Statistical Analysis of Minimum Electrostatic Spark Ignition Energy of Dust Cloud

-

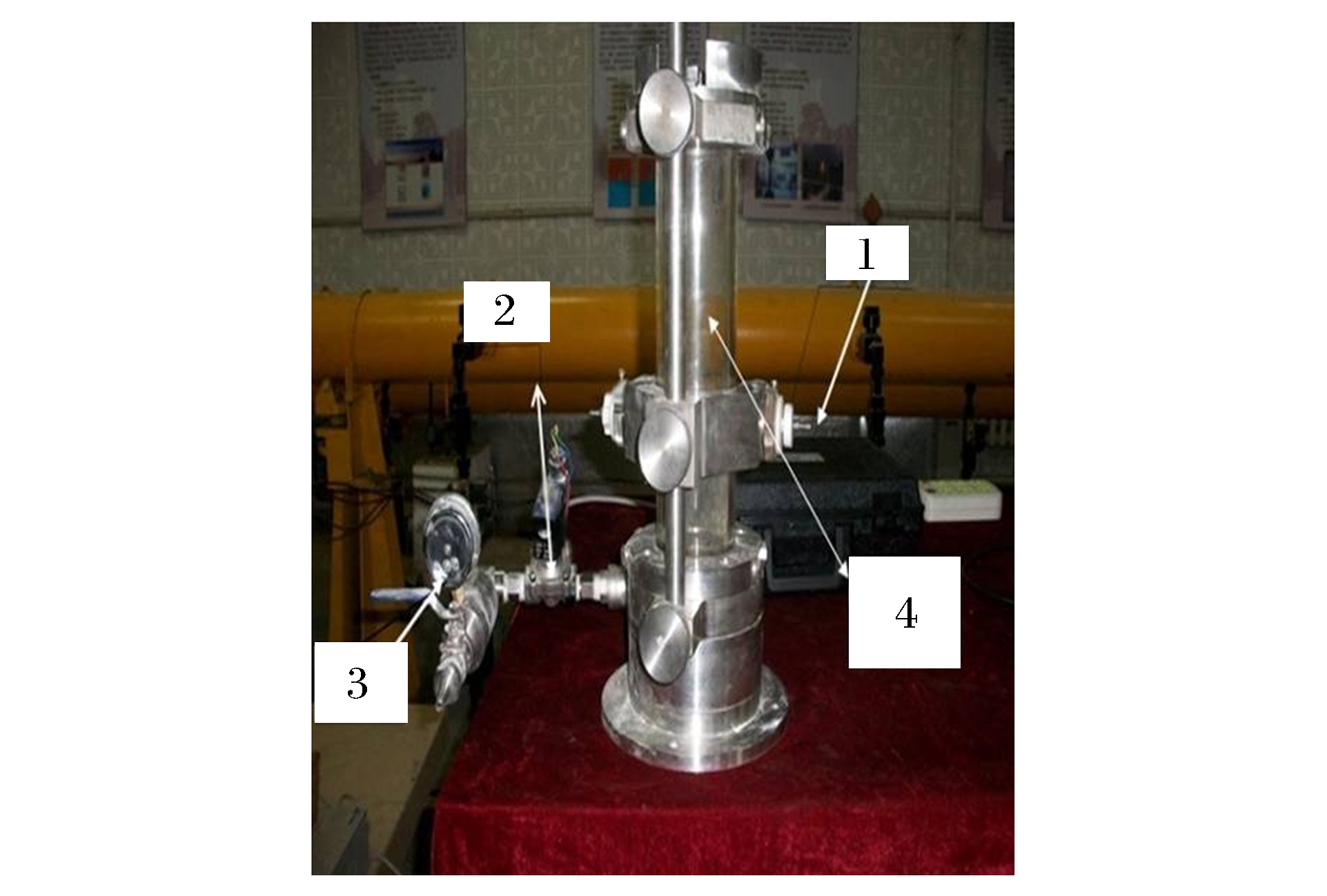

摘要: 基于统计分析的Logistic回归模型,应用以概率表示粉尘云最小点火能的计算方法,在容积为1.28 L的Mike 3管内对不同浓度的烟酸粉尘-空气混合物进行了最小点火能测试实验,利用SPSS软件计算得到了各浓度下烟酸粉尘云点火成功概率为10%和50%时的最小点火能。结果表明,烟酸粉尘云最小点火能随浓度的增大呈现先减小后增大的趋势,最后保持在一定的能量范围内。与其他标准的计算结果相比,这种方法给出的结果更符合实际情况,也能满足不同生产环境对安全控制的需要。Abstract: According to the logistic regression model based on statistical analysis, the experiments on the minimum ignition energy of different concentrations of nicotinic acid dust-air mixtures have been conducted in the Mike 3 tube by the calculation method of the minimum ignition energy of dust cloud which represented by probability, the volume of Mike 3 tube is 1.28 L.Utilizing SPSS software, the minimum ignition energy of various concentrations of nicotinic acid dust cloud when the ignition probabilities are 10% and 50% has been calculated.The results show that the minimum ignition energy of nicotinic acid dust cloud has a tendency to first decrease and then increase with increasing concentrations, finally maintain at a certain energy range.Compared with other standard calculations, the viewpoint of ignition as a statistical phenomenon appears to be more consistent with the test data in engineering, it can also meet the needs of different production environments for security control.

-

表 1 不同浓度烟酸粉尘云最小点火能计算结果

Table 1. Calculation results of the minimum ignition energy for different concentrations of nicotinic acid dust cloud

ρ/(g) Concentration/(g/m3) β0 β1 Emin(P=10%)/(mJ) Emin(P=50%)/(mJ) 0.5 174 -4.518 0.425 5.47 10.63 1.0 462 -3.519 0.340 3.92 10.35 1.5 671 -2.843 0.419 1.55 6.79 2.0 1 085 -2.945 0.569 1.32 5.18 3.0 1 207 -2.710 0.343 1.50 7.90 4.0 2 585 -2.962 0.441 1.75 6.72 5.0 3 026 -3.263 0.679 1.58 4.81 6.0 3 978 -6.088 1.513 2.57 4.02 8.0 5 709 -9.017 2.195 3.11 4.11 10.0 6 760 -3.977 0.547 3.27 7.27 20.0 14 064 -3.719 0.511 2.98 7.28 30.0 21 049 -4.598 0.617 3.90 7.45 表 2 按BS EN 13821:2002标准得到的粉尘云最小点火能量统计值

Table 2. Statistical results of the minimum ignition energy of nicotinic acid dust cloud based on the standard of BS EN 13821:2002

Ignition energy/

(mJ)Dust concentration/(g/m3) Ignition probability

P1 085 2 585 3 026 3 978 5 709 6 760 21 049 E2=3.12 NI I I I I I NI 5/7 E1=1.88 NI NI NI NI NI 表 3 烟酸粉尘云最小点火能分析结果对比

Table 3. Analysis results of the minimum ignition energy of nicotinic acid dust cloud contrast with different standards

Analysis method Minimum ignition energy/(mJ) Remark GB/T 16428-1996 2.09 < Emin < 2.28 Ignition within 10 times BS EN 13821:2002 2.27 Logistic regression model 1.32/2.13/5.18 Ignition probability is 10%, 15% and 50% -

[1] IEC 61241-2-3. Electrical apparatus for use in the presence of combustible dust-Part 2: Test methods-Section 3: Method for determining minimum ignition energy of dust/air mixtures[S]. Geneva: International Electrotechnical Commission, 1994. [2] BS EN 13821: 2002. Potentially explosive atmospheres-explosion prevention and protection-determination of minimum ignition energy of dust/air mixtures[S]. Brussels: European Committee for Standardization, 2002. [3] Cesana C, Siwek R. MIKE 3. Minimum ignition energy 3.3[EB/OL]. http://scholar.googleusercontent.com,2012-06-23. [4] Janes A, Chaineaux J, Carson D, et al. MIKE 3 versus HARTMANN apparatus: Comparison of measured minimum ignition energy(MIE)[J]. Hazard Mater, 2008, 152(1): 32-39. doi: 10.1016/j.jhazmat.2007.06.066 [5] Bane S P M, Ziegler J L, Boettcher P A, et al. Investigation of spark ignition in hydrogen, hexane, and kerosene: Experiment and simulation[C]//The 8th International Symposium on Hazards, Prevention, and Mitigation of Industrial Explosions(ISHPMIE). Yokohama, 2010: ISH075. [6] Bane S P M, Shepherd J E, Kwon E, et al. Statistical analysis of electrostatic spark ignition of lean H2/O2/Ar mixtures[J]. Int J Hydrogen Energy, 2011, 36(7): 2344-2350. http://www.sciencedirect.com/science/article/pii/S0360319910010517 [7] Bernard S, Lebecki K, Gillard P, et al. Statistical method for the determination of the ignition energy of dust cloud experimental validation[J]. J Loss Prevent Proces Indust, 2010, 23(1): 404-411. http://www.sciencedirect.com/science/article/pii/S0950423010000185 [8] Ngo M. Determination of the minimum ignition energy(MIE)of premixed propane/air[D]. Norway: University of Bergen, 2009. [9] GB/T 16428-1996.粉尘云最小着火能测定方法[S].北京: 煤炭工业出版社, 1996.GB/T 16428-1996. Determination of the minimum ignition energy of dust cloud[S]. Beijing: Coal Industry Press, 1996. (in Chinese) [10] ASTM E2019-02e1. Standard test method for minimum ignition energy of a dust cloud in air[S]. West Conshohocken: American Society for Testing and Materials, 2002. [11] 何宁, 吴黎兵, 腾冲.统计分析系统SAS与SPSS[M].北京: 机械工业出版社, 2008: 155-157.He N, Wu L B, Teng C. Statistical Analysis System SAS and SPSS[M]. Beijing: Machinery Industry Press, 2008: 155-157. (in Chinese) [12] 王保进.多变量分析: 统计软件与数据分析[M].北京: 北京大学出版社, 2007: 378-380.Wang B J. Multi-Variable Analysis: Statistical Software and Data Analysis[M]. Beijing: Peking University Press, 2007: 378-380. (in Chinese) [13] Nifuku M, Katoh H. Incendiary characteristics of electrostatic discharge for dust and gas explosion[J]. J Loss Prevent Process Indust, 2001, 14(6): 547-551. doi: 10.1016/S0950-4230(01)00046-8 -

下载:

下载: