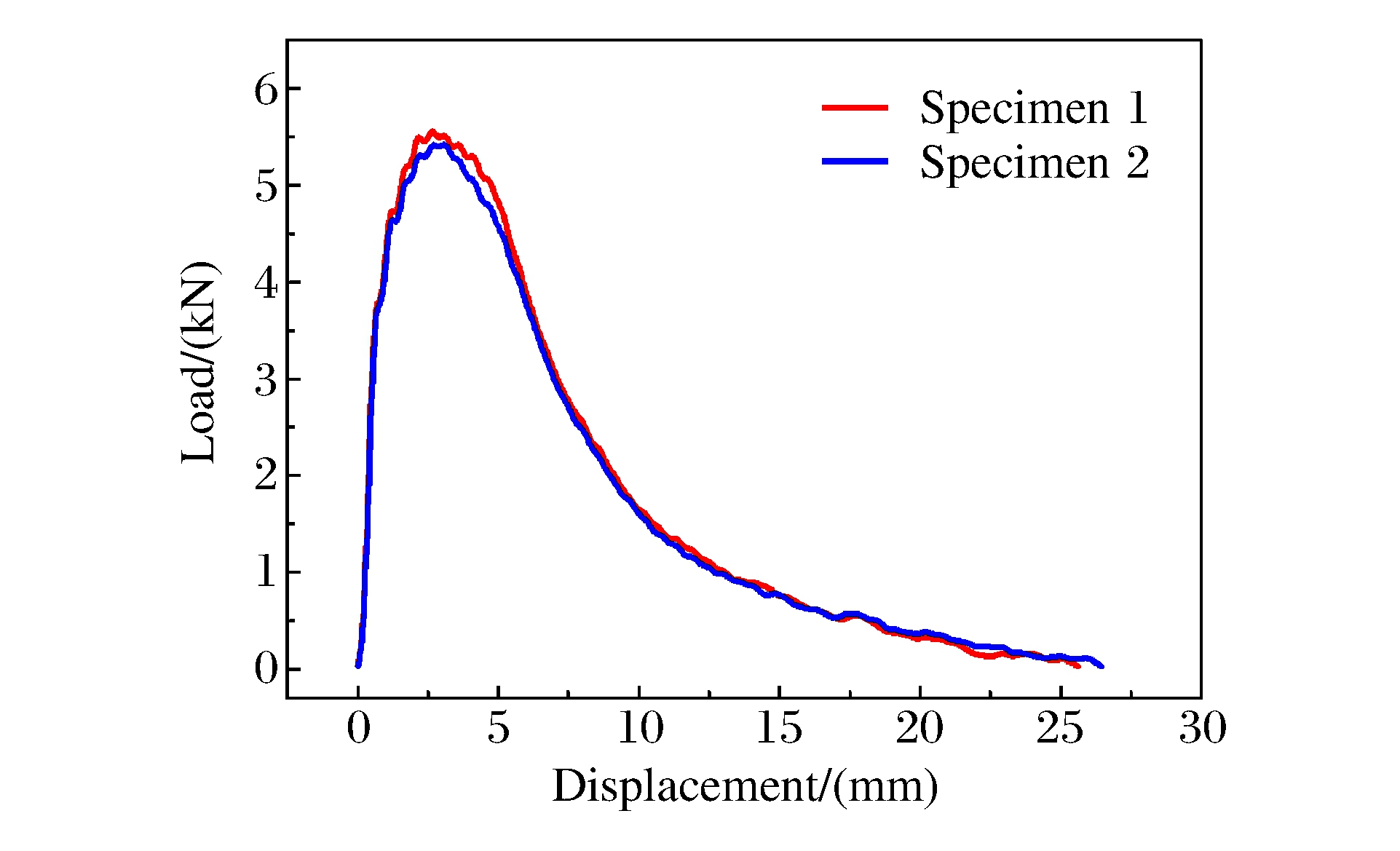

摘要: 对典型压力容器用钢Q345R预制裂纹夏比冲击试样进行示波冲击试验,得到了Q345R钢的载荷-位移曲线,并根据试验数据,利用J积分增量方程和Schindler方法分别计算得到Q345R钢在冲击加载下的动态裂纹扩展阻力曲线(J-R曲线)。然后将动态J-R曲线和准静态加载条件下试验得到的J-R曲线进行对比发现,动态加载条件下的J-R曲线高于准静态加载时得到的结果。最后,建立了动态和准静态加载下J-R曲线之间的关系式,对工程应用具有重要的参考意义。Abstract: Instrumented impact tests are carried out using precrack Charpy specimens of typical pressure vessel steel Q345R, the load-displacement curves are obtained.Based on the test data, the J-integral incremental equation procedure and Schindler method are used to estimate dynamic crack resistance curve of Q345R steel under impact loading respectively.The results of them are compared and verified each other.After comparing the dynamic J-R curve with the qusi-static curve, it is found that the J-R curve under dynamic loading is always higher than that obtained under quasi-static loading.Further analyses of test data lead to an equation which quantitatively describes the relationship between Q345R quasi-static and dynamic crack growth resistance curve.The equation may have important significance in engineering application.

-

表 1 Q345R钢的化学成分

Table 1. Chemical composition of Q345R steel

Element Mass fraction/(%) C 0.150 Si 0.345 Mn 1.450 P 0.014 Cr 0.068 Ni 0.028 Cu 0.094 0 S 0.006 4 Mo 0.009 3 表 2 夏比冲击试样疲劳预制裂纹参数

Table 2. Parameters of fatigue precrack Charpy specimen

Specimen

No.Ratio of

stressMax.fatigue

load/(N)Min.fatigue

load/(N)Cycle

timesFront crack

length/(mm)Back crack

length/(mm)1 0.1 3 000 300 38 000 1.49 1.53 2 0.1 3 000 300 38 000 1.48 1.51 -

[1] Yoon J H, Lee B S, Oh Y J, et al. Effects of loading rate and temperature on J-R fracture resistance of an SA516-Gr. 70 steel for nuclear piping[J]. Int J Pres Ves Pip, 1999, 76(9): 663-670. doi: 10.1016/S0308-0161(99)00033-2 [2] Ritchie R O, Server W L, Wullaert R A. Critical fracture stress and fracture strain models for the prediction of lower and upper shelf toughness in nuclear pressure vessel steels[J]. Metall Trans A, 1979, 10(10): 1557-1570. doi: 10.1007/BF02812022 [3] Barsom J M. Development of the AASHTO fracture toughness requirements for bridge steels[J]. Eng Fract Mech, 1975, 7(3): 605-618. http://www.sciencedirect.com/science/article/pii/0013794475900600 [4] Kobayashi T, Yamada S. Evaluation of static and dynamic fracture toughness in ductile cast iron[J]. Metall Mater Trans A, 1994, 25(11): 2427-2436. doi: 10.1007/BF02648862 [5] Joyce J A, Hacket E M. Dynamic J-R curve testing of a high strength steel using the multispecimen and key curve techniques[J]. ASTM Spec Tech Publ, 1986(905): 741-774. http://www.astm.org/DIGITAL_LIBRARY/STP/PAGES/STP17426S.htm [6] Luna S, Fernndez-sez J, Pérez-Castellanos J L, et al. An analysis of the static and dynamic fracture behaviour of a pipeline steel[J]. Int J Pres Vess Pip, 2000, 77(11): 691-696. doi: 10.1016/S0308-0161(00)00058-2 [7] Tronskar J P, Mannan M A, Lai M O. Correlation between quasi-static and dynamic crack resistance curves[J]. Eng Fract Mech, 2003, 70(12): 1527-1542. doi: 10.1016/S0013-7944(02)00148-0 [8] Turner C E. The umbiquitous η factor[J]. ASTM Spec Tech Publ, 1980(700): 314-337. [9] ASTM. E1820-99. Standard Test Method for Measurement of Fracture Toughness[S]. 1999. [10] 李志安.压力容器断裂理论与缺陷评定[M].大连: 大连理工大学出版社, 1994: 73-76.Li Z A. Pressure Vessel Fracture Mechanics and Defect Assessment[M]. Dalian: Dalian University of Technology Press, 1994: 73-76. (in Chinese) [11] Clarke G A, Landes J D. Evaluation of the J-integral for the compact specimen[J]. J Test Eval, 1979, 7(5): 264-269. doi: 10.1520/JTE10222J [12] Sumpter J D G.Jc determination for shallow notch welded bend specimens[J]. Fatigue Fract Eng Mater Struct, 1987, 10(6): 479-493. doi: 10.1111/j.1460-2695.1987.tb00498.x [13] Zhu X K, Joyce J A. J-resistance curve testing of HY80 steel using SE(B)specimens and normalization method[J]. Eng Fract Mech, 2007, 74: 2263-2281. doi: 10.1016/j.engfracmech.2006.10.018 [14] Chaouadi R. An energy-based crack extension formulation for crack resistance characterization of ductile materials[J]. J Test Eval, 2004, 32(6): 469-475. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b53861e5969098c96c5068c946929cb8 [15] Kobayashi T, Yamanoto I, Niionomi M. Introduction of a new dynamic fracture toughness evaluation system[J]. J Test Eval, 1993, 21(3): 145-153. doi: 10.1520/JTE11763J [16] Schindler H J. Estimation of the dynamic J-R curve from a single impact bending test[C]//Petit J, de Fouquet J, Henaff G, et al. ECF 11-Mechanisms and Mechanics of Damage and Failure(Vol. Ⅱ). UK: EMAS, 1996: 2007-2012. [17] Sathyanarayanan S, Sasikala G, Ray S K. Evaluation of dynamic fracture toughness of cold worked 9Cr-1Mo steel[J]. Int J Pres Ves Pip, 2004, 81(4): 19-425. http://www.sciencedirect.com/science/article/pii/S030801610400078X [18] Sreenivasan P R, Shastry C G, Mathew M D, et al. Dynamic fracture toughness and Charpy transition properties of a service-exposed 2.25Cr-1Mo reheater header pipe[J]. J Eng Mater Technol, 2003, 125: 227-233. doi: 10.1115/1.1543969 [19] Koppenhoefer K C, Dodds R H. Ductile crack growth in pre-cracked CVN specimens: Numerical studies[J]. Nucl Eng Des, 1998, 180: 221-241. doi: 10.1016/S0029-5493(97)00218-5 [20] Biswas P, Narasimhan R. A numerical study of constraint effects on dynamic ductile crack initiation[J]. Mech Mater, 2002, 45: 577-592. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=17bb7e14baa93a76b2fe27d3a9c25188 [21] Xia L, Shih C F. Ductile crack growth-I. A numerical study using computational cells with microstructurally based length scales[J]. J Mech Phys Solids, 1995, 43: 233-259. doi: 10.1016/0022-5096(94)00064-C -

下载:

下载: