Topological Optimization and Dynamic Response of Periodic Porous Sandwich Structure under Impact Load

-

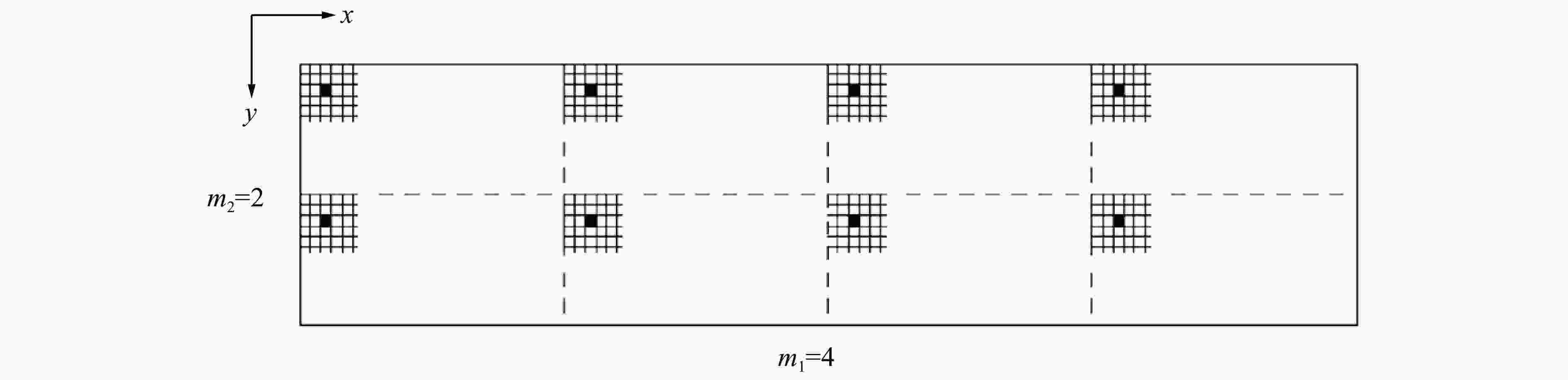

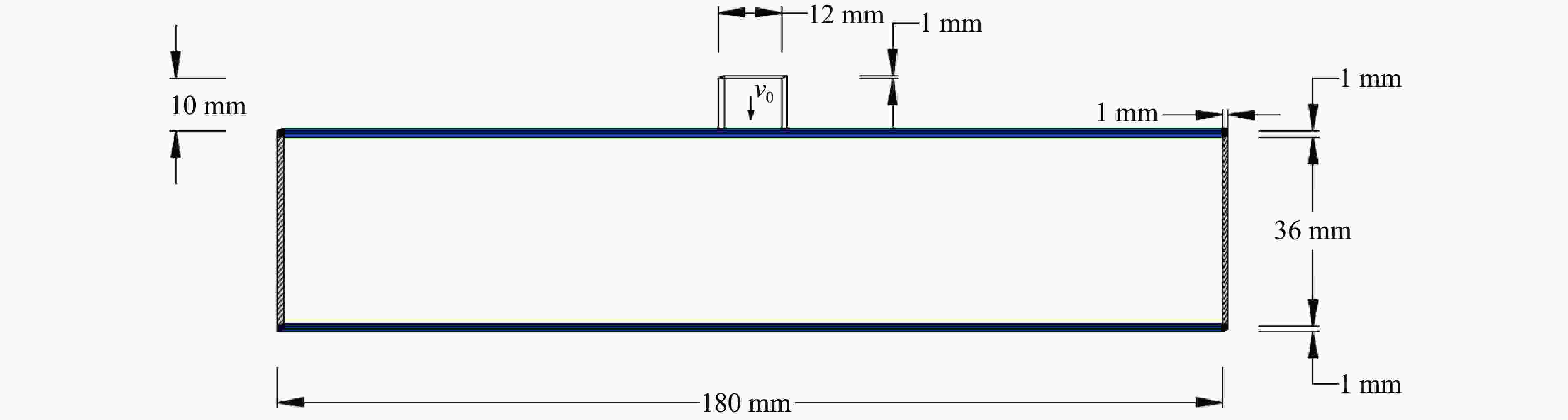

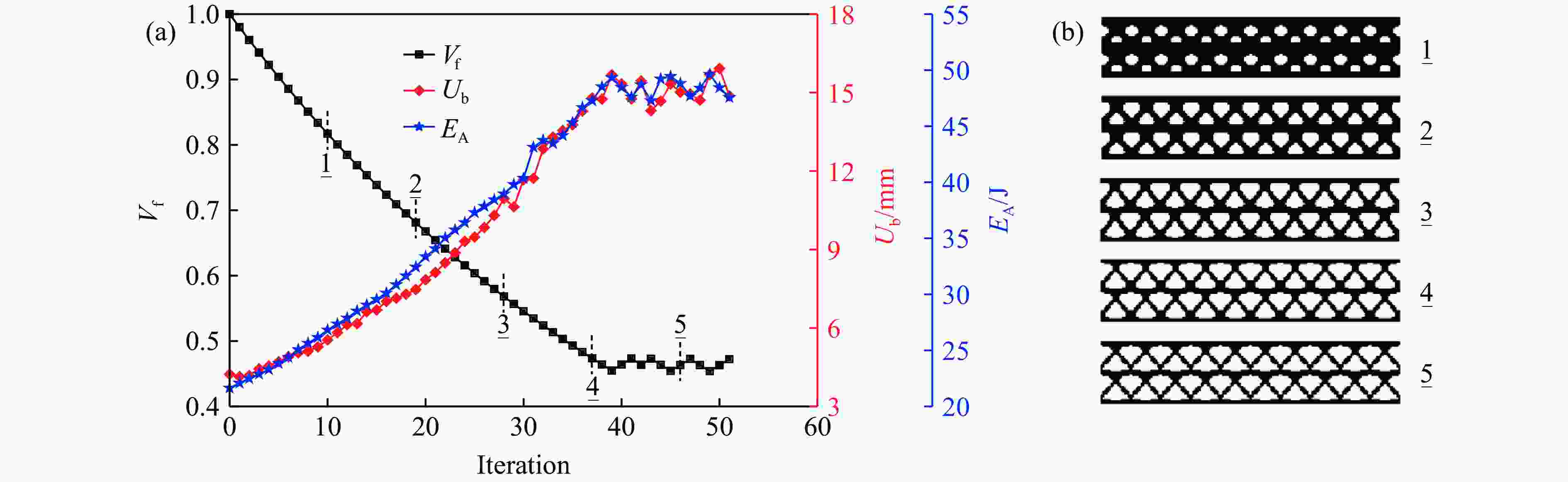

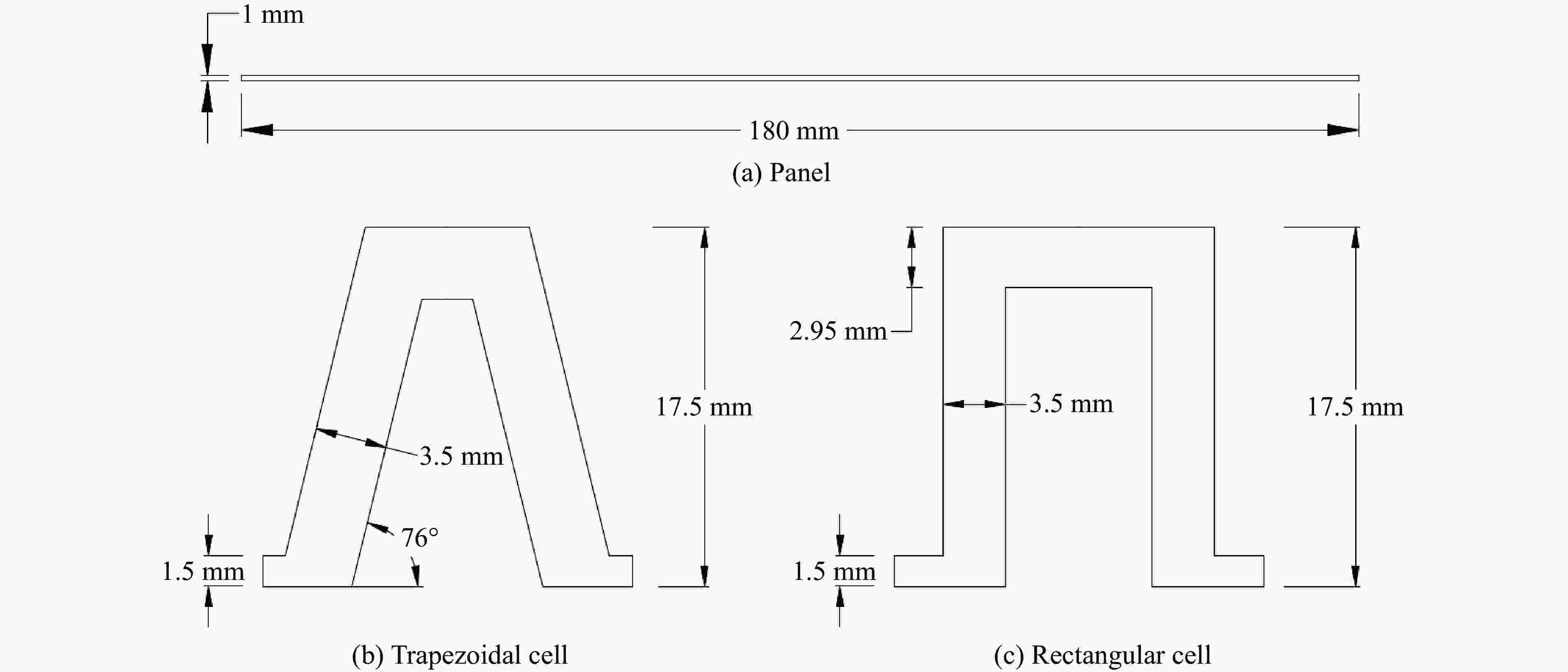

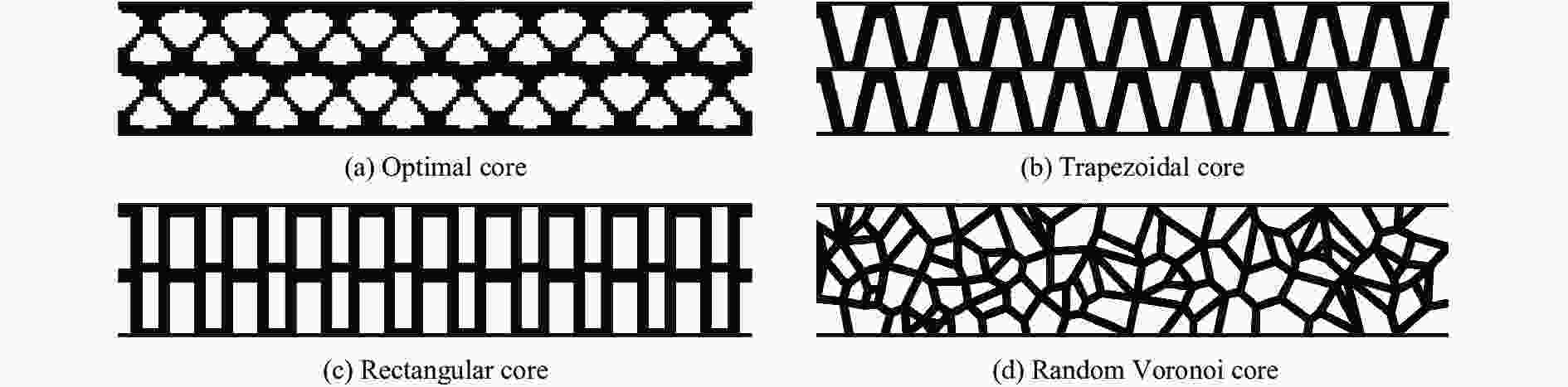

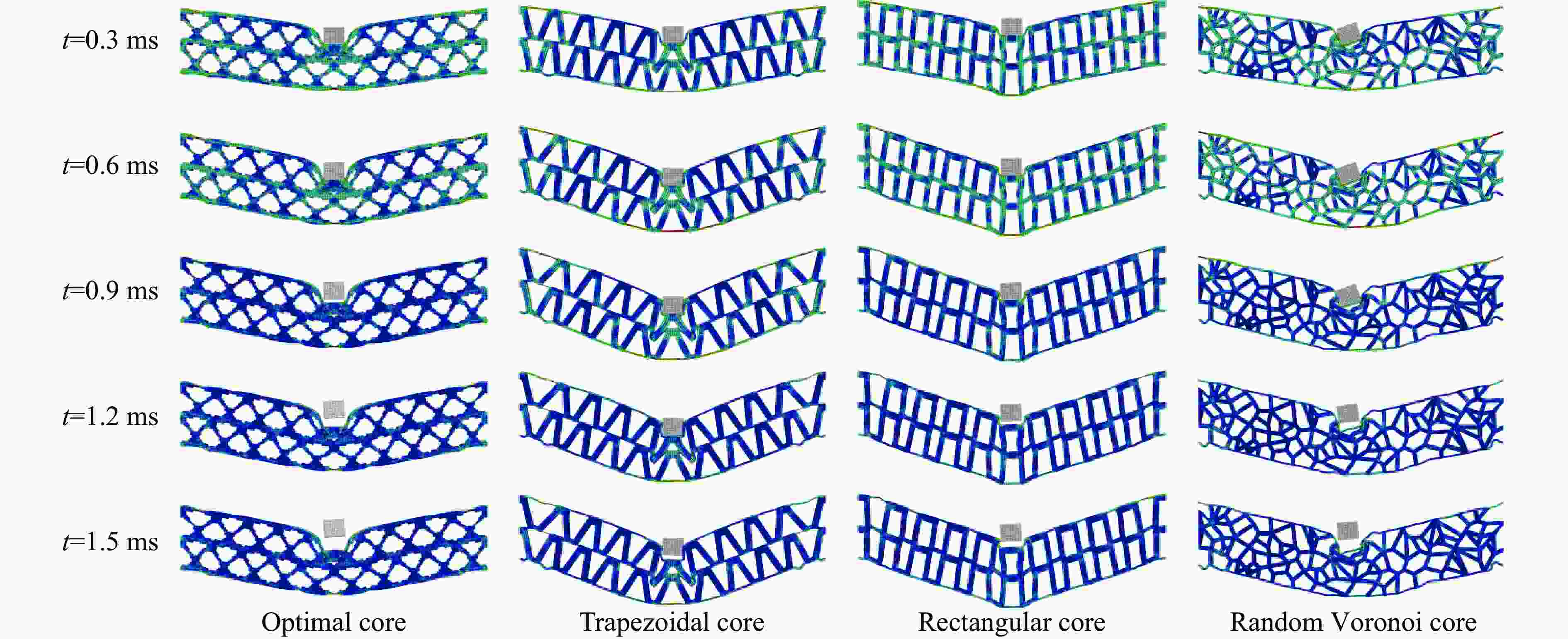

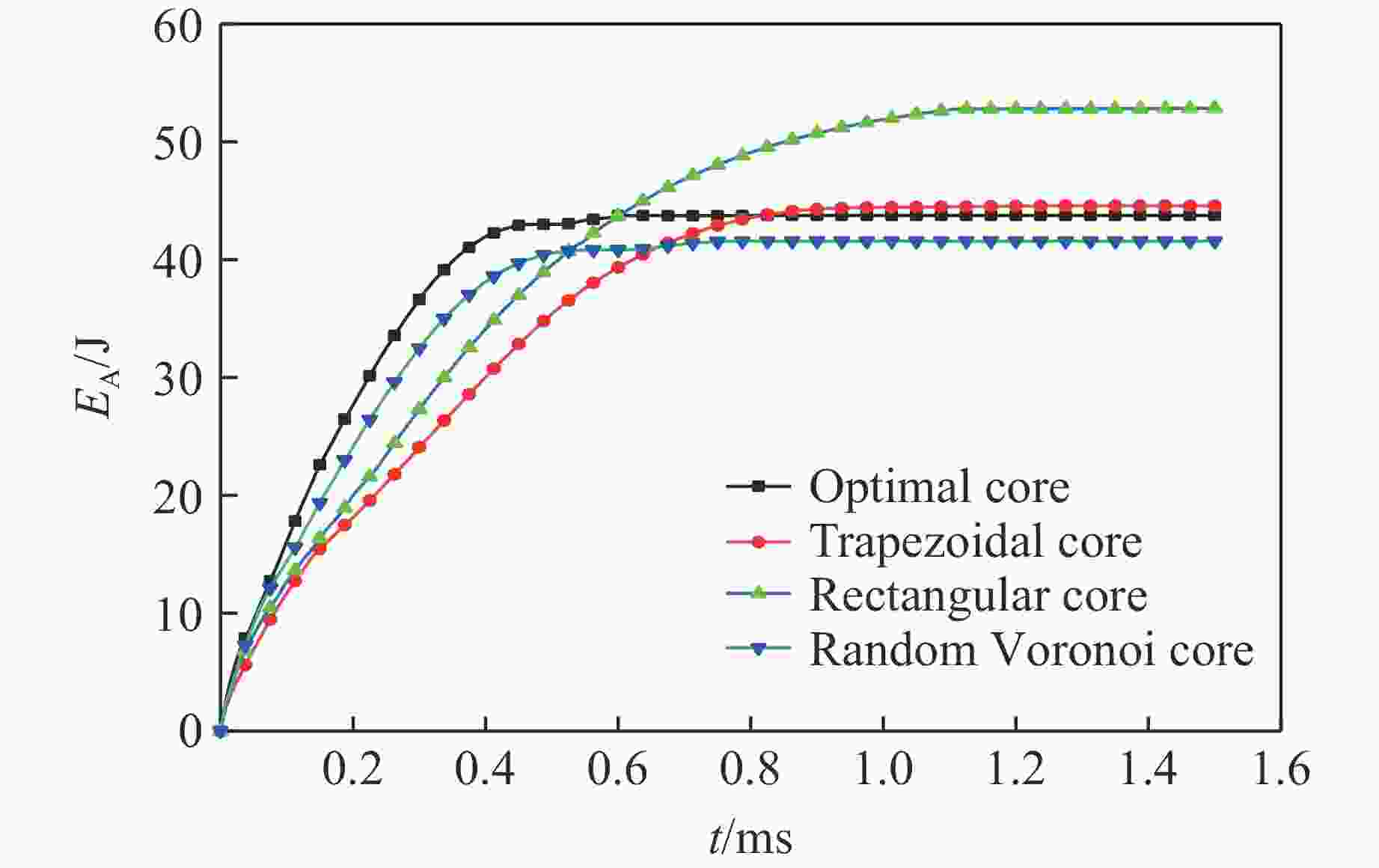

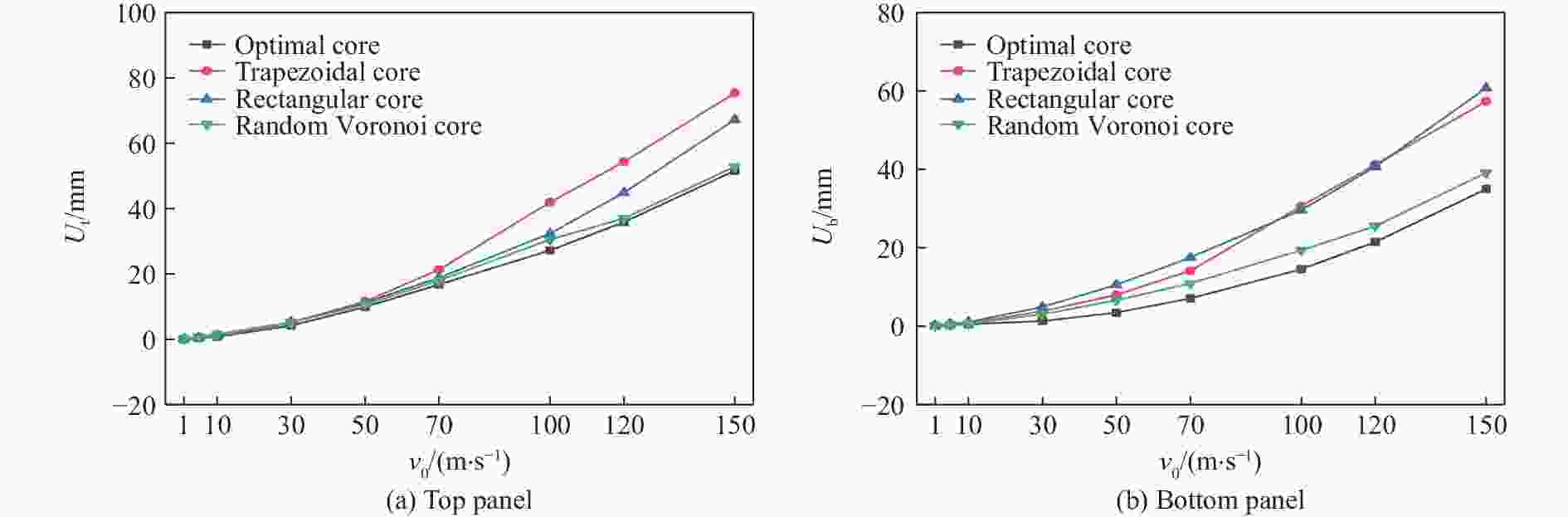

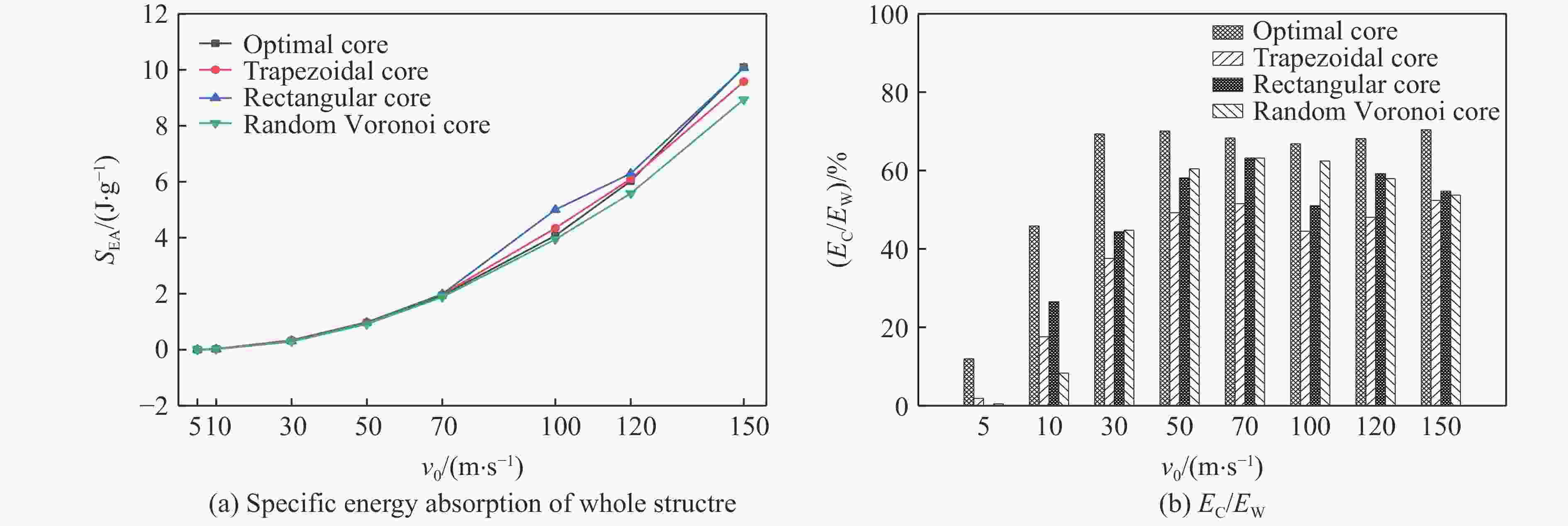

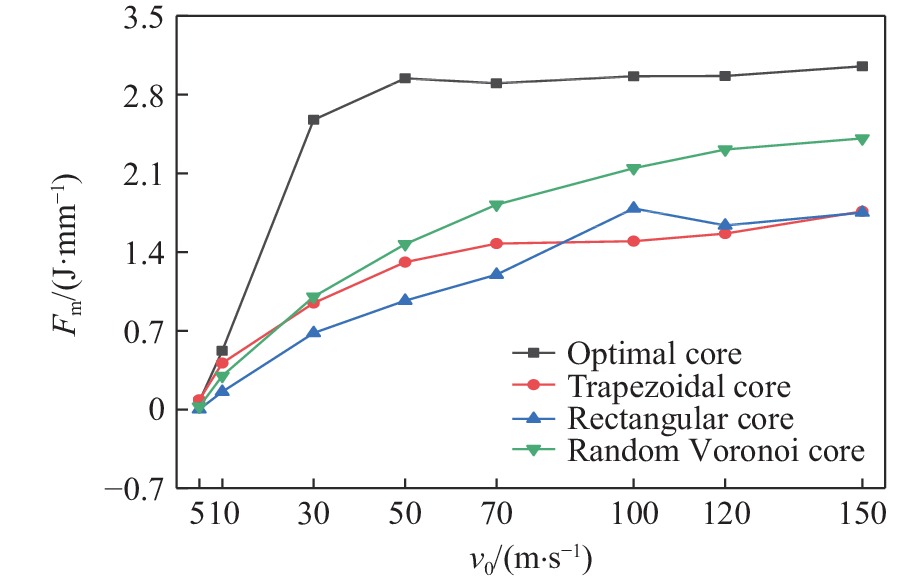

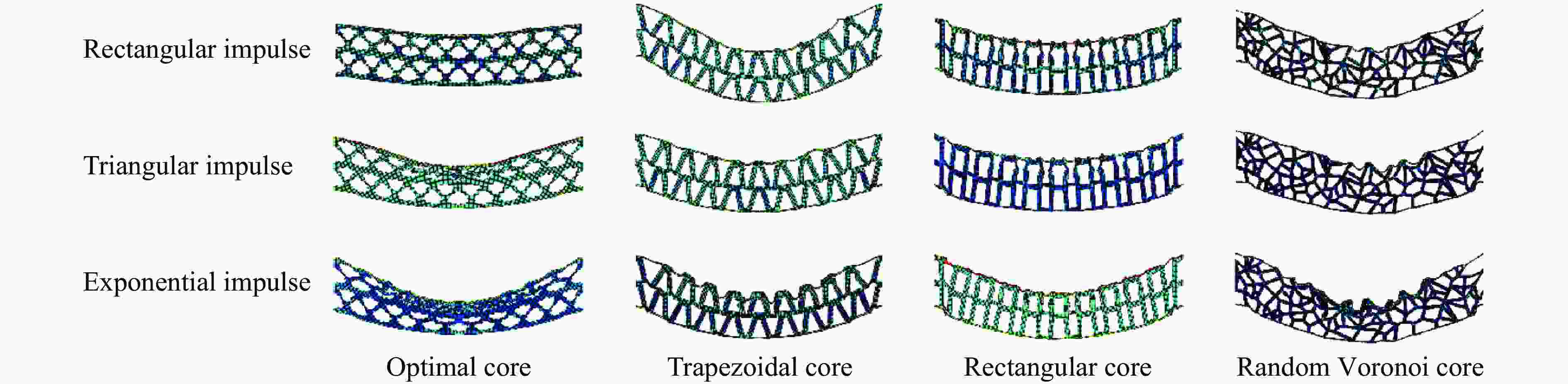

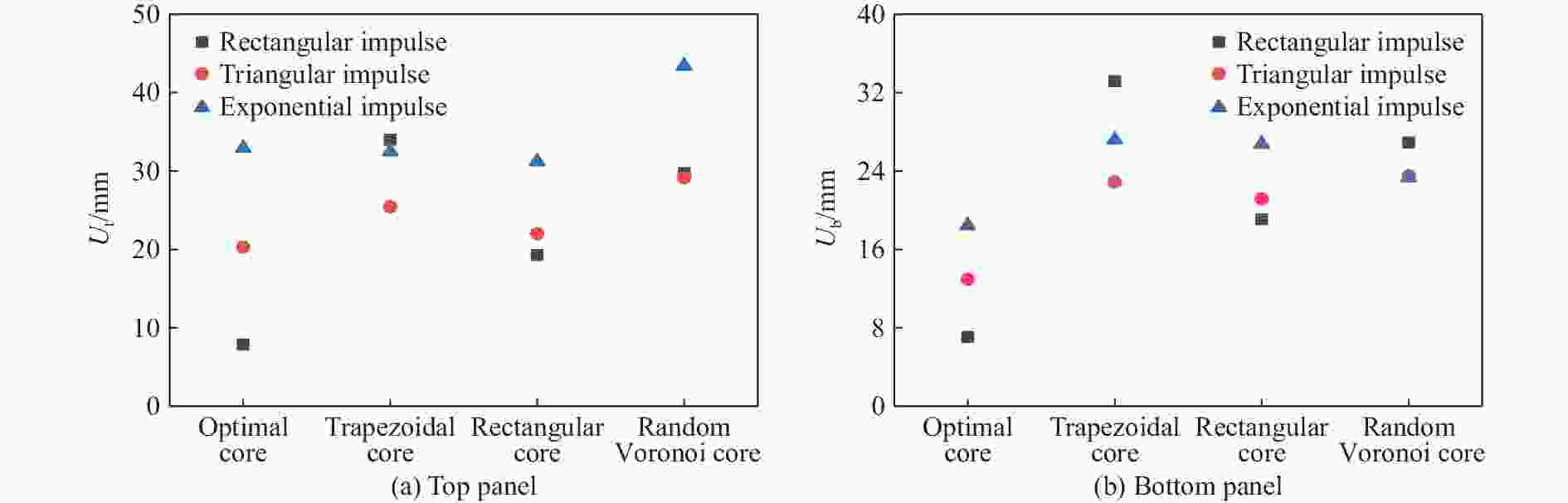

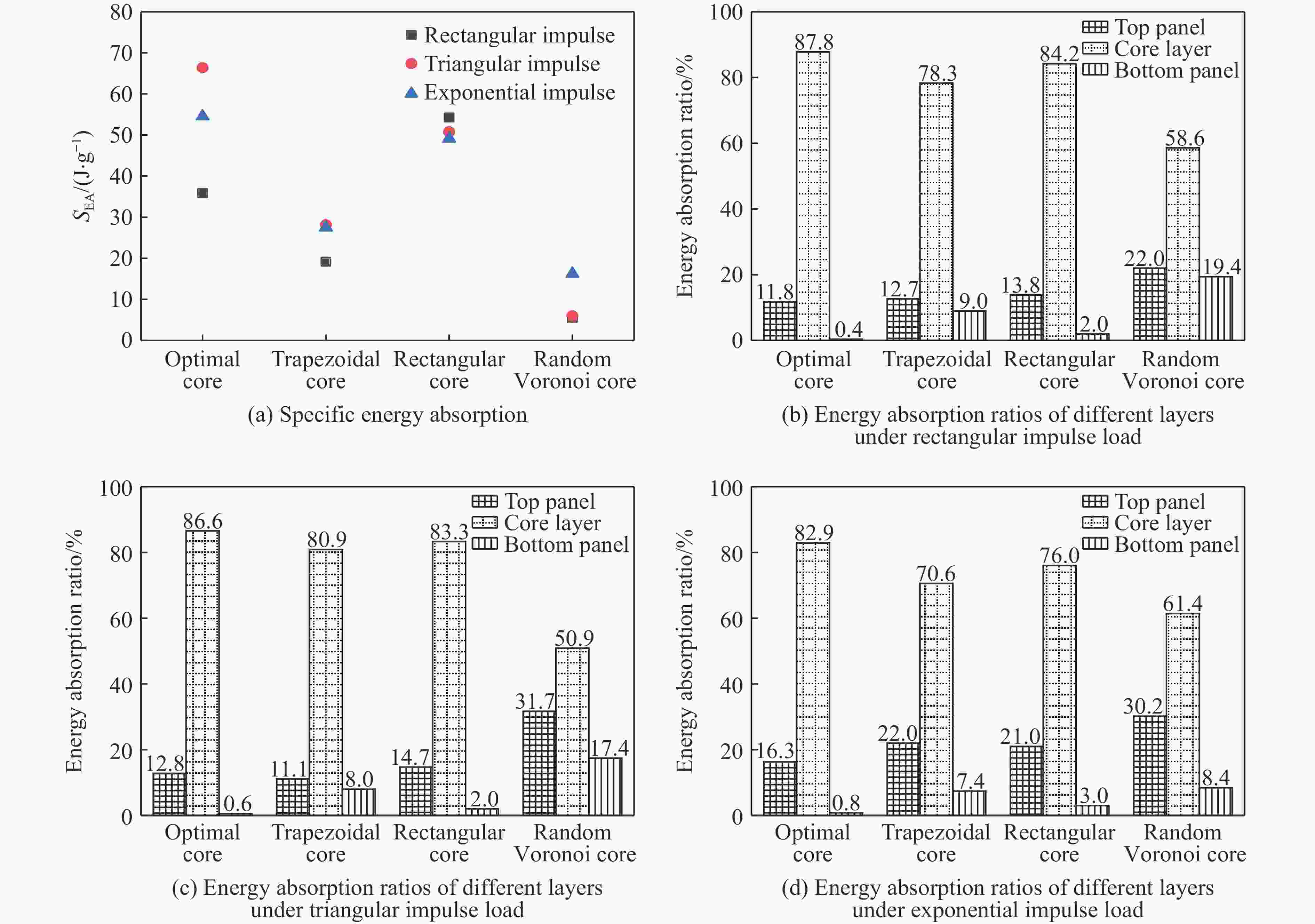

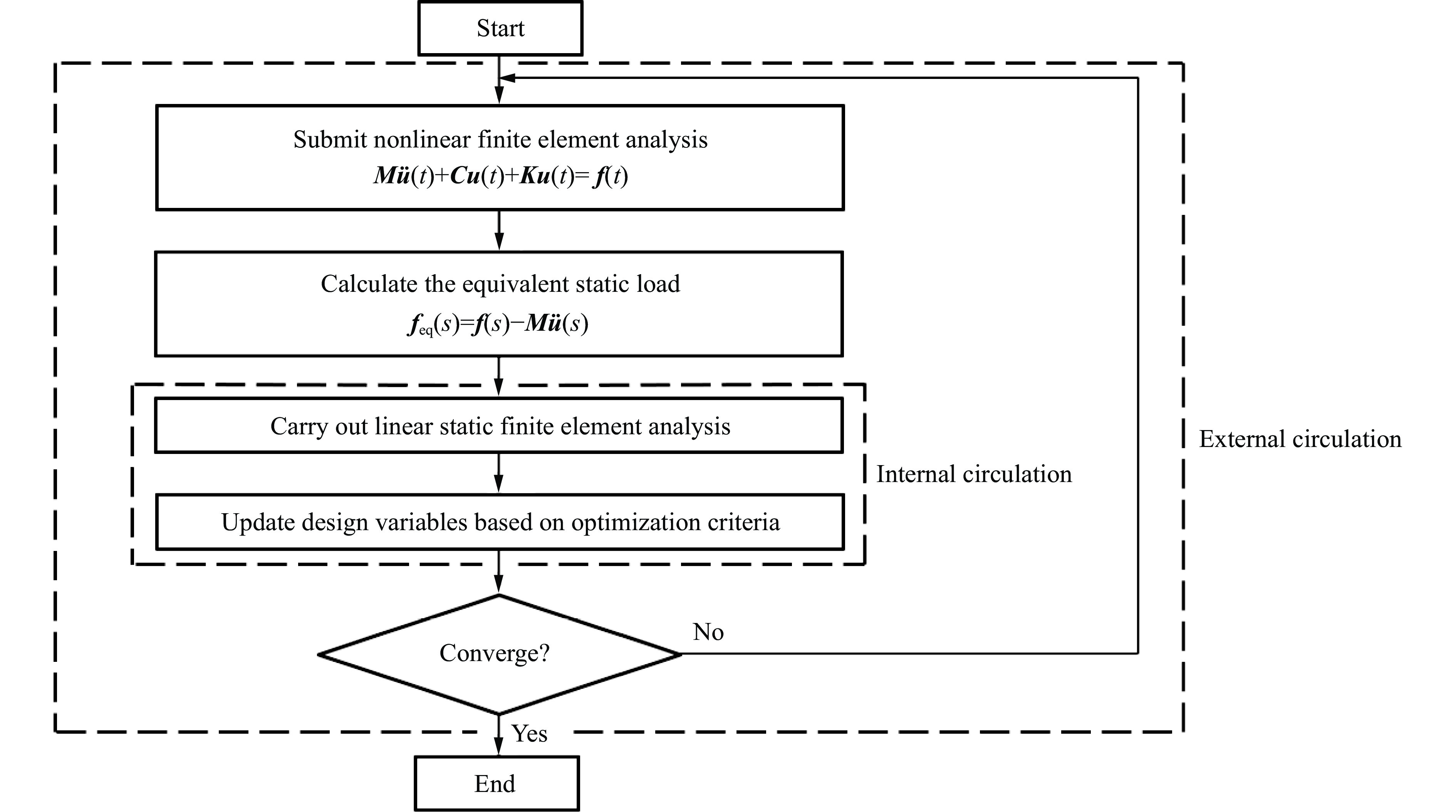

摘要: 在等效静力方法框架下基于双向渐进结构优化硬杀法构建了冲击载荷下周期性多孔夹芯结构的拓扑优化方法。采用ABAQUS有限元软件,研究了周期性优化夹芯结构与梯形波纹芯层、矩形波纹芯层和随机Voronoi芯层夹芯梁在刚体以100 m/s的速度撞击下的变形失效模式。在载荷作用前期,优化夹芯结构的上半部分芯层被完全压缩,能量吸收优于其他3种结构;在载荷作用后期,由于优化夹芯结构的最终塑性变形较小,在整个响应过程中总能量吸收略小于其他3种结构。为检验单一载荷工况下优化夹芯结构在其他载荷作用下的性能,采用不同速度的刚体以3种不同类型的脉冲载荷加载,比较了4种夹芯结构的能量吸收性能。综合考虑夹芯结构上下面板的跨中挠度、比吸能、芯层吸能占比和平均冲击力后发现:在刚体冲击下,优化夹芯结构具有更好的能量吸收性能和抗冲击性能;在矩形脉冲下,优化夹芯结构的比吸能小于矩形波纹芯夹芯结构,未能体现结构优化的优势。研究表明,单一工况下优化所得的结构不能在任意载荷下均表现出最优异的性能,因此,针对不同的载荷工况,需要进一步的研究。Abstract: In this study, under the frame of equivalent static loads (ESL) method structural optimization and based on hard-kill bi-directional evolutionary structural optimization (hard-kill BESO), the topological optimization method for periodic porous sandwich structure under impact load was carried out. The commercial software ABAQUS was used to investigate the deformation patterns of the optimized periodic sandwich structure and the sandwich structures with trapezoidal, rectangular and random Voronoi cores under the impact load imposed by a rigid body with an initial velocity of 100 m/s. In the early stage of load, the upper half of the core layer of the optimized periodic sandwich structure is completely compressed and the energy absorption is higher than the other three structures. However, the total energy absorption of the optimal sandwich structure is slightly less than the other three due to the small plastic deformation at the end stage of load. To study the capabilities of the topologically optimized structure under different load conditions, the energy absorption performance of the four sandwich structures subjected to the rigid body impact loads at different velocities and three impulse loads were compared. After comprehensively considering the deflection at the centers of top and bottom panels, the specific energy absorption, the ratio of energy absorption of core layer, as well as the mean impact load, it shows that the optimized sandwich periodic structure performs higher energy absorption capability and resistance under the rigid body impact. The specific energy absorption of the optimal sandwich structure is less than the sandwich structure with rectangular core under rectangular impulse, losing advantages of the structural optimization. It indicates that the optimization design obtained under a single load condition cannot get the best performance for any load condition, and further research is required for different load conditions.

-

Key words:

- topology optimization /

- impact load /

- sandwich periodic structure /

- energy absorption

-

表 1 优化结构的上面板挠度与其他3种结构中上面板挠度的最大值的对比

Table 1. Comparison of top panel deflection of optimal structure and the maximum value of other three structures

v0/(m∙s−1) Core with the maximum deflection of the

top panel for other three structuresUt,max/mm $U{_{\rm {t} }^{ {\rm{op} } } }$/mm (Ut,max−$U{_{\rm {t} }^{ {\rm{op} } } }$)/mm Error/% 30 Rectangular core 5.20 4.17 1.03 19.8 50 Trapezoidal core 11.57 9.84 1.73 15.0 70 Rectangular core 21.28 16.73 4.55 21.4 100 Trapezoidal core 41.90 27.36 14.54 34.7 120 Trapezoidal core 54.28 35.86 18.42 33.9 150 Trapezoidal core 75.40 51.56 23.84 31.6 表 2 优化结构的下面板挠度与其他3种结构中最大值的对比

Table 2. Comparison of bottom panel deflection of optimal structure and the maximum value of other three structures

v0/(m∙s−1) Core with the maximum deflection of the

bottom panel for other three structuresUb,max/mm $U{_{\rm {t} }^{ {\rm{op} } } } $/mm (Ub,max−$U{_{\rm {t} }^{ {\rm{op} } } } $)/mm Error/% 30 Rectangular core 5.05 1.32 3.73 73.9 50 Rectangular core 10.96 3.46 7.50 68.4 70 Rectangular core 18.20 7.08 11.12 61.1 100 Trapezoidal core 30.62 14.86 15.76 51.5 120 Trapezoidal core 49.75 21.47 28.28 56.8 150 Rectangular core 63.48 34.96 28.52 44.9 -

[1] LI S Q, WU G X, WANG Z H, et al. Finite element simulation of metallic cylindrical sandwich shells with graded aluminum tubular cores subjected to internal blast loading [J]. International Journal of Mechanical Sciences, 2015, 96/97: 1–12. doi: 10.1016/j.ijmecsci.2015.03.011 [2] 张振聪, 张旭, 黄辉秀, 等. 风电叶片夹芯结构的疲劳性能 [J]. 塑料工业, 2021, 49(11): 79–84. doi: 10.3969/j.issn.1005-5770.2021.11.017ZHANG Z C, ZHANG X, HUANG H X, et al. Fatigue behavior of sandwich structure of wind turbine blade [J]. China Plastics Industry, 2021, 49(11): 79–84. doi: 10.3969/j.issn.1005-5770.2021.11.017 [3] 陈昕, 朱锡, 张力军, 等. 雷达防弹天线罩夹芯结构设计与性能研究 [J]. 兵工学报, 2010, 31(10): 1298–1302.CHEN X, ZHU X, ZHANG L J, et al. Design and properties of sandwich structure for ballistic-resistant radome [J]. Acta Armamentarii, 2010, 31(10): 1298–1302. [4] 徐平, 石瑞瑞, 阮文松, 等. 泡沫铝夹芯结构汽车顶板的研究 [J]. 机械科学与技术, 2016, 35(10): 1636–1640. doi: 10.13433/j.cnki.1003-8728.2016.1027XU P, SHI R R, RUAN W S, et al. Studying car roof of aluminum foam sandwich structure [J]. Mechanical Science and Technology for Aerospace Engineering, 2016, 35(10): 1636–1640. doi: 10.13433/j.cnki.1003-8728.2016.1027 [5] MUKHERJEE G S, SARAF M N. Studies on a fiber reinforced plastics honeycomb structure [J]. Polymer Composites, 1994, 15(3): 217–222. doi: 10.1002/pc.750150307 [6] GIBSON L J, ASHBY M F. Cellular solids: structure and properties [M]. Cambridge: Cambridge University Press, 1997: 546. [7] YU J L, WANG X, WEI Z G, et al. Deformation and failure mechanism of dynamically loaded sandwich beams with aluminum-foam core [J]. International Journal of Impact Engineering, 2003, 28(3): 331–347. doi: 10.1016/S0734-743X(02)00053-2 [8] RUAN D, LU G X, WONG Y C. Quasi-static indentation tests on aluminium foam sandwich panels [J]. Composite Structures, 2010, 92(9): 2039–2046. doi: 10.1016/j.compstruct.2009.11.014 [9] JANDAGHI SHAHI V, MARZBANRAD J. Analytical and experimental studies on quasi-static axial crush behavior of thin-walled tailor-made aluminum tubes [J]. Thin-Walled Structures, 2012, 60: 24–37. doi: 10.1016/j.tws.2012.05.015 [10] HANSSEN A G, LANGSETH M, HOPPERSTAD O S. Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler [J]. International Journal of Impact Engineering, 2000, 24(5): 475–507. doi: 10.1016/S0734-743X(99)00170-0 [11] SUN G Y, ZHANG J T, LI S Q, et al. Dynamic response of sandwich panel with hierarchical honeycomb cores subject to blast loading [J]. Thin-Walled Structures, 2019, 142: 499–515. doi: 10.1016/j.tws.2019.04.029 [12] SUN Y L, LI Q M. Dynamic compressive behaviour of cellular materials: a review of phenomenon, mechanism and modelling [J]. International Journal of Impact Engineering, 2018, 112: 74–115. doi: 10.1016/j.ijimpeng.2017.10.006 [13] NURICK G N, LANGDON G S, CHI Y, et al. Behaviour of sandwich panels subjected to intense air blast: part 1: experiments [J]. Composite Structures, 2009, 91(4): 433–441. doi: 10.1016/j.compstruct.2009.04.009 [14] LI S Q, LI X, WANG Z H, et al. Sandwich panels with layered graded aluminum honeycomb cores under blast loading [J]. Composite Structures, 2017, 173: 242–254. doi: 10.1016/j.compstruct.2017.04.037 [15] LI S Q, LI X, WANG Z H, et al. Finite element analysis of sandwich panels with stepwise graded aluminum honeycomb cores under blast loading [J]. Composites Part A: Applied Science and Manufacturing, 2016, 80: 1–12. doi: 10.1016/j.compositesa.2015.09.025 [16] YAHAYA M A, RUAN D, LU G, et al. Response of aluminium honeycomb sandwich panels subjected to foam projectile impact: an experimental study [J]. International Journal of Impact Engineering, 2015, 75: 100–109. doi: 10.1016/j.ijimpeng.2014.07.019 [17] CHEN W J, TONG L Y, LIU S T. Concurrent topology design of structure and material using a two-scale topology optimization [J]. Computers & Structures, 2017, 178: 119–128. [18] BENDSØE M P. Optimal shape design as a material distribution problem [J]. Structural Optimization, 1989, 1(4): 193–202. doi: 10.1007/BF01650949 [19] XIE Y M, STEVEN G P. A simple evolutionary procedure for structural optimization [J]. Computers & Structures, 1993, 49(5): 885–896. [20] HUANG X, XIE Y M. Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method [J]. Finite Elements in Analysis and Design, 2007, 43(14): 1039–1049. doi: 10.1016/j.finel.2007.06.006 [21] XIA L, XIA Q, HUANG X D, et al. Bi-directional evolutionary structural optimization on advanced structures and materials: a comprehensive review [J]. Archives of Computational Methods in Engineering, 2018, 25(2): 437–478. doi: 10.1007/s11831-016-9203-2 [22] GUO X, ZHANG W S, ZHANG J, et al. Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons [J]. Computer Methods in Applied Mechanics and Engineering, 2016, 310: 711–748. doi: 10.1016/j.cma.2016.07.018 [23] ZHOU Y, ZHANG W H, ZHU J H, et al. Feature-driven topology optimization method with signed distance function [J]. Computer Methods in Applied Mechanics and Engineering, 2016, 310: 1–32. doi: 10.1016/j.cma.2016.06.027 [24] WANG M Y, WANG X M, GUO D M. A level set method for structural topology optimization [J]. Computer Methods in Applied Mechanics and Engineering, 2003, 192(1/2): 227–246. [25] LI H, LUO Z, GAO L, et al. Topology optimization for functionally graded cellular composites with metamaterials by level sets [J]. Computer Methods in Applied Mechanics and Engineering, 2018, 328: 340–364. doi: 10.1016/j.cma.2017.09.008 [26] 彭细荣, 隋允康. 考虑破损-安全的连续体结构拓扑优化ICM方法 [J]. 力学学报, 2018, 50(3): 611–621. doi: 10.6052/0459-1879-17-366PENG X R, SUI Y K. ICM method for fail-safe topology optimization of continuum structures [J]. Chinese Journal of Theoretical and Applied Mechanics, 2018, 50(3): 611–621. doi: 10.6052/0459-1879-17-366 [27] YOO S H, CHANG S H, SUTCLIFFE M P F. Compressive characteristics of foam-filled composite egg-box sandwich panels as energy absorbing structures [J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(3): 427–434. doi: 10.1016/j.compositesa.2009.11.010 [28] WANG L S, BASU P K, LEIVA J P. Automobile body reinforcement by finite element optimization [J]. Finite Elements in Analysis and Design, 2004, 40(8): 879–893. doi: 10.1016/S0168-874X(03)00118-5 [29] CAVAZZUTI M, BALDINI A, BERTOCCHI E. High performance automotive chassis design: a topology optimization based approach [J]. Structural and Multidisciplinary Optimization, 2011, 44(1): 45–56. doi: 10.1007/s00158-010-0578-7 [30] MRZYGŁÓD M, KUCZEK T. Uniform crashworthiness optimization of car body for high-speed trains [J]. Structural and Multidisciplinary Optimization, 2014, 49(2): 327–336. doi: 10.1007/s00158-013-0972-z [31] HUANG X, XIE Y M, LU G. Topology optimization of energy-absorbing structures [J]. International Journal of Crashworthiness, 2007, 12(6): 663–675. doi: 10.1080/13588260701497862 [32] DUDDECK F, HUNKELER S, LOZANO P, et al. Topology optimization for crashworthiness of thin-walled structures under axial impact using hybrid cellular automata [J]. Structural and Multidisciplinary Optimization, 2016, 54(3): 415–428. doi: 10.1007/s00158-016-1445-y [33] PATEL N M, KANG B S, RENAUD J E, et al. Crashworthiness design using topology optimization [J]. Journal of Mechanical Design, 2009, 131(6): 061013. doi: 10.1115/1.3116256 [34] SOTO C A. Structural topology optimization for crashworthiness [J]. International Journal of Crashworthiness, 2004, 9(3): 277–283. doi: 10.1533/ijcr.2004.0288 [35] PARK G J. Technical overview of the equivalent static loads method for non-linear static response structural optimization [J]. Structural and Multidisciplinary Optimization, 2011, 43(3): 319–337. doi: 10.1007/s00158-010-0530-x [36] NELSON M F, WOLF JR J A. The use of inertia relief to estimate impact loads [C]//Proceeding of the 2nd International Conference on Vehicle Structural Mechanics. SAE, 1977: 149−155. [37] WU S Z, ZHENG G, SUN G Y, et al. On design of multi-cell thin-wall structures for crashworthiness [J]. International Journal of Impact Engineering, 2016, 88: 102–117. doi: 10.1016/j.ijimpeng.2015.09.003 [38] 孙晓辉, 丁晓红. 结构多目标拓扑优化设计 [J]. 机械设计与研究, 2018, 28(4): 1–4, 9. doi: 10.13952/j.cnki.jofmdr.2012.04.016SUN X H, DING X H. Research on multi-objective topology optimization design methods for structure [J]. Machine Design and Research, 2018, 28(4): 1–4, 9. doi: 10.13952/j.cnki.jofmdr.2012.04.016 [39] DAVIS J R, JOSEPH R. Metals handbook [M]. Ohio: Materials Park, 1998: 878. [40] KARAGIOZOVA D, NURICK G N, LANGDON G S. Behaviour of sandwich panels subject to intense air blasts: part 2: numerical simulation [J]. Composite Structures, 2009, 91(4): 442–450. doi: 10.1016/j.compstruct.2009.04.010 -

下载:

下载: