Influence Factors of the Failure of Adjacent Pipeline under Explosion in Gas Compartment of Utility Tunnel

-

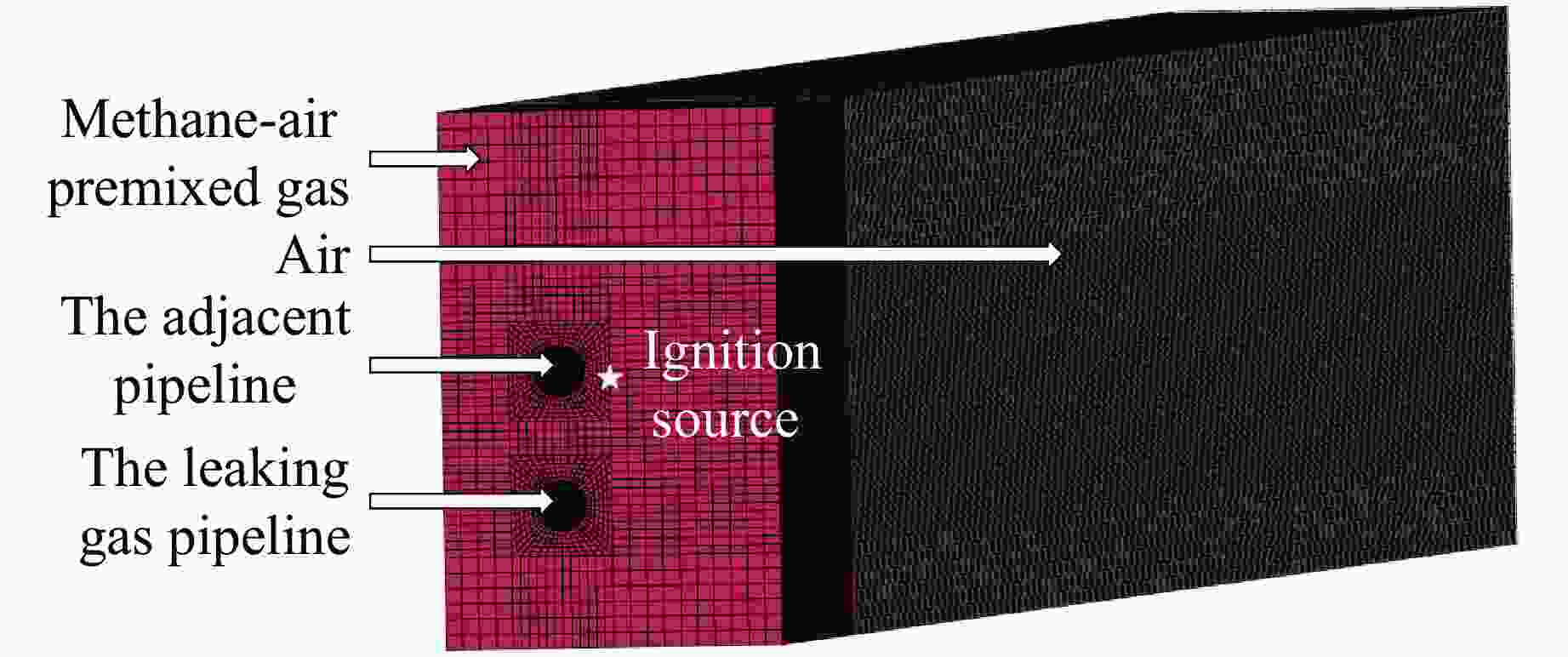

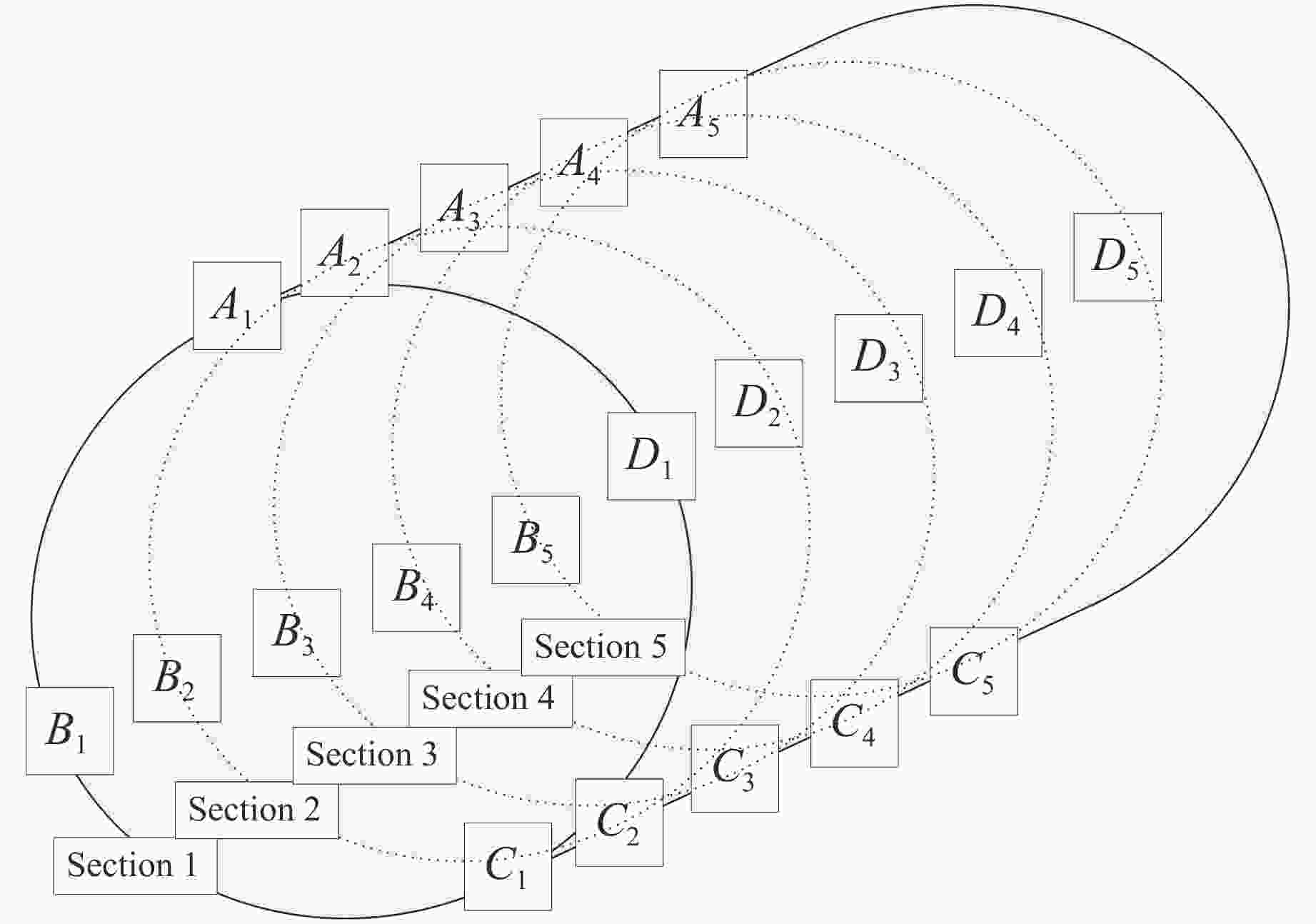

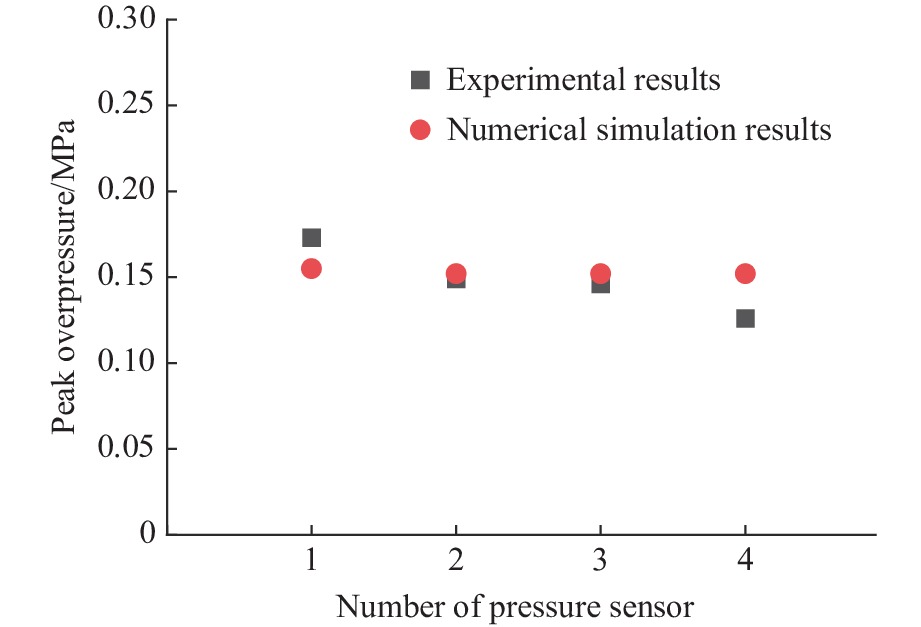

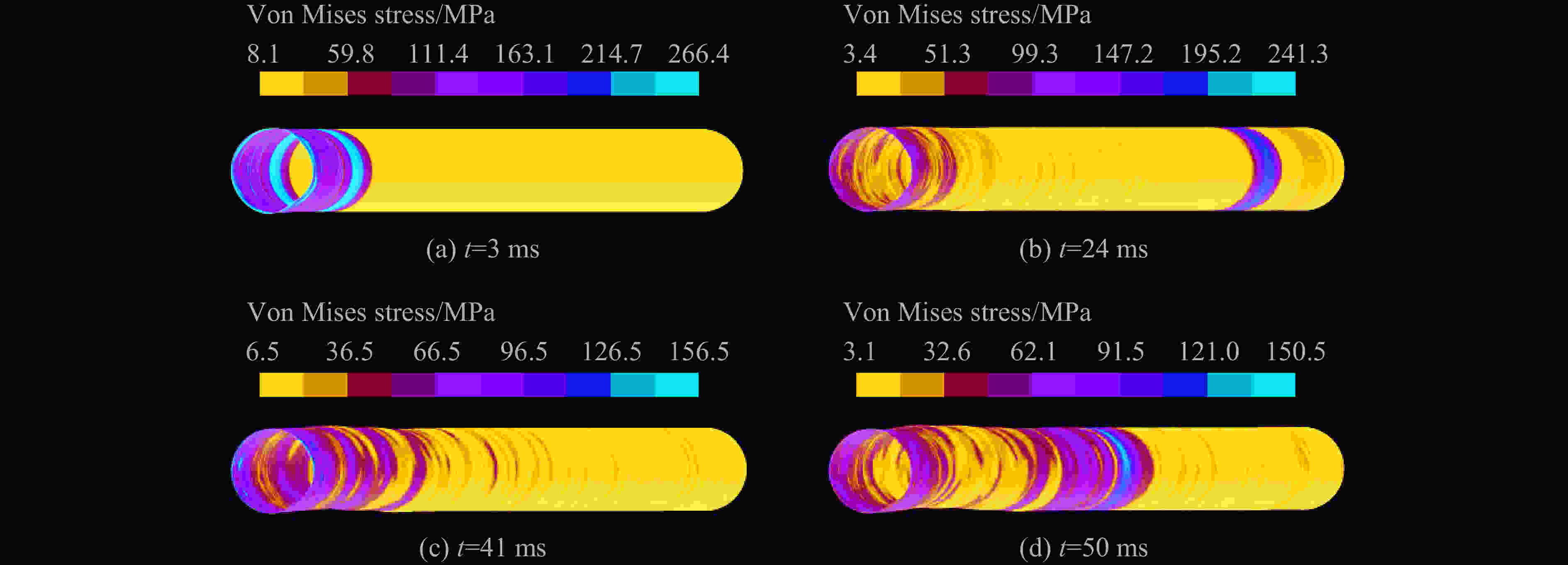

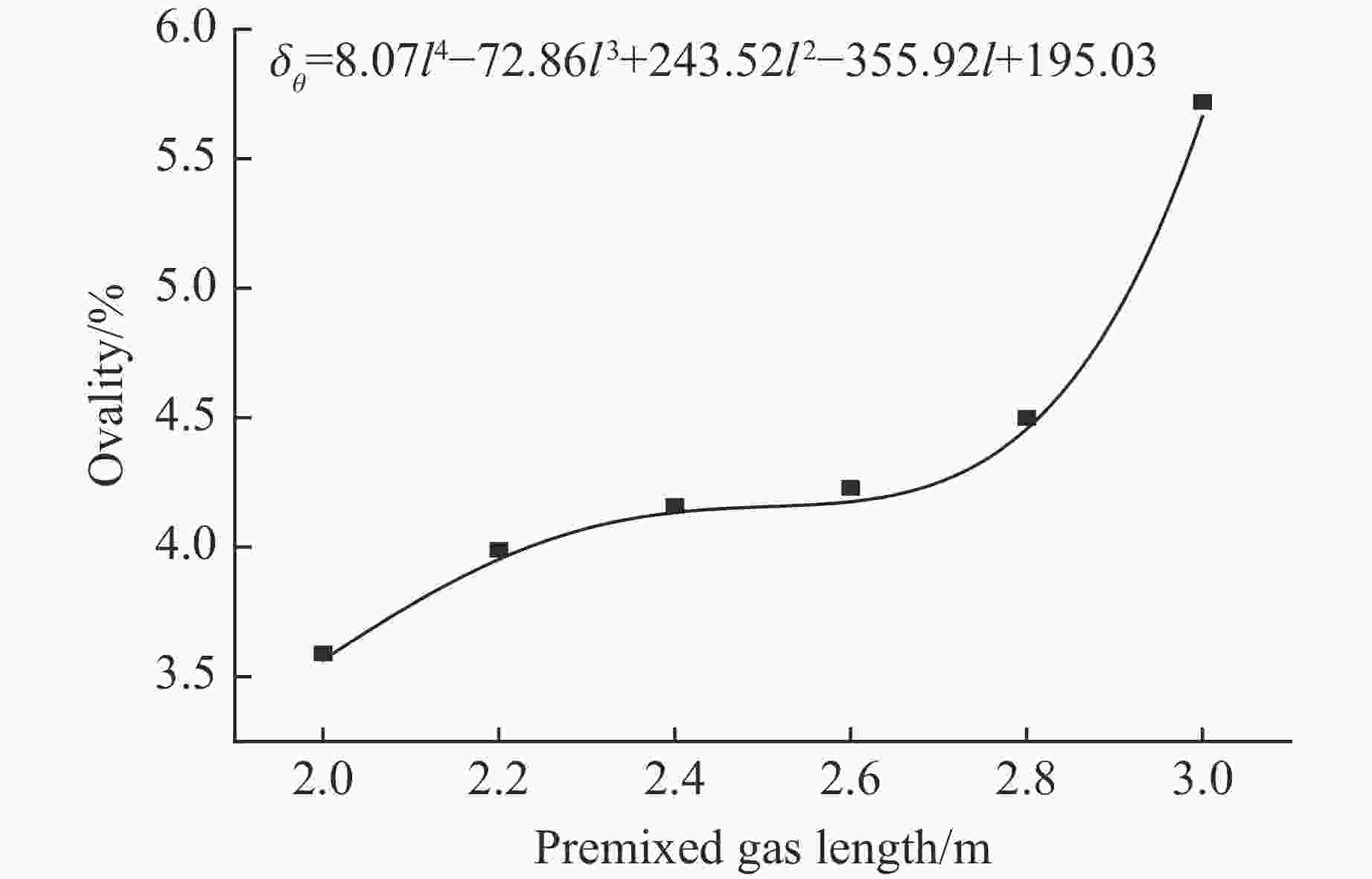

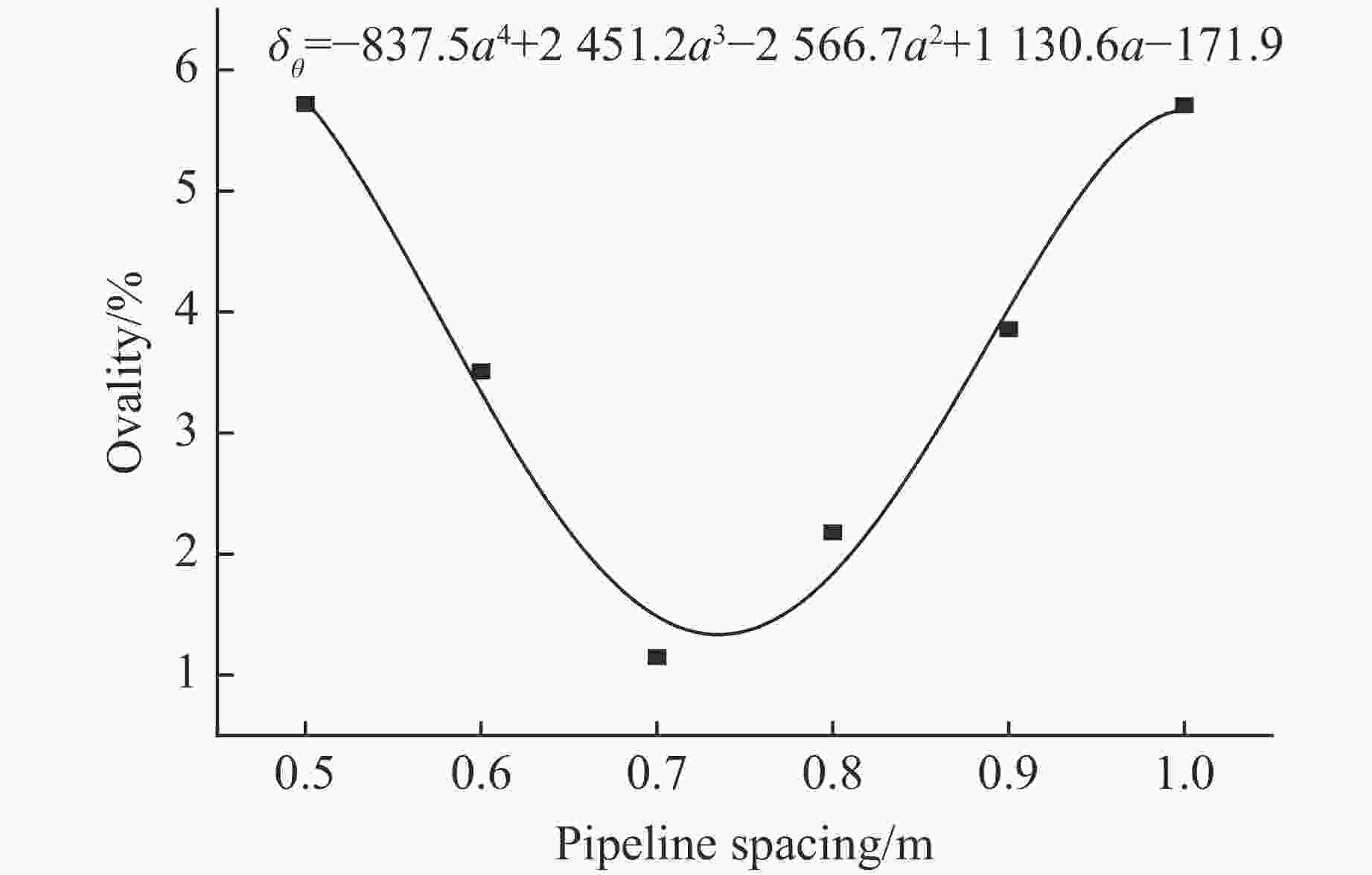

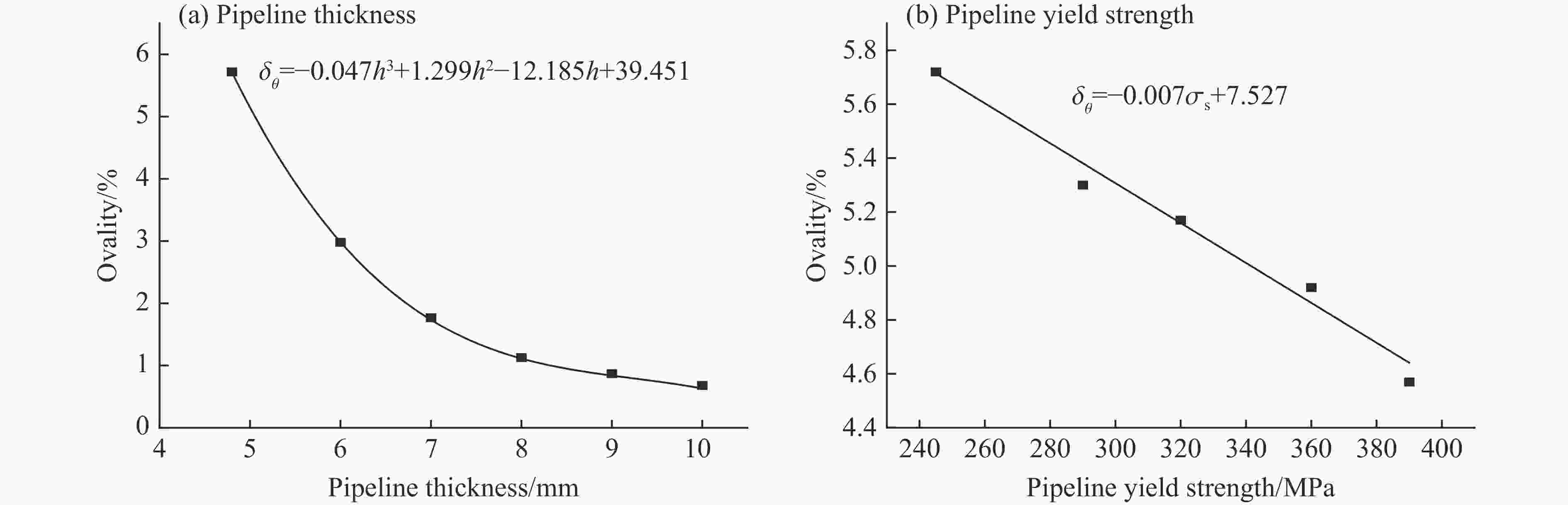

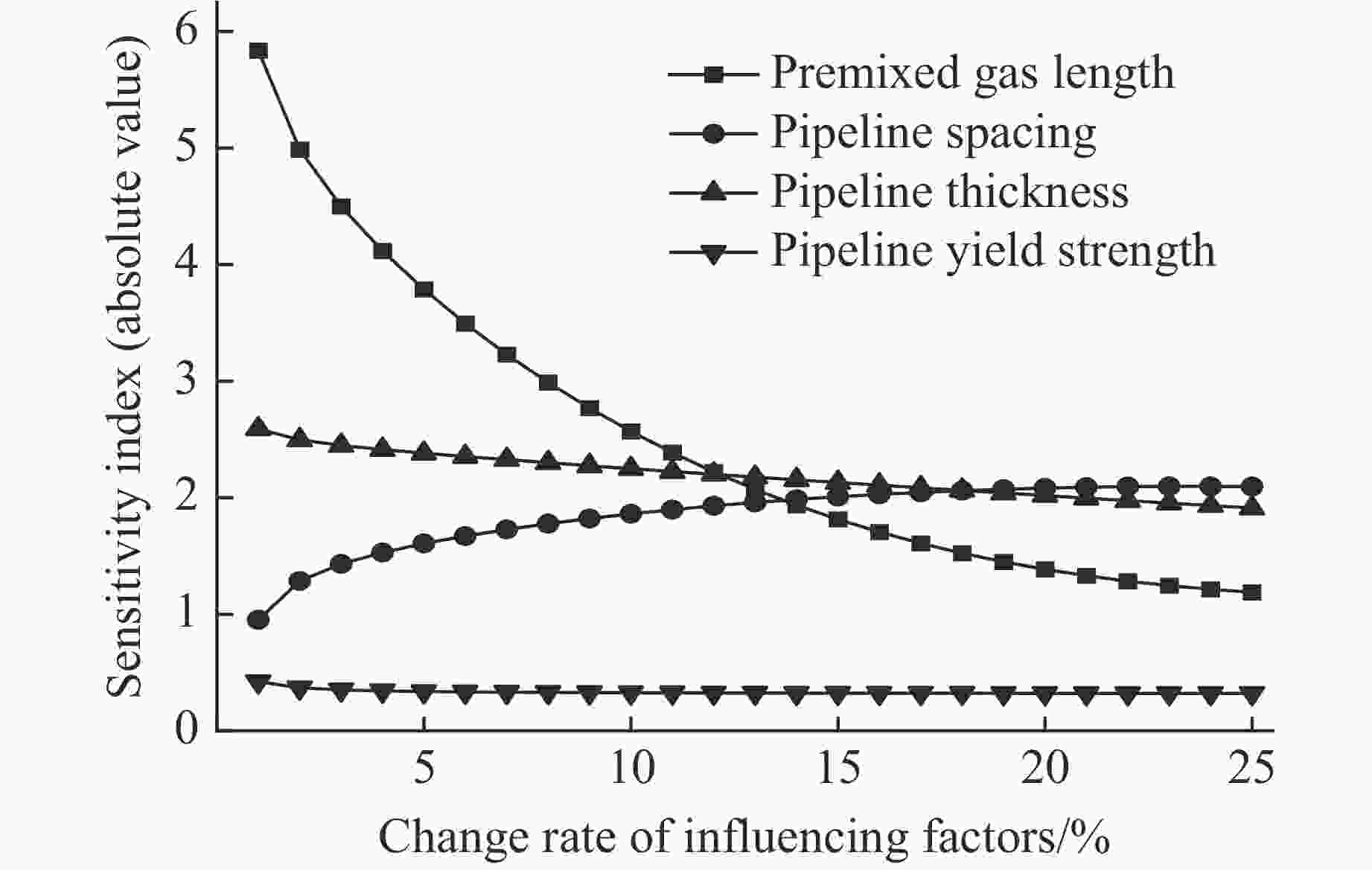

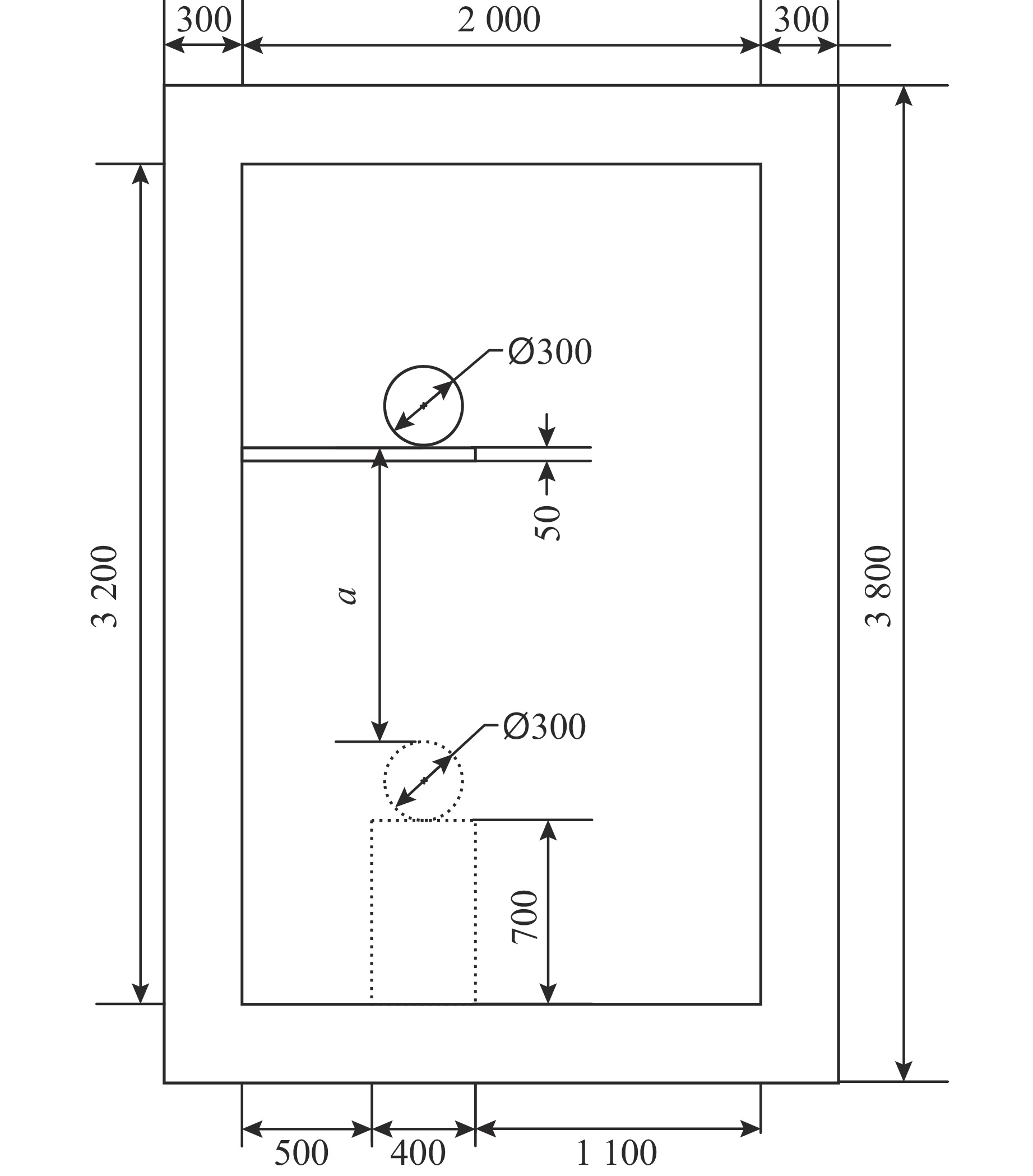

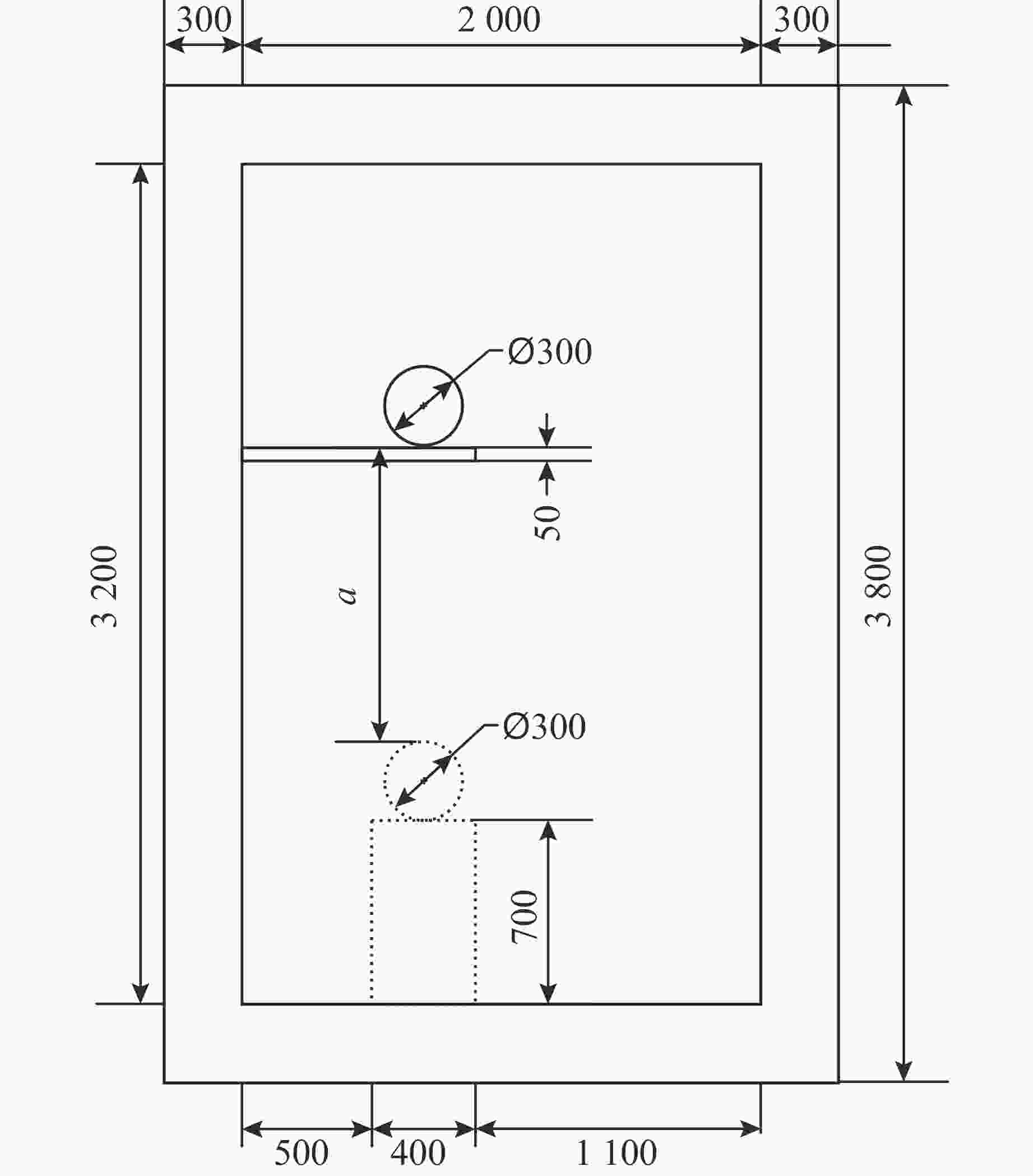

摘要: 为研究综合管廊燃气舱内天然气爆炸时预混气体长度、管道间距、管道壁厚和管道屈服强度4种因素对同舱管道失效的影响规律和影响程度,采用非线性有限元软件ANSYS/LS-DYNA,根据实际案例建立燃气舱三维模型,基于应变的失效判定标准,获取同舱管道的椭圆度变化情况。结果表明:天然气爆炸作用下,同舱管道的椭圆度与预混气体长度正相关,与管道壁厚和管道屈服强度负相关;同舱管道椭圆度与管道间距先负相关后正相关,该燃气舱内最优管道安全间距为0.74 m;管道屈服强度对同舱管道椭圆度的影响程度最小;当影响因素的变化率在1%~12%、13%~18%和19%~25% 3个区间时,对同舱管道椭圆度影响最大的因素分别为预混气体长度、管道壁厚和管道间距。研究结论可为综合管廊燃气舱的设计提供参考。Abstract: In order to study the influence law and degree of premixed gas length, pipeline spacing, pipeline thickness and pipeline yield strength on the failure of the adjacent pipeline under the action of natural gas explosion in the gas compartment of the utility tunnel, a three-dimensional model of the gas compartment is established based on the actual case by using the nonlinear finite element software ANSYS/LS-DYNA to obtain the ovality change of the adjacent pipeline. The results show that under the action of natural gas explosion, the ovality of the adjacent pipeline is positively correlated with the length of premixed gas, and negatively correlated with the thickness and yield strength of the pipeline; the ovality of the adjacent pipeline is negatively correlated first and then positively correlated with the pipeline spacing, the safest pipeline spacing in this gas compartment is 0.74 m; the yield strength of the pipeline has the least influence on the ovality of the adjacent pipeline; the change rate of influencing factors is in the range of 1%–12%, 13%–18% and 19%–25%, the factors that have the greatest influence on the ovality of the adjacent pipeline are the length of premixed gas, pipeline thickness and pipeline spacing. This research can provide a reference for the design of the gas compartment in the utility tunnel.

-

Key words:

- utility tunnel /

- gas compartment /

- gas explosion /

- pipeline /

- ovality

-

Group Working condition Premixed gas size a/m h/mm σs/MPa Length/m Width/m Height/m a Ⅰ 3.0 2.0 3.2 0.5 4.8 245 Ⅱ 2.8 2.0 3.2 0.5 4.8 245 Ⅲ 2.6 2.0 3.2 0.5 4.8 245 Ⅳ 2.4 2.0 3.2 0.5 4.8 245 Ⅴ 2.2 2.0 3.2 0.5 4.8 245 Ⅵ 2.0 2.0 3.2 0.5 4.8 245 b Ⅰ 3.0 2.0 3.2 0.5 4.8 245 Ⅱ 3.0 2.0 3.2 0.6 4.8 245 Ⅲ 3.0 2.0 3.2 0.7 4.8 245 Ⅳ 3.0 2.0 3.2 0.8 4.8 245 Ⅴ 3.0 2.0 3.2 0.9 4.8 245 Ⅵ 3.0 2.0 3.2 1.0 4.8 245 c Ⅰ 3.0 2.0 3.2 0.5 4.8 245 Ⅱ 3.0 2.0 3.2 0.5 6.0 245 Ⅲ 3.0 2.0 3.2 0.5 7.0 245 Ⅳ 3.0 2.0 3.2 0.5 8.0 245 Ⅴ 3.0 2.0 3.2 0.5 9.0 245 Ⅵ 3.0 2.0 3.2 0.5 10.0 245 d Ⅰ 3.0 2.0 3.2 0.5 4.8 245 Ⅱ 3.0 2.0 3.2 0.5 4.8 290 Ⅲ 3.0 2.0 3.2 0.5 4.8 320 Ⅳ 3.0 2.0 3.2 0.5 4.8 360 Ⅴ 3.0 2.0 3.2 0.5 4.8 390 表 2 甲烷-空气预混气体的材料参数

Table 2. Material parameters of the methane-air premixed gas

Density/

(kg·m−3)Ratio of

specific heatDetonation velocity/

(km·s−1)Explosion pressure/MPa Instantaneous explosion pressure/MPa Initial internal energy/(MJ·m−3) 1.234 1.274 1.855 1.87 0.935 3.408 表 3 天然气管道材料参数

Table 3. Material parameters of natural gas pipeline

Density/(g·cm−3) Elastic modulus/GPa Poisson’s ratio C P 7.85 206 0.3 40.4 5 -

[1] LUO Y, ALAGHBANDRAD A, GENGER T K, et al. History and recent development of multi-purpose utility tunnels [J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2020, 103: 103511. doi: 10.1016/j.tust.2020.103511 [2] 中国建筑标准设计研究院. 综合管廊燃气管道敷设与安装 [M]. 北京: 中国计划出版社, 2018: 23–30.China Institute of Building Standard Design and Research Co., Ltd. Laying and installation of gas pipeline in utility tunnel [M]. Beijing: China Planning Press, 2018: 23–30. [3] 龚燚. 燃气管线入综合管廊的抗爆防护技术研究 [D]. 南京: 南京理工大学, 2018.GONG Y. Study on anti-explosion protection technology of gas pipeline entering the utility tunnel [D]. Nanjing: Nanjing University of Science and Technology, 2018. [4] 詹武刚. 某城市综合管廊通风系统及燃气舱设计 [J]. 建筑热能通风空调, 2017, 36(4): 99–103. doi: 10.3969/j.issn.1003-0344.2017.04.026ZHAN W G. Ventilation system and natural gas tank design of urban utility tunnel [J]. Building Energy & Environment, 2017, 36(4): 99–103. doi: 10.3969/j.issn.1003-0344.2017.04.026 [5] 刘希亮, 李烨, 王新宇, 等. 地下管廊在燃气爆炸作用下的动力响应分析 [J]. 高压物理学报, 2018, 32(6): 064104. doi: 10.11858/gywlxb.20180544LIU X L, LI Y, WANG X Y, et al. Dynamic response analysis of underground pipe gallery under gas explosion [J]. Chinese Journal of High Pressure Physics, 2018, 32(6): 064104. doi: 10.11858/gywlxb.20180544 [6] 刘希亮, 李烨, 王新宇, 等. 管廊内燃气爆炸作用下不同抗爆结构性能研究 [J]. 高压物理学报, 2019, 33(4): 045204. doi: 10.11858/gywlxb.20180640LIU X L, LI Y, WANG X Y, et al. Anti-explosion performance of different anti-explosion structures under gas explosion in pipe gallery [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 045204. doi: 10.11858/gywlxb.20180640 [7] 黄有波. 天然气管道燃烧爆炸危害评价研究 [D]. 北京: 首都经济贸易大学, 2016.HUANG Y B. Study on hazard assessment of combustion and explosion in natural gas pipeline [D]. Beijing: Capital University of Economics and Business, 2016. [8] GUO Y B, LIU C C, WANG D G, et al. Numerical study and safety spacing of buried parallel gas pipelines: a study based on TNT equivalent method [J]. International Journal of Pressure Vessels and Piping, 2018, 168: 246–257. doi: 10.1016/j.ijpvp.2018.11.002 [9] GUO Y B, HE L G, WANG D G, et al. Numerical investigation of surface conduit parallel gas pipeline explosive based on the TNT equivalent weight method [J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 360–368. doi: 10.1016/j.jlp.2016.10.006 [10] MA H Y, ZHONG M S, LI X H, et al. Experimental and numerical simulation study on the shock and vibration effect of OD1422-X80 mainline natural gas pipeline explosion [J]. Shock and Vibration, 2019: 6824819. doi: 10.1155/2019/6824819 [11] MA H Y, LONG Y, LI X H, et al. Attenuation and time-frequency characteristics of explosion ground vibration of shallow buried OD1422-X80 mm-12 MPa pipeline based on prototype experiment [J]. Journal of Performance of Constructed Facilities, 2020, 34(1): 04019092. doi: 10.1061/(ASCE)CF.1943-5509.0001349 [12] LI Z X, WU J S, LIU M Y, et al. Numerical analysis of the characteristics of gas explosion process in natural gas compartment of utility tunnel using FLACS [J]. Sustainability, 2019, 12(1): 153. doi: 10.3390/su12010153 [13] ZHANG S H, MA H T, HUANG X M, et al. Numerical simulation on methane-hydrogen explosion in gas compartment in utility tunnel [J]. Process Safety and Environmental Protection, 2020, 140: 100–110. doi: 10.1016/j.psep.2020.04.025 [14] 张书豪, 彭世尼, 杜建梅, 等. 国内综合管廊燃气舱安全研究综述 [J]. 煤气与热力, 2019, 39(11): B01–B09. doi: 10.13608/j.cnki.1000-4416.2019.11.015ZHANG S H, PENG S N, DU J M, et al. Summary of research on safety of gas compartment in domestic utility tunnel [J]. Gas and Heat, 2019, 39(11): B01–B09. doi: 10.13608/j.cnki.1000-4416.2019.11.015 [15] 中国石油集团工程设计有限责任公司西南分公司. 输气管道工程设计规范: GB 50251—2015 [S]. 北京: 中国计划出版社, 2015.Southwest Branch of CNPC Engineering Design Co., Ltd. Code for design of gas transmission pipeline engineering: GB 50251—2015 [S]. Beijing: China Planning Publishing House, 2015. [16] 辛春亮, 薛在清, 涂建, 等. 有限元分析常用材料参数手册 [M]. 北京: 机械工业出版社, 2020: 2–18.XIN C L, XUE Z Q, TU J, et al. Handbook of common material parameters for finite element analysis [M]. Beijing: China Machine Press, 2020: 2–18. [17] 赵威. 管道中可燃气体爆炸动力学特征研究 [D]. 青岛: 青岛科技大学, 2018.ZHAO W. Study on explosive dynamics characterristics of flammable gas in pipeline [D]. Qingdao: Qingdao University of Science & Technology, 2018. [18] 刘洋, 李展, 方秦, 等. 惰性气体和水蒸气对长直空间燃气爆炸超压及其振荡的抑制作用 [J]. 高压物理学报, 2021, 35(5): 055201. doi: 10.11858/gywlxb.20200654LIU Y, LI Z, FANG Q, et al. Inert gas and water vapor suppressing overpressure and its oscillation of gas explosion in long straight space [J]. Chinese Journal of High Pressure Physics, 2021, 35(5): 055201. doi: 10.11858/gywlxb.20200654 [19] 文霞. 隧道内输气管道泄漏爆炸数值模拟及对邻管的损伤研究 [D]. 成都: 西南石油大学, 2018.WEN X. Numerical simulation of leakage and explosion of gas pipeline and damage to adjacent pipeline in tunnel [D]. Chengdu: Southwest Petroleum University, 2018. [20] 陈国华, 徐佳, 周志航, 等. 埋地输气管道泄漏爆炸作用下并行邻管的动力响应 [J]. 油气储运, 2020, 39(11): 1228–1237.CHEN G H, XU J, ZHOU Z H, et al. Dynamic response of adjacent parallel pipes to leakage and explosion of buried gas pipelines [J]. Oil & Gas Storage and Transportation, 2020, 39(11): 1228–1237. [21] 韩文海, 周晶. 腐蚀海底管道可靠性分析 [J]. 石油学报, 2015, 36(4): 516–520. doi: 10.7623/syxb201504014HAN W H, ZHOU J. Reliability analysis of corroded subsea pipeline [J]. Acta Petrolei Sinica, 2015, 36(4): 516–520. doi: 10.7623/syxb201504014 -

下载:

下载: