Containment Mechanism and Structural Optimization Research for Disk Containment of High-Energy Rotor

-

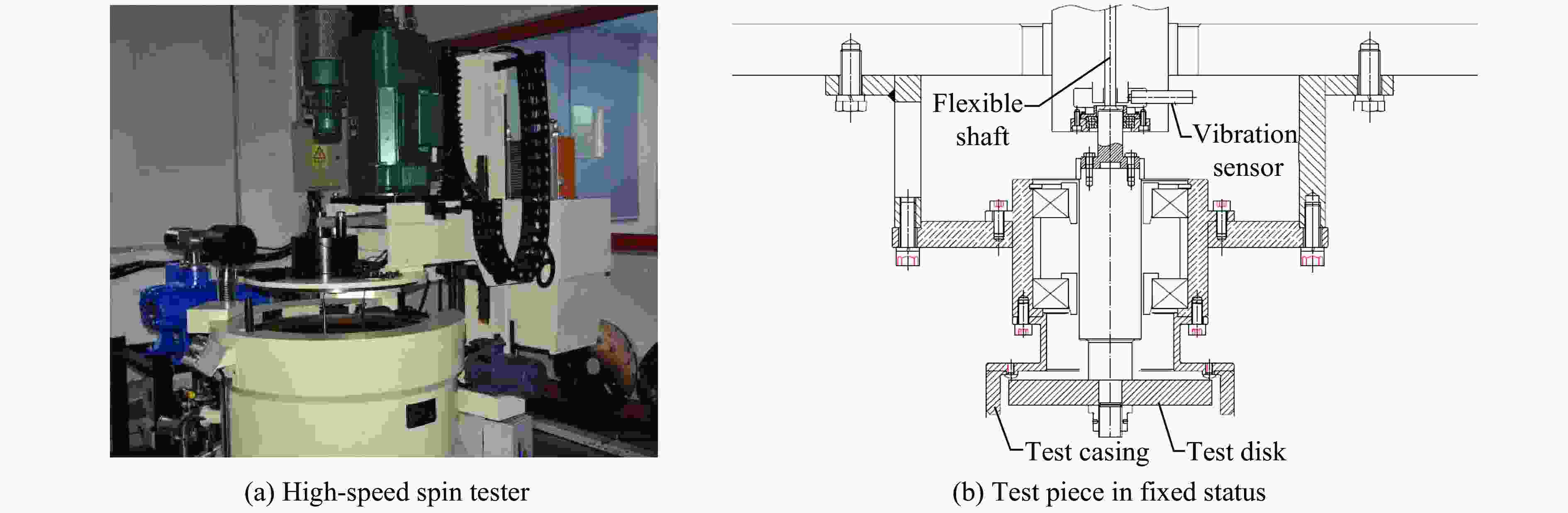

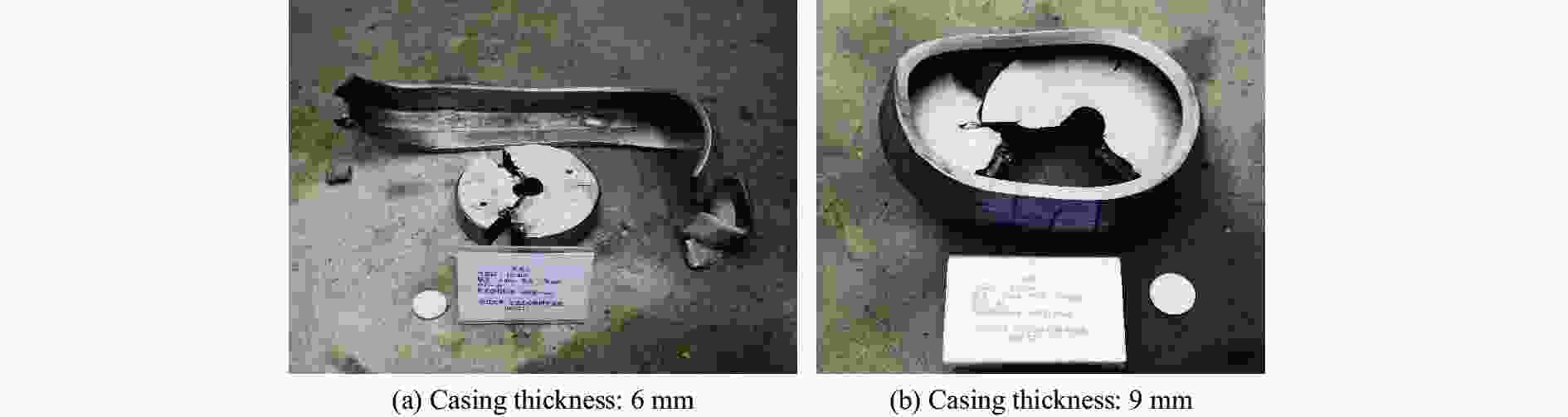

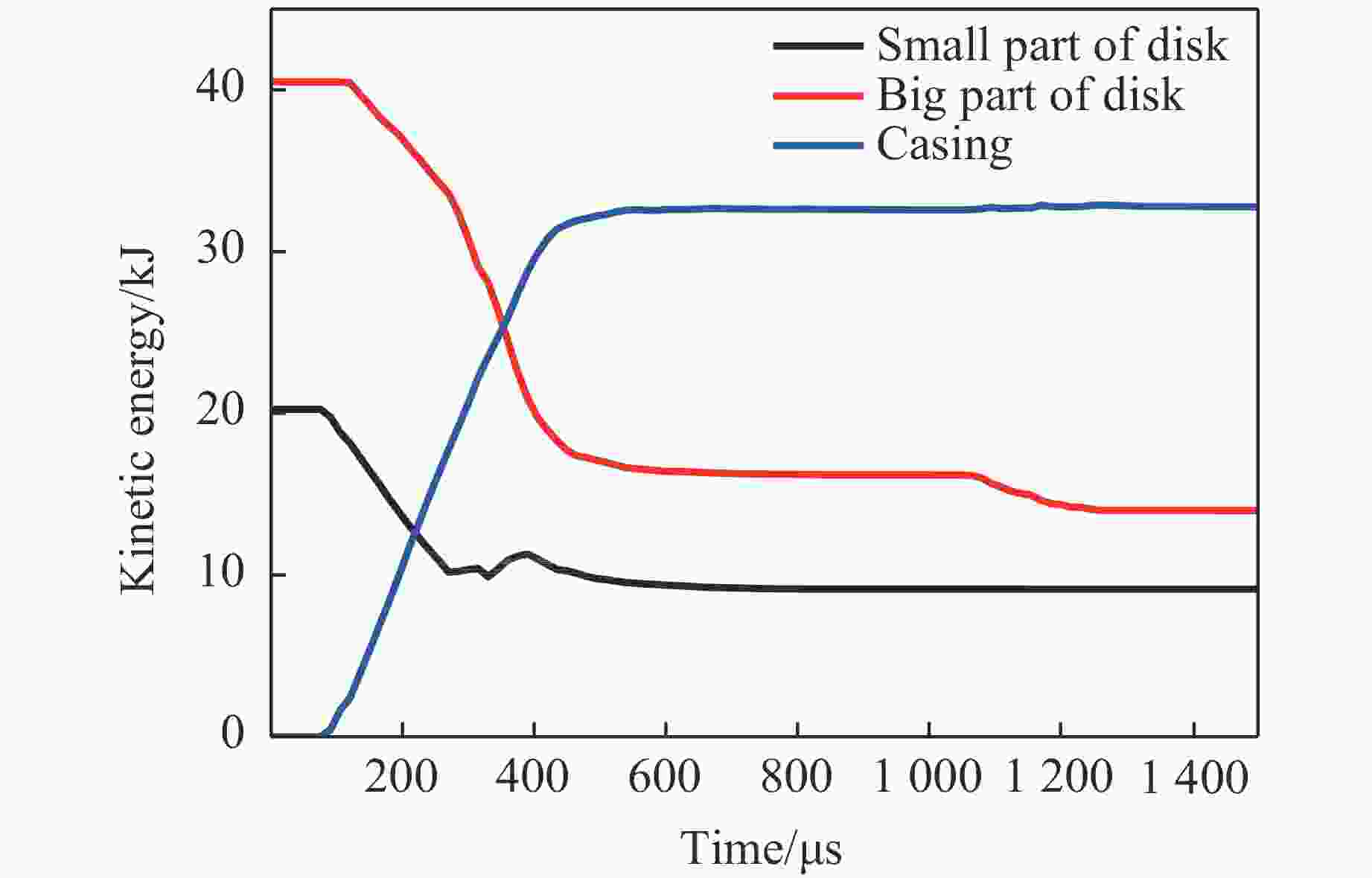

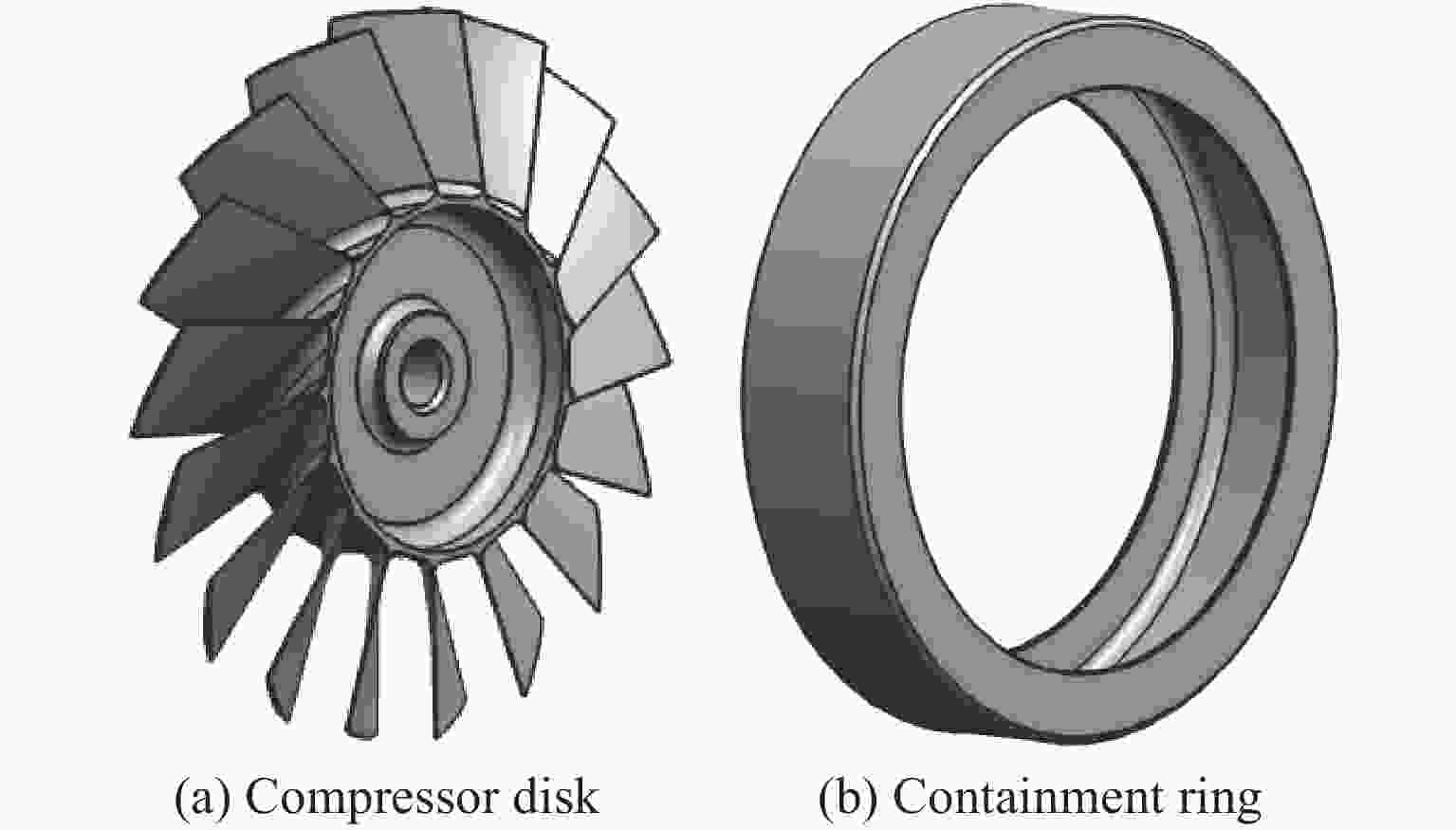

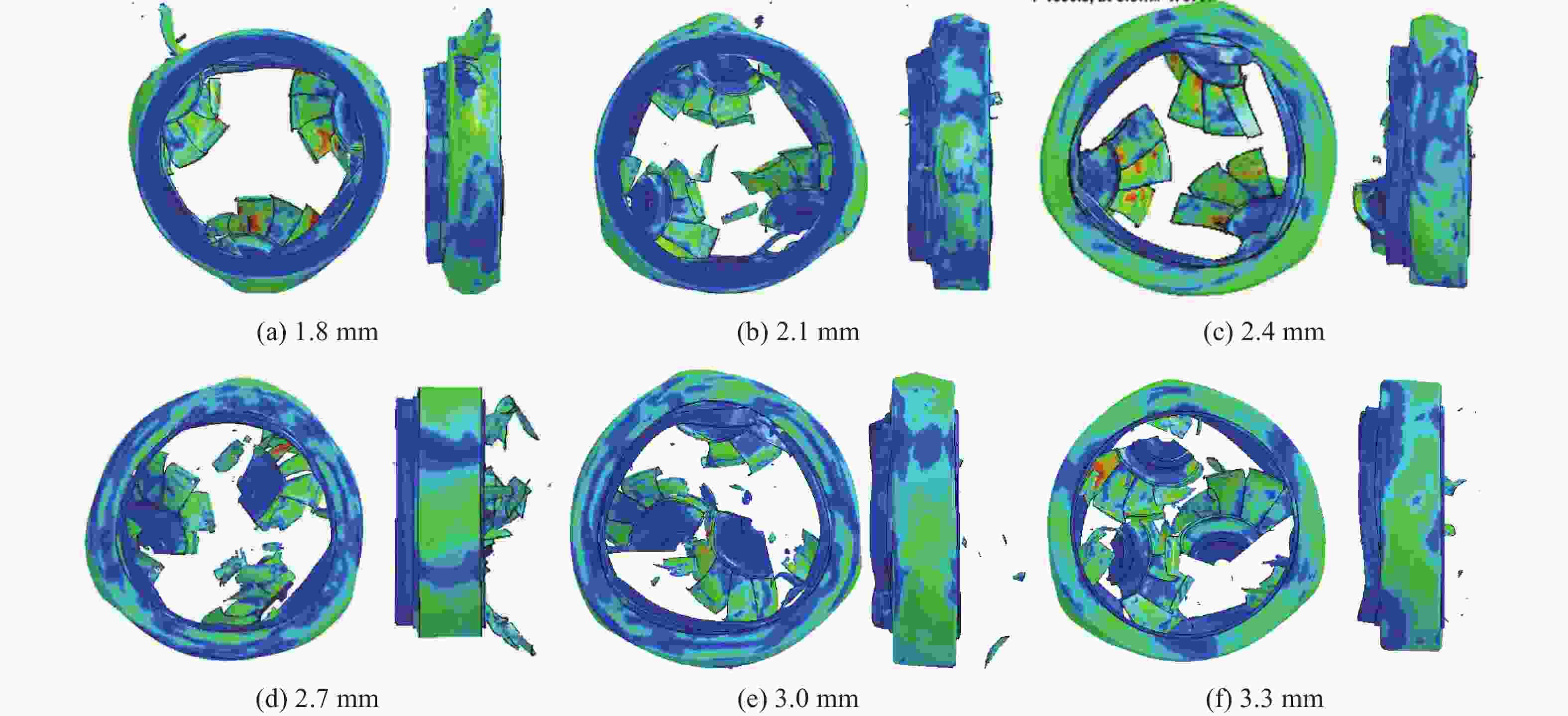

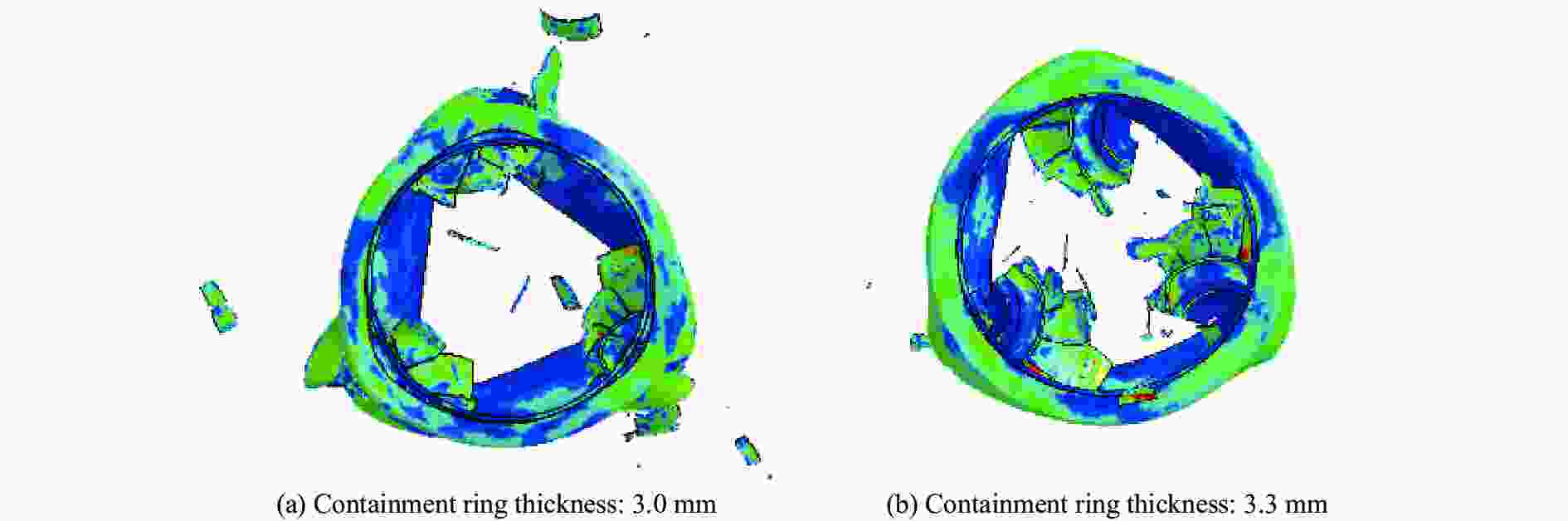

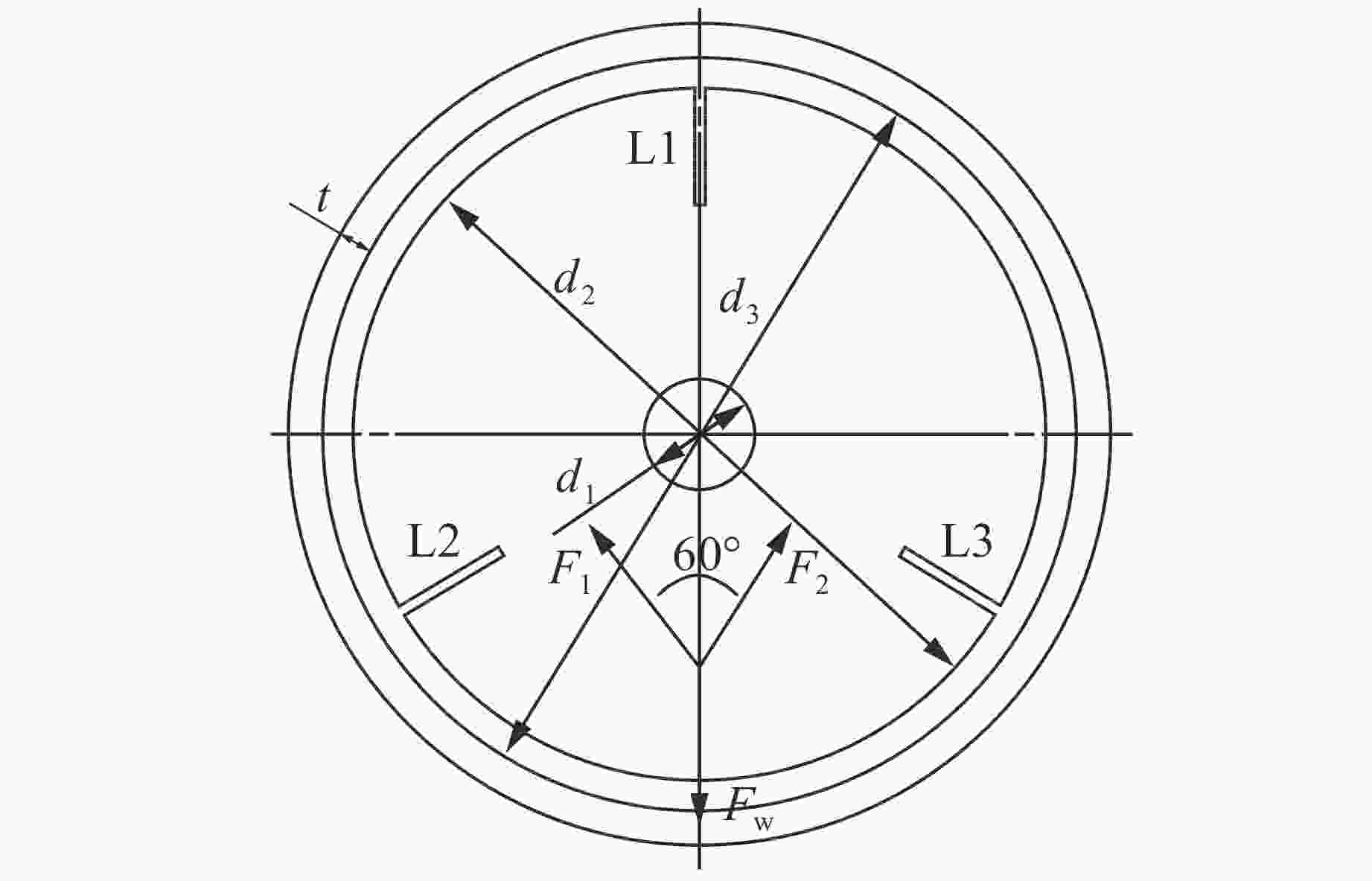

摘要: 为研究高能转子轮盘的包容机理,加工了预制裂纹的试验轮盘,在高速旋转试验台上进行高能转子轮盘的包容性试验,采用非线性显式动力学商用软件对高能转子包容性进行数值仿真。试验结果和仿真分析结果表明,轮盘碎片与包容壳撞击后,撞击区域和边缘材料分别受压缩和剪切作用,如果局部的穿孔失效没有发生,则碎片是否逃逸由壳体材料撞击区和延伸区域的拉伸应变能决定。以某空气涡轮起动机为例,讨论了轮盘包容环厚度与选材,证明了以1.15倍临界包容厚度值作为安全系数确定工程许用包容环厚度的设计方法,通过比较不同材料包容环的包容能力,得出用高极限强度和高延伸率的材料作为包容环材料能够实现明显减重。研究结果对高能转子轮盘的包容结构设计具有指导意义。Abstract: In order to study the mechanism for disk containment of high-energy rotor, with test rotor manufactured with precast cracks, containment tests are carried out using a high-speed spin tester, and the nonlinear explicit dynamics commercial software is used to simulate the containment process of the high-energy rotor. It is found that the impacted area and the edge material in the containment case are compressed and sheared respectively after the impact of the disk fragments by test and simulation results. If the local perforation failure does not occur, the penetration of the fragment is determined by the tensile strain energy of the impacted area and the circumferential extension of the case. Then taking some turbine starter disk an example, the thickness and material analysis of the containment ring are discussed. The design method of determining the allowable thickness of the containment ring by the critical containment thickness 1.15 times of the safety factor is proved. By comparing the containment capacity of different materials, it is concluded that using higher ultimate strength and elongation material to achieve significant weight reduction. This study has some significance to the design of the containment structure of the high energy rotor.

-

Key words:

- high-energy rotor /

- disk containment /

- containment ring /

- structural optimization

-

表 1 试验结果

Table 1. Test results

No. Calculated burst speed/(r·min–1) Test burst speed/(r·min–1) Casing thickness/mm Containment 1 n1

n10.9852n1 6 No 2 0.9896n1 9 Yes Basic parameters Johnson-Cook plastic constructive parameters Johnson-Cook damage parameters E/GPa ν ρ/(kg·m–3) A/MPa B/MPa C n m D1 D2 D3 D4 D5 200 0.30 7800 506 320 0.064 0.28 1.06 0.10 0.76 1.57 0.005 −0.84 表 3 3种材料的基本力学性能

Table 3. Basic mechanical properties of three kinds of materials

Material σb,c/MPa δe/% Density/(g·cm–3) 1Cr13Ni 930 13.0 7.70 GH4169 1299 23.5 8.24 GH625 799 30.0 8.40 -

[1] MOUSA N A, WHALE M D, GROSZMANN D E, et al. The potential for fuel tank fire and hydrodynamic ram from uncontained aircraft engine debris: DOT/FAA/AR-96/95 [R]. Washington DC, USA: US Department of Transportation, Federal Aviation Administration, 1997. [2] XUAN H J, LIU L L, FENG Y M, et al. Containment of high-speed rotating disk fragments [J]. Journal of Zhejiang University–Science A, 2012, 13(9): 665−673. [3] 宣海军, 何泽侃, 牛丹丹, 等. 航空发动机软壁风扇机匣包容性研究 [J]. 航空发动机, 2015, 41(6): 81–87. doi: 10.13477/j.cnki.aeroengine.2015.06.016XUAN H J, HE Z K, NIU D D. Investigation on containment of aeroengine soft-wall fan case [J]. Aeroengine, 2015, 41(6): 81–87. doi: 10.13477/j.cnki.aeroengine.2015.06.016 [4] NAIK D, SANKARAN S, MOBASHER B, et al. Development of reliable modeling methodologies for fan blade out containment analysis, part Ⅰ: experimental studies [J]. International Journal of Impact Engineering, 2009, 36(1): 1–11. doi: 10.1016/j.ijimpeng.2008.03.007 [5] STAHLECKER Z, MOBASHER B, RAJAN S D, et al. Development of reliable modeling methodologies for engine fan blade out containment analysis, part Ⅱ: finite element analysis [J]. International Journal of Impact Engineering, 2009, 36(3): 447–459. doi: 10.1016/j.ijimpeng.2008.08.004 [6] XUAN H J, WU R R. Aero-engine turbine blade containment tests using high-speed rotor spin testing facility [J]. Aerospace Science and Technology, 2006, 10(6): 501–508. doi: 10.1016/j.ast.2006.04.006 [7] STAMPER E, HALE S. The use of LS-DYNA model to predict containment of disk burst fragments [C]//Proceedings of 10th International LS-DYNA Users Conference. Dearborn, Michigan, USA, 2008. [8] HAGG A C, SANKEY G O. The containment of disk burst fragment by cylindrical shells [J] . Journal of Engineering for Gas Turbines & Power, 1974, 96(2): 114. [9] LI J J, XUAN H J, LIAO L F, et al. Penetration of disk fragments following impact on thin plate [J]. Journal of Zhejiang University–Science A, 2009, 10(5): 677–684. doi: 10.1631/jzus.A0820746 [10] 唐金, 唐广, 宣海军, 等. 航空发动机涡轮机匣轮盘包容性研究 [J]. 航空动力学报, 2016, 31(6): 1393−1399.TANG J, TANG G, XUAN H J, et al. Investigation on disk containment of aero-engine turbine casing [J]. Journal of Aerospace Power, 2016, 31(6): 1393−1399. [11] 周琳, 王子豪, 文鹤鸣. 简论金属材料JC本构模型的精确性 [J]. 高压物理学报, 2019, 33(4): 042101. doi: 10.11858/gywlxb.20190721ZHOU L, WANG Z H, WEN H M. On the accuracy of the Johnson-Cook constitutive model for metals [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 042101. doi: 10.11858/gywlxb.20190721 [12] 陈刚. 半穿甲战斗部弹体穿甲效应数值模拟与实验研究 [D]. 绵阳: 中国工程物理研究院, 2006.CHEN G. Numerical and experimental investigation on penetration effects of semi-armor-piercing warhead [D]. Mianyang: China Academy of Engineering Physics, 2006. [13] WANG Y F, YANG Z G. A coupled finite element and meshfree analysis of erosive wear [J]. Tribology International, 2009, 42(2): 373−377. -

下载:

下载: