Energy Absorption and Multi-Objective Optimization for Sandwich Tubes with a Corrugated Core under Axial Compression

-

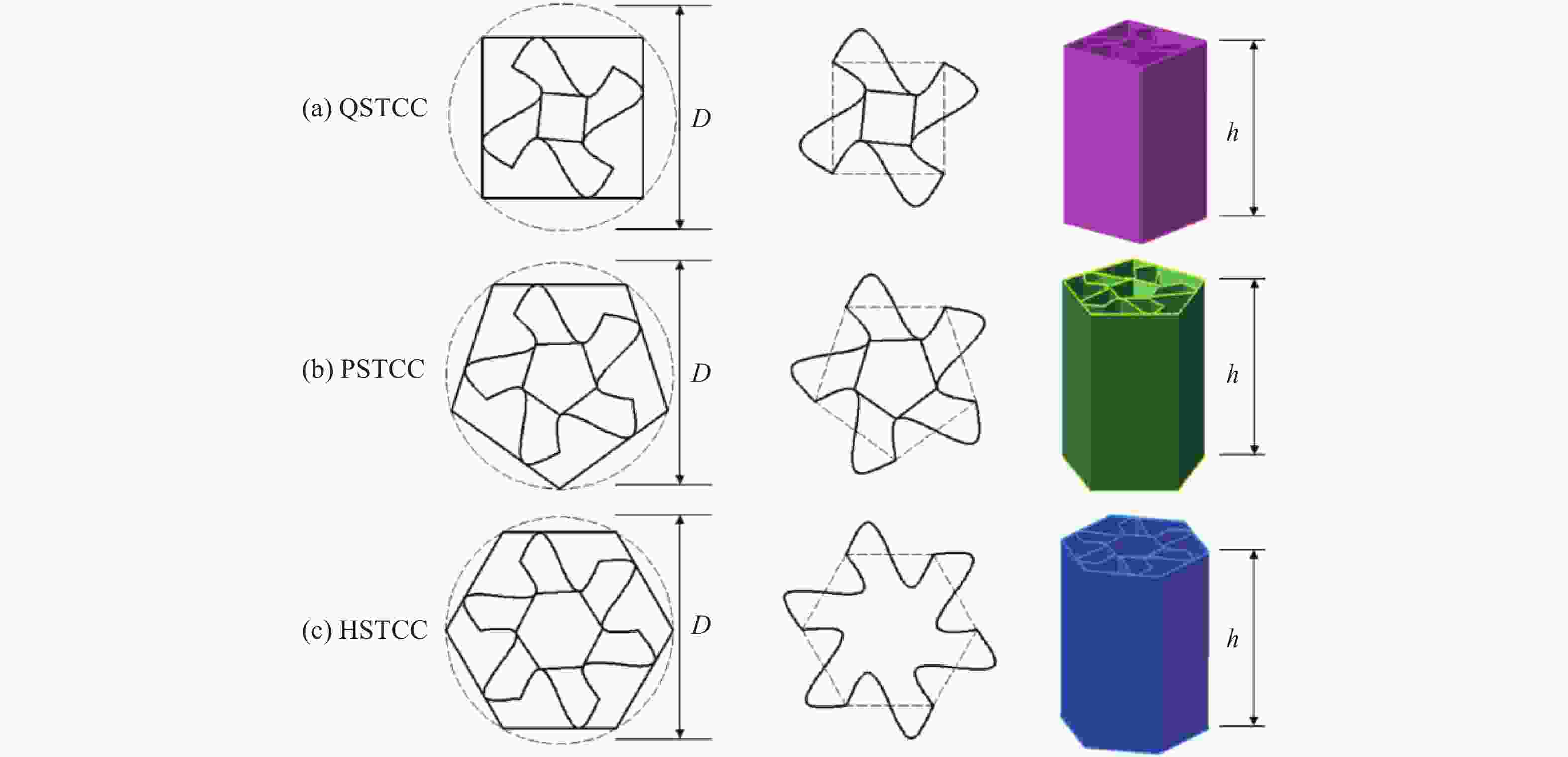

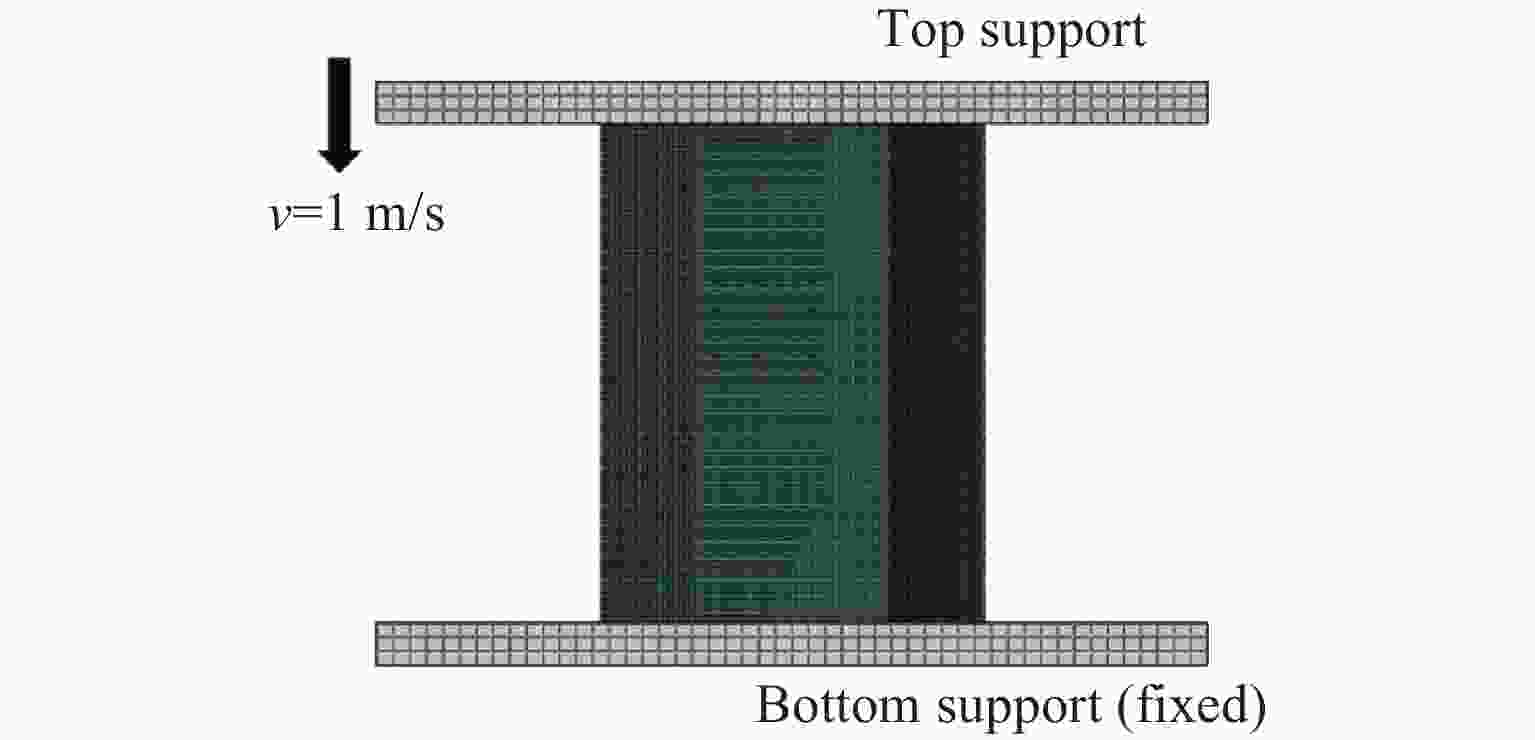

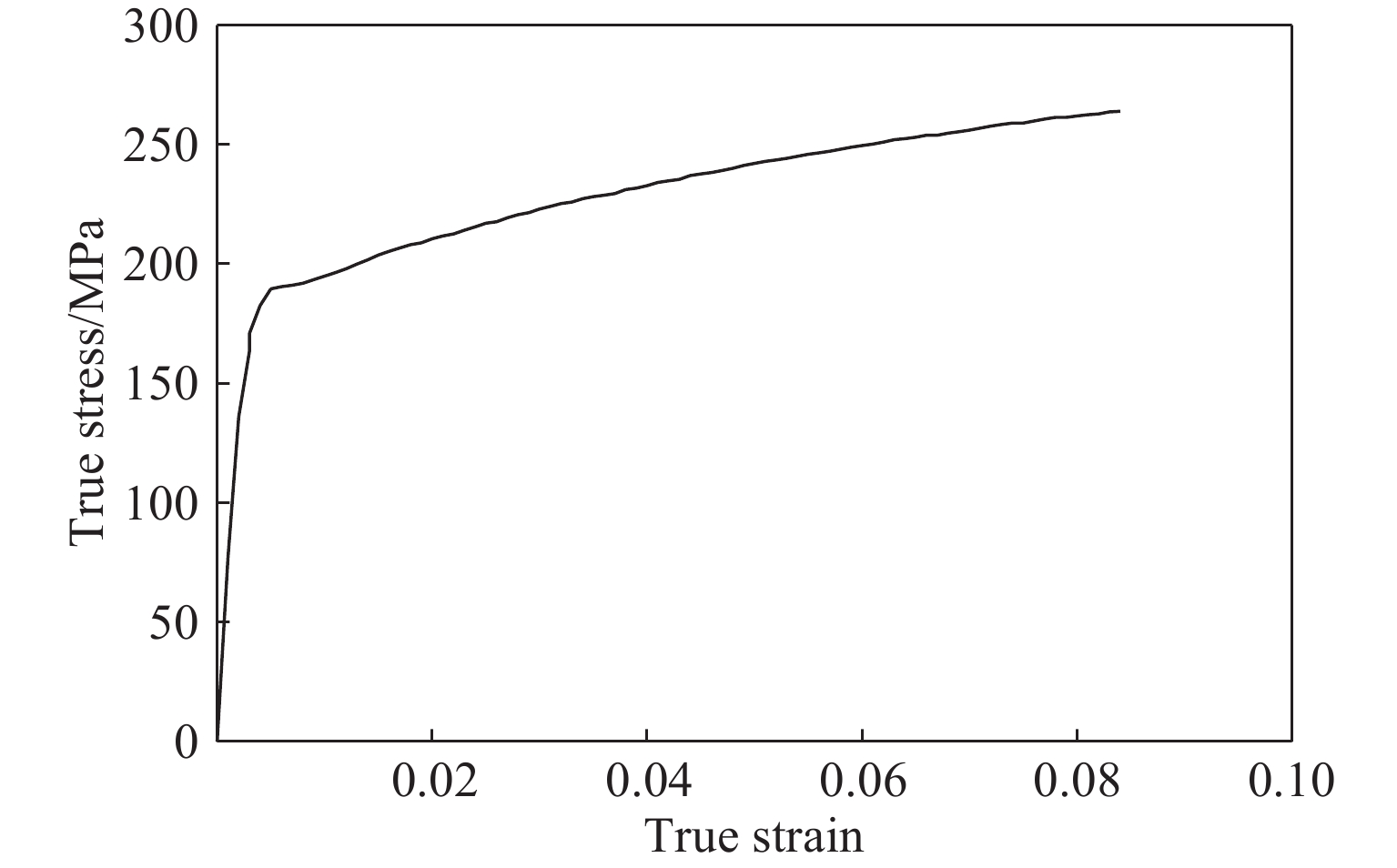

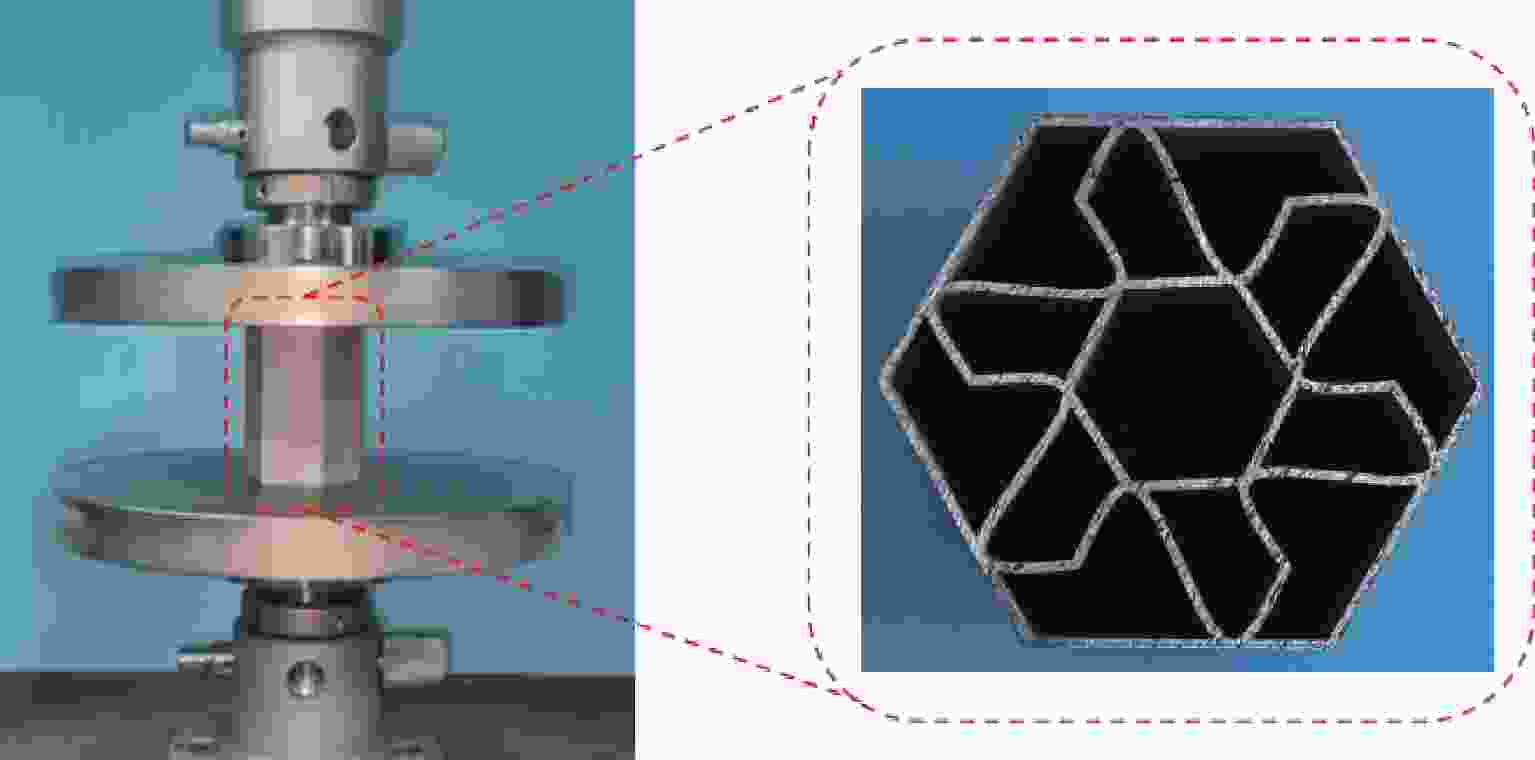

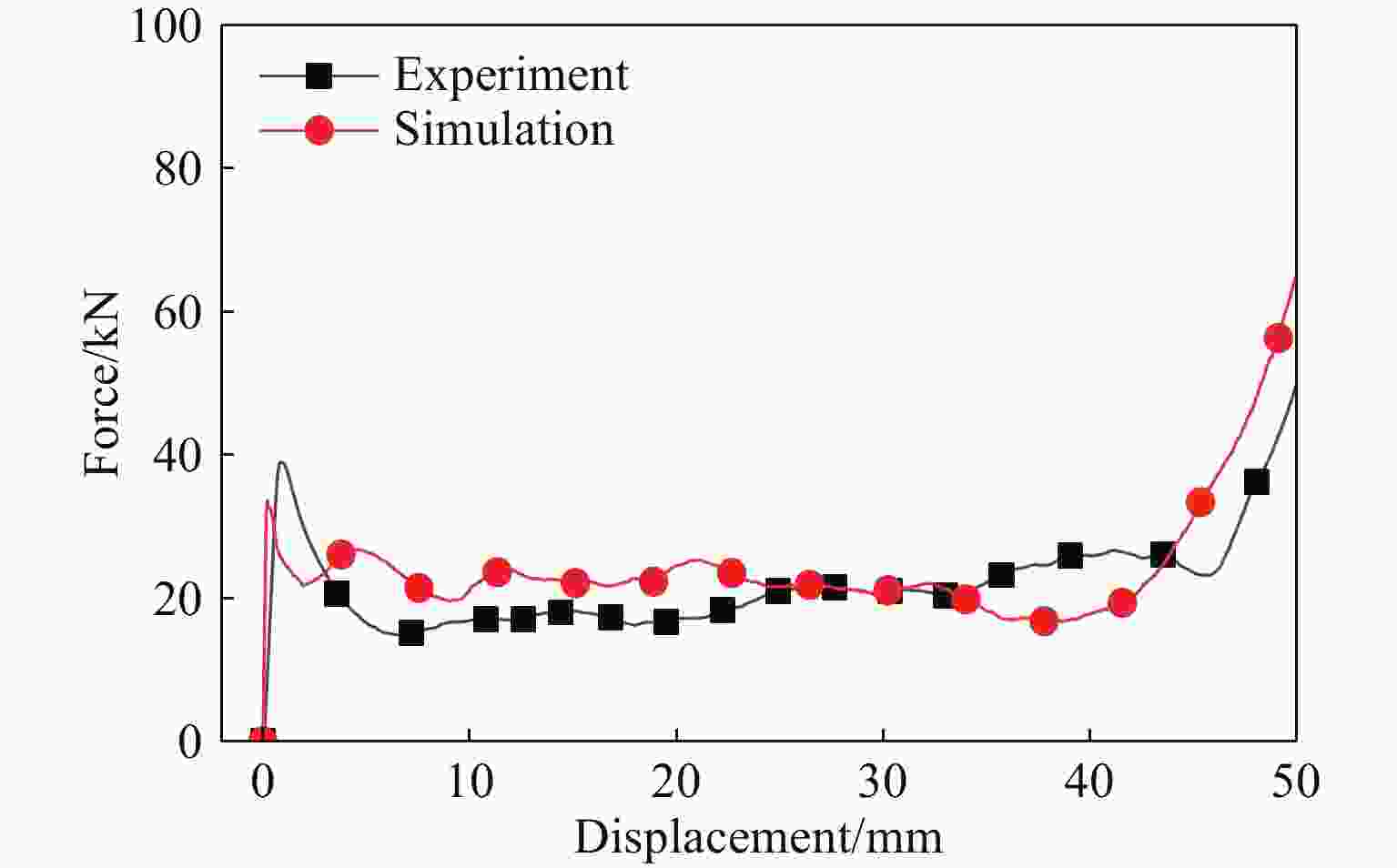

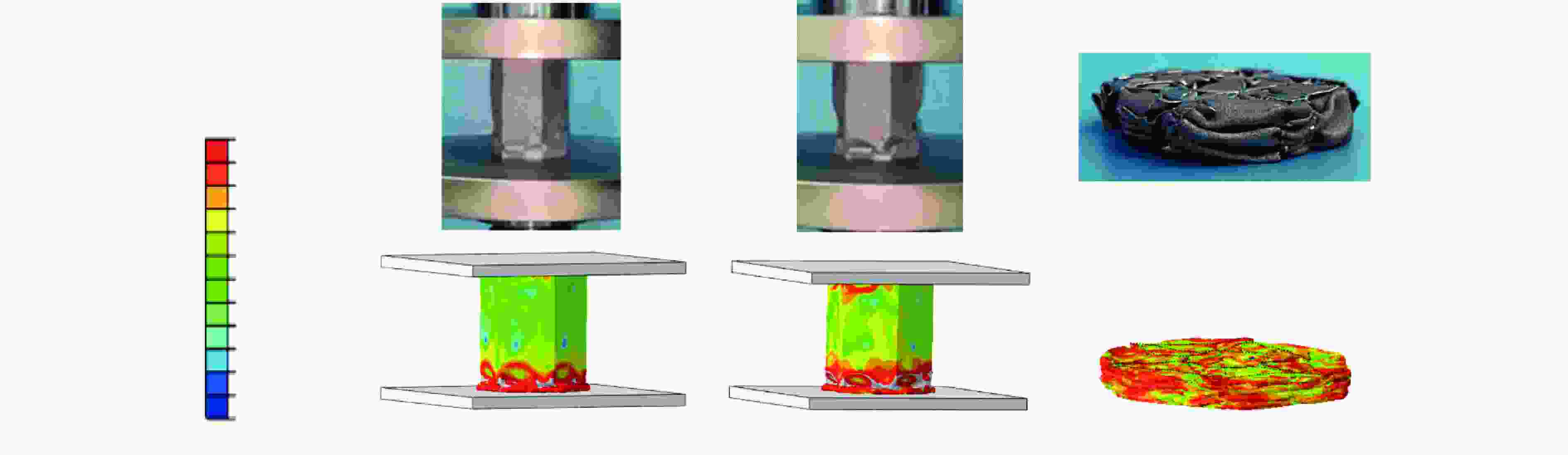

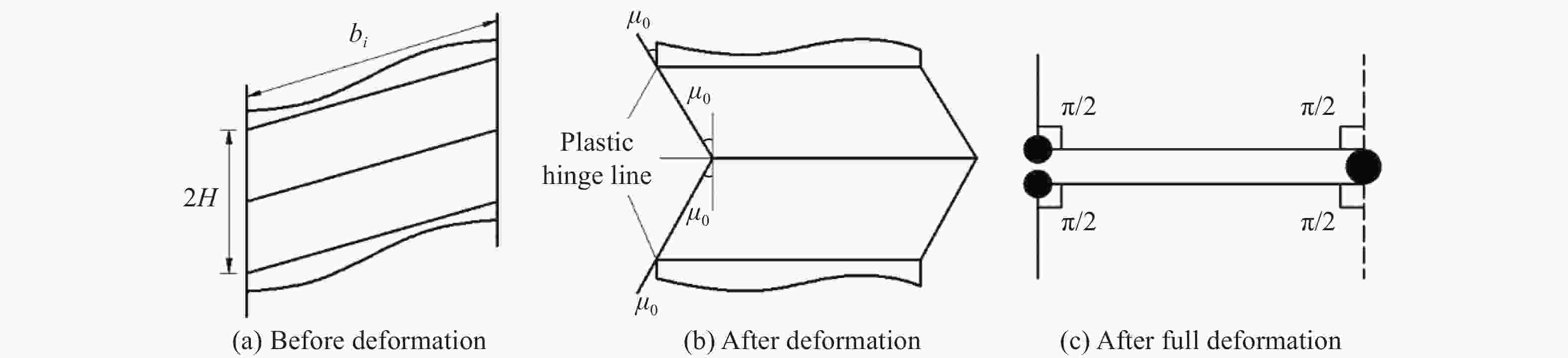

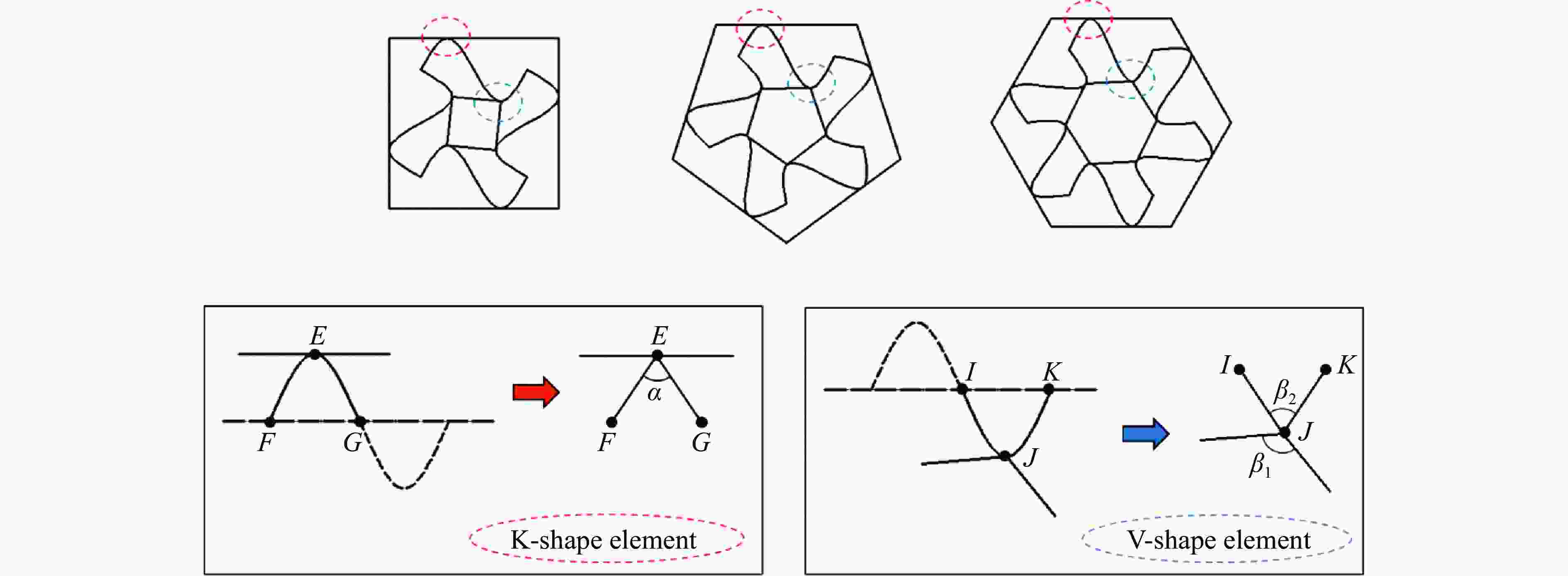

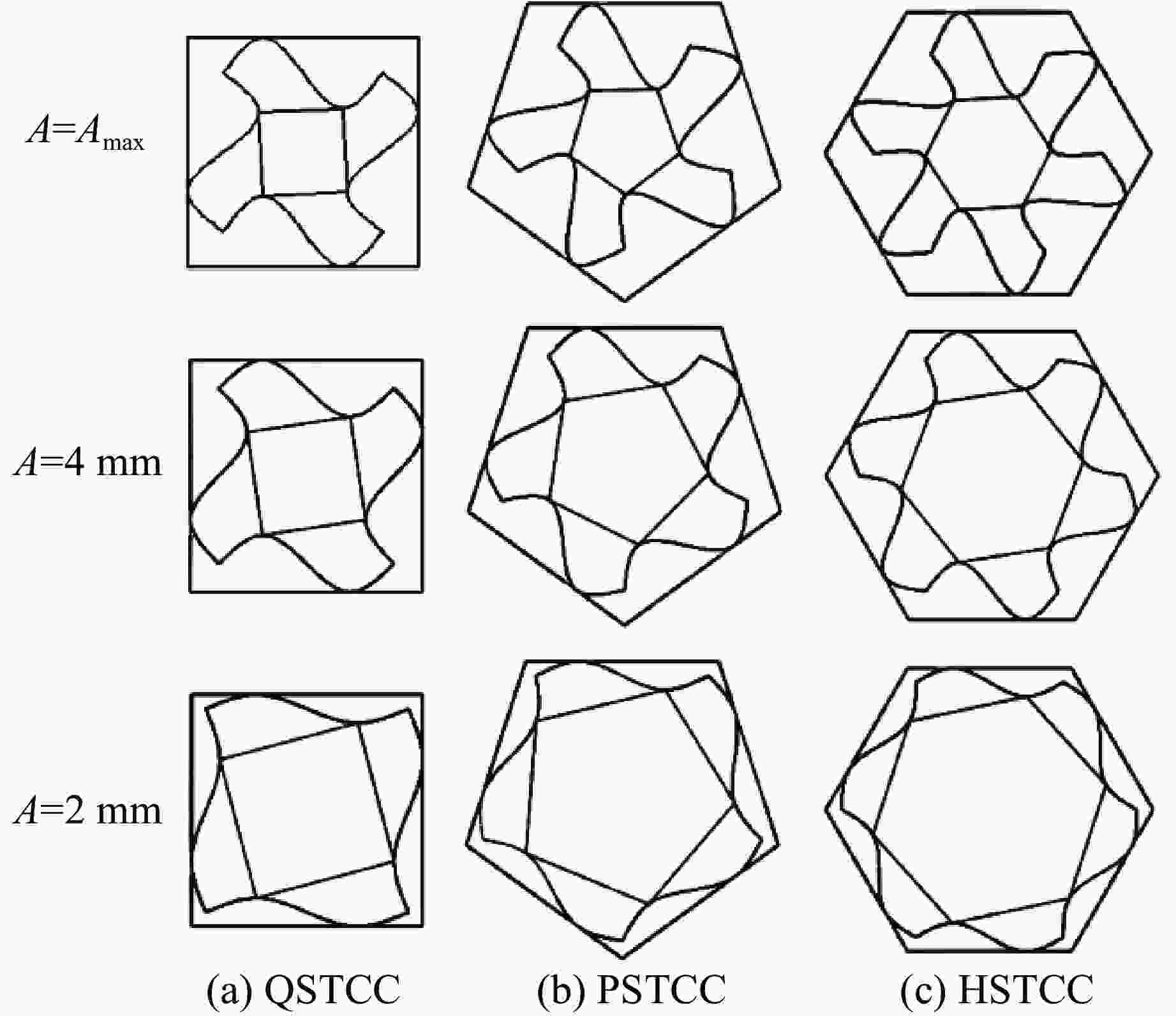

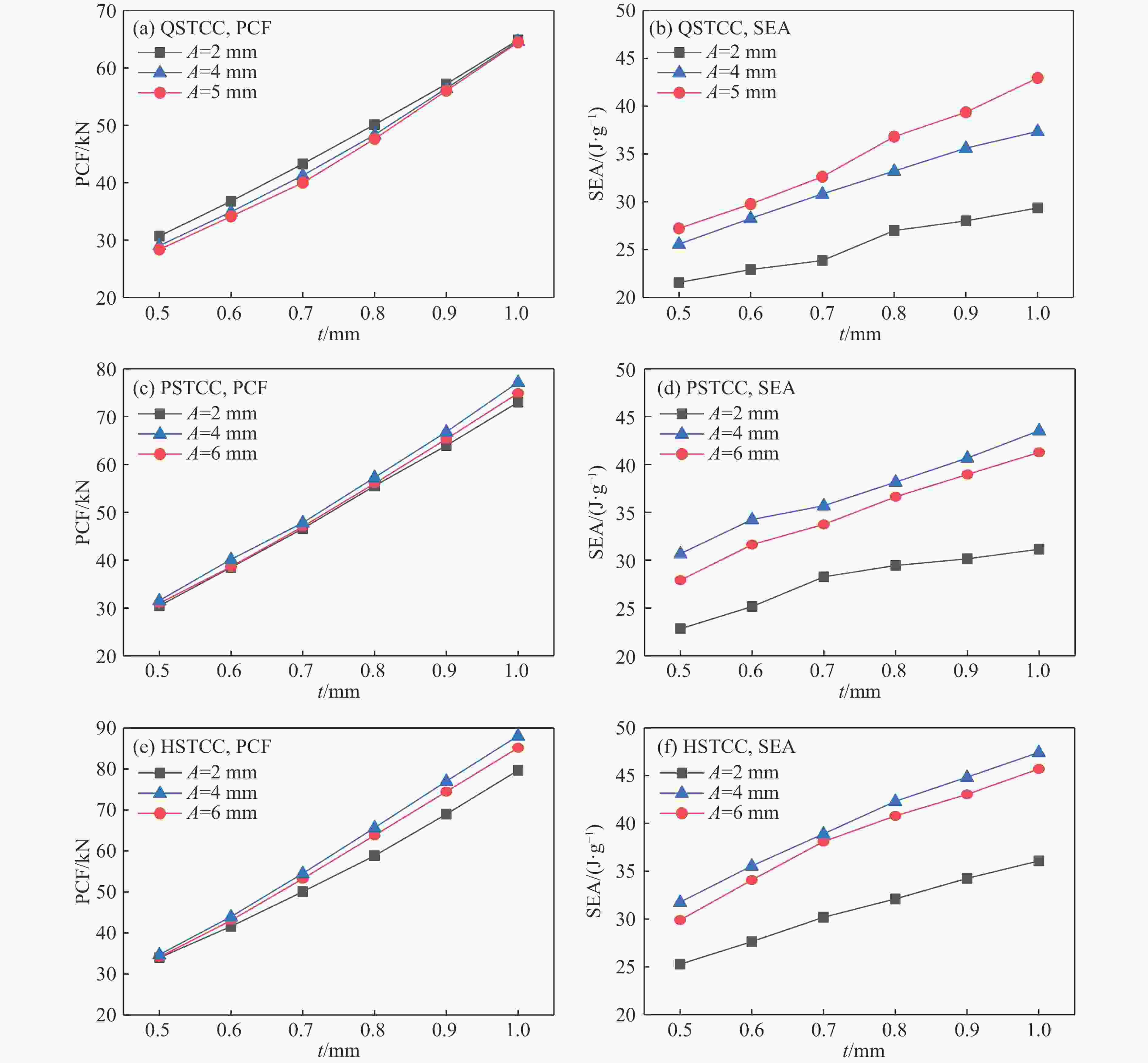

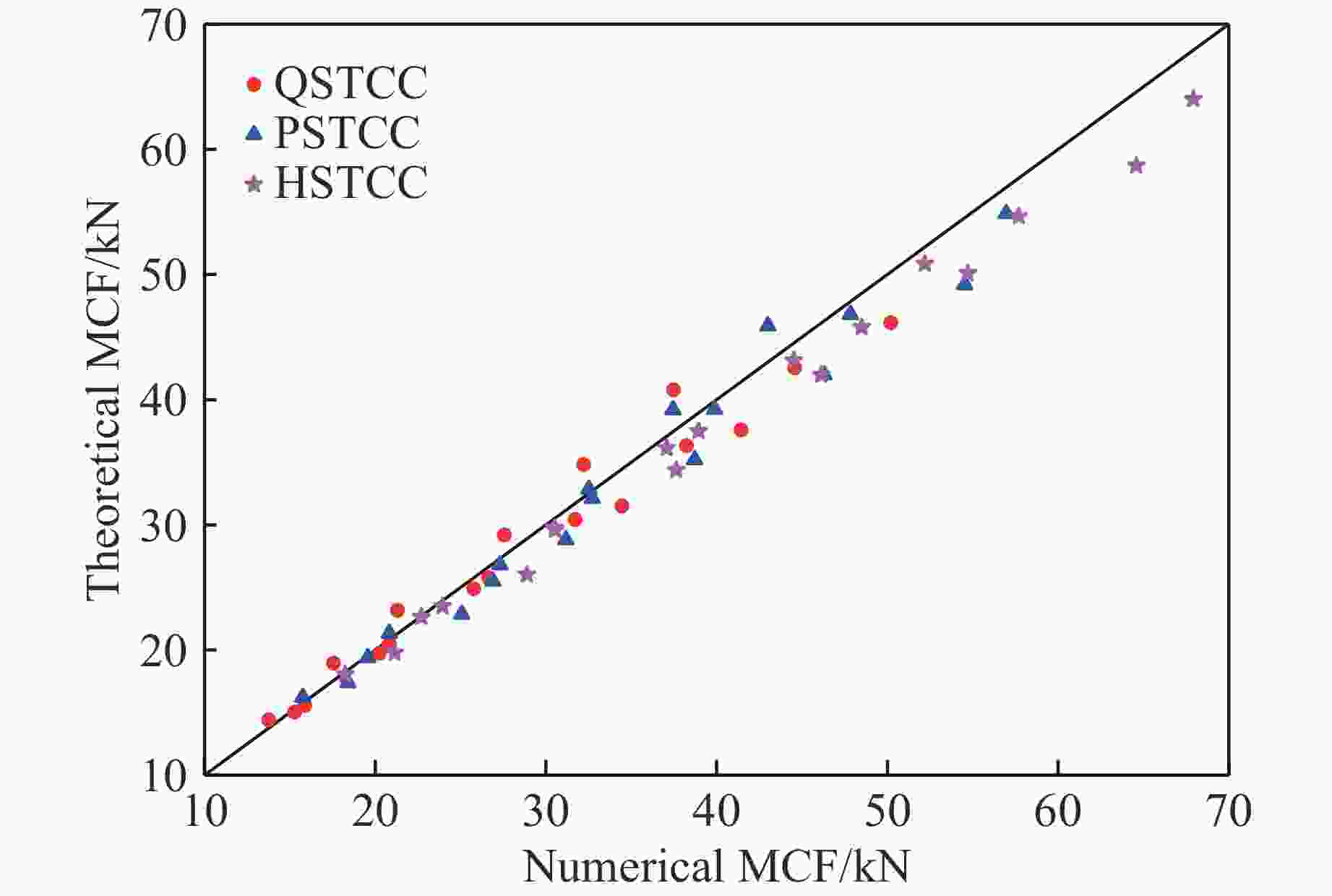

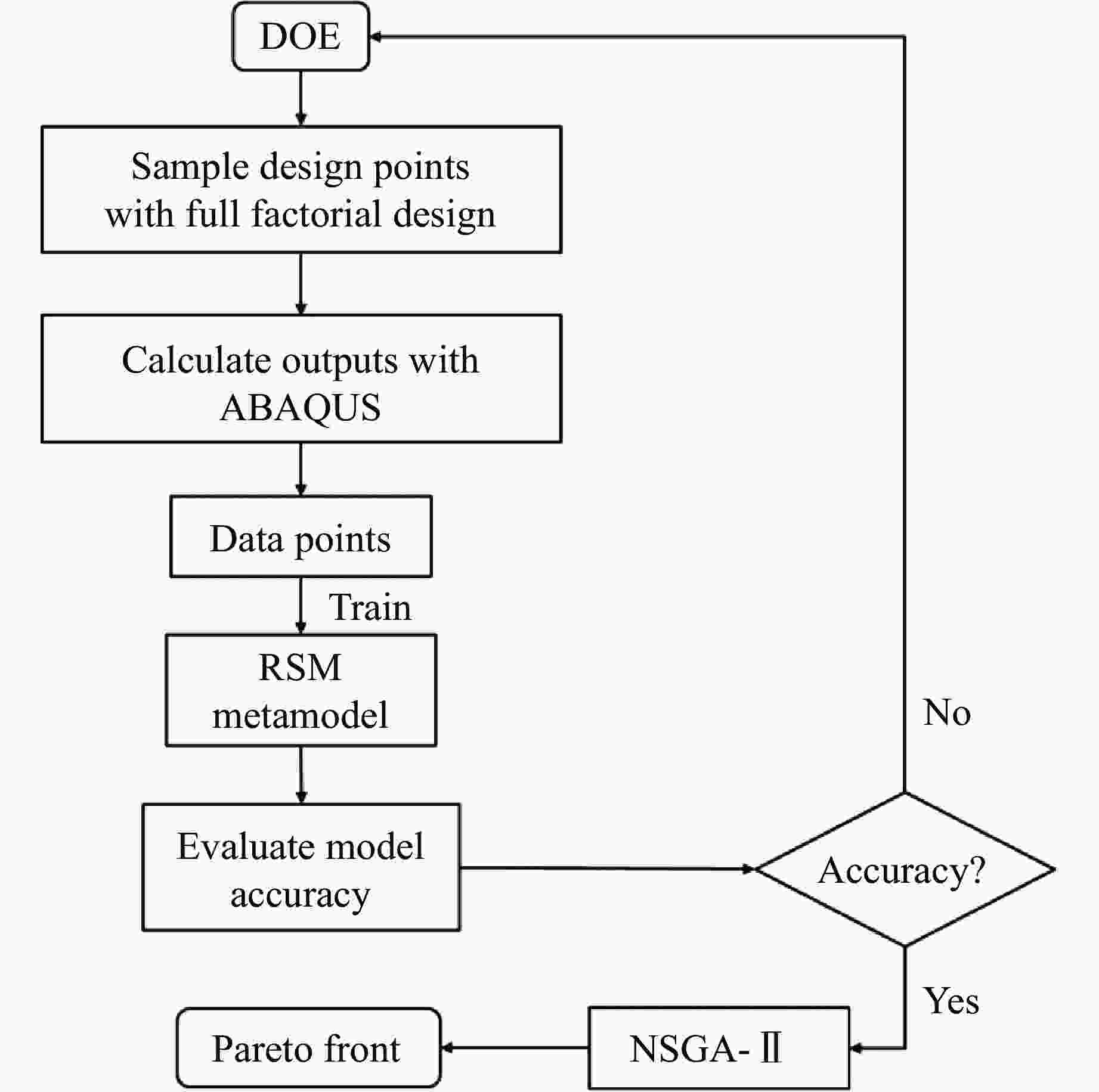

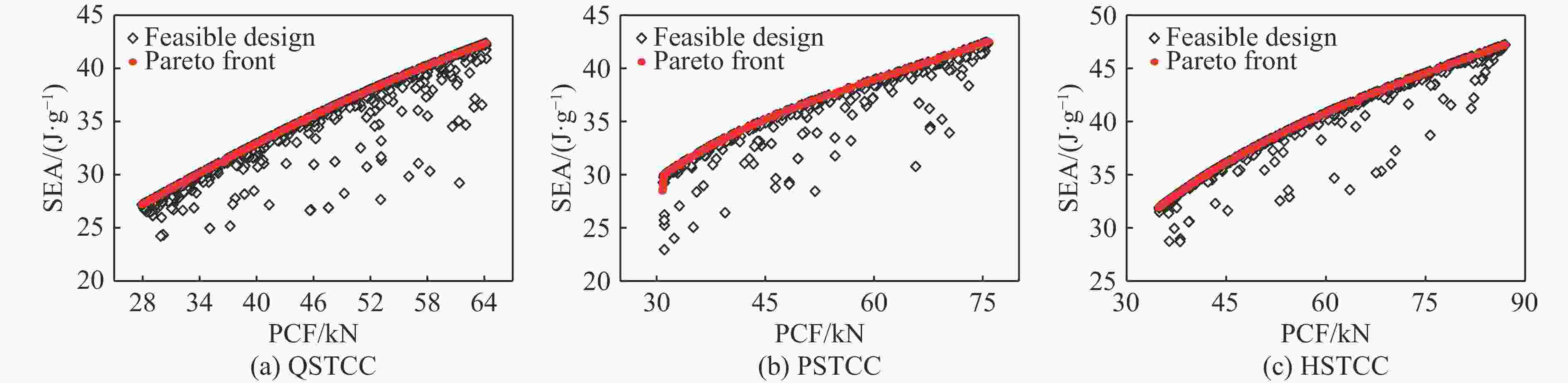

摘要: 将正弦波纹薄壁管作为芯层引入多边形薄壁管,获得了四边形、五边形、六边形3种波纹芯层夹芯管。首先,采用实验与数值模拟相结合的方法研究了3种波纹芯层夹芯管在轴向准静态压缩载荷下的力学响应,包括能量吸收性能,分析了结构壁厚和芯层波幅对夹芯管压缩性能的影响,数值模拟与实验结果吻合较好。其次,基于超折叠单元理论,给出了准静态压缩载荷下波纹芯层夹芯管的平均轴向压缩力的解析解。其中,波纹芯层六边形夹芯管在准静态轴向压缩过程中表现出渐进折叠屈曲的变形模式,理论预测的平均压缩力与实验结果吻合较好,相对误差为6.1%,与数值模拟结果相比,相对误差均在9.8%以内。波纹芯层夹芯管的比吸能随着结构壁厚和芯层波幅的增大而增大;而当波幅和壁厚相同时,六边形夹芯管的吸能能力优于四边形夹芯管和五边形夹芯管。最后,以最大比吸能和最小初始峰值力为目标,对3种结构的芯层波幅和结构壁厚进行了多目标优化,给出了最大比吸能与最小峰值载荷之间的平衡策略,得到了相应的Pareto前沿。Abstract: Sinusoidal corrugated thin-walled tubes are introduced as a core layer into polygonal thin-walled tubes, and quadrilateral, pentagonal and hexagonal sandwich tubes with corrugated cores are then obtained. First of all, their mechanical responses including energy absorption performance under quasi-static axial compression are studied by a combination of experiment, numerical simulation and theoretical analysis. Effects of the structural wall thickness and the wave amplitude of the core layer on the compression performance of the sandwich tube are analyzed, and the numerical simulation results agree well with the experimental ones. Then, the analytical solution for the mean compression force of the sandwich tube with corrugated cores under quasi-static compression is derived based on the simplified super folding element theory. The hexagonal sandwich tube subjected to quasi-static axial compression exhibits a deformation mode of progressive folding collapse. The theoretical mean compression force of the hexagonal sandwich tube agrees approximately with the experimental results with a relative error of 6.1%, while at a relative error within 9.8% compared to the simulation results. The specific energy absorption of the sandwich tubes with corrugated cores increases with increasing structure wall thickness and core-layer wave amplitude. For the same wave amplitude and wall thickness, the energy absorption capacity of the hexagonal sandwich tube is better than those of the quadrilateral and pentagonal sandwich tubes. Finally, with the objectives of maximum specific energy absorption and minimum initial peak force, multi-objective optimization is carried out on the core wave amplitude and structure wall thickness of the three types of sandwich tubes. The compromise and balance scheme for the maximum specific energy absorption and minimum peak crushing force is given, and the corresponding Pareto front is obtained.

-

Key words:

- sandwich tube /

- energy absorption /

- mean compression force /

- multi-objective optimization

-

表 1 模拟和实验得到的吸能评价指标对比

Table 1. Comparison of the energy absorption evaluation indices between simulation and experiment

PCF SEA Sim./kN Exp./kN Error/% Sim./(J·g−1) Exp./(J·g−1) Error/% 34.71 38.90 −10.7 31.77 29.83 6.3 表 2 准静态载荷下MCF的理论预测值与模拟结果的对比(部分)

Table 2. Comparison of the theoretical prediction and finite element simulation results on the MCF under quasi-static loading (partial)

Type A/mm t/mm MCF/kN Error/% Sim. Theor. QSTCC 2 0.5 13.76 14.42 4.8 2 1.0 37.48 40.78 8.8 4 0.5 15.29 15.03 −1.7 4 1.0 44.57 45.52 −4.6 5 0.5 15.88 15.56 −2.0 5 1.0 50.21 46.15 −8.1 PSTCC 2 0.5 15.76 16.23 3.0 2 1.0 43.00 45.89 6.7 4 0.5 18.40 17.38 −5.6 4 1.0 54.52 49.18 −9.8 6 0.5 19.57 19.38 −1.0 6 1.0 56.96 54.88 −3.7 HSTCC 2 0.5 18.24 18.05 −1.0 2 1.0 52.20 50.85 −2.6 4 0.5 21.14 19.78 −6.4 4 1.0 64.59 58.68 −9.1 6 0.5 22.71 22.63 −0.4 6 1.0 67.93 64.00 −5.8 表 3 响应面模型精度评估

Table 3. Accuracy evaluation of the response surface model

Type PCF SEA R2 RMSE R2 RMSE QSTCC 0.968 0.049 0.988 0.027 PSTCC 0.999 0.010 0.961 0.054 HSTCC 0.998 0.013 0.982 0.038 表 4 优化与模拟结果对比

Table 4. Comparison between the optimized and simulation results

Type A/

mmt/

mmPCF SEA Opt./kN Sim./kN Error/% Opt./(J·g−1) Sim./(J·g−1) Error/% QSTCC 4.6 0.5 27.39 28.60 −4.23 26.31 26.40 −0.34 QSTCC 5.0 1.0 64.47 64.45 0.03 42.94 42.95 −0.02 PSTCC 4.0 0.5 30.87 30.98 −0.36 28.98 27.91 3.83 PSTCC 5.0 1.0 75.80 76.73 −1.21 42.54 41.25 3.05 HSTCC 6.0 0.5 34.49 34.71 −0.63 31.36 31.77 −1.29 HSTCC 5.7 1.0 87.11 88.34 −1.39 47.79 49.11 −2.69 -

[1] VINAYAGAR K, SENTHIL KUMAR A. Crashworthiness analysis of double section bi-tubular thin-walled structures [J]. Thin-Walled Structures, 2017, 112: 184–193. doi: 10.1016/j.tws.2016.12.008 [2] LI Z X, MA W, XU P, et al. Crashworthiness of multi-cell circumferentially corrugated square tubes with cosine and triangular configurations [J]. International Journal of Mechanical Sciences, 2020, 165: 105205. doi: 10.1016/j.ijmecsci.2019.105205 [3] 张涛, 吴英友, 朱显明, 等. 多边形截面薄壁管撕裂卷曲吸能研究 [J]. 爆炸与冲击, 2007, 27(3): 223–229. doi: 10.11883/1001-1455(2007)03-0223-07ZHANG T, WU Y Y, ZHU X M, et al. Energy absorption in splitting metal tubes with polygonal section [J]. Explosion and Shock Waves, 2007, 27(3): 223–229. doi: 10.11883/1001-1455(2007)03-0223-07 [4] ABRAMOWICZ W, WIERZBICKI T. Axial crushing of multicorner sheet metal columns [J]. Journal of Applied Mechanics, 1989, 56(1): 113–120. doi: 10.1115/1.3176030 [5] SUN G Y, WANG Z, YU H, et al. Experimental and numerical investigation into the crashworthiness of metal-foam-composite hybrid structures [J]. Composite Structures, 2019, 209: 535–547. doi: 10.1016/j.compstruct.2018.10.051 [6] YIN H F, WEN G L, HOU S J, et al. Crushing analysis and multiobjective crashworthiness optimization of honeycomb-filled single and bitubular polygonal tubes [J]. Materials & Design, 2011, 32(8/9): 4449–4460. doi: 10.1016/j.matdes.2011.03.060 [7] ZOU M, XU S C, WEI C G, et al. A bionic method for the crashworthiness design of thin-walled structures inspired by bamboo [J]. Thin-Walled Structures, 2016, 101: 222–230. doi: 10.1016/j.tws.2015.12.023 [8] WIERZBICKI T, ABRAMOWICZ W. On the crushing mechanics of thin-walled structures [J]. Journal of Applied Mechanics, 1983, 50(4a): 727–734. doi: 10.1115/1.3167137 [9] JUSUF A, DIRGANTARA T, GUNAWAN L, et al. Crashworthiness analysis of multi-cell prismatic structures [J]. International Journal of Impact Engineering, 2015, 78: 34–50. doi: 10.1016/j.ijimpeng.2014.11.011 [10] HOU Y B, ZHANG Y, YAN X L, et al. Crushing behaviors of the thin-walled sandwich column under axial load [J]. Thin-Walled Structures, 2021, 159: 107229. doi: 10.1016/j.tws.2020.107229 [11] LIU W Y, LIN Z Q, HE J Y, et al. Crushing behavior and multi-objective optimization on the crashworthiness of sandwich structure with star-shaped tube in the center [J]. Thin-Walled Structures, 2016, 108: 205–214. doi: 10.1016/j.tws.2016.08.021 [12] WU S Z, ZHENG G, SUN G Y, et al. On design of multi-cell thin-wall structures for crashworthiness [J]. International Journal of Impact Engineering, 2016, 88: 102–117. doi: 10.1016/j.ijimpeng.2015.09.003 [13] HU D Y, WANG Y Z, SONG B, et al. Energy-absorption characteristics of a bionic honeycomb tubular nested structure inspired by bamboo under axial crushing [J]. Composites Part B: Engineering, 2019, 162: 21–32. doi: 10.1016/j.compositesb.2018.10.095 [14] YANG X F, SUN Y X, YANG J L, et al. Out-of-plane crashworthiness analysis of bio-inspired aluminum honeycomb patterned with horseshoe mesostructure [J]. Thin-Walled Structures, 2018, 125: 1–11. doi: 10.1016/j.tws.2018.01.014 [15] ZHANG X, ZHANG H. Axial crushing of circular multi-cell columns [J]. International Journal of Impact Engineering, 2014, 65: 110–125. doi: 10.1016/j.ijimpeng.2013.12.002 [16] 邓志芳. 双级薄壁吸能管的抗撞性理论推导和实验研究 [D]. 长沙: 湖南大学, 2017.DENG Z F. Crashworthiness research of two-stage thin-walled tube from theoretical derivation and experimental study [D]. Changsha: Hunan University, 2017. -

下载:

下载: