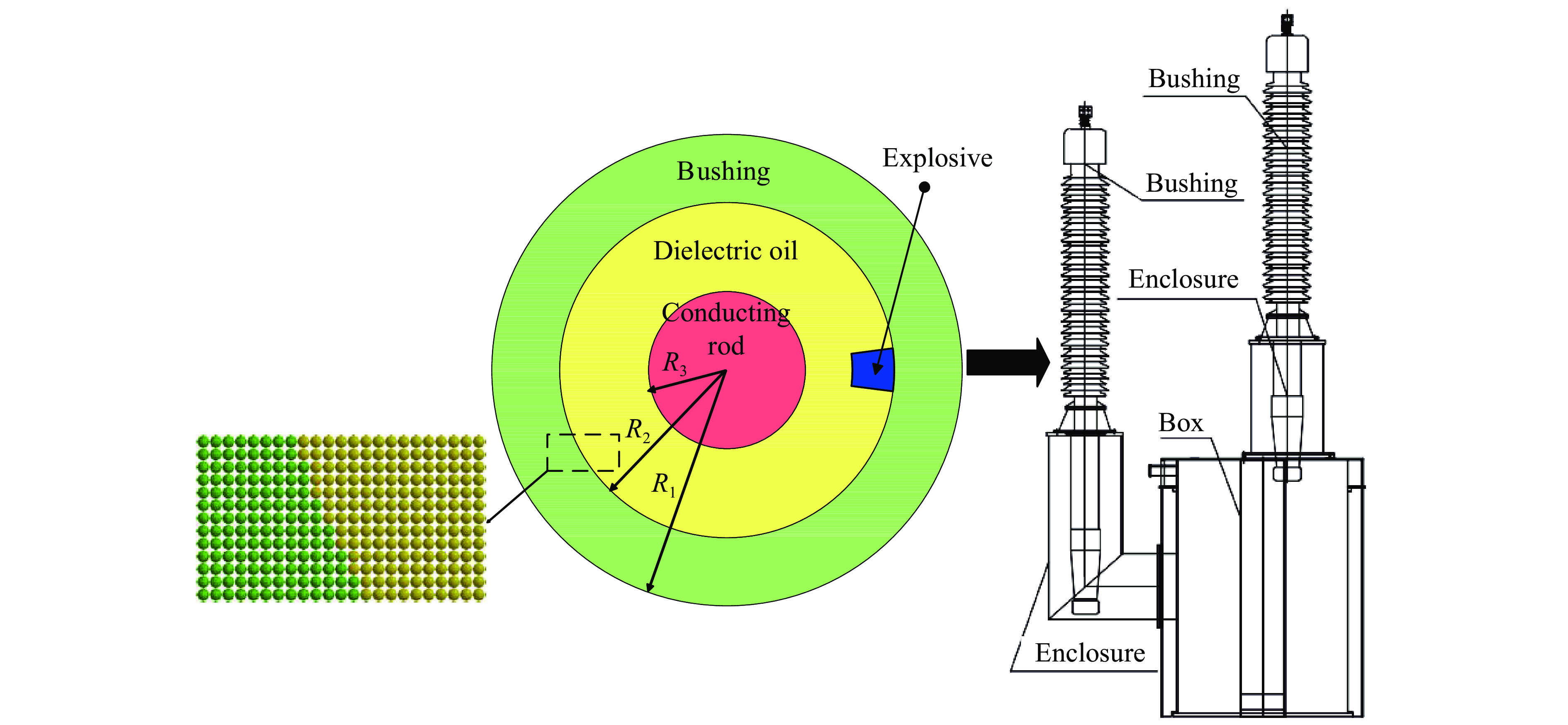

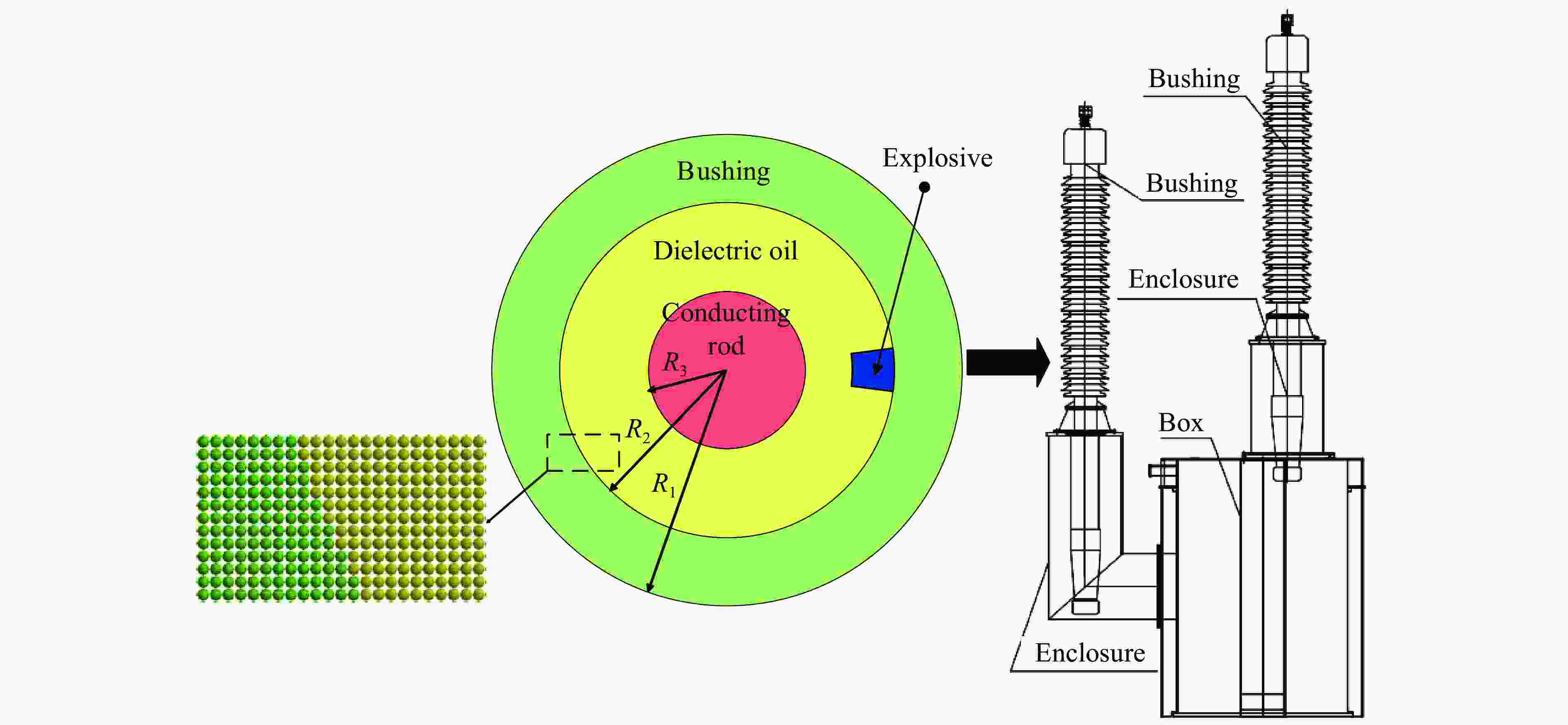

Numerical Simulation and Stability Analysis of Internal Explosion of Transformer Net Side Bushing by SPH Method

-

摘要: 网侧套管是变压器的重要组成部分,在使用过程中因绝缘击穿现象可能引起套管内部冷却油爆炸,给变压器箱体造成很大的安全隐患,因此开展网侧套管爆炸事故的定量评估具有重要意义。通过非线性有限元软件ANSYS/LS-DYNA建立了二维变压器套管模型,采用光滑粒子流体动力学法对变压器套管在内部爆炸作用下的动态响应进行了模拟,分析了不同参数对套管破坏特征的影响规律。通过基于套管径向粒子速度曲线的稳定性判断方法,评估了各套管的失稳时间。结果表明:在内部爆炸作用下,套管管壁中部在内外壁拉压联合作用下率先产生破坏,在冲击波传播过程中套管整体损伤呈凸状变化趋势。过高的爆炸当量、冷却油的存在和初始裂纹缺陷对套管保持稳定有较大影响。爆炸当量的减小可以使套管破坏模式由双向剪切破坏向受拉破坏转变,整体稳定性也随之增强。当爆源位于引线外壁时,冷却油流体所辐射出的冲击波不仅使套管失稳时间有所提前,还会造成外壁膨胀破坏范围变大。应力集中现象和有效壁厚的减小使含初始裂纹缺陷套管剪切破坏失稳现象发展迅速。

-

关键词:

- 变压器套管 /

- 光滑粒子流体动力学法 /

- 失稳时间 /

- 破坏模式

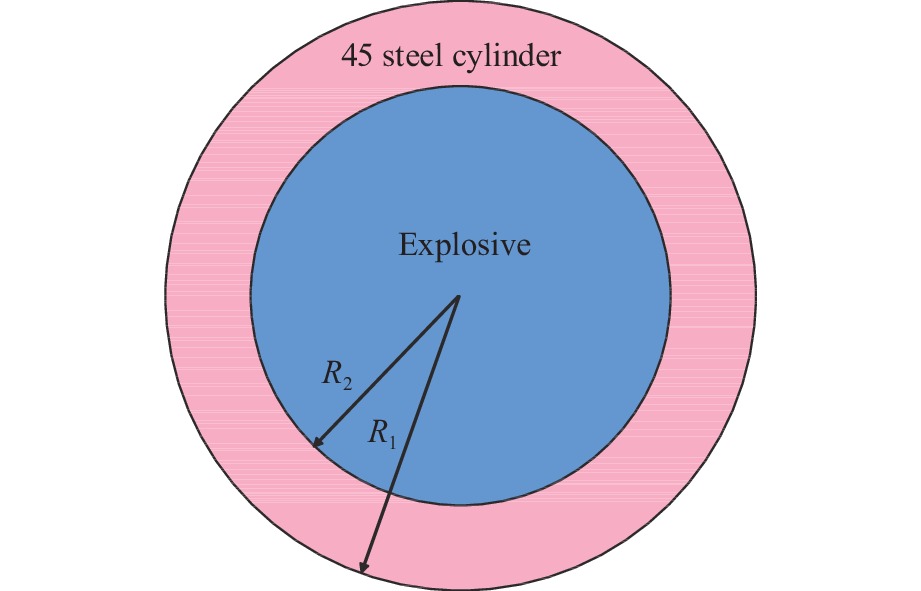

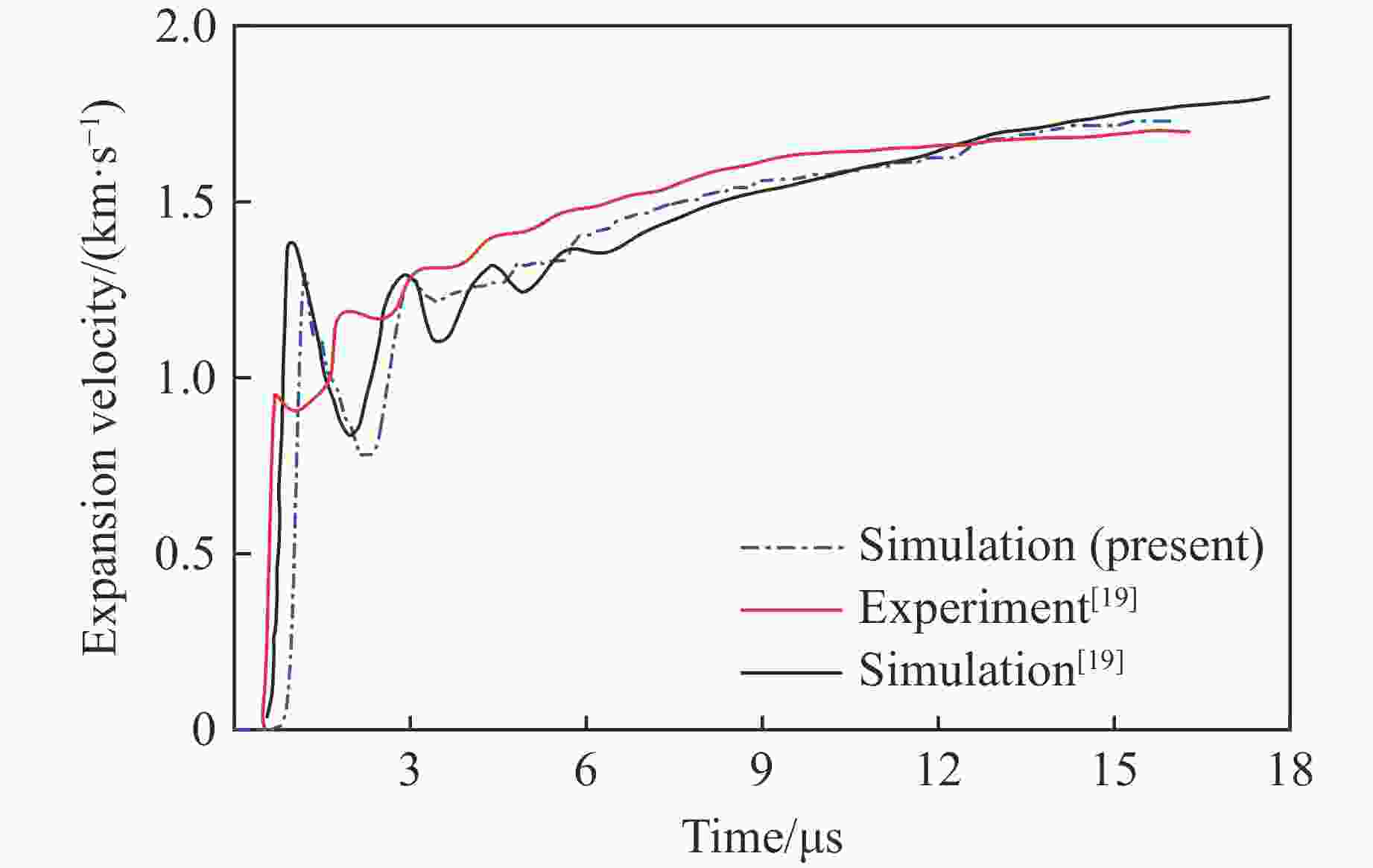

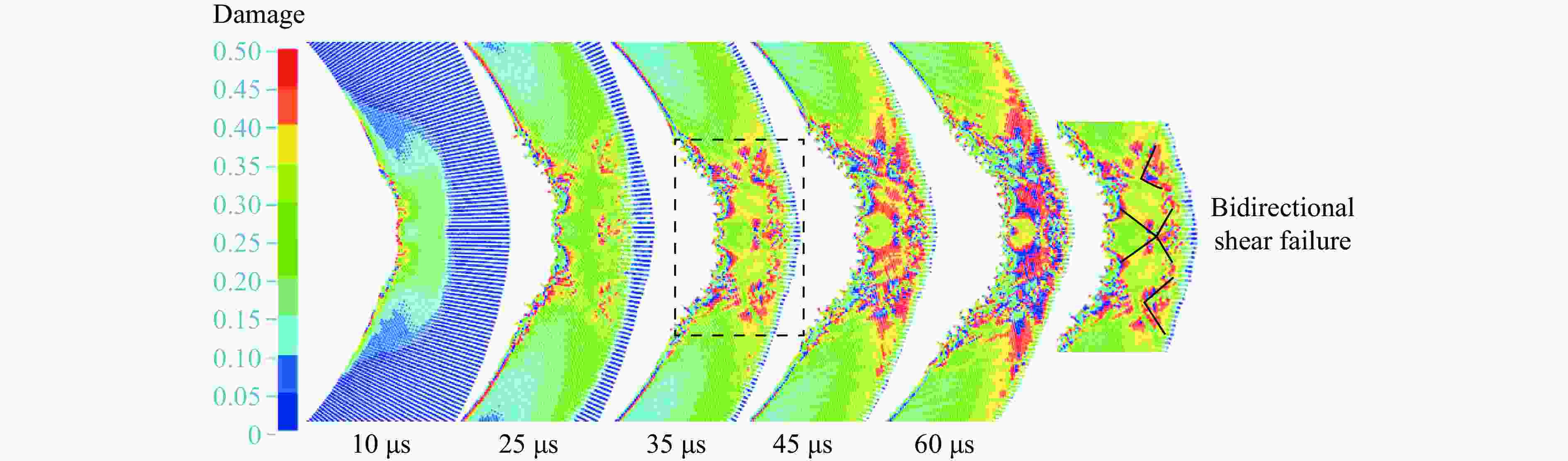

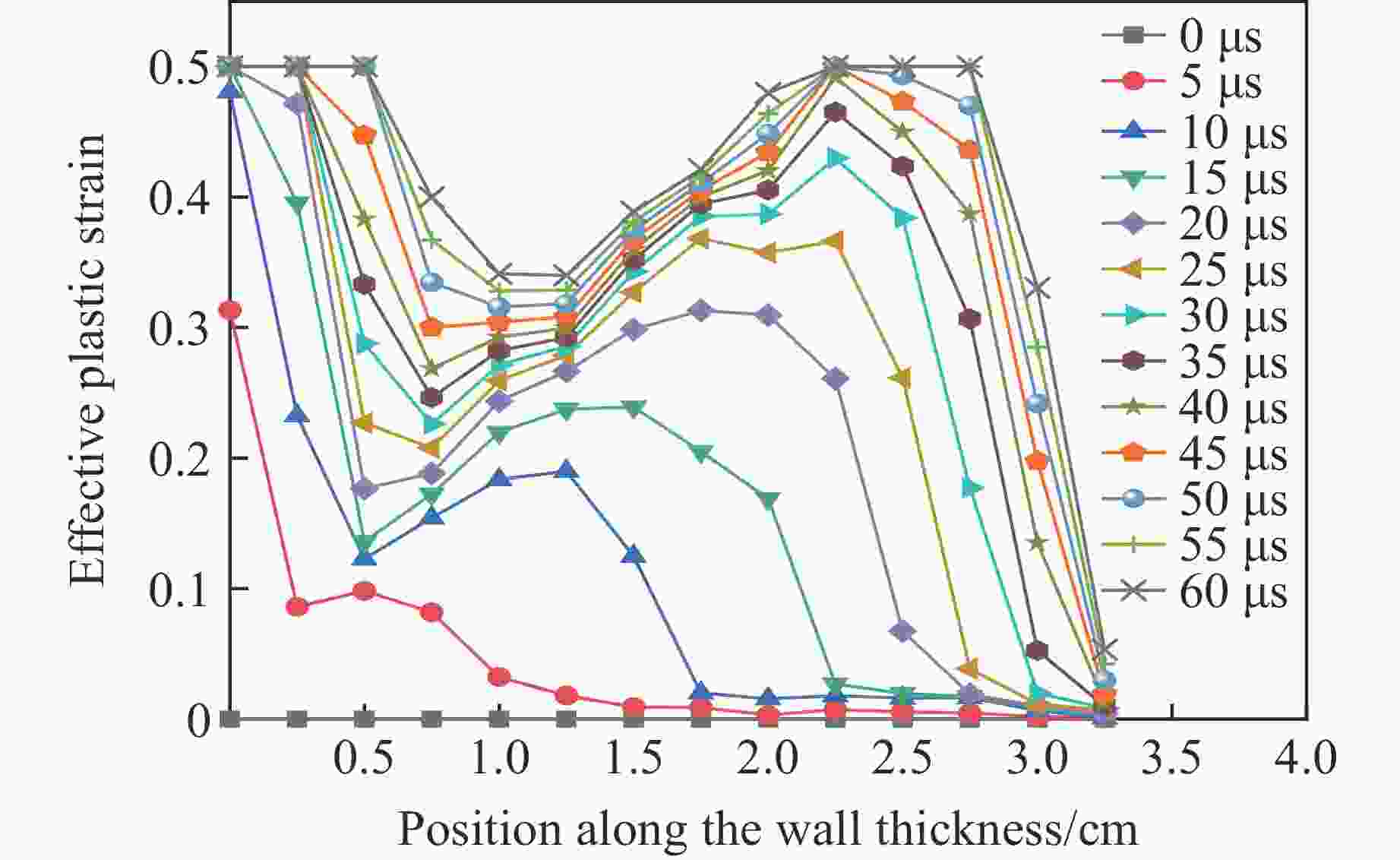

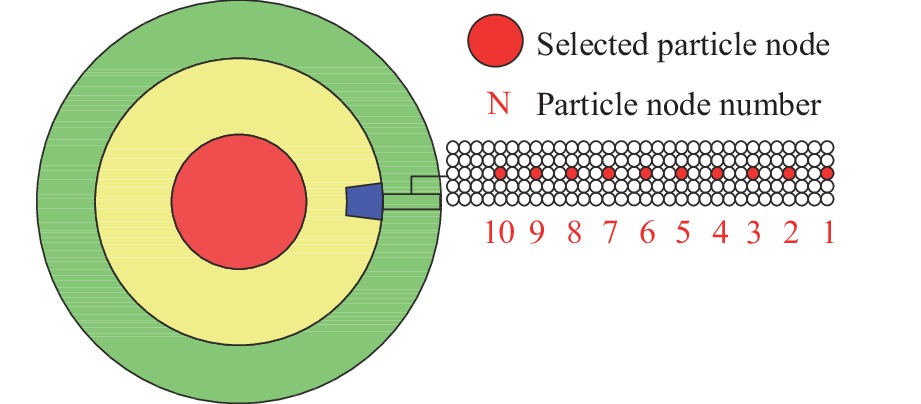

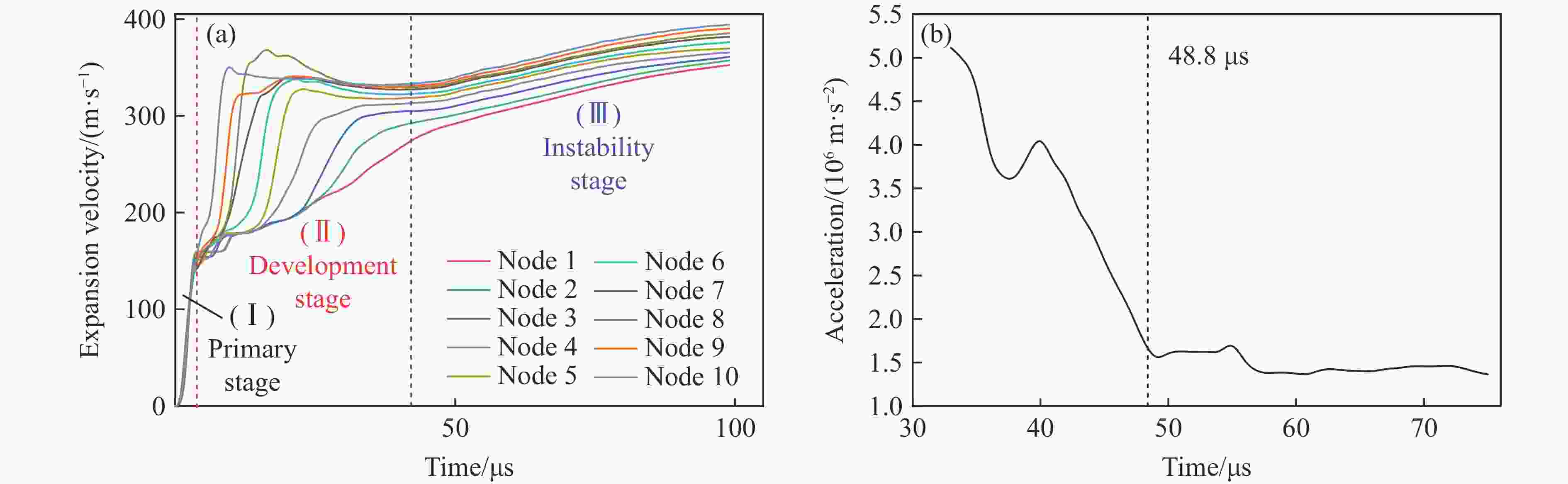

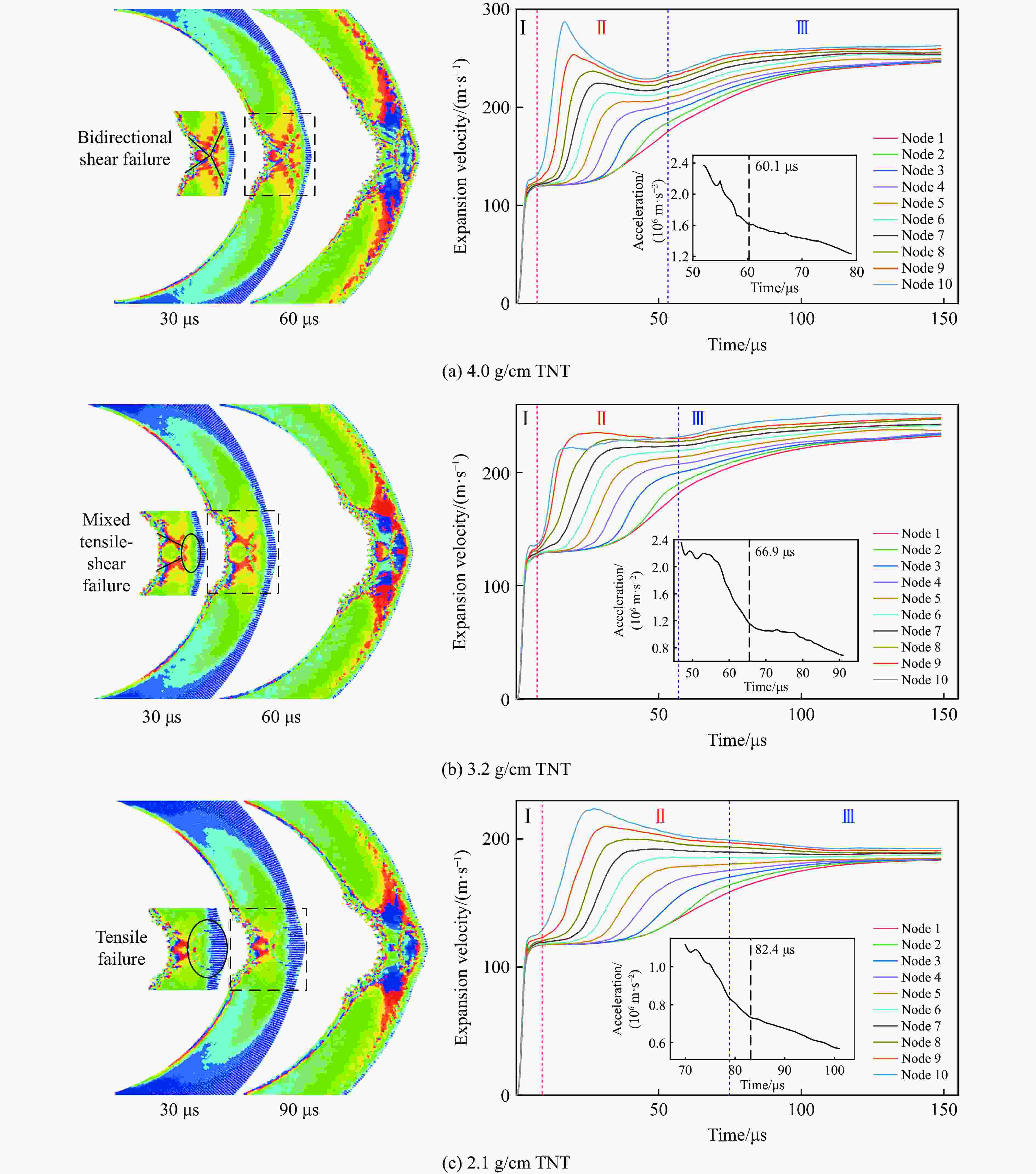

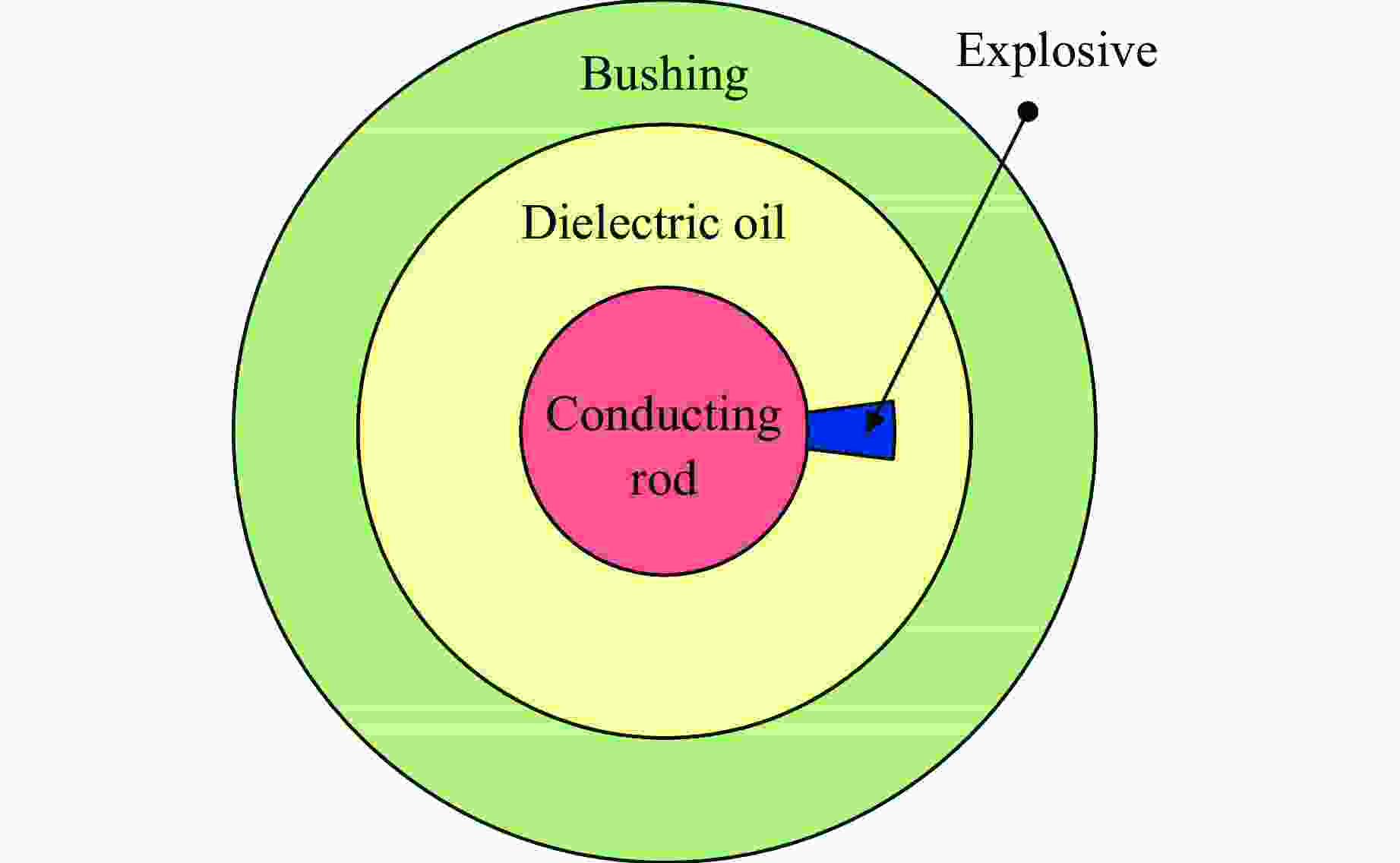

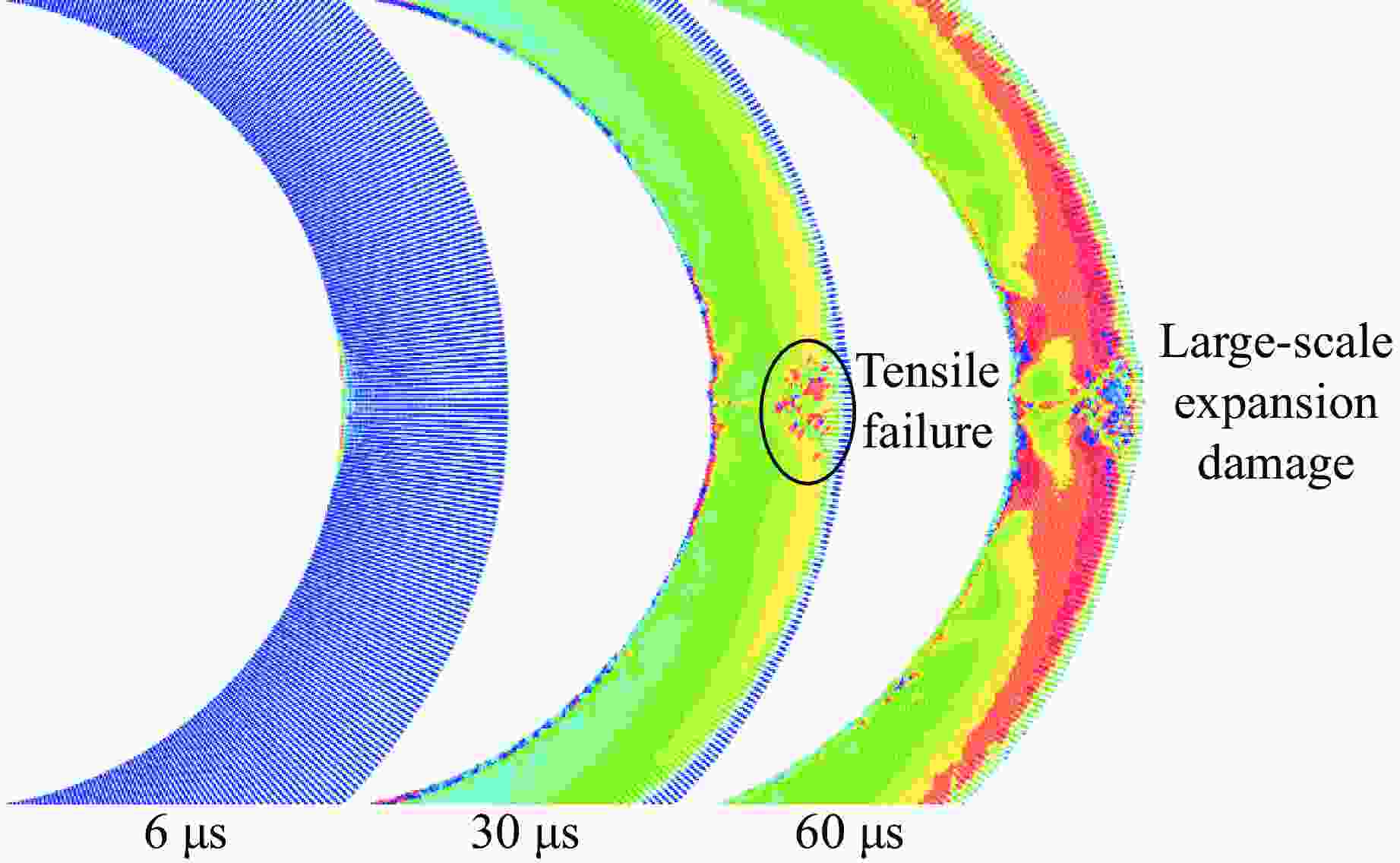

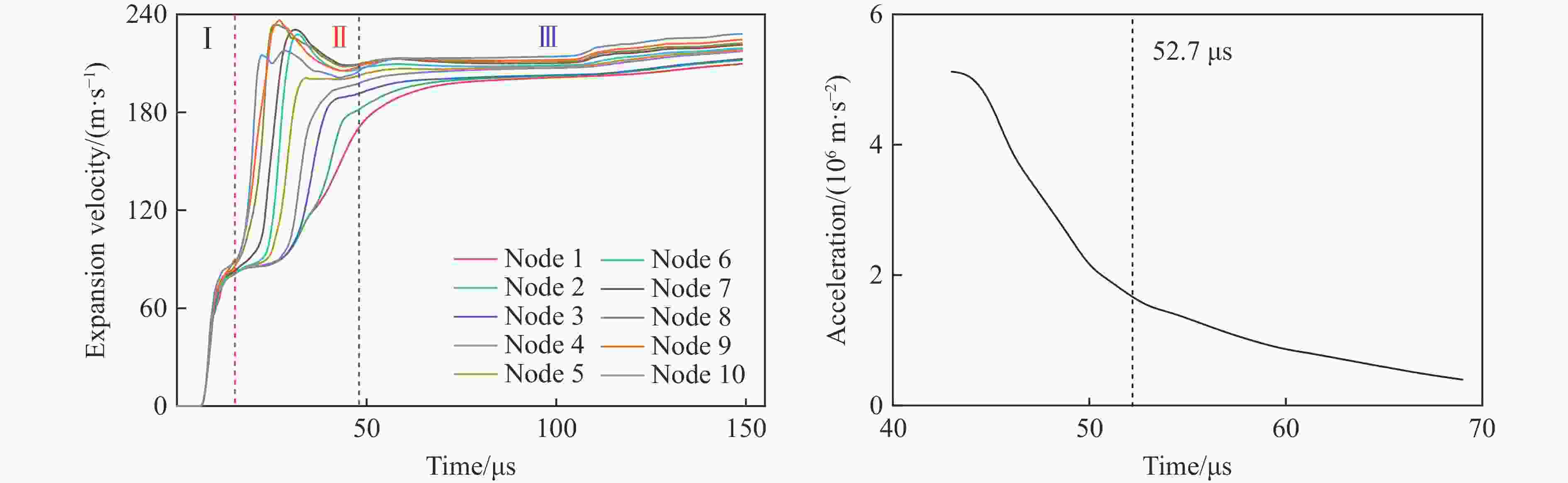

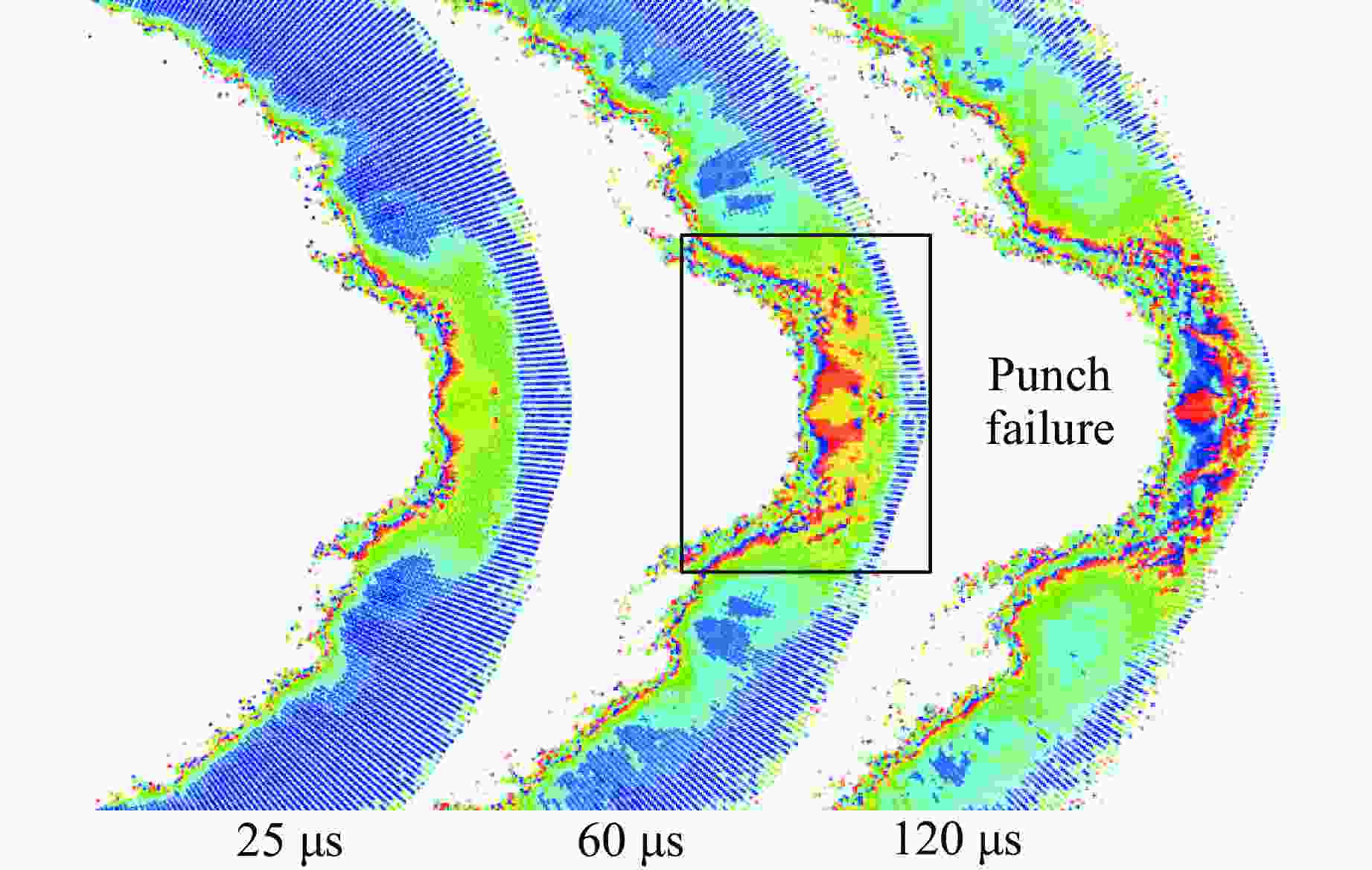

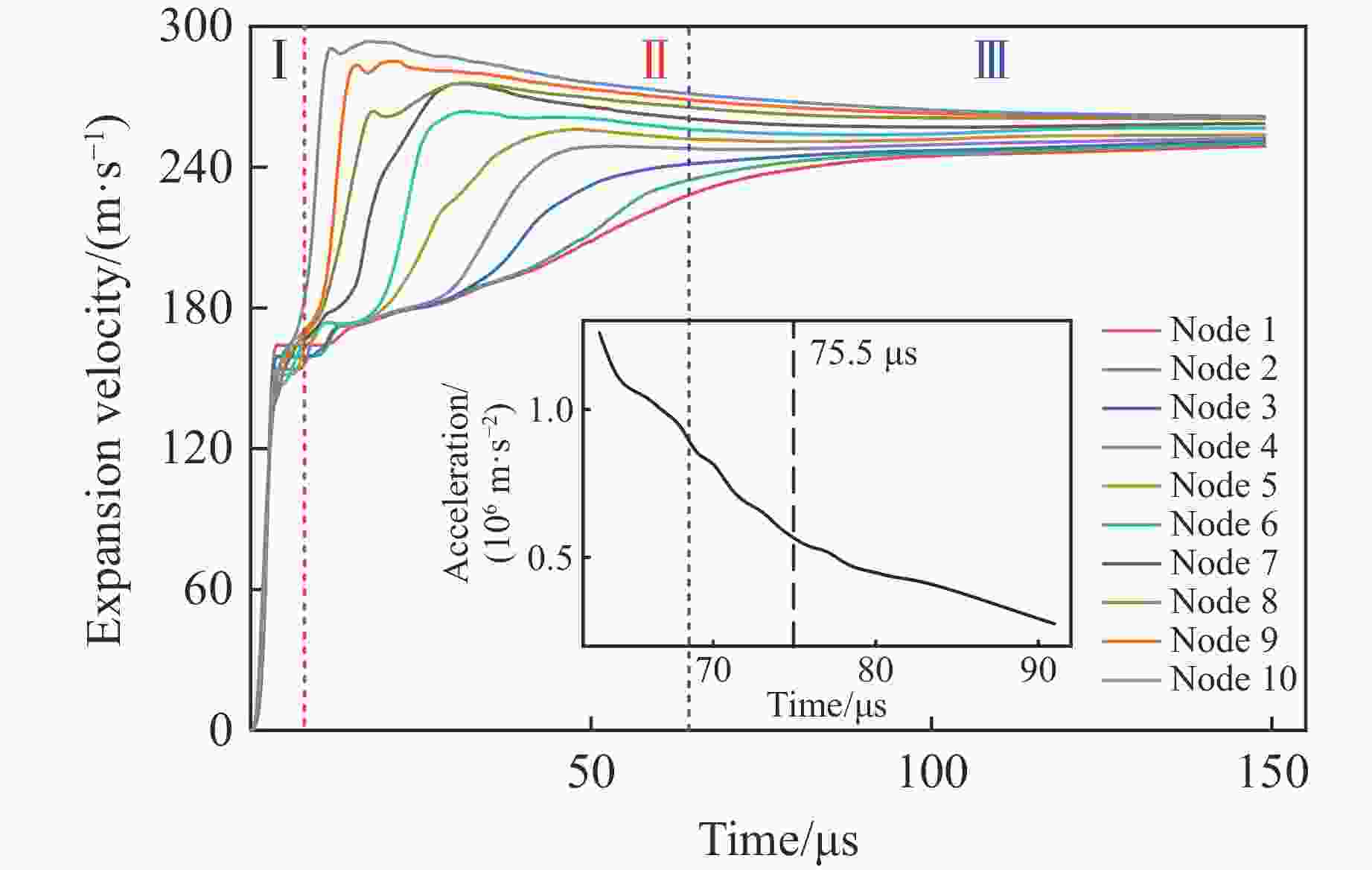

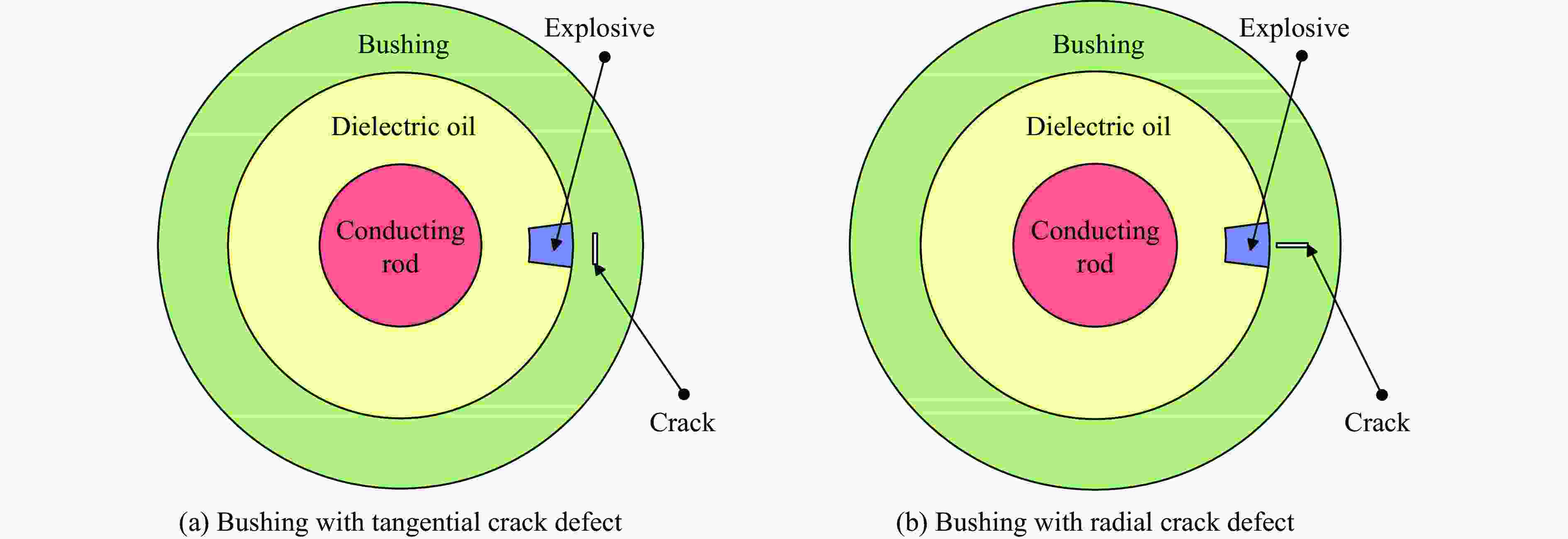

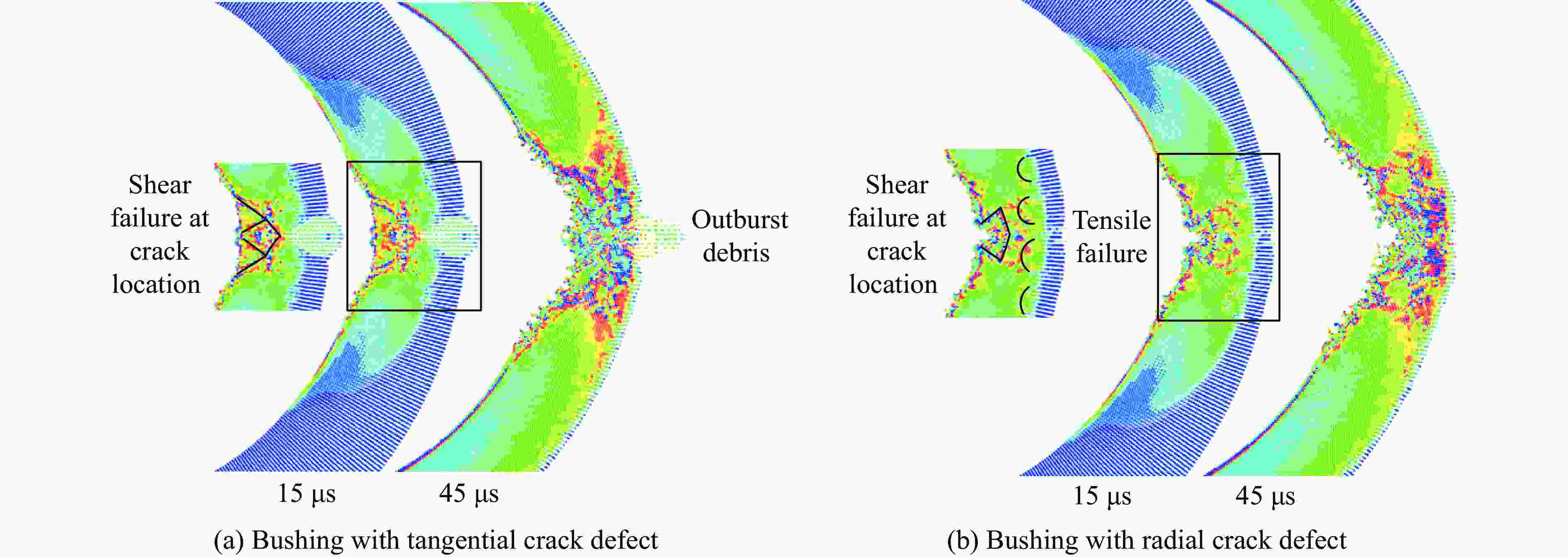

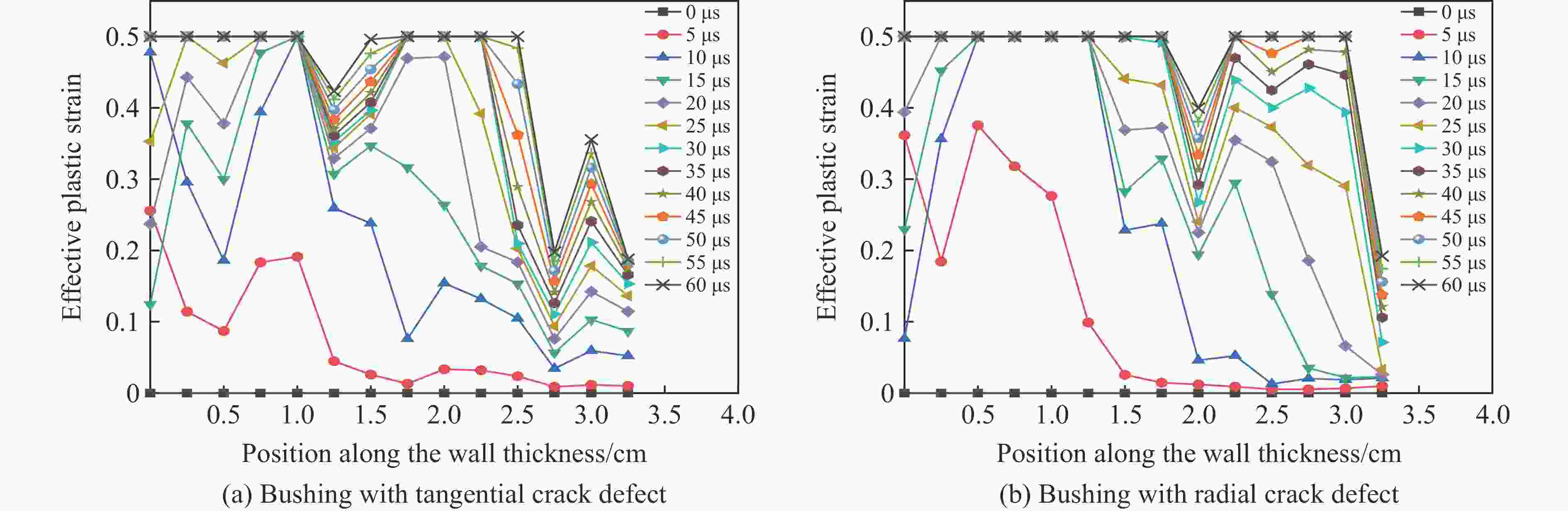

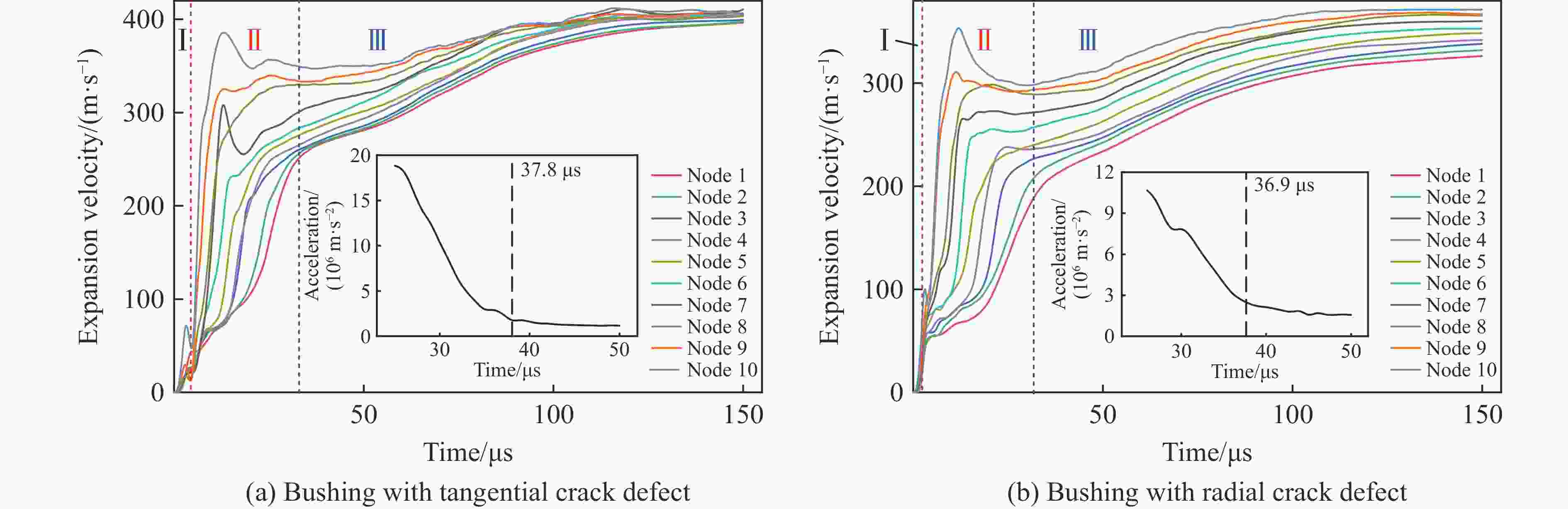

Abstract: The net side bushing is an important part of the transformer. During operation, the cooling oil inside the bushing will explode due to insulation breakdown, which will cause great potential safety hazard to the transformer. Therefore, it is of great significance to carry out quantitative evaluation of the net side bushing explosion accident. In this paper, a two-dimensional transformer bushing model was established by nonlinear finite element software ANSYS/LS-DYNA with smooth particle hydrodynamics (SPH) method. The dynamic response of transformer bushing under internal explosion was simulated. And the influence of different parameters on the failure characteristics of bushing was analyzed. The instability time of bushing was evaluated by the stability judgment method based on the curves of radial particle velocity. The results show that under the action of internal explosion, the middle part of the bushing is first damaged under the combined action of tension and compression of the inner and outer surfaces, and the overall damage of the bushing shows a convex trend during the propagation of the shock wave. The high explosion equivalent, the existence of cooling oil and initial crack defects have a greater influence on the stability of bushing. The decrease of explosion equivalent can change the failure mode of bushing from bidirectional shear failure to tensile failure, and the influence on overall stability is also reduced. When the explosion source is located on the outer wall of the conductive rod, the shock wave radiated by the cooling oil not only makes the bushing instability time advance, but also causes the outer wall expansion damage range to become wider. The stress concentration and the decrease of effective wall thickness make the shear failure instability of bushing with initial crack defects develop rapidly. -

pHEL/GPa Density/(kg·m−3) Shear modulus/GPa Tensile strength/GPa ${\dot \varepsilon }{_0}$/s–1 3.63 3 280 157 0.26 1.0 Density/(kg·m−3) A/MPa B/MPa n m 8 960 905 292 0.31 1.095 cp/(J·kg−1·K−1) C c/(m·s−1) S1 γ0 383 0.025 3 4 578 1.33 1.67 Density/(kg·m−3) Ae/GPa Be/GPa R1 R2 ω E0/GPa 1 630 540 9.4 4.5 1.1 0.35 8 Density/(kg·m–3) c/(m·s−1) S1 γ0 895 1 480 1.75 0.28 表 5 不同TNT当量下响应的数值模拟结果对比

Table 5. Comparison of numerical results of response under different TNT equivalents

W/(g·cm−1) Failure mode Expansion velocity/(m·s−1) Instability time/μs 6.0 Bidirectional shear failure (three locations) 289.18 48.8 4.0 Bidirectional shear failure (one location) 196.09 60.1 3.2 Mixed tensile-shear failure 188.06 66.9 2.1 Tensile failure 164.97 82.6 -

[1] 谢强, 孙新豪, 赖炜煌. 变压器-套管体系抗震加固理论分析及振动台试验 [J]. 中国电机工程学报, 2020, 40(19): 6390–6399.XIE Q, SUN X H, LAI W H. Theoretical analysis and shaking table test on seismic reinforcement of transformer-bushing system [J]. Proceedings of the CSEE, 2020, 40(19): 6390–6399. [2] 陈星, 谢强, 李晓璇, 等. 地震作用下变压器侧壁套管的理论建模及摆动效应分析 [J]. 电网技术, 2020, 44(1): 114–121.CHEN X, XIE Q, LI X X, et al. Seismic theoretical modelling and rocking effect analysis on transformer lateral bushing [J]. Power System Technology, 2020, 44(1): 114–121. [3] 何畅, 谢强, 马国梁, 等. ±800 kV换流变压器-套管体系的抗震性能 [J]. 高电压技术, 2018, 44(6): 1878–1883.HE C, XIE Q, MA G L, et al. Seismic behavior of ±800 kV UHV converter transformer and bushing system [J]. High Voltage Engineering, 2018, 44(6): 1878–1883. [4] HENDERSON C N, DEFRANCE C S, PREDECKI P, et al. Ballistic fragmentation confinement of coated brittle transformer bushing models [J]. International Journal of Impact Engineering, 2018, 122: 363–373. [5] 张少华, 蒋慧灵, 刘国平. 某特高压变压器爆炸事故数值模拟重构 [J]. 消防科学与技术, 2021, 40(3): 356–359.ZHANG S H, JIANG H L, LIU G P. Numerical simulation and reconstruction of explosion accident of an UHV transformer [J]. Fire Science and Technology, 2021, 40(3): 356–359. [6] 余阳, 阮娅琳, 杨黎波, 等. 换流变压器油蒸汽爆炸的三维仿真研究 [J]. 电瓷避雷器, 2021(2): 155–161.YU Y, RUAN Y L, YANG L B, et al. 3D simulation of oil vapor explosion in converter transformer [J]. Insulators and Surge Arresters, 2021(2): 155–161. [7] 赵春风, 何凯城, 卢欣, 等. 弧形双钢板混凝土组合板抗爆性能数值研究 [J]. 爆炸与冲击, 2022, 42(2): 025101. doi: 10.11883/bzycj-2021-0205ZHAO C F, HE K C, LU X, et al. Numerical study of blast resistance of curved steel-concrete-steel composite slabs [J]. Explosion and Shock Waves, 2022, 42(2): 025101. doi: 10.11883/bzycj-2021-0205 [8] 赵铮, 李晓杰, 闫鸿浩, 等. 爆炸压实过程中颗粒碰撞问题的SPH法数值模拟 [J]. 高压物理学报, 2007, 21(4): 373–378. doi: 10.11858/gywlxb.2007.04.007ZHAO Z, LI X J, YAN H H, et al. Numerical simulation of partides impact in explosive-diven compaction process using SPH method [J]. Chinese Journal of High Pressure Physics, 2007, 21(4): 373–378. doi: 10.11858/gywlxb.2007.04.007 [9] 赵春风, 何凯城, 卢欣, 等. 双钢板混凝土组合板抗爆性能分析 [J]. 爆炸与冲击, 2021, 41(9): 095102. doi: 10.11883/bzycj-2020-0291ZHAO C F, HE K C, LU X, et al. Analysis on the blast resistance of steel concrete composite slab [J]. Explosion and Shock Waves, 2021, 41(9): 095102. doi: 10.11883/bzycj-2020-0291 [10] LIU G R, LIU M B. Smoothed particle hydrodynamics: a meshfree particle method [M]. SG Singapore: World Scientific Publishing Company, 2003. [11] FRAGASSA C, TOPALOVIC M, PAVLOVIC A, et al. Dealing with the effect of air in fluid structure interaction by coupled SPH-FEM methods [J]. Materials, 2019, 12(7): 1162. [12] 姚安林, 田晓建, 徐涛龙, 等. 管道爆炸对同沟邻管的冲击效应及防爆墙抗爆性能 [J]. 石油学报, 2020, 41(6): 753–761. doi: 10.7623/syxb202006010YAO A L, TIAN X J, XU T L, et al. Impact effect of pipeline explosion to adjacent pipelines in the same trench and explosion-proof performance of explosion-proof wall [J]. Acta Petrolei Sinica, 2020, 41(6): 753–761. doi: 10.7623/syxb202006010 [13] 强洪夫, 孙新亚, 王广, 等. 钢箱内部爆炸破坏的SPH数值模拟 [J]. 爆炸与冲击, 2019, 39(5): 052201. doi: 10.11883/bzycj-2017-0439QIANG H F, SUN X Y, WANG G, et al. Numerical simulation on steel box damage under internal explosion by smoothed particle hydrodynamics [J]. Explosion and Shock Waves, 2019, 39(5): 052201. doi: 10.11883/bzycj-2017-0439 [14] CRONIN D S, BUI K, KAUFMANN C, et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA [C]//4th European LS-DYNA Users Conference, 2003: 47-60. [15] HALLQUIST J O. LS-DYNA keyword user’s manual version 971 [M]. Livermore, USA: Livermore Software Technology Corporation, 2007. [16] 辛春亮. 有限元分析常用材料参数手册 [M]. 北京: 机械工业出版社, 2019.XIN C L. Manual of material parameters for finite element analysis [M]. Beijing: Mechanical Industry Press, 2019. [17] 李晓杰, 赵春风, 于娜, 等. TNT炸药和乳化炸药驱动飞板的通用状态方程特征线法研究 [J]. 高压物理学报, 2012, 26(4): 462–468. doi: 10.11858/gywlxb.2012.04.016LI X J, ZHAO C F, YU N, et al. Characteristic curve method for movement of flyer driven by TNT and emulsion explosives with general equation of state [J]. Chinese Journal of High Pressure Physics, 2012, 26(4): 462–468. doi: 10.11858/gywlxb.2012.04.016 [18] 赵铮, 陶钢, 杜长星. 爆轰产物JWL状态方程应用研究 [J]. 高压物理学报, 2009, 23(4): 277–282. doi: 10.3969/j.issn.1000-5773.2009.04.007ZHAO Z, TAO G, DU C X. Application research on JWL equation of state of det onation products [J]. Chinese Journal of High Pressure Physics, 2009, 23(4): 277–282. doi: 10.3969/j.issn.1000-5773.2009.04.007 [19] 吴思思, 董新龙, 俞鑫炉. 45钢柱壳爆炸膨胀断裂的SPH模拟分析 [J]. 爆炸与冲击, 2021, 41(10): 103101. doi: 10.11883/bzycj-2021-0172WU S S, DONG X L, YU X L. An investigating on explosive expanding fracture of 45 steel cylinders by SPH method [J]. Explosion and Shock Waves, 2021, 41(10): 103101. doi: 10.11883/bzycj-2021-0172 [20] 谢富佩, 徐绯, 曾卓, 等. 复合圆柱壳冲击压缩数值模拟及稳定性研究 [J]. 爆炸与冲击, 2021, 41(11): 112201. doi: 10.11883/bzycj-2020-0431XIE F P, XU F, ZENG Z, et al. Numerical simulation on stability of compositecylindrical shell under impact compression [J]. Explosion and Shock Waves, 2021, 41(11): 112201. doi: 10.11883/bzycj-2020-0431 [21] MOTT N F. Fragmentation of shell cases [J]. Proceedings of the Royal Society of London, Series A, Mathematical and Physical Sciences, 1947, 189(1018): 300–308. -

下载:

下载: