Effect of High Hydrostatic Pressure and Thermal Sterilization on Quality of Cloudy and Clear Strawberry Juice

-

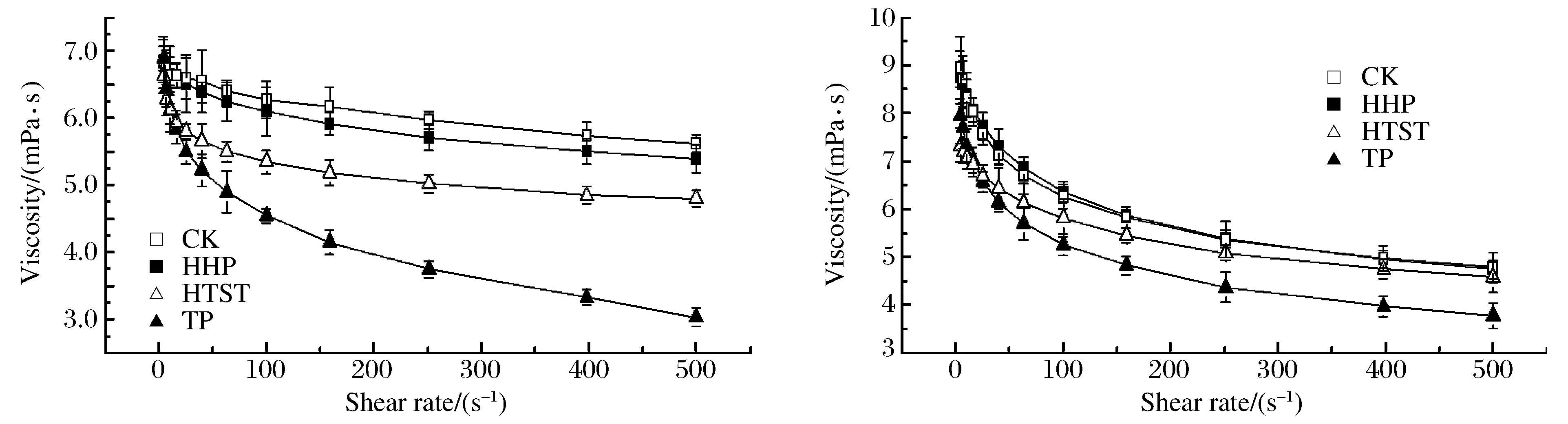

摘要: 研究超高压(常温下,550 MPa,处理5 min)、热处理(中心温度90 ℃,处理1 min)及高温短时杀菌(110 ℃,处理8.6 s)对草莓浊汁和清汁品质的影响。结果表明:(1)经超高压处理后,草莓浊汁的黏度、果胶含量和浊度无显著变化,悬浮稳定性显著增加;而热处理和高温短时杀菌处理后,浊汁的黏度和果胶含量显著减小,浊度增大,悬浮稳定性降低,但高温短时杀菌组好于热处理组;(2)草莓浊汁和清汁经超高压处理后Vc分别损失11.09%和13.59%,而热烫结合超高压处理后分别损失7.75%和10.73%;热处理和高温短时杀菌组浊汁和清汁中Vc的损失率高于超高压组,分别为28.86%~38.89%和20.38%~29.02%;(3)超高压处理对草莓浊汁和清汁的单体花色苷、聚合色度及总酚含量、DPPH和FRAP抗氧化活性没有显著影响;热处理和高温短时杀菌处理后草莓浊汁中的花色苷总量分别损失了3.89%~4.63%和7.46%~8.02%,而清汁中分别损失了5.97%~6.02%和8.09%~9.20%;聚合色度和聚合色度百分比增加,总酚含量无显著变化,抗氧化活性显著降低;(4)超高压处理对草莓浊汁和清汁的亮度L*、红值a*、黄值b*、彩度C*及色调角hab均没有显著影响;而热处理和高温短时杀菌处理使L*值和a*值均显著减小。Abstract: Effects of high hydrostatic pressure (550 MPa/5 min/ambient temperature), thermal process (90 ℃/1 min) and high temperature with short time (110 ℃/8.6 s) treatment on the quality of cloudy and clear strawberry juice were investigated.The viscosity, pectin, cloud and cloudy stability of cloudy juice showed no significant change after HHP treatment, while those of TP and HTST juice significantly decreased.Ascorbic acid in HHP cloudy and clear juice reduced by 11.09% and 13.59%, and it decresaed by 7.75% and 10.73% in juices treated by HHP combined with blanching.The loss rates of ascorbic acid in TP and HTST-treated cloudy and clear juice are higher, which are 28.86%-38.89% and 20.38%-29.02%, respectivity.Monomeric and polymeric anthocyanins, total phenols, DPPH and FRAP in HHP cloudy and clear juice well retain.The monomeric anthocyanins and antioxidant activity of juices treated by TP and HTST significantly decrease, while the PC and PPC significantly increase, and total phenols do not change.The color parameters includingL*, a*, b*, C*and hab exhibite no significant change, and the L* and a* values of TP and HTST juices significantly decrease.

-

Key words:

- high hydrostatic pressure /

- strawberry /

- cloudy juice /

- clear juice /

- quality

-

表 1 超高压和热杀菌对草莓浊汁抗氧化物质及活性的影响

Table 1. Effect of HHP, TP and HTST on antioxidative compounds and antioxidant capacity of cloudy strawberry juice

Processing

methodAscorbic acid

/(mg/100 g)Total

phenolsMonomeric anthocyanins/(mg/100 g) Antioxidant capacity Polymeric anthocyanins Cy-3-glu Pg-3-glu Pg-3-rut Total DPPH FRAP ψCD ψPC ψPPC/(%) CK (Un-blanched) 9.91±0.54a 126.26±3.55a 0.98±0.04a 7.57±0.34a 1.17±0.06a 9.72±0.62a 72.66±3.28a 35.52±1.62a 1.28±0.02b 0.15±0.04b 11.92±0.40b HHP(Un-blanched) 8.81±0.39b 127.77±1.07a 0.98±0.05a 7.65±0.41a 1.13±0.03a 9.76±0.43a 72.84±2.02a 35.36±2.67a 1.27±0.03b 0.15±0.02b 11.98±0.47b TP (Un-blanched) 7.05±0.24d 127.39±3.25a 0.96±0.03a 7.27±0.31a 1.04±0.05a 9.27±0.31b 67.94±4.13b 33.76±1.09b 1.40±0.01a 0.19±0.01a 13.73±0.59a HTST (Un-blanched) 7.89±0.23c 121.69±1.11a 0.93±0.04a 6.98±0.30b 1.02±0.01a 8.94±0.34b 66.55±5.32b 32.09±0.92b 1.37±0.01a 0.20±0.01a 14.18±0.48a CK (Blanched) 9.03±0.51a 134.33±4.53a 0.93±0.07a 7.23±0.22a 1.09±0.02a 9.25±0.40a 72.77±3.76a 36.99±1.39a 1.36±0.01a 0.16±0.01b 11.91±0.31b HHP (Blanched) 8.13±0.54b 133.48±2.61a 0.94±0.03a 7.25±0.48a 1.10±0.03a 9.29±0.21a 73.38±1.99a 37.13±1.54a 1.36±0.02a 0.16±0.01b 11.94±0.52b TP (Blanched) 6.03±0.39d 130.64±2.47a 0.92±0.05a 7.18±0.17a 1.08±0.04a 8.89±0.18a 65.95±1.19b 33.99±0.97b 1.38±0.01a 0.18±0.01a 13.30±0.39a HTST (Blanched) 6.98±0.38c 126.70±1.94b 0.91±0.03a 7.02±0.29a 1.06±0.03a 8.56±0.25a 64.21±1.06b 33.08±1.21b 1.39±0.02a 0.19±0.02a 14.08±0.44a Note:(1) Total phenols (Equal to mg gallic acid/100 mL), DPPH (Equal to mg Vc/100 mL), FRAP (Equal to mg Vc/100 mL).

(2) Different letters (a, b, c) in the same column indicate significant differences (P<0.05).表 2 超高压和热杀菌对草莓清汁抗氧化物质及活性的影响

Table 2. Effect of HHP, TP and HTST on antioxidative compounds and antioxidant capacity of clear strawberry juice

Processing method Ascorbic acid /(mg/100 g) Total phenols Monomeric anthocyanins/(mg/100 g) Antioxidant capacity Polymeric anthocyanin Cy-3-glu Pg-3-glu Pg-3-rut Total DPPH FRAP ψCD ψPC ψPPC/(%) CK(Un-blanchcd) 9.20±0.41a 107.46±2.37a 0.92±0.03a 6.52±0.21a 0.82±0.02a 8.26±0.29a 65.98±3.76a 27.63±1.29a 0.85±0.01b 0.02±0.007a 2.59±0.08b HHP(Un-blanchcd) 7.95±0.26b 106.48±2.61a 0.92±0.04a 6.37±0.18a 0.80±0.01a 8.09±0.39a 65.32±2.75a 26.98±0.53a 0.85±0.01b 0.02±0.006a 2.65±0.09b TP(Un-blanchcd) 6.04±0.20d 94.57±2.77b 0.91±0.06a 6.08±0.26b 0.79±0.02a 7.79±0.12b 60.14±1.19b 24.77±0.88b 0.88±0.09b 0.03±0.005a 2.93±0.09a HTST(Un-blanchcd) 6.53±0.36c 88.51±2.82c 0.85±0.02a 5.87±0.22b 0.78±0.02a 7.50±0.19b 57.51±0.88b 23.98±1.21b 0.93±0.05a 0.03±0.003a 3.01±0.12a CK(Blanched) 8.95±0.59a 112.59±3.33a 0.87±0.04a 5.89±0.15a 0.79±0.03a 7.54±0.18a 66.92±2.16a 27.98±0.86a 0.95±0.01a 0.02±0.003a 2.48±0.07b HHP(Blanched) 7.99±0.61b 113.04±1.16a 0.86±0.03a 5.85±0.26a 0.80±0.02a 7.50±0.33a 67.58±4.53a 28.05±1.76a 0.95±0.01a 0.02±0.005a 2.57±0.13b TP(Blanched) 5.47±0.20d 103.55±2.28b 0.78±0.05a 5.73±0.33a 0.78±0.04a 7.09±0.28a 63.07±1.77a 26.08±1.15b 0.93±0.01a 0.03±0.003a 2.82±0.11a HTST(Blanched) 6.50±0.28c 101.74±2.11b 0.77±0.05a 5.62±0.28a 0.75±0.05a 6.93±0.23b 61.57±2.53b 25.89±1.56b 0.90±0.01a 0.03±0.002a 3.03±0.16a Note:(1) Total phenols (Equal to mg gallic acid/100 mL), DPPH (Equal to mg Vc/100 mL), FRAP (Equal to mg Vc/100 mL).

(2) Different letters (a, b, c) in the same column indicate significant differences (P<0.05).表 3 超高压和热杀菌对草莓浊汁和清汁颜色的影响

Table 3. Effect of HHP, TP and HTST on color of cloudy and clear strawberry juice

Strawberry juice Processing method L* a* b* C* hab ΔE Cloudy juice CK (Un-blanched) 28.94±1.26a 40.32±1.31a 45.48±1.49a 60.77±2.65a 0.85±0.04a - HHP (Un-blanched) 29.3±0.54a 40.25±1.75a 44.29±1.30a 59.85±1.87a 0.83±0.03a 1.20 TP (Un-blanched) 27.64±0.99b 38.02±1.02b 45.71±2.72a 59.85±1.87a 0.88±0.04b 2.65 HTST (Un-blanched) 27.59±0.91b 36.56±1.30c 44.92±1.90a 57.92±3.76b 0.89±0.02b 4.03 CK (Blanched) 26.48±1.02a 40.11±1.56a 46.98±1.87a 61.77±4.01a 0.89±0.02b - HHP (Blanched) 27.29±0.88a 40.34±1.68a 45.86±1.56a 61.08±2.59a 0.85±0.04a 1.40 TP (Blanched) 24.71±0.81b 38.17±0.78b 45.65±1.36a 59.51±3.42a 0.87±0.03a 2.94 HTST (Blanched) 22.85±0.70c 35.21±0.65c 42.61±2.17b 55.92±4.27b 0.87±0.03a 6.89 Clear juice CK (Un-blanched) 72.42±2.61a 46.99±1.17a 45.12±1.47a 65.15±3.24a 0.77±0.03a - HHP (Un-blanched) 72.84±3.02a 45.64±1.61a 45.79±1.83a 64.65±2.91a 0.79±0.02a 1.56 TP (Un-blanched) 71.1±1.54a 45.55±1.37a 46.24±1.70a 64.91±1.96a 0.79±0.02a 2.25 HTST (Un-blanched) 68.86±3.90b 44.95±1.47b 46.1±1.33a 64.39±3.05a 0.80±0.02b 3.41 CK (Blanched) 70.33±2.52a 49.46±1.81a 49.77±2.19a 70.17±2.59a 0.79±0.02a - HHP (Blanched) 71.20±2.15a 49.31±1.63a 49.21±1.60a 69.66±2.73a 0.78±0.03a 1.04 TP (Blanched) 68.78±3.14b 47.12±1.97a 49.18±1.47a 68.11±3.92a 0.81±0.02a 2.86 HTST (Blanched) 68.91±3.77b 46.78±1.02b 48.89±1.06a 67.67±2.74b 0.81±0.02a 3.15 -

[1] Wrolstad R E, Putnam T P, Varseveld G W. Color quality of frozen strawberries: Effect of anthocyanin, pH, total acidity, and ascorbic acid availability[J]. J Food Science, 1970, 35(5): 448-452. doi: 10.1111/j.1365-2621.1970.tb00954.x [2] Koponen J M, Happonen A M, Mattila P H, et al. Contents of anthocyanins and ellagitannins in selected foods consumed in Finland[J]. J Agric Food Chem, 2007, 55(4): 1612-1619. doi: 10.1021/jf062897a [3] 陆道礼, 李国文, 董英, 等.草莓汁加工贮藏过程中维生素稳定性的研究[J].食品研究与开发, 2004, 25(6): 121-123. http://d.wanfangdata.com.cn/Periodical/spyjykf200406046Lu D L, Li G W, Dong Y, et al. Study on the stability of vitamin C in strawberry juice processing and storage[J]. Food Research and Development, 2004, 25(6): 121-123. (in Chinese) http://d.wanfangdata.com.cn/Periodical/spyjykf200406046 [4] Blumenkrantz N, Asboe-Hansen G. New method for quantitative determination of uronic acids[J]. Analytic Biochem, 1973, 54: 484-489. doi: 10.1016/0003-2697(73)90377-1 [5] 张文佳.高静压对树莓汁品质影响研究[D].北京: 中国农业大学, 2010.Zhang W J. Effect of high hydrostatic pressure on the quality of raspberry juice[D]. Beijing: China Agriculture University, 2010. (in Chinese) [6] Cao X M, Zhang Y, Zhang F S, et al. Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps[J]. J Science Food Agric, 2011, 91: 877-885. doi: 10.1002/jsfa.4260 [7] Tiwari B K, O'Donnell C P, Patras A, et al. Effect of ozone processing on anthocyanins and ascorbic acid degradation of strawberry juice[J]. Food Chem, 2009, 113(4): 1119-1126. http://www.cabdirect.org/abstracts/20093029763.html [8] Polydera A C, Stoforosb N G, Taoukis P S. Quality degradation kinetics of pasteurised and high pressure processed fresh navel orange juice, nutritional parameters and shelf life[J]. Innova Food Science Emerg Tech, 2005, 6: 1-9. doi: 10.1016/j.ifset.2004.10.004 [9] Chou T D, Kokini J L. Rheological properties and conformation of tomato paste pectins, citrus and apple pectins[J]. J Food Science, 1987, 52(6): 1658-1664. doi: 10.1111/j.1365-2621.1987.tb05900.x [10] Goodner J K, Braddock R J, Parish M E, et al. Cloud stabilization of orange juice by high pressure processing[J]. J Food Science, 1999, 64(4): 699-700. doi: 10.1111/j.1365-2621.1999.tb15113.x [11] Oey I, Verlinde P, Hendrickx M, et al. Temperature and pressure stability of L-ascorbic acid and/or[6s]5-methyltetrahydrofolic acid, a kinetic study[J]. Europ Food Res Tech, 2006, 219: 161-166. doi: 10.1007/s00217-005-0123-x [12] Taoukis P S, Panagiotidis P, Stoforos N G, et al. High pressure food science, bioscience and chemistry[C]//The Proceedings of the 35th Joint Meeting of the European High Pressure Research Group and Food Chemistry Group of The Royal Society of Chemistry on High Pressure Food Science. Cambridge: The Royal Society of Chemistry, 1998: 506-507. [13] Sánchez-Moreno C, Plaza L, Elez-Martǐnez P, et al. Impact of high-pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice and comparison with traditional thermal processing[J]. J Agric Food Chem, 2005, 53: 4403-4409. doi: 10.1021/jf048839b [14] Andersen M, Fossen T, Torskangerpoll K, et al. Anthocyanin from strawberry(Fragaria ananassa)with the novel aglycone, 5-carboxypyranopelargonidin[J]. Phytochemistry, 2004, 65(4): 405-410. doi: 10.1016/j.phytochem.2003.10.014 [15] Fossen T, Rayyan S, Andersen M. Dimeric anthocyanins from strawberry(fragaria ananassa)consisting of pelargonidin 3-glucoside covalently linked to four flavan-3-ols[J]. Phytochemistry, 2004, 65: 1421-1428. doi: 10.1016/j.phytochem.2004.05.003 [16] Oey I, Van P I, van Loey A, et al. Does high pressure processing influence nutritional aspects of plant based food systems[J]. Trends Food Science Tech, 2008, 19(20): 300-308. http://www.ingentaconnect.com/content/el/09242244/2008/00000019/00000006/art00004 [17] Patrasa A, Bruntona N P, Pieve S D. Impact of high presure processing on total antioxidant activity, phenolic, ascorbic acid, anthocyanin content and colour of strawberry and blackberry purées[J]. Innovat Food Science Emerg Tech, 2009, 10(3): 308-313. doi: 10.1016/j.ifset.2008.12.004 [18] Corrales M, García A F, Butz P, et al. Extraction of anthocyanins from grape skins assisted by high hydrostatic pressure[J]. J Food Eng, 2009, 90(4): 415-421. doi: 10.1016/j.jfoodeng.2008.07.003 [19] Sánchez-Moreno C, Plaza L, de Ancos B, et al. Impact of high pressure and traditional thermal processing of tomato purée on carotenoids, vitamin C and antioxidant activity[J]. J Science Food Agric, 2006, 86: 171-179. doi: 10.1002/jsfa.2321 [20] 许文文, 曹霞敏, 胡小松, 等.超高压对草莓果肉饮料的杀菌效果与品质影响[J].食品科学, 2011, 32(23): 28-34. http://www.cqvip.com/QK/95574X/201123/40499574.htmlXu W W, Cao X M, Hu X S, et al. Effects of high hydrostatic pressure processing on microbial inactivation and quality of strawberry nectar[J]. Food Science, 2011, 32(23): 28-34. (in Chinese) http://www.cqvip.com/QK/95574X/201123/40499574.html -

下载:

下载: