Research on Dynamic Behaviors of Cylindrical Shells with Different Wall-Thickness under Explosion Loading

-

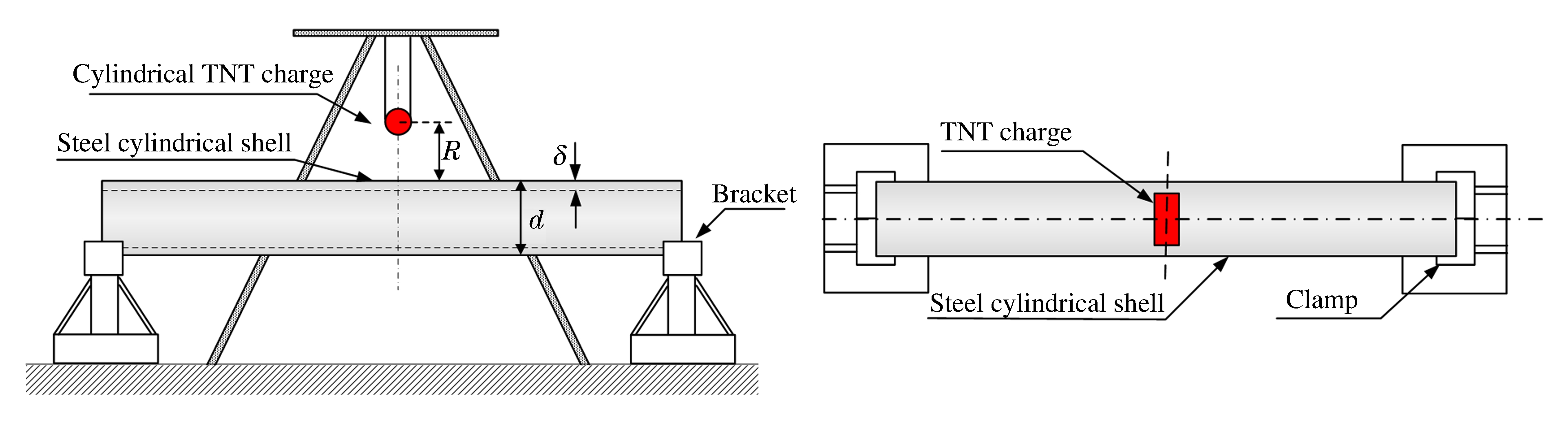

摘要: 对爆炸荷载下圆柱壳的动力学行为进行了实验研究及数值模拟。将外径均为100 mm的3种壁厚的Q235钢质圆柱壳置于由TNT药柱产生的爆炸场中进行冲击实验,系统分析了在不同装药高度及壳壁厚度参数条件下圆柱壳的冲击变形模式,即迎爆面局部凹陷变形模式(Mode Ⅰ)、迎爆面局部凹陷与壳整体弯曲变形耦合模式(Mode Ⅱ)、整体变形失效模式(Mode Ⅲ)及局部穿透与整体变形失效耦合模式(Mode Ⅳ)。采用LS-DYNA有限元程序及Lagrangian-Eulerian流固耦合算法,对圆柱壳的非线性动力响应过程进行了数值模拟,分析了圆柱壳的变形历程及最终残余变形的情况,计算结果与实验现象吻合较好。研究结论可为圆柱壳结构爆炸破坏分级及抗爆技术设计提供科学依据。Abstract: Experimental and numerical simulation researches were presented on dynamical behaviors of cylindrical shell structure affected by lateral explosion loading.Impact experiments of explosion loading caused by cylindrical TNT charge on the Q235 steel cylindrical shells with different wall-thicknesses were carried out.The deformation modes of cylindrical shells were analyzed under explosion conditions with different charges and stuctures.These deformation modes include local dent mode(Mode Ⅰ), coupling of local dent and whole bending mode (Mode Ⅱ), whole strcture collapse mode (Mode Ⅲ) and coupling of local perforation and whole strcture collapse mode (Mode Ⅳ).By means of the finite element computer code LS-DYNA, the nonlinear dynamic response process of the cylindrical shells subjected to explosion loading were numerically simulated with Lagrangian-Eulerian coupling method.The deformation process of the cylindrical shells and the final modes were described.The numerical simulation results are in good agreement with experimental data.The results provide a reference for the classification of explosion damage and the design of explosion-resisting structures.

-

表 1 圆柱壳在各工况下受爆炸荷载作用的冲击变形模式

Table 1. Deformation modes of cylindrical shells subjected to explosion loading

Experimental

conditionsDeformation of cylindrical shells

(Top view)Deformation of cylindrical shells

(Lateral view)Deformation modes δ=1.50 mm

R=6.0 cm, Mode Ⅳ

R=8.0 cm, Mode Ⅲ

R=10.0 cm, Mode Ⅲ

R=12.0 cm, Mode Ⅲδ=2.00 mm

R=3.0 cm, Mode Ⅳ

R=4.0 cm, Mode Ⅱ

R=6.0 cm, Mode Ⅰ

R=8.0 cm, Mode Ⅰδ=2.75 mm

R=3.0 cm, Mode Ⅰ

R=4.0 cm, Mode Ⅰ

R=6.0 cm, Mode Ⅰ

R=8.0 cm, Mode Ⅰ -

[1] Hoo Fatt M S, Wierzbicki T. Damage of plastic cylinders under localized pressure loading[J]. Int J Mech Sci, 1991, 33(12): 999-1016. doi: 10.1016/0020-7403(91)90055-8 [2] Wierzbicki T, Hoo Fatt M S. Damage assessment of cylinders due to impact and explosive loading[J]. Int J Impact Eng, 1993, 13(2): 215-241. doi: 10.1016/0734-743X(93)90094-N [3] 孙韬, 冯顺山.自由圆柱壳体在侧向非对称脉冲载荷下的塑性破坏[J].爆炸与冲击, 1998, 18(2): 103-111. http://www.cqvip.com/Main/Detail.aspx?id=2950667Sun T, Feng S S. Damage of free plastic cylinders under lateral impulsive loading[J]. Explosion and Shock Waves, 1998, 18(2): 103-111. (in Chinese) http://www.cqvip.com/Main/Detail.aspx?id=2950667 [4] 唐德高, 周布奎, 周早生.侧向爆炸冲击波加载作用下钢管吸能特性的实验研究[J].爆炸与冲击, 2002, 22(2): 179-183. http://www.cqvip.com/QK/94778X/20022/6213029.htmlTang D G, Zhou B K, Zhou Z S. The energy dissipation characteristics of steel tubes side loaded with explosion shock waves[J]. Explosion and Shock Waves, 2002, 22(2): 179-183. (in Chinese) http://www.cqvip.com/QK/94778X/20022/6213029.html [5] 金乾坤.破片和冲击波毁伤圆柱靶的数值仿真[J].兵工学报, 2006, 27(2): 215-218.Jin Q K. Simulation of cylindrical shell damage by fragments and shock waves[J]. Acta Armamentarii, 2006, 27(2): 215-218. (in Chinese) [6] 陈敏, 隋允康, 阳志光.侧向荷载下圆柱壳体断裂的ALE法数值模拟[J].北京工业大学学报, 2006, 32(增刊): 92-95. http://www.cqvip.com/Main/Detail.aspx?id=1000208353Chen M, Sui K, Yang Z G. ALE numerical simulation of dynamic fracture of cylindrical shells under lateral impulsion[J]. Journal of Beijing University of Technology, 2006, 32(Suppl): 92-95. (in Chinese) http://www.cqvip.com/Main/Detail.aspx?id=1000208353 [7] 郭志昀, 王占江, 王伟, 等.侧向爆炸引起圆柱壳弹性响应的初步实验研究[J].兵工学报, 2011, 32(增刊2): 196-199. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-AGLU201107002032.htmGuo Z Y, Wang Z J, Wang W, et al. Experimental study on elatic reponse of cylindrical shells under side explosive loading[J]. Acta Armamentarii, 2011, 32(Suppl 2): 196-199. (in Chinese) http://cpfd.cnki.com.cn/Article/CPFDTOTAL-AGLU201107002032.htm [8] 路国运.充水压力管道受弹体侧向冲击动力响应及穿透失效破坏研究[D].太原: 太原理工大学, 2004.Lu G Y. Studies on the dynamic response and the perforation failure of the water-filled pre-pressurized pipeline impacted laterally by missile[D]. Taiyuan: Taiyuan University of Technology, 2004. (in Chinese) [9] 章冠人, 陈大年.凝聚炸药起爆动力学[M].北京: 国防工业出版社, 1991.Zhang G R, Chen D N. Condensed Explosive Detonation Dynamics[M]. Beijing: National Defense Industry Press, 1991. (in Chinese) [10] Zakrisson B, Wikman B, Häggbland H A. Numerical simulation of blast loads and structural deformantion from near-field explosion in air[J]. Int J Impact Eng, 2011, 38(3): 597-612. http://www.sciencedirect.com/science/article/pii/S0734743X11000200 [11] Johnson G R, Cook W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperature[C]//Proceedings of 7th Symposium on Ballistics. Hegue, Netherlands: International Ballistics Committee, 1983: 541-547. [12] 肖新科.双层金属靶的抗侵彻性能和Taylor杆的变形与断裂[D].哈尔滨: 哈尔滨工业大学, 2010.Xiao X K. The ballistic resistance of double-layerd metallic target and the deformation and fracture of taylor rod[D]. Harbin: Harbin Institute of Technology, 2010. (in Chinese) -

下载:

下载: