Study on the Compression Properties of Periodic Copper Wire Closed-Packed Structure

-

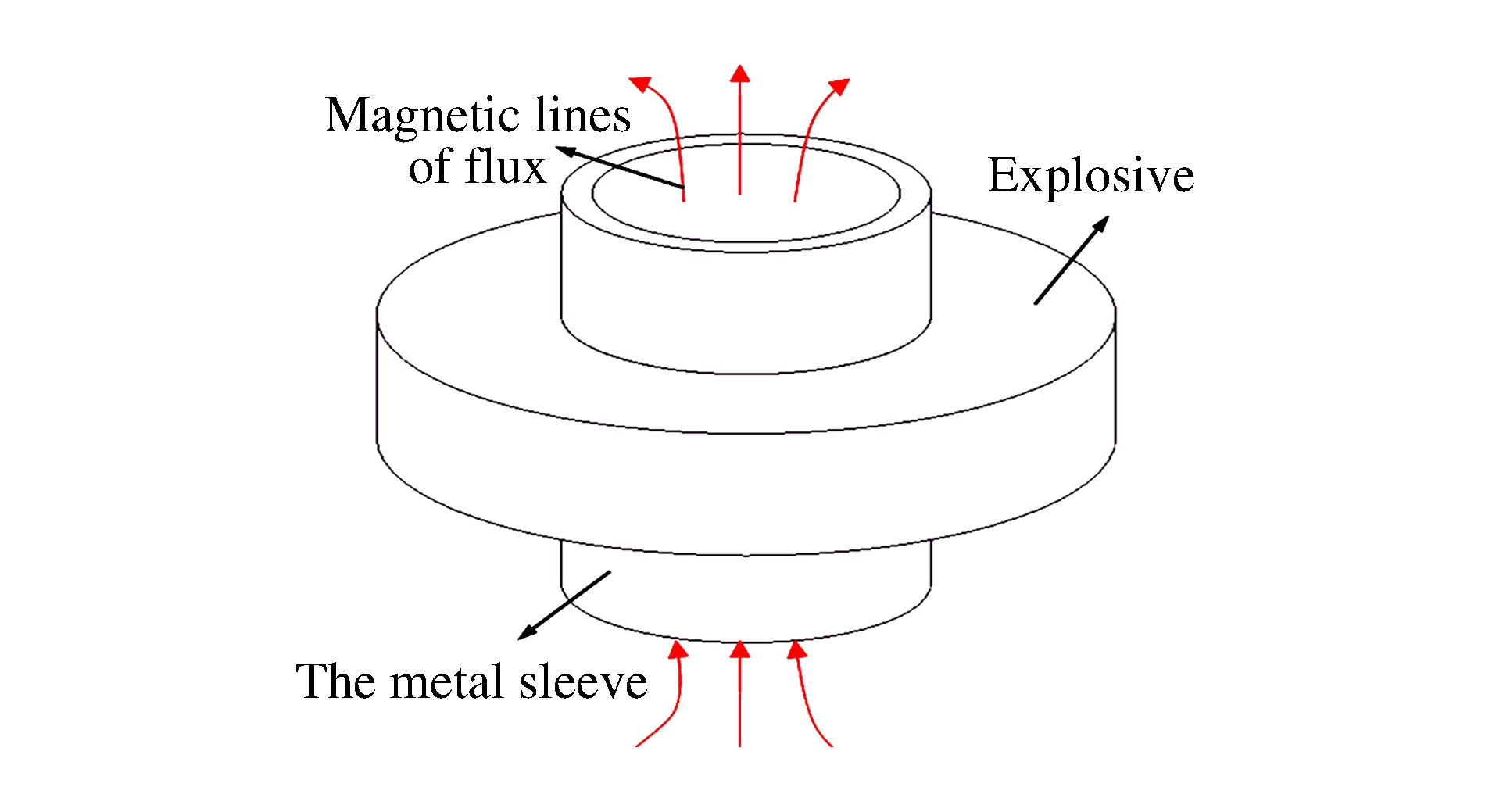

摘要: 对铜线密排结构材料开展了一维平面应变冲击压缩实验与数值模拟研究。利用激光位移干涉仪测量了样品/窗口界面速度剖面,获取了有效的结构冲击压缩实验数据。从样品界面速度曲线可以推断,密排结构冲击压缩时没有形成致密结构,在卸载过程中发生了分层。应用光滑粒子流体动力学方法(SPH)建立了平面铜线密排结构的三维计算模型,计算得到样品冲击加载下的压缩特性,实验和数值模拟得到的界面速度和压力结果吻合较好, 为后续开展柱面铜线密排结构的冲击压缩过程研究奠定了基础。Abstract: A kind of copper wire closed-packed structure was compressed by one-dimensional strain impacting and the dynamic process was numerically simulated.The laser displacement interferometer was used to measure the interface particle velocity profile and the effective experimental data of structure impact compression were obtained.It can be inferred from the interface velocity curve that no compact structure was formed in the sample during the shock compressing progress, and the delamination of sample happened during the unloading progress.The three-dimensional numerical model of plane copper wire closed-packed structure was built by using smoothed particle hydrodynamics (SPH) method, and the shock compression properties of sample were obtained.The interface particle velocities and pressure of the sample were in good agreement between experiments and simulations.

-

表 1 冲击实验中飞片、基板和窗口属性

Table 1. Properties of flyer, base board and window in the impact experiment

Parts Material Diameter

/(mm)Thickness

/(mm)Flyer OFHC 24 2 Base plate OFHC 25 2 Window Al2O3 22 6 表 2 4发冲击实验结果

Table 2. Experimental data of the four impact experiments

Exp.No. Sample Measured flyer

velocity/(km/s)Measured velocity

peak/(km/s)Pulse width

/(ns)Interface pressure

/(GPa)Shot 1 4 layers 2.01 1.20 455 47.5 Shot 2 4 layers 2.48 1.39 440 56.1 Shot 3 7 layers 2.00 1.19 433 47.1 Shot 4 7 layers 2.51 1.40 378 56.6 表 3 计算结果与实验结果的比较

Table 3. The contrast between experiment results and numerical results

Exp.No. Numerical velocity peak/(km/s) Experiment Numerical Contrast Shot 1 1.20 1.10 8.3% Shot 2 1.39 1.37 1.4% Shot 3 1.19 1.12 5.9% Shot 4 1.40 1.38 1.4% -

[1] Hawke R S, Duerre D E, Huebel J G, et al. Method of isentropically compressing materials to several megabars[J]. J Appl Phys, 1972, 43(11): 2734-2741. http://www.nature.com/nature-physci/journal/v233/n39/abs/physci233079a0.html [2] Boriskov G V, Belov S I, Bykov A I, et al. Conductivity and permittivity of hydrogen under isentropic magnetic compression up to 3 Mbar[J]. J Low Temp Phys, 2010, 159(1): 307-310. doi: 10.1007/s10909-009-0124-4 [3] Bykov A I. VNIIEF achievements on ultra-high magnetic fields generation[J]. Phys B, 2002, 294(2): 574-578. http://www.sciencedirect.com/science/article/pii/S0921452600007237 [4] Bykov A I, Dolotenko M I, Kolokol′chikov N P, et al. The cascade magnetocumulative generator of ultra-high magnetic fields—A reliable tool for megagauss physics[J]. Physica B, 1996, 216(1): 215-217. http://www.sciencedirect.com/science/article/pii/0921452695004750 [5] 张柱, 赵慧, 于晖.混凝土材料动态力学性能实验与数值模拟研究[J].高压物理学报, 2011, 25(6): 533-538. http://www.cnki.com.cn/Article/CJFDTotal-GYWL201106010.htmZhang Z, Zhao H, Yu H. Experiments and numerical simulations of concrete dynamic mechanical properties[J]. Chinese Journal of High Pressure Physic, 2011, 25(6): 533-538. (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-GYWL201106010.htm [6] 胡时胜, 王道荣, 刘剑飞.混凝土材料动态力学性能的试验研究[J].工程力学, 2001, 8(5): 115-126.Hu S S, Wang D R, Liu J F. Experiment study on dynamic mechanical behavior of concrete materials[J]. Engineering Mechanics, 2001, 8(5): 115-126. (in Chinese) [7] Richardson M O W, Wisheart M J. Review of low-velocity impact properties of composite materials[J]. Composites, 1996, 27(12): 1123-1131. doi: 10.1016/1359-835X(96)00074-7 [8] Choi H Y. Damage in grahite-expoxy laminated composites due to low-velocity impact[D]. ProQuest Dissertations and Thesises, 1991. [9] Ramadhan A A, Abu Talib A R, Mohd Rafie A S, et al. High velocity impact response of Kevlar-29/epoxy and 6061-T6 aluminum laminated panels[J]. Mater Des, 2013, 43(2): 307-321. http://www.sciencedirect.com/science/article/pii/S0261306912004074 [10] Silvestrov V V, Plastinin A V, Gorshkov N N. Hypervelocity impact on Laminate composite panels[J]. Int J Impact Eng, 1995, 17: 751-762. doi: 10.1016/0734-743X(95)99897-Z [11] Ryan S, Schaefer F, Riedel W. Numerical simulation of hypervelocity impact on CFRP/Al HC SP spacecraft structures causing penetration and fragment ejection[J]. Int J Impact Eng, 2006, 33: 703-712. doi: 10.1016/j.ijimpeng.2006.09.072 [12] Chen J K, Allahdadi F A, Carney T C. High-velocity impact of graphite/epoxy composite laminates[J]. Compos Sci Technol, 1997, 57(9/10): 1369-1379. http://www.sciencedirect.com/science/article/pii/S0266353897000675 [13] Clegg R A, White D M, Riedelb W, et al. Hypervelocity impact damage prediction in composites: Part I-material model and characterisation[J]. Int J Impact Eng, 2006, 33: 190-200. doi: 10.1016/j.ijimpeng.2006.09.055 [14] 赵士操.基于AUTODYN二次开发的超高速碰撞建模与计算[D].绵阳: 中国工程物理研究院, 2012.Zhao S C. Hypervelocity impact modeling and calculation of two secondary development based on AUTODYN[D]. Mianyang: China Academy of Engineering Physics, 2012. (in Chinese) -

下载:

下载: