Mechanical Properties and Constitutive Relation for 42CrMo Steel under Impact Load

-

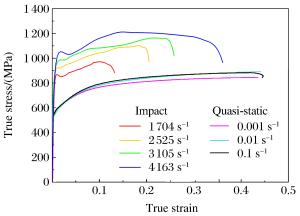

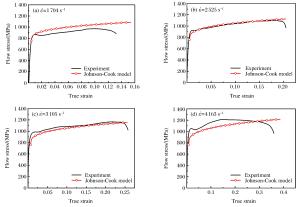

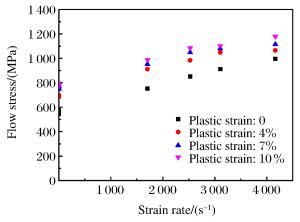

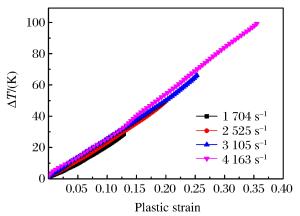

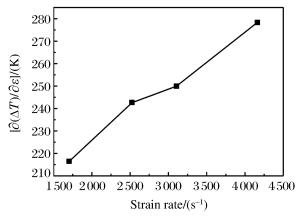

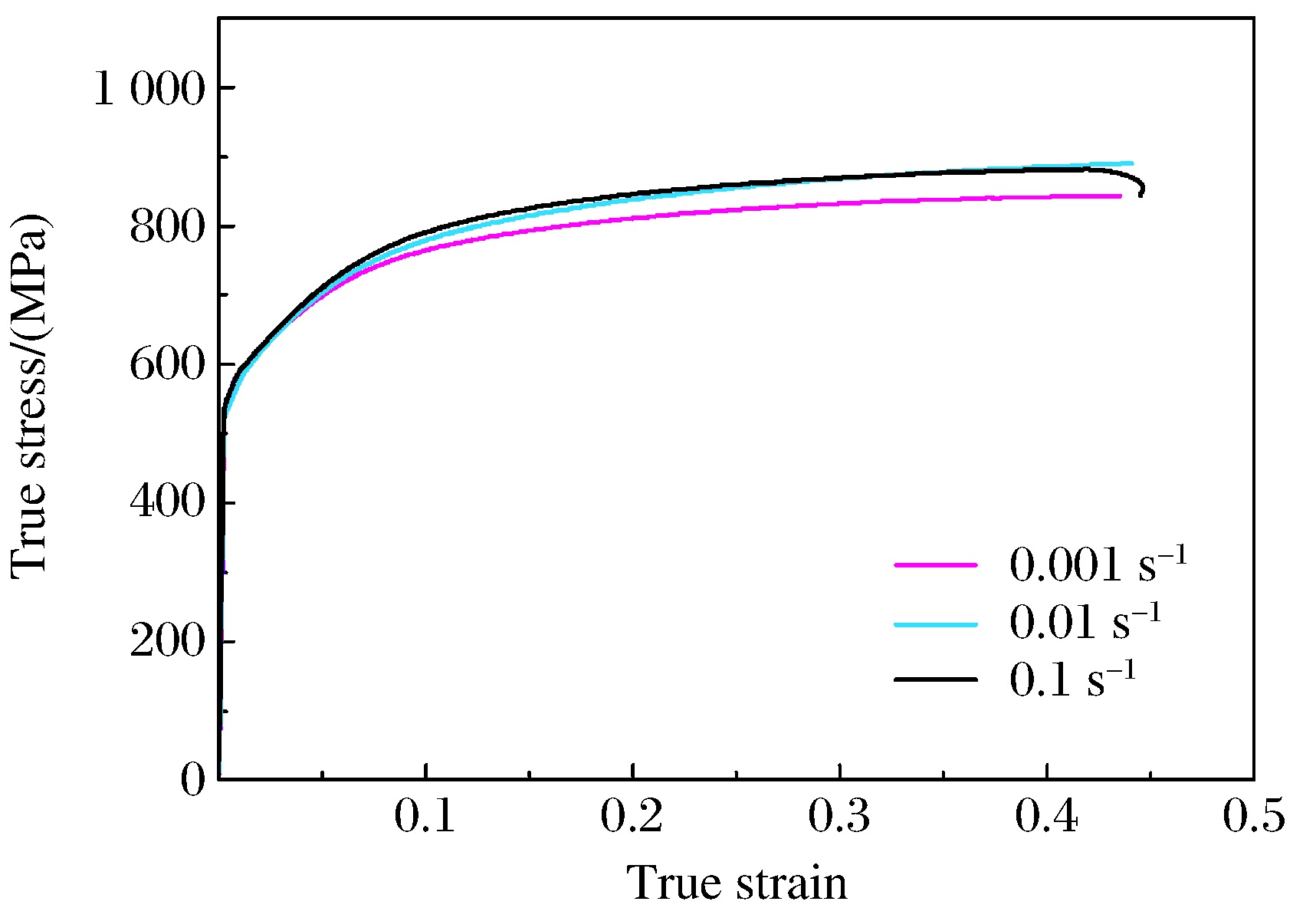

摘要: 车轴作为高速列车走行部中的重要部件,不可避免地需承受冲击载荷作用。为研究车轴用42CrMo钢的冲击动态力学性能,对其进行了应变率0.001~4 163 s-1范围内的压缩实验,结果显示42CrMo钢在高应变率下表现出明显的应变率效应,存在应变硬化以及一定的热软化效应。根据实验结果对Johnson-Cook模型中应变项和应变率项解耦,并引入绝热温升,得到改进的Johnson-Cook模型,改进Johnson-Cook模型能够较好地描述42CrMo钢的动态力学特性,为实际工程结构力学分析提供了参考。Abstract: As an important part of high-speed trains, the axle has to withstand complex loads, especially the shock load in the train's operating conditions.To study the dynamic mechanical properties of the 42CrMo steel used in axle production, quasi-static and dynamic compression experiments of 42CrMo steel were conducted at strain rates from 0.001 s-1 to 4 163 s-1.The results of these experiments show that the 42CrMo steel has an effect of strain rate, strain hardening and thermal softening at high strain rate.Based on the experimental results, we improved the Johnson-Cook model by decoupling the terms of the strain and the strain rate, and also by considering the adiabatic temperature rise.The improved Johnson-Cook model has proved to be capable of describing the dynamic mechanical properties of the 42CrMo steel well and providing reference for practical engineering structural mechanics analysis.

-

Key words:

- 42CrMo steel /

- strain rate effect /

- adiabatic temperature rise /

- constitutive relation

-

表 1 动态压缩实验后试样尺寸变化

Table 1. Longitudinal size and strain variations of specimens after dynamic compression experiments

Strain rate/(s-1) Longitudinal size/(mm) Longitudinal strain/(%) 0 4.00 0 1 704 3.64 9 2 525 3.12 22 3 105 2.72 32 4 163 2.36 41 表 2 Johnson-Cook模型参数

Table 2. Parameters' value of Johnson-Cook model

A/(MPa) B/(MPa) n C 538.09 424.70 0.303 57 0.027 86 表 3 改进Johnson-Cook模型参数

Table 3. Parameters' value of improved Johnson-Cook model

A/(MPa) B/(MPa) C/(Pa) D/(K) E/(K) n m 607.226 1 235.781 92.89 0.244×10-4 176.6 0.494 0.489 -

[1] 刘鑫贵, 吴毅, 项彬, 等.动车组车轴标准研究及其技术发展展望[J].铁道机车车辆, 2014, 34(6):18-22. doi: 10.3969/j.issn.1008-7842.2014.06.04LIU X G, WU Y, XIANG B, et al.Standard study and technical development prospect of emu axle[J].Railway Locomotive & Car, 2014, 34(6):18-22. doi: 10.3969/j.issn.1008-7842.2014.06.04 [2] 赵永翔, 杨冰, 孙亚芳, 等.LZ50车轴钢的概率循环本构模型[J].机械工程学报, 2004, 40(9):48-53. doi: 10.3321/j.issn:0577-6686.2004.09.010ZHAO Y X, YANG B, SUN Y F, et al.Probability-based cyclic constitution models for LZ50 axle steel[J].Chinese Journal of Mechanical Engineering, 2004, 40(9):48-53. doi: 10.3321/j.issn:0577-6686.2004.09.010 [3] YANG B, ZHAO Y X.Experimental research on dominant effective short fatigue crack behavior for railway LZ50 axle steel[J].Int J Fatigue, 2012, 35(1):71-78. doi: 10.1016/j.ijfatigue.2010.11.012 [4] QUAN G, LUO G, MAO A, et al.Evaluation of varying ductile fracture criteria for 42CrMo steel by compressions at different temperatures and strain rates[J].Sci World J, 2014: 579328. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000003718094 [5] KUNC R, PREBIL I.Low-cycle fatigue properties of steel 42CrMo4[J].Mater Sci Eng A, 2003, 345(1):278-285. http://www.sciencedirect.com/science/article/pii/S0921509302004641 [6] 孟扬, 梁益龙.不同成分EA4T车轴钢的高周疲劳性能[J].机械工程材料, 2010, 34(4):55-57. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201000092490MENG Y, LIANG Y L.High cycle fatigue property of EA4T axle steel with different components[J].Materials for Mechanical Engineering, 2010, 34(4):55-57. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201000092490 [7] VARFOLOMEEV I, LUKE M, BURDACK M.Effect of specimen geometry on fatigue crack growth rates for the railway axle material EA4T[J].Eng Fract Mech, 2011, 78(5):742-753. doi: 10.1016/j.engfracmech.2010.11.011 [8] LINHART V, ČERNÝ I.An effect of strength of railway axle steels on fatigue resistance under press fit[J].Eng Fract Mech, 2011, 78(6):731-741. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d656a1ba7efa1d67e75877804bf56778 [9] WEERTMAN J, WEERTMAN J R.Elementary dislocation theory[M].Oxford:Oxford University Press, 1992:72-79. [10] GUO W G, NEMAT-NASSER S.Flow stress of Nitronic-50 stainless steel over a wide range of strain rates and temperatures[J].Mech Mater, 2006, 38(11):1090-1103. doi: 10.1016/j.mechmat.2006.01.004 [11] SHI D Q, YANG X G, WANG Y R.Constitutive modeling of hardening and creep response of a nickel-based superalloy udimet 720Li[J].Chinese Journal of Aeronautics, 2003, 16(3):187-192. doi: 10.1016/S1000-9361(11)60182-9 [12] JOHNSON G R, COOK W H.A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[C]//Proceedings of the 7th International Symposium on Ballistics, 1983: 541-547. [13] 刘旭红, 黄西成, 陈裕泽, 等.强动载荷下金属材料塑性变形本构模型评述[J].力学进展, 2007, 37(3):361-374. doi: 10.3321/j.issn:1000-0992.2007.03.004LIU X H, HUANG X C, CHEN Y Z, et al.A review on constitutive models for plastic deformation of metal materials under dynamic loading[J].Advances in Mechanics, 2007, 37(3):361-374. doi: 10.3321/j.issn:1000-0992.2007.03.004 [14] 彭建祥.钽的本构关系研究[D].绵阳: 中国工程物理研究院, 2001. http://cdmd.cnki.com.cn/Article/CDMD-82818-2001004177.htm [15] RULE W K, JONES S E.A revised form for the Johnson-Cook strength model[J].Int J Impact Eng, 1998, 21(8):609-624. doi: 10.1016/S0734-743X(97)00081-X [16] KAPOOR R, NEMAT-NASSER S.Determination of temperature rise during high strain rate deformation[J].Mech Mater, 1998, 27(1):1-12. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7c17e09746f2eec0386fd35b3d3e02c8 -

下载:

下载: